Navigating the complexities of tire inflation can be a significant challenge for international B2B buyers, especially when sourcing reliable tire inflation guides that cater to diverse regional needs. In a global market where the performance and safety of vehicles hinge on proper tire inflation, understanding the intricacies of tire pressure specifications, load capacities, and maintenance requirements is crucial. This guide provides a comprehensive overview of tire inflation, covering various types of tires, their applications, and the critical factors to consider when selecting suppliers.

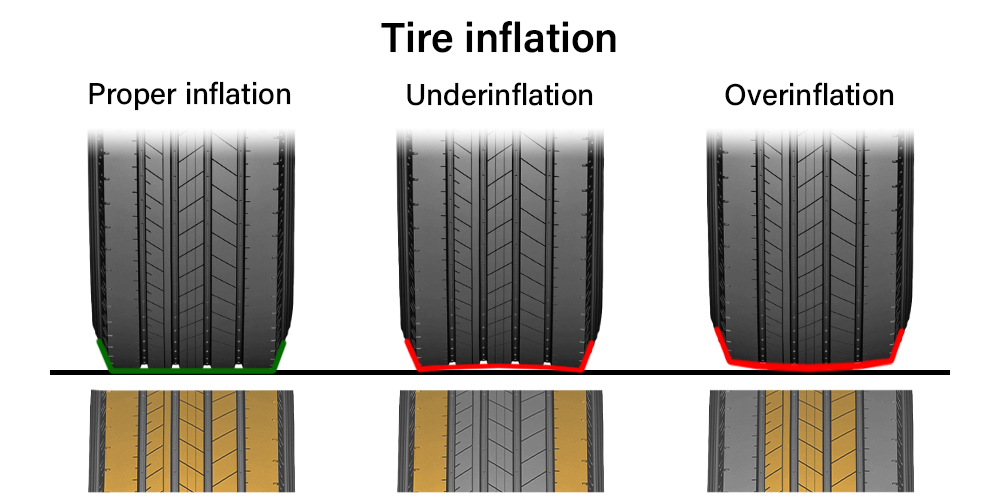

Buyers will gain insights into the importance of adhering to manufacturer recommendations, understanding inflation pressure metrics, and the implications of under- or over-inflation on tire longevity and vehicle performance. Additionally, we delve into supplier vetting processes, cost considerations, and regional compliance standards, ensuring that businesses from Africa, South America, the Middle East, and Europe—like Brazil and Saudi Arabia—can make informed purchasing decisions.

Empowering buyers with actionable insights, this guide serves as a vital resource for enhancing tire safety and efficiency, ultimately leading to improved operational performance and cost savings in a competitive marketplace. With the right knowledge, businesses can navigate the tire inflation landscape with confidence, ensuring their fleets remain safe, efficient, and compliant with international standards.

| Tipo Nombre | Principales rasgos distintivos | Aplicaciones B2B principales | Breves pros y contras para los compradores |

|---|---|---|---|

| Standard Tire Inflation Guide | Provides recommended PSI based on vehicle type and load capacity. | Automotive manufacturers, tire retailers | Pros: Easy to use; standardizes tire pressure checks. Contras: May not account for unique vehicle modifications. |

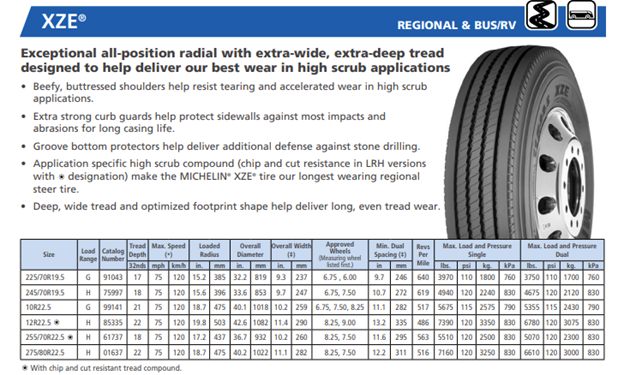

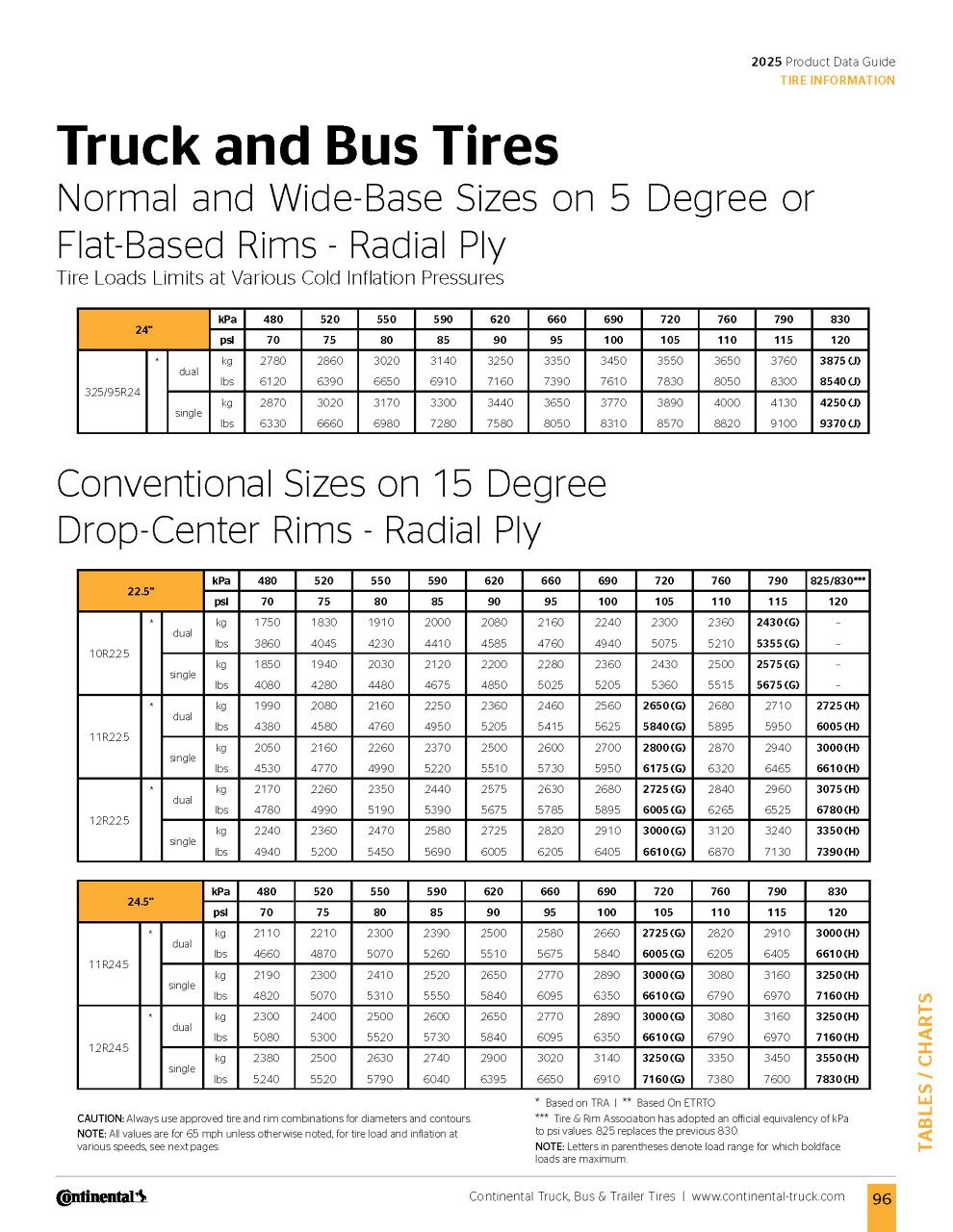

| Load and Inflation Tables | Detailed tables correlating tire sizes with load capacities and pressures. | Fleet management, logistics companies | Pros: Precise load management; enhances safety. Contras: Requires regular updates as tire models change. |

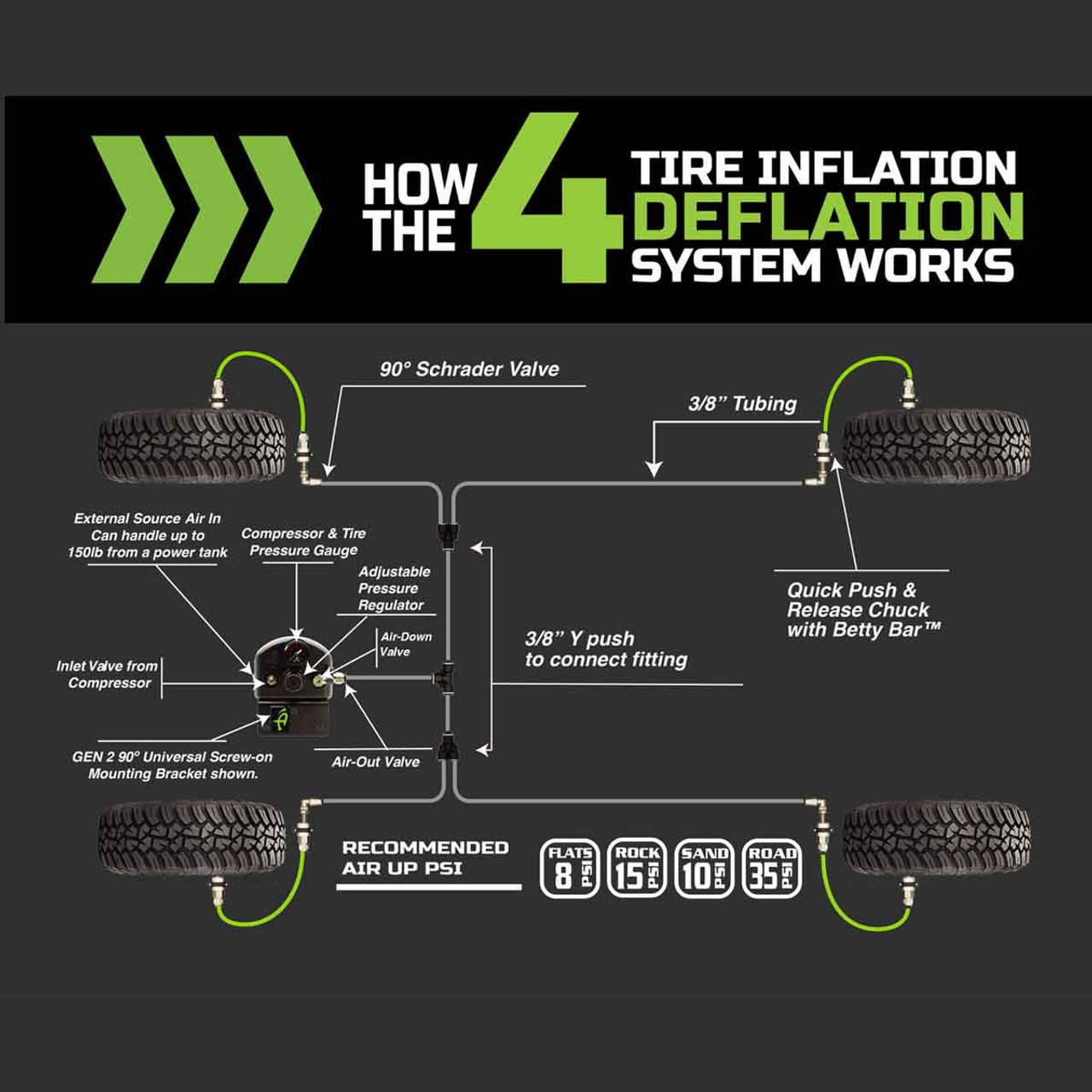

| Tire Pressure Monitoring Systems | Electronic systems that provide real-time tire pressure readings. | Transportation and logistics industries | Pros: Immediate alerts for under/over-inflation; reduces manual checks. Contras: Higher initial cost; potential technical issues. |

| Plus Sizing Guidelines | Guidelines for replacing tires with larger sizes while maintaining safety. | Performance vehicle manufacturers, aftermarket suppliers | Pros: Improves vehicle aesthetics and performance. Contras: Complex installation; may require recalibration. |

| Regional Tire Pressure Standards | Localized recommendations based on climate and road conditions. | International shipping, vehicle manufacturers | Pros: Tailors pressure to environmental conditions; improves safety. Contras: Requires knowledge of local regulations. |

A Standard Tire Inflation Guide provides essential information regarding the recommended tire pressure (in PSI) based on vehicle specifications and load capacities. This type of guide is crucial for automotive manufacturers and tire retailers as it ensures compliance with safety standards. Buyers benefit from its straightforward application, making it easy to implement in various vehicle types. However, it may not accommodate unique vehicle modifications, which can limit its effectiveness in specialized applications.

Load and Inflation Tables offer a comprehensive overview of tire sizes, corresponding load capacities, and recommended pressures. This type of guide is particularly valuable for fleet management and logistics companies, where precise load management is essential for safety and efficiency. The primary advantage lies in its ability to enhance safety by providing clear guidelines for tire selection based on load demands. However, these tables require regular updates to reflect the latest tire models and specifications, which can be a logistical challenge for businesses.

Tire Pressure Monitoring Systems (TPMS) represent a technological advancement in tire maintenance by providing real-time tire pressure readings. This type of system is widely used in transportation and logistics industries, where timely alerts for under or over-inflation can prevent tire failures and enhance safety. The immediate feedback significantly reduces the need for manual checks, saving time and resources. However, the initial investment can be higher, and potential technical issues may arise, which buyers should consider.

Plus Sizing Guidelines are designed for those looking to replace tires with larger sizes, offering insights into maintaining safety while enhancing vehicle performance. This is particularly relevant for performance vehicle manufacturers and aftermarket suppliers. The benefits include improved aesthetics and potentially better handling. However, the complexity of installation and the need for recalibration can pose challenges, making it essential for buyers to assess their technical capabilities before proceeding.

Regional Tire Pressure Standards provide localized recommendations based on specific climate conditions and road environments. This type of guide is particularly useful for international shipping and vehicle manufacturers operating in diverse geographic areas. By tailoring tire pressure recommendations to local conditions, businesses can significantly enhance safety and performance. However, understanding local regulations and ensuring compliance can add an extra layer of complexity for international buyers.

| Industria/Sector | Specific Application of tire inflation guide | Valor/beneficio para la empresa | Consideraciones clave para el aprovisionamiento de esta aplicación |

|---|---|---|---|

| Transportation & Logistics | Regular maintenance of commercial fleet tires | Enhanced safety, reduced fuel costs, and extended tire lifespan | Compliance with local regulations and availability of inflation tools |

| Agricultura | Tire inflation for agricultural machinery | Improved efficiency in field operations and reduced downtime | Access to localized inflation guides suitable for various terrains |

| Construcción | Tire management for heavy machinery | Increased operational safety and reduced risk of equipment failure | Durability of inflation equipment and compatibility with machinery |

| Mining | Tire pressure management in harsh environments | Enhanced safety and reduced maintenance costs | Availability of robust inflation tools capable of extreme conditions |

| Automotive Services | Tire pressure monitoring and maintenance for service centers | Improved customer satisfaction and reduced liability risks | Training for staff on tire inflation techniques and monitoring systems |

In the transportation and logistics sector, the tire inflation guide is crucial for maintaining the optimal tire pressure of commercial fleets. Regularly checking tire pressure according to the guide helps prevent blowouts and ensures safe driving conditions. Furthermore, maintaining the correct tire pressure can lead to significant fuel savings, as under-inflated tires increase rolling resistance, thereby reducing fuel efficiency. For B2B buyers, sourcing reliable inflation tools and ensuring compliance with local regulations are essential considerations.

In agriculture, the tire inflation guide assists farmers in optimizing the performance of their machinery. Properly inflated tires on tractors and harvesters reduce soil compaction and improve traction, which is vital for efficient field operations. This not only enhances productivity but also minimizes wear and tear on equipment. Buyers in this sector should consider localized guides that account for varying terrains and recommend inflation levels based on load conditions.

For the construction industry, managing tire inflation for heavy machinery is critical for operational safety and efficiency. The tire inflation guide provides specifications to ensure that tires are inflated to the correct pressure, thereby reducing the risk of tire-related failures that could halt work. Buyers should focus on sourcing durable inflation equipment that can withstand the rugged environments typical of construction sites, as well as ensure that their staff is trained in proper inflation techniques.

In mining operations, tire pressure management is essential due to the extreme conditions faced by vehicles and machinery. The tire inflation guide helps operators maintain the correct tire pressure, which is vital for safety and reducing maintenance costs. Properly inflated tires improve the vehicle’s load-carrying capacity and stability on uneven terrain. B2B buyers in this sector should prioritize sourcing robust inflation tools that can handle the demands of mining environments.

Automotive service centers utilize the tire inflation guide for effective tire pressure monitoring and maintenance. By following the guide, these centers can provide better service, ensuring customer vehicles are safe and efficient on the road. This leads to increased customer satisfaction and reduced liability risks for the service provider. Key considerations for buyers include staff training on the latest tire inflation technologies and the implementation of monitoring systems to streamline operations.

El problema: B2B buyers operating in international markets often encounter discrepancies in tire inflation standards, which can vary significantly from one region to another. For instance, a company based in Brazil may face challenges adhering to local regulations that differ from those in Saudi Arabia or Europe. This inconsistency not only complicates compliance but also risks vehicle safety and operational efficiency, leading to potential financial losses and reputational damage.

La solución: To effectively navigate these varied standards, B2B buyers should establish a centralized tire inflation management system that incorporates a comprehensive tire inflation guide tailored to each operational region. This system should include localized load and inflation tables from recognized organizations like The Tire and Rim Association and the European Tyre and Rim Technical Organization. By leveraging these resources, companies can ensure that their fleet maintains the correct tire pressures according to regional specifications. Additionally, investing in a robust training program for staff can help reinforce the importance of adhering to these standards, ultimately enhancing safety and operational performance.

El problema: Many B2B buyers manage diverse fleets that include various vehicle types, from light-duty trucks to heavy-duty commercial vehicles. A common challenge is the misunderstanding of optimal tire inflation pressures for different vehicles, which can lead to underinflation or overinflation. This mistake not only impacts tire longevity but also compromises fuel efficiency and safety, particularly for companies that rely heavily on their fleet for transportation and logistics.

La solución: To address this issue, buyers should utilize a tire inflation guide that clearly outlines the recommended tire pressures for each vehicle type in their fleet. This guide should be easily accessible, possibly integrated into fleet management software, allowing for quick reference during routine maintenance checks. Additionally, implementing a tire pressure monitoring system (TPMS) can provide real-time data on tire conditions, alerting operators to any deviations from the recommended pressures. Regular training sessions on the significance of proper tire inflation tailored to specific vehicle requirements will further enhance compliance and efficiency across the fleet.

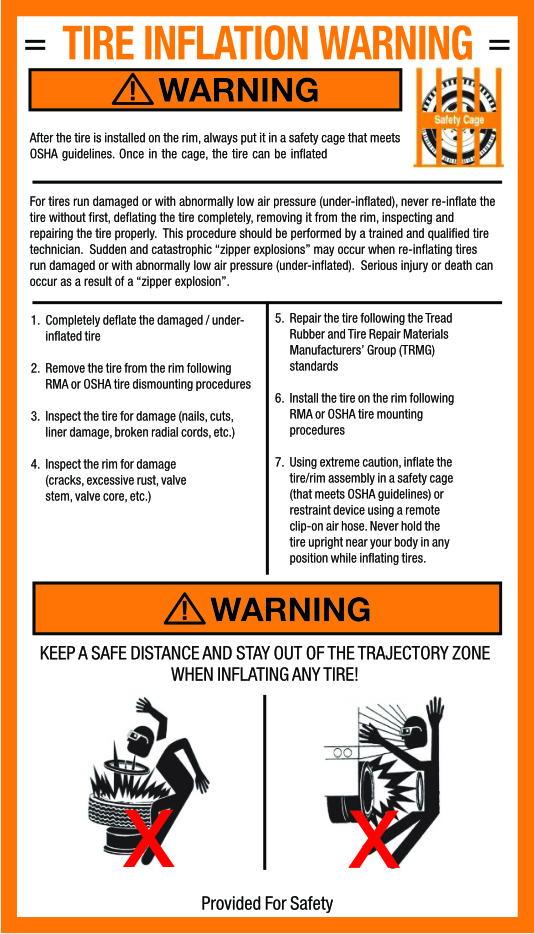

El problema: Many B2B buyers underestimate the critical role that proper tire inflation plays in vehicle safety and operational costs. This lack of awareness can lead to neglect in regular tire pressure checks, resulting in increased tire wear, higher fuel consumption, and a greater risk of accidents. Such oversights can be particularly detrimental for businesses with high operational standards or those in regulated industries, where safety is paramount.

Illustrative image related to tire inflation guide

La solución: To combat this lack of awareness, companies should develop an educational program that emphasizes the importance of maintaining optimal tire pressure. This program can incorporate data-driven insights, such as the correlation between tire pressure and fuel efficiency, as well as case studies highlighting the repercussions of neglecting tire maintenance. Providing employees with practical tools, such as tire pressure gauges and access to a detailed tire inflation guide, will empower them to take proactive measures. Additionally, establishing a routine schedule for tire pressure checks—ideally monthly or before long trips—will help instill a culture of safety and responsibility regarding tire maintenance. Regular audits of tire conditions and pressures can further reinforce this commitment, ensuring compliance and reducing the likelihood of costly incidents.

When selecting materials for tire inflation guides, it’s essential to consider the properties that directly influence performance, durability, and overall effectiveness. Here, we analyze four common materials used in the production of components related to tire inflation, focusing on their key properties, advantages, disadvantages, and specific considerations for international B2B buyers.

Rubber is the most widely used material for tire components due to its excellent elasticity and resilience. It can withstand a wide range of temperatures, typically rated between -40°F to 200°F (-40°C to 93°C), and maintains performance under varying pressure conditions. Its inherent flexibility allows for a tight seal around valves and fittings, which is crucial for maintaining tire pressure.

Pros: Rubber is durable and cost-effective, making it suitable for mass production. It offers good resistance to wear and tear, which is essential for components subjected to frequent use.

Contras: While rubber is resistant to many chemicals, it can degrade when exposed to certain oils and solvents. Additionally, its performance can be affected by extreme temperatures, leading to potential failure in harsh environments.

Impacto en la aplicación: Rubber is compatible with air and nitrogen, the two most common gases used for tire inflation. However, its degradation in extreme conditions can lead to leaks, affecting tire performance.

Consideraciones para compradores internacionales: Buyers should ensure that rubber components meet local compliance standards, such as ASTM in the U.S. or EN standards in Europe. Understanding local climate conditions is also critical, as they can influence material selection.

Metal, particularly aluminum and steel, is often used in tire inflation equipment such as valves and gauges. Metals offer high strength and rigidity, with temperature ratings that can exceed 300°F (149°C) without significant deformation.

Pros: Metal components are highly durable and resistant to physical damage. They provide excellent structural integrity, which is vital for maintaining accuracy in pressure readings.

Contras: Metals can corrode over time, especially in humid or saline environments, which can affect their performance. They are also typically more expensive than rubber alternatives.

Illustrative image related to tire inflation guide

Impacto en la aplicación: Metal components are essential for precision instruments like tire pressure gauges, where accuracy is paramount. Corrosion resistance is a crucial factor in ensuring longevity.

Consideraciones para compradores internacionales: Compliance with international standards such as ISO and ASTM is necessary. Buyers should also consider the local environment, as regions with high humidity or salt exposure may require additional protective coatings.

Plastics, such as polypropylene and polycarbonate, are increasingly used in tire inflation systems for components like connectors and housings. These materials are lightweight and can be engineered to provide specific performance characteristics.

Illustrative image related to tire inflation guide

Pros: Plastics are resistant to corrosion and can be manufactured at a lower cost than metals. They can also be molded into complex shapes, allowing for innovative designs.

Contras: While plastics are generally durable, they may not withstand high temperatures or pressures as effectively as metals. Their long-term performance can also be affected by UV exposure.

Impacto en la aplicación: Plastic components are suitable for low-pressure applications and can be used in environments where corrosion is a concern. However, they may not be ideal for high-stress components.

Consideraciones para compradores internacionales: Buyers should ensure that plastic components meet relevant standards for chemical resistance and temperature ratings. Understanding local regulations regarding plastic use is also important.

Composite materials, which combine fibers (like carbon or glass) with a polymer matrix, offer a unique blend of strength and lightweight properties. They can withstand high pressures and temperatures, making them suitable for specialized tire inflation applications.

Pros: Composites provide excellent strength-to-weight ratios and can be tailored for specific applications, enhancing performance without adding excessive weight.

Contras: The manufacturing process for composites can be complex and costly, which may limit their use in mass-produced items. Additionally, they may require specialized recycling processes.

Illustrative image related to tire inflation guide

Impacto en la aplicación: Composites are ideal for high-performance applications where weight savings are critical, such as in racing or specialized vehicles.

Consideraciones para compradores internacionales: Buyers should be aware of the specific certifications required for composite materials, as well as the potential for higher costs. Understanding the local market’s acceptance of advanced materials is also crucial.

| Material | Typical Use Case for tire inflation guide | Ventajas clave | Principales desventajas/limitaciones | Coste relativo (Bajo/Medio/Alto) |

|---|---|---|---|---|

| Goma | Tire valves and seals | Cost-effective and durable | Degrades under extreme conditions | Bajo |

| Metal | Pressure gauges and connectors | Alta resistencia y durabilidad | Susceptible to corrosion | Med |

| Plástico | Connectors and housings | Ligero y resistente a la corrosión | Limited high-temperature performance | Bajo |

| Compuesto | High-performance tire inflation systems | Excelente relación resistencia-peso | Complex and costly manufacturing | Alta |

This strategic material selection guide provides a comprehensive overview for B2B buyers in diverse regions, helping them make informed decisions based on their specific operational needs and environmental conditions.

The manufacturing process for tire inflation guides involves several critical stages that ensure the final product is both informative and reliable for users. These stages can be categorized into material preparation, forming, assembly, and finishing.

Preparación del material: This initial phase involves gathering high-quality materials, including durable paper or synthetic substrates that can withstand environmental factors like moisture and temperature fluctuations. The choice of materials is crucial, as they must be able to convey information clearly and resist wear over time.

Formando: In this stage, the prepared materials are cut to size and printed with necessary information such as tire pressure recommendations, load capacity, and safety warnings. Advanced printing techniques, including digital and offset printing, are employed to ensure clarity and precision in the text and graphics. This step may also include the incorporation of color coding or symbols for quick reference.

Montaje: After forming, the components of the tire inflation guide are assembled. This could involve binding multiple pages together or laminating the guide for added durability. In some cases, manufacturers may integrate QR codes or NFC technology to provide additional digital resources, enhancing the user experience.

Acabado: The final stage includes quality checks and packaging. The guides are often subjected to trimming, lamination, or other finishing processes to enhance durability and aesthetics. Proper packaging is essential to protect the guides during shipping and storage, ensuring they arrive in pristine condition for the end user.

Quality assurance (QA) plays a vital role in the manufacturing of tire inflation guides, ensuring that the final product meets international standards and customer expectations. The QA process typically adheres to various international standards and industry-specific regulations.

Relevant International Standards: Compliance with ISO 9001 is a primary focus for manufacturers. This standard outlines a framework for quality management systems, emphasizing customer satisfaction, process efficiency, and continuous improvement. In addition, specific certifications like CE (Conformité Européenne) may apply in the European market, ensuring that products meet safety and health requirements.

Puntos de control de calidad: The quality control process involves multiple checkpoints, including:

– Control de calidad entrante (IQC): Materials are inspected upon arrival to ensure they meet specified standards.

– Control de calidad durante el proceso (IPQC): Continuous monitoring during the manufacturing process helps identify defects early, allowing for immediate corrective actions.

– Control de calidad final (CCF): The finished product undergoes a comprehensive review to ensure it meets all quality standards before packaging and shipping.

Common Testing Methods: Various testing methods are employed to assess the durability, legibility, and accuracy of the tire inflation guides. This may include:

– Adhesion tests to ensure printed information withstands wear.

– Environmental tests to evaluate how the guides perform under different temperature and humidity conditions.

– Readability assessments to ensure that all information is clear and legible.

For B2B buyers, especially those in diverse markets such as Africa, South America, the Middle East, and Europe, verifying the quality control practices of suppliers is critical. Here are actionable steps to ensure that suppliers adhere to high-quality standards:

Auditorías de proveedores: Conducting on-site audits of potential suppliers allows buyers to assess their manufacturing processes, quality control systems, and compliance with international standards. This firsthand evaluation can reveal insights into the supplier’s commitment to quality.

Solicitud de informes de calidad: Buyers should request detailed quality reports that document the results of various testing methods and the outcomes of quality control checkpoints. These reports should include data on previous production runs, highlighting any issues encountered and how they were resolved.

Contratación de inspectores externos: Utilizing third-party inspection services can provide an unbiased assessment of a supplier’s quality control processes. These inspections can be particularly beneficial for international transactions, where buyers may not be able to conduct physical audits themselves.

International B2B buyers must navigate specific nuances in quality control that can vary by region. Understanding these factors is essential for successful procurement.

Illustrative image related to tire inflation guide

Cumplimiento de la normativa: Different regions may have varying regulatory requirements for product safety and quality. For instance, products sold in the European market must comply with CE marking requirements, while those in the U.S. may need to adhere to ANSI (American National Standards Institute) standards. Buyers should familiarize themselves with these regulations to ensure compliance.

Consideraciones culturales: Cultural differences may affect communication and expectations regarding quality. For example, buyers from South America might prioritize different aspects of quality assurance compared to those from Europe. Understanding these cultural nuances can help facilitate better supplier relationships.

Barreras lingüísticas: Documentation and quality reports may be presented in different languages, potentially complicating the assessment process. Buyers should ensure that all critical documents are available in a language they understand, or engage translation services when necessary.

By focusing on these manufacturing processes and quality assurance practices, B2B buyers can make informed decisions that enhance the reliability and safety of tire inflation guides. This thorough approach not only mitigates risks but also fosters long-term partnerships with suppliers who prioritize quality and compliance.

In the tire industry, ensuring proper tire inflation is critical for safety, performance, and longevity. This guide serves as a step-by-step checklist for B2B buyers seeking to procure tire inflation guides or related resources. By following these steps, you can make informed decisions that align with your operational needs and enhance your overall tire management strategy.

Before initiating the procurement process, clarify the technical specifications required for your tire inflation guide. Consider factors such as the types of vehicles in your fleet, tire sizes, and the regions where your vehicles operate. This ensures that the guide will be relevant and effective for your specific applications.

Start by identifying suppliers with a strong reputation in the tire industry. Look for companies that specialize in tire maintenance products and have a track record of reliability and quality.

Once you have a list of potential suppliers, assess their product offerings to ensure they meet your technical specifications. This involves comparing the features of their tire inflation guides and any associated tools or services.

Before making a final decision, ask for samples or demonstrations of the tire inflation guides. This hands-on approach allows you to evaluate the usability and clarity of the information provided.

Pricing is an important factor in the procurement process. Collect quotes from multiple suppliers and compare them based on the value offered, not just the price.

After thorough evaluation, finalize your choice of supplier and place an order. Ensure that all contractual details, including delivery timelines and return policies, are clearly outlined.

Once you receive the tire inflation guide, implement it within your operations. Train your team on its usage and monitor its effectiveness in maintaining proper tire inflation.

By following this checklist, B2B buyers can effectively source and implement a tire inflation guide that enhances safety, performance, and tire longevity across their fleet.

When evaluating the cost structure for a tire inflation guide, several key components should be considered. These include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margin.

Materiales: The choice of materials directly impacts the cost. High-quality materials that offer durability and reliability will typically increase the price. For instance, guides made from weather-resistant materials might be more expensive but provide better longevity, particularly in regions with harsh climates.

Trabajo: Labor costs can vary significantly based on geographic location. In regions like Africa and South America, labor may be less expensive compared to Europe, potentially impacting the overall pricing of the guide.

Gastos generales de fabricación: This includes the indirect costs associated with production, such as utilities, rent, and administrative expenses. Understanding the manufacturing environment can provide insights into pricing.

Herramientas: Custom tooling for specialized guides can be a significant upfront cost. If the guide requires unique features or specifications, these costs should be factored into the pricing.

Control de calidad: Effective QC processes are essential for ensuring the reliability of the tire inflation guide. Higher QC standards can lead to increased costs but are crucial for maintaining product integrity.

Logística: Transportation and handling costs can vary based on the distance from the manufacturing site to the buyer. International shipping, especially to regions like the Middle East or Europe, may incur additional costs due to tariffs and customs duties.

Margen: The profit margin expected by suppliers will also influence the final price. This can vary widely based on market competition and the perceived value of the product.

Several factors can influence the pricing structure for tire inflation guides:

Volumen/MOQ: The minimum order quantity (MOQ) and the volume of the order significantly affect pricing. Bulk orders often result in lower per-unit costs due to economies of scale.

Especificaciones y personalización: Customization options, such as tailored guides for specific tire types or vehicle models, can lead to higher costs. Buyers should evaluate their needs carefully to avoid unnecessary expenses.

Materiales y certificaciones de calidad: The level of quality and any relevant certifications will influence the price. Buyers should consider the long-term benefits of investing in higher-quality guides that may reduce the risk of tire-related incidents.

Factores del proveedor: Supplier reputation, reliability, and experience in the industry can also impact pricing. Established suppliers may charge a premium for their expertise and reliability.

Incoterms: The chosen Incoterms (International Commercial Terms) will dictate the responsibilities and costs associated with shipping. Understanding these terms can help buyers negotiate better deals.

International B2B buyers, particularly from Africa, South America, the Middle East, and Europe, should consider the following tips to optimize costs:

Negociación: Engage suppliers in discussions to negotiate better pricing, especially for larger orders. Building a relationship with suppliers can also yield favorable terms.

Rentabilidad: Evaluate the Total Cost of Ownership (TCO) rather than just the upfront price. Consider long-term benefits such as durability, warranty, and the potential for fewer replacements.

Pricing Nuances for International Purchases: Be aware of currency fluctuations, import taxes, and potential tariffs that may apply when sourcing from different countries. These factors can significantly affect overall costs.

Buscar y comparar proveedores: Conduct thorough market research to compare different suppliers and their offerings. Look for suppliers that provide transparency in their pricing structure and have a proven track record in the industry.

Pricing for tire inflation guides can vary widely based on numerous factors outlined above. Buyers should seek specific quotes from suppliers to obtain accurate pricing tailored to their needs and circumstances. Always factor in the total cost implications when making purchasing decisions to ensure optimal value.

In the realm of tire maintenance, ensuring proper inflation is critical for safety, performance, and longevity. While tire inflation guides serve as a reliable resource for determining the appropriate pressure, various alternative solutions exist that may offer additional benefits or efficiencies. This analysis will compare the traditional tire inflation guide against two viable alternatives: Tire Pressure Monitoring Systems (TPMS) and automated tire inflation systems.

| Aspecto comparativo | Tire Inflation Guide | Tire Pressure Monitoring System (TPMS) | Automated Tire Inflation System |

|---|---|---|---|

| Rendimiento | Provides recommended PSI based on vehicle specifications | Continuously monitors tire pressure and alerts drivers | Automatically adjusts tire pressure as needed |

| Coste | Low (manual reference) | Moderate (installation and maintenance costs) | High (initial investment and maintenance) |

| Facilidad de aplicación | Simple; requires user knowledge and manual checking | Requires installation, but easy to use once set up | Requires professional installation; user-friendly interface |

| Mantenimiento | Minimal; periodic manual checks | Low; requires occasional sensor battery replacement | Moderate; needs regular checks and potential repairs |

| El mejor caso de uso | Ideal for occasional users or small fleets | Best for fleets needing real-time monitoring and alerts | Suitable for large fleets or operations requiring constant tire performance monitoring |

Tire Pressure Monitoring Systems (TPMS)

TPMS provides a modern solution for tire pressure management by continuously monitoring the air pressure in tires and alerting the driver when it falls below a specified threshold. This proactive approach enhances safety and can prevent tire blowouts, making it particularly advantageous for fleets that prioritize vehicle uptime. However, the system does come with moderate costs for installation and maintenance, as sensors may require battery replacements over time. While it offers excellent performance and ease of use, it may not be necessary for users with infrequent driving needs.

Illustrative image related to tire inflation guide

Automated Tire Inflation Systems

Automated tire inflation systems are designed for larger operations that require constant monitoring and adjustment of tire pressure. These systems can automatically inflate tires to the optimal pressure, reducing the risk of under-inflation and improving fuel efficiency. While they provide significant performance benefits and ease of use, they also entail a higher upfront investment and ongoing maintenance costs. Their best use case lies in environments where tire performance is critical, such as in logistics and transportation fleets where downtime due to tire issues can lead to substantial losses.

When considering the best tire inflation solution, B2B buyers should assess their specific operational requirements, budget constraints, and the scale of their fleet. For businesses with lower tire usage or limited resources, a traditional tire inflation guide may suffice. Conversely, companies that operate larger fleets or require real-time monitoring should explore TPMS or automated tire inflation systems to enhance safety, efficiency, and overall performance. By aligning the chosen solution with operational needs, businesses can optimize tire management and contribute to long-term cost savings.

Understanding the technical properties related to tire inflation is crucial for B2B buyers, especially those in industries reliant on vehicle fleets. Here are some essential specifications to consider:

Illustrative image related to tire inflation guide

Inflation Pressure (PSI/kPa)

– Definición: The amount of air pressure within the tire, measured in pounds per square inch (PSI) or kilopascals (kPa).

– Importancia: Proper inflation pressure is critical for tire performance, safety, and longevity. Underinflated tires can lead to increased wear, reduced fuel efficiency, and higher risk of tire failure, which can significantly affect operational costs.

Load Index

– Definición: A numerical code that indicates the maximum load a tire can carry at its maximum inflation pressure.

– Importancia: Understanding load index helps in selecting the correct tire for specific applications, ensuring safety and efficiency. This is particularly vital for businesses operating heavy vehicles, as exceeding load limits can lead to accidents and increased maintenance costs.

Tread Depth

– Definición: The measurement of the depth of the grooves in a tire’s tread.

– Importancia: Tread depth affects traction, handling, and braking performance. Regular monitoring can prevent accidents and enhance safety, ultimately leading to reduced liability for businesses.

Temperature Resistance

– Definición: The ability of a tire to withstand heat generated during operation.

– Importancia: Tires that can handle higher temperatures reduce the risk of blowouts and extend service life. This is essential for companies operating in hot climates or those that require high-performance tires.

Calidad del material

– Definición: The quality and type of materials used in tire construction, including rubber compounds and reinforcement materials.

– Importancia: Higher-grade materials can improve durability and performance. For B2B buyers, investing in better quality tires can lead to lower long-term costs through reduced maintenance and replacement needs.

Familiarity with industry jargon is essential for effective communication and negotiation. Here are some key terms to know:

OEM (fabricante de equipos originales)

– Definición: Empresa que produce piezas o equipos que pueden ser comercializados por otro fabricante.

– Importancia: Understanding OEM specifications helps buyers ensure compatibility with existing vehicles and maintain warranty coverage.

MOQ (Cantidad mínima de pedido)

– Definición: Cantidad mínima de un producto que un proveedor está dispuesto a vender.

– Importancia: Knowing the MOQ can help businesses manage inventory and cash flow effectively. Buyers should negotiate terms that align with their purchasing capabilities.

RFQ (solicitud de presupuesto)

– Definición: A document sent to suppliers to request pricing and terms for specific products or services.

– Importancia: An RFQ allows businesses to compare offers, facilitating better purchasing decisions and cost management.

Incoterms (Términos comerciales internacionales)

– Definición: A series of predefined commercial terms published by the International Chamber of Commerce (ICC).

– Importancia: Understanding Incoterms is crucial for international transactions, as they define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs.

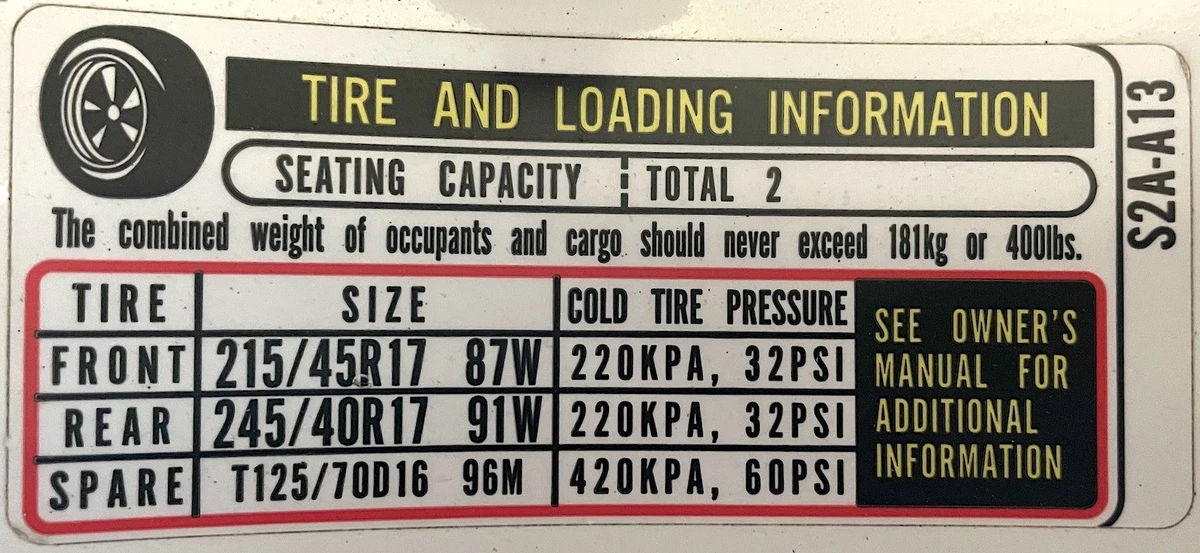

Cold Inflation Pressure

– Definición: The tire pressure measured when the tire has not been driven for several hours.

– Importancia: Accurate cold inflation pressure is essential for safety and performance. B2B buyers must ensure that inflation checks are conducted under these conditions for reliable data.

Tire Pressure Monitoring System (TPMS)

– Definición: An electronic system that monitors the air pressure inside the tires.

– Importancia: TPMS helps prevent underinflation and improves safety by alerting drivers when tire pressure is low, thereby reducing the risk of tire-related incidents.

By understanding these technical properties and industry terms, B2B buyers can make informed decisions regarding tire inflation, ultimately enhancing operational efficiency and safety.

The tire inflation guide sector is experiencing significant transformation, driven by advancements in technology and heightened awareness of safety and environmental standards. Internationally, B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, are increasingly influenced by the demand for accurate tire inflation data to enhance vehicle safety, fuel efficiency, and operational costs. In particular, the rise of digital platforms and mobile applications for real-time tire pressure monitoring systems (TPMS) is changing how businesses manage tire maintenance. Such innovations are not only improving operational efficiencies but also addressing the critical need for compliance with safety regulations.

Emerging trends in the market include the integration of artificial intelligence and IoT in tire management solutions, which allow for predictive analytics and proactive maintenance strategies. This technology empowers fleet operators to monitor tire conditions remotely, minimizing downtime and optimizing fleet performance. Additionally, the global shift towards electric and hybrid vehicles is propelling demand for specialized tire inflation guides that cater to unique specifications and pressures associated with these vehicles. As a result, international buyers must stay informed about evolving tire technologies and ensure that their sourcing strategies align with these advancements to maintain a competitive edge.

Sustainability is becoming a cornerstone of business practices in the tire inflation guide sector, with a growing emphasis on minimizing environmental impact throughout the supply chain. B2B buyers are increasingly prioritizing suppliers who implement sustainable practices, such as reducing carbon footprints and utilizing eco-friendly materials in tire production. The importance of ethical sourcing cannot be overstated; it influences brand reputation and customer loyalty, particularly in regions where consumers are more environmentally conscious.

Adopting “green” certifications and materials in tire inflation guides is not just a trend but a necessity. Certifications such as ISO 14001 for environmental management systems signal to buyers that a company is committed to sustainability. Moreover, using recycled materials in tire manufacturing can substantially decrease waste and resource depletion. B2B buyers should actively seek out suppliers who demonstrate transparency in their sourcing processes and are committed to ethical production practices, as this will not only enhance their brand image but also meet the expectations of a growing segment of eco-aware consumers.

The evolution of tire inflation practices can be traced back to the invention of the pneumatic tire in the late 19th century. Initially, tire inflation was a rudimentary process, with drivers relying on manual pumps and pressure gauges to maintain their tires. As vehicle technology advanced, so did the complexity of tire inflation systems. The introduction of tire pressure monitoring systems (TPMS) in the early 2000s marked a significant milestone, allowing for real-time monitoring of tire pressures, which greatly improved safety and efficiency.

In recent years, the focus has shifted towards digital solutions and integration with mobile technology, enabling users to access tire pressure data and maintenance guidelines with ease. This evolution reflects a broader trend in the automotive industry towards smarter, more connected vehicles. For B2B buyers, understanding this history is crucial as it informs current sourcing decisions and highlights the importance of keeping pace with technological advancements in tire maintenance and inflation practices.

Illustrative image related to tire inflation guide

How do I ensure accurate tire inflation for my fleet?

To maintain optimal tire performance in your fleet, regularly check tire pressures at least once a month or before long trips. Use a calibrated tire pressure gauge to measure pressures when the tires are cold. Always refer to the vehicle’s tire information placard for the recommended PSI. Additionally, consider implementing a tire pressure monitoring system (TPMS) for real-time monitoring, which can help prevent underinflation and overinflation, extending tire life and improving fuel efficiency.

What is the best tire inflation guide for international suppliers?

The best tire inflation guide for international suppliers should be comprehensive, covering various tire sizes, load capacities, and inflation pressures across different vehicle types. Look for guides that include data from reputable organizations like The Tire and Rim Association and European Tyre and Rim Technical Organization. Ensure the guide also addresses regional specifications, as tire standards may vary by country, particularly in markets such as Africa, South America, the Middle East, and Europe.

How can I vet suppliers for tire inflation products?

When vetting suppliers for tire inflation products, assess their industry reputation, certifications, and compliance with international standards. Request references from previous clients and investigate their experience in your target market. Evaluate their product quality through samples and inquire about their manufacturing processes. Additionally, consider their ability to provide technical support and customized solutions tailored to your specific needs.

What are the typical minimum order quantities (MOQs) for tire inflation guides?

Minimum order quantities for tire inflation guides can vary significantly based on the supplier and the complexity of the product. Generally, MOQs range from 100 to 1,000 units for printed guides. For digital formats, suppliers might offer lower MOQs or even customizable options. Discuss your needs with potential suppliers to negotiate MOQs that align with your purchasing capabilities while ensuring you receive the best pricing.

What payment terms should I expect from international suppliers?

Payment terms with international suppliers often range from 30% upfront and 70% upon delivery to net 30 or net 60 days post-delivery. Some suppliers may also offer letters of credit or escrow services to mitigate risks. Ensure you clarify these terms before finalizing contracts, and consider negotiating terms that provide you with adequate time to assess the product upon arrival.

How do logistics impact the sourcing of tire inflation guides?

Logistics play a crucial role in the sourcing of tire inflation guides, affecting delivery times, costs, and product quality. Evaluate the supplier’s shipping methods, delivery timelines, and logistics partners. Consider suppliers with experience in your region to navigate customs and local regulations effectively. A reliable logistics strategy can also reduce lead times and ensure that you receive products in optimal condition.

What quality assurance (QA) measures should I look for in tire inflation guides?

When sourcing tire inflation guides, inquire about the supplier’s quality assurance measures, including certifications like ISO 9001. Ensure they conduct regular audits and have a robust inspection process for their products. Additionally, ask about the testing methods they use to validate the accuracy and reliability of the information provided in the guides, as this will directly impact the safety and performance of the tires.

Can I customize tire inflation guides for my business needs?

Yes, many suppliers offer customization options for tire inflation guides to meet specific business requirements. You can request tailored content that reflects your fleet’s tire specifications, regional standards, or branding. Discuss your needs with potential suppliers to explore available formats, such as printed, digital, or interactive guides, ensuring they align with your operational goals and customer needs.

Dominio: toyotires.com

Inscrita: 1997 (28 años)

Introducción: Load and Inflation Tables provide assistance for replacing tires with optional sizes, including plus sizes not listed on the vehicle’s tire information placard (T.I.P) or in the owner’s manual. For original equipment (OE) size inflation pressure, refer to the T.I.P., commonly found on the vehicle door jam, glove compartment, or near the gas cap. Important: Consult the vehicle’s owner’s manual for …

Dominio: yournexttire.com

Inscrito: 2008 (17 años)

Introducción: Tire Inflation Chart provides a formula for calculating load capacity based on tire weight and pressure. Example: A 265/75R16 10-ply tire at 80 psi carries 3,085 pounds; at 60 psi, it carries 2,314 pounds; at 65 psi, it carries 2,507 pounds. The formula is Tire Weight / Tire Pressure = Load Capacity Pounds per PSI. It also mentions that a 265/75R16 6-ply tire at 50 psi holds 2,470 pounds, offering…

Dominio: rvsafety.com

Inscrita: 1997 (28 años)

Introducción: Tire Inflation Tables & Codes for various tire brands including Michelin, Goodyear, Bridgestone, Firestone, B.F. Goodrich, Hankook, Yokohama, Toyo, Continental, Maxxis, Cooper, Sailun, and Towmax. Includes speed ratings (G to H) and load index with corresponding load capacities (from 81 to 170).

Dominio: hankooktire.com

Matriculado: 2000 (25 años)

Introducción: Tire pressure is crucial for safety, driving performance, tire lifespan, and fuel efficiency. Tires can lose up to 1 psi monthly. It is recommended to check tire pressure at least once a month and before long trips. Low air pressure increases contact patch width, causing uneven wear and potential damage. High air pressure focuses force at the center, leading to irregular tread wear. Optimum tire p…

Dominio: mastercrafttires.com

Inscrita: 1997 (28 años)

Introducción: Recommended inflation pressures for tires are specified in pounds per square inch (psi) or kilopascals (kPa) as indicated on the vehicle’s tire placard, certification label, or in the owner’s manual. Underinflation causes excessive heat buildup and internal structural damage, leading to tire failure. Overinflated tires are more likely to be damaged by impacts. Proper inflation is critical for tire…

Dominio: pirelli.com

Matriculado: 1995 (30 años)

Introducción: Recommended tire pressure is established by the vehicle manufacturer and typically falls between 28 and 36 PSI. The correct pressure can be found in the car’s operator manual or on a sticker inside the driver’s door. Tire pressure should be checked when the tire is cold for an accurate reading. Maximum tire pressure is indicated on the tire sidewall and should not be used for everyday driving as i…

Dominio: radpowerbikes.com

Inscrito: 2015 (10 años)

Introducción: This company, Rad Power Bikes – Tire Pressure Guidelines, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

In summary, effective tire inflation is critical for ensuring safety, optimizing performance, and extending the lifespan of tires. B2B buyers must prioritize strategic sourcing of high-quality tires and inflation equipment, as the right products directly influence operational efficiency and cost savings. Understanding the nuances of load and inflation tables, as well as adhering to manufacturer specifications, empowers businesses to make informed purchasing decisions.

By investing in reliable tire inflation solutions, companies can minimize the risks associated with underinflated or overinflated tires, thus enhancing fleet safety and reducing maintenance costs. For international buyers in Africa, South America, the Middle East, and Europe, this is particularly relevant given the diverse driving conditions and regulatory environments across regions like Brazil and Saudi Arabia.

Looking ahead, it is essential to stay informed about evolving tire technologies and inflation practices. Engaging with trusted suppliers and leveraging data-driven insights will position your business for sustainable growth. Take action now—evaluate your tire sourcing strategy and ensure your operations are equipped for the future.

La información facilitada en esta guía, incluido el contenido relativo a fabricantes, especificaciones técnicas y análisis de mercado, tiene únicamente fines informativos y educativos. No constituye asesoramiento profesional en materia de adquisiciones, asesoramiento financiero ni asesoramiento jurídico.

Illustrative image related to tire inflation guide

Aunque hemos hecho todo lo posible por garantizar la exactitud y actualidad de la información, no nos hacemos responsables de posibles errores, omisiones o información obsoleta. Las condiciones del mercado, los detalles de las empresas y las normas técnicas están sujetos a cambios.

Los compradores B2B deben llevar a cabo su propia diligencia debida independiente y exhaustiva antes de tomar cualquier decisión de compra. Esto incluye ponerse en contacto directamente con los proveedores, verificar las certificaciones, solicitar muestras y buscar asesoramiento profesional. El riesgo de confiar en la información contenida en esta guía es responsabilidad exclusiva del lector.