In the competitive landscape of cycling products, understanding how to inflate road bike tires effectively is crucial for B2B buyers seeking to optimize their inventory and meet customer demands. Sourcing the right tools and equipment for tire inflation not only enhances the cycling experience but also significantly impacts customer satisfaction and retention. This comprehensive guide delves into various types of pumps, valve systems, and inflation techniques, equipping international buyers with the knowledge needed to make informed purchasing decisions.

The guide covers essential topics, including the differences between Presta and Schrader valves, the advantages of various pump types, and best practices for tire inflation. Additionally, it provides insights into supplier vetting processes, ensuring that businesses select reliable manufacturers who meet quality standards and regional requirements. By addressing common challenges faced by cyclists and retailers alike, this resource empowers B2B buyers from regions such as Africa, South America, the Middle East, and Europe—including key markets like Saudi Arabia and Nigeria—to enhance their product offerings and improve operational efficiency.

With actionable insights and detailed information, this guide serves as a valuable tool for businesses aiming to navigate the global market for cycling accessories, ensuring they stay competitive while meeting the evolving needs of their customers.

| Tipo Nombre | Principales rasgos distintivos | Aplicaciones B2B principales | Breves pros y contras para los compradores |

|---|---|---|---|

| Track Pump | Tall, high-capacity, designed for home use | Bike shops, rental services, enthusiasts | Pros: Quick inflation, high pressure; Contras: Bulky, less portable. |

| Mini Pump | Compact, portable, suitable for emergencies | Retailers, individual cyclists, events | Pros: Lightweight, easy to carry; Contras: Slower inflation, limited pressure. |

| Inflador de CO2 | Uses disposable canisters for rapid inflation | Roadside assistance, racing teams | Pros: Fast inflation, compact; Contras: Single-use canisters, ongoing costs. |

| Bomba eléctrica | Automated inflation, often with digital pressure readouts | Bike manufacturers, workshops | Pros: Consistent inflation, user-friendly; Contras: Higher cost, requires power source. |

| Compresor de aire | High-capacity, suitable for professional environments | Pro teams, bike repair shops | Pros: Efficient for multiple tires; Contras: Expensive, requires space. |

Track pumps are essential tools for any serious cyclist or bike shop. They feature a tall, sturdy design, allowing for high-volume air inflation with minimal effort. Most track pumps can inflate tires to pressures exceeding 100 PSI, making them ideal for road bikes. B2B buyers should consider the build quality, ease of use, and pressure gauge accuracy when purchasing track pumps, as these factors significantly impact customer satisfaction and operational efficiency.

Mini pumps are compact and designed for portability, making them perfect for cyclists on the go. They can fit easily into a jersey pocket or a bike bag, which is crucial for emergency repairs during rides. While they may not inflate tires as quickly or to as high a pressure as track pumps, their convenience is unmatched. Retailers should focus on the durability and ease of use of mini pumps, as these attributes directly influence customer loyalty and repeat purchases.

CO2 inflators offer a fast and efficient way to inflate tires using disposable canisters. They are especially popular among competitive cyclists and those who need quick fixes during rides. B2B buyers should be aware of the ongoing costs associated with purchasing replacement canisters, as this can affect long-term profitability. Despite their single-use nature, the compact size and rapid inflation capabilities make them a valuable addition to any product lineup.

Illustrative image related to how to inflate road bike tires

Electric pumps streamline the inflation process with automated features and digital pressure gauges. They are particularly beneficial in workshop settings where efficiency is key, allowing mechanics to quickly inflate multiple tires to precise pressures. For B2B buyers, investing in electric pumps can enhance service speed and accuracy, but they come at a higher initial cost and require a reliable power source. This makes them a worthwhile investment for shops aiming to improve service quality.

Air compressors are high-capacity tools suited for professional cycling teams and bike repair shops. They provide rapid inflation for multiple tires and can easily reach high pressures, making them ideal for pre-race setups. However, their higher price point and need for dedicated space may deter some smaller businesses. B2B buyers should weigh the initial investment against the potential for increased efficiency and customer satisfaction when considering air compressors for their operations.

| Industria/Sector | Specific Application of how to inflate road bike tires | Valor/beneficio para la empresa | Consideraciones clave para el aprovisionamiento de esta aplicación |

|---|---|---|---|

| Bicycle Retail | Providing tire inflation services for customers | Enhances customer satisfaction and loyalty | Quality of pumps, availability of parts, and technician training |

| Fabricación de bicicletas | Quality control in tire assembly and testing | Ensures product reliability and safety | Precision equipment for consistent PSI measurements |

| Bicycle Rental Services | Ensuring all rental bikes are properly inflated | Reduces maintenance costs and improves user experience | Durable pumps, ease of use, and compatibility with multiple valve types |

| Sports Events Management | On-site tire inflation for competitive events | Supports athletes’ performance and minimizes delays | Portable inflation solutions and quick access to supplies |

| Cycling Tours and Expeditions | Providing inflation support during guided rides | Enhances safety and convenience for participants | Lightweight, portable pumps, and training for guides |

Bicycle retailers can enhance customer satisfaction by offering tire inflation services. Properly inflated tires are essential for safety and performance, and having the right equipment available can help customers avoid flat tires. Retailers must source high-quality pumps that are reliable and easy to use, ensuring that staff are trained to assist customers effectively. This service can also lead to increased foot traffic and repeat business.

Illustrative image related to how to inflate road bike tires

In the bicycle manufacturing sector, tire inflation is critical during quality control processes. Proper inflation ensures that tires meet safety standards and perform as expected under various conditions. Manufacturers need precision equipment to maintain consistent PSI measurements during assembly and testing. This attention to detail can significantly impact the brand’s reputation and customer satisfaction, making it essential for manufacturers to invest in reliable inflation technology.

Bicycle rental services must ensure that all bikes are adequately inflated before each rental. This practice not only reduces maintenance costs associated with flat tires but also enhances the overall user experience. Rental businesses should focus on sourcing durable pumps that can accommodate various valve types, particularly Presta and Schrader, to cater to different bike models. Additionally, ease of use is vital for quick turnaround times between rentals.

On-site tire inflation during competitive events is crucial for maintaining athletes’ performance. Quick access to tire inflation services can minimize delays and ensure that participants are ready to compete without equipment issues. Event organizers should consider portable inflation solutions that are easy to transport and operate. Having trained staff on hand can also enhance the service provided, contributing to a smoother event experience.

Cycling tours can significantly improve participant safety and convenience by providing tire inflation support during rides. Properly inflated tires reduce the risk of flats and enhance the overall ride quality. Tour operators should invest in lightweight, portable pumps that can easily be carried by guides. Training for guides on how to inflate tires efficiently can further enhance the experience for participants, ensuring a successful and enjoyable tour.

El problema: Many B2B buyers, especially those new to cycling or managing bike rental fleets, often encounter confusion regarding the different valve types used in road bike tires. The most common valves, Presta and Schrader, are not interchangeable, which can lead to frustration during tire inflation. This confusion can result in wasted time, additional costs from purchasing incorrect pumps or adapters, and even potential damage to bike components if the wrong equipment is used.

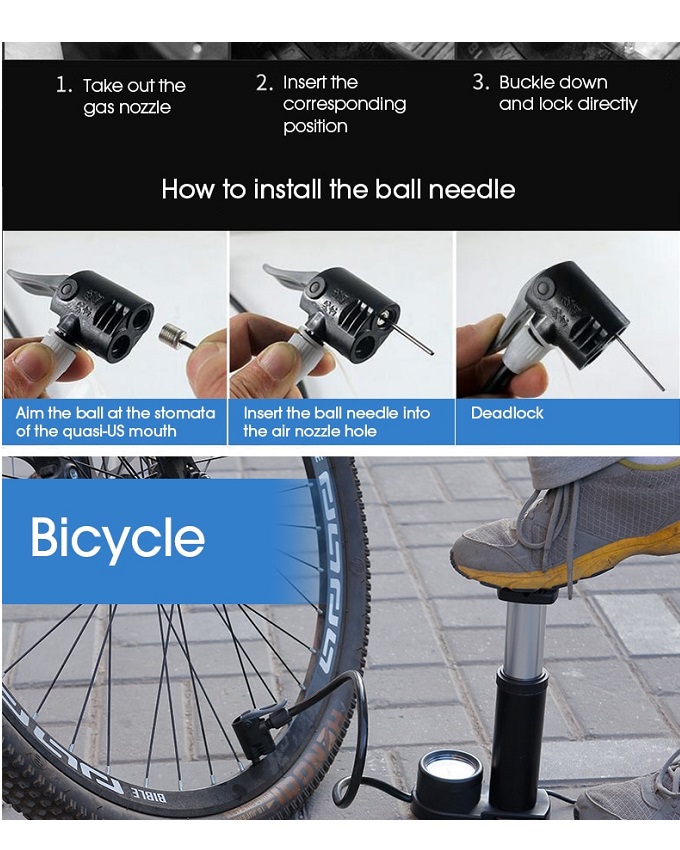

La solución: To mitigate this issue, it’s crucial to educate buyers about the specific valve types associated with their fleet of bikes. Suppliers should provide comprehensive guides or training sessions highlighting the differences between Presta and Schrader valves, including visual aids for easy identification. Additionally, investing in dual-head pumps that accommodate both valve types can streamline operations. Retailers can also offer a selection of adapters that allow Presta valves to be used with Schrader-compatible pumps, ensuring compatibility without requiring multiple tools. Regular training and informational resources will empower buyers to confidently manage tire inflation without operational delays.

El problema: A common challenge faced by B2B buyers is the lack of knowledge regarding the appropriate PSI (pounds per square inch) levels for different types of road bike tires. Inflating tires beyond the recommended PSI can lead to blowouts, while under-inflation can cause poor performance and increased wear. This misunderstanding can result in safety hazards and costly repairs, negatively impacting customer satisfaction and operational efficiency.

La solución: To address this pain point, it is essential to clearly communicate the recommended PSI levels for each tire model within the fleet. Providing detailed specifications on the sidewall of each tire, along with easy-to-understand guidelines, can significantly reduce confusion. Suppliers can create informative materials, such as infographics or quick-reference charts, to distribute to B2B clients, ensuring that staff members are trained to check and adhere to these specifications during routine maintenance. Furthermore, implementing a regular inspection schedule for tire pressure can help maintain optimal performance and safety, ultimately enhancing the overall cycling experience for end-users.

El problema: B2B buyers managing bike shops or rental services often face inefficiencies due to inadequate or inappropriate inflation tools. The use of low-quality or unsuitable pumps can lead to slow inflation times, resulting in operational delays during peak rental periods or repairs. Additionally, if staff members are not trained on proper inflation techniques, it can lead to improper tire inflation, increasing the risk of tire damage and customer complaints.

Illustrative image related to how to inflate road bike tires

La solución: Investing in high-quality, reliable inflation tools tailored for the specific needs of road bike tires can significantly improve efficiency. Suppliers should prioritize offering robust track pumps with dual valve compatibility and accurate pressure gauges to enhance the inflation process. Additionally, training staff on effective pumping techniques, such as ensuring a secure seal on the valve and monitoring pressure during inflation, can minimize mistakes. Providing hands-on training and demonstrations during equipment onboarding can ensure that staff is confident and skilled in using the tools effectively. Establishing a maintenance routine for all inflation equipment will also keep it in optimal condition, reducing the likelihood of breakdowns during high-demand periods.

When selecting materials for pumps used in inflating road bike tires, several factors come into play, including durability, compatibility with various valve types, and performance under different environmental conditions. Below, we analyze four common materials used in pump construction, focusing on their properties, advantages, disadvantages, and considerations for international B2B buyers.

Propiedades clave: Aluminum is lightweight, resistant to corrosion, and can withstand high pressures, making it ideal for pump bodies. It typically has a temperature rating that allows it to perform well in various climates.

Ventajas e inconvenientes: The main advantage of aluminum is its strength-to-weight ratio, which makes it easy to handle and transport. However, it can be more expensive than plastic alternatives and may require more complex manufacturing processes, such as precision machining.

Impacto en la aplicación: Aluminum pumps are compatible with high-pressure applications and can effectively handle the pressures needed for road bike tires. However, care must be taken to avoid dents that could compromise performance.

Consideraciones para compradores internacionales: Buyers in regions with high humidity, such as parts of Africa and South America, should prioritize aluminum due to its corrosion resistance. Compliance with standards like ASTM for material quality is essential.

Propiedades clave: Plastic materials, particularly high-density polyethylene (HDPE) and polycarbonate, offer good impact resistance and lightweight characteristics. They can handle moderate pressures but generally have lower temperature ratings compared to metals.

Ventajas e inconvenientes: The primary advantage of plastic is its cost-effectiveness and ease of manufacturing. However, it may not withstand high pressures as effectively as aluminum, leading to potential failures in extreme conditions.

Impacto en la aplicación: Plastic pumps are suitable for casual cyclists and mid-range applications but may not be ideal for professional use where high PSI is required. They can be less durable over time, especially in harsh environments.

Consideraciones para compradores internacionales: In regions like the Middle East, where temperatures can soar, selecting high-quality plastics that can withstand heat is crucial. Compliance with local manufacturing standards is also important.

Propiedades clave: Steel is known for its durability and strength, with high resistance to deformation under pressure. It generally has a high temperature and pressure rating, making it suitable for heavy-duty applications.

Ventajas e inconvenientes: The main advantage of steel is its robustness, which ensures longevity and reliability. However, it is heavier than aluminum and plastic, which may be a drawback for portable pumps. Additionally, it is more prone to rust if not properly treated.

Impacto en la aplicación: Steel pumps are ideal for professional cyclists and high-performance applications where durability is paramount. They can handle extreme pressures, making them suitable for competitive environments.

Consideraciones para compradores internacionales: In regions like Europe, where strict manufacturing standards exist, buyers should ensure that steel pumps comply with relevant regulations, such as DIN standards. Rust resistance treatments are also essential for humid climates.

Propiedades clave: Composite materials combine various substances, such as carbon fiber and plastics, to create lightweight yet strong components. They often have excellent pressure ratings and can be engineered for specific applications.

Ventajas e inconvenientes: The key advantage of composites is their ability to offer high strength with reduced weight. However, they can be more expensive and may require advanced manufacturing techniques, which could affect lead times.

Impacto en la aplicación: Composite pumps are suitable for high-performance cycling and competitive environments due to their lightweight nature and strength. They can handle high pressures effectively, making them versatile.

Consideraciones para compradores internacionales: For buyers in regions with emerging markets, the initial investment in composite materials may be higher, but the long-term benefits in performance and weight savings can justify the cost. Compliance with international standards is crucial for market acceptance.

| Material | Typical Use Case for how to inflate road bike tires | Ventajas clave | Principales desventajas/limitaciones | Coste relativo (Bajo/Medio/Alto) |

|---|---|---|---|---|

| Aluminio | High-performance pumps for road cycling | Ligero y resistente a la corrosión | Mayor complejidad de fabricación | Alta |

| Plástico | Casual use and mid-range applications | Cost-effective and easy to manufacture | Lower pressure tolerance | Bajo |

| Acero | Heavy-duty, professional cycling applications | Durable and long-lasting | Más pesado y propenso a oxidarse | Medio |

| Compuesto | High-performance, competitive cycling | Elevada relación resistencia/peso | Fabricación costosa y compleja | Alta |

This strategic material selection guide provides a comprehensive overview for B2B buyers looking to procure pumps for inflating road bike tires, ensuring informed decisions based on performance, cost, and regional considerations.

The manufacturing process for road bike tire inflation equipment, including pumps and valves, consists of several critical stages: material preparation, forming, assembly, and finishing. Each stage is essential to ensure that the final product meets the necessary performance and quality standards expected by B2B buyers.

Material preparation involves sourcing high-quality materials that meet specific industry requirements. Common materials include aluminum for pumps and synthetic rubber for valve components. Suppliers must ensure that these materials are free from defects and meet international quality standards, such as ISO 9001, which emphasizes a quality management system that enhances customer satisfaction.

During this stage, suppliers may conduct preliminary tests on raw materials to verify their properties, such as tensile strength and durability. This is crucial as the quality of materials directly impacts the longevity and performance of the tire inflation products.

The forming process involves shaping the prepared materials into the necessary components. For pumps, this often includes machining aluminum parts and molding plastic components. Techniques such as CNC machining, injection molding, and extrusion are commonly employed.

For instance, the aluminum body of a pump may be produced through CNC machining, allowing for precise dimensions and tolerances. Similarly, valve components like Presta and Schrader valves are often created using injection molding techniques to ensure consistency and reliability. These techniques not only enhance the quality of the components but also improve production efficiency, which is vital for meeting the demands of international markets.

Assembly is a critical stage where individual components come together to form the final product. This process typically occurs in a controlled environment to minimize contamination and ensure precision. Workers must be trained in best practices to ensure that each component is correctly fitted, and any seals or gaskets are installed properly to prevent air leaks.

Quality control checkpoints during assembly, such as in-process quality control (IPQC), are essential. These checkpoints help identify any defects early in the assembly process, reducing waste and ensuring that only products meeting quality standards proceed to the next stage.

Finishing techniques include surface treatments, painting, and packaging. These processes not only enhance the aesthetic appeal of the products but also contribute to their durability. Anodizing aluminum components can provide additional corrosion resistance, while UV-resistant coatings can protect painted surfaces from fading.

Before packaging, final inspections (final quality control, or FQC) are conducted to ensure that the products are free from defects and function as intended. This stage is crucial for maintaining the reputation of manufacturers in international markets, as any defects can lead to costly returns and damage to brand integrity.

Quality assurance (QA) is integral to the manufacturing process, ensuring that all products meet the established standards before reaching the market. Manufacturers often adhere to international standards such as ISO 9001 and CE certification, which require comprehensive documentation and process validation.

International standards like ISO 9001 focus on quality management systems, while CE marking signifies that products meet EU safety and health requirements. For tire inflation equipment, adherence to these standards is crucial, especially for B2B buyers operating in regions with stringent regulatory requirements.

Industry-specific certifications, such as those from the American Petroleum Institute (API), may apply depending on the materials and technologies used. These certifications assure buyers that the products have been tested and meet specific performance criteria.

Illustrative image related to how to inflate road bike tires

Quality control checkpoints are established throughout the manufacturing process to ensure product integrity. Common checkpoints include:

B2B buyers should conduct due diligence when selecting suppliers. This may involve:

Buyers should also be aware of specific QC/certification nuances relevant to their regions. For example, buyers in Africa, South America, the Middle East, and Europe may face different regulatory challenges and consumer expectations. Understanding these nuances can help buyers make informed decisions and minimize risks associated with product quality.

Common testing methods for tire inflation equipment include pressure testing, durability testing, and performance testing.

These testing methods help manufacturers identify weaknesses and improve their products, ensuring they meet the high standards expected by international B2B buyers.

Understanding the manufacturing processes and quality assurance measures for road bike tire inflation equipment is essential for B2B buyers. By focusing on material preparation, forming, assembly, and finishing, along with rigorous quality control measures, manufacturers can deliver reliable products that meet international standards. Buyers should leverage audits, quality reports, and third-party inspections to verify supplier quality, ensuring that their investments result in high-performance, durable products.

Illustrative image related to how to inflate road bike tires

To ensure your operations run smoothly and your clients receive high-quality service, it is essential to have a comprehensive understanding of how to inflate road bike tires. This guide provides actionable steps for B2B buyers looking to procure the necessary equipment and knowledge for efficient tire inflation.

Understanding valve types is critical for effective tire inflation. Most road bikes use Presta valves, while mountain bikes typically utilize Schrader valves. Ensure you source pumps compatible with Presta valves, as they offer a better fit and ease of use for road bike tires.

Select a pump based on your specific needs. The three main types include track pumps, mini pumps, and CO2 inflators. Each type serves different purposes and knowing when to use each is vital for operational efficiency.

Investing in high-quality pumps and tools will ensure longevity and reliability. Evaluate the materials and construction of the pumps you plan to procure. Durable products minimize maintenance costs and downtime.

Illustrative image related to how to inflate road bike tires

Before finalizing your purchase, vet suppliers for credibility and industry certifications. A reputable supplier will have a proven track record and customer testimonials that affirm their reliability.

Understand the logistics involved in your procurement process. Shipping terms can greatly impact your operations, especially when sourcing from international suppliers.

If possible, request demonstrations or samples of the pumps and equipment you intend to buy. This hands-on experience can provide insights into usability and performance.

After procurement, develop a maintenance plan to ensure the longevity of your equipment. Regular checks and servicing can prevent issues and extend the life of your pumps.

By following this checklist, B2B buyers can effectively procure the necessary tools for inflating road bike tires, ensuring they meet the demands of their customers while maintaining operational efficiency.

Illustrative image related to how to inflate road bike tires

When analyzing the cost structure for inflating road bike tires, several components must be considered. These include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and the supplier’s margin.

Materiales: The primary materials involved in inflating bike tires include the pump, valve, and any CO2 canisters if applicable. The choice of materials impacts both performance and durability. For example, high-quality pumps made from lightweight aluminum may be more expensive than plastic alternatives, but they offer better longevity and user experience.

Trabajo: Labor costs can vary significantly based on the region and the skill level required. In regions with lower labor costs, such as parts of Africa and South America, manufacturers can offer competitive pricing, but this may affect quality if not managed properly.

Gastos generales de fabricación: This includes costs associated with the facility, utilities, and administrative expenses. Efficient manufacturing processes can help reduce these costs, ultimately benefiting the buyer.

Herramientas: The initial investment in tooling for different pump designs or valve types can be substantial. Companies that require customized solutions may face higher tooling costs, which can influence pricing.

Control de calidad: Ensuring the reliability and safety of the product through rigorous QC processes is crucial, especially for international markets. QC costs can add to the overall price but are essential for maintaining brand reputation and customer satisfaction.

Logística: Shipping costs, especially for international buyers, can vary widely based on the destination, weight, and dimensions of the products. Understanding Incoterms is vital for determining who is responsible for shipping and customs costs.

Margen: Suppliers typically add a margin to cover their costs and generate profit. This margin can vary based on market competition and the perceived value of the product.

Several factors influence the pricing of products related to inflating road bike tires:

Volumen/MOQ: Bulk purchases often lead to lower per-unit costs. Buyers should negotiate minimum order quantities (MOQs) to achieve better pricing.

Especificaciones/Personalización: Customized pumps or specific valve types can increase costs. Buyers should assess their needs carefully to avoid unnecessary expenditures.

Materiales y calidad/certificaciones: High-quality materials and certifications (e.g., ISO standards) can justify higher prices. Buyers must evaluate whether these attributes align with their target market demands.

Factores del proveedor: Supplier reputation, reliability, and their ability to meet delivery schedules can affect pricing. Engaging with established suppliers may yield better long-term pricing agreements.

Incoterms: The choice of Incoterms can significantly impact overall costs. Buyers should be aware of whether they are responsible for transportation, insurance, and duties to avoid unexpected expenses.

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, understanding pricing nuances is critical:

Negociación: Always negotiate terms and prices. Building a good relationship with suppliers can lead to better deals and flexible payment terms.

Cost Efficiency: Evaluate the total cost of ownership, which includes not only the purchase price but also logistics, maintenance, and potential return on investment (ROI) from using high-quality products.

Matices en la fijación de precios: Be aware of local market conditions and currency fluctuations that may affect pricing. Conducting market research can provide insights into fair pricing in specific regions.

While the cost and pricing structure for inflating road bike tires may seem straightforward, it involves a complex interplay of various factors. International B2B buyers should take a comprehensive approach to understand these dynamics, ensuring they secure the best deals while maintaining quality and reliability. Always remember that indicative prices can vary, and it’s essential to engage with multiple suppliers for comparative analysis.

When it comes to inflating road bike tires, traditional methods often involve using pumps that cater to specific valve types. However, as the cycling market evolves, alternative solutions have emerged that provide various advantages. This section will compare conventional tire inflation techniques with innovative alternatives, helping B2B buyers understand the options available for their businesses.

| Aspecto comparativo | How To Inflate Road Bike Tires | Infladores de CO2 | Bombas eléctricas |

|---|---|---|---|

| Rendimiento | High PSI capability, manual control | Quick inflation, high PSI | Automated inflation, precise PSI |

| Coste | Moderate (manual pumps range from $20 to $100) | Low to moderate (canisters $1-$5 each) | Higher initial investment ($50-$300) |

| Facilidad de aplicación | Simple; requires manual effort | Very easy; minimal setup | Very easy; plug and inflate |

| Mantenimiento | Low; occasional checks needed | Low; replace canisters as needed | Moderate; requires battery checks or charging |

| El mejor caso de uso | Regular use at home or shop | Emergency repairs on-the-go | High-volume shops or professional teams |

CO2 inflators are a popular choice for cyclists needing quick fixes during rides. They use small, disposable canisters to inflate tires rapidly, making them ideal for emergency situations. The primary advantage of CO2 inflators is their speed; they can fully inflate a tire in seconds. However, their reliance on single-use canisters can lead to recurring costs and waste, making them less sustainable for businesses focused on eco-friendliness. Additionally, if a cyclist needs to inflate multiple tires, they must carry several canisters, which can be cumbersome.

Electric pumps represent a modern alternative to traditional tire inflation methods. These devices offer automatic inflation and can achieve precise PSI levels without manual effort. The convenience of simply plugging in and letting the pump do the work makes electric pumps appealing, especially for high-volume bicycle shops or professional teams. However, the initial cost can be significantly higher than manual pumps, and they may require regular maintenance, such as battery checks or charging. This might deter some individual cyclists or smaller businesses that prefer budget-friendly solutions.

When choosing the right tire inflation method, B2B buyers should consider their specific needs, including the volume of use, cost constraints, and the target market’s preferences. For businesses that require quick, on-the-go solutions for cyclists, CO2 inflators could be ideal. Conversely, for those who prioritize precision and are willing to invest in equipment, electric pumps may offer the best return on investment. Traditional inflation methods remain reliable for routine maintenance and general use, making them a staple for most bike shops. Ultimately, understanding the strengths and weaknesses of each solution will help businesses make informed purchasing decisions that align with their operational goals.

When it comes to inflating road bike tires, understanding the technical specifications is essential for ensuring safety, performance, and longevity. Here are several critical properties to consider:

Valve Type (Presta vs. Schrader)

– Definición: The two primary valve types used in bike tires are Presta and Schrader. Presta valves are slimmer, designed for road bikes, while Schrader valves are wider and typically found on mountain bikes.

– B2B Importance: Knowing the valve type is crucial for selecting compatible pumps and accessories. This knowledge can prevent costly mistakes and product returns, ensuring that buyers can efficiently manage inventory.

Inflation Pressure (PSI)

– Definición: PSI (pounds per square inch) refers to the recommended air pressure for a tire, which is usually indicated on the tire sidewall.

– B2B Importance: Adhering to the correct PSI is essential for optimal tire performance, affecting ride quality, safety, and tire lifespan. B2B buyers must ensure that products meet these specifications to avoid liability issues.

Material Grade of Inner Tubes

– Definición: Inner tubes are often made from butyl rubber or latex, with various grades affecting durability and performance.

– B2B Importance: Selecting the right material grade can influence the cost and quality of the product. Buyers need to understand these differences to make informed purchasing decisions, especially when dealing with high-volume orders.

Pump Compatibility

– Definición: Not all pumps work with both valve types. Compatibility often involves the pump head design, which may require adapters for different valves.

– B2B Importance: Buyers must consider pump compatibility when sourcing products, as this can impact inventory management and customer satisfaction. A comprehensive understanding of compatibility will streamline operations.

Pressure Gauge Accuracy

– Definición: Pressure gauges on pumps indicate the current PSI and should be calibrated for accuracy.

– B2B Importance: Accurate pressure gauges are vital for safety and performance. Buyers should prioritize products with reliable gauges to reduce the risk of improper inflation, which can lead to accidents or product failures.

Understanding industry jargon is critical for effective communication and negotiation in the B2B landscape. Here are some common terms:

OEM (fabricante de equipos originales)

– Definición: Refers to companies that produce parts or equipment that may be marketed by another manufacturer.

– Importancia: For B2B buyers, partnering with OEMs can ensure high-quality components that meet specific performance standards, essential for building a reputable product line.

MOQ (Cantidad mínima de pedido)

– Definición: Cantidad mínima de un producto que un proveedor está dispuesto a vender.

– Importancia: Understanding MOQ is crucial for inventory planning and cost management. Buyers need to align their purchasing strategy with supplier requirements to optimize stock levels.

RFQ (solicitud de presupuesto)

– Definición: A document sent to suppliers to solicit pricing information for specific products or services.

– Importancia: An RFQ helps buyers compare offers and negotiate better terms. It’s an essential step in the procurement process that influences pricing strategies.

Incoterms (Términos comerciales internacionales)

– Definición: A set of international rules that define the responsibilities of sellers and buyers for the delivery of goods.

– Importancia: Familiarity with Incoterms helps B2B buyers understand shipping responsibilities, costs, and risks, facilitating smoother international transactions.

SKU (unidad de mantenimiento de existencias)

– Definición: A unique identifier for each distinct product and service that can be purchased.

– Importancia: SKUs aid in inventory management and tracking, helping businesses streamline operations and improve order fulfillment efficiency.

By grasping these technical properties and trade terms, B2B buyers can make more informed decisions, optimize their procurement processes, and enhance customer satisfaction in the competitive road bike tire market.

The global market for road bike tire inflation is experiencing significant growth, driven by increasing cycling participation and a heightened focus on health and fitness. Emerging markets in Africa and South America are witnessing a surge in cycling activities, fueled by urbanization and the need for sustainable transport options. This trend is further supported by government initiatives promoting cycling as a viable mode of transportation. In the Middle East, countries like Saudi Arabia are investing in cycling infrastructure, enhancing the appeal of road biking.

Technological advancements are reshaping the sourcing landscape, with innovations in pump designs and materials. For instance, the introduction of digital pressure gauges and smart pumps that connect to mobile apps is becoming increasingly popular. These technologies not only provide accurate readings but also enhance user experience, particularly for novices. Additionally, the rise of e-commerce platforms has simplified the procurement process for B2B buyers, allowing them to source a variety of inflation tools and accessories from global suppliers with ease.

International buyers should also be aware of regional preferences. For example, while Presta valves are predominantly used in Europe, other regions may favor different valve types. Understanding these nuances can aid in effective sourcing strategies, ensuring that products meet local demand and specifications.

Illustrative image related to how to inflate road bike tires

Sustainability has become a critical factor for B2B buyers in the road bike tire inflation market. Companies are increasingly expected to adopt environmentally friendly practices throughout their supply chains. This includes sourcing materials that have a lower environmental impact and ensuring that production processes adhere to ethical standards.

For instance, many manufacturers are now focusing on recyclable materials for pumps and accessories, contributing to a circular economy. Certifications such as ISO 14001 for environmental management systems are becoming essential for suppliers looking to establish credibility in the market. Buyers should prioritize partnerships with manufacturers who demonstrate a commitment to sustainability, as this can enhance brand reputation and customer loyalty.

Furthermore, consumers are more inclined to support brands that align with their values regarding environmental responsibility. This trend is particularly pronounced in regions like Europe, where eco-consciousness is a significant driver of purchasing decisions. Thus, integrating sustainability into procurement strategies not only addresses compliance and ethical considerations but also positions businesses favorably in a competitive market.

Illustrative image related to how to inflate road bike tires

The evolution of the road bike tire inflation sector reflects broader technological advancements and changing consumer preferences. Historically, tire inflation relied heavily on manual pumps, which posed challenges in terms of efficiency and user-friendliness. However, the advent of high-pressure track pumps revolutionized the process, enabling cyclists to inflate tires quickly and accurately.

In recent years, the introduction of mini pumps and CO2 inflators has further diversified the market, catering to the needs of cyclists who require portable solutions for on-the-go inflation. The rise of digital technology has also influenced the sector, with smart pumps that offer precise pressure readings and connectivity features gaining traction among tech-savvy consumers.

As cycling continues to gain popularity across various demographics, the market for road bike tire inflation is expected to continue evolving, driven by innovations that enhance convenience and performance. B2B buyers should stay informed about these trends to effectively navigate the changing landscape and capitalize on new opportunities.

How do I inflate a road bike tire properly?

To inflate a road bike tire, first identify the valve type, which is typically a Presta valve for road bikes. Unscrew the top of the valve to open it fully, then attach the pump head securely. Use a track pump for the best results, monitoring the pressure gauge to ensure you reach the recommended PSI indicated on the tire sidewall. Avoid over-inflating, as this can lead to tire blowouts and damage.

What is the best pump for inflating road bike tires?

The ideal pump for inflating road bike tires is a track pump, which offers high capacity and ease of use. Track pumps can inflate tires to high pressures quickly, making them perfect for pre-ride setups. If portability is a concern, a mini pump can be a good alternative for emergencies, although it requires more effort to achieve the same pressure. Ensure the pump has a dual head for compatibility with Presta valves.

What should I consider when sourcing bike tire pumps for resale?

When sourcing bike tire pumps for resale, consider factors such as pump type (track vs. mini), compatibility with valve types, build quality, and ease of use. Additionally, assess the supplier’s reputation, production capacity, and ability to meet your minimum order quantities (MOQ). Look for suppliers that offer customization options to align with your brand and target market preferences.

How can I ensure quality assurance (QA) for bike tire pumps?

To ensure quality assurance for bike tire pumps, establish clear specifications and performance standards with your supplier. Request samples for testing before placing a bulk order. Implement regular inspections during production and after delivery to ensure compliance with quality standards. Collaborating with suppliers who have ISO certifications or similar quality management systems can also enhance product reliability.

What are common payment terms when purchasing bike accessories?

Common payment terms for purchasing bike accessories, including tire pumps, may include options such as 30% upfront and 70% upon delivery, or full payment before shipment. It is crucial to negotiate terms that align with your cash flow and risk tolerance. Additionally, consider using secure payment methods like letters of credit or escrow services to protect your investment, especially when dealing with international suppliers.

What logistics considerations should I keep in mind for importing bike tire pumps?

When importing bike tire pumps, consider shipping methods (air vs. sea), customs duties, and import regulations specific to your target market. Assess the total landed cost, including shipping, insurance, and taxes, to determine the viability of your pricing strategy. Partnering with a reliable freight forwarder can streamline the logistics process and help navigate any complexities in international shipping.

Are there customization options available for bike tire pumps?

Yes, many suppliers offer customization options for bike tire pumps, including branding with your logo, specific color schemes, or unique features tailored to your market’s needs. Discuss your requirements with potential suppliers early in the negotiation process to understand their capabilities and any associated costs. Customization can enhance your product’s appeal and differentiate it in a competitive marketplace.

What are the best practices for supplier vetting in the bicycle accessory industry?

Best practices for supplier vetting in the bicycle accessory industry include conducting thorough background checks, reviewing customer testimonials, and assessing product quality through samples. Verify certifications and compliance with international safety standards, especially for products sold in diverse markets. Establishing strong communication channels and visiting the supplier’s facilities, if possible, can also help build trust and ensure a reliable partnership.

Dominio: roadcyclinguk.com

Inscrito: 2004 (21 años)

Introducción: Types of pumps: Track pumps, Mini pumps, Mini inflators, Air compressors. Valve types: Presta valves, Schrader valves. Notable products: Birzman pump (requires unscrewing for Schrader), PRO pump (dual head for Presta and Schrader), SKS Airboy CO2 (combines mini pump and CO2 inflator). Track pumps inflate to high pressures (up to 160psi), Mini pumps are portable for mid-ride punctures, Mini inflato…

Dominio: reddit.com

Matriculado: 2005 (20 años)

Introducción: The user mentions having a “pretty shitty pump” and expresses the need for a better pump with a gauge. A suggestion is made for the Topeak Joe Blow as a decent pump option.

Dominio: schwinnbikes.com

Inscrito: 2003 (22 años)

Introducción: 1. Tire Inflation Pressure: Each tire has a maximum inflation recommendation labeled on the side, usually in PSI or bars. It’s crucial to check this before pumping to avoid pinch flats or poor traction.

2. Valve Types: There are two main valve types:

– Presta: Commonly found on higher-end and road bikes.

– Schrader: Similar to car valves, used on many mountain, hybrid, and kids’ bike tir…

Dominio: bicicletas.stackexchange.com

Inscrito: 2009 (16 años)

Introducción: Presta valve, floor pump, tire pressure of 110 psi (7.5 atm), pump gauge up to 100 psi, valve stem length issues, valve adapter option, difficulty in attaching pump head, need for proper valve positioning (12 o’clock or 6 o’clock), potential for tire pressure gauge not showing pressure.

In conclusion, mastering the art of inflating road bike tires is not just about ensuring a smooth ride; it also emphasizes the importance of strategic sourcing in the cycling industry. By understanding the nuances of valve types, pump compatibility, and inflation techniques, B2B buyers can enhance their product offerings and cater to the specific needs of their markets.

Investing in quality pumps and accessories that accommodate both Presta and Schrader valves can streamline operations and improve customer satisfaction. Moreover, sourcing products that emphasize durability and ease of use will resonate well with consumers, particularly in regions like Africa, South America, the Middle East, and Europe, where cycling is gaining popularity as a sustainable mode of transport.

As you look to the future, consider expanding your product lines to include innovative inflation solutions, such as CO2 inflators or multi-use pumps, which appeal to the growing community of cycling enthusiasts. By prioritizing strategic sourcing, you position your business to not only meet current demands but also to lead in the evolving landscape of the cycling industry. Embrace the opportunity to enhance your inventory and drive growth in this vibrant market.

La información facilitada en esta guía, incluido el contenido relativo a fabricantes, especificaciones técnicas y análisis de mercado, tiene únicamente fines informativos y educativos. No constituye asesoramiento profesional en materia de adquisiciones, asesoramiento financiero ni asesoramiento jurídico.

Aunque hemos hecho todo lo posible por garantizar la exactitud y actualidad de la información, no nos hacemos responsables de posibles errores, omisiones o información obsoleta. Las condiciones del mercado, los detalles de las empresas y las normas técnicas están sujetos a cambios.

Illustrative image related to how to inflate road bike tires

Los compradores B2B deben llevar a cabo su propia diligencia debida independiente y exhaustiva antes de tomar cualquier decisión de compra. Esto incluye ponerse en contacto directamente con los proveedores, verificar las certificaciones, solicitar muestras y buscar asesoramiento profesional. El riesgo de confiar en la información contenida en esta guía es responsabilidad exclusiva del lector.