In today’s rapidly evolving automotive landscape, sourcing reliable tire inflators is a critical concern for international B2B buyers, particularly those seeking the RYOBI tire inflator. As the demand for efficient and versatile inflators grows, businesses across Africa, South America, the Middle East, and Europe (including key markets like Germany and Brazil) face the challenge of navigating diverse supplier options and product specifications. This guide aims to simplify that process by providing a comprehensive overview of RYOBI tire inflators, exploring various types, applications, and features that cater to both personal and commercial use.

Understanding the intricacies of tire inflators is essential for making informed purchasing decisions. This guide will cover essential factors such as performance specifications, pricing structures, and supplier vetting processes. It will also delve into the distinct advantages of RYOBI’s 18V ONE+ system, which offers compatibility across over 300 tools, enhancing value for businesses looking to invest in a versatile tool ecosystem.

By empowering B2B buyers with actionable insights, this guide serves as a strategic resource for selecting the right tire inflator that meets operational needs, ensuring optimal performance and reliability. Whether you are a distributor, retailer, or fleet manager, understanding the global market dynamics of RYOBI tire inflators will be pivotal in enhancing your procurement strategy and ensuring customer satisfaction.

| Tipo Nombre | Principales rasgos distintivos | Aplicaciones B2B principales | Breves pros y contras para los compradores |

|---|---|---|---|

| RYOBI ONE+ 18V Cordless High Pressure Inflator | High pressure capability, cordless design | Automotive service, construction | Pros: Portable, versatile; Contras: Tool only option requires battery purchase. |

| 18V ONE+ Dual Function Digital Inflator/Deflator | Digital pressure gauge, auto shut-off | Sports equipment, large inflatables | Pros: Hands-free operation; Contras: Limited to 160 PSI. |

| RYOBI ONE+ High Volume Inflator | Whisper series for quiet operation | Large inflatable structures, camping | Pros: Low noise level; Contras: May be less powerful for high-pressure needs. |

| RYOBI ONE+ High Pressure Digital Inflator Kit | Comes with battery and charger, high PSI capability | Tire repair shops, fleet maintenance | Pros: Complete kit; Contras: Heavier due to battery. |

| RYOBI ONE+ Compact Inflator | Lightweight, compact design | On-the-go applications, emergencies | Pros: Fácil de transportar; Contras: Lower pressure output. |

The RYOBI ONE+ 18V Cordless High Pressure Inflator is designed for high-pressure applications, making it ideal for automotive service and construction. Its cordless design enhances portability, allowing users to operate it anywhere without being tethered to a power source. For B2B buyers, this model is particularly appealing due to its versatility in various settings. However, it is important to note that this version is sold as a tool-only option, necessitating a separate battery purchase, which may affect initial costs.

This model features a digital pressure gauge and an auto shut-off function, allowing users to inflate or deflate items with precision. It is well-suited for businesses dealing with sports equipment or large inflatables, such as event organizers and recreational facilities. The hands-free operation adds convenience, especially in busy environments. However, its maximum pressure of 160 PSI may limit its use for more demanding applications, which buyers should consider based on their specific needs.

The RYOBI ONE+ High Volume Inflator is part of the Whisper series, engineered for quiet operation. This feature is particularly beneficial for businesses that operate in noise-sensitive environments, such as residential areas or indoor venues. It excels in inflating larger items like air mattresses and inflatable structures. However, its lower pressure output may not meet the requirements for high-pressure applications, making it less suitable for tire inflation or similar tasks.

This kit includes a battery and charger, making it a complete solution for businesses requiring a reliable inflator. With its high PSI capability, it is ideal for tire repair shops and fleet maintenance operations where efficiency is crucial. The added convenience of having a complete kit enhances its value proposition. However, potential buyers should consider its heavier weight due to the battery, which could affect portability in certain scenarios.

The RYOBI ONE+ Compact Inflator is lightweight and designed for easy transport, making it an excellent choice for on-the-go applications and emergency situations. Its compact size allows for storage in vehicles or small workspaces, appealing to businesses that prioritize mobility. However, its lower pressure output may not suffice for all inflation needs, so B2B buyers should evaluate whether its capabilities align with their operational requirements.

| Industria/Sector | Specific Application of tire inflator ryobi | Valor/beneficio para la empresa | Consideraciones clave para el aprovisionamiento de esta aplicación |

|---|---|---|---|

| Reparación de automóviles | Routine tire maintenance and emergency inflation | Reduce el tiempo de inactividad y mejora la satisfacción del cliente | Ensure compatibility with various tire types and pressure needs |

| Logistics and Transportation | Fleet vehicle tire inflation and pressure monitoring | Improves fuel efficiency and prolongs tire lifespan | Consider battery life and portability for on-the-go use |

| Sports and Recreation | Inflation of sports equipment (e.g., balls, inflatable gear) | Enhances operational efficiency and user experience | Look for models with digital pressure gauges for precision |

| Construction and Heavy Equipment | Inflating tires on machinery and equipment | Minimizes equipment failure and downtime | Assess the inflator’s PSI range and durability for heavy use |

| Hospitality and Events | Quick inflation of event-related inflatables (e.g., bouncy castles) | Streamlines event setup and enhances guest experience | Evaluate ease of transport and storage options |

In the automotive repair sector, the RYOBI tire inflator is essential for routine tire maintenance and emergency situations. Technicians can quickly inflate tires to the correct pressure, ensuring vehicles are safe and efficient. This tool not only helps in maintaining optimal tire performance but also reduces customer wait times, thereby enhancing satisfaction. For B2B buyers in this sector, compatibility with various tire sizes and types, as well as ease of use, are critical considerations.

In logistics and transportation, maintaining the correct tire pressure is crucial for fleet management. The RYOBI tire inflator allows fleet operators to perform quick inflation checks and adjustments on-site, which can significantly improve fuel efficiency and extend tire life. This capability is particularly beneficial in regions with varying climate conditions, where tire pressure can fluctuate. Buyers should focus on the inflator’s battery life and portability to ensure it meets the demands of mobile operations.

The sports and recreation industry relies on the RYOBI tire inflator for quickly inflating sports equipment such as balls and inflatable gear. This tool streamlines operations, allowing organizations to prepare equipment rapidly for games or events. The digital pressure gauge feature ensures that equipment is inflated to the precise specifications needed for optimal performance. B2B buyers in this sector should prioritize models that offer versatility and precision to cater to various types of sports equipment.

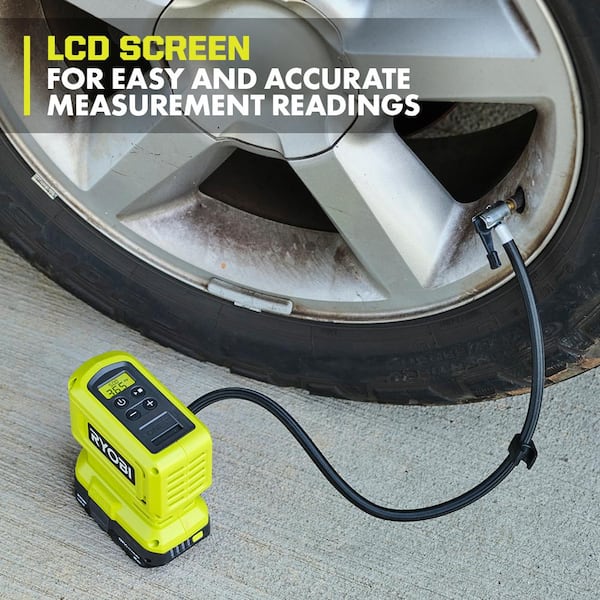

Illustrative image related to tire inflator ryobi

In construction, the RYOBI tire inflator is vital for maintaining the tires of heavy machinery and equipment. Properly inflated tires minimize the risk of equipment failure and reduce downtime, which is critical in a fast-paced construction environment. Buyers in this industry should consider the inflator’s PSI range and overall durability, as heavy equipment often requires higher pressure levels and robust tools that can withstand harsh conditions.

In the hospitality and events sector, the RYOBI tire inflator is ideal for quickly inflating inflatables, such as bouncy castles or promotional displays. Efficient setup is crucial for successful events, and this tool helps streamline the process, ensuring that attractions are ready for guests promptly. Buyers in this field should evaluate the inflator’s portability and storage options, as these factors can significantly impact event logistics and overall guest experience.

El problema: B2B buyers, particularly those in automotive service and fleet management, often encounter challenges when inflating tires to the precise manufacturer-recommended pressure. This can be due to variances in pressure gauges, lack of familiarity with the inflator settings, or the need to switch between different tire types. Failing to achieve the correct PSI can lead to decreased fuel efficiency, increased tire wear, and safety hazards, which are critical concerns for businesses relying on vehicle performance.

La solución: To ensure accurate inflation, users should take advantage of the RYOBI 18V ONE+ Dual Function Inflator/Deflator’s digital pressure gauge and auto-shutoff feature. Before use, it’s essential to familiarize the team with the inflator’s interface, especially the setting options for different PSI levels. When inflating, set the desired pressure based on the vehicle’s specifications, which can typically be found in the owner’s manual or on the driver’s side door jamb. The automatic shut-off feature will stop inflation once the set PSI is reached, preventing over-inflation and enhancing safety. Regularly calibrating the inflator against a known accurate gauge can also help maintain its reliability.

El problema: In a diverse fleet environment, B2B buyers often deal with a variety of tire types, each requiring different inflation pressures and volume capacities. This inconsistency can lead to confusion among staff and delays in service, impacting overall operational efficiency. For instance, inflating high-pressure tires versus low-pressure tires can pose significant challenges if the inflator isn’t equipped for versatility.

La solución: The RYOBI 18V ONE+ High-Pressure Inflator is designed to handle a range of inflation tasks, from high-pressure tires to low-pressure sports balls. To maximize its effectiveness, buyers should train their staff on the inflator’s dual functionality. For high-pressure applications, such as tires for trucks or SUVs, users should ensure the inflator is set to the appropriate PSI and monitor the digital gauge during inflation. For lower pressure items, such as pool toys or air mattresses, the inflator’s high-volume feature can be employed, enabling efficient inflation without excessive effort. By understanding the inflator’s capabilities and having a clear guideline for each tire type, businesses can streamline their inflation processes and enhance service delivery.

El problema: For businesses operating in remote locations or those managing multiple vehicles, limited battery life of the tire inflator can lead to operational downtime. B2B buyers may find that the inflator’s battery does not last long enough to complete multiple inflation tasks, which can be particularly troublesome during peak service periods or emergencies.

La solución: To mitigate battery life issues, B2B buyers should consider investing in additional RYOBI 18V ONE+ batteries or battery kits. This allows for quick replacements when one battery runs out, ensuring continuous operation without delays. Additionally, implementing a battery management system can help track battery usage and optimize charging schedules. It’s also advisable to educate staff on best practices for battery maintenance, such as not fully depleting the battery before recharging, which can extend battery lifespan. By having a robust battery strategy in place, businesses can enhance their tire inflating capabilities and reduce the risk of downtime significantly.

When selecting materials for tire inflators, particularly for models like the RYOBI ONE+ series, several options are commonly considered. Each material has unique properties that influence product performance, durability, and suitability for various applications. Here, we analyze four prevalent materials used in tire inflators from a B2B perspective.

Key Properties:

Plastic materials such as polypropylene and acrylonitrile butadiene styrene (ABS) offer excellent resistance to impact and corrosion. They can withstand a range of temperatures, typically from -20°C to 80°C, making them suitable for various environmental conditions.

Pros y contras:

Plastics are lightweight and cost-effective, which reduces shipping costs and overall product pricing. However, their durability can be a concern under extreme pressure or temperature conditions, potentially leading to failure in high-stress applications.

Impacto en la aplicación:

Plastics are often used for housing components, ensuring that the inflator remains lightweight and portable. However, they may not be suitable for high-pressure applications exceeding 160 PSI without additional reinforcement.

Illustrative image related to tire inflator ryobi

Consideraciones para compradores internacionales:

Buyers in regions like Africa and South America should ensure compliance with local regulations regarding plastic use, as some plastics may not meet environmental standards. Additionally, understanding the thermal and impact resistance properties is crucial for ensuring reliability in varying climates.

Key Properties:

Aluminum is lightweight yet strong, with excellent corrosion resistance and a high strength-to-weight ratio. It can handle temperatures up to 200°C and pressures exceeding 200 PSI, making it ideal for high-performance applications.

Pros y contras:

The primary advantage of aluminum is its durability and resistance to corrosion, which extends the product’s lifespan. However, it is more expensive than plastics and may require more complex manufacturing processes.

Impacto en la aplicación:

Aluminum is often used for critical components such as the inflator body and pressure chambers, where strength and durability are paramount. Its compatibility with various media makes it suitable for both tire inflation and deflation.

Consideraciones para compradores internacionales:

In Europe, compliance with standards such as DIN EN 573 for aluminum alloys is essential. Buyers should also consider the cost implications of aluminum, particularly in regions with high import tariffs.

Key Properties:

Steel offers exceptional strength and durability, with a high resistance to wear and tear. It can withstand extreme temperatures and pressures, making it suitable for heavy-duty applications.

Pros y contras:

While steel is incredibly durable and can handle high-stress situations, it is heavier and more expensive than both plastic and aluminum. Additionally, it is susceptible to corrosion unless properly treated or coated.

Impacto en la aplicación:

Steel is typically used in the construction of high-pressure components and fittings, ensuring that the inflator can operate safely under maximum pressure conditions. Its robustness makes it ideal for industrial applications.

Illustrative image related to tire inflator ryobi

Consideraciones para compradores internacionales:

B2B buyers in the Middle East and Africa should be aware of the need for corrosion-resistant coatings, especially in humid environments. Compliance with ASTM standards for steel products is also critical for ensuring safety and reliability.

Key Properties:

Rubber is known for its flexibility and excellent sealing properties. It can withstand a range of temperatures and is resistant to various chemicals, making it suitable for tire inflators.

Pros y contras:

The primary advantage of rubber is its ability to provide airtight seals, which is crucial for maintaining pressure. However, rubber can degrade over time when exposed to UV light and extreme temperatures, necessitating regular replacement.

Impacto en la aplicación:

Rubber is commonly used in seals and hoses within tire inflators, ensuring efficient operation. Its compatibility with air and various gases makes it ideal for tire inflation.

Consideraciones para compradores internacionales:

Buyers should consider the quality and type of rubber used, as some formulations may not meet international standards for durability. Understanding local climate conditions is also essential, as UV exposure can significantly affect rubber longevity.

Illustrative image related to tire inflator ryobi

| Material | Typical Use Case for tire inflator ryobi | Ventajas clave | Principales desventajas/limitaciones | Coste relativo (Bajo/Medio/Alto) |

|---|---|---|---|---|

| Plástico | Housing components | Ligero y rentable | Less durable under high pressure | Bajo |

| Aluminio | Body and pressure chambers | High strength and corrosion resistance | Más caro y complejo de fabricar | Medio |

| Acero | High-pressure components and fittings | Exceptional strength and durability | Heavier and susceptible to corrosion | Alta |

| Goma | Seals and hoses | Excellent sealing properties | Se degrada con el tiempo por la exposición a los rayos UV | Medio |

This analysis provides a comprehensive overview of material options for tire inflators, equipping international B2B buyers with the insights needed to make informed purchasing decisions.

The manufacturing process of Ryobi tire inflators involves several critical stages that ensure the final product meets the high standards expected by B2B buyers. The main stages include material preparation, forming, assembly, and finishing.

In the initial stage, raw materials are sourced and prepared. Ryobi typically utilizes high-quality plastics, metals, and electronic components. These materials undergo rigorous testing to ensure they meet the required specifications for durability and performance. Suppliers are often vetted for quality compliance, and materials are subjected to inspections before being accepted into the production line.

The forming stage involves shaping the prepared materials into components of the inflator. This may include injection molding for plastic parts and stamping or machining for metal components. Advanced techniques such as Computer Numerical Control (CNC) machining are often employed to achieve precise dimensions, which is critical for ensuring compatibility between parts and overall functionality.

During the assembly phase, the individual components are brought together. This process can be automated or manual, depending on the complexity of the product and the volume of production. Automated assembly lines may utilize robotic systems for tasks such as screwing, soldering, and component placement, which enhances efficiency and reduces the potential for human error.

After assembly, the tire inflators undergo various finishing processes. These may include surface treatments, painting, and quality checks to ensure aesthetic appeal and functionality. Packaging is also a crucial aspect of this stage, as it protects the product during transportation and communicates essential information to buyers.

Quality assurance is paramount in ensuring that Ryobi tire inflators meet international standards. Compliance with ISO 9001 is common practice, which outlines the requirements for a quality management system. This standard helps organizations ensure they consistently meet customer and regulatory requirements, thereby enhancing customer satisfaction.

In addition to ISO 9001, Ryobi products may also comply with industry-specific certifications such as CE marking for the European market and various safety standards applicable in different regions. For instance, in the Middle East, adherence to GCC standards may be required, while in South America, compliance with INMETRO regulations could be relevant.

Illustrative image related to tire inflator ryobi

Quality control (QC) checkpoints are critical for maintaining product integrity throughout the manufacturing process. Key checkpoints typically include:

Control de calidad entrante (IQC): This initial checkpoint ensures that all incoming materials meet specified standards before being used in production.

Control de calidad durante el proceso (IPQC): During manufacturing, regular inspections are conducted to identify any defects or deviations from the manufacturing process. This proactive approach helps to mitigate issues before they escalate.

Control de calidad final (CCF): Once the inflators are fully assembled, a comprehensive inspection is conducted. This includes functional testing, pressure tests, and aesthetic checks to ensure the product meets all specifications.

Testing methods for tire inflators can include:

B2B buyers can take several steps to verify the QC processes of potential suppliers:

Audits: Conducting regular audits of the manufacturing facility can provide insights into the supplier’s quality management practices. This can include reviewing their QC protocols and inspection records.

Informes de calidad: Requesting detailed quality reports can help buyers understand how defects are managed and how often products are subjected to quality checks.

Inspecciones de terceros: Engaging third-party inspection services can offer an impartial assessment of the manufacturing process and ensure that products meet specified standards before shipment.

International buyers, especially from diverse regions like Africa, South America, the Middle East, and Europe, should be aware of the nuances in certifications and quality standards. Regulations can vary significantly based on local laws and market expectations. For example, while CE marking is essential for European markets, buyers in Africa may prioritize certifications that demonstrate compliance with regional standards.

Additionally, language barriers and differing documentation requirements can complicate the verification process. It is advisable for buyers to engage local representatives or consultants who understand the regulatory landscape and can assist in navigating these complexities.

In summary, the manufacturing processes and quality assurance measures for Ryobi tire inflators are designed to ensure high-quality products that meet international standards. By understanding the stages of manufacturing, the significance of quality control, and how to verify supplier practices, B2B buyers can make informed decisions when sourcing tire inflators. This knowledge is particularly valuable in navigating the complexities of international trade and ensuring that products meet the specific needs of diverse markets.

To assist B2B buyers in sourcing the RYOBI tire inflator effectively, this guide outlines essential steps to ensure informed procurement decisions. By following this checklist, businesses can secure quality products while aligning with their operational needs and budget constraints.

Understanding your specific requirements is crucial before initiating the procurement process. Identify the inflator’s intended use, such as high-pressure applications for tires or lower-pressure tasks for inflatables. Consider factors like maximum PSI, battery compatibility (e.g., RYOBI’s 18V ONE+ system), and whether you need features like digital pressure gauges or automatic shut-off.

Conduct thorough market research to gauge current pricing trends and product availability. Comparing costs across various suppliers helps in identifying competitive pricing while ensuring quality. Be aware of seasonal fluctuations and promotional offers that may impact pricing in different regions, particularly in Africa, South America, and the Middle East.

Before committing to a supplier, it’s vital to conduct a comprehensive evaluation. Request detailed company profiles, product catalogs, and references from existing customers. Look for suppliers who have a proven track record in the region you are targeting, as local expertise can significantly impact service levels and after-sales support.

Ensure that potential suppliers meet international quality standards and certifications relevant to the tire inflator. This includes checking for compliance with safety regulations and product testing certifications. Verified suppliers are more likely to deliver reliable products that meet your operational needs, minimizing the risk of defects or performance issues.

Before placing a bulk order, request product samples to evaluate the inflator’s performance firsthand. Testing the inflator allows you to assess its functionality, ease of use, and durability. This step is particularly important when sourcing for larger fleets or businesses that rely heavily on these tools.

Once you have identified a suitable supplier, engage in negotiations to establish favorable terms and conditions. Discuss pricing, payment terms, warranty provisions, and delivery timelines. Clear agreements can prevent misunderstandings and ensure that both parties have aligned expectations.

After completing your purchase, consider building a long-term relationship with your supplier. Regular communication can lead to better pricing on future orders, priority service, and access to new products. A strong partnership can enhance your supply chain efficiency and support your business’s growth strategies.

Illustrative image related to tire inflator ryobi

By following this checklist, B2B buyers can make informed decisions when sourcing RYOBI tire inflators, ensuring they select the best products to meet their operational needs while fostering reliable supplier relationships.

When analyzing the cost structure for RYOBI tire inflators, several key components must be taken into account.

Materiales: The primary materials used in tire inflators include high-quality plastics, metals, and electronic components. The choice of materials directly impacts durability and performance. For instance, a model featuring robust casing and advanced electronics may command a higher price due to the increased material costs.

Trabajo: Labor costs vary significantly based on the manufacturing location. Countries with higher labor costs, such as Germany, may see increased pricing compared to regions with lower labor expenses, like parts of Africa or South America. Automation in manufacturing can also influence these costs, as more efficient processes can lead to reduced labor input.

Gastos generales de fabricación: This encompasses the indirect costs associated with production, including utilities, rent, and administrative expenses. Efficient factories with streamlined processes can minimize these overheads, thereby impacting the final pricing of the tire inflators.

Herramientas: Custom tooling for specific inflator designs can add significant upfront costs. For B2B buyers, understanding the tooling investment required for customized inflators is crucial when evaluating pricing.

Control de calidad: Rigorous quality assurance processes can increase costs but are essential for ensuring product reliability. Models with extensive testing protocols may have higher price points, reflecting the investment in quality assurance.

Logística: Shipping and logistics costs are critical, especially for international buyers. Factors such as shipping distance, mode of transportation, and customs duties must be considered, as these can substantially affect the overall cost of the product.

Margen: The profit margin varies between suppliers and regions, influenced by market competition and perceived value. Buyers should expect different margins based on the supplier’s reputation and the product’s unique features.

Several factors can influence the pricing of RYOBI tire inflators, especially for international buyers:

Volumen/MOQ: Minimum Order Quantities (MOQ) often dictate price breaks. Larger orders typically yield better pricing due to economies of scale.

Especificaciones y personalización: Customized inflators tailored to specific market needs may incur additional costs, impacting the overall price. Understanding the specifications that drive costs can help buyers negotiate better deals.

Materiales y certificaciones de calidad: Higher-quality materials and certifications (e.g., ISO standards) can lead to increased costs. Buyers should weigh the benefits of quality against pricing when sourcing.

Factores del proveedor: The reputation and reliability of the supplier can influence pricing. Established suppliers may charge a premium for their products due to perceived reliability and brand strength.

Incoterms: Understanding the agreed terms of sale (Incoterms) is crucial. FOB (Free On Board) pricing may lead to additional shipping costs for the buyer, while CIF (Cost, Insurance, Freight) may include these in the overall price.

Comprender el coste total de propiedad (TCO): Beyond the purchase price, consider maintenance, warranty, and potential repair costs. A lower upfront price may lead to higher long-term costs if the product is of inferior quality.

Leverage Volume Discounts: If planning to purchase in bulk, negotiate pricing based on volume. Suppliers are often willing to offer discounts for larger orders.

Request Detailed Quotes: Ensure quotes include all cost components. This transparency can help identify hidden costs and facilitate more effective negotiations.

Compare Multiple Suppliers: Conducting a competitive analysis of suppliers can provide leverage during negotiations. Understanding market pricing can help in securing a fair deal.

Be Aware of Regional Pricing Nuances: Pricing can vary significantly between regions. For instance, a supplier in Brazil may have different cost structures than one in Germany. Understanding these nuances can aid in negotiation strategies.

The prices and cost structures referenced in this analysis are indicative and subject to change based on market conditions, supplier negotiations, and evolving economic factors. It is advisable for buyers to conduct thorough market research and obtain multiple quotations to ensure the best value for their investment.

In the competitive landscape of tire inflators, the RYOBI ONE+ series stands out for its versatility and performance. However, B2B buyers should consider alternative solutions that may better fit their specific needs, such as unique operational environments, cost constraints, or user preferences. This analysis will compare the RYOBI tire inflator against two other viable options: the DEWALT DCC020IB Inflator and the Viair 88P Portable Air Compressor.

Illustrative image related to tire inflator ryobi

| Aspecto comparativo | Tire Inflator Ryobi | DEWALT DCC020IB Inflator | Viair 88P Portable Air Compressor |

|---|---|---|---|

| Rendimiento | Up to 160 PSI, auto-shutoff | Up to 160 PSI, dual power source | 120 PSI, continuous duty cycle |

| Coste | Approx. $39.97 (tool only) | Approx. $79.00 | Approx. $69.99 |

| Facilidad de aplicación | Cordless, lightweight | Cordless, includes AC/DC options | Requires vehicle power source |

| Mantenimiento | Low, standard battery care | Low, battery maintenance | Moderate, check for air leaks |

| El mejor caso de uso | Ideal for home and light-duty tasks | Suitable for on-the-go professionals | Designed for heavy-duty inflations |

The DEWALT DCC020IB is a robust alternative that offers dual power options, allowing it to be used both cordlessly and when plugged into an AC outlet. This flexibility is beneficial for B2B users who may need to inflate tires in various environments, from remote job sites to indoor workshops. With a performance of up to 160 PSI and a built-in digital pressure gauge, it provides accurate inflation control. However, the higher price point may be a consideration for budget-conscious buyers.

The Viair 88P is engineered for heavy-duty tasks, making it an excellent choice for commercial applications. With a maximum pressure of 120 PSI and a continuous duty cycle, it is particularly effective for inflating larger tires or dealing with multiple vehicles. While it requires a vehicle power source, which can limit its usability in certain settings, its performance and durability make it a strong contender for businesses that prioritize reliability. Its price is competitive, but buyers should factor in the need for a power outlet.

When choosing the right tire inflator for specific needs, B2B buyers should assess several factors. The RYOBI ONE+ is ideal for those who prioritize portability and ease of use for light-duty tasks, particularly in home or small business settings. The DEWALT DCC020IB is suitable for professionals requiring versatility and higher pressure capabilities, while the Viair 88P is best for commercial applications where durability and continuous operation are critical.

Ultimately, understanding the operational environment, budget constraints, and the specific requirements of the tasks at hand will guide buyers toward the most appropriate solution. By comparing these alternatives thoughtfully, businesses can invest in equipment that enhances efficiency and meets their unique needs.

When evaluating tire inflators for B2B purchases, understanding the essential technical properties is crucial. Here are several specifications that are particularly important:

Pressure Capacity (PSI)

The maximum pressure a tire inflator can achieve is measured in pounds per square inch (PSI). For instance, RYOBI inflators can reach up to 160 PSI, making them suitable for various applications, from standard vehicle tires to sports equipment. This specification is vital for B2B buyers as it determines the inflator’s versatility and suitability for different tasks.

Voltage and Power Source

RYOBI tire inflators operate on an 18V battery system, compatible with over 300 RYOBI tools. This standardization allows businesses to streamline their operations by using the same battery across various tools, reducing costs and storage needs. Understanding the voltage is key for ensuring compatibility with existing equipment.

Inflation and Deflation Rate

The speed at which an inflator can inflate or deflate an object is crucial for efficiency, especially in a commercial setting. RYOBI inflators are designed for high-volume inflation and deflation, enabling quick setups for multiple applications, such as air mattresses or pool toys. Fast inflation rates can significantly improve productivity in a business environment.

Digital Pressure Gauge

Many RYOBI inflators feature a digital pressure gauge, providing accurate readings of current pressure levels. This is especially important for businesses that require precision in inflation, such as automotive repair shops. A digital gauge can help prevent under- or over-inflation, ensuring safety and compliance with industry standards.

Auto-Shutoff Feature

This feature allows the inflator to automatically shut off when the desired pressure is reached. It enhances user safety and convenience, reducing the risk of over-inflation. For B2B buyers, this can lead to fewer accidents and lower liability in commercial settings.

Accessory Storage

On-board accessory storage is a practical feature for businesses that require portability and efficiency. This allows users to keep all necessary attachments organized and readily accessible, which is particularly beneficial for mobile applications or fieldwork.

Understanding industry terminology is essential for making informed purchasing decisions. Here are several key terms that B2B buyers should be familiar with:

OEM (fabricante de equipos originales)

This term refers to companies that produce parts and equipment that may be marketed by another manufacturer. When purchasing RYOBI inflators, knowing whether you are dealing with an OEM can affect warranty and service options.

MOQ (Cantidad mínima de pedido)

This term denotes the smallest number of units a supplier is willing to sell. For businesses looking to stock RYOBI tire inflators, understanding MOQ can help in budgeting and inventory management.

RFQ (solicitud de presupuesto)

An RFQ is a document sent to suppliers to request pricing and terms for specific products. B2B buyers should issue an RFQ when seeking competitive pricing for RYOBI inflators, ensuring they receive the best possible deal.

Incoterms (Términos comerciales internacionales)

These are pre-defined commercial terms published by the International Chamber of Commerce (ICC) that clarify the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms is essential for B2B transactions involving RYOBI inflators, as they dictate shipping costs, risks, and delivery terms.

Warranty and Support

Understanding warranty terms is crucial for B2B buyers, as it affects the long-term cost of ownership. RYOBI typically offers warranties on their products, which can be a significant factor in the purchasing decision.

Plazos de entrega

This term refers to the amount of time it takes for an order to be fulfilled. Knowing the lead time for RYOBI tire inflators is essential for planning and inventory management, especially for businesses with tight schedules or specific project timelines.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions that align with their operational needs and budget constraints.

The tire inflator market, particularly for Ryobi products, is experiencing robust growth driven by several global factors. Firstly, the increasing demand for portable and efficient inflation solutions is fueled by the rise in vehicle ownership across emerging markets in Africa and South America. This trend is particularly significant in regions where road infrastructure is still developing, making reliable tire maintenance crucial for vehicle longevity and safety. Furthermore, the growing popularity of outdoor activities and sports is boosting demand for inflators that can handle various applications, from car tires to sports equipment.

Technological advancements are also shaping market dynamics. The introduction of smart inflators, such as those in the Ryobi ONE+ series, offers features like digital pressure gauges and auto shut-off capabilities, enhancing user convenience. B2B buyers are increasingly prioritizing products that offer efficiency, versatility, and ease of use, which aligns with the current trend towards multifunctional tools. Additionally, the rise of e-commerce platforms is reshaping sourcing strategies, allowing buyers in regions like Europe and the Middle East to access a broader range of products and compare prices more effectively.

Sustainability has become a critical consideration in the B2B landscape, particularly for industries like tools and automotive accessories. For tire inflators, including those from Ryobi, the environmental impact of manufacturing processes and materials is under scrutiny. Buyers are increasingly looking for products that not only perform well but are also made from sustainable materials. This includes the use of recyclable plastics and metals in the construction of inflators, as well as energy-efficient manufacturing processes.

Illustrative image related to tire inflator ryobi

Moreover, ethical sourcing practices are gaining traction. B2B buyers are more informed and concerned about the supply chains behind the products they purchase. Certifications such as ISO 14001, which demonstrates a commitment to environmental management, are becoming essential for suppliers aiming to attract conscientious buyers. By aligning with suppliers who prioritize sustainability, businesses can enhance their brand reputation and appeal to environmentally conscious consumers, particularly in Europe, where regulatory pressures for sustainable practices are more pronounced.

The tire inflator segment has evolved significantly over the past few decades, transitioning from basic, manual pumps to advanced, battery-operated devices like the Ryobi ONE+ series. Initially, tire inflators were primarily manual, requiring considerable effort to achieve desired pressure levels. As automotive technology advanced, the need for quicker and more efficient solutions became apparent.

The introduction of electric inflators marked a pivotal shift, allowing for faster inflation and convenience. The Ryobi brand capitalized on this trend by developing versatile, battery-operated models that cater to both automotive and recreational needs. The integration of smart technology, such as digital pressure gauges and automatic shut-off features, reflects a growing demand for user-friendly, efficient tools that enhance the overall consumer experience. This evolution underscores the importance of innovation in meeting the diverse needs of B2B buyers in an increasingly competitive market.

How do I ensure the quality of the RYOBI tire inflator before purchasing?

To ensure the quality of the RYOBI tire inflator, request product samples from the supplier. Conduct thorough quality assurance tests, including performance evaluations and safety checks. Additionally, review certifications and warranties provided by RYOBI, which indicate adherence to international quality standards. If possible, visit the manufacturing facility or seek third-party inspections to verify the production processes and materials used.

What is the best RYOBI tire inflator for commercial use?

The RYOBI 18V ONE+ Dual Function Digital Inflator/Deflator is highly recommended for commercial use due to its high-pressure capabilities (up to 160 PSI) and versatility in inflating various items. Its auto-shutoff feature ensures optimal inflation without over-pressurizing, making it ideal for tire maintenance and large inflatables. The hands-free operation and digital pressure gauge also enhance efficiency, which is essential in a commercial setting.

What are the minimum order quantities (MOQ) for RYOBI tire inflators?

Minimum order quantities (MOQ) for RYOBI tire inflators can vary by supplier and region. Typically, wholesale suppliers may set an MOQ of 10 to 50 units to ensure cost-effectiveness. It’s advisable to negotiate with suppliers, especially if you’re entering a new market or require a lower quantity for testing demand. Always clarify the MOQ before finalizing any agreements to avoid unexpected costs.

What payment terms are generally offered for international purchases of RYOBI tire inflators?

Payment terms for international purchases of RYOBI tire inflators can vary significantly based on the supplier’s policies and the buyer’s creditworthiness. Common terms include 30% upfront payment and 70% upon delivery, or net 30 days after invoice. Some suppliers may offer letters of credit for larger transactions. Always discuss payment options early in negotiations to establish trust and ensure a smooth transaction process.

How can I customize RYOBI tire inflators for my brand?

Customizing RYOBI tire inflators often involves private labeling or branding options. Engage with the supplier to explore available customization features such as logo placement, color options, and packaging designs. Depending on the volume and type of customization required, there may be additional costs or MOQs. Ensure that any modifications comply with local regulations and standards in your target market.

What logistics considerations should I keep in mind when importing RYOBI tire inflators?

When importing RYOBI tire inflators, consider logistics factors such as shipping methods, customs duties, and lead times. Choose reliable freight forwarders familiar with international trade regulations to facilitate smooth transportation. Additionally, ensure all import documentation is in order, including invoices, packing lists, and certificates of origin, to avoid delays at customs. Assess the total landed cost, including freight and duties, to calculate profitability.

What should I look for in a supplier of RYOBI tire inflators?

When vetting suppliers of RYOBI tire inflators, prioritize their experience, reputation, and product certifications. Research their history in the industry, customer reviews, and any partnerships with reputable brands. Request references from other businesses and verify their ability to meet your specific requirements, including quality standards and delivery timelines. A reliable supplier should also have clear communication channels and a responsive customer service team.

How can I ensure compliance with international trade regulations when sourcing RYOBI tire inflators?

To ensure compliance with international trade regulations, familiarize yourself with the import/export laws of both your country and the supplier’s country. This includes tariffs, product safety standards, and environmental regulations. Work with legal advisors or customs brokers to understand the necessary documentation, such as import permits and customs declarations. Additionally, verify that the RYOBI tire inflators meet all relevant certifications and safety standards required in your market.

Dominio: ryobitools.com

Matriculado: 1999 (26 años)

Introducción: Product Name: 18V ONE+ DUAL FUNCTION DIGITAL INFLATOR/DEFLATOR PCL031B

Price: $39.97 (Tool Only), $69.97 (2Ah Battery/Charger)

Características principales:

– High Pressure Inflation for Tires and Sports Balls

– Digital Pressure Gauge

– On-board Accessory Storage

– Hands-free Use with Auto-Shutoff when desired PSI is reached

– High Volume Inflation and Deflation for pool toys, air mattresses, and other large infl…

In the rapidly evolving landscape of tire inflators, RYOBI’s 18V ONE+ series stands out as a versatile and efficient solution for international buyers. The dual-functionality of the digital inflator/deflator, combined with features like auto-shutoff and high-pressure capabilities, positions these tools as invaluable assets for both personal and commercial use. For businesses in Africa, South America, the Middle East, and Europe, strategic sourcing of RYOBI inflators not only ensures high-quality performance but also aligns with sustainability goals through the use of rechargeable batteries across multiple tools.

Effective procurement strategies can enhance operational efficiency, reduce costs, and improve customer satisfaction. By investing in RYOBI’s innovative inflators, businesses can meet diverse inflation needs—from automotive applications to recreational equipment—while leveraging the extensive ONE+ battery system for seamless integration across their tool inventory.

As you consider your sourcing options, prioritize suppliers that can provide not only the product but also comprehensive support and warranties. Embrace the opportunity to enhance your business’s capabilities with RYOBI inflators, setting a course for increased productivity and customer loyalty in the years ahead.

La información facilitada en esta guía, incluido el contenido relativo a fabricantes, especificaciones técnicas y análisis de mercado, tiene únicamente fines informativos y educativos. No constituye asesoramiento profesional en materia de adquisiciones, asesoramiento financiero ni asesoramiento jurídico.

Illustrative image related to tire inflator ryobi

Aunque hemos hecho todo lo posible por garantizar la exactitud y actualidad de la información, no nos hacemos responsables de posibles errores, omisiones o información obsoleta. Las condiciones del mercado, los detalles de las empresas y las normas técnicas están sujetos a cambios.

Los compradores B2B deben llevar a cabo su propia diligencia debida independiente y exhaustiva antes de tomar cualquier decisión de compra. Esto incluye ponerse en contacto directamente con los proveedores, verificar las certificaciones, solicitar muestras y buscar asesoramiento profesional. El riesgo de confiar en la información contenida en esta guía es responsabilidad exclusiva del lector.