In today’s global market, sourcing the nearest air pump can pose significant challenges for international B2B buyers, particularly in diverse regions such as Africa, South America, the Middle East, and Europe. Buyers often grapple with varying regulations, supply chain complexities, and the need for reliable access to quality equipment. This guide aims to streamline the procurement process by providing an in-depth exploration of air pump types, applications, and essential supplier vetting strategies.

From portable air compressors ideal for personal use to industrial-grade inflators for commercial applications, understanding the specific needs of your target market is crucial. This comprehensive resource will cover the diverse functionalities of air pumps, helping buyers assess which models best align with their operational requirements. Additionally, we will delve into cost considerations, including bulk purchasing options and long-term investment value.

By equipping B2B buyers with actionable insights and a clear framework for making informed purchasing decisions, this guide empowers businesses to optimize their sourcing strategies. Whether you’re looking to enhance fleet maintenance in Saudi Arabia or improve logistics in Vietnam, understanding the landscape of air pump suppliers will enable you to make choices that elevate your operational efficiency and customer satisfaction.

| Tipo Nombre | Principales rasgos distintivos | Aplicaciones B2B principales | Breves pros y contras para los compradores |

|---|---|---|---|

| Portable Air Compressors | Compact, battery-operated or plug-in, various PSI settings | Automotive maintenance, construction, outdoor activities | Pros: High portability, versatile use. Contras: Limited capacity for large jobs. |

| Stationary Air Pumps | High-capacity, often powered by electricity, fixed installation | Manufacturing, automotive repair shops | Pros: Continuous operation, high output. Contras: Requires dedicated space, higher initial investment. |

| Free Air Stations | Publicly accessible, usually at gas stations, no cost for users | Community services, automotive services | Pros: No cost for users, convenient locations. Contras: Availability can vary, often limited to specific hours. |

| Bicycle Repair Pumps | Manual or foot-operated, designed for bicycle tires | Bike shops, community cycling events | Pros: Low cost, easy maintenance. Contras: Slower operation, limited to smaller tires. |

| Inflatable Air Pumps | Designed for inflating larger items (e.g., air mattresses, sports equipment) | Recreational facilities, events | Pros: Quick inflation, versatile for various items. Contras: Less useful for vehicles, can be bulky. |

Portable air compressors are essential tools for businesses that require mobility and versatility. These devices are typically compact, battery-operated, or plug-in, making them ideal for automotive maintenance, construction sites, and outdoor activities. When considering a purchase, B2B buyers should evaluate the PSI settings, battery life, and ease of transport. While they provide high portability and adaptability for various tasks, their limited capacity makes them less suitable for large-scale operations.

Stationary air pumps are designed for high-capacity, continuous operation, making them a staple in manufacturing and automotive repair shops. These pumps are usually powered by electricity and require a fixed installation, which means they need dedicated space. Buyers should consider factors such as power supply, maintenance needs, and output pressure when selecting a stationary air pump. While they offer significant output and efficiency, the initial investment can be higher compared to portable options.

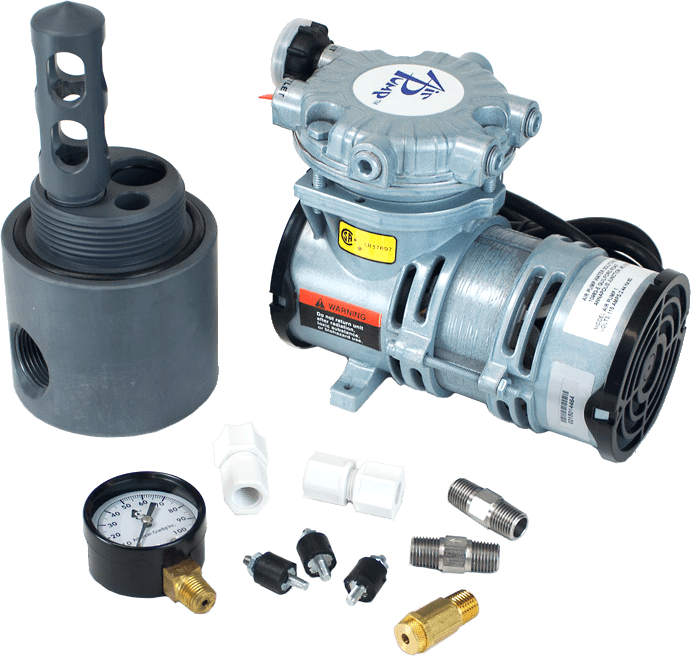

Free air stations, commonly found at gas stations, provide a cost-effective solution for businesses and consumers alike. These stations offer complimentary air for tires, making them a valuable community service. Businesses can leverage these locations to enhance customer satisfaction and loyalty. However, the availability of free air can be inconsistent and typically limited to specific hours. B2B buyers should assess the reliability and accessibility of these stations for their operational needs.

Bicycle repair pumps are designed for inflating bicycle tires and are often found in bike shops and community cycling events. These manual or foot-operated pumps are low-cost and easy to maintain, making them ideal for businesses focused on cycling. When purchasing, buyers should consider the pump’s durability and ease of use. While they are economical and effective for smaller tires, their slower operation may not meet the needs of high-traffic cycling areas.

Inflatable air pumps are specialized for inflating larger items, such as air mattresses and sports equipment. These pumps are commonly used in recreational facilities and events where quick inflation is necessary. B2B buyers should evaluate the pump’s inflation speed, capacity, and portability. While they offer rapid inflation and versatility, their bulkiness and limited utility for vehicle tires may deter some buyers from investing in them for broader applications.

| Industria/Sector | Specific Application of nearest air pump | Valor/beneficio para la empresa | Consideraciones clave para el aprovisionamiento de esta aplicación |

|---|---|---|---|

| Reparación de automóviles | Inflado y mantenimiento de neumáticos | Improved customer service and retention | Reliability of pump, ease of use, maintenance requirements |

| Logistics and Transport | Fleet vehicle tire management | Enhanced safety and reduced operational costs | Durability, portability, and compatibility with various tires |

| Fabricación | Pneumatic tools and machinery operation | Increased efficiency and productivity | Power requirements, air pressure capacity, and safety features |

| Construcción | Inflating construction equipment and tools | Time savings and increased project efficiency | Mobility, air volume output, and ruggedness for outdoor use |

| Recreational Services | Air supply for sports equipment and activities | Enhanced customer experience and service offerings | Ease of access, speed of inflation, and safety standards |

In the automotive repair sector, nearest air pumps are essential for tire inflation and maintenance. Tire health is crucial for vehicle performance and safety, making regular pressure checks a standard service offering. By providing easy access to air pumps, repair shops can enhance customer satisfaction, as clients appreciate the convenience of quick tire services. B2B buyers in this sector should consider the reliability and user-friendliness of the pumps, as well as their maintenance requirements to ensure a smooth operation.

In logistics and transport, nearest air pumps are vital for managing fleet vehicle tire pressure. Proper tire inflation not only ensures safety but also improves fuel efficiency, reducing operational costs. Fleet operators can benefit from having a reliable air supply at their depots or along transportation routes. When sourcing pumps, businesses should focus on durability and portability, ensuring that the pumps can withstand constant use and varying environmental conditions.

Manufacturing industries utilize nearest air pumps primarily for operating pneumatic tools and machinery. Consistent air pressure is critical for the efficiency and productivity of these tools, which are often used in assembly lines and production settings. By ensuring a steady air supply, manufacturers can minimize downtime and enhance operational efficiency. Buyers in this sector should prioritize pumps that meet specific power requirements, have adequate air pressure capacity, and include safety features to prevent accidents.

Construction companies rely on nearest air pumps to inflate various tools and equipment, such as pneumatic nailers and compressors. Quick inflation can significantly reduce project timelines and enhance on-site productivity. For B2B buyers in construction, sourcing pumps that are mobile and capable of delivering high air volume output is essential. Additionally, the ruggedness of the pump is crucial, as construction environments can be harsh and demanding.

Recreational services, such as parks and sports facilities, use nearest air pumps for inflating equipment like sports balls and inflatable toys. Providing easy access to air pumps enhances the customer experience, encouraging more visitors and repeat business. When sourcing these pumps, businesses should consider ease of access and the speed of inflation, as well as compliance with safety standards to ensure a positive user experience.

El problema: For B2B buyers managing fleets of vehicles or heavy machinery, finding a reliable source for air pumps can be a significant challenge. Many businesses operate in regions where air pump availability is inconsistent, leading to increased downtime for vehicles that require regular tire inflation. The frustration is compounded when drivers waste time searching for air pumps that either do not exist or are malfunctioning, resulting in productivity losses and additional operational costs.

La solución: To overcome this challenge, B2B buyers should consider establishing partnerships with local service stations or tire shops that consistently offer air pump services. A proactive approach involves creating a database of vetted air pump locations that can be easily accessed by drivers through a mobile app or internal software system. Additionally, businesses can negotiate service agreements with specific stations to ensure they are prioritized for air services. Leveraging technology, such as GPS-enabled apps that locate nearby air pumps and provide real-time availability updates, can significantly streamline operations and reduce downtime.

El problema: The rising costs associated with using commercial air pump services can strain the budgets of businesses, especially small to medium-sized enterprises. Paying for air services at gas stations or tire shops can add up quickly, particularly for companies that require frequent tire maintenance for their vehicles. This financial burden can hinder the ability to allocate funds for other essential operational needs.

La solución: A cost-effective strategy for B2B buyers is to invest in portable air compressors for their fleet. By equipping vehicles with portable inflators, businesses can eliminate reliance on external air services, thereby controlling expenses. Furthermore, companies can explore bulk purchasing options or leasing agreements for air compressors, which can reduce initial investment costs. Training drivers on how to properly use these devices ensures that tire inflation is handled efficiently on-site, leading to long-term savings and better budget management.

El problema: Another common pain point for B2B buyers is the inconsistent air quality available at various pumps, which can lead to improper tire inflation. Suboptimal air pressure not only affects vehicle performance but can also pose safety risks and increase wear and tear on tires, leading to costly repairs. Businesses operating in diverse geographical regions may face this issue more acutely, where air pump quality can vary widely.

La solución: To address air quality concerns, B2B buyers should implement a quality assurance protocol for their air pump sources. This could involve regular audits of air pump locations to ensure they maintain equipment to a high standard and provide clean, dry air. Buyers can also collaborate with manufacturers to install high-quality air pumps at strategic locations, ensuring that all pumps meet specific standards for air quality. Additionally, educating drivers about the importance of monitoring tire pressure and recognizing signs of poor inflation can further mitigate risks associated with air quality issues. Investing in pressure monitoring systems that alert drivers when tire pressure falls below optimal levels can help maintain vehicle performance and safety.

When selecting materials for air pumps, particularly for international markets in Africa, South America, the Middle East, and Europe, it is essential to consider the properties, advantages, and limitations of common materials. This analysis will cover four prevalent materials: aluminum, stainless steel, thermoplastics, and rubber.

Illustrative image related to nearest air pump

Aluminum is a lightweight, corrosion-resistant metal that is commonly used in air pump manufacturing. Its key properties include a high strength-to-weight ratio and good thermal conductivity, allowing for efficient heat dissipation during operation. Aluminum pumps can typically handle moderate pressure and temperature ranges, making them suitable for various applications.

Pros y contras: Aluminum is durable and cost-effective, but it can be less resistant to extreme temperatures compared to other metals. Manufacturing complexity is relatively low, allowing for mass production. However, its susceptibility to corrosion in certain environments (e.g., coastal areas) can be a limitation.

Impacto en la aplicación: Aluminum is compatible with air and non-corrosive gases but may not be suitable for aggressive chemicals. International buyers should ensure compliance with local standards, such as ASTM or DIN, particularly in regions with stringent environmental regulations.

Stainless steel is renowned for its exceptional corrosion resistance and durability, making it a preferred choice for high-performance air pumps. Key properties include high tensile strength and the ability to withstand extreme temperatures and pressures, which are critical for industrial applications.

Illustrative image related to nearest air pump

Pros y contras: The primary advantage of stainless steel is its longevity and reliability, even in harsh environments. However, it is generally more expensive than aluminum and can present manufacturing challenges due to its hardness. Despite these challenges, stainless steel is often favored for applications requiring stringent hygiene standards, such as in food processing or pharmaceuticals.

Impacto en la aplicación: Stainless steel is compatible with a wide range of gases and liquids, making it versatile. B2B buyers should consider compliance with international standards like JIS or ISO, especially in regions with high regulatory scrutiny.

Thermoplastics, such as polycarbonate or nylon, are increasingly used in air pump applications due to their lightweight and flexible properties. These materials exhibit good chemical resistance and can be molded into complex shapes, enhancing design versatility.

Pros y contras: Thermoplastics are generally more affordable than metals and offer ease of manufacturing. However, they may not withstand high temperatures or pressures as effectively as metals. Their durability can vary significantly based on the specific type of plastic used.

Impacto en la aplicación: Thermoplastics are suitable for applications involving air and non-corrosive gases. Buyers from emerging markets should assess the availability of specific thermoplastics that meet local standards and regulations.

Rubber is primarily used for seals and gaskets in air pumps due to its excellent elasticity and ability to form tight seals. Key properties include resistance to wear and tear, as well as the ability to withstand various environmental conditions.

Pros y contras: Rubber is cost-effective and provides excellent sealing capabilities, but it can degrade over time when exposed to ozone or UV light. Additionally, the manufacturing process can be complex, particularly when creating custom shapes.

Impacto en la aplicación: Rubber is compatible with air and many gases but may not be suitable for aggressive chemicals. B2B buyers should consider the specific type of rubber used, ensuring it complies with industry standards relevant to their region.

| Material | Typical Use Case for nearest air pump | Ventajas clave | Principales desventajas/limitaciones | Coste relativo (Bajo/Medio/Alto) |

|---|---|---|---|---|

| Aluminio | Lightweight air pumps | Elevada relación resistencia/peso | Susceptible to corrosion | Medio |

| Acero inoxidable | High-performance industrial pumps | Durabilidad excepcional | Mayor coste y complejidad de fabricación | Alta |

| Thermoplastics | Flexible, lightweight designs | Cost-effective and versatile | Limited high-temperature performance | Bajo |

| Goma | Juntas y empaquetaduras | Excelente capacidad de sellado | Degrades under UV exposure | Bajo |

This material selection guide provides crucial insights for international B2B buyers, helping them make informed decisions based on performance, cost, and compliance with regional standards.

Manufacturing air pumps, particularly those designed for automotive and bicycle applications, involves a series of well-defined stages that ensure the product meets the necessary quality and performance standards. Understanding these processes is crucial for international B2B buyers who seek reliable suppliers, especially in regions like Africa, South America, the Middle East, and Europe. This guide provides an in-depth look into the manufacturing processes and quality assurance protocols relevant to air pumps.

The manufacturing of air pumps begins with the careful selection of materials. Common materials include high-grade plastics for the body and rubber for seals and hoses. These materials must be durable, resistant to wear, and able to withstand varying pressure levels. Before production, these materials undergo rigorous testing to verify their quality and suitability.

Manufacturers often source materials from certified suppliers to ensure compliance with international standards. This is particularly important for B2B buyers in regions with stringent import regulations, as they need to ensure that all components meet local and international quality benchmarks.

The forming stage involves shaping the materials into the desired components of the air pump. Techniques such as injection molding are commonly used for plastic parts, allowing for precise dimensions and consistent quality. For rubber components, processes like extrusion or compression molding are utilized.

Once the components are formed, they are subjected to initial quality checks to ensure they meet specifications. This stage is critical, as any defects can compromise the performance and safety of the air pump.

After forming, the assembly process begins. This typically involves the integration of various components such as the motor, pressure gauge, and hoses. Automated assembly lines are often employed to enhance efficiency and minimize human error. Each assembly station is equipped with tools and fixtures designed to ensure accurate assembly.

During assembly, manufacturers implement in-process quality control (IPQC) measures, which include visual inspections and functional tests to catch any issues before the product moves to the next stage. This proactive approach reduces the likelihood of defects in the final product.

The finishing stage includes surface treatments and final inspections. Components may undergo painting, coating, or other treatments to enhance durability and aesthetics. After finishing, each air pump is subjected to final quality checks, including pressure tests and operational tests, to ensure it meets performance specifications.

Packaging is also a crucial part of this stage, as it protects the product during shipping and enhances presentation for retail. Proper labeling with compliance marks, such as CE or API certifications, is essential for international markets.

Quality assurance in air pump manufacturing is governed by various international standards, with ISO 9001 being one of the most recognized. This standard outlines the requirements for a quality management system and emphasizes continuous improvement and customer satisfaction. B2B buyers should verify that suppliers are ISO 9001 certified, as this indicates a commitment to maintaining high-quality standards.

Illustrative image related to nearest air pump

In addition to ISO certifications, industry-specific standards such as CE marking (for products sold in Europe) and API standards (for certain industrial applications) are critical for ensuring compliance with safety and performance regulations.

Quality control in air pump manufacturing is typically structured around several key checkpoints:

Each checkpoint plays a vital role in maintaining the integrity of the final product, and B2B buyers should inquire about the specific QC processes their suppliers employ.

B2B buyers can utilize several methods to verify the quality control measures of potential suppliers:

Auditorías de proveedores: Conducting on-site audits allows buyers to assess the manufacturing environment, processes, and adherence to quality standards. This can provide invaluable insights into the supplier’s capabilities.

Informes de calidad: Requesting documentation such as quality inspection reports and certificates of compliance can help buyers understand the supplier’s quality assurance processes.

Inspecciones de terceros: Engaging third-party inspection services can provide an unbiased assessment of the supplier’s quality control measures. This is particularly useful for buyers in regions where local regulations may differ.

International B2B buyers should be aware that quality standards can vary significantly across regions. For example, while CE marking is crucial for products entering the European market, buyers in the Middle East may need to comply with different local certifications. Understanding these nuances is essential for ensuring that products meet local regulations and can be sold without issues.

Furthermore, buyers should also consider the implications of logistics and supply chain management. Different regions may have specific challenges related to the transportation of goods, which can impact the overall quality of the product upon arrival.

Illustrative image related to nearest air pump

For B2B buyers, understanding the manufacturing processes and quality assurance standards of air pumps is critical for making informed purchasing decisions. By focusing on the material preparation, forming, assembly, and finishing stages, alongside rigorous quality control measures, buyers can ensure they partner with reliable suppliers. Verifying compliance with international standards and employing effective supplier verification methods can further safeguard against quality issues, ensuring a successful and sustainable supply chain.

The following guide serves as a practical checklist for B2B buyers seeking to procure the nearest air pump. This resource is designed to streamline the sourcing process, ensuring that companies can efficiently locate and acquire air pumps that meet their operational needs.

Understanding the specific requirements for your air pump is crucial. Assess the intended use—whether it’s for automotive, industrial, or recreational purposes. Each application may have different pressure and volume requirements, so clarify what you need to avoid overspending or purchasing inappropriate equipment.

Conducting thorough research on potential suppliers is essential. Utilize online resources, trade directories, and industry networks to identify manufacturers or distributors that specialize in air pumps.

Before proceeding with any supplier, it’s important to vet their credentials. This includes checking for certifications, industry standards compliance, and customer reviews.

Once you have a shortlist of suppliers, examine the technical specifications of the air pumps they offer. This evaluation will help ensure that the equipment aligns with your operational needs.

After narrowing down your options, request quotes from multiple suppliers. This will provide insight into the price range and help identify the best value for your investment.

Once you’ve selected a preferred supplier, engage in negotiations to finalize terms and conditions. This step is critical for establishing a mutually beneficial agreement.

Illustrative image related to nearest air pump

After agreeing on terms, finalize the purchase and prepare for logistics. This includes planning for delivery and installation.

Following this checklist will aid B2B buyers in making informed decisions when sourcing the nearest air pump, ensuring that they find equipment that meets their operational needs efficiently and effectively.

When sourcing air pumps, understanding the cost structure is crucial for B2B buyers. The primary components include:

Materiales: The type of materials used in manufacturing air pumps, such as metals and plastics, significantly affects the cost. Higher quality materials may incur a premium but can enhance durability and performance.

Trabajo: Labor costs vary based on the region of manufacturing. Countries with lower labor costs may offer more competitive pricing, but it’s essential to balance this with quality standards.

Gastos generales de fabricación: This encompasses indirect costs such as factory utilities, equipment depreciation, and salaries of non-production staff. Efficient manufacturing processes can help reduce these costs.

Herramientas: Initial setup costs for molds and tools can be substantial, especially for custom or specialized air pumps. Buyers should consider these costs as part of the overall investment.

Control de calidad: Implementing robust QC measures is vital for ensuring product reliability. While this may add to the upfront costs, it can prevent expensive returns and replacements in the long run.

Logística: Transportation costs, including shipping and warehousing, can vary significantly based on the supplier’s location and the chosen Incoterms. Understanding these costs is essential for accurate budgeting.

Margen: Suppliers typically add a margin to cover their expenses and profit. This margin can vary based on competition, demand, and the supplier’s market positioning.

Several factors influence the pricing of air pumps, particularly in international B2B transactions:

Volumen/MOQ: Minimum Order Quantities (MOQs) can affect pricing. Larger orders often attract discounts, making it essential for buyers to assess their needs accurately.

Especificaciones y personalización: Custom air pumps tailored to specific requirements can incur higher costs. Buyers should clearly define their specifications to avoid unexpected expenses.

Materiales: The choice of materials directly correlates with pricing. Premium materials may lead to higher costs but can offer better performance and longevity.

Certificaciones de calidad: Compliance with international quality standards may increase costs but is often a requirement in regulated markets, ensuring safety and reliability.

Factores del proveedor: The reputation and reliability of the supplier can influence pricing. Established suppliers may charge more due to their proven track record, while new entrants might offer lower prices to gain market share.

Incoterms: The chosen Incoterms dictate the responsibility for shipping costs and risks. Understanding these terms is vital for calculating total costs effectively.

Negotiation is a critical component of B2B purchasing, particularly in international markets. Here are some tips:

Illustrative image related to nearest air pump

Conduct Thorough Market Research: Understanding market rates and competitor offerings can provide leverage in negotiations.

Leverage Volume Discounts: If feasible, consolidate purchases to meet MOQs and negotiate better pricing.

Discuss Payment Terms: Flexible payment options can sometimes lead to better pricing arrangements.

Evaluar el coste total de propiedad (TCO): Consider not just the purchase price but the lifetime costs associated with maintenance, energy efficiency, and potential replacements.

Establecer relaciones con los proveedores: Establishing a strong rapport can lead to better terms and potential future savings.

International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should consider several pricing nuances:

Currency Fluctuations: Exchange rates can impact overall costs. Contracts should account for potential fluctuations.

Import Duties and Taxes: These can significantly increase the total cost of imported goods. Understanding local regulations is crucial.

Logistics and Shipping Times: Longer shipping times can lead to increased costs due to inventory holding. Buyers should factor in these elements when planning orders.

Diferencias culturales: Negotiation styles and purchasing processes can vary by region, so understanding local practices can facilitate smoother transactions.

Prices for air pumps can vary widely based on the factors discussed above. It is essential for buyers to obtain quotes from multiple suppliers and conduct thorough due diligence to ensure they receive competitive and fair pricing tailored to their specific needs.

In the quest for efficient tire inflation solutions, B2B buyers often seek alternatives to the nearest air pump. While traditional air pumps are widely available, several other methods and technologies can fulfill the same purpose. This analysis will compare the nearest air pump against two viable alternatives: portable air compressors and free air stations.

Illustrative image related to nearest air pump

| Aspecto comparativo | Nearest Air Pump | Compresor de aire portátil | Free Air Stations |

|---|---|---|---|

| Rendimiento | Moderate, depends on location and availability | High, provides consistent pressure and faster inflation | Variable, often dependent on maintenance and local availability |

| Coste | Typically free or low cost, may require payment in some areas | Initial investment required, generally ranges from $30 to $150 | Free, but may involve travel costs to reach the location |

| Facilidad de aplicación | Simple, usually requires no setup | Requires some knowledge for optimal use | Very easy, just drive to the location |

| Mantenimiento | Minimal, relies on the host’s upkeep | Moderate, requires occasional maintenance to ensure functionality | Low, depends on the hosting entity’s upkeep |

| El mejor caso de uso | Quick, on-the-go inflation for nearby users | Ideal for users needing frequent tire inflation or in remote locations | Suitable for occasional users with no immediate need for a pump |

Portable air compressors offer a robust alternative to nearest air pumps. They are typically battery-operated or plug into a vehicle’s power source, making them versatile for various settings. The primary advantage is their performance; they can inflate tires quickly and consistently, regardless of location. However, the initial investment can be a downside, as quality compressors range from $30 to $150. Furthermore, users must ensure they understand how to operate the device correctly to avoid damage or inefficiency.

Free air stations, often located at gas stations or repair shops, represent another alternative that many users may overlook. The significant advantage of free air stations is the cost—these services are typically free for customers. However, their availability can be inconsistent, particularly in less urban areas, and users may need to travel to access them. Additionally, the quality of service can vary based on the maintenance of the air pump, which can lead to delays or inefficiencies.

When selecting the right tire inflation solution, B2B buyers should consider their specific needs. If frequent tire maintenance is required, investing in a portable air compressor may offer the best long-term value and convenience. Conversely, for those who prefer not to make an upfront investment, locating nearby free air stations can be a cost-effective solution. Ultimately, the decision will depend on factors such as budget, frequency of use, and the operational environment. Understanding these alternatives allows buyers to make informed choices that align with their operational requirements and cost considerations.

When sourcing air pumps, understanding their technical specifications is essential for making informed purchasing decisions. Here are some critical properties to consider:

Illustrative image related to nearest air pump

Calidad del material

The material grade of an air pump determines its durability and resistance to environmental factors. Common materials include high-grade plastics and metals like aluminum or stainless steel. Higher-grade materials may offer better longevity, which is crucial for businesses that rely on these pumps for continuous use.

Pressure Rating

This specification indicates the maximum pressure the pump can safely handle, typically measured in PSI (pounds per square inch). Understanding the pressure rating is vital for ensuring compatibility with the intended application, whether for inflating tires or other pneumatic needs. Selecting a pump with an appropriate pressure rating can prevent equipment failure and ensure safety.

Flow Rate

Measured in liters per minute (LPM) or cubic feet per minute (CFM), the flow rate indicates how quickly the pump can deliver air. A higher flow rate is advantageous for businesses needing to inflate multiple tires quickly or for large-scale applications. Evaluating flow rates can help organizations optimize operational efficiency and reduce downtime.

Fuente de energía

Air pumps can be powered through various means, including electric, battery-operated, or manual hand pumps. For B2B buyers, the choice of power source affects operational flexibility and convenience. Electric pumps might offer higher performance but require access to power sources, while battery-operated options provide portability.

Tamaño y portabilidad

The dimensions and weight of the pump are crucial factors, especially for businesses that need to transport the pump frequently. Compact and lightweight models are ideal for mobile service providers or companies with limited storage space.

Familiarizing yourself with industry jargon can streamline the purchasing process and facilitate better communication with suppliers. Here are several essential terms to know:

OEM (fabricante de equipos originales)

This term refers to companies that produce parts and equipment that may be marketed by another manufacturer. Understanding whether a supplier is an OEM can help buyers gauge the quality and authenticity of the air pumps they are sourcing.

MOQ (Cantidad mínima de pedido)

MOQ indicates the smallest quantity of product that a supplier is willing to sell. This is particularly important for B2B buyers, as it can affect inventory costs and purchasing strategies. Knowing the MOQ can help businesses plan their orders effectively.

RFQ (solicitud de presupuesto)

An RFQ is a document that invites suppliers to bid on specific products or services. For B2B buyers, issuing an RFQ allows them to compare prices and terms from multiple suppliers, ensuring they secure the best deal for their air pump needs.

Incoterms (Términos comerciales internacionales)

Incoterms define the responsibilities of buyers and sellers in international trade. Familiarity with these terms is crucial for B2B transactions, as they dictate who pays for shipping, insurance, and tariffs, helping to avoid misunderstandings and disputes.

Plazos de entrega

This term refers to the time taken from placing an order to receiving the product. Understanding lead times is critical for businesses that operate on tight schedules and need timely deliveries to maintain operations.

Periodo de garantía

The warranty period is the duration during which a product is guaranteed against defects. For B2B buyers, knowing the warranty terms can provide peace of mind and protect against unforeseen failures, which could impact business operations.

By grasping these key properties and terms, B2B buyers can make more informed decisions when sourcing air pumps, ultimately leading to better procurement strategies and enhanced operational efficiency.

The nearest air pump sector is witnessing significant evolution driven by global economic changes, technological advancements, and shifting consumer preferences. As vehicle ownership continues to rise in emerging markets across Africa, South America, and the Middle East, the demand for efficient and accessible air pumping solutions is increasing. Particularly in regions like Saudi Arabia and Vietnam, the push for improved infrastructure and services is creating opportunities for international B2B buyers.

Key trends include the integration of smart technology into air pump systems. Manufacturers are increasingly adopting IoT (Internet of Things) capabilities, allowing for real-time data collection and usage tracking. This tech-driven approach enhances the customer experience by providing convenience and reliability. Additionally, the rise of e-commerce platforms is facilitating access to a broader range of products, enabling buyers to compare features and prices easily.

Moreover, sustainability is becoming a pivotal factor in purchasing decisions. Buyers are increasingly looking for products that minimize environmental impact, which includes energy-efficient pumps and systems that use recyclable materials. The competitive landscape is also evolving, with both established brands and new entrants vying for market share by offering innovative solutions tailored to regional needs.

Sustainability and ethical sourcing are gaining traction as significant drivers in the nearest air pump sector. The environmental impact of manufacturing and disposing of air pumps cannot be overlooked, prompting buyers to seek suppliers committed to reducing their carbon footprint. This includes using eco-friendly materials and sustainable manufacturing processes that minimize waste.

Ethical supply chains are becoming increasingly important as international buyers demand transparency and accountability from their suppliers. Certifications such as ISO 14001 (Environmental Management) and other ‘green’ labels are essential for demonstrating compliance with sustainability standards. Furthermore, the use of biodegradable or recyclable materials in product design is a growing trend, appealing to environmentally conscious consumers.

The demand for sustainable products is not just a regulatory requirement but also a competitive advantage. Companies that prioritize sustainability often enjoy enhanced brand loyalty and can justify premium pricing due to their commitment to ethical practices. For B2B buyers, aligning with manufacturers who prioritize sustainability can lead to long-term partnerships and better market positioning.

The evolution of the nearest air pump sector can be traced back to the early days of automotive development when manual pumps dominated the market. As automobiles became more accessible, the need for convenient air inflation solutions emerged, leading to the introduction of electric and portable air pumps in the late 20th century.

The 21st century has seen rapid advancements in technology, with digital displays and automatic shut-off features becoming standard in many air pumps. This evolution reflects broader trends in consumer electronics, where connectivity and user-friendliness are paramount. Today, air pumps are not merely functional tools; they are increasingly integrated into the automotive ecosystem, with smart technologies enhancing their usability and efficiency.

Illustrative image related to nearest air pump

As the sector continues to innovate, international B2B buyers must stay informed about emerging technologies and market dynamics to leverage opportunities effectively. Understanding these historical shifts provides valuable context for making informed sourcing decisions in an ever-changing marketplace.

1. How do I find the nearest air pump for my business needs?

To locate the nearest air pump, utilize online mapping tools or apps that specialize in finding service stations and air pumps. Many websites and mobile applications allow you to enter your location to identify nearby gas stations, tire shops, or service centers that offer air pumps. For businesses operating in specific regions, consider reaching out to local suppliers or industry associations who can provide information about the most accessible air pump locations tailored to your operational needs.

2. What are the benefits of using a portable air compressor for my business?

A portable air compressor offers convenience and flexibility, enabling your business to inflate tires or equipment on-site without relying on external sources. This can save time and reduce downtime during operations, especially in industries like logistics and transportation. Additionally, portable compressors often come with various attachments, making them versatile for other inflation tasks. Investing in a high-quality compressor can also enhance your operational efficiency and reduce costs associated with frequent trips to external air sources.

3. What should I consider when vetting air pump suppliers for international trade?

When vetting air pump suppliers for international trade, consider factors such as their manufacturing capabilities, quality assurance processes, and compliance with international standards. Review their certifications and inspect their product quality through samples or third-party testing. Additionally, assess their reputation in the market by checking references and customer reviews. Understanding their logistics capabilities, including shipping times and costs, is crucial for maintaining your supply chain efficiency.

4. What are typical minimum order quantities (MOQs) for air pumps in international trade?

Minimum order quantities (MOQs) for air pumps can vary widely based on the supplier, the type of pump, and your specific requirements. Typically, MOQs can range from 100 to 1,000 units, especially for manufacturers looking to cover production costs. It’s essential to communicate your needs directly with potential suppliers, as some may offer flexibility in MOQs for first-time buyers or bulk orders. Negotiating favorable terms could lead to better pricing and terms for your business.

5. What payment terms should I expect when sourcing air pumps internationally?

Payment terms for international orders can vary significantly among suppliers, but common arrangements include partial upfront payments (usually 30-50%) with the balance due upon shipment or delivery. Some suppliers may offer net payment terms, allowing you to pay within 30 to 90 days after receiving the goods. It’s important to discuss and agree upon payment terms before finalizing orders, ensuring they align with your cash flow and financial planning strategies.

6. How can I ensure the quality of air pumps sourced from overseas suppliers?

To ensure quality, establish clear specifications and standards that the supplier must meet. Request samples before placing large orders and consider using third-party inspection services to evaluate the products during manufacturing or before shipment. Additionally, inquire about the supplier’s quality control processes and any certifications they hold. Building a strong relationship with your supplier and maintaining open lines of communication can also help address quality issues proactively.

7. What logistics considerations should I take into account when importing air pumps?

When importing air pumps, consider logistics aspects such as shipping methods, customs regulations, and delivery timelines. Assess whether air freight or sea freight is more suitable based on urgency and cost. Be aware of customs duties and tariffs that may apply, and ensure all paperwork is in order to avoid delays. Collaborating with a reputable logistics provider can streamline the process and help navigate potential challenges during shipping and customs clearance.

8. How do I handle potential disputes with air pump suppliers?

Handling disputes with air pump suppliers requires clear communication and documentation. Always refer back to the terms agreed upon in your contract, including quality standards and delivery timelines. If issues arise, attempt to resolve them amicably through direct dialogue. If resolution is not achieved, consider involving a third-party mediator or arbitration, especially for international transactions. Establishing a clear dispute resolution process in your initial agreements can help mitigate risks and foster a more collaborative relationship.

Dominio: freeairpump.com

Inscrito: 2012 (13 años)

Introducción: FreeAirPump.com provides a crowdsourced map of locations that offer free air for tires, including gas stations and bike repair stations. Users can add locations to the map. The site also offers a guide to portable air compressors for those who cannot find free air. In Connecticut, free air is available at gas stations, while in California, it is required for paying customers. The site encourages u…

Dominio: freeairnear.me

Registered: 2023 (2 years)

Introducción: Free air pumps for tires available at 219 locations in 127 cities in New York. 23 locations provide free air for bicycles only, while 196 businesses offer free air for cars and bikes. 138 gas stations in New York provide free air, including Stewart’s (63), Byrne Dairy (18), Sunoco (12), Mobil (11), BJ’s Gas (10), Fastrac (6), Shell (5), Speedway (4), Gulf (3), Citgo (2), Exxon (2), BP (1), Conoco …

Dominio: yelp.com

Inscrito: 2003 (22 años)

Introducción: This company, Yelp – Best Gas Stations with Air Pumps, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Dominio: freetireair.com

Registered: 2023 (2 years)

Introducción: Free air tire pumps available at 43 verified locations in Philadelphia, including gas stations and convenience stores. Users can browse locations or use an interactive map to find nearby tire air pumps. The service promotes the purchase of a personal tire pump for unlimited free air, saving time and effort.

Dominio: reddit.com

Matriculado: 2005 (20 años)

Introducción: Free air pumps for tires available at gas stations with mechanics, particularly on the South Fork east of Riverhead. Costco is mentioned as a location that offers free air pumps. Additionally, a suggestion is made to purchase a $20 air compressor from Walmart or Target to keep in the trunk.

In navigating the landscape of air pump sourcing, international B2B buyers must prioritize strategic partnerships and reliable supply chains. The importance of sourcing from trustworthy suppliers cannot be overstated, as it ensures access to high-quality products and services that meet the diverse needs of various markets, including those in Africa, South America, the Middle East, and Europe. Leveraging local resources, such as free air stations and community-driven platforms, can not only reduce costs but also foster sustainable practices within the industry.

As buyers explore their options, it’s crucial to consider the evolving trends in air pump technology and customer expectations. Investing in portable air compressors and understanding the regulatory frameworks governing air services in different regions can provide a competitive edge.

Looking ahead, fostering collaborations with suppliers who share a commitment to innovation and sustainability will be key. By staying informed about market developments and consumer preferences, businesses can better position themselves to capitalize on emerging opportunities. Engage with local distributors and explore partnerships that enhance your service offerings to meet the growing demand for air solutions. This proactive approach will empower your business to thrive in an increasingly interconnected marketplace.

Illustrative image related to nearest air pump

La información facilitada en esta guía, incluido el contenido relativo a fabricantes, especificaciones técnicas y análisis de mercado, tiene únicamente fines informativos y educativos. No constituye asesoramiento profesional en materia de adquisiciones, asesoramiento financiero ni asesoramiento jurídico.

Aunque hemos hecho todo lo posible por garantizar la exactitud y actualidad de la información, no nos hacemos responsables de posibles errores, omisiones o información obsoleta. Las condiciones del mercado, los detalles de las empresas y las normas técnicas están sujetos a cambios.

Los compradores B2B deben llevar a cabo su propia diligencia debida independiente y exhaustiva antes de tomar cualquier decisión de compra. Esto incluye ponerse en contacto directamente con los proveedores, verificar las certificaciones, solicitar muestras y buscar asesoramiento profesional. El riesgo de confiar en la información contenida en esta guía es responsabilidad exclusiva del lector.