In today’s global marketplace, sourcing reliable reset tire inflation sensors is a critical challenge for B2B buyers, especially in regions like Africa, South America, the Middle East, and Europe. As the automotive industry increasingly prioritizes safety and efficiency, the demand for effective tire pressure monitoring systems (TPMS) is on the rise. However, the complexity of selecting the right sensors, understanding their applications, and ensuring proper supplier vetting can overwhelm even the most experienced procurement professionals.

This comprehensive guide aims to empower international buyers by providing in-depth insights into various types of reset tire inflation sensors, their applications across different vehicle models, and the nuances of supplier evaluation. We will explore factors influencing costs, the importance of regulatory compliance in different markets, and best practices for integrating these sensors into existing TPMS. By addressing common pain points and offering actionable strategies, this guide serves as a valuable resource for making informed purchasing decisions.

Whether you are a buyer in Vietnam looking to enhance your fleet’s safety features or a procurement manager in Saudi Arabia seeking to streamline operations, this guide equips you with the knowledge necessary to navigate the complexities of the reset tire inflation sensor market. With the right information, you can confidently select high-quality products that enhance vehicle safety and performance, ultimately driving business success.

| Tipo Nombre | Principales rasgos distintivos | Aplicaciones B2B principales | Breves pros y contras para los compradores |

|---|---|---|---|

| Direct TPMS | Uses individual sensors on each tire; provides real-time data | Automotive manufacturing, fleet management | Pros: Accurate readings; enhanced safety. Contras: Higher replacement costs. |

| Indirect TPMS | Monitors wheel speed to infer tire pressure | Used in cost-sensitive vehicle models | Pros: Lower cost; no additional sensors needed. Contras: Less accurate; requires calibration after tire changes. |

| Universal TPMS | Compatible with multiple vehicle makes and models | Aftermarket installations, repair shops | Pros: Versatile; simplifies inventory. Contras: May not integrate seamlessly with all vehicles. |

| Bluetooth TPMS | Syncs with mobile devices for real-time monitoring | Mobile applications, fleet management | Pros: User-friendly; accessible data. Contras: Battery dependency; potential connectivity issues. |

| Programmable TPMS | Allows customization for specific vehicle settings | Automotive customization, performance tuning | Pros: Tailored solutions; enhanced performance. Contras: Complexity in setup; requires technical knowledge. |

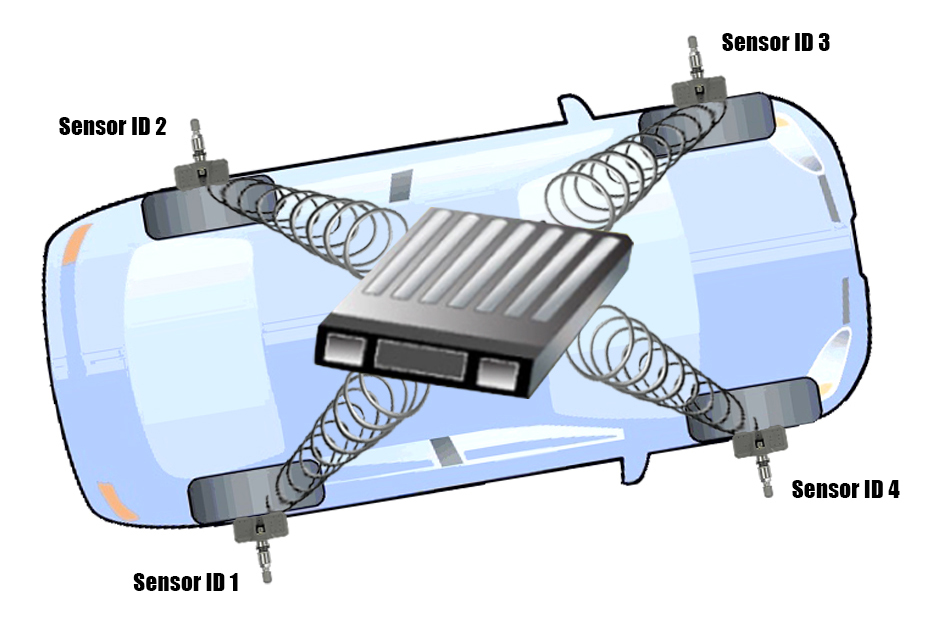

Direct Tire Pressure Monitoring Systems (TPMS) utilize individual sensors mounted on each tire, providing real-time data regarding tire pressure. This type is commonly found in higher-end vehicles and is favored for its accuracy and reliability. B2B buyers in automotive manufacturing and fleet management often prefer direct TPMS due to its ability to enhance safety and reduce the risk of blowouts. When considering a purchase, buyers should evaluate the cost of replacement sensors and the potential need for specialized installation tools.

Indirect TPMS relies on the vehicle’s ABS (Anti-lock Braking System) to monitor wheel speed as an indirect measure of tire pressure. This system is less expensive than direct TPMS and is often used in budget-friendly vehicle models. B2B applications include cost-sensitive automotive designs and repair shops that aim to provide affordable solutions. Buyers should consider the need for recalibration after tire changes and the system’s potential for less accurate readings compared to direct TPMS.

Universal TPMS sensors are designed to be compatible with multiple vehicle makes and models, making them an attractive option for aftermarket installations and repair shops. Their versatility simplifies inventory management for B2B buyers, allowing them to stock fewer parts while servicing a broader range of vehicles. However, it’s essential to assess whether these sensors will integrate seamlessly with specific vehicle systems, as compatibility issues can arise, affecting performance.

Bluetooth TPMS systems connect with mobile devices, offering real-time tire pressure monitoring that is particularly beneficial for fleet management applications. This technology enhances user experience by providing accessible data directly to drivers and fleet managers. B2B buyers should weigh the convenience of mobile integration against the potential for battery dependency and connectivity issues, which could impact reliability in critical situations.

Programmable TPMS allows users to customize settings specific to vehicle requirements, making it ideal for automotive customization and performance tuning. This flexibility appeals to businesses focused on high-performance vehicles or specialized applications. However, B2B buyers must consider the complexity of setup and the technical knowledge required to program these systems effectively. The investment in programmable TPMS can yield significant performance benefits when properly implemented.

| Industria/Sector | Specific Application of reset tire inflation sensor | Valor/beneficio para la empresa | Consideraciones clave para el aprovisionamiento de esta aplicación |

|---|---|---|---|

| Automotive Manufacturing | Integration in production lines for vehicle assembly | Ensures consistent quality and safety standards | Compliance with international safety regulations |

| Logistics & Transportation | Fleet management for commercial vehicles | Enhances fuel efficiency and reduces maintenance costs | Compatibility with various vehicle models and sensors |

| Mining & Heavy Machinery | Usage in mining trucks and equipment | Increases operational safety and reduces downtime | Robustness to withstand harsh environments and conditions |

| Agricultura | Application in agricultural machinery | Improves efficiency and reduces tire-related issues | Adaptability to different tire sizes and types |

| Public Transport | Implementation in buses and public transport vehicles | Enhances passenger safety and reduces operational costs | Reliability and ease of integration with existing systems |

In automotive manufacturing, reset tire inflation sensors are integrated into production lines to monitor and manage tire pressure for vehicles. This technology ensures that each vehicle meets safety and quality standards before leaving the assembly line. By automating tire pressure checks, manufacturers can minimize human error and enhance overall vehicle performance. For international buyers, particularly in regions like Europe and the Middle East, sourcing sensors that comply with stringent safety regulations is crucial to maintaining brand integrity and customer trust.

Illustrative image related to reset tire inflation sensor

In logistics and transportation, companies utilize reset tire inflation sensors within their fleet management systems to monitor tire pressure across commercial vehicles. This proactive approach helps enhance fuel efficiency, as properly inflated tires reduce rolling resistance. Additionally, it lowers maintenance costs by preventing tire blowouts and extending tire life. Buyers in Africa and South America should consider sensors that offer real-time monitoring capabilities, ensuring that fleet managers can address tire issues promptly, thus optimizing operational efficiency.

Mining and heavy machinery applications heavily rely on reset tire inflation sensors for their large trucks and equipment. These sensors are vital in ensuring that tires are properly inflated, which significantly increases operational safety and reduces the risk of accidents caused by tire failures. The rugged nature of mining environments necessitates sourcing durable sensors capable of withstanding extreme conditions. Buyers must prioritize sensors with high resistance to dust, moisture, and physical damage to ensure reliability in such demanding applications.

In the agriculture sector, reset tire inflation sensors are applied in various machinery, including tractors and harvesters. Maintaining optimal tire pressure is crucial for maximizing efficiency and minimizing tire-related issues that can disrupt operations. Properly inflated tires also contribute to better fuel economy and less soil compaction, which is vital for crop health. When sourcing these sensors, agricultural businesses in regions like Africa and South America should look for products that can adapt to a variety of tire sizes and types, ensuring versatility across different machinery.

Illustrative image related to reset tire inflation sensor

Public transport systems, including buses and commuter trains, implement reset tire inflation sensors to enhance passenger safety and operational efficiency. By ensuring that tires are consistently at the correct pressure, transport operators can reduce the risk of accidents and improve ride quality. Furthermore, this contributes to lower fuel consumption and maintenance costs. For international buyers in Europe and the Middle East, sourcing reliable and easy-to-integrate sensors is essential for maintaining service standards and compliance with local regulations.

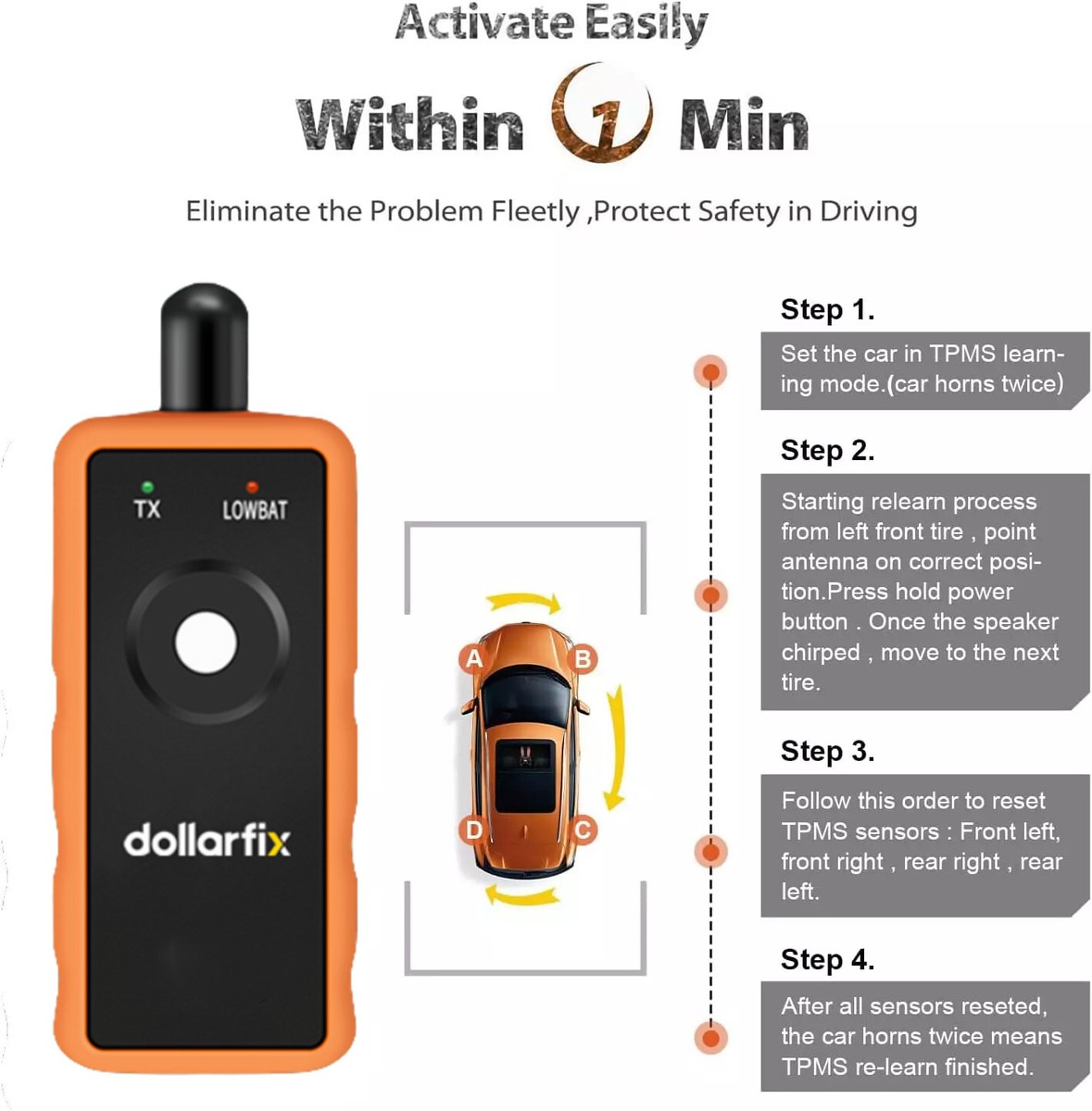

El problema: After conducting regular tire maintenance—such as inflation or rotation—many businesses face the frustrating challenge of the Tire Pressure Monitoring System (TPMS) light remaining illuminated. This can lead to unnecessary worry about tire safety and performance, especially when the underlying issue has already been resolved. For fleet managers, a persistent warning light can also result in time-consuming checks and potential downtime, impacting overall operational efficiency.

La solución: To effectively reset the TPMS light, it’s crucial to follow the vehicle manufacturer’s specific reset procedure. Typically, this involves ensuring all tires are inflated to the recommended pressure. For vehicles with a dedicated reset button, locate it (often found under the dashboard) and press it until the light blinks three times. Alternatively, some systems automatically reset after driving for a certain distance at a consistent speed. Fleet managers should also invest in a reliable diagnostic tool that can not only reset the TPMS but also check for sensor health. By proactively maintaining tire pressure and understanding the reset procedures, businesses can minimize downtime and enhance fleet safety.

El problema: In multinational operations, discrepancies in tire pressure monitoring can arise due to variations in reporting standards across different regions. For instance, a fleet in South America might report tire pressures using different units or thresholds than a fleet in Europe. This miscommunication can lead to incorrect adjustments, causing inefficiencies and safety concerns.

La solución: To tackle this issue, businesses should standardize their tire pressure reporting protocols across all regions. This can be achieved by using digital tools and software that convert pressure readings to a common unit (e.g., PSI or bar) and providing training to staff on these standards. Additionally, leveraging advanced TPMS solutions that offer real-time data monitoring can help centralize pressure information. This ensures that all teams are aligned on tire maintenance practices, reducing the risk of errors and enhancing the safety and performance of the fleet.

El problema: Many businesses experience challenges with faulty TPMS sensors, which can lead to inaccurate tire pressure readings. This issue not only compromises vehicle safety but can also lead to increased fuel costs due to improper tire inflation. Fleet operators often find themselves in a cycle of troubleshooting that disrupts operations and diverts resources from core business activities.

La solución: To address this pain point, it is essential to invest in high-quality TPMS sensors that are compatible with the specific vehicles in the fleet. Regular inspections and maintenance checks should be scheduled to identify any signs of sensor damage or malfunction. For fleets operating in regions with extreme weather conditions, consider sensors designed to withstand temperature fluctuations. Additionally, establishing a partnership with a reliable supplier for TPMS components can ensure timely replacements and support. By prioritizing sensor quality and maintenance, businesses can improve vehicle safety, reduce operational costs, and enhance overall fleet efficiency.

When selecting materials for reset tire inflation sensors, it is crucial to consider their performance characteristics, durability, and compatibility with various environmental conditions. Below, we analyze four common materials used in the manufacturing of these sensors, highlighting their properties, advantages, disadvantages, and specific considerations for international B2B buyers.

Policarbonato is a popular choice for the housing of tire inflation sensors due to its high impact resistance and optical clarity. It can withstand temperatures ranging from -40°C to 120°C, making it suitable for various climates. Additionally, polycarbonate exhibits good electrical insulation properties, essential for sensor functionality.

Pros y contras: Polycarbonate is lightweight and offers excellent durability against mechanical stress. However, it can be susceptible to UV degradation over time, which may affect its longevity in outdoor applications. The cost of polycarbonate is generally moderate, making it an appealing option for manufacturers.

Impacto en la aplicación: Polycarbonate’s resistance to moisture and temperature fluctuations makes it a reliable choice for tire inflation sensors, ensuring accurate readings even in extreme conditions.

Illustrative image related to reset tire inflation sensor

Consideraciones para compradores internacionales: Compliance with standards such as ISO 4892 for UV exposure is essential, particularly in regions with high sun exposure like Africa and the Middle East. Buyers should also consider the availability of polycarbonate in local markets to avoid supply chain disruptions.

Acero inoxidable is often used for components that require high corrosion resistance, such as valve stems and sensor housings. It can withstand temperatures up to 500°C and is resistant to various chemicals, making it ideal for harsh environments.

Pros y contras: The durability of stainless steel is unmatched, providing longevity and reliability. However, it is heavier than other materials, which may affect the overall weight of the sensor assembly. The cost of stainless steel is typically higher, which could impact the final product pricing.

Impacto en la aplicación: Stainless steel’s compatibility with various media, including air and moisture, ensures accurate sensor readings. Its robustness also minimizes the risk of mechanical failure.

Consideraciones para compradores internacionales: Buyers should ensure that the stainless steel used complies with ASTM A276 standards for corrosion resistance, especially in humid climates found in South America and Southeast Asia.

Thermoplastic Elastomers (TPE) are increasingly used in tire inflation sensors due to their flexibility and resilience. TPE materials can operate effectively in a temperature range of -30°C to 100°C, making them suitable for diverse environments.

Pros y contras: TPE offers excellent chemical resistance and can be molded into complex shapes, enhancing design flexibility. However, TPE may not provide the same level of rigidity as other materials, which could limit its application in certain sensor components. The cost is generally medium, making it a viable option for many manufacturers.

Impacto en la aplicación: TPE’s flexibility allows for better sealing and protection against moisture ingress, which is critical for maintaining sensor accuracy.

Illustrative image related to reset tire inflation sensor

Consideraciones para compradores internacionales: Compliance with environmental regulations, such as RoHS, is essential for TPE materials, particularly in Europe. Buyers should also consider the local availability of TPE to ensure timely production.

Aluminio is frequently used for its lightweight properties and good thermal conductivity. It can withstand temperatures up to 200°C and is resistant to corrosion when anodized.

Pros y contras: Aluminum’s lightweight nature contributes to overall vehicle efficiency, while its strength provides durability. However, it can be more expensive than plastic alternatives, which may deter some manufacturers. Additionally, aluminum requires careful machining, which can complicate manufacturing processes.

Impacto en la aplicación: Aluminum’s thermal properties help in dissipating heat generated by the sensor, ensuring accurate performance under varying conditions.

Consideraciones para compradores internacionales: Buyers should verify that aluminum components meet international standards such as ISO 9001 for quality management, especially in regions with stringent regulatory environments like Europe.

Illustrative image related to reset tire inflation sensor

| Material | Typical Use Case for reset tire inflation sensor | Ventajas clave | Principales desventajas/limitaciones | Coste relativo (Bajo/Medio/Alto) |

|---|---|---|---|---|

| Policarbonato | Housing for tire inflation sensors | Gran resistencia a los impactos | Degradación UV con el tiempo | Medio |

| Acero inoxidable | Valve stems and sensor housings | Excellent corrosion resistance | Heavier than alternatives | Alta |

| Thermoplastic Elastomers (TPE) | Seals and flexible components | Flexibility and chemical resistance | Limited rigidity | Medio |

| Aluminio | Lightweight structural components | Ligero y duradero | Higher machining complexity | Alta |

This guide provides a comprehensive overview of material selection for reset tire inflation sensors, equipping international B2B buyers with the insights needed to make informed decisions based on performance, cost, and regional compliance.

The manufacturing process for reset tire inflation sensors is intricate and involves several key stages. Understanding these stages is crucial for B2B buyers looking to source high-quality products.

The first stage in manufacturing involves sourcing high-quality raw materials. Typically, these materials include semiconductors, plastic housings, and metal components. Suppliers must ensure that materials meet specific standards to guarantee durability and reliability. This often includes conducting tests to verify material properties such as tensile strength, thermal stability, and corrosion resistance.

Illustrative image related to reset tire inflation sensor

Once the materials are prepared, they undergo various forming processes. Injection molding is frequently used for the plastic components, allowing for precision and consistency. Metal parts may be created through stamping or machining processes, ensuring accurate dimensions and surface finishes. Advanced techniques such as laser cutting or CNC machining are also employed for high-precision components.

The assembly stage is critical for ensuring that all components work seamlessly together. This process typically involves both manual and automated assembly techniques. Automated assembly lines can enhance efficiency and reduce human error, while manual assembly allows for detailed inspection and adjustment. During this phase, components are integrated, and initial functionality tests are performed to verify that the sensor communicates correctly with the vehicle’s TPMS.

Finishing processes are essential to enhance the performance and longevity of tire inflation sensors. These may include surface treatments to improve corrosion resistance, such as anodizing or galvanization for metal components. Additionally, protective coatings may be applied to plastic parts to enhance UV resistance and durability. After finishing, the sensors undergo final inspection to ensure they meet aesthetic and functional specifications.

Quality assurance is a critical component of the manufacturing process for tire inflation sensors. It ensures that each sensor meets stringent performance and safety standards.

For B2B buyers, understanding international quality standards is paramount. ISO 9001 is the most recognized quality management standard, ensuring that manufacturers maintain consistent quality throughout the production process. Additionally, industry-specific certifications such as CE marking for European markets and API specifications for certain applications may apply. These certifications indicate compliance with safety, health, and environmental protection standards.

Quality control (QC) checkpoints should be integrated throughout the manufacturing process. These typically include:

Testing methods play a vital role in ensuring the reliability of tire inflation sensors. Common testing protocols include:

B2B buyers must take proactive steps to verify the quality control practices of potential suppliers. Here are several strategies:

Illustrative image related to reset tire inflation sensor

For international buyers, particularly those from Africa, South America, the Middle East, and Europe, understanding regional regulations and certifications is crucial. Different regions may have specific requirements for product safety and environmental standards. For instance, products sold in the European Union must comply with CE marking regulations, while Middle Eastern markets may require adherence to Gulf Cooperation Council (GCC) standards.

Buyers should also be aware of potential language barriers and cultural differences that may affect communication and negotiation with suppliers. Establishing a clear understanding of expectations and requirements upfront can facilitate smoother transactions and ensure compliance with local regulations.

In summary, robust manufacturing processes and stringent quality assurance measures are vital in producing reliable reset tire inflation sensors. For B2B buyers, understanding these processes not only helps in sourcing high-quality products but also in mitigating risks associated with poor performance and non-compliance with international standards. By prioritizing quality control and verifying supplier practices, buyers can ensure that they invest in products that enhance safety and performance in the automotive sector.

Illustrative image related to reset tire inflation sensor

In the competitive landscape of tire maintenance and automotive safety, ensuring the reliability and functionality of tire pressure monitoring systems (TPMS) is essential. This guide aims to equip B2B buyers with a comprehensive checklist for sourcing solutions to reset tire inflation sensors effectively. By following these steps, businesses can enhance their operational efficiency and provide better service to their clients.

Before engaging suppliers, clearly define your needs regarding the reset tire inflation sensor. Consider the types of vehicles your business services, the frequency of maintenance, and whether you require manual or automated solutions.

Conduct thorough research to identify reputable suppliers who specialize in tire pressure monitoring systems and reset solutions. A strong supplier network can significantly impact your operational capabilities.

Verify that potential suppliers hold relevant certifications and adhere to industry standards. This step is crucial for ensuring the quality and safety of the products you will be sourcing.

Before making a bulk purchase, request samples of the reset tire inflation sensors or tools. This allows you to assess the quality and functionality firsthand.

Strong after-sales support is essential for resolving any issues that may arise post-purchase. Evaluate the warranty policies and support services offered by potential suppliers.

Once you have shortlisted suppliers, compare pricing structures and payment terms. This step is vital for maintaining budgetary control while ensuring quality.

Illustrative image related to reset tire inflation sensor

After thorough evaluation, choose a supplier that best aligns with your operational requirements, quality standards, and budget.

By following this structured sourcing checklist, B2B buyers can confidently procure solutions for resetting tire inflation sensors, enhancing both safety and performance in their operations.

Analyzing the cost structure and pricing dynamics of reset tire inflation sensors is essential for international B2B buyers looking to optimize their procurement strategies. Understanding the various cost components and price influencers can lead to more informed sourcing decisions, especially for markets in Africa, South America, the Middle East, and Europe.

Materiales: The primary materials for tire inflation sensors include high-quality plastics, metals, and electronic components. The choice of materials directly impacts durability and sensor accuracy. Buyers should consider sourcing from suppliers who provide certifications to ensure material quality.

Trabajo: Labor costs vary significantly based on the region of manufacturing. Regions with lower labor costs, such as parts of Southeast Asia, may offer competitive pricing, but buyers should also assess the skill level and experience of the workforce, as this affects the quality of the finished product.

Gastos generales de fabricación: This encompasses the costs associated with facilities, equipment, and utilities. Efficient manufacturing processes can help reduce overhead costs, making it vital to partner with manufacturers who employ lean production techniques.

Herramientas: Initial tooling costs can be substantial, especially for customized sensors. Buyers should evaluate the necessity of unique tooling against potential long-term savings, particularly for high-volume orders.

Control de calidad: Effective quality assurance processes are critical to ensuring the reliability of sensors. Investing in robust QC can prevent costly returns and warranty claims, which is particularly important in sectors where safety is paramount.

Logística: Shipping costs can vary widely based on the supplier’s location and the chosen Incoterms. Understanding the implications of different shipping terms is crucial for international buyers to manage total landed costs.

Margen: Supplier profit margins can fluctuate based on market demand, competition, and product differentiation. Buyers should negotiate to find a balance between quality and cost while ensuring fair margins for suppliers.

Volumen y cantidad mínima de pedido (MOQ): Higher order volumes typically yield better pricing. Buyers should assess their demand forecasts to negotiate favorable terms with suppliers. Understanding the MOQ can help in planning inventory and cash flow.

Especificaciones y personalización: Custom features or advanced technology integrations can increase costs. Buyers must weigh the benefits of customization against budget constraints, particularly in competitive markets.

Calidad y certificaciones: Sensors that meet international quality standards or possess specific certifications may command higher prices. Buyers in regulated industries should prioritize these factors to ensure compliance and safety.

Factores del proveedor: The reliability and reputation of suppliers can influence pricing. Established suppliers may offer premium products but can also provide better support and warranty services. Conducting thorough due diligence on suppliers can mitigate risks.

Incoterms: Understanding the implications of different Incoterms on shipping responsibilities and costs is vital. Terms like FOB (Free on Board) can shift costs and risks, impacting the overall pricing strategy.

Negotiate Wisely: Engage suppliers in discussions about pricing structures, considering the total cost of ownership rather than just the unit price. Building long-term relationships can also lead to better terms over time.

Considerar el coste total de propiedad (TCO): TCO includes not only the purchase price but also maintenance, warranty, and potential downtime costs. Assessing these factors can lead to more strategic purchasing decisions.

Matización de precios para compradores internacionales: Be aware of currency fluctuations, tariffs, and local taxes that can affect overall costs when sourcing from abroad. Engaging local experts can provide insights into the specific nuances of different markets.

Manténgase informado sobre las tendencias del mercado: Keeping abreast of technological advancements and market shifts can help buyers anticipate changes in pricing and availability, allowing for proactive sourcing strategies.

Descargo de responsabilidad: Prices for reset tire inflation sensors can vary based on many factors, including market conditions and supplier negotiations. Buyers are encouraged to conduct thorough research and seek multiple quotes to ensure the best value for their needs.

In the automotive industry, ensuring optimal tire performance is crucial for safety and efficiency. While reset tire inflation sensors (TPMS) are commonly used to monitor and recalibrate tire pressure, there are alternative solutions available. This analysis will compare reset tire inflation sensors with other viable methods that serve similar purposes, helping B2B buyers make informed decisions.

| Aspecto comparativo | Reset Tire Inflation Sensor | Manual Tire Pressure Gauge | Portable Tire Pressure Monitoring System (TPMS) |

|---|---|---|---|

| Rendimiento | Highly accurate; requires proper calibration | Moderate accuracy; dependent on user skill | Real-time monitoring; alerts for irregularities |

| Coste | Moderate; varies by vehicle model | Low; one-time purchase | High; involves an upfront investment and potential subscriptions |

| Facilidad de aplicación | Requires technical knowledge; may need professional help | Simple; user-operated | User-friendly; easy installation with some models requiring professional assistance |

| Mantenimiento | Minimal; occasional recalibration needed | None; requires regular checks | Regular battery replacement; software updates may be necessary |

| El mejor caso de uso | Ideal for fleet management and professional vehicle maintenance | Suitable for individual drivers and occasional checks | Best for businesses requiring constant monitoring of multiple vehicles |

A manual tire pressure gauge is a straightforward tool that allows users to check tire pressure manually. It is cost-effective, typically requiring a one-time purchase. However, its accuracy can vary based on the user’s skill in reading the gauge and ensuring proper placement on the valve stem. This method is best suited for individual drivers or businesses with limited vehicle fleets, as it requires regular checks to maintain tire health.

Portable TPMS devices offer real-time monitoring of tire pressure, providing immediate alerts if pressure deviates from the desired range. These systems can be easily installed and are user-friendly, making them accessible for most drivers. However, they tend to be more expensive due to the technology involved and may require regular battery changes or software updates. They are ideal for businesses with a larger fleet that needs constant monitoring and quick responses to tire pressure issues.

When selecting between a reset tire inflation sensor and alternative solutions like a manual gauge or portable TPMS, B2B buyers should consider their specific operational needs. If managing a fleet with multiple vehicles, investing in a portable TPMS may provide the best value through real-time monitoring and reduced downtime. For smaller operations or individual drivers, a manual tire pressure gauge offers a cost-effective and straightforward approach. Ultimately, the choice should align with the company’s operational scale, budget constraints, and maintenance capabilities to ensure optimal tire performance and safety.

When considering the procurement of reset tire inflation sensors, understanding the critical technical specifications is essential for ensuring product quality and reliability. Here are some of the most important properties:

Composición del material

– Definition: The materials used in the construction of tire inflation sensors, typically a combination of plastics and metals resistant to environmental stressors.

– B2B Importance: High-quality materials enhance durability and performance, ensuring sensors withstand harsh conditions such as extreme temperatures and moisture, which is particularly relevant for buyers in diverse climates across Africa, South America, and the Middle East.

Rango de presión

– Definition: The operational range of tire pressure that the sensor can accurately monitor, usually measured in psi (pounds per square inch).

– B2B Importance: Ensuring that the sensor covers the necessary pressure range for different vehicle types is crucial. This prevents under- or over-inflation, enhancing vehicle safety and efficiency, which is a priority for fleet operators.

Sensor Accuracy

– Definition: The degree to which the sensor’s pressure readings reflect the actual tire pressure, often expressed as a percentage.

– B2B Importance: High accuracy minimizes false alerts and potential vehicle damage, making it a critical factor for automotive manufacturers and service providers who prioritize safety and customer satisfaction.

Response Time

– Definition: The time it takes for the sensor to detect a change in tire pressure and communicate that information to the vehicle’s onboard system.

– B2B Importance: A rapid response time is essential for timely alerts to drivers, which can prevent accidents caused by sudden tire failures. This is particularly vital for businesses that operate in regions with varying road conditions.

Duración de la batería

– Definition: The expected lifespan of the sensor’s battery, typically measured in years or the number of miles driven.

– B2B Importance: Longer battery life reduces maintenance costs and downtime for businesses relying on fleet vehicles. Knowing the battery specifications helps in planning replacements and service schedules.

Compatibility Standards

– Definition: The industry standards that the sensor adheres to, ensuring it works with various vehicle makes and models.

– B2B Importance: Ensuring compatibility with OEM (Original Equipment Manufacturer) standards is crucial for automotive suppliers and service centers, as it guarantees that the sensors can be integrated seamlessly into a wide range of vehicles without requiring extensive modifications.

Familiarity with industry jargon is vital for effective communication and negotiation in the B2B landscape. Here are some key terms:

OEM (fabricante de equipos originales)

– Definition: A company that produces parts and equipment that may be marketed by another manufacturer.

– Importance: Understanding OEM specifications is critical for ensuring that replacement sensors meet original quality standards, which is essential for maintaining vehicle warranties.

MOQ (Cantidad mínima de pedido)

– Definition: The smallest quantity of a product that a supplier is willing to sell.

– Importance: Knowing the MOQ helps buyers plan their inventory and budget effectively, ensuring they meet demand without overstocking.

RFQ (solicitud de presupuesto)

– Definition: A document sent to suppliers asking for price proposals on specific products or services.

– Importance: Submitting an RFQ allows businesses to compare prices and terms from multiple suppliers, aiding in cost-effective purchasing decisions.

Incoterms (Términos comerciales internacionales)

– Definition: A series of pre-defined commercial terms published by the International Chamber of Commerce (ICC) related to international shipping.

– Importance: Understanding Incoterms is crucial for international buyers to clarify responsibilities regarding shipping, risk, and costs, ensuring smooth transactions across borders.

Calibration

– Definition: The process of adjusting the sensor to ensure accurate readings, often done after installation or maintenance.

– Importance: Regular calibration is essential for maintaining sensor accuracy and reliability, which impacts vehicle safety and performance.

TPMS (Tire Pressure Monitoring System)

– Definition: An electronic system that monitors the air pressure inside the tires and alerts the driver when the pressure falls below a certain threshold.

– Importance: Knowledge of TPMS functionality is vital for suppliers and manufacturers, as it influences product design and customer education efforts.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions when sourcing reset tire inflation sensors, ultimately enhancing their operational efficiency and safety standards.

Illustrative image related to reset tire inflation sensor

The reset tire inflation sensor market is experiencing significant growth driven by several global factors. Increasing vehicle safety regulations and the growing awareness of road safety among consumers are pivotal in propelling demand for tire pressure monitoring systems (TPMS). In regions like Africa, South America, the Middle East, and Europe, the rise in vehicle ownership coupled with urbanization is creating a larger customer base for automotive components, including reset tire inflation sensors.

Emerging technologies such as IoT integration in automotive systems are reshaping the market landscape. Sensors that provide real-time data on tire pressure and performance are becoming standard, enhancing the user experience and safety. Furthermore, the trend towards electric vehicles (EVs) is leading to innovations in tire technology, with reset tire inflation sensors becoming crucial for optimizing energy efficiency and performance in these vehicles.

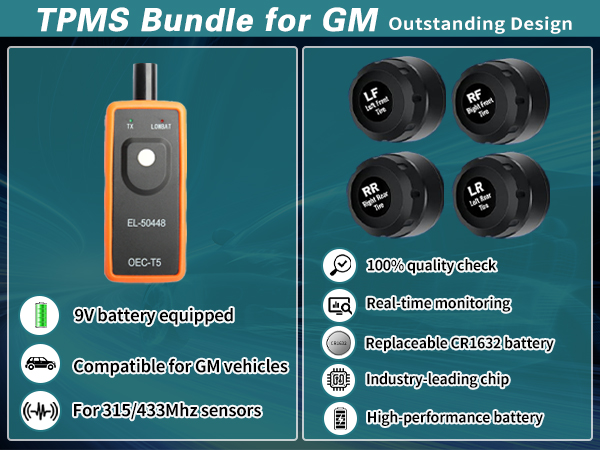

In terms of sourcing trends, international buyers are increasingly looking for suppliers who can offer advanced technology at competitive prices. Countries like Vietnam and Saudi Arabia are becoming key players in manufacturing and sourcing these components due to lower production costs and improving manufacturing capabilities. Strategic partnerships and local sourcing are vital for businesses aiming to reduce lead times and improve supply chain efficiency.

Sustainability is becoming an essential consideration in the sourcing of reset tire inflation sensors. The environmental impact of manufacturing processes and the lifecycle of automotive components is under scrutiny, prompting buyers to seek suppliers who prioritize eco-friendly practices. This includes the use of recycled materials, reducing waste during production, and ensuring that manufacturing processes are compliant with international environmental standards.

Ethical sourcing is equally critical. Buyers are increasingly focused on ensuring that their suppliers adhere to labor rights and fair trade practices. Certifications such as ISO 14001 (Environmental Management) and ISO 45001 (Occupational Health and Safety) are becoming prerequisites for suppliers seeking to establish credibility in the international market.

Moreover, as the automotive industry pivots towards greener technologies, materials used in reset tire inflation sensors are evolving. Innovations in biodegradable plastics and recyclable metals not only meet regulatory requirements but also appeal to environmentally conscious consumers and businesses. By prioritizing sustainability and ethical sourcing, companies can enhance their brand reputation and attract a growing segment of eco-aware buyers.

The reset tire inflation sensor technology has evolved significantly over the past few decades. Initially introduced in the early 2000s, tire pressure monitoring systems were primarily mechanical, offering limited functionality. As safety regulations tightened, the industry witnessed a shift towards electronic sensors that could provide real-time data, allowing for more accurate monitoring of tire pressure.

With the advent of digital technology and the Internet of Things (IoT), reset tire inflation sensors have transformed into sophisticated devices capable of integrating with vehicle management systems. This evolution has led to enhanced functionalities such as remote monitoring and alerts, enabling drivers to maintain optimal tire pressure proactively.

Illustrative image related to reset tire inflation sensor

Today, the reset tire inflation sensor market is at the forefront of automotive innovation, with ongoing advancements in sensor accuracy, durability, and user interface design. As the market continues to grow, international B2B buyers must remain informed about these developments to leverage the latest technology for competitive advantage.

How do I solve the issue of a persistent tire pressure warning light?

To address a persistent tire pressure warning light, first ensure all tires are inflated to the manufacturer’s recommended pressure. If the light remains on, attempt to reset the TPMS using the vehicle’s reset button or by driving at a steady speed for 10-30 minutes. If these steps do not work, inspect the tire pressure sensors for damage or battery issues. It may be necessary to consult a professional to diagnose potential software problems or sensor malfunctions.

What is the best method for resetting a tire inflation sensor?

The best method for resetting a tire inflation sensor varies by vehicle make and model. Common methods include using the TPMS reset button, driving at a specific speed for a certain distance, or employing a scan tool for more complex resets. Always refer to the vehicle’s manual for specific instructions. Ensuring all tires are properly inflated before attempting a reset is critical for accurate sensor calibration.

How can I vet suppliers for tire inflation sensors?

When vetting suppliers for tire inflation sensors, consider their industry reputation, certifications, and previous client reviews. Request samples to assess product quality and ensure they meet international standards. Additionally, verify their capacity for timely delivery and after-sales support. Engaging in direct communication to discuss your specific needs can also provide insights into their reliability and responsiveness.

What customization options are available for tire inflation sensors?

Many manufacturers offer customization options for tire inflation sensors, including branding, color variations, and sensor programming to meet specific vehicle requirements. Discuss your customization needs with potential suppliers, ensuring they can accommodate your specifications. Additionally, inquire about the minimum order quantities for customized products, as this can affect your purchasing decisions.

What is the minimum order quantity (MOQ) for tire inflation sensors?

The minimum order quantity (MOQ) for tire inflation sensors varies by supplier and may depend on factors such as product type and customization requests. Generally, MOQs can range from a few hundred to several thousand units. It’s essential to discuss MOQs with potential suppliers upfront to align your purchasing strategy with their production capabilities.

What payment terms should I expect when sourcing tire inflation sensors internationally?

Payment terms for international purchases of tire inflation sensors can vary widely. Common terms include upfront payment, partial payment upon order confirmation, or payment on delivery. Be sure to clarify payment methods accepted, such as wire transfers or letters of credit, and negotiate terms that are favorable to your cash flow while ensuring security in the transaction.

How do I ensure quality assurance (QA) for tire inflation sensors?

To ensure quality assurance (QA) for tire inflation sensors, establish clear specifications and standards that the supplier must meet. Request documentation for quality control processes, including testing and inspection protocols. Consider implementing third-party inspections or audits to verify product quality before shipment. Regular communication and feedback with the supplier can also help maintain quality standards throughout the production process.

What logistics considerations should I keep in mind when importing tire inflation sensors?

When importing tire inflation sensors, consider logistics factors such as shipping methods, customs clearance, and delivery timelines. Select reliable freight forwarders who understand the regulations in your country and the supplier’s location. Additionally, factor in potential tariffs and duties, as well as insurance options to protect your shipment during transit. Planning for potential delays and ensuring proper documentation will facilitate a smoother import process.

Dominio: reddit.com

Matriculado: 2005 (20 años)

Introducción: Tire pressure indicator reset procedure for 2016 WRX; users suggest driving after inflating tires to reset the indicator.

Dominio: lincolnoflafayettein.com

Inscrito: 2022 (3 años)

Introducción: How to Reset Tire Pressure Light: 1. Drive at or above 50 mph for 10 minutes to reset the sensor. 2. With the vehicle off, turn the key to the “On” position, hold the TPMS reset button until the light blinks three times, then release it. 3. Inflate all tires to 3 PSI over their recommended amount, then deflate completely and reinflate to the recommended pressure. 4. Disconnect the positive battery…

In conclusion, effective strategic sourcing for reset tire inflation sensors is essential for B2B buyers aiming to enhance vehicle safety and performance across diverse markets. As the global demand for reliable tire pressure monitoring systems continues to rise, understanding the intricacies of TPMS technology and its reset mechanisms becomes critical. By prioritizing quality sensors and ensuring proper calibration, businesses can significantly reduce the risk of tire-related incidents, optimize fleet operations, and ultimately drive down costs.

For international B2B buyers, particularly in regions such as Africa, South America, the Middle East, and Europe, leveraging partnerships with reputable suppliers will be key. Establishing strong relationships with manufacturers can provide access to innovative solutions and technical support, ensuring that your operations remain efficient and compliant with safety standards.

Illustrative image related to reset tire inflation sensor

As we look toward the future, consider investing in advanced TPMS technology that not only meets current demands but is also adaptable for evolving automotive needs. Embrace the opportunity to enhance your product offerings and improve customer satisfaction by integrating state-of-the-art tire pressure solutions. Engage with suppliers today to secure a competitive edge in the ever-evolving automotive landscape.

La información facilitada en esta guía, incluido el contenido relativo a fabricantes, especificaciones técnicas y análisis de mercado, tiene únicamente fines informativos y educativos. No constituye asesoramiento profesional en materia de adquisiciones, asesoramiento financiero ni asesoramiento jurídico.

Aunque hemos hecho todo lo posible por garantizar la exactitud y actualidad de la información, no nos hacemos responsables de posibles errores, omisiones o información obsoleta. Las condiciones del mercado, los detalles de las empresas y las normas técnicas están sujetos a cambios.

Los compradores B2B deben llevar a cabo su propia diligencia debida independiente y exhaustiva antes de tomar cualquier decisión de compra. Esto incluye ponerse en contacto directamente con los proveedores, verificar las certificaciones, solicitar muestras y buscar asesoramiento profesional. El riesgo de confiar en la información contenida en esta guía es responsabilidad exclusiva del lector.