As the global market for motorcycle hard cases continues to expand, international B2B buyers face the critical challenge of sourcing high-quality, durable solutions that meet diverse operational needs. Whether catering to the adventurous rider in Africa or the urban commuter in Germany, the right motorcycle hard cases can enhance safety, convenience, and overall riding experience. This comprehensive guide addresses the complexities of selecting motorcycle hard cases, exploring various types, applications, and innovative designs tailored for different markets.

In this guide, you will find detailed insights on the latest trends in motorcycle luggage systems, including side cases and top cases, as well as essential considerations for supplier vetting to ensure reliability and quality. Cost analysis and value comparisons will empower you to make informed purchasing decisions that align with your business objectives.

By navigating the intricacies of the motorcycle hard case market, this guide equips B2B buyers from regions such as South America, the Middle East, and Europe with the knowledge to select the most suitable products for their target demographics. Whether you are looking to enhance your product offering or streamline your supply chain, understanding the nuances of motorcycle hard cases will position your business for success in a competitive landscape.

| Tipo Nombre | Principales rasgos distintivos | Aplicaciones B2B principales | Breves pros y contras para los compradores |

|---|---|---|---|

| Monokey Cases | Single-key locking mechanism, compatible with various mounts | General-purpose touring and commuting | Pros: Easy to use, versatile; Contras: May lack ruggedness compared to aluminum. |

| Monolock Cases | Lightweight, plastic construction, designed for urban use | City commuting and short trips | Pros: Affordable, lightweight; Contras: Less durable, not waterproof. |

| Aluminum Cases | Sturdy construction, often waterproof, designed for adventure | Long-distance touring and off-road use | Pros: Highly durable, weather-resistant; Contras: Heavier, more expensive. |

| Side Cases | Typically mounted on either side of the motorcycle, varying sizes | Suitable for both daily use and long trips | Pros: Balanced weight distribution; Contras: Can be cumbersome for narrow spaces. |

| Casos principales | Mounted on the rear, easy access, often larger capacity | Ideal for additional storage on trips | Pros: Convenient access, spacious; Contras: Can affect handling if overloaded. |

Monokey cases feature a single-key locking mechanism that streamlines the user experience, making them a preferred choice for general-purpose touring and commuting. Their compatibility with various mounts enhances versatility, allowing businesses to cater to diverse customer needs. When considering B2B purchases, factors such as ease of installation, weight capacity, and adaptability to different motorcycle models are crucial for ensuring customer satisfaction and repeat business.

Monolock cases are characterized by their lightweight plastic construction, making them ideal for urban commuting and short trips. Their affordability appeals to budget-conscious buyers, particularly in markets like South America and Africa. However, while they are economical, B2B buyers should consider durability and weather resistance, as these cases may not withstand harsh conditions as effectively as their aluminum counterparts.

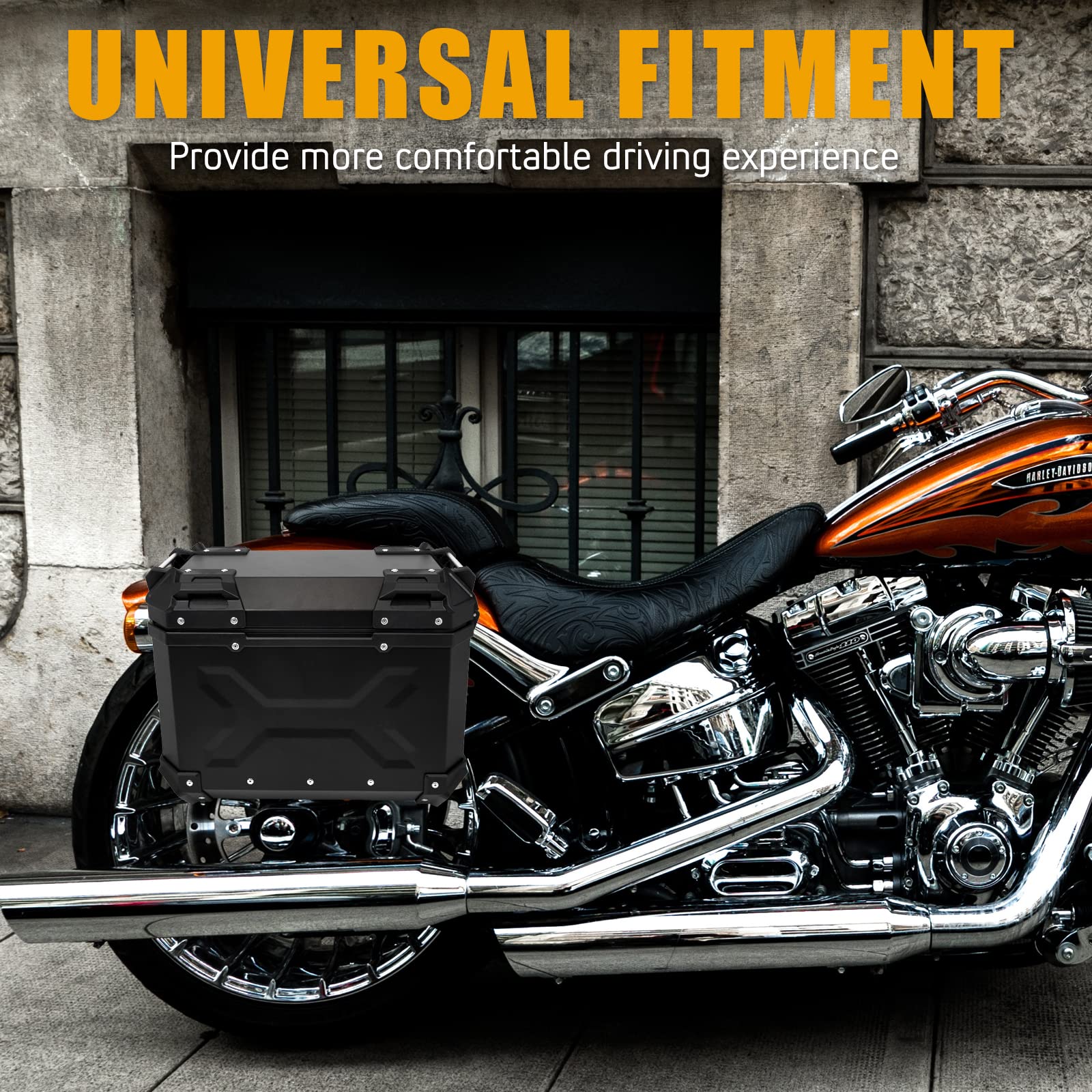

Illustrative image related to motorcycle hard cases

Aluminum cases are known for their rugged construction and weatherproof features, making them suitable for long-distance touring and off-road adventures. Their durability is a significant selling point for B2B buyers targeting adventure riders. When purchasing, businesses should evaluate the weight-to-capacity ratio and the availability of accessories, as these factors can enhance the overall customer experience and satisfaction.

Side cases provide a balanced weight distribution by mounting on either side of the motorcycle, making them versatile for both daily use and extended trips. Their varying sizes allow businesses to offer tailored solutions to customers based on their specific storage needs. However, B2B buyers must consider the potential challenges of maneuverability in tight spaces, which can affect customer satisfaction.

Top cases are mounted on the rear of the motorcycle, providing convenient access and additional storage capacity. They are particularly useful for riders who require extra space for longer trips. In B2B contexts, businesses should assess the impact of top cases on motorcycle handling and customer preferences for ease of access versus weight distribution, ensuring that they meet the diverse needs of their clientele.

| Industria/Sector | Specific Application of Motorcycle Hard Cases | Valor/beneficio para la empresa | Consideraciones clave para el aprovisionamiento de esta aplicación |

|---|---|---|---|

| Logistics & Transportation | Secure transport of goods on motorcycles | Enhanced safety and security of cargo; reduced damage risk | Waterproofing, lockability, and durability are crucial. |

| Turismo de aventura | Luggage for guided motorcycle tours | Improved customer experience; reliable storage for personal items | Lightweight options and ease of mounting are essential. |

| Servicios de emergencia | Rapid deployment of medical supplies | Quick access to critical equipment; protection from elements | Must meet strict durability and weatherproof standards. |

| Industrial Maintenance | Transporting tools and equipment on-site | Efficient mobility; organized storage of tools | Compatibility with various motorcycle models is important. |

| Militar y defensa | Transporting tactical gear and supplies | Enhanced protection for sensitive equipment; adaptability for various missions | Must comply with military specifications and ruggedness. |

In logistics, motorcycle hard cases are utilized for securely transporting goods across urban and rural landscapes. They provide a stable environment that minimizes the risk of damage during transit, especially in challenging terrains often found in regions like Africa and South America. Buyers in this sector should prioritize features such as waterproofing and lockability, ensuring that cargo remains protected from environmental factors and theft.

Adventure tourism companies rely on motorcycle hard cases to enhance their guided tours. These cases allow tourists to securely store their belongings while enjoying the ride, thus improving the overall experience. International buyers should consider lightweight and easy-to-mount options to accommodate different motorcycle models, ensuring that the cases can be quickly adapted for various tours.

Emergency services, such as medical response teams, use motorcycle hard cases to transport medical supplies rapidly. These cases ensure that critical equipment is protected from the elements and can be accessed quickly when needed. Buyers in this field must focus on durability and weatherproof standards, as the reliability of the equipment can be a matter of life and death.

Illustrative image related to motorcycle hard cases

In industrial maintenance, motorcycle hard cases serve as mobile storage solutions for tools and equipment. They allow technicians to efficiently transport their gear to various job sites, ensuring that tools are organized and readily available. Buyers should ensure compatibility with different motorcycle models, as well as seek features that promote durability and ease of access, which are essential for maintaining workflow efficiency.

Military and defense sectors utilize motorcycle hard cases for transporting tactical gear and supplies in diverse environments. These cases provide enhanced protection for sensitive equipment and can be adapted for various missions, ensuring that personnel have the necessary tools at hand. Buyers in this sector must ensure that cases meet stringent military specifications, focusing on ruggedness and reliability to withstand harsh conditions.

El problema:

B2B buyers often face significant challenges when it comes to selecting motorcycle hard cases that are compatible with specific motorcycle models. The vast array of options can lead to confusion regarding dimensions, fitment, and mounting systems. A buyer may find a hard case that appears ideal, only to discover post-purchase that it doesn’t fit their fleet of motorcycles or meets safety regulations. This results in wasted time, increased costs, and potential dissatisfaction from clients.

La solución:

To avoid these pitfalls, B2B buyers should conduct thorough research before making a purchase. Start by consulting with manufacturers or reputable distributors to understand the specifications of the hard cases. It’s essential to create a compatibility chart that includes motorcycle models, year of manufacture, and required mounting hardware. Moreover, consider investing in customizable hard cases that can be adapted to fit various models. Engaging with product support teams can also help clarify any doubts about fitment. By prioritizing compatibility, buyers can ensure that their investments serve their intended purpose without unnecessary returns or modifications.

El problema:

Another prevalent pain point for B2B buyers is the balance between durability and weight in motorcycle hard cases. Heavy cases can compromise the motorcycle’s handling and performance, especially during long-distance rides. Buyers may struggle to find hard cases that provide adequate protection for cargo while remaining lightweight enough for optimal performance. This concern is particularly acute for businesses in regions with challenging terrains or long-distance travel requirements.

La solución:

To effectively manage weight and load capacity, buyers should focus on materials used in hard case construction. Look for options made from advanced composite materials that offer strength without the bulk. For example, aluminum cases, while heavier than plastic, can be designed with structural reinforcements that maintain durability while reducing weight. It’s advisable to review product specifications meticulously, paying attention to load ratings, and to invest in cases that come with load distribution features, such as adjustable mounting systems. Additionally, educating end-users on optimal packing techniques can prevent overloading, thereby enhancing safety and performance.

El problema:

Security is a major concern for B2B buyers in the motorcycle hard case market, particularly in regions where theft rates are higher. Buyers often find that standard locking mechanisms are insufficient for protecting valuable cargo, leading to potential losses and increased insurance costs. This is especially critical for businesses that transport sensitive materials or equipment.

La solución:

To enhance security, buyers should prioritize hard cases with advanced locking mechanisms, such as integrated keyless entry systems or dual-lock features that add an extra layer of protection. Consider hard cases that are designed with tamper-proof materials and reinforced corners, making them more challenging for thieves to breach. Additionally, investing in GPS tracking systems can provide real-time monitoring of the cases, adding a valuable layer of security. Collaborating with manufacturers to understand the security features of different hard cases can guide buyers toward making informed choices that protect their investments and enhance customer trust.

When selecting materials for motorcycle hard cases, understanding the key properties of each material is essential for ensuring product performance. Here, we analyze four common materials: aluminum, ABS plastic, polypropylene, and fiberglass.

Aluminum is renowned for its strength and lightweight properties. With a high-temperature rating and excellent corrosion resistance, aluminum cases can withstand harsh environments, making them ideal for adventure touring. The manufacturing process involves techniques such as welding and anodizing, which enhance durability and aesthetics.

Illustrative image related to motorcycle hard cases

Pros: Aluminum cases are extremely durable and can handle impacts and extreme weather conditions. They are also lightweight, which is crucial for maintaining motorcycle performance.

Contras: The cost of aluminum is relatively high compared to plastic options, and the manufacturing process can be complex, leading to longer lead times.

Impacto en la aplicación: Aluminum cases are compatible with a variety of media, including oils and fuels, making them suitable for long-distance travel.

Consideraciones para compradores internacionales: Compliance with international standards such as ASTM and DIN is critical. Buyers in regions like Germany may prioritize aluminum for its strength, while those in Africa may consider weight and cost-effectiveness.

ABS (Acrylonitrile Butadiene Styrene) plastic is commonly used for motorcycle hard cases due to its good impact resistance and lightweight nature. It has a moderate temperature rating and is resistant to many chemicals.

Illustrative image related to motorcycle hard cases

Pros: ABS is relatively inexpensive and easy to mold, allowing for complex shapes and designs. It is also lightweight, which is beneficial for motorcycle handling.

Contras: While durable, ABS is less resistant to extreme temperatures compared to aluminum and may degrade under prolonged UV exposure.

Impacto en la aplicación: ABS cases are suitable for general use and can handle a variety of contents, but may not be ideal for extreme conditions.

Consideraciones para compradores internacionales: Buyers should ensure that ABS products meet local regulations regarding chemical safety and environmental impact, especially in regions with strict compliance standards.

Polypropylene is another popular choice for motorcycle hard cases, known for its excellent chemical resistance and lightweight properties. It is often used in applications requiring flexibility and impact resistance.

Pros: Polypropylene is cost-effective, lightweight, and resistant to many chemicals, making it suitable for various environments.

Contras: While it offers good impact resistance, it may not perform as well under high temperatures compared to aluminum or fiberglass.

Impacto en la aplicación: Polypropylene cases are ideal for everyday use and can accommodate a range of items, but may not be suitable for extreme conditions.

Consideraciones para compradores internacionales: Buyers should be aware of the material’s recyclability and environmental impact, as sustainability is becoming increasingly important in many markets, including Europe.

Illustrative image related to motorcycle hard cases

Fiberglass is a composite material that offers a unique combination of strength and aesthetics. It has a high-temperature rating and excellent resistance to corrosion and UV light.

Pros: Fiberglass cases are exceptionally strong and can be molded into aesthetically pleasing designs. They are also resistant to environmental factors, making them suitable for long-term use.

Contras: The manufacturing process for fiberglass can be complex and costly, leading to higher prices compared to other materials.

Impacto en la aplicación: Fiberglass cases are ideal for high-end applications where aesthetics and durability are prioritized.

Consideraciones para compradores internacionales: Compliance with international manufacturing standards is crucial, especially for buyers in Europe who may have specific quality expectations.

Illustrative image related to motorcycle hard cases

| Material | Typical Use Case for motorcycle hard cases | Ventajas clave | Principales desventajas/limitaciones | Coste relativo (Bajo/Medio/Alto) |

|---|---|---|---|---|

| Aluminio | Adventure touring | Gran durabilidad y resistencia a la corrosión | Coste más elevado y fabricación más compleja | Alta |

| Plástico ABS | General use | Cost-effective and easy to mold | Less UV resistance and durability | Bajo |

| Polypropylene | Everyday use | Lightweight and chemical resistant | Moderate temperature performance | Med |

| Fibra de vidrio | Premium applications | Exceptional strength and aesthetics | Coste más elevado y fabricación más compleja | Alta |

This guide provides B2B buyers with essential insights into material selection for motorcycle hard cases, helping them make informed decisions based on performance, cost, and compliance considerations.

The manufacturing of motorcycle hard cases involves several critical stages, each contributing to the overall quality and durability of the final product. Understanding these stages helps B2B buyers appreciate the craftsmanship and technology that go into producing reliable hard cases.

The first step in manufacturing motorcycle hard cases is the selection and preparation of materials. Manufacturers typically use high-quality plastics (like ABS or polycarbonate) or aluminum due to their durability, lightweight characteristics, and resistance to environmental factors. Advanced materials may also include reinforced composites for added strength.

Illustrative image related to motorcycle hard cases

Once the materials are chosen, they undergo a series of processes such as cutting, shaping, and treatment to enhance their properties. For instance, aluminum cases often undergo anodizing to prevent corrosion, while plastic components might be treated to improve UV resistance and impact strength.

The forming process involves shaping the prepared materials into the desired case forms. This is typically achieved through techniques such as:

Each technique has its advantages and is chosen based on the specific requirements of the hard case, including weight, strength, and cost-effectiveness.

Illustrative image related to motorcycle hard cases

After forming, the next step is assembly. This involves integrating various components, such as locks, hinges, and mounting systems, to create a fully functional hard case. Manufacturers may employ methods like:

Quality during assembly is critical, as it directly affects the case’s functionality and durability.

The finishing stage enhances both aesthetics and performance. This may include:

Finishing processes also incorporate branding elements, ensuring that the hard cases reflect the manufacturer’s identity.

Quality assurance (QA) is integral to the manufacturing of motorcycle hard cases, ensuring that products meet both international standards and customer expectations. A robust QA process involves several key components.

B2B buyers should prioritize manufacturers that comply with relevant international standards, such as:

These certifications assure buyers of the quality and safety of the products they are purchasing.

Quality control (QC) involves several checkpoints throughout the manufacturing process:

Implementing these QC checkpoints helps maintain high standards and reduces the risk of defective products reaching the market.

Manufacturers employ various testing methods to ensure the durability and functionality of motorcycle hard cases, including:

These tests help manufacturers identify weaknesses and improve product designs.

For B2B buyers, especially those in regions like Africa and South America, verifying a supplier’s quality control processes is essential. Here are effective strategies:

Audits are a crucial way to assess a supplier’s manufacturing practices. Buyers should look for:

Buyers should request detailed reports on quality control processes, including:

This information can provide insights into the supplier’s commitment to quality.

Utilizing third-party inspection services can add an extra layer of assurance. These independent auditors can evaluate the supplier’s manufacturing processes, quality control practices, and compliance with international standards, providing unbiased feedback.

For international B2B buyers, navigating the nuances of quality control and certification can be complex. Factors to consider include:

By understanding these nuances, buyers can better navigate the complexities of sourcing high-quality motorcycle hard cases on an international scale.

Sourcing motorcycle hard cases requires careful consideration to ensure that your investment meets both quality and functionality standards. This guide provides a structured checklist for B2B buyers, enabling you to navigate the procurement process efficiently. By following these steps, you can make informed decisions that align with your business needs and customer expectations.

Before reaching out to suppliers, it’s essential to have a clear understanding of your requirements. Consider factors such as size, weight capacity, material (e.g., aluminum vs. plastic), and waterproofing features. This clarity will help you narrow down options that fit your operational needs and ensure compatibility with specific motorcycle models.

Illustrative image related to motorcycle hard cases

Invest time in identifying reputable manufacturers and distributors. Look for suppliers with a proven track record in the motorcycle industry, particularly those who have experience in your target markets, such as Africa, South America, and Europe. Utilize online platforms, trade shows, and industry forums to gather insights and reviews from other businesses.

Verification of supplier certifications is crucial for quality assurance and compliance with industry standards. Check if the supplier meets international quality standards such as ISO certifications or relevant safety regulations. This not only ensures product reliability but also safeguards your brand’s reputation by minimizing risks associated with subpar products.

Before making bulk purchases, request product samples to evaluate their quality and performance. This step allows you to assess durability, ease of installation, and overall functionality in real-world conditions. Testing samples helps you identify any design flaws and ensures the product aligns with customer expectations.

Once you have shortlisted potential suppliers, analyze their pricing structures and payment terms. Look for transparency in pricing and consider the total cost of ownership, which includes shipping, duties, and potential customs fees. Favor suppliers who offer flexible payment terms that align with your cash flow needs.

A robust warranty and reliable customer support can significantly enhance your purchasing decision. Confirm the warranty duration and coverage details, as well as the supplier’s responsiveness to inquiries and issues. Strong after-sales support can be a vital factor in maintaining customer satisfaction and loyalty.

Illustrative image related to motorcycle hard cases

Building a long-term partnership with your supplier can lead to better pricing, priority service, and access to new products. Communicate your business goals and seek suppliers who are willing to collaborate on future projects or adaptations based on market trends. A solid relationship fosters trust and can provide strategic advantages in a competitive marketplace.

By following this checklist, B2B buyers can streamline their sourcing process for motorcycle hard cases, ensuring they select products that meet their operational needs while also fostering strong supplier relationships.

Understanding the cost structure and pricing of motorcycle hard cases is crucial for international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe. The following analysis outlines the key components of costs, pricing influencers, and strategic tips for buyers looking to optimize their sourcing decisions.

Materials: The choice of materials significantly impacts the cost of motorcycle hard cases. Common materials include aluminum, ABS plastic, and composite materials. High-quality aluminum cases tend to be more expensive due to their durability and resistance to harsh conditions, while ABS plastic cases offer a lighter alternative at a lower cost.

Labor: Labor costs vary depending on the manufacturing location. Countries with lower labor costs may provide more competitive pricing, but this can also affect quality. Skilled labor is essential for ensuring that cases meet safety and durability standards.

Manufacturing Overhead: This includes costs associated with facilities, utilities, and administrative expenses. Companies that produce hard cases in regions with higher operational costs may pass these expenses onto buyers, resulting in higher prices.

Tooling: Custom tooling for specialized designs can be a significant upfront cost. Buyers should consider whether the investment in tooling is justified by the expected volume of orders.

Quality Control (QC): Ensuring product quality incurs costs related to testing and inspections. Robust QC processes may increase initial costs but can save money in the long run by reducing returns and warranty claims.

Logistics: Shipping costs can vary greatly based on the origin and destination of the products. Buyers should account for freight, insurance, and customs duties when evaluating total costs.

Margin: Suppliers typically apply a margin to cover their costs and generate profit. Understanding the margin expectations in different markets can help buyers negotiate better prices.

Volume and Minimum Order Quantity (MOQ): Larger orders often result in lower per-unit costs due to economies of scale. Buyers should negotiate MOQs that align with their purchasing capabilities while considering potential stockholding costs.

Specifications and Customization: Custom features, such as specific colors or additional compartments, can increase costs. Buyers should weigh the benefits of customization against the potential price increase.

Materials and Quality Certifications: Higher quality materials and certifications (e.g., ISO, TÜV) can drive prices up but also enhance the product’s perceived value and reliability, which is crucial for safety-conscious markets.

Supplier Factors: Supplier reputation and reliability can significantly influence pricing. Established suppliers may charge a premium for their products due to their proven track record, while new entrants might offer lower prices to gain market share.

Incoterms: The choice of Incoterms affects logistics costs and responsibilities. Buyers should clarify shipping terms to avoid unexpected costs and ensure timely delivery.

Negotiation: Buyers should be prepared to negotiate pricing and terms. Leverage market knowledge, such as competitor pricing and material costs, to strengthen your position.

Cost-Efficiency: Consider the Total Cost of Ownership (TCO), which includes not only the purchase price but also maintenance, durability, and potential resale value. Investing in higher-quality products may lead to long-term savings.

Pricing Nuances for International Buyers: Different regions may have unique pricing structures influenced by local demand, currency fluctuations, and import regulations. Buyers should conduct thorough market research to understand these factors.

Disclaimer: The prices for motorcycle hard cases vary widely based on specifications, materials, and suppliers. The prices referenced in this analysis are indicative and subject to change based on market conditions, supplier negotiations, and other variables.

By comprehensively understanding these cost components, price influencers, and strategic buying tips, international B2B buyers can make informed decisions, ensuring they source the best motorcycle hard cases for their needs while optimizing their purchasing costs.

In the market for motorcycle storage solutions, motorcycle hard cases are a popular choice for secure and durable luggage. However, there are alternative products and methods that can also fulfill the need for effective storage on motorcycles. This analysis will compare motorcycle hard cases against soft luggage systems and integrated storage solutions, providing insights into their respective advantages and limitations.

Illustrative image related to motorcycle hard cases

| Aspecto comparativo | Motorcycle Hard Cases | Sistemas de equipaje blando | Integrated Storage Solutions |

|---|---|---|---|

| Rendimiento | High durability, weatherproof | Moderate durability, often waterproof | Varies; generally robust but may lack waterproofing |

| Coste | Higher initial investment | Coste generalmente inferior | Variable, often depends on customization |

| Facilidad de aplicación | Requires specific mounting systems | Easy to attach/detach; often universal fit | Built-in; no additional mounting needed |

| Mantenimiento | Bajo; mantenimiento mínimo | Moderate; may require repairs | Low; integrated with bike’s structure |

| El mejor caso de uso | Recorridos de larga distancia | Short trips, daily commuting | Urban use, casual riders |

Soft luggage systems, such as saddle bags and tank bags, offer a lightweight and flexible option for motorcycle storage. They typically attach easily to various bike models, making them user-friendly. However, while they are generally waterproof, they may not provide the same level of protection as hard cases against impacts or theft. Soft luggage can also be more prone to wear and tear over time, which could lead to additional costs for replacements or repairs. These systems are ideal for short trips or daily commuting where weight and ease of use are more critical than maximum protection.

Integrated storage solutions refer to built-in compartments designed within the motorcycle frame or body. This type of storage is convenient, as it does not require additional mounting systems and often utilizes space that would otherwise be wasted. While integrated storage can be aesthetically pleasing and provides a seamless look, its performance varies greatly depending on the motorcycle model. Additionally, these solutions may not offer the same waterproofing or security features as hard cases. Integrated storage is best suited for urban environments where quick access and minimal bulk are priorities.

When selecting the most suitable storage solution for motorcycles, B2B buyers must consider several factors, including the type of riding, budget constraints, and the desired level of protection. Motorcycle hard cases stand out for their durability and security, making them the best option for long-distance touring and adventure riding. Conversely, soft luggage systems provide a cost-effective and flexible alternative for short trips, while integrated storage solutions offer convenience for urban commuting. By assessing their specific needs and weighing the pros and cons of each option, buyers can make informed decisions that enhance their riding experience.

When selecting motorcycle hard cases, understanding the key technical properties is crucial for ensuring durability, functionality, and compatibility with various motorcycle models. Here are the essential specifications to consider:

The materials used in manufacturing motorcycle hard cases significantly impact their performance. Common materials include aluminum, ABS plastic, and polycarbonate. Aluminum cases are known for their robustness and ability to withstand harsh conditions, making them ideal for adventure touring. ABS plastic, while lighter and often more affordable, provides decent protection against impacts and weather. Understanding material properties helps businesses choose cases that align with their specific use cases and environmental conditions.

Capacity, measured in liters, indicates the volume of storage space available in the hard case. Typical capacities range from 22 liters to over 58 liters. It’s essential for buyers to match case dimensions with their intended use—whether for daily commuting or long-distance travel. This specification also affects the design of the motorcycle, as cases must fit securely without affecting the bike’s balance or aerodynamics.

Waterproofing is a critical feature for motorcycle hard cases, especially for riders facing adverse weather conditions. The presence of rubber seals, locking mechanisms, and the overall design can determine how well a case can protect its contents from water and dust. Buyers should evaluate the IP (Ingress Protection) ratings provided by manufacturers, as these ratings inform the level of protection against moisture and particles.

Security is paramount for riders who leave their motorcycles unattended. Many hard cases come with integrated locking systems, which may include key locks, combination locks, or even advanced electronic locking mechanisms. Understanding the security features available can help businesses mitigate the risk of theft and ensure the safety of valuable cargo.

The weight of the hard case is a vital consideration, especially for long-distance riders. Lighter cases reduce the overall load on the motorcycle, enhancing fuel efficiency and handling. Additionally, load tolerance refers to the maximum weight a case can carry without compromising its structural integrity. Buyers should assess the weight limits to ensure they do not exceed the motorcycle’s carrying capacity.

Illustrative image related to motorcycle hard cases

Familiarity with industry terminology is essential for effective communication and decision-making. Here are some key terms that B2B buyers should understand:

OEM refers to a company that produces parts or products that are used in another company’s end product. In the context of motorcycle hard cases, buyers may work directly with OEMs for custom solutions or branded products, ensuring that they receive high-quality, compatible accessories for their motorcycles.

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is crucial for buyers as it affects inventory management and cost calculations. For businesses, negotiating lower MOQs can improve cash flow and reduce excess inventory risks.

An RFQ is a formal process where buyers request pricing and terms from suppliers for specific products or services. It is a vital step in procurement, allowing businesses to compare offers and select the most suitable supplier based on price, quality, and delivery terms.

Incoterms are a set of international rules that define the responsibilities of buyers and sellers in international transactions. They clarify aspects such as shipping, insurance, and delivery responsibilities. Familiarity with Incoterms is essential for B2B buyers to avoid misunderstandings and ensure smooth logistics.

Illustrative image related to motorcycle hard cases

This term refers to how well a motorcycle hard case fits with specific motorcycle models and accessories. Buyers should ensure that cases are compatible with their motorcycles to prevent installation issues and ensure optimal performance.

Understanding these technical properties and trade terms will empower B2B buyers to make informed decisions when sourcing motorcycle hard cases, leading to better product alignment and enhanced customer satisfaction.

The motorcycle hard cases market is experiencing significant growth, driven by an increase in motorcycle ownership globally, particularly in regions such as Africa, South America, the Middle East, and Europe. In Africa, rising disposable incomes and an expanding middle class are boosting motorcycle sales, while in Europe, the trend leans towards adventure and touring motorcycles, which necessitate robust luggage solutions. Notably, the demand for lightweight yet durable materials is influencing product development, with manufacturers increasingly incorporating advanced composites and aluminum into their designs.

Emerging B2B tech trends include the integration of smart technology into hard cases, such as GPS tracking and anti-theft features, appealing to a tech-savvy demographic. Additionally, the rise of e-commerce platforms is transforming the sourcing landscape, allowing international buyers to access a broader range of products and suppliers. This shift enhances competition and drives innovation, as manufacturers seek to differentiate their offerings with unique features and designs.

Furthermore, partnerships between manufacturers and motorcycle brands are becoming commonplace, facilitating tailored solutions that meet specific customer needs. International buyers should keep an eye on these partnerships, as they often lead to exclusive products that can enhance their inventory.

Sustainability is a growing concern among B2B buyers, prompting manufacturers in the motorcycle hard cases sector to adopt environmentally friendly practices. The environmental impact of production processes, including carbon emissions and waste generation, is under scrutiny. Buyers are increasingly prioritizing suppliers who demonstrate a commitment to sustainability through responsible sourcing and production practices.

Ethical supply chains are gaining importance, with buyers seeking transparency in the materials used for hard cases. Manufacturers are responding by utilizing recycled materials and eco-friendly coatings, which not only reduce environmental impact but also appeal to eco-conscious consumers. Certifications such as ISO 14001 and the Forest Stewardship Council (FSC) are becoming critical in supplier selection, as they ensure adherence to environmental standards.

The trend towards sustainable materials extends to the use of durable plastics and metals that offer longevity, reducing the need for frequent replacements and ultimately contributing to a lower carbon footprint. For international buyers, emphasizing sustainability in procurement decisions not only aligns with corporate social responsibility goals but also enhances brand reputation in an increasingly eco-aware market.

The evolution of motorcycle hard cases can be traced back to the early days of motorcycling when riders used leather saddlebags for storage. As motorcycle technology advanced, so did the need for more robust and secure storage solutions. The introduction of hard cases revolutionized the market, providing enhanced protection against weather elements and theft.

In the late 20th century, manufacturers began to explore materials like ABS plastic and aluminum, leading to the lightweight yet durable options available today. This shift not only improved the performance and reliability of hard cases but also opened the door to innovative designs that cater to various riding styles and preferences.

Understanding this historical context is vital for B2B buyers, as it highlights the trajectory of product development and the ongoing demand for durability, security, and functionality. As the market continues to evolve, buyers should consider how historical trends influence current offerings, ensuring that they select products that meet modern consumer expectations while maintaining a legacy of quality and performance.

How do I choose the right motorcycle hard case for my needs?

Choosing the right motorcycle hard case involves assessing your specific requirements, including the type of motorcycle you have, the purpose of the case, and your budget. Consider factors such as capacity, material durability, waterproof features, and ease of mounting and removal. Research various brands and models, comparing user reviews and ratings to ensure you select a reliable product. Additionally, consult with suppliers to gain insights into which cases are most popular in your target market.

What are the key features to look for in motorcycle hard cases?

When evaluating motorcycle hard cases, prioritize features such as waterproofing, lockability, material quality (like aluminum or high-grade plastic), and ease of installation. Cases with removable lids and integrated carrying handles offer added convenience. Additionally, consider modular designs that allow for versatile use as side or top cases, enhancing functionality. Accessories like inner bags or mounting systems can also improve usability and organization.

What are the typical minimum order quantities (MOQs) for motorcycle hard cases?

Minimum order quantities (MOQs) for motorcycle hard cases can vary significantly based on the manufacturer and product type. Generally, MOQs may range from 50 to 200 units per order. It’s essential to discuss MOQs with potential suppliers, as they may offer flexibility depending on your business needs or long-term partnership agreements. Consider negotiating lower MOQs if you are a new buyer or if you plan to order regularly in the future.

How do I vet suppliers for motorcycle hard cases?

Vetting suppliers involves a thorough evaluation of their reputation, experience, and product quality. Start by checking online reviews and industry ratings. Request references from other B2B buyers and inquire about their experiences. It’s also beneficial to verify certifications and compliance with international standards. Consider visiting the supplier’s manufacturing facility if possible or requesting product samples to assess quality firsthand.

What payment terms should I expect when sourcing motorcycle hard cases?

Payment terms can vary among suppliers but typically include options like a deposit upon order confirmation (often 30-50%) and the balance upon shipment or delivery. Some suppliers may offer credit terms for long-standing customers. Be clear about your payment preferences and negotiate terms that work for both parties. Additionally, consider the risks associated with international transactions, such as currency fluctuations and transfer fees.

What logistics options are available for shipping motorcycle hard cases internationally?

International shipping logistics for motorcycle hard cases typically include sea freight, air freight, and express courier services. Sea freight is the most cost-effective option for large orders, while air freight is faster but more expensive. When selecting a logistics provider, consider their experience with customs clearance and international regulations. Ensure they offer tracking services for transparency throughout the shipping process.

How do I ensure quality assurance for motorcycle hard cases?

To ensure quality assurance, request detailed product specifications and certifications from your suppliers. Implement a quality control process that includes inspecting samples before full production runs and conducting inspections at the factory. Consider third-party inspection services for additional assurance. Establish clear return and warranty policies to address any quality issues that may arise after purchase.

Can I customize motorcycle hard cases with my branding?

Yes, many manufacturers offer customization options for motorcycle hard cases, including branding, color, and specific features tailored to your market. Discuss your requirements with potential suppliers to understand the customization capabilities and associated costs. Be mindful of lead times for customized products, as they may take longer to produce compared to standard models. Ensure that the final design aligns with your brand image and appeals to your target audience.

Dominio: giviusa.com

Matriculado: 2000 (25 años)

Introducción: This company, GIVI – Motorcycle Hard Case Luggage, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Dominio: shadusa.com

Matriculado: 2005 (20 años)

Introducción: SHAD Motorcycle Side Cases are designed for durability and spacious storage. Key features include: 1. Expandable designs for increased capacity. 2. Aerodynamic construction for improved performance. 3. Secure mounting systems compatible with various bike models. 4. Multiple options available, including: – SH38X Expandable Side Cases (Aluminum) – $649.00 – SH38X Expandable Side Cases (Carbon Fiber)…

Dominio: sw-motech.es

Matriculado: 2019 (6 años)

Introducción: SW-MOTECH offers a variety of motorcycle side cases designed for durability and functionality. Key product lines include:

1. TRAX ADV aluminum cases:

– Material: 1.5 mm robot-welded aluminum

– Features: Waterproof, removable lids, stainless-steel latches, integrated carrying handles, various accessories available.

– Capacity: 37/37 liters or 37/45 liters.

– Price: $1,500.00.

2. …

Dominio: revzilla.com

Registrado: 2006 (19 años)

Introducción: This company, RevZilla – Motorcycle Gear, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Dominio: vikingbags.com

Registrado: 2006 (19 años)

Introducción: Adventure Touring Hard Side Cases from Viking Bags feature sturdy aluminum construction, stainless steel rivets, and reinforced fiberglass clips for built-in weather, rust, and impact resistance. Sold in pairs, these cases offer optimal storage capacity while maintaining low overall weight and stability on uneven trails. They include a bolt-on installation system with high-quality mounting hardwar…

Dominio: moskomoto.com

Inscrito: 2013 (12 años)

Introducción: Mosko Moto offers adventure motorcycle luggage and apparel with free shipping on orders over $200 USD.

Dominio: touratech-usa.com

Matriculado: 2001 (24 años)

Introducción: Motorcycle Panniers & Luggage available for various motorcycle brands including BMW, KTM, Triumph, Honda, Yamaha, Aprilia, Harley-Davidson, Suzuki, Kawasaki, Ducati, and Husqvarna. Specific models supported include R1300GS, R1250GS, R1200GS, Africa Twin CRF1000L, F900GS, 790 Adventure, and many others. Product categories include Pannier Systems, Topcase Systems, Tank & Tail Bags, Individual Pannie…

In the dynamic landscape of motorcycle hard cases, strategic sourcing is not just beneficial; it is essential. By leveraging data-driven insights and market intelligence, international B2B buyers can streamline their procurement processes, reduce costs, and enhance product quality. Engaging with reputable suppliers who prioritize innovation and sustainability can lead to significant competitive advantages. For instance, selecting durable materials and weatherproof designs ensures longevity, which is paramount for customers who depend on these cases for both leisure and adventure.

Furthermore, understanding regional preferences and compliance requirements can aid in selecting the right products tailored to specific markets in Africa, South America, the Middle East, and Europe. As consumer demand evolves, staying ahead of trends—such as the rising popularity of lightweight and modular designs—will be crucial for maintaining relevance.

As you consider your next sourcing strategy, prioritize partnerships with manufacturers known for quality and reliability. Embrace the opportunity to innovate and adapt to changing market conditions. The future of motorcycle hard cases is bright, and proactive sourcing will position your business at the forefront of this thriving industry. Seize this moment to transform your supply chain and drive growth.

La información facilitada en esta guía, incluido el contenido relativo a fabricantes, especificaciones técnicas y análisis de mercado, tiene únicamente fines informativos y educativos. No constituye asesoramiento profesional en materia de adquisiciones, asesoramiento financiero ni asesoramiento jurídico.

Aunque hemos hecho todo lo posible por garantizar la exactitud y actualidad de la información, no nos hacemos responsables de posibles errores, omisiones o información obsoleta. Las condiciones del mercado, los detalles de las empresas y las normas técnicas están sujetos a cambios.

Los compradores B2B deben llevar a cabo su propia diligencia debida independiente y exhaustiva antes de tomar cualquier decisión de compra. Esto incluye ponerse en contacto directamente con los proveedores, verificar las certificaciones, solicitar muestras y buscar asesoramiento profesional. El riesgo de confiar en la información contenida en esta guía es responsabilidad exclusiva del lector.