In the dynamic landscape of global commerce, sourcing manual air pumps for car tires presents a unique challenge for B2B buyers across diverse markets. The ability to provide reliable inflation solutions is critical, especially in regions such as Africa, South America, the Middle East, and Europe, where vehicle maintenance plays a pivotal role in transportation infrastructure. This comprehensive guide aims to equip international buyers with the insights needed to navigate the complexities of sourcing manual air pumps effectively.

Within these pages, you will discover a detailed exploration of various types of manual air pumps, including hand and foot-operated models, designed for different applications and tire sizes. We will delve into the essential factors to consider when vetting suppliers, from quality assurance to compliance with international standards. Additionally, we will cover pricing structures and cost analysis to help you make informed purchasing decisions that align with your budget and operational needs.

By synthesizing key information and actionable insights, this guide empowers B2B buyers to confidently source manual air pumps that meet their specific requirements. Whether you’re in Saudi Arabia managing a fleet of vehicles, or in Nigeria addressing the needs of local consumers, understanding the nuances of the manual air pump market will enhance your procurement strategy and drive successful business outcomes.

| Tipo Nombre | Principales rasgos distintivos | Aplicaciones B2B principales | Breves pros y contras para los compradores |

|---|---|---|---|

| Bombas manuales | Manual operation; lightweight and portable; typically lower PSI (up to 70 PSI) | Small automotive shops; bicycle repair shops | Pros: Cost-effective, lightweight, easy to store. Contras: Mano de obra intensiva, inflación más lenta. |

| Bombas de pie | Operated by foot pedal; higher PSI capabilities (up to 100 PSI) | Workshops, tire shops, roadside assistance | Pros: Hands-free operation, faster inflation for larger tires. Contras: Requires space for use, can be less portable. |

| Dual-Power Inflators | Can operate on both 12V and 120V; built-in pressure gauges; faster inflation | Automotive service centers, fleet maintenance | Pros: Versatile power options, quick inflation, user-friendly. Contras: Higher initial investment, may require additional maintenance. |

| Portable Battery Pumps | Rechargeable, cordless; often includes additional features like LED lights | Mobile tire repair services, outdoor recreational use | Pros: Highly portable, convenient for remote locations. Contras: Limited battery life, requires charging before use. |

| Infladores de CO2 | Utilizes CO2 cartridges for rapid inflation; compact and lightweight | Emergency kits, cycling events | Pros: Extremely portable, fast inflation for emergencies. Contras: Cartridge replacement costs, limited to small tire sizes. |

Hand pumps are the simplest form of manual air pumps, relying solely on human power for operation. These pumps are lightweight and portable, making them an ideal choice for small automotive shops and bicycle repair services. They typically achieve pressures up to 70 PSI, which is sufficient for many applications. B2B buyers should consider the cost-effectiveness and ease of storage of hand pumps, but also acknowledge the labor-intensive nature of operation and slower inflation rates compared to other types.

Foot pumps provide a hands-free solution for tire inflation by utilizing a foot pedal to generate air pressure. They can achieve higher pressures, often up to 100 PSI, making them suitable for workshops and tire shops. Their design allows for faster inflation, particularly for larger tires, which is advantageous for businesses that prioritize efficiency. While foot pumps require more space for operation and can be less portable, their speed and ease of use can justify their inclusion in a professional setting.

Dual-power inflators are versatile machines that operate on both 12V and 120V power sources. They often feature built-in pressure gauges and can inflate tires more quickly than manual options. Ideal for automotive service centers and fleet maintenance operations, these inflators streamline the tire inflation process. Although they come with a higher initial investment, their user-friendly design and efficiency can lead to significant time savings and improved service delivery.

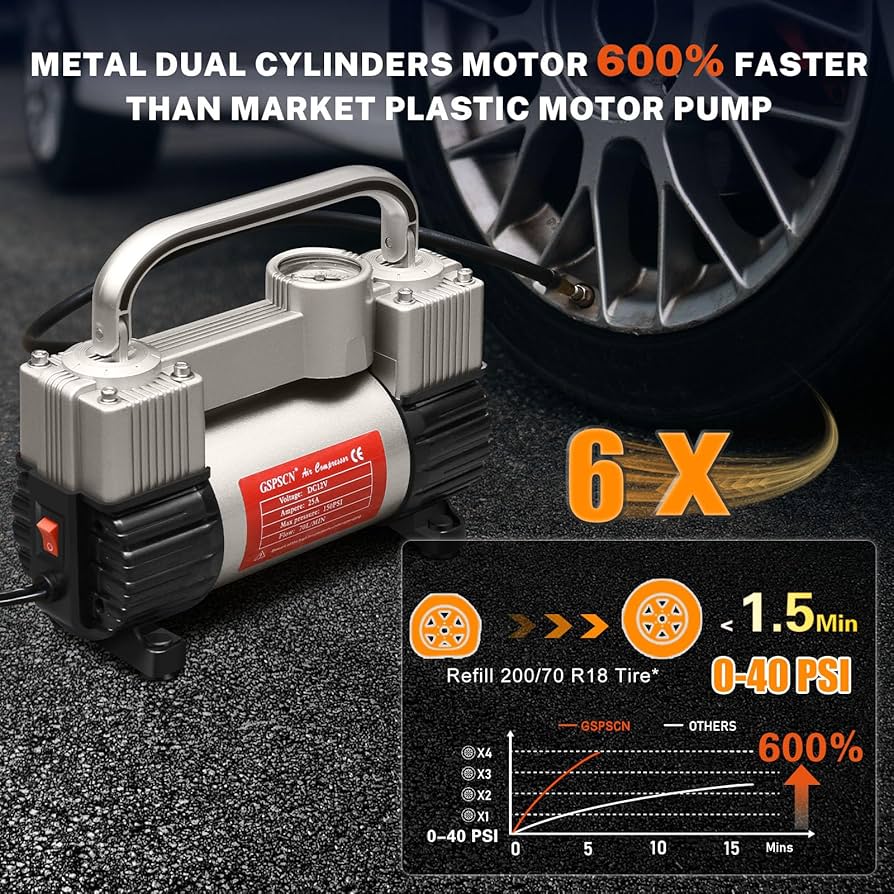

Illustrative image related to manual air pump for car tires

Portable battery pumps are designed for convenience, operating cordlessly and often equipped with features such as LED lights for nighttime use. These pumps are particularly beneficial for mobile tire repair services and outdoor recreational activities. While they offer high portability and ease of use, B2B buyers should be aware of the limited battery life and the need for regular charging, which may impact their utility in high-demand scenarios.

CO2 inflators are compact devices that utilize CO2 cartridges for rapid tire inflation. They are especially useful in emergency kits and during cycling events where speed is critical. Their portability makes them easy to carry, but businesses should consider the ongoing costs of cartridge replacements and their limitations in inflating larger tire sizes. For applications where quick, on-the-go inflation is essential, CO2 inflators can be a valuable addition to a B2B inventory.

| Industria/Sector | Specific Application of manual air pump for car tires | Valor/beneficio para la empresa | Consideraciones clave para el aprovisionamiento de esta aplicación |

|---|---|---|---|

| Talleres de reparación de automóviles | Routine tire maintenance and emergency inflation | Enhances service efficiency and customer satisfaction | Durability, ease of use, and compact design for storage |

| Transportation & Logistics | Quick tire inflation for delivery vehicles | Reduces downtime and improves fleet productivity | Pressure range compatibility and portability |

| Agricultura | Inflation of agricultural vehicle tires | Ensures operational readiness in remote locations | Robust construction and resistance to harsh conditions |

| Recreational Vehicle Rentals | Tire maintenance for rental fleets | Increases safety and minimizes liability risks | Lightweight design and ease of transport |

| Sports and Leisure | Inflating sports equipment and recreational vehicles | Versatile use across various applications | Multi-functional attachments and ease of handling |

In automotive repair shops, manual air pumps are essential for routine tire maintenance and emergency inflation. These pumps allow technicians to quickly inflate tires for various vehicles, ensuring that customers leave with safe and properly inflated tires. This not only enhances service efficiency but also improves customer satisfaction. Buyers in this sector should prioritize durability and ease of use, as well as compact designs for convenient storage in often space-limited environments.

In the transportation and logistics sector, manual air pumps are invaluable for quickly inflating tires on delivery vehicles. Reducing downtime is crucial in this industry, as delays can lead to significant financial losses. A reliable manual air pump allows drivers to address tire issues on the go, thus maintaining fleet productivity. Buyers should consider the pressure range compatibility and portability of the pumps, ensuring they can be easily stored and accessed in various vehicle types.

Agricultural operations frequently require tire inflation for tractors and other heavy machinery, often in remote locations where access to power sources is limited. Manual air pumps provide the necessary inflation without reliance on electricity, ensuring that equipment remains operational and ready for use. Buyers in this sector should focus on robust construction and resistance to harsh conditions, as agricultural settings can be demanding on tools and equipment.

Illustrative image related to manual air pump for car tires

For recreational vehicle rental companies, maintaining tire pressure is critical for safety and performance. Manual air pumps enable quick tire inflation, ensuring that rental vehicles are in optimal condition for customers. This practice not only increases safety but also minimizes liability risks associated with vehicle breakdowns. Buyers should look for lightweight designs that facilitate easy transport and handling, as these pumps will often need to be moved between multiple rental units.

Manual air pumps are versatile tools in the sports and leisure industry, used for inflating various equipment such as balls, inflatable boats, and recreational vehicles. Their portability and ease of use make them ideal for sports teams and outdoor enthusiasts who require quick inflation solutions. Buyers should consider multi-functional attachments that allow for a range of inflation tasks, as well as ease of handling to accommodate different user needs in dynamic environments.

El problema: Many B2B buyers in the automotive sector struggle with ensuring that their fleet vehicles maintain optimal tire pressure. This issue can arise from a lack of accurate pressure measurement when using manual air pumps. Often, these pumps do not come with integrated pressure gauges, leading to potential over-inflation or under-inflation of tires. This not only affects vehicle performance and fuel efficiency but also increases wear and tear on tires, resulting in premature replacements and increased operational costs.

Illustrative image related to manual air pump for car tires

La solución: To address this challenge, B2B buyers should prioritize sourcing manual air pumps that include a built-in, high-quality pressure gauge. When evaluating suppliers, ask for specifications regarding the accuracy of the gauge and consider products that feature an automatic shutoff function to prevent over-inflation. It is also advisable to train staff on how to properly check and adjust tire pressure regularly, ideally during routine vehicle inspections. Implementing a systematic schedule for tire pressure checks will ensure that all fleet vehicles operate at peak efficiency, ultimately saving costs on fuel and extending tire life.

El problema: A common pain point for businesses operating in remote or rural areas, especially in regions like Africa or South America, is the limited accessibility of electricity. Many manual air pumps are designed with electric options, making them ineffective in situations where a power source is unavailable. This can lead to downtime and operational delays when tires need inflation in the field, impacting service delivery and customer satisfaction.

La solución: To mitigate this issue, B2B buyers should focus on sourcing high-quality manual air pumps that are specifically designed for portability and ease of use without reliance on electricity. Look for pumps that are lightweight, compact, and equipped with ergonomically designed handles for efficient operation. Additionally, consider investing in foot pumps or hand pumps that can deliver high PSI levels to accommodate various vehicle types. Incorporating these pumps into vehicle kits ensures that teams are always prepared to handle tire issues on the go, thus enhancing operational efficiency and minimizing downtime.

Illustrative image related to manual air pump for car tires

El problema: In the B2B landscape, durability and reliability of equipment are paramount, particularly for businesses that rely on manual air pumps for regular tire maintenance. Many buyers face challenges with low-quality pumps that can break easily or fail to provide consistent performance, leading to frustration and increased costs due to replacements and repairs. In regions with harsh climates, such as the Middle East, the quality of materials used in air pumps can significantly affect their lifespan and performance.

La solución: When selecting manual air pumps, B2B buyers should prioritize products made from robust materials that can withstand extreme conditions. Research suppliers who offer warranties or guarantees on their products, indicating confidence in their durability. Additionally, consider purchasing pumps with replaceable parts, which can extend the product’s lifespan and reduce waste. Encouraging regular maintenance checks and proper storage practices will also help ensure that the pumps remain in good working condition, ultimately reducing the total cost of ownership and increasing reliability in critical situations.

When selecting materials for manual air pumps designed for car tires, it’s essential to consider the performance, durability, and cost-effectiveness of each option. The following analysis highlights four common materials used in the construction of these pumps: aluminum, plastic, rubber, and steel. Each material has unique properties and implications for international B2B buyers, particularly those operating in diverse markets such as Africa, South America, the Middle East, and Europe.

Aluminum is a popular choice for manual air pumps due to its lightweight and corrosion-resistant properties. It typically has a pressure rating of up to 150 PSI, making it suitable for inflating car tires effectively. The primary advantages of aluminum include its durability and resistance to rust, which is particularly important in humid or coastal environments. However, aluminum can be more expensive than other materials and may require more complex manufacturing processes, including precision machining.

For international buyers, compliance with standards such as ASTM B221 (for aluminum extrusions) is crucial. Additionally, aluminum’s recyclability can appeal to environmentally conscious markets, enhancing its attractiveness in regions with stringent environmental regulations.

Illustrative image related to manual air pump for car tires

Plastic, particularly high-density polyethylene (HDPE) and polypropylene, is often used in the construction of manual air pumps. These materials are lightweight, resistant to corrosion, and can withstand a range of temperatures. Plastic pumps typically have lower pressure ratings, often around 70 PSI, making them suitable for smaller applications like bicycle tires or sports equipment.

The advantages of plastic include lower manufacturing costs and ease of production, which can be beneficial for high-volume orders. However, plastic may not offer the same durability as metal counterparts, leading to concerns about long-term performance. Buyers in regions like Africa and South America should consider local climate conditions and potential exposure to UV light, which can degrade some plastics over time.

Rubber is primarily used in seals and hoses within manual air pumps, providing excellent flexibility and air-tightness. It can handle pressures up to 100 PSI, making it suitable for a variety of tire inflation tasks. The key advantage of rubber is its ability to maintain a seal under varying temperatures and pressures, ensuring consistent performance.

Illustrative image related to manual air pump for car tires

However, rubber can be susceptible to degradation from ozone and UV exposure, which may limit its lifespan in harsh environments. For international buyers, it’s vital to ensure that the rubber used meets relevant standards, such as ASTM D2000, which specifies rubber materials for automotive applications.

Steel is often used in the construction of more robust manual air pumps, particularly those designed for heavy-duty applications. It offers exceptional durability and can handle high pressure ratings, often exceeding 150 PSI. Steel pumps are typically more resistant to wear and tear, making them suitable for commercial or industrial uses.

The main disadvantage of steel is its weight and susceptibility to rust if not properly coated. This can lead to higher shipping costs and maintenance requirements. Buyers from regions with high humidity or saline conditions, such as coastal areas in the Middle East, should prioritize steel pumps with protective coatings or consider alternative materials to mitigate corrosion risks.

Illustrative image related to manual air pump for car tires

| Material | Typical Use Case for manual air pump for car tires | Ventajas clave | Principales desventajas/limitaciones | Coste relativo (Bajo/Medio/Alto) |

|---|---|---|---|---|

| Aluminio | General automotive use | Ligero y resistente a la corrosión | Higher manufacturing complexity and cost | Medio |

| Plástico | Bicycle tires and sports equipment | Low manufacturing cost and lightweight | Less durable than metals; UV degradation | Bajo |

| Goma | Seals and hoses in pumps | Excellent flexibility and air-tightness | Susceptible to ozone and UV degradation | Medio |

| Acero | Heavy-duty commercial applications | Exceptional durability and high pressure ratings | Heavy and prone to rust without coating | Alta |

By understanding the properties and implications of each material, international B2B buyers can make informed decisions that align with their market needs and compliance requirements.

The manufacturing process for manual air pumps involves several critical stages, each contributing to the final product’s quality and functionality. The main stages include material preparation, forming, assembly, and finishing.

Preparación del material: The first step is sourcing high-quality materials, typically including durable plastics and metals like aluminum or steel. These materials must withstand high pressure and frequent use. Suppliers often conduct rigorous testing of raw materials to ensure compliance with industry standards.

Formando: In this stage, the prepared materials are shaped into the required components. Techniques such as injection molding for plastic parts and metal stamping for metallic components are commonly employed. Advanced machinery is utilized to ensure precision and consistency in dimensions, which is crucial for the pump’s performance.

Montaje: Once the individual components are formed, they are assembled into the final product. This process may involve both manual labor and automated systems, depending on the complexity of the design. Skilled workers ensure that all components fit together correctly, which is vital for the pump’s efficiency and durability.

Acabado: The final stage involves surface treatments, painting, and quality checks. Finishing processes enhance aesthetics and protect against corrosion and wear. This stage also includes testing the pumps to ensure they meet performance specifications before packaging.

Quality assurance is paramount in the manufacturing of manual air pumps, especially for B2B buyers who demand reliability and safety. Several international standards guide manufacturers in maintaining quality throughout their processes.

ISO 9001: This standard focuses on quality management systems and is applicable to any organization, regardless of size or industry. It ensures that manufacturers consistently provide products that meet customer and regulatory requirements.

Marcado CE: For products sold in the European market, CE marking is essential. It indicates compliance with health, safety, and environmental protection standards. Manufacturers must conduct rigorous testing to demonstrate that their products meet these requirements.

API Certification: The American Petroleum Institute (API) sets standards for products related to the oil and gas industry. While not directly applicable to all manual air pumps, it can be relevant for those used in specific industrial applications.

Quality control (QC) is integrated throughout the manufacturing process to ensure that each pump meets established standards. Key checkpoints include:

Control de calidad entrante (IQC): This initial checkpoint involves inspecting raw materials upon delivery. Manufacturers assess materials for defects and verify that they meet specified standards before proceeding with production.

Control de calidad durante el proceso (IPQC): During manufacturing, periodic inspections are conducted to monitor the production process. This includes checking the dimensions of components, ensuring correct assembly, and verifying that machinery is functioning properly.

Control de calidad final (CCF): Once the pumps are fully assembled, they undergo final inspections. This stage includes functional testing, where the pumps are pressurized to ensure they operate correctly and safely. Any defective units are identified and addressed before packaging.

For international B2B buyers, verifying a supplier’s quality control processes is crucial to ensuring product reliability. Here are effective strategies for doing so:

Auditorías de proveedores: Conducting on-site audits allows buyers to assess the manufacturing environment, processes, and adherence to quality standards. This firsthand evaluation can reveal a lot about a supplier’s commitment to quality.

Informes de calidad: Requesting detailed quality reports can provide insights into a supplier’s QC processes. These reports should outline testing methods, results, and any corrective actions taken for non-conformities.

Inspecciones de terceros: Engaging third-party inspection services can provide an unbiased assessment of the manufacturing process and product quality. This is particularly beneficial for buyers in regions with less stringent oversight.

Testing methods play a crucial role in verifying the performance and safety of manual air pumps. Common testing methods include:

Pressure Testing: Pumps are subjected to pressures beyond their maximum rating to ensure they can handle real-world conditions without failure. This test helps identify weak points in the design or materials.

Functional Testing: This involves operating the pump under various conditions to ensure it inflates tires to the specified PSI levels and operates smoothly without leaks.

Pruebas de durabilidad: Manufacturers may simulate extended use by cycling the pump through multiple inflation cycles to assess its longevity and performance over time.

When sourcing manual air pumps from international suppliers, particularly in regions like Africa, South America, the Middle East, and Europe, there are several nuances to consider:

Cumplimiento de la normativa: Different regions have specific regulations regarding product safety and quality. Buyers should ensure that suppliers comply with local laws and international standards relevant to their markets.

Cultural Factors: Understanding cultural attitudes toward quality and safety can influence suppliers’ practices. Establishing clear communication regarding expectations can help bridge any gaps.

Logistical Considerations: The distance between buyers and suppliers can complicate quality assurance efforts. Utilizing technology for remote inspections and quality assessments can mitigate these challenges.

By focusing on these aspects of manufacturing processes and quality assurance, B2B buyers can make informed decisions when sourcing manual air pumps for car tires. Ensuring that suppliers adhere to high-quality standards not only enhances product reliability but also builds trust in international business relationships.

Illustrative image related to manual air pump for car tires

To assist B2B buyers in the procurement of manual air pumps for car tires, this practical sourcing guide outlines essential steps to ensure a successful purchasing experience. By following this checklist, you can make informed decisions that align with your business needs and operational standards.

Before initiating the procurement process, clarify the technical requirements for the manual air pump. Consider factors such as maximum pressure (PSI), pump type (hand or foot), and size for portability. Knowing these specifications will help streamline your search and ensure you select a product that meets your operational needs.

Investigate current market trends and pricing for manual air pumps in your target regions, such as Africa, South America, the Middle East, and Europe. This research helps you understand competitive pricing and the features that are most valued by customers in different markets. Take note of any seasonal variations that might affect supply and demand.

Finding reliable suppliers is crucial for a successful procurement process. Look for suppliers with a proven track record in the industry, especially those who specialize in automotive products. Consider using platforms that provide supplier ratings and reviews to gauge credibility.

Before finalizing your order, request samples of the manual air pumps from potential suppliers. This step allows you to assess the quality, durability, and usability of the products firsthand. Pay attention to the material used, ease of operation, and overall craftsmanship.

Assess the level of customer support and warranty options offered by your potential suppliers. Reliable suppliers should provide robust after-sales support and clear warranty policies. This is particularly important in regions where product maintenance may be challenging, ensuring you have recourse in case of defects or issues.

Once you’ve identified a suitable supplier, it’s time to negotiate terms and conditions. Discuss pricing, payment terms, minimum order quantities, and delivery timelines. Ensure that all agreements are documented to avoid misunderstandings later. A well-negotiated contract can lead to better pricing and service in the long run.

Illustrative image related to manual air pump for car tires

Finally, consider the logistics involved in transporting the manual air pumps from the supplier to your business location. Evaluate shipping options, costs, and delivery times to ensure that you can meet your operational deadlines. Additionally, plan for how you will distribute the pumps within your supply chain or to end customers.

By following this structured checklist, you can enhance your procurement process for manual air pumps for car tires, ensuring that you make informed decisions that align with your business objectives.

When sourcing manual air pumps for car tires, understanding the comprehensive cost structure is critical for international B2B buyers. The main cost components include:

Illustrative image related to manual air pump for car tires

Materiales: The choice of materials significantly influences the cost. High-quality plastics, metals, and rubber components contribute to durability but may increase the price. Sourcing local materials can reduce costs, especially in regions like Africa and South America, where local suppliers may offer competitive pricing.

Trabajo: Labor costs vary widely by region. In countries with lower labor costs, such as certain parts of Africa or South America, manufacturers can provide more cost-effective solutions. However, it’s essential to balance labor costs with quality, as lower wages can sometimes correlate with less skilled labor.

Gastos generales de fabricación: This includes expenses related to factory operations, utilities, and equipment maintenance. Manufacturers with efficient production processes can offer lower prices, so understanding their operational efficiencies is essential.

Herramientas: The initial investment in tooling for production can be substantial. Custom designs or complex features will require more advanced tooling, which can drive up costs. Buyers should inquire about shared tooling options to lower upfront expenses.

Control de calidad: Implementing rigorous QC processes adds to the overall cost but is crucial for ensuring product reliability. Buyers should evaluate the manufacturer’s QC standards and certifications, as this impacts the final product’s performance and safety.

Logística: Shipping costs, customs duties, and warehousing fees can significantly affect the total cost. Understanding the Incoterms (International Commercial Terms) involved in the transaction is vital for anticipating these expenses.

Margen: Suppliers typically add a margin to cover their costs and profit. This margin can vary based on the supplier’s market position, brand reputation, and the buyer’s negotiation power.

Several factors can influence the pricing of manual air pumps for car tires:

Volumen y cantidad mínima de pedido (MOQ): Larger orders often lead to reduced per-unit costs due to economies of scale. Buyers should negotiate favorable MOQs to maximize cost efficiency.

Especificaciones y personalización: Custom designs or specific features may incur additional costs. Buyers should weigh the benefits of customization against budget constraints.

Materiales: The choice of materials not only affects quality but also pricing. Understanding the trade-offs between cost and durability is essential.

Calidad y certificaciones: Products that meet international safety and quality standards may come at a premium. However, these certifications can lead to lower liability and higher customer satisfaction.

Factores del proveedor: The supplier’s reputation, reliability, and production capacity can influence pricing. Conducting thorough due diligence on potential suppliers is crucial.

Incoterms: The agreed-upon shipping terms can affect overall costs. DDP (Delivered Duty Paid) might be more expensive upfront but can simplify logistics for buyers unfamiliar with customs processes.

To ensure cost-efficiency in sourcing manual air pumps, B2B buyers should consider the following strategies:

Leverage Volume Discounts: If planning to place bulk orders, negotiate with suppliers for volume discounts. This can significantly reduce costs.

Evaluar el coste total de propiedad (TCO): Beyond the purchase price, consider long-term costs, including maintenance, operational efficiency, and potential replacement needs. A slightly higher initial investment may yield savings in the long run.

Entender los matices de los precios: Be aware of regional pricing differences. For instance, suppliers in Africa or South America may offer better pricing due to lower labor costs or favorable local materials.

Establecer relaciones con los proveedores: Establishing a strong relationship can lead to better terms and more favorable pricing. Regular communication can also foster trust and reliability.

Manténgase informado sobre las tendencias del mercado: Keeping abreast of market conditions, raw material prices, and competitor offerings can empower buyers during negotiations.

Understanding the comprehensive cost structure and pricing influences of manual air pumps for car tires is vital for making informed sourcing decisions. By analyzing these factors and employing effective negotiation strategies, international B2B buyers can optimize their procurement processes and enhance their overall purchasing effectiveness.

In the automotive maintenance landscape, ensuring optimal tire pressure is crucial for safety and performance. While manual air pumps for car tires are a popular choice due to their simplicity and portability, various alternative solutions exist that offer different advantages. This section will compare manual air pumps against electric tire inflators and CO2 inflators, providing B2B buyers with valuable insights to make informed purchasing decisions.

| Aspecto comparativo | Manual Air Pump For Car Tires | Electric Tire Inflator | Inflador de CO2 |

|---|---|---|---|

| Rendimiento | Moderate, requires physical effort | High, can inflate tires quickly | Quick, but limited air supply |

| Coste | Low (typically $10-$30) | Moderate ($30-$100) | Moderate to High ($20-$80) |

| Facilidad de aplicación | Simple, requires no power | Requires access to power source | Very easy, minimal setup |

| Mantenimiento | Low, minimal parts | Moderate, occasional maintenance | Low, but cartridges need replacement |

| El mejor caso de uso | Remote areas, no power access | Quick inflation in various settings | Quick fixes, emergency situations |

Electric tire inflators are designed for convenience and speed, providing rapid inflation for various tire sizes. These devices typically operate on a 12V battery or can be plugged into a household outlet. They offer a user-friendly experience with features such as automatic shutoff and digital pressure gauges, making them suitable for both personal and commercial use. However, they require access to a power source, which can limit their usability in remote areas or during outdoor activities. Additionally, they come at a higher price point than manual pumps, which could be a consideration for budget-conscious buyers.

Illustrative image related to manual air pump for car tires

CO2 inflators are compact and lightweight, making them ideal for emergency situations, especially for cyclists and motorcyclists. They utilize pressurized CO2 cartridges to inflate tires quickly, allowing for a fast response to flat tires. Their portability is a significant advantage, as they can easily fit into a glove compartment or backpack. However, the main drawback is that the air supply is limited to the number of cartridges on hand, making them less suitable for larger vehicles or extensive tire maintenance. They also require ongoing costs for cartridge replacements, which can add up over time.

Selecting the right tire inflation solution involves assessing the specific needs of your operations. For businesses operating in remote areas or those with limited access to power, manual air pumps can be invaluable due to their low cost and ease of use. Electric tire inflators are better suited for environments where speed and efficiency are prioritized, such as automotive shops or roadside assistance services. Meanwhile, CO2 inflators serve well in emergency situations, particularly for cyclists or in scenarios where space is at a premium. By evaluating performance, cost, and use case scenarios, B2B buyers can make informed decisions that align with their operational requirements.

Understanding the essential technical properties of manual air pumps for car tires is crucial for B2B buyers looking to make informed purchasing decisions. Here are the key specifications:

The maximum pressure rating, typically measured in pounds per square inch (PSI), indicates how much pressure the pump can generate. For most manual air pumps used for car tires, this figure ranges from 60 to 120 PSI. A higher PSI rating is essential for inflating larger tires, making it a critical factor for automotive and commercial applications. Buyers should consider their specific needs, particularly if they service vehicles that require higher pressure.

Illustrative image related to manual air pump for car tires

The materials used in the construction of manual air pumps significantly affect durability and performance. Common materials include high-grade plastics, aluminum, and steel. A pump made from high-quality materials will withstand wear and tear, particularly in demanding environments. For B2B buyers, understanding the material grade can help assess the product’s longevity and reliability, which is vital for reducing operational costs over time.

This metric refers to the time it takes to inflate a tire from flat to the desired pressure. For example, a high-quality manual air pump might inflate a standard car tire in approximately 5-10 minutes. This property is particularly important for businesses that rely on quick turnaround times, such as tire repair shops or service stations. An efficient inflation time can enhance customer satisfaction and operational efficiency.

The weight of a manual air pump affects its portability. Lighter pumps are easier to transport, making them ideal for on-the-go applications. For B2B buyers in sectors like automotive repair or roadside assistance, a portable pump can enhance service delivery by allowing technicians to quickly address tire issues in various locations.

The length of the air hose and the type of fittings included with the pump can impact usability. A longer hose allows for easier access to tires without the need to reposition the pump frequently. Additionally, compatibility with various valve types (e.g., Schrader, Presta) is essential for ensuring the pump can service a wide range of vehicles and applications.

Familiarity with industry-specific jargon is crucial for effective communication and negotiation in the B2B sector. Here are some common terms:

This term refers to a company that produces parts or equipment that may be marketed by another manufacturer. For B2B buyers, knowing whether a product is OEM can indicate quality and compatibility with existing systems.

MOQ is the smallest number of units a supplier is willing to sell in a single order. Understanding MOQ is vital for B2B buyers as it can affect inventory management and cost efficiency. Buyers should negotiate MOQs to align with their purchasing needs and budget.

An RFQ is a document that a buyer sends to suppliers requesting pricing information for specific products. This is a standard practice in B2B transactions, allowing buyers to compare prices and terms effectively before making a purchase decision.

These are a series of predefined commercial terms published by the International Chamber of Commerce (ICC) that are widely used in international shipping. Understanding Incoterms is essential for B2B buyers as they clarify the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs.

Lead time refers to the amount of time it takes from placing an order to receiving the goods. For businesses, shorter lead times can enhance operational efficiency, particularly in industries where quick turnaround is critical. Understanding lead times helps buyers plan their inventory and manage customer expectations effectively.

By grasping these technical properties and trade terminologies, B2B buyers can make more informed decisions when sourcing manual air pumps for car tires, ensuring they choose products that meet their operational needs and standards.

The global manual air pump market for car tires is experiencing notable growth, driven by increasing vehicle ownership and rising awareness about tire maintenance. In regions like Africa and South America, where road conditions can be challenging, the demand for portable and efficient tire inflation solutions is surging. The Middle East and European markets are also seeing a shift towards more compact and user-friendly designs, catering to both individual consumers and businesses in automotive services.

Emerging trends include the integration of technology, with some manufacturers developing pumps equipped with digital pressure gauges and auto shut-off features. B2B buyers are increasingly prioritizing products that offer ease of use, reliability, and durability. Moreover, the rise of e-commerce platforms has facilitated easier access to diverse product ranges, enabling international buyers to compare and source products efficiently. The trend towards cordless and battery-operated pumps is gaining traction, reflecting a growing preference for convenience and portability, especially among consumers in remote areas.

Illustrative image related to manual air pump for car tires

Sustainability is becoming a pivotal concern for B2B buyers in the manual air pump sector. The environmental impact of manufacturing processes and the materials used are under scrutiny. Buyers are increasingly seeking products that are made from recycled or sustainable materials, as well as those that comply with green certifications. This shift not only meets consumer expectations but also aligns with global sustainability goals.

Ethical sourcing is equally crucial, as businesses are held accountable for their supply chain practices. Manufacturers that demonstrate transparency in their sourcing processes and prioritize fair labor practices can gain a competitive edge. B2B buyers are encouraged to establish partnerships with suppliers who adhere to ethical standards, ensuring that their procurement practices contribute positively to the environment and society. This focus on sustainability and ethics is not just a trend; it is becoming a fundamental aspect of business strategy in the manual air pump market.

The evolution of manual air pumps dates back to their initial use in the early 20th century, primarily for bicycles. As automobile ownership surged post-World War II, the demand for more robust and efficient tire inflation solutions increased. Over the decades, manual air pumps have undergone significant innovations, transitioning from basic hand-operated designs to more sophisticated models that incorporate ergonomic features and improved materials.

The introduction of portable electric pumps in the late 20th century marked a pivotal shift, offering consumers greater convenience. Today, manual air pumps continue to evolve, reflecting technological advancements and changing consumer preferences. Modern pumps are designed not only for efficiency but also for user-friendliness, catering to a diverse audience that ranges from individual car owners to businesses in the automotive sector. This ongoing evolution underscores the importance of innovation in meeting the needs of a dynamic market.

Illustrative image related to manual air pump for car tires

How do I choose the right manual air pump for car tires?

Selecting the appropriate manual air pump involves considering several factors. First, assess the pressure requirements for the tires you will inflate; most car tires require around 30-35 PSI. Look for pumps that offer a pressure gauge for accuracy. Additionally, consider the size and portability of the pump, especially if it will be used in various locations. Durability is crucial; select models made from high-quality materials to withstand regular use. Finally, check if the pump includes multiple nozzle adapters for versatility across different tire types.

What are the advantages of using a manual air pump versus electric inflators?

Manual air pumps offer several benefits over electric models, particularly in terms of portability and reliability. They are lightweight and do not require a power source, making them ideal for remote locations or emergencies. Manual pumps also tend to have lower maintenance costs and are generally more durable, as they have fewer electronic components that can fail. Additionally, they provide better control over the inflation process, allowing users to inflate tires at their own pace.

What should I look for in terms of supplier credentials when sourcing manual air pumps?

When vetting suppliers for manual air pumps, prioritize those with proven experience in the automotive accessories sector. Check for certifications such as ISO 9001, which indicates quality management standards. Request product samples to assess quality firsthand. Also, investigate customer reviews and testimonials to gauge reliability and service quality. Finally, ensure that the supplier can comply with international shipping standards and offer after-sales support, especially for warranty claims.

What is the minimum order quantity (MOQ) for manual air pumps?

The MOQ for manual air pumps can vary significantly based on the supplier and the specific product. Typically, it ranges from 100 to 500 units for bulk orders. However, some suppliers may accommodate smaller orders for new buyers or specific needs. It’s advisable to discuss your requirements directly with the supplier to negotiate terms that suit your business model. Additionally, consider the potential for pricing discounts with larger orders, which can enhance your profit margins.

What payment terms should I negotiate with my manual air pump supplier?

When negotiating payment terms, aim for flexibility that aligns with your cash flow. Common terms include a 30% deposit upfront with the balance due upon shipment or delivery. Consider options for letter of credit or escrow services to safeguard your investment. Additionally, inquire about discounts for early payment or bulk orders, which can improve your overall cost structure. Clear communication about payment timelines will help build trust and facilitate smoother transactions.

How can I ensure quality assurance for my manual air pump orders?

To ensure quality assurance, request detailed product specifications and quality certifications from your supplier. Conduct pre-shipment inspections or hire third-party inspection services to evaluate the products before they leave the factory. Establish clear quality standards and communicate them to your supplier upfront. Additionally, consider implementing a return policy that allows for defective items to be returned or exchanged, providing an extra layer of security for your investment.

What logistics considerations are important when importing manual air pumps?

Logistics play a critical role in importing manual air pumps, especially regarding shipping methods and costs. Evaluate options such as air freight for faster delivery or sea freight for cost-effectiveness, depending on your timeline and budget. Additionally, consider customs regulations and tariffs in your destination country, which can affect overall costs. Collaborate with reliable freight forwarders who understand the specific requirements for automotive products to streamline the import process.

How can I customize manual air pumps for my brand?

Many suppliers offer customization options, allowing you to add your branding, colors, and packaging. Discuss your specific requirements with potential suppliers, including logo placement, pump colors, and additional features like integrated gauges or storage cases. Ensure that the supplier has the capability to meet your design specifications and can provide prototypes for review. Customization can enhance brand recognition and differentiate your products in competitive markets.

Dominio: reddit.com

Matriculado: 2005 (20 años)

Introducción: Corded tire pump preferred (no batteries), can be stored in trunk, budget under $100.

In conclusion, strategic sourcing of manual air pumps for car tires can significantly enhance operational efficiency and customer satisfaction. The variety of options available—ranging from hand and foot pumps to electric and cordless models—allows businesses to cater to diverse needs across different markets. Understanding regional preferences and the specific demands of countries in Africa, South America, the Middle East, and Europe is crucial for making informed purchasing decisions.

Quality, durability, and ease of use should be prioritized when selecting suppliers, as these factors directly impact user experience and brand reputation. Additionally, considering logistical aspects such as shipping and local regulations will streamline the procurement process, ensuring timely availability of products.

As you evaluate your sourcing strategy, consider forming partnerships with reputable manufacturers that align with your values and operational goals. Embrace the opportunity to innovate and differentiate your offerings in a competitive marketplace. By investing in high-quality manual air pumps, you not only meet your customers’ needs but also position your business for sustained growth in emerging markets. Take action now to secure your supply chain and enhance your product portfolio, ensuring you are well-equipped for future demands.

La información facilitada en esta guía, incluido el contenido relativo a fabricantes, especificaciones técnicas y análisis de mercado, tiene únicamente fines informativos y educativos. No constituye asesoramiento profesional en materia de adquisiciones, asesoramiento financiero ni asesoramiento jurídico.

Aunque hemos hecho todo lo posible por garantizar la exactitud y actualidad de la información, no nos hacemos responsables de posibles errores, omisiones o información obsoleta. Las condiciones del mercado, los detalles de las empresas y las normas técnicas están sujetos a cambios.

Los compradores B2B deben llevar a cabo su propia diligencia debida independiente y exhaustiva antes de tomar cualquier decisión de compra. Esto incluye ponerse en contacto directamente con los proveedores, verificar las certificaciones, solicitar muestras y buscar asesoramiento profesional. El riesgo de confiar en la información contenida en esta guía es responsabilidad exclusiva del lector.