In the ever-evolving landscape of cycling accessories, sourcing reliable tire inflators for bikes presents a significant challenge for international B2B buyers. Whether operating in bustling markets across Africa, South America, the Middle East, or Europe, securing high-quality and efficient tire inflators is crucial for meeting the demands of an expanding customer base. This guide aims to illuminate the complexities of the tire inflator market, providing insights into various types of inflators, their applications, and essential considerations for supplier vetting.

By diving into the specifics of electric pumps, CO2 inflators, and traditional hand pumps, this comprehensive resource equips businesses with the knowledge to make informed purchasing decisions. Buyers will gain a thorough understanding of cost structures, performance metrics, and market trends, enabling them to identify the best products to meet their operational needs.

Moreover, this guide emphasizes the importance of selecting reliable suppliers who can ensure consistent product quality and availability. With actionable insights tailored for B2B stakeholders, especially those in regions like Vietnam and Brazil, this resource is designed to empower businesses to navigate the global tire inflator market effectively. Ultimately, by leveraging this guide, international buyers can enhance their product offerings, satisfy customer demands, and drive profitability in a competitive marketplace.

| Tipo Nombre | Principales rasgos distintivos | Aplicaciones B2B principales | Breves pros y contras para los compradores |

|---|---|---|---|

| Bombas manuales | Manual operation, lightweight, portable | Retail bike shops, cycling events | Pros: Cost-effective, no need for power. Contras: Mano de obra intensiva, inflación más lenta. |

| CO2 Tire Inflators | Uses CO2 cartridges for rapid inflation | Emergency kits, racing teams | Pros: Fast inflation, compact size. Contras: Limited air supply, recurring costs for cartridges. |

| Electric Mini Pumps | Battery-operated, digital pressure gauge | E-commerce, bike rental services | Pros: Effortless operation, precise inflation. Contras: Requires charging, potentially higher cost. |

| Floor Pumps | Larger, stable design for high volume inflation | Workshops, bike repair shops | Pros: Quick inflation, accurate pressure readings. Contras: Less portable, requires space. |

| Hybrid Pumps | Combines hand pump and CO2 inflator functionalities | Retail, adventure cycling | Pros: Versatile, suitable for various situations. Contras: Heavier than standard pumps, can be more complex. |

Hand pumps are a staple in the cycling industry, especially in retail bike shops and during cycling events. They are lightweight, portable, and operate manually, making them an economical choice. However, while they are cost-effective and require no power source, the inflation process is labor-intensive and can be slower compared to other options. B2B buyers should consider the trade-off between initial investment and the potential need for quick inflation in high-demand situations.

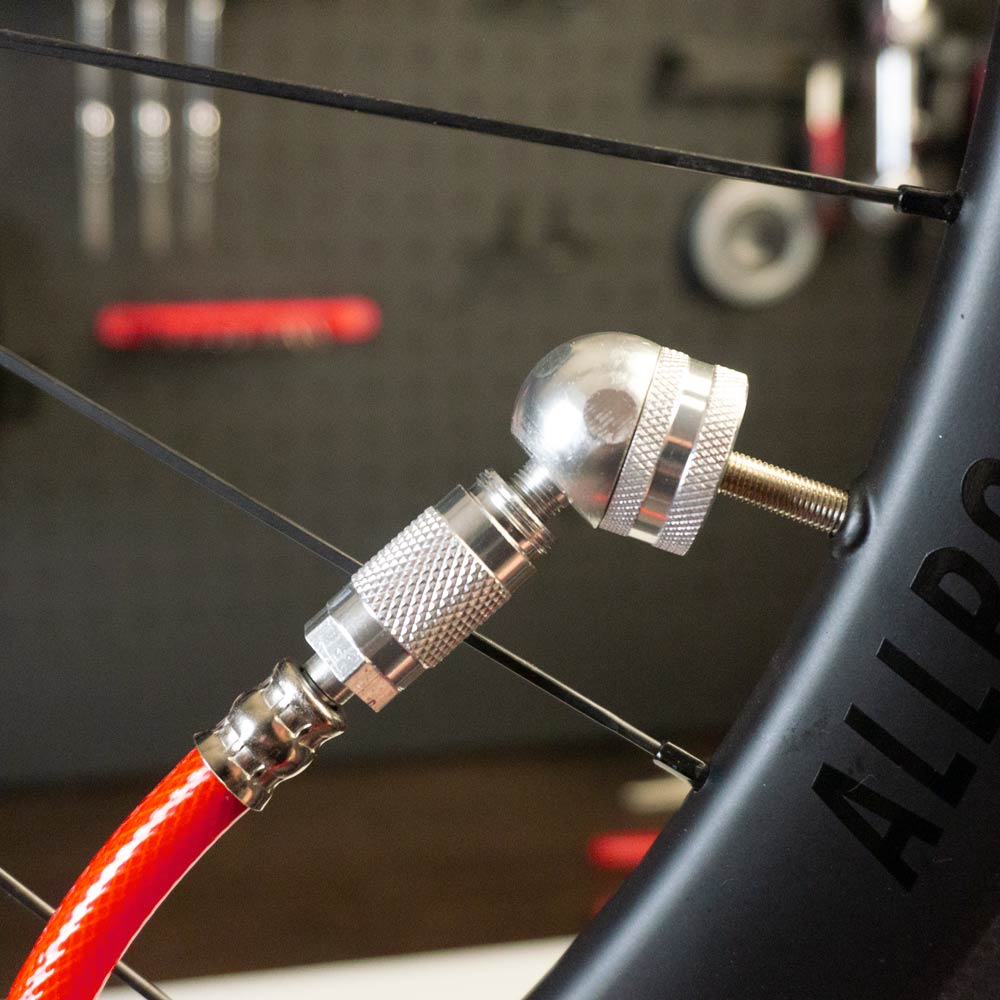

Illustrative image related to tire inflator bike

CO2 tire inflators are designed for rapid inflation using disposable cartridges, making them ideal for emergency kits and racing teams. Their compact size allows for easy transport, and they can inflate a tire in seconds, which is crucial during time-sensitive events. However, the need for recurring purchases of CO2 cartridges can add to operational costs. B2B buyers should weigh the benefits of speed and convenience against the ongoing expense of cartridge replenishment.

Electric mini pumps have gained popularity due to their ease of use and precision. They typically feature a digital pressure gauge, allowing users to set desired pressure levels with minimal effort. These pumps are particularly suitable for e-commerce platforms and bike rental services, where customer satisfaction is paramount. Despite their advantages, electric mini pumps require charging and may have a higher upfront cost, which businesses should factor into their purchasing decisions.

Floor pumps are larger and designed for high-volume inflation, making them a preferred choice for workshops and bike repair shops. They provide quick inflation and highly accurate pressure readings, which are essential for professional maintenance. The downside is their lack of portability and the space they occupy. B2B buyers should consider the volume of tires they service and the space available in their facilities when selecting floor pumps.

Hybrid pumps combine the functionalities of hand pumps and CO2 inflators, making them versatile tools for retail and adventure cycling. They can handle various inflation scenarios, from quick fixes to more extensive tire needs. While they offer the flexibility of multiple inflation methods, they tend to be heavier than standard pumps and may require more complex usage. B2B buyers should evaluate their specific use cases to determine if the added versatility justifies the potential downsides.

| Industria/Sector | Specific Application of tire inflator bike | Valor/beneficio para la empresa | Consideraciones clave para el aprovisionamiento de esta aplicación |

|---|---|---|---|

| Transportation | Emergency tire inflation for delivery vehicles | Reduces downtime during deliveries, enhancing efficiency | Durability, portability, and battery life |

| Turismo y ocio | Rental services for bicycles | Increases customer satisfaction and safety | Compact design, ease of use, and maintenance support |

| Fabricación | On-site maintenance for warehouse vehicles | Lowers operational costs by minimizing downtime | Power source options and compatibility with various vehicles |

| Sports and Fitness | Support for cycling events and competitions | Ensures quick response to tire issues, enhancing performance | Speed of inflation and accuracy of pressure measurement |

| Construcción | Inflation for utility vehicles and equipment | Improves project timelines by ensuring equipment readiness | Robustness, ease of transport, and inflation capacity |

In the transportation sector, tire inflators are vital for emergency inflation of delivery vehicles. Businesses can mitigate costly downtime caused by flat tires by equipping their fleets with portable inflators. These devices offer rapid inflation, allowing drivers to resume deliveries quickly. Buyers should consider the durability and portability of these inflators, as well as battery life, particularly in regions where access to power sources may be limited.

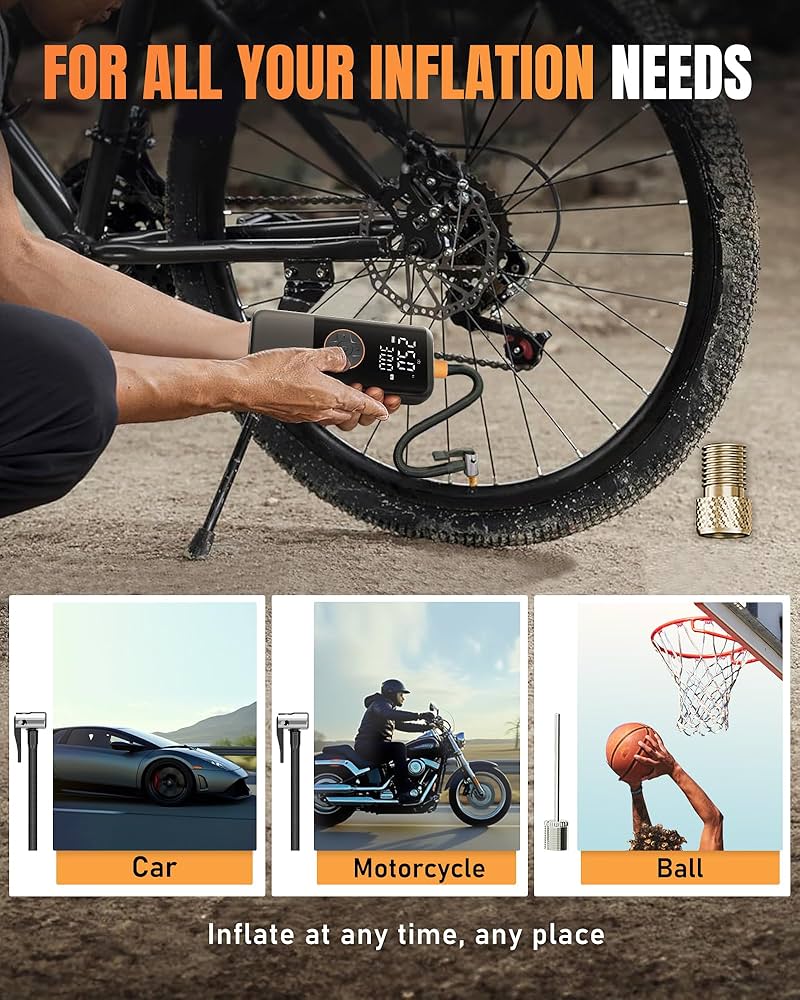

Illustrative image related to tire inflator bike

For tourism and recreational businesses, particularly those that rent bicycles, tire inflators are essential for maintaining safety and satisfaction. Quick inflation capabilities ensure that customers can easily resolve tire issues, enhancing their experience. Buyers should prioritize compact designs and ease of use, as these factors contribute to customer satisfaction and operational efficiency. Additionally, maintenance support is crucial to ensure the inflators remain functional during peak seasons.

In manufacturing settings, tire inflators are used for on-site maintenance of warehouse vehicles, such as forklifts and pallet jacks. Quick inflation of tires minimizes operational disruptions, ultimately lowering costs associated with equipment downtime. When sourcing inflators, businesses should focus on compatibility with various vehicle types and available power source options to ensure seamless operation across their fleet.

During cycling events and competitions, tire inflators play a critical role in ensuring participants can quickly address tire issues. The ability to inflate tires rapidly and accurately can significantly impact performance and safety. B2B buyers in this sector should look for inflators that offer speed and precision in pressure measurement, as these features can enhance the overall event experience for competitors and organizers alike.

In the construction industry, tire inflators are used to maintain utility vehicles and equipment, ensuring that all machinery is ready for operation. By keeping tires properly inflated, construction companies can avoid delays and keep projects on schedule. Buyers should consider the robustness and transportability of inflators, as well as their inflation capacity, especially when working in remote locations where access to traditional air sources may be limited.

El problema: Many B2B buyers face the challenge of ensuring that their tire inflator bike products deliver precise and consistent tire pressure. Inconsistent pressure can lead to poor riding performance, increased tire wear, and safety concerns. For businesses that provide tire inflators to consumers or cyclists, this inconsistency can result in negative customer feedback and potential returns. Additionally, buyers in regions with varying climate conditions may find it challenging to maintain optimal tire pressure, further complicating the issue.

La solución: To overcome this problem, it is essential for B2B buyers to source tire inflators equipped with high-quality pressure gauges and automatic shut-off features. When selecting a product, prioritize models that have been tested for accuracy and reliability. Implementing digital inflators with preset pressure settings allows users to simply choose their desired pressure, ensuring accuracy without manual intervention. Educating customers on the importance of regular pressure checks and providing guidance on how to use the inflators effectively can also enhance user experience. For instance, providing instructional materials or videos on how to calibrate and utilize the inflator can significantly improve customer satisfaction.

El problema: Many B2B buyers struggle with the challenge of providing a tire inflator bike that is both portable and convenient for cyclists. This issue is particularly pronounced in regions where cyclists may need to travel long distances and cannot afford to carry heavy equipment. In markets like Africa or South America, where terrain can vary widely, the demand for lightweight, compact inflators that can easily fit into a backpack or bike frame is critical. Buyers who fail to address this need may find their products underperforming in the market.

La solución: To meet this demand, buyers should seek compact, lightweight models that do not compromise on power or functionality. Electric mini pumps and hybrid models that combine CO2 inflators with hand pumps offer versatile solutions for cyclists. When sourcing these products, consider the weight, size, and battery life. Additionally, offering accessories such as carrying cases or mounts can enhance portability and convenience. Providing information on how these inflators can be easily stowed away or integrated into cyclists’ gear can be an effective selling point. Highlighting these features in marketing materials can also attract customers looking for practical solutions for their cycling needs.

Illustrative image related to tire inflator bike

El problema: A significant pain point for B2B buyers is the lack of user knowledge regarding tire inflators. Many consumers may be unfamiliar with the different types of inflators available, their features, and how to use them correctly. This knowledge gap can lead to improper usage, resulting in dissatisfaction and potential safety risks. For businesses, this translates into increased customer service inquiries and potential product returns, impacting profitability and brand reputation.

La solución: To bridge this knowledge gap, B2B buyers should invest in comprehensive educational resources. This can include detailed product manuals, instructional videos, and online tutorials that explain how to operate different types of tire inflators. Additionally, consider offering workshops or webinars for retailers and end-users to demonstrate the proper use of these products. Partnering with influencers in the cycling community to create content that highlights the benefits and functionalities of tire inflators can also enhance visibility and user understanding. Providing exceptional customer support, including easily accessible FAQs and live chat options, can further empower users and improve their overall experience with the product.

When selecting materials for tire inflator bikes, manufacturers often consider a variety of factors, including performance, durability, cost, and specific application requirements. Here, we analyze four common materials used in the construction of tire inflators: aluminum, plastic, rubber, and stainless steel.

Aluminum is widely used in tire inflators due to its lightweight nature and excellent strength-to-weight ratio. It typically has a temperature rating of up to 150°C and can withstand high pressure, making it suitable for inflating various tire types. Aluminum is also resistant to corrosion, which is particularly beneficial for outdoor applications.

Pros: Aluminum is durable, lightweight, and offers good thermal conductivity. It is relatively easy to manufacture and can be anodized for additional surface protection.

Illustrative image related to tire inflator bike

Contras: The primary drawback of aluminum is its cost, which can be higher than other materials like plastic. Additionally, while aluminum is resistant to corrosion, it can be prone to dents and scratches.

Impacto en la aplicación: Aluminum is compatible with various media, including air and nitrogen, making it versatile for different tire inflating needs.

Consideraciones para compradores internacionales: Buyers in regions like Africa and South America should ensure that aluminum components meet local standards for safety and performance, such as ASTM or ISO certifications.

Plastic is another common material used in tire inflators, particularly for housing and components that do not require high strength. Its temperature resistance generally ranges from -20°C to 80°C, depending on the type of plastic used.

Pros: Plastic is lightweight, cost-effective, and can be molded into complex shapes, making it suitable for intricate designs. It also provides good insulation properties.

Illustrative image related to tire inflator bike

Contras: Plastic is less durable than metals and can degrade over time, especially when exposed to UV light and extreme temperatures. It may not be suitable for high-pressure applications.

Impacto en la aplicación: Plastic is typically used for non-structural components, such as casing or handles, where high strength is not critical.

Consideraciones para compradores internacionales: Buyers should look for plastics that comply with local environmental regulations, especially in Europe, where there are stringent rules regarding material safety and recyclability.

Rubber is primarily used in seals and hoses within tire inflators due to its excellent elasticity and pressure resistance. It can typically handle temperatures from -30°C to 100°C, making it suitable for various climates.

Pros: Rubber provides excellent sealing capabilities, preventing air leaks during inflation. It is also durable and can withstand repeated flexing without failure.

Contras: Rubber can degrade over time due to ozone exposure and UV radiation, leading to cracks and loss of elasticity. It may also be more expensive than some synthetic alternatives.

Impacto en la aplicación: Rubber is essential for components that require flexibility and airtight seals, ensuring efficient tire inflation.

Consideraciones para compradores internacionales: Buyers should ensure that rubber components meet international standards for safety and performance, particularly in regions with extreme weather conditions.

Stainless steel is often used for high-pressure components such as valves and fittings due to its exceptional strength and corrosion resistance. It can withstand extreme temperatures and pressures, making it ideal for demanding applications.

Pros: Stainless steel is highly durable, resistant to corrosion, and can handle high-pressure environments, making it suitable for long-term use.

Contras: The primary disadvantage is the cost, as stainless steel is generally more expensive than aluminum or plastic. Additionally, it can be heavier, which may affect the overall weight of the inflator.

Impacto en la aplicación: Stainless steel is compatible with various gases and is particularly effective in applications requiring high pressure and durability.

Consideraciones para compradores internacionales: Buyers should verify that stainless steel components comply with local and international standards, such as DIN or JIS, to ensure quality and safety.

| Material | Typical Use Case for tire inflator bike | Ventajas clave | Principales desventajas/limitaciones | Coste relativo (Bajo/Medio/Alto) |

|---|---|---|---|---|

| Aluminio | Body and structural components | Ligero y resistente a la corrosión | Higher cost, prone to dents | Medio |

| Plástico | Housing and non-structural parts | Cost-effective and easy to mold | Less durable, UV degradation | Bajo |

| Goma | Seals and hoses | Excellent sealing properties | Degrades over time, ozone sensitivity | Medio |

| Acero inoxidable | High-pressure valves and fittings | Highly durable and corrosion-resistant | Higher cost, heavier | Alta |

This strategic material selection guide provides B2B buyers with essential insights into the materials used in tire inflator bikes, helping them make informed decisions based on performance, cost, and application suitability.

The manufacturing process of tire inflators for bikes involves several key stages, ensuring that the final product meets the necessary quality and performance standards. Each stage incorporates specific techniques designed to enhance efficiency and product reliability.

The initial stage of manufacturing involves the careful selection and preparation of materials. Common components include high-grade plastics, metals (such as aluminum or steel), and rubber for seals. Suppliers often source these materials from certified vendors to ensure they meet international quality standards. Before production, materials undergo rigorous testing for durability and resistance to wear, which is crucial for the longevity of the inflators.

Once materials are prepared, the next step is forming. This can involve techniques such as injection molding for plastic components and die-casting for metal parts. Advanced CNC (Computer Numerical Control) machining may also be employed for precision parts. The use of automated machinery in this phase helps maintain consistency and reduces the risk of human error, ensuring that each component adheres to design specifications.

Illustrative image related to tire inflator bike

The assembly stage combines all the formed parts into a finished product. This is typically performed in a clean environment to minimize contamination. Workers or robotic systems assemble components such as the motor, air reservoir, and inflation nozzle. During this phase, manufacturers may employ techniques like ultrasonic welding or adhesive bonding to ensure secure connections. Attention to detail is crucial here, as any oversight can lead to product malfunction.

Finishing processes are essential for enhancing the aesthetics and functionality of the tire inflators. This may include surface treatments, painting, or coating with protective finishes to prevent corrosion and wear. Quality assurance checks during this stage ensure that all visual and functional requirements are met, contributing to the overall appeal and performance of the product.

Quality assurance (QA) is an integral part of the manufacturing process, ensuring that the tire inflators meet both international standards and customer expectations.

For tire inflators, adherence to international quality standards such as ISO 9001 is essential. This standard focuses on maintaining a quality management system that enhances customer satisfaction and ensures consistent product quality. Additionally, certifications like CE (Conformité Européenne) for products sold in Europe and API (American Petroleum Institute) standards for components related to pressure and safety should be considered. These certifications provide assurance that the products have undergone rigorous testing and meet necessary safety requirements.

Quality control (QC) checkpoints are established at various stages of the manufacturing process to maintain high standards. These checkpoints typically include:

These checkpoints are vital for minimizing defects and ensuring that only high-quality products reach the market.

Testing methods for tire inflators often include:

B2B buyers should inquire about the specific testing protocols employed by manufacturers to ensure they align with industry best practices.

Illustrative image related to tire inflator bike

For international B2B buyers, verifying the quality control measures of potential suppliers is crucial in establishing a reliable supply chain. Here are several strategies:

Conducting supplier audits is a fundamental step in assessing quality control practices. These audits can include on-site evaluations of manufacturing facilities, reviewing quality management systems, and examining product testing procedures. Buyers should prepare a checklist of criteria based on industry standards to evaluate suppliers effectively.

Buyers can request detailed quality control reports from suppliers, which should outline the testing methodologies, results, and compliance with international standards. Regularly reviewing these reports helps buyers gauge the consistency and reliability of the products they intend to purchase.

Engaging third-party inspection services can provide an unbiased assessment of a supplier’s quality control practices. These inspectors can conduct random checks during production and verify that products meet specified standards before shipment. This added layer of scrutiny is particularly beneficial for buyers from regions with less stringent regulatory frameworks.

Illustrative image related to tire inflator bike

For B2B buyers in regions such as Africa, South America, the Middle East, and Europe, understanding the nuances of quality control is vital. Different markets may have varying compliance requirements, and manufacturers must adapt to these regulations. Buyers should familiarize themselves with local standards and ensure that suppliers can navigate these effectively.

In conclusion, a comprehensive understanding of the manufacturing processes and quality assurance measures for tire inflators is crucial for B2B buyers. By prioritizing quality at every stage of production and maintaining a diligent approach to supplier verification, businesses can ensure they source reliable, high-quality products that meet the demands of their markets.

This guide aims to equip international B2B buyers with a comprehensive checklist for sourcing tire inflators for bikes. As the cycling market continues to grow, understanding the critical factors in selecting reliable and effective tire inflators is essential for ensuring customer satisfaction and maintaining a competitive edge.

Establishing clear technical specifications is the first step in the sourcing process. Consider the types of bikes and tires your target market uses, as well as the inflator’s compatibility with different valve types (Presta and Schrader). Additionally, determine the required PSI range to ensure the inflator meets your customers’ needs.

Staying informed about market trends can give you a competitive advantage. Review the latest advancements in tire inflator technology, such as electric pumps and CO2 inflators, which are gaining popularity for their convenience and efficiency. Understanding these trends will help you identify products that appeal to modern cyclists and set your offerings apart.

Illustrative image related to tire inflator bike

Thoroughly vetting suppliers is crucial to ensuring product quality and reliability. Request detailed company profiles, product catalogs, and references from other B2B buyers in your region. Look for suppliers with a proven track record of delivering high-quality products and excellent customer service.

Once you’ve shortlisted potential suppliers, compare their product features and pricing. Look for key aspects such as inflation speed, portability, battery life (for electric models), and ease of use. Analyze the pricing structure to determine whether it aligns with your budget and desired profit margins.

Before finalizing your purchase, request samples of the tire inflators for testing. This step allows you to evaluate their performance, durability, and ease of use firsthand. Ensure that the inflators can meet the demands of your target market and provide a satisfactory user experience.

Illustrative image related to tire inflator bike

A reliable after-sales support system is essential for maintaining customer satisfaction. Inquire about warranty options and the availability of replacement parts or accessories. Strong support can enhance your reputation and help resolve any issues that may arise post-purchase.

Once you’ve selected a supplier and tested their products, it’s time to finalize the terms and negotiate contracts. Pay attention to delivery timelines, payment terms, and bulk order discounts. Clear agreements help avoid misunderstandings and ensure a smooth procurement process.

By following this checklist, B2B buyers can confidently source high-quality tire inflators that meet market demands and enhance their product offerings.

When analyzing the cost structure for sourcing tire inflators, several components play a critical role. Materiales typically account for the largest share of costs, influenced by the type of materials used in the inflators, such as plastics, metals, and electronic components. Labor costs also contribute significantly, particularly in regions with varying wage scales. For manufacturers, gastos generales de fabricación—which includes utilities, rent, and administrative expenses—can vary widely based on location.

Illustrative image related to tire inflator bike

Tooling costs are another essential factor, especially for custom designs or specialized inflators. These costs can escalate if unique molds or machinery are required. Moreover, quality control (QC) processes are crucial for maintaining product standards and can add to overall costs, especially if third-party inspections or certifications are needed. Finally, logistics costs should not be overlooked, as they encompass shipping, warehousing, and handling fees, which can vary greatly depending on the distance and method of transport.

Several factors influence the pricing of bike tire inflators in the B2B marketplace. Volume and minimum order quantities (MOQ) play a significant role; larger orders often lead to reduced unit costs due to economies of scale. Additionally, the specifications and customization of the inflators—such as size, digital features, or compatibility with different valve types—can significantly impact pricing.

La elección de materiales is another crucial influencer, where high-quality materials may result in higher upfront costs but can enhance durability and customer satisfaction, potentially leading to lower warranty claims in the long run. Quality certifications (like ISO or CE) can also affect pricing; products with higher standards may command a premium but can appeal to quality-conscious buyers.

Illustrative image related to tire inflator bike

Supplier factors, including their production capacity, reputation, and reliability, can also influence costs. Understanding Incoterms is essential for international buyers, as they define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs, all of which can impact the final price.

B2B buyers looking to source tire inflators should consider several strategies to enhance cost-efficiency. Negociación is key; leveraging multiple quotes can provide a competitive edge. Establishing long-term relationships with suppliers may also yield better pricing as trust and familiarity grow.

Comprender la Coste total de propiedad (TCO) is vital. This includes not only the purchase price but also maintenance, replacement, and operational costs over the product’s lifecycle. A higher initial investment in quality inflators may result in lower costs over time through reduced maintenance and higher customer satisfaction.

For international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, being aware of matices en la fijación de precios is critical. Factors such as currency fluctuations, import tariffs, and local market demand can affect overall costs. Additionally, consider the potential for bulk purchasing agreements, which can further drive down costs.

While indicative pricing for tire inflators varies widely, it typically ranges from $49 to $129 depending on specifications and features. However, these prices are subject to change based on market conditions and supplier negotiations. Buyers should remain flexible and proactive in seeking the best deals while ensuring that they do not compromise on quality. Understanding the broader market landscape, including competitor pricing, can also aid in making informed purchasing decisions.

Illustrative image related to tire inflator bike

In the cycling industry, ensuring optimal tire pressure is crucial for performance, safety, and rider satisfaction. While tire inflator bikes have become a popular choice, various alternative solutions exist that cater to different needs and scenarios. This section will compare tire inflator bikes against traditional hand pumps and CO2 inflators, providing valuable insights for B2B buyers.

| Aspecto comparativo | Tire Inflator Bike | Bomba manual | Inflador de CO2 |

|---|---|---|---|

| Rendimiento | Quick inflation, often with digital pressure settings | Slower inflation, requires manual effort | Very fast inflation, but limited by cartridge capacity |

| Coste | $49 – $129 | $15 – $60 | $20 – $50 (plus cartridges) |

| Facilidad de aplicación | Simple to use, often portable | Requires physical effort, but straightforward | Easy to use, but requires cartridge replacement |

| Mantenimiento | Low maintenance, battery life varies | Minimal, generally long-lasting | Low, but cartridges need to be replenished |

| El mejor caso de uso | Ideal for regular riders needing convenience | Suitable for emergency use or casual cyclists | Best for racing or quick fixes on the go |

Hand pumps have been a staple in the cycling community for decades. They are simple devices requiring no power source, making them a reliable option for emergencies. The primary advantage of hand pumps is their affordability and durability; they can often last for years with minimal maintenance. However, they require significant physical effort and time to inflate tires, which can be a drawback for those looking for quick fixes. Additionally, their inflation capacity may not match that of electric options, making them less suitable for high-volume tires.

CO2 inflators provide an excellent solution for cyclists who prioritize speed and efficiency. These devices can inflate a tire in seconds, which is invaluable during races or long rides where time is of the essence. CO2 inflators are compact and lightweight, making them easy to carry. However, they do have limitations: the need for CO2 cartridges can become expensive over time, and once a cartridge is used, it cannot be reused. Additionally, they may not provide precise pressure settings, which can be critical for competitive cyclists.

When deciding between a tire inflator bike, hand pump, or CO2 inflator, B2B buyers should consider their specific use cases and operational needs. For businesses focused on retail or distribution of cycling accessories, understanding the target market’s preferences is crucial. If the primary clientele consists of competitive cyclists, offering CO2 inflators may be beneficial due to their speed and compactness. Conversely, for casual cyclists or those in remote areas, tire inflator bikes or hand pumps could serve as more practical options.

Ultimately, the choice will depend on factors such as budget, the expected frequency of use, and the type of cycling activities most common among your customer base. By analyzing these aspects, B2B buyers can make informed decisions that align with market demand and operational capabilities.

When considering tire inflators for bikes, several critical specifications define their functionality and reliability. Understanding these properties is essential for B2B buyers to make informed purchasing decisions.

The maximum pressure rating, typically measured in pounds per square inch (PSI), indicates how much air pressure the inflator can deliver. This specification is crucial for compatibility with different types of bike tires, which may require varying pressures. For instance, road bikes often need higher PSI compared to mountain bikes. Buyers should ensure that the inflator can meet the required PSI for their target market.

The material used in the construction of tire inflators affects durability and performance. Common materials include high-grade plastics and aluminum alloys. High-quality materials ensure resistance to wear and tear, which is vital for long-term use in diverse environments, particularly in regions with varying climates like Africa and South America. Buyers should prioritize inflators made from robust materials to reduce replacement costs and enhance customer satisfaction.

Inflation time refers to how quickly an inflator can fill a tire to the desired pressure. This is particularly important for consumers who value convenience and efficiency. For B2B buyers, offering products with shorter inflation times can significantly enhance market appeal, especially in competitive regions where time-saving features are a key selling point.

Illustrative image related to tire inflator bike

The power source of a tire inflator—manual, battery-operated, or electric—determines its usability and convenience. Battery-operated inflators are increasingly popular due to their portability, allowing users to inflate tires without needing an external power source. Understanding the power requirements can help buyers assess the target market’s preferences, especially in areas with limited access to electricity.

Compatibility with different valve types, such as Presta and Schrader, is crucial for a tire inflator’s versatility. An inflator that can accommodate multiple valve types appeals to a broader audience, making it a more attractive option for retailers. B2B buyers should consider this compatibility to ensure they meet the diverse needs of their clientele.

Familiarity with industry terminology is essential for effective communication in the B2B marketplace. Here are several key terms to understand:

Illustrative image related to tire inflator bike

OEM refers to companies that manufacture products that are sold under another company’s brand name. In the context of tire inflators, understanding OEM relationships can help buyers identify reliable suppliers and negotiate better pricing and terms.

MOQ is the smallest number of units that a supplier is willing to sell. Knowing the MOQ is crucial for buyers to manage inventory effectively and maintain cash flow. It’s particularly relevant for businesses looking to import products, as it can influence initial investment decisions.

An RFQ is a document sent to suppliers requesting pricing and terms for specific products. This is a vital step in the procurement process, enabling buyers to compare costs and negotiate better deals. A well-structured RFQ can lead to favorable pricing and terms.

Incoterms are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Familiarity with these terms is crucial for B2B buyers engaged in global trade, as they help clarify shipping, insurance, and delivery responsibilities, reducing the risk of disputes.

Lead time refers to the time taken from placing an order to receiving the goods. Understanding lead times is essential for inventory management and planning, especially for businesses operating in fast-paced markets.

By comprehending these technical properties and trade terms, B2B buyers can make informed decisions that align with their business objectives and market demands.

Illustrative image related to tire inflator bike

The tire inflator bike sector is experiencing significant growth driven by several global factors. The increasing popularity of cycling for both recreational and commuting purposes has heightened the demand for reliable and efficient tire inflation solutions. Additionally, the rise in e-commerce has facilitated easier access for international B2B buyers in regions like Africa, South America, the Middle East, and Europe, allowing them to source innovative products from various suppliers worldwide.

Emerging trends in this market include the development of electric mini pumps, which offer convenience and efficiency compared to traditional hand pumps and CO2 inflators. These electric models often come equipped with digital gauges and automatic shut-off features, catering to the tech-savvy consumer base. Furthermore, the integration of smart technology, such as Bluetooth connectivity for monitoring tire pressure, is becoming more prevalent, appealing to a growing segment of eco-conscious and performance-oriented cyclists.

For B2B buyers, understanding regional preferences is crucial. In Europe, for instance, there is a strong inclination toward high-quality, durable products, while markets in Africa and South America may prioritize affordability and ease of use. Additionally, the competitive landscape is evolving, with both established brands and startups vying for market share, making it essential for buyers to assess suppliers not only on price but also on innovation and reliability.

Sustainability is increasingly becoming a focal point in the tire inflator bike sector, driven by both consumer demand and regulatory pressures. Environmental impact considerations are prompting manufacturers to adopt more sustainable practices in product design and production. B2B buyers are now more inclined to partner with suppliers who prioritize sustainability in their operations, including the use of recycled materials and energy-efficient manufacturing processes.

Ethical sourcing is another critical aspect influencing purchasing decisions. Buyers are seeking transparency in supply chains, looking for suppliers who can demonstrate responsible sourcing of materials and fair labor practices. Certifications such as ISO 14001 for environmental management and Fair Trade can enhance a supplier’s credibility in the eyes of international buyers. Additionally, companies that actively engage in sustainability initiatives—like carbon offset programs or partnerships with environmental organizations—are likely to gain a competitive edge.

Illustrative image related to tire inflator bike

Investing in ‘green’ certifications and materials not only meets the growing demand for eco-friendly products but can also open doors to new markets, particularly in Europe, where regulatory frameworks are increasingly favoring sustainable goods. By aligning with these trends, B2B buyers can enhance their brand reputation while contributing positively to the environment.

The evolution of the tire inflator bike sector reflects broader technological advancements and changing consumer preferences. Initially dominated by manual hand pumps, the market saw a significant shift with the introduction of CO2 inflators, which offered quick inflation solutions for cyclists on the go. However, as battery technology improved, electric mini pumps began to emerge, providing an even more convenient and efficient option for tire inflation.

This transition has been influenced by the growing cycling culture and the need for practical solutions in urban commuting. As cycling continues to gain traction worldwide, particularly in urban environments, the demand for reliable tire inflators has surged. This evolution is indicative of a broader trend toward innovation and consumer-centric design, as manufacturers strive to meet the diverse needs of today’s cyclists.

How do I choose the right tire inflator for my business needs?

Choosing the right tire inflator involves evaluating your target market and specific requirements. Consider factors such as the inflator’s size, portability, and power source (manual, CO2, or electric). Assess the inflator’s compatibility with various valve types and its maximum pressure output. Additionally, look for features like built-in gauges for accuracy and ease of use. Analyzing customer feedback and product reviews can also provide insights into reliability and performance, which are crucial for long-term business success.

What is the best type of tire inflator for bicycles?

The best type of tire inflator for bicycles depends on the intended use. For quick fixes on the go, CO2 inflators are compact and deliver fast inflation. Electric mini pumps offer convenience and precision, particularly for regular maintenance. For more extensive usage, a high-capacity floor pump may be ideal. Evaluate your customer base’s preferences and typical riding conditions to determine which inflator type will best meet their needs and expectations.

What are the minimum order quantities (MOQ) for tire inflators?

Minimum order quantities (MOQ) for tire inflators can vary significantly by supplier and manufacturer. Generally, MOQs for wholesale purchases can range from 100 to 1,000 units, depending on the product type and customization options. It’s advisable to negotiate MOQs with suppliers, especially if you are entering a new market. Some manufacturers may offer lower MOQs for first-time buyers or bulk discounts for larger orders, so be sure to discuss your needs directly with potential partners.

How can I vet suppliers for tire inflators?

To vet suppliers effectively, start by researching their market reputation and years of experience in the industry. Request references or case studies from existing clients to gauge their reliability. Additionally, assess their compliance with international quality standards, such as ISO certifications. Conducting a factory audit or visiting their facilities, if feasible, can provide insights into their production capabilities and quality control processes. Finally, consider reviewing customer feedback and ratings on third-party platforms to further validate their credibility.

What payment terms should I negotiate with tire inflator suppliers?

When negotiating payment terms, aim for conditions that balance risk and cash flow. Common terms include a deposit (usually 30-50%) upon order confirmation, with the remaining balance due before shipment. Consider requesting letter of credit arrangements for larger transactions, as this provides security for both parties. Additionally, explore flexible payment options such as installment payments or net terms (e.g., net 30 or net 60) to better manage your finances and build a positive relationship with your supplier.

What quality assurance measures should I expect from suppliers?

Reputable suppliers should have comprehensive quality assurance measures in place. Expect them to conduct regular quality checks throughout the production process, from raw material sourcing to final product testing. Request documentation of their quality control procedures, including any certifications (e.g., ISO 9001). Additionally, consider asking for samples or trial products before placing a large order, as this will help you assess the quality and performance of their tire inflators firsthand.

How do I handle logistics and shipping for tire inflators?

Handling logistics for tire inflators involves coordinating with suppliers and freight forwarders to ensure timely delivery. Discuss shipping options, including air freight for faster delivery or sea freight for cost-effective bulk shipping. Be aware of import duties, taxes, and customs clearance procedures in your target market. Establish a clear timeline with your supplier, and ensure they provide necessary shipping documentation. Collaborating with a logistics expert can streamline this process, mitigating potential delays and ensuring compliance with international regulations.

What customization options are available for tire inflators?

Customization options for tire inflators can include branding, color schemes, and packaging design. Many manufacturers offer the ability to print your logo on the product or its packaging, which enhances brand visibility. Additionally, you may request specific features tailored to your market, such as enhanced pressure gauges or unique nozzle designs. Discuss your requirements with potential suppliers to understand their capabilities and lead times for customization, ensuring that the final product aligns with your business objectives.

Dominio: cycplus.com

Inscrito: 2017 (8 años)

Introducción: [{‘name’: ‘AS2 Ultra Tiny E-pump for Bike’, ‘regular_price’: ‘$119.00’}, {‘name’: ‘AS2 Pro Tiny E-Pump For Bike’, ‘regular_price’: ‘$109.00’, ‘discount’: ‘12% OFF’, ‘sale_price’: ‘$114.00’}, {‘name’: ‘AS2 Pro Max Tiny E-Pump For Bike’, ‘regular_price’: ‘$129.00’, ‘sale_price’: ‘$114.00’}, {‘name’: ‘AS2 Tiny E-Pump For Bike’, ‘regular_price’: ‘$69.00’}, {‘name’: ‘Electric Air Pump A2 Pro’, ‘regular…

Dominio: planetbike.com

Inscrita: 1997 (28 años)

Introducción: [{‘name’: ‘ALX 2.0 bike floor pump’, ‘price’: ‘$60.00’}, {‘name’: ’20g CO2 replacement cartridges – threaded’, ‘price’: ‘$15.00 – $55.00’}, {‘name’: ‘Red Zeppelin CO2 bike tire inflator’, ‘price’: ‘$20.00’}, {‘name’: ‘Comp 2.0 bike floor pump’, ‘price’: ‘$30.00’}, {‘name’: ‘STX bike floor pump’, ‘price’: ‘$55.00’}, {‘name’: ‘Fresh Air mini pump’, ‘price’: ‘$20.00’}, {‘name’: ‘Shockmate 3.0 bike su…

Dominio: ridepdw.com

Inscrito: 2008 (17 años)

Introducción: Bike Pumps & CO2 Tire Inflators from Portland Design Works include various models with key features and pricing:

1. Timber to Town: Cloud Cap CO2 Inflator – Regular price: $39.00, Sale price: $25.00, Save: $14.00

2. Shiny Object – Regular price: $19.00, Sale price: from $14.25, Save: $4.75

3. Tiny Object – Regular price: $22.00, Sale price: $16.50, Save: $5.50

4. Fatty Object – Regular price: …

Dominio: rei.com

Matriculado: 1996 (29 años)

Introducción: Bike Pumps: Portable, Hand, Mini Bicycle Pumps | REI Co-op

Dominio: intheknowcycling.com

Inscrito: 2013 (12 años)

Introducción: The best electric bike pumps are compact, easy to use, and accurate, replacing traditional inflation tools like floor pumps, CO2 inflators, hand pumps, and digital gauges. They are approximately the size of a GoPro camera or small bike computer, weighing around 150 grams (5½ ounces), and cost between $50 and $75. These pumps can fully inflate a flat 28mm road tire to 70 psi or a 40mm gravel tire t…

In the evolving landscape of bike accessories, tire inflators stand out as essential tools for enhancing rider safety and convenience. For B2B buyers, particularly in emerging markets across Africa, South America, the Middle East, and Europe, strategic sourcing of high-quality tire inflators can significantly impact product offerings and customer satisfaction. Key considerations include understanding diverse consumer needs, such as portability, inflation speed, and compatibility with various tire types.

Moreover, leveraging insights from market trends, such as the growing popularity of electric and CO2 inflators, can position suppliers to meet the demands of both casual cyclists and serious enthusiasts. Establishing relationships with reliable manufacturers ensures access to innovative products that can differentiate offerings in competitive markets.

As the cycling industry continues to expand, now is the time for international buyers to act. By strategically sourcing tire inflators that align with market preferences and technological advancements, businesses can enhance their value proposition. Embrace this opportunity to enrich your product lineup and cater to the evolving needs of cyclists worldwide. Take the next step toward optimizing your supply chain and ensuring your customers enjoy a seamless riding experience.

La información facilitada en esta guía, incluido el contenido relativo a fabricantes, especificaciones técnicas y análisis de mercado, tiene únicamente fines informativos y educativos. No constituye asesoramiento profesional en materia de adquisiciones, asesoramiento financiero ni asesoramiento jurídico.

Aunque hemos hecho todo lo posible por garantizar la exactitud y actualidad de la información, no nos hacemos responsables de posibles errores, omisiones o información obsoleta. Las condiciones del mercado, los detalles de las empresas y las normas técnicas están sujetos a cambios.

Los compradores B2B deben llevar a cabo su propia diligencia debida independiente y exhaustiva antes de tomar cualquier decisión de compra. Esto incluye ponerse en contacto directamente con los proveedores, verificar las certificaciones, solicitar muestras y buscar asesoramiento profesional. El riesgo de confiar en la información contenida en esta guía es responsabilidad exclusiva del lector.