In today’s fast-paced automotive industry, sourcing reliable air inflators for cars presents a significant challenge for international B2B buyers. As vehicle owners increasingly prioritize convenience and safety, the demand for high-quality, portable tire inflators has surged. This guide aims to streamline the purchasing process by providing a comprehensive overview of the various types of air inflators available, their applications, and key considerations for supplier vetting.

From compact battery-operated models ideal for personal use to heavy-duty inflators suited for commercial fleets, understanding the diverse options is crucial for making informed decisions. Additionally, the guide will delve into cost analysis, highlighting how to balance quality with budget constraints while ensuring compliance with regional standards.

With a focus on international markets, particularly those in Africa, South America, the Middle East, and Europe—including countries like Germany and Nigeria—this resource empowers B2B buyers to navigate the complexities of the global air inflator market. By equipping you with actionable insights and best practices, this guide facilitates effective sourcing strategies, ensuring you secure the best products to meet your customers’ needs. Whether you are a distributor, retailer, or fleet manager, understanding these nuances will enhance your competitive edge and drive business success in the evolving automotive landscape.

| Tipo Nombre | Principales rasgos distintivos | Aplicaciones B2B principales | Breves pros y contras para los compradores |

|---|---|---|---|

| Portable Electric Inflator | Compact, battery-operated, often rechargeable | Automotive repair shops, fleet services | Pros: Easy to use, portable; Contras: Limited power for larger vehicles. |

| AC/DC Tire Inflator | Dual power options (AC for home, DC for car) | Service stations, workshops | Pros: Versatile; can be used at home or on-the-go; Contras: May require a power source. |

| Heavy-Duty Air Compressor | High PSI output, designed for larger tires | Commercial fleets, heavy machinery | Pros: Powerful, fast inflation; Contras: Bulky, requires more storage space. |

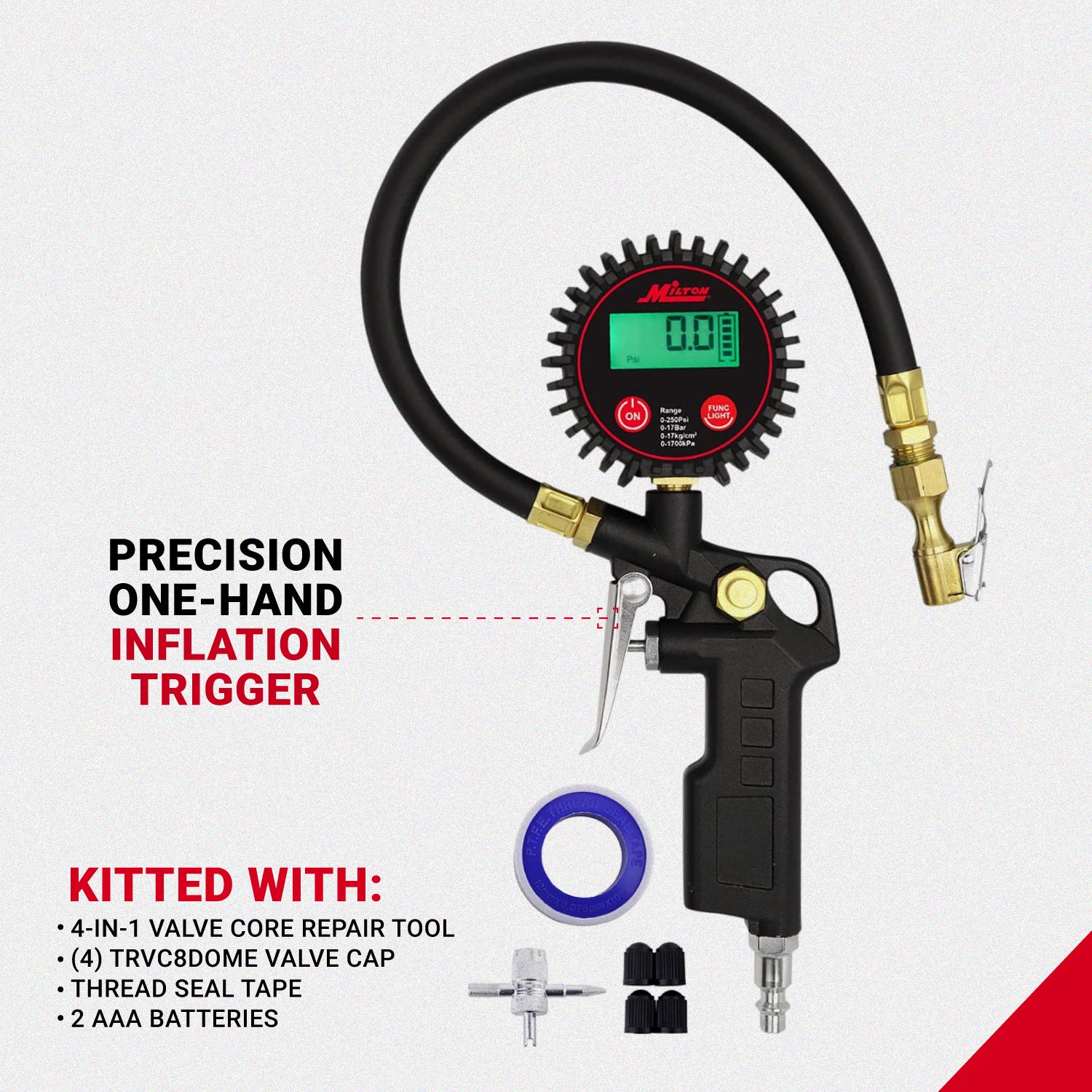

| Digital Tire Inflator | Integrated digital pressure gauge, preset settings | Automotive manufacturers, retailers | Pros: Accurate readings, user-friendly; Contras: Generally more expensive. |

| Inflator with Sealant | Combines air inflation with tire sealant | Emergency roadside assistance | Pros: Quick fix for punctures; Contras: Sealant may not work on all types of damage. |

Portable electric inflators are compact devices powered by rechargeable batteries, making them ideal for on-the-go inflation. They are particularly suited for individual vehicle owners or small automotive repair shops that require quick, efficient tire inflation without the need for an external power source. When considering a purchase, buyers should evaluate battery life, inflation speed, and ease of use, as these factors significantly impact operational efficiency.

AC/DC tire inflators can operate on both AC power (for home use) and DC power (for vehicle use), providing unparalleled versatility. They are commonly used in service stations and workshops where a reliable and adaptable inflator is essential. B2B buyers should consider the inflator’s compatibility with different power sources, inflation speed, and durability, particularly in high-usage environments.

Heavy-duty air compressors are designed to deliver high PSI outputs, making them suitable for larger tires found on commercial vehicles and heavy machinery. They are ideal for commercial fleets and industrial applications where rapid inflation is crucial. Buyers should assess the compressor’s power output, portability, and maintenance requirements, as these elements can affect overall operational costs and efficiency.

Illustrative image related to air inflator for car

Digital tire inflators feature integrated digital pressure gauges and preset inflation settings, enhancing user accuracy and convenience. They are particularly beneficial for automotive manufacturers and retailers who prioritize precision in tire maintenance. When purchasing, B2B buyers should focus on the accuracy of the pressure gauge, ease of setting adjustments, and overall build quality to ensure longevity.

Inflators with sealant are designed to quickly inflate tires while simultaneously applying a sealant to repair minor punctures. They are invaluable for emergency roadside assistance services. Buyers should consider the effectiveness of the sealant, shelf life, and ease of use, as these factors influence the product’s reliability during critical situations.

| Industria/Sector | Specific Application of air inflator for car | Valor/beneficio para la empresa | Consideraciones clave para el aprovisionamiento de esta aplicación |

|---|---|---|---|

| Reparación de automóviles | Routine tire pressure checks and maintenance | Enhances customer safety and satisfaction; reduces tire-related incidents | Reliability and ease of use; durability under frequent use; compliance with international standards |

| Transportation & Logistics | Emergency roadside assistance for commercial fleets | Minimizes downtime and enhances operational efficiency | Compact design for storage; fast inflation speed; multi-vehicle compatibility |

| Automotive Manufacturing | Quality control in tire assembly and testing | Ensures product quality and safety; reduces warranty claims | Precision accuracy; integration with production line systems; scalability for production volume |

| Car Rental Services | Pre-rental tire inspections and maintenance | Improves fleet reliability and customer experience; reduces maintenance costs | Portability; battery life; ease of use for non-technical staff |

| Outdoor & Recreational Vehicles | Tire inflation for off-road and recreational vehicles | Expands service offerings; attracts adventure-seeking customers | Versatility for different vehicle types; rugged design; quick inflation for varied tire sizes |

In automotive repair shops, air inflators are essential for routine tire pressure checks and maintenance. These devices ensure that vehicles are operating under optimal tire pressure, which is critical for safety and performance. Problems such as uneven tire wear or decreased fuel efficiency can arise from improper tire inflation. For B2B buyers in this sector, sourcing reliable and user-friendly inflators that comply with international safety standards is crucial, especially in regions like Africa and South America, where varied road conditions may affect tire performance.

In the transportation and logistics sector, air inflators are vital for emergency roadside assistance for commercial fleets. These inflators help minimize vehicle downtime, allowing companies to maintain efficient operations. A flat tire can lead to significant delays, impacting delivery schedules and customer satisfaction. Buyers in this field should consider inflators that are compact for easy storage, offer quick inflation speeds, and can service a variety of vehicle types, particularly in regions with extensive logistics networks, such as the Middle East and Europe.

In automotive manufacturing, air inflators play a crucial role in quality control during tire assembly and testing. Ensuring that tires are inflated to precise specifications is vital for product safety and performance. This application helps reduce warranty claims and enhances overall product reliability. Buyers in this sector must focus on inflators that offer high precision and can be integrated with existing production line systems. Scalability is also essential for manufacturers in Europe and Africa, where production volumes can vary significantly.

Car rental services utilize air inflators for pre-rental tire inspections and maintenance. Ensuring that tires are properly inflated before customers take vehicles is essential for enhancing fleet reliability and improving the overall customer experience. This proactive approach can significantly reduce maintenance costs associated with tire issues. B2B buyers in this industry should prioritize portable inflators with long battery life and ease of use, as staff may not always have technical expertise. This is particularly relevant in regions with diverse customer bases, such as South America and Africa.

In the outdoor and recreational vehicle sector, air inflators are indispensable for quickly inflating tires on off-road and recreational vehicles. These inflators allow businesses to expand their service offerings, catering to adventure-seeking customers who require dependable equipment. Buyers should look for versatile inflators that can accommodate various tire sizes and are built to withstand rugged conditions. In regions like Africa and the Middle East, where outdoor activities are popular, having a durable and efficient inflator can significantly enhance customer satisfaction and loyalty.

El problema: B2B buyers often encounter issues with the inconsistent performance of air inflators. Whether it’s due to subpar quality or improper specifications, these inconsistencies can lead to unreliable tire pressure readings, resulting in safety concerns and increased operational costs. For example, if a fleet manager in Nigeria purchases low-quality inflators, they may experience frequent breakdowns or inaccurate pressure levels, leading to tire wear and potential accidents.

La solución: To address these challenges, buyers should prioritize sourcing air inflators from reputable manufacturers known for their quality and reliability. Look for inflators that offer precise pressure readings and automatic shut-off features to prevent over-inflation. When specifying products, consider inflators with durable construction and those that have undergone rigorous testing for performance in various climates, especially in regions with extreme temperatures. Additionally, providing training for staff on the correct usage and maintenance of these inflators can enhance their longevity and effectiveness.

Illustrative image related to air inflator for car

El problema: Many B2B buyers struggle to find air inflators that cater to a variety of vehicle types within their fleet. For instance, a company operating in South America may have a mix of commercial trucks, passenger vehicles, and motorcycles, each requiring different inflator specifications. The challenge lies in sourcing a universal solution that meets the diverse needs without compromising efficiency.

La solución: To overcome this sourcing challenge, it is essential to conduct a thorough analysis of the fleet’s requirements. Buyers should seek out versatile air inflators that come with multiple nozzle attachments and adjustable pressure settings. Collaborating with suppliers who offer customizable solutions can also be beneficial. By investing in high-capacity inflators that can handle various tire sizes and pressures, companies can streamline their maintenance operations and ensure that all vehicles are consistently roadworthy. Additionally, creating a partnership with a reliable distributor can facilitate easier access to a range of models tailored to specific vehicle needs.

El problema: A significant pain point for B2B buyers is the lack of knowledge regarding the proper maintenance and usage of air inflators. In many cases, employees may not fully understand how to operate the inflators effectively, leading to mishandling that can result in equipment damage or inefficiency. For example, a fleet operating in Europe may find that their inflators are underperforming due to improper settings or lack of regular maintenance.

La solución: To mitigate this issue, companies should invest in comprehensive training programs for their staff that cover the operation and care of air inflators. This training should include hands-on demonstrations and clear guidelines on how to check tire pressures accurately, adjust settings, and perform routine maintenance. Creating easy-to-follow instructional materials or videos can reinforce learning. Furthermore, establishing a regular maintenance schedule for the inflators, including routine checks and calibrations, can significantly enhance their performance and lifespan. Buyers should also consider purchasing models with user-friendly interfaces to simplify operation for all team members.

When selecting materials for air inflators for cars, it is crucial to consider properties that affect performance, durability, and compliance with international standards. The following analysis covers four common materials: plastic, aluminum, steel, and rubber.

Plastic is often used for the casing and internal components of air inflators due to its lightweight nature and resistance to corrosion. Key properties include a temperature rating of up to 80°C and a pressure rating that varies based on the type of plastic used.

Pros: The primary advantage of plastic is its low cost and ease of manufacturing, allowing for complex shapes and designs. It is also resistant to rust and corrosion, making it suitable for various environments.

Contras: However, plastic can be less durable than metals, especially under high-pressure conditions. It may also be less effective in extreme temperatures, which could affect performance.

Impacto en la aplicación: Plastic is compatible with most air media, but buyers should ensure that the specific type of plastic used can withstand the intended pressure and temperature ranges.

Consideraciones para compradores internacionales: Compliance with standards such as ASTM D638 for tensile properties is essential. Buyers from regions like Africa and South America should consider the availability of specific plastic types that meet these standards.

Illustrative image related to air inflator for car

Aluminum is another popular choice for air inflators, especially for components that require strength and lightweight properties. It typically has a temperature rating of up to 150°C and excellent corrosion resistance.

Pros: The key advantage of aluminum is its durability and strength-to-weight ratio, making it ideal for portable inflators. It can withstand higher pressures without deforming.

Contras: The main drawback is the higher cost compared to plastic. Additionally, aluminum requires more complex manufacturing processes, which can increase production time.

Impacto en la aplicación: Aluminum is suitable for high-performance applications where pressure and temperature are critical factors.

Consideraciones para compradores internacionales: Buyers should check for compliance with standards like DIN 1725 for aluminum alloys. In Europe, particularly Germany, there is a strong preference for aluminum due to its recyclability.

Illustrative image related to air inflator for car

Steel is often used in high-pressure applications, particularly for the tank or housing of air inflators. It has a temperature rating of up to 300°C and is highly resistant to deformation under pressure.

Pros: Steel’s primary advantage is its strength and durability, making it ideal for heavy-duty applications. It can withstand extreme conditions and has a long lifespan.

Contras: However, steel is heavier than other materials, which can affect portability. It is also prone to rust and corrosion if not properly coated.

Impacto en la aplicación: Steel is suitable for applications where high pressure is required, but it may not be ideal for portable inflators due to weight.

Consideraciones para compradores internacionales: Compliance with standards such as ASTM A36 for structural steel is crucial. Buyers in regions like the Middle East should consider the effects of humidity on steel components.

Illustrative image related to air inflator for car

Rubber is primarily used for seals and hoses in air inflators due to its flexibility and elasticity. It can handle a temperature range of -40°C to 100°C and offers good pressure resistance.

Pros: The key advantage of rubber is its ability to create airtight seals, preventing air leakage during inflation. It is also resistant to wear and tear.

Contras: However, rubber can degrade over time, especially when exposed to UV light or extreme temperatures.

Impacto en la aplicación: Rubber is essential for ensuring efficient operation, but buyers should be aware of its lifespan and replaceability.

Illustrative image related to air inflator for car

Consideraciones para compradores internacionales: Compliance with standards like ASTM D2000 for rubber products is important. Buyers in Europe and Africa should consider sourcing rubber that meets local environmental regulations.

| Material | Typical Use Case for air inflator for car | Ventajas clave | Principales desventajas/limitaciones | Coste relativo (Bajo/Medio/Alto) |

|---|---|---|---|---|

| Plástico | Casing and internal components | Ligero y resistente a la corrosión | Less durable under high pressure | Bajo |

| Aluminio | Componentes de alto rendimiento | Durable with a high strength-to-weight ratio | Coste más elevado y fabricación más compleja | Medio |

| Acero | High-pressure tanks and housing | Extremely durable and long-lasting | Heavy and prone to rust | Alta |

| Goma | Seals and hoses | Creates airtight seals | Se degrada con el tiempo y la exposición | Bajo |

This strategic material selection guide provides B2B buyers with critical insights into the properties, advantages, and limitations of materials used in air inflators for cars. Understanding these factors will aid in making informed purchasing decisions that align with regional standards and application requirements.

The manufacturing of air inflators for cars is a multi-stage process that requires precision and adherence to industry standards. The main stages of production include material preparation, forming, assembly, and finishing. Each stage plays a critical role in ensuring that the final product meets quality and performance expectations.

Illustrative image related to air inflator for car

Material preparation is the first step in the manufacturing process. Manufacturers typically use high-quality plastics, metals, and rubber, depending on the components of the inflator. Suppliers must ensure that the materials comply with international standards, such as RoHS (Restriction of Hazardous Substances) and REACH (Registration, Evaluation, Authorisation, and Restriction of Chemicals), to guarantee safety and environmental compliance.

During this stage, materials are inspected for defects, and samples are often tested to ensure they meet specified characteristics, such as tensile strength and flexibility. This initial quality control (IQC) step helps to minimize defects later in the process.

Once materials are prepared, they undergo forming processes. Common techniques include injection molding for plastic components and stamping or machining for metal parts.

Injection molding is particularly prevalent for creating the outer casing and internal components of the inflator. This process allows for high-volume production with consistent quality. For metal parts, manufacturers may employ techniques like CNC (Computer Numerical Control) machining, which provides precision and reduces waste.

Quality checks during this stage often include dimensional inspections and functionality tests, ensuring that components fit together correctly and perform as intended.

The assembly stage combines all components into a finished product. This may involve manual labor or automated assembly lines, depending on the scale of production. In many cases, manufacturers employ modular assembly techniques, which streamline the process and allow for easy replacement of parts if defects are found.

During assembly, manufacturers conduct in-process quality control (IPQC) checks. These checks may include functional tests to ensure that each inflator operates correctly, checking for air leakage and verifying the accuracy of pressure gauges.

Finishing processes enhance the durability and aesthetic appeal of the air inflators. Common finishing techniques include surface treatment, painting, and labeling. Surface treatments, such as powder coating or anodizing, are applied to protect metal components from corrosion and wear.

Before packaging, final quality control (FQC) inspections are critical. These inspections ensure that each inflator meets the required specifications and is free from defects. Common testing methods include pressure tests, where the inflator is checked for leaks, and performance tests to confirm that it can inflate tires to the required pressure within a specified timeframe.

Quality assurance is paramount in the manufacturing of air inflators. Many manufacturers adhere to international quality management standards, such as ISO 9001, which outlines criteria for a quality management system. Compliance with ISO standards signifies that a manufacturer consistently meets customer and regulatory requirements.

In addition to ISO 9001, industry-specific certifications such as CE marking (indicating conformity with health, safety, and environmental protection standards) and API (American Petroleum Institute) certifications may be relevant, especially if the inflators are designed for specialized applications.

For B2B buyers, especially those from diverse regions like Africa, South America, the Middle East, and Europe, verifying supplier quality control is crucial. Here are some actionable steps:

Illustrative image related to air inflator for car

Audits and Inspections: Conduct regular audits of potential suppliers to assess their manufacturing processes and quality control measures. This can be done through on-site visits or third-party inspections.

Solicitar informes de calidad: Suppliers should provide quality assurance reports that detail their compliance with relevant standards and testing results. This documentation can give buyers confidence in the supplier’s capabilities.

Third-Party Certifications: Look for suppliers who have third-party certifications from recognized organizations. These certifications can be a strong indicator of the supplier’s commitment to quality.

Evaluate Testing Methods: Inquire about the testing methods used by suppliers. Common tests, such as pressure and durability tests, should be standardized and documented.

Comprender los matices regionales: Buyers should be aware of specific quality control nuances in their regions. For instance, regulations in Europe may differ significantly from those in Africa or South America, impacting the certification processes and standards required.

Manufacturers employ several testing methods to ensure the quality and reliability of air inflators:

Pressure Testing: This method checks for leaks and ensures that the inflator can maintain the specified pressure levels. Inflators are often tested at various pressure points to simulate real-world conditions.

Pruebas de durabilidad: Inflators are subjected to repetitive use scenarios to evaluate their longevity and performance under stress. This helps in identifying potential failure points early in the production cycle.

Functional Testing: Each inflator is tested to ensure it operates correctly, including checking the accuracy of pressure gauges and the efficiency of inflation.

By implementing rigorous testing methods, manufacturers can enhance product reliability and reduce the likelihood of returns or warranty claims, which is a critical factor for B2B buyers.

The manufacturing processes and quality assurance for air inflators for cars involve meticulous attention to detail across multiple stages. B2B buyers should prioritize suppliers who adhere to international standards and demonstrate robust quality control measures. By understanding the intricacies of manufacturing and quality assurance, buyers can make informed decisions that ensure they source reliable and high-quality air inflators for their business needs.

Sourcing an air inflator for cars requires careful consideration to ensure you meet your operational needs while also aligning with quality and compliance standards. This guide provides a step-by-step checklist designed for B2B buyers aiming to procure reliable and efficient air inflators. Follow these steps to streamline your sourcing process and make informed decisions.

Establish clear technical specifications for the air inflator based on your target market and application. Consider factors such as power source (electric or battery-operated), inflation speed, maximum pressure, and portability. This will help in identifying models that meet your operational needs and ensure compatibility with various vehicle types.

Understanding market trends is crucial for making informed purchasing decisions. Analyze regional demand for air inflators in your target markets—Africa, South America, the Middle East, and Europe. Look for insights on features that are popular among consumers, such as digital pressure gauges or compact designs, which can enhance customer satisfaction.

Before committing to a supplier, conduct thorough evaluations. Request company profiles, product catalogs, and references from existing clients in similar industries. Pay special attention to their production capabilities and past performance to ensure they can meet your order volume and quality standards.

Once you have shortlisted potential suppliers, request product samples for testing. This step is critical as it allows you to evaluate the performance, durability, and usability of the air inflators firsthand. During testing, consider factors such as ease of use, accuracy of pressure readings, and overall build quality.

Engage in negotiations to establish favorable terms and conditions with your selected supplier. Discuss pricing, payment terms, delivery timelines, and after-sales support. Ensure that you have a clear understanding of warranty policies and return procedures, which can mitigate risks associated with product defects.

Consider the logistics involved in transporting the air inflators from the supplier to your target market. Evaluate shipping options, customs regulations, and potential tariffs that may apply based on the regions you are targeting. Efficient logistics planning can significantly reduce costs and improve time-to-market.

Finally, implement a quality assurance process to monitor the inflators once they are in your inventory. Regularly inspect products for compliance with your specifications and customer expectations. This step is essential for maintaining brand reputation and customer satisfaction.

By following this structured checklist, B2B buyers can effectively source high-quality air inflators that meet their operational needs while ensuring compliance with market demands.

When sourcing air inflators for cars, understanding the cost structure is crucial for making informed purchasing decisions. The primary cost components include:

Materiales: The choice of materials significantly impacts the cost. Common materials used in inflators include high-grade plastics, metals for the casing, and internal components such as motors and pumps. Higher-quality materials may increase upfront costs but can enhance durability and performance.

Trabajo: Labor costs encompass wages for workers involved in the manufacturing process, including assembly line workers, quality control personnel, and engineers. Regions with higher wage standards, such as Europe, may have elevated labor costs compared to countries in Africa or South America.

Gastos generales de fabricación: This includes costs related to utilities, equipment maintenance, and facility management. Efficient manufacturing processes can help reduce overhead costs, influencing the final pricing of the product.

Herramientas: Initial tooling costs can be significant, particularly for custom designs or specifications. These costs are often amortized over the production run, making them a crucial factor in pricing for smaller orders.

Control de calidad: Implementing stringent QC measures ensures that inflators meet safety and performance standards. However, this can add to the cost structure. Certifications such as ISO or CE may be required, further impacting the overall price.

Logística: Shipping and handling costs vary widely based on the origin and destination of the products. International shipping, particularly from manufacturers in Asia to buyers in Europe or Africa, can involve additional tariffs and customs duties.

Margen: Suppliers typically include a profit margin in their pricing. Understanding the typical margins in the industry can provide leverage during negotiations.

Several factors can influence the pricing of air inflators for cars:

Volumen y cantidad mínima de pedido (MOQ): Suppliers often offer discounts for bulk purchases. Understanding the MOQ can help buyers negotiate better pricing, especially for larger quantities.

Especificaciones y personalización: Custom features, such as unique designs or additional functionalities (like built-in battery packs or digital displays), can increase costs. Buyers should weigh the benefits of customization against the associated costs.

Calidad del material y certificaciones: Higher-quality inflators with certifications may command higher prices, but they can also offer improved performance and reliability, contributing to lower total ownership costs.

Factores del proveedor: The supplier’s reputation, experience, and reliability can affect pricing. Established suppliers with a proven track record may charge more but offer better quality assurance and service.

Incoterms: The shipping terms defined by Incoterms can impact total costs. For instance, “CIF” (Cost, Insurance, Freight) may include shipping costs in the quoted price, while “FOB” (Free on Board) may require the buyer to handle shipping logistics, potentially increasing costs.

B2B buyers can adopt several strategies to negotiate effectively:

Realizar estudios de mercado: Understanding the market rates for air inflators allows buyers to set realistic budget expectations and identify competitive offers.

Negotiate on Volume: Leverage larger order quantities to negotiate better pricing. Suppliers are often willing to reduce prices for bulk purchases.

Considere el coste total de propiedad: Evaluate not just the purchase price but also the long-term costs associated with maintenance, durability, and performance. Sometimes, a higher upfront cost can lead to savings over time.

Conozca los matices de los precios: International buyers should be mindful of currency fluctuations, import tariffs, and local taxes that can affect the final cost.

Establecer relaciones: Establishing a rapport with suppliers can lead to more favorable terms and pricing adjustments over time.

It’s important to note that the prices for air inflators can vary widely based on the aforementioned factors, and the information provided here serves as a general guide. Prospective buyers should obtain tailored quotes from suppliers to understand the specific pricing landscape for their needs.

In the automotive sector, ensuring optimal tire pressure is crucial for safety, fuel efficiency, and overall vehicle performance. While air inflators for cars are commonly used to maintain tire pressure, there are several alternative solutions worth considering. This section delves into a comparative analysis of air inflators against other viable methods, helping B2B buyers make informed decisions based on performance, cost, and ease of use.

| Aspecto comparativo | Air Inflator For Car | Tire Sealant Kits | Manual Foot Pumps |

|---|---|---|---|

| Rendimiento | Quickly inflates tires; reliable for emergencies | Seals punctures and inflates; effective for minor leaks | Requires physical effort; slower inflation rate |

| Coste | Moderate ($30-$100) | Low ($10-$30) | Low ($15-$40) |

| Facilidad de aplicación | Plug-and-play; user-friendly | Simple application; requires no tools | Requires more effort; may need skill to operate |

| Mantenimiento | Minimal; check for battery and functionality | Limited; check expiration date | Regular cleaning; may require replacement |

| El mejor caso de uso | Road trips, emergencies, general maintenance | Temporary fixes for minor tire punctures | Camping, outdoor activities, budget-conscious users |

Tire sealant kits are designed to temporarily fix punctures and inflate tires simultaneously. They are particularly useful in emergency situations where a quick fix is needed. The primary advantage of sealant kits is their low cost and ease of use; they often come in a compact package that can be stored in the vehicle. However, they may not be suitable for larger punctures and can create a messy situation if not applied correctly. Additionally, sealants are meant for temporary solutions and may require a professional repair afterward, which can incur further costs.

Manual foot pumps are another alternative, relying on physical effort to inflate tires. They are generally more affordable and do not require electricity or batteries, making them a viable option for outdoor activities or remote locations. The main advantage is their durability and independence from power sources. However, they require significant effort and time to inflate tires, which can be impractical in urgent situations. Moreover, users may need some level of skill to achieve the desired pressure accurately.

When selecting the right solution for tire inflation and maintenance, B2B buyers should consider their specific needs, including the context in which the product will be used. Air inflators for cars offer speed and reliability, making them ideal for regular maintenance and emergencies. Tire sealant kits provide an economical option for minor repairs, while manual foot pumps serve well in outdoor settings. Ultimately, understanding the performance, cost, and ease of use of each alternative will guide buyers in making a choice that aligns with their operational requirements and budget constraints.

When considering air inflators for cars, several critical specifications are essential for B2B buyers to understand. These properties not only reflect the quality and reliability of the product but also impact operational efficiency and customer satisfaction.

Inflation Pressure (PSI)

The inflation pressure, measured in pounds per square inch (PSI), indicates the maximum pressure the inflator can generate. Most car tires require a pressure range of 30-35 PSI. Understanding this specification is crucial for buyers to ensure that the inflator can adequately service various vehicles. An inflator with a higher PSI rating can accommodate a wider range of tire types, making it more versatile for different markets.

Caudal (CFM)

The flow rate, expressed in cubic feet per minute (CFM), denotes how quickly the inflator can fill a tire. A higher CFM means faster inflation times, which is particularly valuable in commercial settings where time efficiency is critical. Buyers should evaluate this specification based on their target market’s needs, as rapid service can enhance customer satisfaction and retention.

Fuente de energía

Air inflators can be powered by various sources, including AC power, DC power from car batteries, or rechargeable batteries. Understanding the power source is vital for B2B buyers as it influences portability and usability. For instance, inflators powered by car batteries are ideal for emergency use, while AC-powered models are suitable for garage settings. Buyers should consider the prevalent power infrastructure in their target regions when selecting inflators.

Calidad del material

The material grade refers to the quality of materials used in the construction of the inflator. High-grade materials enhance durability and reliability, minimizing the risk of failure in demanding environments. Buyers must assess the material specifications to ensure that the inflators can withstand the rigors of repeated use, especially in regions with harsher climates.

Noise Level (dB)

The noise level, measured in decibels (dB), is an important consideration for both consumer satisfaction and regulatory compliance. Inflators that operate at lower noise levels can be more appealing to end-users, especially in residential areas. B2B buyers should consider this aspect to cater to markets where noise regulations are stringent.

Familiarity with industry jargon is essential for effective communication and negotiation in the B2B marketplace. Here are some common terms relevant to air inflators for cars:

OEM (fabricante de equipos originales)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of air inflators, understanding OEM relationships can help buyers identify high-quality products that meet specific standards and compatibility requirements.

MOQ (Cantidad mínima de pedido)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is critical for B2B buyers to understand as it affects inventory management and cost. Knowing the MOQ helps businesses plan their purchases more effectively and negotiate better pricing.

RFQ (solicitud de presupuesto)

An RFQ is a formal document used to solicit price quotes from suppliers. It is essential for B2B transactions, allowing buyers to compare prices and terms from different manufacturers, ensuring they secure the best deal for air inflators.

Incoterms (Términos comerciales internacionales)

Incoterms are a set of predefined international trade terms that clarify the responsibilities of buyers and sellers. Understanding these terms is crucial for B2B buyers, as they determine who is responsible for shipping, insurance, and tariffs during the transportation of air inflators.

Periodo de garantía

The warranty period specifies the duration for which the manufacturer guarantees the product against defects. A longer warranty can be a significant selling point for B2B buyers, indicating higher confidence in product quality and longevity.

By grasping these technical properties and trade terminology, B2B buyers can make informed decisions when sourcing air inflators for cars, ensuring they meet market demands and maintain competitive advantages.

The air inflator market for cars is witnessing significant transformations driven by technological advancements and shifting consumer preferences. Globally, the demand for portable and electric tire inflators is on the rise, particularly in emerging markets in Africa and South America, where the need for efficient, easy-to-use solutions is paramount. B2B buyers are increasingly seeking products that combine functionality with convenience, such as inflators equipped with digital pressure gauges and automatic shut-off features. These innovations not only enhance user experience but also cater to the growing trend of smart automotive accessories.

In Europe, particularly in Germany, there is a notable shift towards inflators that integrate with electric vehicles (EVs), reflecting the broader transition to sustainable mobility. As EV adoption grows, the demand for compatible charging solutions and accessories, including tire inflators, is expected to increase. Additionally, international buyers are leveraging e-commerce platforms to source products, allowing for greater accessibility to various brands and models, as well as competitive pricing.

Furthermore, the focus on lightweight and compact designs is gaining traction, making inflators more portable for consumers. This trend is particularly relevant in regions with challenging terrains, where road assistance may not be readily available. B2B buyers must stay informed about these dynamics to align their sourcing strategies with market demands and ensure competitiveness.

Sustainability is becoming a cornerstone of purchasing decisions in the air inflator market. As environmental concerns rise, B2B buyers are increasingly prioritizing suppliers who demonstrate commitment to ethical sourcing practices and sustainability. This encompasses the use of eco-friendly materials, energy-efficient manufacturing processes, and adherence to environmental regulations.

Incorporating ‘green’ certifications into products can significantly enhance their marketability. Certifications such as ISO 14001 or Energy Star signal to buyers that a product meets rigorous environmental standards, which is particularly appealing in regions with stringent environmental policies. Additionally, buyers are encouraged to engage with manufacturers that utilize recyclable materials in their inflators, as this aligns with the growing consumer demand for sustainable products.

The importance of ethical supply chains cannot be overstated. Buyers are now more scrutinizing of the entire lifecycle of products, from raw material extraction to end-of-life disposal. By prioritizing suppliers that uphold ethical labor practices and sustainable sourcing, B2B buyers can not only mitigate risks associated with supply chain disruptions but also enhance their brand reputation in an increasingly eco-conscious market.

The air inflator industry has evolved significantly from the basic manual pumps of the early 20th century to today’s sophisticated digital models. Initially, tire inflation was a labor-intensive task that relied on physical exertion. The introduction of electric inflators marked a turning point, making the process quicker and more efficient.

In recent years, the integration of smart technology has revolutionized the market, with features such as Bluetooth connectivity and mobile app integration allowing users to monitor tire pressure remotely. This evolution is particularly relevant for B2B buyers looking to stock products that meet modern consumer expectations for convenience and technology.

Illustrative image related to air inflator for car

As the market continues to evolve, understanding the historical context of air inflators can provide valuable insights into future trends and innovations. Buyers who recognize these changes can better anticipate market shifts and align their inventory strategies accordingly, ensuring they remain competitive in an increasingly dynamic landscape.

How do I choose the right air inflator for my business needs?

Selecting the right air inflator involves assessing your specific requirements. Consider factors such as the inflator’s pressure output, volume capacity, and portability. Evaluate the types of vehicles or equipment you will be inflating; for instance, if you cater to a diverse range of vehicles, a multi-purpose inflator may be ideal. Additionally, look for features like automatic shut-off, LED lights, and built-in pressure gauges for enhanced usability. Finally, research suppliers that offer quality assurance and after-sales support to ensure reliability.

What is the best air inflator for heavy-duty use?

For heavy-duty applications, consider inflators that are designed for high performance, such as those with a higher PSI rating and faster inflation times. Brands like Fanttik and AstroAI are known for robust models that can handle commercial-grade tire sizes. Look for inflators with durable construction, such as metal housing and reinforced hoses, to withstand rigorous use. Additionally, ensure the inflator includes safety features like overheat protection and a reliable power source, whether it’s AC, DC, or battery-operated.

What are the key considerations when sourcing air inflators from international suppliers?

When sourcing air inflators internationally, it is crucial to evaluate suppliers based on their manufacturing standards, certifications, and compliance with regional regulations. Verify their production capabilities, lead times, and whether they can meet your specific customization needs. It’s also important to assess their logistics capabilities, including shipping times and costs, to ensure timely delivery. Lastly, consider their payment terms and the option for trade financing to manage cash flow effectively.

How can I verify the quality of air inflators before purchasing?

To ensure quality, request samples from potential suppliers to assess performance and durability firsthand. Review product specifications, certifications (like ISO or CE), and customer testimonials to gauge reliability. Conduct factory audits if possible, or use third-party inspection services to evaluate manufacturing processes. Additionally, inquire about warranty policies and return options to protect your investment, ensuring you have recourse if the product does not meet your expectations.

What is the typical minimum order quantity (MOQ) for air inflators?

Minimum order quantities (MOQs) for air inflators can vary widely depending on the supplier and the product specifications. Generally, MOQs can range from 100 to 1,000 units for standard models, while customized products may have higher MOQs. Discuss your specific needs with potential suppliers to negotiate suitable order quantities that align with your business model and market demand. Keep in mind that larger orders often lead to better pricing and lower per-unit costs.

What payment terms should I expect when importing air inflators?

Payment terms for importing air inflators typically include options such as upfront payment, partial payments, or payment upon delivery. Common methods include Letters of Credit (LC), wire transfers, or escrow services for added security. It’s essential to negotiate terms that protect your investment while also considering the supplier’s requirements. Ensure that all payment terms are clearly outlined in the purchase agreement to avoid misunderstandings and to facilitate smoother transactions.

What logistics considerations should I keep in mind for shipping air inflators?

When shipping air inflators, consider the mode of transport (air, sea, or land) based on cost, urgency, and destination. Evaluate the packaging requirements to prevent damage during transit, especially for sensitive components. Research customs regulations in your target market to ensure compliance and avoid delays. Partnering with a reliable freight forwarder can help streamline the shipping process, manage documentation, and provide insights into best practices for international logistics.

How can I customize air inflators to meet specific market demands?

Customization options for air inflators can include branding, color schemes, and feature modifications to cater to local preferences. Discuss your requirements with suppliers who offer flexible manufacturing capabilities. They may provide options for different PSI ratings, additional attachments for various valve types, or unique packaging designs. Conduct market research to understand your target audience’s needs, ensuring that the customized features align with customer expectations and enhance product appeal in your market.

Dominio: target.com

Inscrita: 1997 (28 años)

Introducción: This company, Target – Portable 150PSI Tire Inflators, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Dominio: macheforum.com

Registrado: 2018 (7 años)

Introducción: 1. **Fanttik X8 Apex Inflator** – Recommended by multiple users for its compact size and efficiency. Users noted it can inflate tires for cars and bikes with minimal battery loss. Available at Costco.

2. **AstroAI Inflator** – Mentioned as a good option that also includes a jump starter.

3. **Ryobi Inflator** – Suggested by a user who has multiple Ryobi batteries for power tools, indicating it can…

As we reflect on the strategic sourcing of air inflators for cars, it becomes clear that the demand for reliable, high-quality inflators is on the rise across international markets. Key takeaways from our analysis include the importance of understanding regional preferences, regulatory requirements, and the need for robust product features such as portability, efficiency, and multi-functionality. Leveraging these insights can enhance supplier relationships and drive competitive advantage in diverse markets like Africa, South America, the Middle East, and Europe.

The value of strategic sourcing cannot be overstated; it not only optimizes procurement processes but also fosters innovation and responsiveness to market trends. B2B buyers are encouraged to prioritize partnerships with manufacturers that demonstrate a commitment to quality and sustainability, as these factors increasingly influence consumer purchasing decisions.

Looking ahead, the air inflator market is poised for growth, driven by advancements in technology and increased awareness of vehicle maintenance. International buyers should seize this opportunity to enhance their product offerings and meet the evolving needs of consumers. Engage with your suppliers now to ensure you are well-positioned for the future of this vital automotive accessory market.

La información facilitada en esta guía, incluido el contenido relativo a fabricantes, especificaciones técnicas y análisis de mercado, tiene únicamente fines informativos y educativos. No constituye asesoramiento profesional en materia de adquisiciones, asesoramiento financiero ni asesoramiento jurídico.

Illustrative image related to air inflator for car

Aunque hemos hecho todo lo posible por garantizar la exactitud y actualidad de la información, no nos hacemos responsables de posibles errores, omisiones o información obsoleta. Las condiciones del mercado, los detalles de las empresas y las normas técnicas están sujetos a cambios.

Los compradores B2B deben llevar a cabo su propia diligencia debida independiente y exhaustiva antes de tomar cualquier decisión de compra. Esto incluye ponerse en contacto directamente con los proveedores, verificar las certificaciones, solicitar muestras y buscar asesoramiento profesional. El riesgo de confiar en la información contenida en esta guía es responsabilidad exclusiva del lector.