In the competitive landscape of global sourcing, finding reliable car air tool compressors can pose significant challenges for B2B buyers. The need for efficient, high-performance compressors is paramount, especially in regions like Africa, South America, the Middle East, and Europe, where diverse applications and environmental conditions demand tailored solutions. This guide serves as a comprehensive resource, empowering international buyers to navigate the complexities of sourcing car air tool compressors.

Within these pages, we will explore various types of compressors—ranging from portable to vehicle-mounted systems—and their specific applications across different industries. Additionally, we will delve into critical factors for supplier vetting, ensuring that you choose partners who meet rigorous quality standards and possess a solid reputation in the market. Cost analysis will also be covered, helping you understand pricing dynamics and enabling you to make budget-conscious decisions without compromising on quality.

By equipping yourself with this knowledge, you will be better positioned to make informed purchasing decisions that align with your operational needs and strategic goals. Whether you are a seasoned buyer or new to the market, this guide will provide the insights necessary to enhance your sourcing strategy, ensuring you secure the best compressors for your business needs.

| Tipo Nombre | Principales rasgos distintivos | Aplicaciones B2B principales | Breves pros y contras para los compradores |

|---|---|---|---|

| Portable Air Compressors | Lightweight, compact design, often 12V powered | Automotive repair, mobile workshops | Pros: Easy transport; versatile use. Contras: Limited power for heavy-duty tasks. |

| Onboard Air Compressors | Installed within the vehicle, designed for continuous use | Off-road vehicles, fleet maintenance | Pros: Always available; ideal for remote locations. Contras: Higher installation cost. |

| Brushless Air Compressors | Enhanced efficiency, reduced noise, longer lifespan | Heavy machinery, automotive assembly | Pros: Better performance; less maintenance. Contras: Mayor inversión inicial. |

| Two-Stage Air Compressors | Higher pressure output, suitable for demanding tasks | Industrial applications, tire shops | Pros: Greater efficiency; faster inflation. Contras: Bulkier and more expensive. |

| Tankless Air Compressors | Compact, continuous duty without a storage tank | Light-duty applications, home garages | Pros: Space-saving; lightweight. Contras: Limited air storage; may require frequent cycling. |

Portable air compressors are designed for mobility and convenience, making them ideal for automotive repair and mobile workshops. Typically powered by 12V, these compressors can easily be transported to various job sites. Buyers should consider their air delivery rates and tank sizes, as these factors will influence efficiency and inflation times. While portable compressors are versatile and easy to use, they may not deliver the power needed for more demanding applications.

Onboard air compressors are permanently installed in vehicles, providing a reliable air source for off-road vehicles and fleet maintenance operations. They are designed for continuous use and can power tools, inflate tires, and perform various tasks without needing to transport separate equipment. When purchasing, buyers should evaluate the compressor’s pressure output and compatibility with their vehicle. Although they offer convenience, the initial installation cost can be significant.

Brushless air compressors are known for their efficiency and longevity, making them suitable for heavy machinery and automotive assembly lines. These compressors operate quietly and require less maintenance due to fewer moving parts. When considering a purchase, businesses should look at the compressor’s output capacity and energy consumption. While the upfront cost is higher, the long-term savings in maintenance and energy use can justify the investment.

Two-stage air compressors provide higher pressure output, making them ideal for demanding tasks like industrial applications and tire shops. They work by compressing air twice, resulting in faster inflation and improved efficiency. Buyers should assess the compressor’s CFM (cubic feet per minute) rating and tank size to ensure it meets their operational needs. However, these compressors tend to be bulkier and more expensive, which may not suit all businesses.

Tankless air compressors operate continuously without a storage tank, making them compact and lightweight for light-duty applications, such as home garages. They are ideal for tasks that require quick bursts of air rather than sustained pressure. Buyers should consider the compressor’s duty cycle and air delivery rates, as these will dictate its effectiveness for their needs. While they save space, their limited air storage can lead to more frequent cycling, which may not suit every application.

| Industria/Sector | Specific Application of car air tool compressor | Valor/beneficio para la empresa | Consideraciones clave para el aprovisionamiento de esta aplicación |

|---|---|---|---|

| Reparación de automóviles | Tire Inflation and Maintenance | Enhances service efficiency and customer satisfaction | Reliability, portability, and compatibility with tools |

| Construcción | Alimentación de herramientas neumáticas | Increases productivity on job sites | Durability, pressure output, and ease of transport |

| Fabricación | Assembly Line Operations | Streamlines production processes | Consistent air supply, energy efficiency, and maintenance support |

| Transportation & Logistics | Fleet Maintenance and Repair | Reduces downtime and operational costs | Capacity, mobility, and spare parts availability |

| Off-Road and Adventure | On-the-Go Tire and Gear Inflation | Ensures readiness for challenging terrains | Compact design, ease of use, and performance reliability |

In the automotive repair sector, car air tool compressors are essential for tire inflation and maintenance. They allow technicians to quickly and accurately inflate tires to the recommended pressure, enhancing safety and performance. This efficiency not only improves customer satisfaction but also reduces the time vehicles spend in the shop. International buyers, especially from regions with diverse climates, should prioritize reliability and compatibility with various tire types to ensure optimal performance.

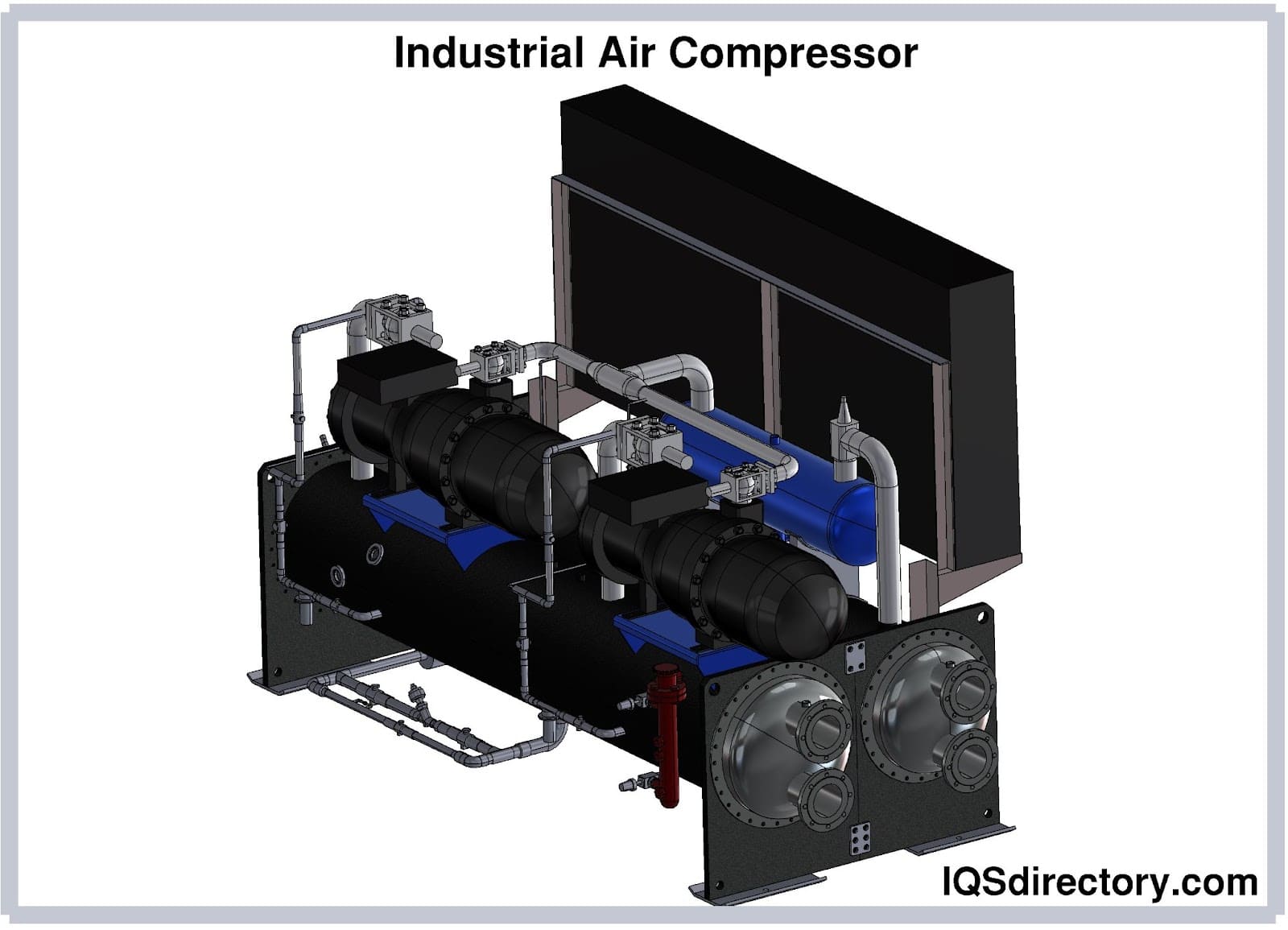

Illustrative image related to car air tool compressor

Construction sites often require the use of pneumatic tools for tasks such as nailing, drilling, and cutting. Car air tool compressors provide a reliable power source for these tools, significantly increasing productivity. For businesses in regions like Africa and South America, where job sites may be remote, sourcing compressors that are durable and portable is crucial. Additionally, compressors with higher pressure outputs can handle a wider range of tools, making them a versatile choice for contractors.

In manufacturing, car air tool compressors are used in assembly line operations to power various pneumatic devices. They ensure a consistent air supply, which is vital for maintaining efficiency and quality in production. For international buyers, energy efficiency and ease of maintenance are critical factors to consider. Compressors that require less downtime for service can significantly reduce operational costs, making them an attractive investment for manufacturers.

In the transportation and logistics sector, car air tool compressors are invaluable for fleet maintenance and repair. They help in quickly inflating tires and performing air-powered repairs, which minimizes vehicle downtime and reduces operational costs. Businesses in Europe and the Middle East should look for compressors with high capacity and mobility features to ensure they can service their fleets effectively, especially in regions with varying road conditions.

For off-road enthusiasts, a car air tool compressor is essential for on-the-go tire inflation and gear maintenance. These compressors provide the flexibility to adjust tire pressure for different terrains, enhancing traction and performance. Buyers from adventure tourism sectors should focus on compact and robust models that can withstand rugged conditions. Additionally, ease of use and reliable performance are critical for ensuring that adventurers are always prepared for unexpected challenges.

El problema:

B2B buyers often face the challenge of sourcing air compressors that can handle a variety of tasks, from inflating tires to powering pneumatic tools. Many suppliers offer generic models that may not meet specific operational requirements or endure rigorous working conditions, particularly in regions with extreme temperatures or rugged terrains. Inadequate performance can lead to inefficiencies, increased downtime, and ultimately, higher operational costs. This is especially critical for businesses in sectors such as automotive repair, construction, and off-road services, where reliability and versatility are paramount.

Illustrative image related to car air tool compressor

La solución:

To overcome this sourcing dilemma, buyers should prioritize suppliers that specialize in high-performance air compressors designed for specific applications. Conduct thorough research into manufacturers with a strong reputation for durability and performance under varying conditions. Look for features such as robust construction, adjustable pressure settings, and compatibility with various pneumatic tools. Additionally, consider portable and vehicle-mounted options that can adapt to different job sites. Engaging in a dialogue with suppliers about your specific needs and asking for case studies or references can also help ensure you make an informed purchase that aligns with your operational requirements.

El problema:

Another common pain point for B2B buyers is the lack of proper maintenance protocols for air compressors. Many organizations fail to implement regular maintenance checks, leading to premature wear and tear, inefficiencies, and unexpected breakdowns. This not only disrupts workflow but also incurs additional costs for repairs and replacements. In regions where access to spare parts may be limited, this issue can become even more pronounced, resulting in prolonged downtimes that impact overall productivity.

La solución:

To mitigate maintenance-related issues, companies should develop a comprehensive maintenance plan that includes regular inspections and servicing of air compressors. This plan should encompass checking air hoses for wear, ensuring filters are clean, and verifying that pressure gauges function correctly. Buyers can also benefit from investing in compressors that are designed for easy maintenance, with readily available spare parts. Furthermore, establishing a relationship with local service providers or manufacturers can facilitate prompt repairs and parts replacement, minimizing downtime and ensuring that the equipment remains in optimal condition.

El problema:

Many B2B buyers struggle with understanding the specifications and capabilities of different air compressor models. This lack of knowledge can lead to purchasing equipment that does not meet the demands of their operations, resulting in underperformance or over-specification, which can waste resources. For instance, a company might invest in a high-capacity compressor that is unnecessary for their tasks, leading to inflated costs without a corresponding return on investment.

La solución:

To navigate the complexities of compressor specifications, buyers should invest time in understanding the key metrics that define compressor performance, such as PSI (pounds per square inch), CFM (cubic feet per minute), and tank capacity. Engaging with technical support teams from manufacturers can provide insights into the best options for specific applications. Buyers should also consider their operational needs, such as frequency of use and types of tools powered, before making a decision. Participating in training sessions or webinars offered by manufacturers can enhance understanding and help buyers make informed choices that align with their business objectives.

When selecting materials for car air tool compressors, several factors must be considered to ensure optimal performance, durability, and compliance with international standards. Below is an analysis of four common materials used in the manufacturing of car air tool compressors.

Aluminum is a popular choice for car air tool compressors due to its lightweight and excellent corrosion resistance. It typically has a temperature rating of up to 150°C (302°F) and can withstand moderate pressures, making it suitable for various applications. Its natural resistance to oxidation enhances its longevity, particularly in humid environments.

Pros: Aluminum’s lightweight nature contributes to easier portability, which is essential for mobile applications. It is also relatively inexpensive compared to other metals, making it a cost-effective option for manufacturers.

Contras: While aluminum is durable, it is not as strong as steel and may deform under extreme pressure. Additionally, its manufacturing process can be complex, requiring specialized techniques such as extrusion or die-casting.

Impacto en la aplicación: Aluminum is compatible with a wide range of media, including air and non-corrosive gases. However, it may not be suitable for applications involving aggressive chemicals or high-temperature fluids.

Consideraciones internacionales: Buyers from regions like Europe and the Middle East should ensure that the aluminum used meets standards such as DIN EN 573 for alloy specifications. Compliance with local regulations regarding material safety is also crucial.

Steel is another common material, known for its strength and durability. It can withstand high pressures (up to 300 psi) and has a temperature rating that can exceed 200°C (392°F) depending on the alloy used. Steel’s inherent toughness makes it ideal for heavy-duty applications.

Pros: The primary advantage of steel is its strength, which allows for the construction of robust compressors capable of handling high-pressure applications. It is also widely available and can be manufactured using various methods, including welding and machining.

Contras: Steel is heavier than aluminum, which can be a disadvantage for portable compressors. Additionally, it is prone to corrosion if not properly treated, requiring protective coatings or galvanization.

Impacto en la aplicación: Steel is suitable for applications involving air, water, and certain oils but may corrode when exposed to saltwater or acidic environments.

Consideraciones internacionales: Buyers should look for compliance with ASTM A36 or equivalent standards for structural steel. In regions like Africa and South America, understanding local corrosion resistance requirements is vital.

Illustrative image related to car air tool compressor

Composite materials, often a blend of plastic and fiberglass, are increasingly used in compressor housings. They offer excellent corrosion resistance and can operate effectively at temperatures up to 100°C (212°F) with moderate pressure ratings.

Pros: Composites are lightweight and provide excellent thermal insulation. They are also resistant to corrosion, making them suitable for humid or chemically aggressive environments.

Contras: The primary drawback is that composites may not withstand high pressures as effectively as metals. Their manufacturing process can also be more expensive, impacting overall cost.

Impacto en la aplicación: Composites are ideal for applications where weight is a concern, such as portable compressors. However, they may not be suitable for high-pressure applications or where mechanical strength is paramount.

Consideraciones internacionales: Compliance with ISO 1043 for plastics is essential for international buyers. Additionally, understanding local preferences for material sustainability can influence purchasing decisions.

Illustrative image related to car air tool compressor

Cast iron is known for its exceptional durability and ability to absorb vibrations, making it a preferred choice for stationary compressors. It can handle high pressures and has a temperature rating of around 200°C (392°F).

Pros: The durability of cast iron ensures a long service life, making it suitable for heavy-duty applications. Its ability to dampen vibrations enhances operational stability.

Contras: Cast iron is heavy and can be prone to rust if not properly maintained. Its brittleness can also lead to cracking under extreme conditions.

Impacto en la aplicación: Cast iron is well-suited for stationary applications where weight is not a concern. It is compatible with air and oil but may not be ideal for corrosive environments.

Consideraciones internacionales: Buyers should ensure compliance with ASTM A48 for cast iron specifications. Understanding local maintenance practices is crucial for ensuring longevity in regions with harsh climates.

| Material | Typical Use Case for car air tool compressor | Ventajas clave | Principales desventajas/limitaciones | Coste relativo (Bajo/Medio/Alto) |

|---|---|---|---|---|

| Aluminio | Portable compressors | Ligero y resistente a la corrosión | Less strong than steel | Medio |

| Acero | Heavy-duty compressors | Alta resistencia y durabilidad | Prone to corrosion | Medio |

| Compuesto | Lightweight, portable compressors | Excellent corrosion resistance | Capacidad limitada de alta presión | Alta |

| Cast Iron | Stationary compressors | Durabilidad excepcional | Heavy and brittle | Medio |

This strategic material selection guide provides essential insights for international B2B buyers, ensuring they make informed decisions aligned with performance requirements and regional compliance standards.

The manufacturing process for car air tool compressors is crucial for ensuring product reliability and efficiency, particularly for B2B buyers who depend on these tools for various applications. Understanding the stages of manufacturing and the quality assurance processes can help international buyers make informed decisions when sourcing these products.

Illustrative image related to car air tool compressor

The manufacturing process begins with material preparation, which involves sourcing high-quality metals and plastics that will be used in the compressor components. Common materials include aluminum for lightweight applications, steel for durability, and various polymers for insulation and seals. Suppliers often conduct thorough inspections of raw materials to ensure they meet industry standards.

Once materials are prepared, forming techniques are employed to shape the components. Common methods include:

These forming techniques are selected based on the specific requirements of the compressor design, balancing cost-effectiveness with performance characteristics.

Illustrative image related to car air tool compressor

The assembly stage involves the integration of all individual components into a final product. This may include:

Quality control checkpoints are integrated throughout the assembly process to catch any defects early.

Finishing processes enhance the durability and aesthetics of car air tool compressors. Common finishing techniques include:

Illustrative image related to car air tool compressor

Quality assurance is a critical aspect of the manufacturing process. B2B buyers should be aware of the relevant international standards that ensure product quality and safety. Key standards include:

Quality control (QC) checkpoints are vital in the manufacturing process to ensure that every compressor meets the required standards. Common QC checkpoints include:

B2B buyers should take proactive measures to verify the quality control processes of potential suppliers. Consider the following methods:

Illustrative image related to car air tool compressor

International buyers, particularly those from regions such as Africa, South America, the Middle East, and Europe, should be aware of certain nuances in quality control:

An in-depth understanding of the manufacturing processes and quality assurance practices for car air tool compressors is essential for B2B buyers. By recognizing the stages of production, the importance of quality standards, and methods for verifying supplier quality, buyers can make informed decisions that ensure they invest in reliable and efficient tools. This knowledge not only enhances operational efficiency but also contributes to long-term partnerships with suppliers across different regions.

This guide is designed to assist B2B buyers in the effective procurement of car air tool compressors. Sourcing the right equipment is crucial for operational efficiency, safety, and long-term value. By following these steps, buyers can make informed decisions that align with their specific needs and business objectives.

Understanding the technical requirements of your application is the first step in sourcing the right compressor. Consider factors such as pressure output, tank size, and power source (e.g., 12V or 24V systems) based on your operational needs.

– Pressure Requirements: Assess the PSI (pounds per square inch) needed for the tools you intend to operate.

– Tank Size: A larger tank allows for longer use without frequent cycling, which can enhance efficiency.

Stay updated on the latest trends and technologies in the air compressor market. Innovations such as brushless motors and advanced cooling systems can significantly impact performance and energy efficiency.

– Performance Enhancements: Look for features that improve airflow and reduce energy consumption.

– User-Friendly Designs: Compact and portable models can enhance mobility and usability, especially in diverse environments.

Before finalizing a supplier, it is essential to conduct thorough evaluations. This includes reviewing company backgrounds, product offerings, and customer feedback.

– Request Documentation: Ask for certifications, product specifications, and warranty information to ensure quality and compliance.

– Seek References: Connect with other businesses in your industry to gather insights on supplier reliability and service quality.

Ensure that the suppliers you are considering meet international quality standards and regulations. This is particularly important for compliance in different regions, such as Europe or South America.

– ISO Certifications: Look for ISO 9001 or other relevant certifications that indicate a commitment to quality management.

– Local Regulations: Understand specific compliance requirements in your region to avoid potential legal issues.

Once you have shortlisted potential suppliers, request detailed quotations that include all associated costs, such as shipping and installation. Comparing these quotes can help you identify the best value for your investment.

– Breakdown of Costs: Ensure that the quote includes all components, such as accessories and warranties.

– Total Cost of Ownership: Consider not just the upfront cost but also maintenance, energy consumption, and lifespan.

Illustrative image related to car air tool compressor

Reliable after-sales support is crucial for minimizing downtime. Evaluate the support services offered by suppliers, including maintenance packages and the availability of spare parts.

– Service Agreements: Inquire about maintenance contracts that can extend the lifespan of your compressor.

– Spare Parts Availability: Ensure that essential components are readily available in your region to facilitate repairs.

After selecting a supplier, finalize the purchase by establishing clear payment terms and delivery timelines. Ensure that all agreements are documented to avoid misunderstandings later.

– Payment Options: Discuss flexible payment methods that suit your cash flow.

– Plazos de entrega: Confirm expected delivery dates and logistics to ensure timely receipt of the equipment.

By following this checklist, B2B buyers can navigate the complexities of sourcing car air tool compressors effectively, ensuring they secure the best products for their operational needs.

Illustrative image related to car air tool compressor

When sourcing car air tool compressors, understanding the cost structure is essential for B2B buyers. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margin.

Materiales: The cost of raw materials such as metals, plastics, and electronic components can significantly impact the overall price. High-quality materials often result in better durability and performance, which can justify a higher price point.

Trabajo: Labor costs vary depending on the region of manufacturing. Skilled labor may be necessary for assembly and quality checks, influencing the overall cost structure. Countries with lower labor costs can offer competitive pricing but may compromise on quality.

Gastos generales de fabricación: This includes utilities, rent, and administrative expenses associated with production. Efficient manufacturing processes can help reduce overhead, contributing to a more favorable pricing strategy.

Herramientas: Initial tooling costs for molds and machinery can be substantial. These costs are typically amortized over the production volume, meaning larger orders may reduce the per-unit cost.

Control de calidad: Rigorous QC processes ensure that compressors meet industry standards. Investing in QC can increase initial costs but enhances product reliability and customer satisfaction, leading to long-term savings.

Logística: Transportation costs, including shipping and handling, play a crucial role in the total cost. International buyers should consider the impact of shipping distances and methods on overall pricing.

Margen: Suppliers will factor in their desired profit margin, which can vary based on market conditions and competition.

Several factors can influence the pricing of car air tool compressors, making it crucial for buyers to be aware of these elements:

Volumen y cantidad mínima de pedido (MOQ): Larger orders can lead to volume discounts, making it essential for buyers to negotiate MOQs that align with their needs. Suppliers often offer better pricing for bulk purchases.

Especificaciones y personalización: Customized compressors that meet specific requirements may incur additional costs. Buyers should clearly communicate their needs to avoid unexpected expenses.

Materiales y certificaciones de calidad: Compressors made from premium materials or those that comply with international quality standards (such as ISO) typically come at a higher price. Buyers should weigh the benefits of certifications against the costs.

Factores del proveedor: The reputation and reliability of the supplier can impact pricing. Established suppliers with a track record of quality may charge more, but the assurance of reliability can offset potential risks.

Incoterms: Understanding Incoterms is vital for international transactions. These terms define who is responsible for shipping, insurance, and tariffs, which can affect the final cost significantly.

For B2B buyers, especially those from diverse regions such as Africa, South America, the Middle East, and Europe, effective negotiation can yield significant savings:

Realizar estudios de mercado: Understanding market trends and competitor pricing can empower buyers during negotiations. Researching similar products can provide leverage.

Evaluar el coste total de propiedad (TCO): Rather than focusing solely on the purchase price, consider the TCO, which includes maintenance, operational costs, and potential downtime. This broader perspective can justify higher upfront costs for more reliable products.

Establecer relaciones con los proveedores: Establishing strong relationships can lead to better terms and pricing. Suppliers may offer discounts to loyal customers or those who place regular orders.

Be Open to Alternative Solutions: Consider alternative models or specifications that may offer similar performance at a lower cost. Flexibility can lead to cost savings.

Understand Regional Pricing Nuances: Be aware of regional differences in pricing and logistics. For example, tariffs or import duties can significantly affect costs for international buyers, particularly in regions with fluctuating trade agreements.

When sourcing car air tool compressors, a comprehensive understanding of cost components, pricing influencers, and negotiation strategies is essential for maximizing value. B2B buyers should approach sourcing with a strategic mindset, focusing not only on upfront costs but also on long-term value and reliability. By considering these factors, buyers can make informed decisions that align with their business goals.

Illustrative image related to car air tool compressor

In the automotive and industrial sectors, the demand for reliable air supply systems is paramount. While car air tool compressors are popular for their versatility and performance, several alternative solutions can also fulfill similar requirements. Understanding these alternatives allows B2B buyers to make informed decisions tailored to their specific operational needs, particularly in diverse markets such as Africa, South America, the Middle East, and Europe.

| Aspecto comparativo | Car Air Tool Compressor | Portable Air Tank | Electric Tire Inflator |

|---|---|---|---|

| Rendimiento | High airflow; suitable for tools | Moderate; limited by tank size | Low; primarily for tires only |

| Coste | $250 – $1,500 | $150 – $600 | $30 – $150 |

| Facilidad de aplicación | Requires setup; may need mounting | Easy to transport; minimal setup | Plug-and-play; very user-friendly |

| Mantenimiento | Moderado; requiere controles periódicos | Low; minimal wear and tear | Low; generally no maintenance |

| El mejor caso de uso | Professional automotive workshops | Mobile tire shops; off-roaders | Personal vehicles; light use |

Portable air tanks are pressurized containers that store compressed air for various applications. They are especially useful in scenarios where immediate air supply is needed but without the necessity of continuous operation. The primary advantage of portable air tanks is their ease of use and transportability. However, they have a limited air capacity, which may restrict prolonged use of air tools. For businesses that require mobility and quick air access, portable air tanks can be a cost-effective alternative, particularly for tire inflation and minor pneumatic tasks.

Electric tire inflators are compact devices designed primarily for inflating vehicle tires. They are lightweight, easy to use, and often come with built-in pressure gauges. Their simplicity makes them an attractive option for personal and light commercial use. However, the performance of electric tire inflators is generally limited compared to traditional compressors, as they usually do not support heavy-duty air tools. For B2B buyers focusing on basic tire maintenance and light-duty inflation tasks, electric tire inflators provide an economical and straightforward solution.

When selecting between a car air tool compressor and its alternatives, B2B buyers should consider several factors, including performance requirements, budget constraints, and specific use cases. For businesses engaged in heavy-duty automotive work, investing in a high-quality air tool compressor is likely the best choice due to its superior airflow and versatility. Conversely, for companies focused on mobility and lighter tasks, portable air tanks or electric tire inflators may offer sufficient performance at a lower cost. Ultimately, understanding the operational demands and the environment in which these tools will be used is crucial for making the best purchasing decision.

Illustrative image related to car air tool compressor

Understanding the critical specifications of car air tool compressors is essential for B2B buyers to ensure they select the right equipment for their operational needs. Here are several key technical properties to consider:

Presión nominal (PSI)

– Definition: The pressure rating, measured in pounds per square inch (PSI), indicates the maximum pressure the compressor can deliver.

– B2B Importance: A higher PSI rating allows for more demanding applications, such as powering air tools or inflating large tires. Buyers must assess the required PSI for their specific applications to avoid underperformance.

Airflow Rate (CFM)

– Definition: Airflow rate, measured in cubic feet per minute (CFM), represents the volume of air the compressor can deliver at a given pressure.

– B2B Importance: Sufficient CFM is crucial for operating air tools effectively. Buyers should match the CFM rating of the compressor with the tools’ requirements to ensure optimal efficiency and performance.

Tank Size (Gallons)

– Definition: Tank size refers to the volume of the air storage tank, measured in gallons.

– B2B Importance: A larger tank size allows for longer periods of operation without needing to refill. This is particularly beneficial in industrial settings where continuous air supply is necessary, reducing downtime.

Fuente de energía

– Definition: Compressors can be powered by electricity (AC or DC), gasoline, or diesel.

– B2B Importance: The choice of power source impacts portability and operational costs. Electric compressors are typically quieter and more suitable for indoor use, while gas-powered compressors offer mobility for outdoor applications.

Weight and Portability

– Definition: This refers to the overall weight of the compressor and its design for mobility.

– B2B Importance: For businesses that require on-the-go solutions, such as automotive repair shops or construction sites, lightweight and portable models are crucial. Buyers must evaluate their operational environments to choose the right balance between portability and functionality.

Durability and Material Grade

– Definition: The material grade of the compressor components, often made from metals like aluminum or steel, affects the overall durability.

– B2B Importance: High-quality materials ensure longevity and reliability, which are vital for reducing maintenance costs and maximizing return on investment.

Navigating the procurement process involves familiarizing oneself with industry jargon. Here are some common terms relevant to car air tool compressors:

OEM (fabricante de equipos originales)

– Definition: An OEM produces parts or equipment that may be marketed by another manufacturer.

– Importance: Understanding OEM relationships can help buyers identify reputable suppliers and ensure compatibility with existing systems.

MOQ (Cantidad mínima de pedido)

– Definition: MOQ refers to the smallest quantity of a product that a supplier is willing to sell.

– Importance: Knowing the MOQ helps businesses manage inventory and budget effectively, especially for large-scale purchases.

RFQ (solicitud de presupuesto)

– Definition: An RFQ is a document issued by a buyer to solicit price quotes from suppliers for specific products or services.

– Importance: Issuing RFQs enables buyers to compare prices and terms, ensuring they make informed purchasing decisions.

Incoterms (Términos comerciales internacionales)

– Definition: Incoterms are a set of predefined commercial terms published by the International Chamber of Commerce (ICC) that clarify the responsibilities of buyers and sellers in international transactions.

– Importance: Familiarity with Incoterms ensures that all parties understand their obligations regarding shipping, insurance, and tariffs, thus preventing disputes.

Periodo de garantía

– Definition: The warranty period is the duration during which the manufacturer guarantees the product’s performance and quality.

– Importance: Understanding warranty terms helps buyers assess the risk of investment and the potential costs of repairs or replacements.

Service Life

– Definition: This term refers to the expected operational lifespan of the compressor under normal usage conditions.

– Importance: Knowing the service life assists buyers in planning for future purchases and budgeting for maintenance or replacements, ensuring long-term operational efficiency.

By grasping these technical properties and trade terms, B2B buyers can make well-informed decisions when investing in car air tool compressors, enhancing their operational capabilities and cost-effectiveness.

The global car air tool compressor market is experiencing robust growth driven by increasing demand for automotive maintenance and repair services. In regions such as Africa, South America, the Middle East, and Europe, particularly Germany and Brazil, the rise in vehicle ownership and the expansion of the automotive aftermarket are significant contributors to this demand. The automotive sector’s shift towards electric vehicles (EVs) is also influencing sourcing trends, as manufacturers seek compressors that are compatible with EV maintenance requirements.

Emerging B2B technologies, such as IoT-enabled compressors, are reshaping how businesses manage and maintain their equipment. These smart compressors provide real-time monitoring and diagnostics, enhancing operational efficiency and reducing downtime. Furthermore, the trend towards portable and compact designs is gaining traction, as businesses increasingly prioritize space-saving solutions that do not compromise on performance.

Additionally, the competitive landscape is evolving, with an increasing number of manufacturers focusing on innovative features like brushless motors for improved energy efficiency and performance. Buyers are advised to stay informed about these advancements, as they can significantly impact procurement decisions and operational costs.

Sustainability is becoming a cornerstone of strategic sourcing in the car air tool compressor sector. As environmental regulations tighten globally, B2B buyers are increasingly prioritizing suppliers who demonstrate a commitment to reducing their environmental footprint. This includes adopting eco-friendly manufacturing processes and utilizing sustainable materials in their products.

The importance of ethical supply chains cannot be overstated. Companies that adhere to ethical sourcing practices not only enhance their brand reputation but also mitigate risks associated with labor violations and environmental degradation. Buyers should look for manufacturers with recognized ‘green’ certifications, such as ISO 14001, which indicate compliance with international environmental management standards.

Illustrative image related to car air tool compressor

Moreover, the growing popularity of products made from recyclable or biodegradable materials is reshaping consumer preferences. B2B buyers are encouraged to engage with suppliers who are transparent about their sourcing practices and offer products that align with sustainability goals. This shift not only meets regulatory demands but also appeals to increasingly eco-conscious end-users.

The evolution of car air tool compressors has been marked by significant technological advancements and changing market needs. Initially, these compressors were primarily mechanical devices, limited in functionality and application. Over the decades, innovations such as the introduction of electric and portable compressors have broadened their usability across various sectors, including automotive repair, construction, and DIY projects.

With the advent of digital technology in recent years, manufacturers have incorporated smart features that enhance user experience and operational efficiency. This transformation reflects a broader trend within the automotive industry towards automation and smart technologies, emphasizing the importance of adaptability in a rapidly changing market landscape.

For international B2B buyers, understanding this historical context is crucial for making informed purchasing decisions, as it highlights the trajectory of product development and the potential for future innovations in the sector.

How do I choose the right car air tool compressor for my business?

Choosing the right car air tool compressor involves assessing your specific needs, such as the types of tools you will be using and the required air pressure. Consider factors like portability, power source (electric or gas), tank size, and PSI ratings. For B2B buyers, it’s also crucial to evaluate the compressor’s durability and maintenance requirements, especially if used in demanding environments. Review supplier specifications and seek recommendations based on industry standards to ensure optimal performance for your business operations.

What are the common specifications to look for in car air tool compressors?

When sourcing car air tool compressors, focus on specifications such as CFM (Cubic Feet per Minute), PSI (Pounds per Square Inch), tank size, and duty cycle. Higher CFM ratings indicate faster airflow, while adequate PSI ensures tools function efficiently. Also, consider the compressor’s noise level, portability, and energy consumption. Understanding these specifications helps ensure the compressor meets your operational needs and aligns with the tools you plan to use.

What are the minimum order quantities (MOQs) for car air tool compressors?

Minimum order quantities for car air tool compressors can vary significantly based on the supplier and the type of compressor. Typically, MOQs may range from a few units to several dozen, depending on the manufacturer’s production capabilities and your negotiation terms. For B2B buyers, it’s advisable to discuss MOQs upfront and explore options for smaller initial orders to test the product’s suitability before committing to larger purchases.

What payment terms should I expect when sourcing compressors internationally?

Payment terms for international purchases of car air tool compressors often include options like advance payment, letters of credit, or payment upon delivery. Common terms may range from 30% deposit and 70% upon shipment to net 30 or net 60 days after delivery. It’s essential to clarify payment terms with suppliers to ensure mutual understanding and mitigate risks. Additionally, consider the currency exchange rate and associated fees when budgeting for your order.

How do I vet suppliers for car air tool compressors?

Vetting suppliers is crucial for ensuring quality and reliability. Start by checking the supplier’s reputation through reviews and testimonials from other B2B buyers. Verify their industry certifications and compliance with international standards. Request samples to evaluate product quality and assess their capacity to meet your volume needs. Building a relationship with suppliers through communication can also help gauge their responsiveness and customer service capabilities.

What is the typical lead time for shipping car air tool compressors?

Lead times for shipping car air tool compressors can vary based on the supplier’s location, production schedule, and shipping method. Generally, expect lead times ranging from 4 to 12 weeks for international shipments. Factors such as customs clearance and local regulations in your country can also impact delivery times. It’s advisable to discuss lead times upfront with your supplier and factor them into your project timelines.

What quality assurance processes should I expect from suppliers?

Reputable suppliers of car air tool compressors typically implement rigorous quality assurance processes. These may include testing for performance, safety, and compliance with international standards. Ask about the supplier’s quality control measures, such as pre-shipment inspections and certifications. Understanding their QA protocols helps ensure that the compressors you receive meet your operational standards and reduce the likelihood of defects or malfunctions.

Are there customization options available for car air tool compressors?

Many suppliers offer customization options for car air tool compressors, allowing you to tailor specifications such as size, power source, and additional features to meet your specific business needs. Customization may also include branding and packaging options. Discuss your requirements with the supplier to explore available options and any associated costs or minimum order requirements for customized products. This flexibility can enhance your brand offering and better serve your clientele.

Dominio: store.arbusa.com

Inscrito: 1998 (27 años)

Introducción: Portable & Vehicle Mounted Air Compressor Systems | ARB 4×4 USA. ARB Air Compressors are known for their reliability and high performance, suitable for powering tires, tools, and Air Lockers. New Brushless Compressors offer 50% more output, smart cooling, and quick-release mounts for unmatched airflow in a compact design. Product categories include Mounted Compressors, Portable Compressors, and Br…

Dominio: reddit.com

Matriculado: 2005 (20 años)

Introducción: A good size air compressor for a mechanic should be capable of being used all day, every day for any car, while also being small enough to transport in the bed of a truck.

Dominio: lowes.com

Matriculado: 1995 (30 años)

Introducción: Air Tools & Compressors at Lowe’s include a variety of options such as Portable Air Compressors, Stationary & Industrial Air Compressors, Electric Air Compressors, Gas Air Compressors, and Quiet Air Compressors. Portable models are suitable for various locations and come in styles like pancake, hot dog, twin stack, and wheelbarrow. They are ideal for DIY projects and tasks like tire inflation. Sta…

Dominio: obsessedgarage.com

Inscrito: 2015 (10 años)

Introducción: Collection of automotive air tools including digital tire inflators, pressure gauges, and tread depth gauges. Featured brand PCL offers the ACCURA 1 digital tire inflator with 0.2 psi accuracy and a 13 CFM fill rate. Other products include pneumatic polishers from Rupes and air compressor blowguns from Prevost. Availability includes 15 in-stock items and 1 out-of-stock item. Price range up to $1,3…

In today’s competitive landscape, strategic sourcing of car air tool compressors is essential for international B2B buyers seeking reliability and performance. Emphasizing the importance of quality and durability, it is crucial to choose compressors that can withstand diverse operational conditions, particularly in regions like Africa, South America, the Middle East, and Europe. Investing in high-performance models, such as brushless and portable compressors, not only enhances efficiency but also reduces long-term operational costs.

Illustrative image related to car air tool compressor

Moreover, understanding the nuances of local market demands and supply chain logistics can significantly impact purchasing decisions. Buyers should prioritize suppliers that offer robust customer support, including maintenance resources and spare parts availability, ensuring longevity and optimal performance of their compressors.

As the market for car air tool compressors continues to evolve, leveraging data-driven insights and fostering relationships with reputable manufacturers will be key to staying ahead. By embracing strategic sourcing practices, you can secure superior products that meet your specific needs while contributing to your business’s growth trajectory.

Now is the time to refine your sourcing strategy and explore innovative solutions that can propel your operations forward. Engage with trusted suppliers to explore the best options for your business and gain a competitive edge in your market.

La información facilitada en esta guía, incluido el contenido relativo a fabricantes, especificaciones técnicas y análisis de mercado, tiene únicamente fines informativos y educativos. No constituye asesoramiento profesional en materia de adquisiciones, asesoramiento financiero ni asesoramiento jurídico.

Aunque hemos hecho todo lo posible por garantizar la exactitud y actualidad de la información, no nos hacemos responsables de posibles errores, omisiones o información obsoleta. Las condiciones del mercado, los detalles de las empresas y las normas técnicas están sujetos a cambios.

Los compradores B2B deben llevar a cabo su propia diligencia debida independiente y exhaustiva antes de tomar cualquier decisión de compra. Esto incluye ponerse en contacto directamente con los proveedores, verificar las certificaciones, solicitar muestras y buscar asesoramiento profesional. El riesgo de confiar en la información contenida en esta guía es responsabilidad exclusiva del lector.