In the ever-evolving landscape of the automotive industry, sourcing the best automotive air compressor poses a significant challenge for international B2B buyers. Whether you are operating in Africa, South America, the Middle East, or Europe, understanding the diverse range of options available is crucial for optimizing vehicle maintenance and operational efficiency. This comprehensive guide explores various types of air compressors, their applications across different automotive sectors, and critical considerations for supplier vetting.

Navigating the global market requires an informed approach to purchasing, particularly given the varied climatic and operational conditions across regions like Vietnam and Brazil. We delve into essential factors such as cost-effectiveness, durability, and performance specifications to help you select the right compressor tailored to your business needs. Additionally, this guide provides insights into evaluating suppliers, ensuring you partner with reputable manufacturers who can deliver quality products reliably.

Empowering B2B buyers with actionable insights, this guide aims to enhance your purchasing decisions, ultimately leading to improved vehicle performance and reduced downtime. With a focus on actionable strategies and detailed comparisons, you will be equipped to make informed choices that align with your operational goals and market demands.

| Tipo Nombre | Principales rasgos distintivos | Aplicaciones B2B principales | Breves pros y contras para los compradores |

|---|---|---|---|

| Portable Tire Inflators | Compact, battery-operated or 12V powered | Automotive repair shops, fleets | Pros: Easy to transport, quick inflation. Contras: Limited duty cycle, may lack power for larger tires. |

| Heavy-Duty Air Compressors | High PSI output, robust construction | Construction, automotive workshops | Pros: Suitable for large tires, durable. Contras: Bulky, higher price point. |

| Cordless Air Compressors | Rechargeable, lightweight, versatile | Mobile service providers, roadside assistance | Pros: No cords, convenient for remote use. Contras: Battery life may limit usage time. |

| AC/DC Air Compressors | Dual power options, versatile for home and vehicle use | Garages, automotive enthusiasts | Pros: Flexible power sources, useful for various tasks. Contras: Can be heavier, may require more maintenance. |

| Inflator/Deflator Units | Multi-functional, often includes additional features | Recreational vehicle maintenance, sports equipment | Pros: Versatile, can handle multiple tasks. Contras: Complexity can lead to user errors. |

Portable tire inflators are designed for ease of use and mobility. Typically powered by a rechargeable battery or a 12V vehicle outlet, these units are compact and lightweight, making them ideal for roadside assistance or personal use. They are particularly suitable for automotive repair shops and fleet management companies that require quick, efficient tire maintenance. When purchasing, consider the maximum PSI, battery life, and the inflator’s ability to handle multiple tires on a single charge.

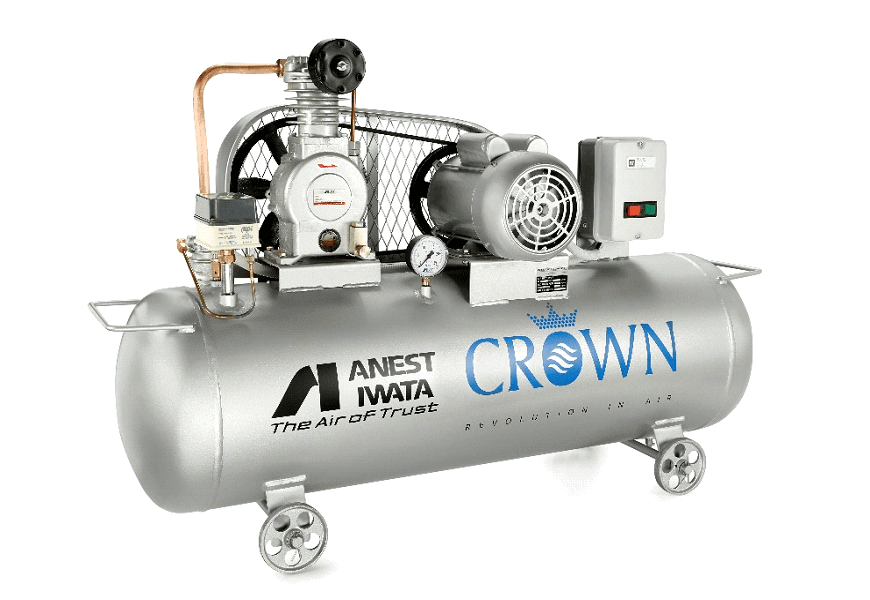

Illustrative image related to best automotive air compressor

Heavy-duty air compressors are characterized by their ability to deliver high PSI outputs, making them essential for inflating larger tires found on trucks and heavy machinery. Their robust construction ensures durability in demanding environments, such as construction sites or automotive workshops. B2B buyers should focus on the compressor’s power rating, duty cycle, and compatibility with various tire sizes. While they may come at a higher price point, their efficiency and reliability can lead to long-term savings.

Cordless air compressors offer significant advantages for mobile service providers, allowing technicians to operate without being tethered to a power source. These lightweight units are rechargeable and designed for versatility, often featuring built-in pressure gauges and preset inflation settings. They are particularly suitable for roadside assistance and emergency tire repairs. Buyers should evaluate battery life, charging time, and ease of use to ensure they meet operational needs effectively.

AC/DC air compressors provide the flexibility of dual power options, allowing them to be used in various settings, from home garages to outdoor locations. Their versatility makes them a popular choice among automotive enthusiasts and small repair shops. When considering these compressors, it is crucial to assess their weight, portability, and maintenance requirements. While they can be heavier than other models, their adaptability often justifies the investment.

Illustrative image related to best automotive air compressor

Inflator/deflator units are multi-functional tools that can quickly inflate and deflate tires, making them ideal for recreational vehicle maintenance and sports equipment. These units often come equipped with additional features such as built-in lights or multiple nozzle attachments. B2B buyers should consider the complexity of operation and potential for user error, but the versatility of these units can significantly enhance operational efficiency in various applications.

| Industria/Sector | Specific Application of best automotive air compressor | Valor/beneficio para la empresa | Consideraciones clave para el aprovisionamiento de esta aplicación |

|---|---|---|---|

| Automotive Repair Services | Tire inflation and maintenance for customer vehicles | Enhances customer satisfaction by ensuring vehicle safety | Reliability, ease of use, and portability for shop environments |

| Logistics and Transportation | Air supply for pneumatic tools and equipment in fleet vehicles | Increases operational efficiency and reduces downtime | Compatibility with various vehicle types and air pressure needs |

| Construcción | Inflating tires for heavy machinery and construction vehicles | Ensures equipment readiness and minimizes project delays | Durability, high PSI capabilities, and rugged design |

| Agricultura | Tire inflation for farm equipment and vehicles | Improves productivity and reduces maintenance costs | Adaptability to diverse agricultural machinery |

| Fabricación | Powering pneumatic tools and machinery in assembly lines | Streamlines production processes and enhances productivity | Consistent air pressure delivery and energy efficiency |

In automotive repair services, the best automotive air compressors are essential for tire inflation and maintenance. They ensure that customer vehicles are safe and road-ready by providing accurate tire pressure. This not only enhances customer satisfaction but also reduces the risk of accidents related to tire underinflation. Buyers in this sector should prioritize reliability, ease of use, and portability, as these compressors are often used in busy workshop environments where speed and efficiency are critical.

In the logistics and transportation sector, automotive air compressors are utilized to supply air for pneumatic tools and equipment used in fleet vehicles. This application is vital for maintaining the functionality of air brakes and other pneumatic systems, which are crucial for vehicle safety. By ensuring that these systems operate efficiently, businesses can reduce downtime and improve overall operational efficiency. Buyers should consider compatibility with various vehicle types and the ability to meet specific air pressure requirements.

Construction companies leverage automotive air compressors for inflating tires on heavy machinery and construction vehicles. This ensures that all equipment is operational and ready for use, significantly minimizing project delays caused by equipment malfunction. The rugged design and high PSI capabilities of these compressors are critical in this sector, as construction environments can be harsh. Buyers must focus on durability and the ability to deliver high-pressure air consistently to meet the demands of their operations.

In the agricultural sector, the best automotive air compressors are used for inflating tires on farm equipment and vehicles, which is essential for maintaining productivity. Properly inflated tires enhance fuel efficiency and reduce wear and tear on equipment, leading to lower maintenance costs. Buyers should seek compressors that can adapt to diverse agricultural machinery, ensuring that they can handle the varying tire sizes and pressure requirements typical in this industry.

Manufacturing facilities employ automotive air compressors to power pneumatic tools and machinery in assembly lines. This application streamlines production processes, allowing for faster and more efficient operations. Consistent air pressure delivery is vital in this context, as fluctuations can disrupt workflows and affect product quality. Buyers should prioritize energy efficiency and the ability to maintain stable pressure levels to optimize their manufacturing operations.

El problema:

B2B buyers in the automotive sector often struggle to find reliable suppliers of high-quality air compressors. With numerous brands and models available, it can be overwhelming to sift through options that vary significantly in performance, price, and durability. In regions like Africa and South America, where supply chains can be inconsistent, this challenge is compounded by a lack of local support and service. Buyers may end up with subpar equipment that fails to meet their operational needs, leading to costly downtime and repairs.

La solución:

To effectively source reliable automotive air compressors, buyers should start by conducting thorough market research. Engage with industry forums and trade shows to connect with reputable manufacturers and distributors. Building relationships with suppliers who have a proven track record in your specific region is crucial. Additionally, consider leveraging platforms that provide reviews and ratings of different models. When evaluating potential purchases, prioritize those with robust warranties and after-sales support. This proactive approach ensures that you invest in durable equipment that aligns with your operational requirements.

El problema:

For businesses that rely on a fleet of vehicles, maintaining optimal tire pressure is essential for safety and fuel efficiency. However, varying tire pressure can lead to inconsistent performance and increased operational costs. In regions with extreme weather conditions, like the Middle East or Europe, tire pressure can fluctuate significantly, making it challenging for fleet managers to maintain the correct air levels consistently.

La solución:

To combat this issue, B2B buyers should invest in automotive air compressors equipped with digital pressure gauges and automatic shut-off features. These advanced compressors can accurately measure and adjust tire pressure, ensuring that tires are always at optimal levels. Additionally, integrating a regular maintenance schedule that includes tire pressure checks can help identify issues before they escalate. Training staff on the importance of monitoring tire pressure regularly, especially before long trips, will also contribute to enhanced fleet efficiency and reduced fuel costs.

El problema:

In many remote or underdeveloped areas, the availability of reliable electricity can be a significant barrier to using traditional automotive air compressors. B2B buyers may find themselves facing downtime when they cannot power their compressors, especially in urgent situations such as flat tires on service vehicles or emergency roadside assistance.

La solución:

To address this challenge, buyers should consider sourcing portable, battery-operated air compressors that offer versatility and convenience. Models that can be charged via a vehicle’s 12V outlet or have rechargeable lithium-ion batteries provide a practical solution for businesses operating in areas with inconsistent power supply. Furthermore, ensuring that your team is equipped with these portable compressors can enhance responsiveness during emergencies, minimizing downtime. When selecting these models, prioritize those with the capacity to inflate larger tires and those that come with additional features, such as built-in lights or USB ports for charging devices, to maximize their utility in various scenarios.

When selecting an automotive air compressor, the choice of materials significantly influences performance, durability, and cost-effectiveness. Here, we analyze four common materials used in the manufacturing of air compressors, focusing on their properties, advantages, disadvantages, and considerations for international B2B buyers.

Key Properties: Aluminum is lightweight and has excellent thermal conductivity, making it suitable for components that require efficient heat dissipation. It typically has a pressure rating of up to 150 psi and can withstand moderate temperature variations.

Pros y contras: The primary advantage of aluminum is its low weight, which enhances portability. It is also resistant to corrosion, which is crucial for outdoor applications. However, aluminum can be more expensive than other materials like steel and may not withstand extreme pressures or temperatures as effectively.

Impacto en la aplicación: Aluminum is ideal for portable air compressors used in light-duty applications, such as inflating tires for passenger vehicles. Its compatibility with various media, including air and non-corrosive gases, makes it versatile.

Consideraciones internacionales: Buyers from regions like Africa and South America should be aware of local regulations regarding aluminum recycling and waste management. Compliance with standards such as ASTM and ISO can also affect procurement decisions.

Key Properties: Steel is known for its high strength and durability, with pressure ratings often exceeding 200 psi. It has good resistance to mechanical stress and can handle high temperatures.

Pros y contras: The strength of steel makes it suitable for heavy-duty applications, such as commercial vehicles and industrial settings. However, it is heavier than aluminum, which can affect portability. Additionally, steel is prone to corrosion unless properly treated, which may increase manufacturing complexity.

Impacto en la aplicación: Steel is often used in stationary air compressors and those designed for heavy-duty tasks. Its robustness allows for compatibility with high-pressure applications, making it suitable for truck and SUV tire inflation.

Consideraciones internacionales: Buyers in Europe and the Middle East should consider compliance with DIN and JIS standards for steel quality. The availability of corrosion-resistant coatings can also influence purchasing decisions.

Illustrative image related to best automotive air compressor

Key Properties: Plastics, particularly high-density polyethylene (HDPE) and polycarbonate, are lightweight and resistant to corrosion. They can handle moderate pressure, typically up to 100 psi, and are effective in temperature ranges from -40°C to 80°C.

Pros y contras: The primary advantage of plastic is its low cost and ease of manufacturing, making it suitable for low-end consumer products. However, plastics may not be suitable for high-pressure applications and can degrade over time under UV exposure.

Impacto en la aplicación: Plastic components are often used in portable tire inflators and smaller compressors designed for light-duty tasks. They are compatible with air and some non-corrosive gases.

Consideraciones internacionales: B2B buyers in regions like Vietnam and Brazil should ensure that plastic components meet local environmental regulations regarding recyclability and safety. Compliance with ASTM standards for plastics can also be a factor.

Key Properties: Cast iron is known for its exceptional durability and resistance to wear and tear. It can handle high pressures (up to 250 psi) and operates effectively at elevated temperatures.

Illustrative image related to best automotive air compressor

Pros y contras: The durability of cast iron makes it ideal for long-term use in industrial applications. However, it is heavy and can be more expensive to manufacture. Additionally, cast iron is prone to rust if not properly coated.

Impacto en la aplicación: Cast iron is commonly used in industrial-grade air compressors where longevity and reliability are paramount. Its compatibility with high-pressure air makes it suitable for heavy-duty tasks.

Consideraciones internacionales: Buyers in the Middle East and Europe should consider the availability of cast iron components that meet local standards. The weight and shipping costs associated with cast iron can also impact overall procurement strategies.

| Material | Typical Use Case for best automotive air compressor | Ventajas clave | Principales desventajas/limitaciones | Coste relativo (Bajo/Medio/Alto) |

|---|---|---|---|---|

| Aluminio | Portable air compressors for light-duty tasks | Ligero y resistente a la corrosión | Higher cost than steel | Medio |

| Acero | Heavy-duty stationary air compressors | Alta resistencia y durabilidad | Más pesado y propenso a la corrosión | Media a alta |

| Plástico | Small, portable tire inflators | Bajo coste y fácil de fabricar | Limited pressure capacity | Bajo |

| Cast Iron | Industrial-grade air compressors | Durabilidad excepcional | Heavy and potentially rusts | Alta |

This analysis provides a comprehensive overview of material options for automotive air compressors, enabling B2B buyers to make informed decisions tailored to their specific needs and regional considerations.

The manufacturing of automotive air compressors involves several critical stages that ensure the final product meets industry standards and customer expectations. Understanding these stages can help B2B buyers make informed decisions when selecting suppliers.

The first step in the manufacturing process is material preparation, which involves sourcing high-quality raw materials. Common materials used in automotive air compressors include aluminum, steel, and various plastics. Suppliers often utilize advanced techniques such as metallurgical testing to assess the properties of metals and ensure they meet the necessary specifications for strength and durability. Additionally, suppliers may conduct chemical analysis to verify the composition of materials, ensuring they are free from defects and contaminants.

Once materials are prepared, the next stage is forming. This can involve various techniques such as casting, machining, and stamping.

Casting: This process is frequently used for creating the compressor housing. Molten metal is poured into molds to form complex shapes, providing structural integrity and reducing weight.

Machining: Precision machining is critical for components such as pistons and cylinders. CNC (Computer Numerical Control) machines are commonly employed to achieve high precision and repeatability, which is essential for performance and longevity.

Stamping: This technique is often used for creating brackets and other metal components. Stamping allows for high-volume production while maintaining cost-effectiveness.

The assembly stage is where all the manufactured components come together. This process is typically divided into several sub-stages, including:

Sub-Assembly: Smaller components, such as valves and fittings, are assembled first. This approach allows for easier handling and quality checks before the final assembly.

Main Assembly: The sub-assemblies are then integrated into the main unit. Automation technologies, such as robotic arms, may be employed to enhance efficiency and accuracy during this stage.

Final Assembly: This includes the installation of electrical components and final adjustments. Quality control measures are often applied throughout this process to ensure every unit meets performance standards.

After assembly, finishing techniques are applied to enhance the product’s aesthetics and durability. Common finishing processes include:

Painting and Coating: Protective coatings are applied to prevent corrosion and improve appearance. This is particularly important for products exposed to harsh environments.

Polishing: Components may undergo polishing to improve surface finish and reduce friction, enhancing the compressor’s overall efficiency.

Quality assurance (QA) is critical in ensuring that automotive air compressors meet international standards and customer requirements. The QA process typically includes multiple checkpoints and adherence to various standards.

B2B buyers should be aware of key international standards relevant to automotive air compressor manufacturing:

ISO 9001: This standard focuses on quality management systems and is applicable to organizations looking to enhance customer satisfaction through effective process control. Manufacturers certified under ISO 9001 demonstrate their commitment to quality and continuous improvement.

Marcado CE: In Europe, the CE mark indicates compliance with health, safety, and environmental protection standards for products sold within the European Economic Area (EEA). It is essential for B2B buyers operating in European markets to ensure their suppliers have CE certification.

Normas API: For compressors used in specific applications, particularly in the oil and gas industry, adherence to American Petroleum Institute (API) standards is crucial. These standards ensure that products are safe, reliable, and environmentally sound.

Quality control (QC) checkpoints are integrated throughout the manufacturing process to ensure that each product meets established standards. Common checkpoints include:

Control de calidad entrante (IQC): Raw materials are inspected upon arrival to verify compliance with specifications. This step helps prevent defects from being introduced early in the manufacturing process.

Control de calidad durante el proceso (IPQC): Throughout production, various tests are conducted to monitor quality. This includes dimensional checks, functional tests, and visual inspections. Real-time monitoring helps in identifying issues before they escalate.

Control de calidad final (CCF): Once the product is fully assembled, it undergoes final testing to ensure it meets performance specifications. This may include pressure testing, noise level assessments, and operational tests.

B2B buyers must take proactive steps to verify the quality control practices of potential suppliers. Here are effective strategies:

Regular audits of suppliers can provide insights into their manufacturing processes and quality control measures. Buyers should consider performing both scheduled and unscheduled audits to assess compliance with industry standards and identify any areas for improvement.

Buyers should request detailed QC reports from suppliers, including data on testing methods, pass/fail rates, and any corrective actions taken for non-conformance. This documentation can provide confidence in the supplier’s commitment to quality.

Engaging third-party inspection services can add an additional layer of assurance. These organizations can conduct independent assessments of the manufacturing processes and product quality, providing unbiased evaluations that can inform purchasing decisions.

International B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, should be aware of specific nuances in quality control:

Diferencias culturales: Understanding cultural attitudes towards quality and compliance can help buyers effectively communicate their expectations to suppliers.

Cumplimiento de la normativa: Different regions may have varying regulatory requirements. Buyers should familiarize themselves with local standards and ensure suppliers comply with both international and regional regulations.

Supply Chain Risks: International supply chains can introduce risks related to logistics, customs, and quality. Buyers should develop strategies to mitigate these risks, including establishing clear communication channels and contingency plans.

In summary, a thorough understanding of the manufacturing processes and quality assurance practices for automotive air compressors can greatly enhance the decision-making process for B2B buyers. By focusing on these aspects, buyers can ensure they select suppliers that not only meet their quality requirements but also contribute to the long-term success of their operations.

This guide aims to provide B2B buyers with a comprehensive checklist for sourcing the best automotive air compressor. Given the growing demand across various regions, including Africa, South America, the Middle East, and Europe, understanding the key factors in selecting an air compressor is essential for ensuring quality and reliability.

Before embarking on your search, it’s crucial to identify the specific technical requirements for your air compressor. Consider factors such as maximum pressure (PSI), tank capacity, and power source (electric vs. gas). This clarity will help streamline your options and ensure you choose a compressor that meets your operational needs.

Illustrative image related to best automotive air compressor

Understanding market trends in your region is vital. Different regions may have unique demands based on climate, vehicle types, and industrial applications. For instance, compressors suited for heavy-duty vehicles may be necessary in regions with a high number of trucks or SUVs. Conducting this research can guide you toward the most relevant features and specifications.

Verify that potential suppliers possess the necessary certifications and quality assurances. Look for ISO certifications and compliance with international standards, which demonstrate a commitment to quality and safety. This step is critical for minimizing risks associated with poor-quality products that could affect your operations.

Before making a bulk purchase, request samples or demonstrations of the air compressors. This allows you to assess performance, usability, and build quality firsthand. Pay attention to factors such as inflation speed, noise levels, and ease of use, particularly if the compressors will be operated in various settings.

A robust warranty and reliable after-sales support can significantly impact your long-term satisfaction with the product. Review the warranty terms carefully and inquire about the supplier’s support services. Having access to technical assistance and parts can be crucial in maintaining operational efficiency.

Illustrative image related to best automotive air compressor

Gather quotes from multiple suppliers to compare pricing and payment terms. Ensure that you assess not only the initial purchase cost but also any potential hidden costs, such as shipping, taxes, and duties. Negotiating favorable payment terms can also improve your cash flow management.

Finally, seek references from previous buyers and examine customer reviews. This can provide insights into the supplier’s reliability and the performance of their air compressors in real-world applications. Engaging with current users can also highlight any potential issues you might encounter, helping you make a more informed decision.

By following this checklist, B2B buyers can navigate the complexities of sourcing automotive air compressors, ensuring they select a product that aligns with their operational needs and regional demands.

When analyzing the cost structure for automotive air compressors, several components play critical roles. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margin.

Materiales: The choice of materials significantly impacts the overall cost. High-quality, durable components such as aluminum for housing and advanced polymers for seals can elevate the price but also enhance performance and longevity. Suppliers often provide options at various price points, so understanding material specifications is crucial.

Trabajo: Labor costs can vary by region. In regions with higher wage standards, such as Europe, labor costs might be significantly higher than in South America or parts of Africa. This factor can affect the final pricing and should be considered when evaluating suppliers.

Gastos generales de fabricación: This includes utilities, rent, equipment depreciation, and other indirect costs associated with the production process. A higher overhead can lead to increased product prices, particularly if the supplier operates in a high-cost area.

Herramientas: Initial tooling costs can be substantial, especially for custom designs. Buyers should inquire about these costs upfront, as they can be amortized over larger order volumes, reducing per-unit costs.

Control de calidad: Rigorous QC processes ensure that each product meets industry standards and specifications. This can add to the manufacturing cost but is essential for maintaining reliability and customer satisfaction.

Logística: Shipping costs can vary significantly based on the destination, mode of transport, and Incoterms. For international buyers, understanding these logistics costs is vital, as they can substantially affect the total cost.

Margen: Suppliers will add a margin to cover their costs and profit. This can vary widely depending on the supplier’s position in the market and their perceived value.

Several factors influence pricing in the automotive air compressor market, particularly for international B2B buyers.

Volumen/MOQ: Minimum order quantities (MOQ) can greatly affect the pricing structure. Larger orders typically yield better pricing per unit, making it advantageous for businesses to negotiate bulk purchases when feasible.

Especificaciones y personalización: Custom features or specifications can increase costs. Buyers must weigh the benefits of customization against the additional expenses incurred.

Calidad y certificaciones: Products certified to international standards may command higher prices due to the assurance of quality. Buyers should assess the importance of these certifications in relation to their market needs.

Factores del proveedor: The reputation, reliability, and location of the supplier can influence pricing. Established suppliers may offer premium pricing due to their market position, while newer entrants may provide competitive pricing to gain market share.

Incoterms: Understanding the terms of trade (Incoterms) is crucial for international transactions. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can significantly impact the total landed cost.

B2B buyers should consider various strategies to enhance cost efficiency when sourcing automotive air compressors.

Estrategias de negociación: Engage suppliers in discussions about pricing flexibility based on order volume or long-term partnership commitments. Understanding their cost structure can also provide leverage in negotiations.

Centrarse en el coste total de propiedad (TCO): Consider not only the purchase price but also the long-term costs associated with maintenance, warranty, and efficiency. A higher upfront cost might be justified by lower operating costs.

Comprender los matices de los precios para los compradores internacionales: Buyers from regions like Africa or South America may face unique challenges such as currency fluctuations, tariffs, and import duties. Being aware of these factors can help in budgeting and negotiating.

Evaluate Multiple Suppliers: Don’t rely solely on one supplier. Comparing multiple offers can provide insights into market pricing and help identify the best value.

Manténgase informado sobre las tendencias del mercado: Awareness of industry trends, including technological advancements and shifts in demand, can inform purchasing decisions and negotiation tactics.

Prices for automotive air compressors can fluctuate based on market conditions, supplier negotiations, and specific buyer requirements. Always request current pricing from suppliers to ensure accurate budgeting and sourcing decisions.

In the automotive maintenance landscape, having the right tools for tire inflation is crucial. While the best automotive air compressors are often the go-to solution, various alternatives can effectively meet similar needs. This analysis will compare the standard automotive air compressor with two viable alternatives: portable tire inflators and electric pumps.

| Aspecto comparativo | Best Automotive Air Compressor | Inflador de neumáticos portátil | Bomba eléctrica |

|---|---|---|---|

| Rendimiento | High PSI, fast inflation | Moderate PSI, slower | Variable PSI, efficient |

| Coste | $70 – $150 | $30 – $100 | $50 – $120 |

| Facilidad de aplicación | Requires setup and power source | Simple, often battery-operated | Requires power outlet |

| Mantenimiento | Low, occasional checks needed | Very low, mainly battery checks | Moderate, regular checks needed |

| El mejor caso de uso | Aplicaciones pesadas | Emergency inflations | Continuous use in garages |

Portable tire inflators are compact devices designed for quick and easy tire inflation. They are typically battery-operated or can be plugged into a vehicle’s 12-volt outlet.

Illustrative image related to best automotive air compressor

Pros:

– Convenience: Their compact size makes them easy to store and transport, ideal for emergency situations.

– User-Friendly: Most models have preset PSI settings, allowing users to inflate tires without needing to monitor pressure manually.

Contras:

– Performance Limitations: They generally have lower PSI capabilities compared to traditional compressors, making them less suitable for larger vehicles or heavy-duty applications.

– Battery Life: Depending on the model, battery life can be a concern, especially when inflating multiple tires.

Electric pumps are designed for use in garages and workshops, providing a steady airflow for tire inflation. They often plug into standard power outlets and can deliver a consistent PSI.

Pros:

– Efficiency: Electric pumps can inflate tires quickly and are capable of reaching higher PSI levels, making them suitable for various vehicle types.

– Continuous Use: They are ideal for workshops where multiple vehicles may require inflation over time.

Illustrative image related to best automotive air compressor

Contras:

– Power Dependency: These devices require a constant power source, limiting their use in remote locations.

– Size and Portability: Electric pumps can be bulkier than portable inflators, making them less convenient for on-the-go scenarios.

When evaluating the best solution for tire inflation, B2B buyers should consider their specific operational needs. The best automotive air compressor is ideal for heavy-duty applications requiring high PSI and rapid inflation. However, for businesses focused on emergency roadside assistance or those with limited storage space, portable tire inflators may offer a more practical solution. Electric pumps serve well in workshop settings where consistent use is necessary. Ultimately, understanding the unique demands of your operations will guide you in selecting the right tool for effective tire maintenance and vehicle performance.

When evaluating automotive air compressors, several technical properties are essential for ensuring performance, reliability, and suitability for various applications. Understanding these specifications will enable B2B buyers to make informed purchasing decisions.

The maximum pressure rating, measured in pounds per square inch (PSI), indicates the compressor’s capability to inflate tires or other inflatables to a specific pressure. For automotive applications, compressors should typically reach between 100 to 160 PSI. This range ensures compatibility with both standard passenger vehicles and heavy-duty trucks. Higher PSI ratings are crucial for applications requiring robust inflation power, which can significantly affect tire longevity and vehicle safety.

Illustrative image related to best automotive air compressor

The duty cycle defines how long a compressor can operate before it needs to cool down. It is typically expressed as a percentage, indicating the time the compressor can run continuously within a specific time frame. A duty cycle of 50% means the compressor can operate for 5 minutes and then requires 5 minutes of rest. Understanding duty cycles is vital for businesses that require frequent or prolonged use, as it impacts operational efficiency and the compressor’s lifespan.

CFM measures the volume of air the compressor can deliver per minute. This specification is critical for determining how quickly a tire can be inflated or how effectively the compressor can power pneumatic tools. For automotive applications, a CFM rating of at least 1.5 is often recommended for passenger vehicles, while larger vehicles may require higher CFM ratings to ensure timely service.

The power source, whether battery-operated, electric, or gas-powered, significantly influences the compressor’s versatility and ease of use. Battery-operated models offer portability, making them ideal for roadside emergencies, while electric compressors are suitable for garage or workshop environments. Understanding the power source helps buyers assess the best fit for their operational needs and infrastructure.

The weight of an air compressor affects its portability, which is particularly important for businesses requiring mobile solutions. Lightweight models are easier to transport and store, whereas heavier models may offer greater durability but can be cumbersome. Buyers should consider their operational context when evaluating weight, as this can impact ease of use and transportation.

Understanding industry jargon is essential for effective communication and negotiation in B2B transactions. Here are key terms related to automotive air compressors that buyers should be familiar with:

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of automotive air compressors, purchasing from an OEM can guarantee compatibility and reliability, as these products are designed to meet specific vehicle requirements.

MOQ is the smallest quantity of goods that a supplier is willing to sell. Understanding MOQ is crucial for businesses to manage inventory and cash flow effectively. Buyers should negotiate MOQs that align with their operational needs to avoid overstocking or understocking.

Illustrative image related to best automotive air compressor

An RFQ is a document sent to suppliers requesting pricing and other terms for specific products. This process is vital for obtaining competitive pricing and understanding available options. A well-structured RFQ can lead to better supplier relationships and more favorable terms.

Incoterms are standardized terms that define the responsibilities of buyers and sellers in international trade. Understanding these terms is essential for clarifying shipping responsibilities, risk management, and costs associated with transportation. Proper use of Incoterms can prevent misunderstandings and disputes during the purchasing process.

Warranty terms outline the manufacturer’s commitment to repair or replace defective products within a specified period. Service agreements detail the support and maintenance services provided post-purchase. Familiarity with these terms ensures that buyers can secure adequate support and protection for their investments.

By understanding these technical properties and trade terminologies, B2B buyers can navigate the complexities of purchasing automotive air compressors more effectively, leading to better choices and enhanced operational efficiencies.

The automotive air compressor market is experiencing significant growth, driven by several global factors. Increasing vehicle ownership in emerging markets, particularly in Africa, South America, and parts of Europe, is a primary driver. As more consumers and businesses invest in vehicles, the demand for reliable air compressors for maintenance, particularly for tire inflation, is surging. Furthermore, the rise of electric vehicles is reshaping the landscape, as these vehicles often require specialized air compressors for efficient performance.

Illustrative image related to best automotive air compressor

Emerging technologies are also influencing sourcing trends within the automotive air compressor sector. Innovations such as smart tire pressure monitoring systems and integrated inflators that communicate with mobile applications are becoming increasingly popular. This trend is particularly relevant for B2B buyers looking to invest in high-tech solutions that enhance user convenience and safety. Additionally, the advent of cordless and portable air compressors, which cater to the needs of both individual consumers and businesses, is reshaping the competitive landscape.

International buyers are also focusing on quality and reliability. The demand for air compressors that can handle high pressures and offer quick inflation times is paramount, especially in regions where tire maintenance is critical for operational efficiency. As companies seek to optimize their supply chains, partnerships with manufacturers who demonstrate a commitment to quality, innovation, and customer service are becoming essential.

Sustainability is increasingly becoming a focal point for B2B buyers in the automotive air compressor market. The environmental impact of manufacturing processes and product life cycles is under scrutiny, prompting companies to consider eco-friendly alternatives. Buyers are now prioritizing suppliers who utilize sustainable materials and practices in their production processes.

Illustrative image related to best automotive air compressor

Ethical sourcing is also gaining traction. Companies are looking for suppliers who can demonstrate transparency in their supply chains, ensuring that materials are sourced responsibly and that labor practices are ethical. Certifications such as ISO 14001 (Environmental Management) and ISO 45001 (Occupational Health and Safety) are becoming benchmarks for assessing potential suppliers.

Furthermore, the integration of ‘green’ certifications and materials in product offerings is not just a trend but a necessity. Buyers are increasingly aware of the importance of reducing carbon footprints, and those who provide eco-friendly options are more likely to gain a competitive edge. This shift is particularly relevant for international buyers from regions like Europe and the Middle East, where regulatory standards for environmental sustainability are becoming stricter.

The evolution of automotive air compressors reflects broader advancements in automotive technology and consumer expectations. Initially, air compressors were bulky, mechanical devices primarily used in service stations. Over time, innovations in materials and design led to the development of portable and more efficient models, catering to the growing consumer market.

The introduction of cordless and battery-operated air compressors marked a significant turning point, providing greater convenience and usability for everyday consumers. As the industry has evolved, the focus has shifted towards integrating smart technology, allowing for enhanced user experience and connectivity. These advancements have not only improved functionality but have also opened new avenues for B2B partnerships, as companies seek to align with manufacturers who are at the forefront of technology and sustainability.

In summary, the automotive air compressor sector is characterized by dynamic market trends driven by consumer demands for convenience and sustainability. For international B2B buyers, understanding these trends and sourcing from ethical, innovative manufacturers will be crucial in navigating this evolving landscape.

Illustrative image related to best automotive air compressor

1. How do I choose the right automotive air compressor for my business needs?

Selecting the right automotive air compressor involves assessing your specific requirements, such as the types of vehicles you service and the compressor’s power and capacity. Consider factors like maximum pressure (psi), portability, and whether you need a cordless or corded model. Additionally, evaluate the build quality and features like built-in pressure gauges and automatic shut-off for convenience. It’s also wise to read reviews and compare products based on performance and reliability to ensure you choose a compressor that meets your operational demands.

2. What is the best air compressor for inflating tires of large vehicles?

For large vehicles such as trucks and SUVs, the Viair 88P is often recommended due to its fast inflation capabilities and ability to handle higher pressures. It can quickly inflate tires from flat to 35 psi, making it ideal for commercial use. However, it requires connection to the vehicle’s battery, which may be a consideration for ease of use. Ensure that any compressor you select can accommodate the specific tire sizes and pressures you regularly encounter in your operations.

3. How can I verify the quality of an automotive air compressor before purchasing?

To verify the quality of an automotive air compressor, consider sourcing products from reputable manufacturers with established track records. Request product samples to assess performance firsthand. Additionally, check for certifications like ISO standards, which indicate adherence to quality management practices. Online reviews and testimonials from other B2B buyers can provide insights into the product’s reliability and durability. It’s also beneficial to inquire about warranty terms and after-sales support.

4. What customization options should I consider when sourcing air compressors?

Customization options can vary significantly among suppliers. Consider whether you need specific features tailored to your market, such as different voltage configurations, branding on the units, or additional attachments for various inflation needs. Discussing customization possibilities with potential suppliers can help ensure the product aligns with your business’s specific requirements and local regulations, ultimately enhancing your customer offering.

5. What are typical minimum order quantities (MOQ) for automotive air compressors?

Minimum order quantities (MOQ) for automotive air compressors can vary widely based on the manufacturer and your negotiation power. Many suppliers set MOQs to ensure production efficiency, often ranging from 50 to 500 units. It’s advisable to communicate your needs clearly and explore options for smaller initial orders, especially if you are testing a new product in your market. Building a relationship with your supplier may also lead to more favorable terms.

6. What payment terms should I negotiate with suppliers for air compressors?

When negotiating payment terms with suppliers, consider options like upfront payments, net 30 or net 60 terms, and potential discounts for early payments. Establishing clear payment schedules can help manage cash flow effectively. Additionally, inquire about secure payment methods such as letters of credit or escrow services, especially for international transactions, to mitigate risks. Building trust with your supplier can also lead to more flexible terms over time.

7. How do I handle logistics and shipping for automotive air compressors?

Logistics and shipping for automotive air compressors require careful planning to ensure timely delivery and cost efficiency. Evaluate different shipping methods (air, sea, or land) based on urgency and budget. Collaborate with logistics providers familiar with international trade regulations in your region. Ensure that you have clear documentation for customs clearance and consider insurance options to protect against potential damages during transit.

8. What quality assurance measures should I expect from suppliers of automotive air compressors?

Quality assurance measures should include thorough testing protocols to ensure that the compressors meet performance standards and specifications. Suppliers should provide documentation of compliance with industry standards and certifications. Additionally, inquire about their quality control processes, such as inspections at different production stages, and whether they offer warranties or guarantees. Establishing a clear quality assurance framework can help mitigate risks and enhance product reliability for your customers.

Dominio: garagejournal.com

Registrado: 2006 (19 años)

Introducción: Husky 33-Gal. Portable Electric Air Compressor Model # F3S33VWD; Kobalt 1.6-HP 30-Gallon 155 PSI Electric Air Compressor; Craftsman Professional 27 Gallon Vertical Portable Air Compressor Sears Item# 00916474000; Kobalt 30-Gallon 155 PSI Electric Air Compressor – Cast iron, V-twin cylinder, oil-lubricated pump, 1-piece cast iron crankcase, thermally stable cast iron cylinder body, aluminum head, m…

Dominio: automoblog.com

Inscrito: 2004 (21 años)

Introducción: Best Portable Air Compressors: 1. Ryobi ONE+ – Overall Rating: 4.3, Power Source: Lithium battery, Weight: 4 pounds, Pros: Lightweight, compact, battery powered, easy to operate; Cons: Batteries and charger sold separately, slower inflation speed. 2. Kobalt Portable Air Compressor – Overall Rating: 4.2. 3. DeWalt Pancake Air Compressor – Overall Rating: 4.0. 4. Viair 450P-RV Automatic Portable Com…

Dominio: grassrootsmotorsports.com

Matriculado: 1999 (26 años)

Introducción: 1. Viair 88P Portable Air Compressor – Good, fast, sturdy, connects to battery, recommended for inflating truck tires up to 80 psi, priced around $50. 2. Viair 70P Heavy Duty Portable Compressor – Similar features as the 88P, suitable for various inflation tasks. 3. Harbor Freight 12V 100 PSI High Volume Air Compressor – Used for off-road tires, can inflate trailer tires and dually tires to 80 lbs…

The competitive landscape for automotive air compressors is evolving, with advancements in technology and an increasing demand for efficient, reliable products. For international B2B buyers, particularly in regions such as Africa, South America, the Middle East, and Europe, strategic sourcing is essential to ensure that procurement decisions align with operational needs and market trends. The best automotive air compressors, such as the AstroAI Cordless Tire Inflator and the Viair 88P, demonstrate the importance of evaluating product performance, portability, and price, enabling businesses to make informed investments.

As you navigate the sourcing process, consider not only the immediate cost but also the long-term value these compressors bring to your operations. Factors like durability, ease of use, and customer support can significantly impact your bottom line. By partnering with reputable suppliers and leveraging market insights, you can secure products that enhance your service offerings and customer satisfaction.

Looking ahead, the automotive air compressor market is poised for growth. Investing in high-quality inflators will not only meet current demands but also position your business for future opportunities. Take action today to refine your sourcing strategies and capitalize on the innovations shaping the automotive industry.

La información facilitada en esta guía, incluido el contenido relativo a fabricantes, especificaciones técnicas y análisis de mercado, tiene únicamente fines informativos y educativos. No constituye asesoramiento profesional en materia de adquisiciones, asesoramiento financiero ni asesoramiento jurídico.

Illustrative image related to best automotive air compressor

Aunque hemos hecho todo lo posible por garantizar la exactitud y actualidad de la información, no nos hacemos responsables de posibles errores, omisiones o información obsoleta. Las condiciones del mercado, los detalles de las empresas y las normas técnicas están sujetos a cambios.

Los compradores B2B deben llevar a cabo su propia diligencia debida independiente y exhaustiva antes de tomar cualquier decisión de compra. Esto incluye ponerse en contacto directamente con los proveedores, verificar las certificaciones, solicitar muestras y buscar asesoramiento profesional. El riesgo de confiar en la información contenida en esta guía es responsabilidad exclusiva del lector.