In an increasingly competitive global market, sourcing reliable tire pressure air can be a daunting task for international B2B buyers. With diverse vehicle specifications and varying regional standards, understanding the nuances of tire pressure management is crucial for optimizing vehicle performance and safety. This guide delves into the multifaceted world of tire pressure air, providing insights into different types, applications, and essential considerations for supplier vetting and cost analysis.

From understanding the importance of maintaining optimal tire pressure for fuel efficiency to navigating the complexities of temperature fluctuations affecting tire performance, this comprehensive resource equips buyers with the knowledge necessary to make informed purchasing decisions. Whether you operate in Africa, South America, the Middle East, or Europe—regions with unique market dynamics and demand profiles—this guide will empower you to identify trustworthy suppliers and select the right tire pressure solutions tailored to your specific needs.

By addressing common challenges and offering actionable insights, we aim to simplify the sourcing process, ensuring that you can confidently enhance your fleet’s operational efficiency and safety. Join us as we explore the critical elements of tire pressure air and unlock the potential for smarter, more effective purchasing strategies.

| Tipo Nombre | Principales rasgos distintivos | Aplicaciones B2B principales | Breves pros y contras para los compradores |

|---|---|---|---|

| Compressed Air | Standard air used in most vehicles; PSI typically 28-36 | General automotive maintenance | Pros: Cost-effective, widely available. Contras: Can lead to pressure loss due to temperature changes. |

| Nitrogen | Inert gas that minimizes oxidation and pressure loss | High-performance vehicles, fleets | Pros: Longer tire life, stable pressure. Contras: Higher initial cost, requires specialized filling equipment. |

| Air with Additives | Air mixed with sealants or other compounds | Emergency services, off-road vehicles | Pros: Reduces puncture risk, enhances durability. Contras: May require specialized equipment for maintenance. |

| Helium | Lightweight gas, used for specialized applications | Racing, aerospace | Pros: Reduces rolling resistance. Contras: Expensive and not widely available. |

| CO2 | Carbon dioxide used in specific tire inflation systems | Specialty vehicles, racing | Pros: Stable pressure, environmental benefits. Contras: Limited availability, may require specialized systems. |

Compressed air is the most common type of tire inflation, typically found in passenger vehicles and commercial fleets. It is readily available and cost-effective, making it a practical choice for businesses focused on routine vehicle maintenance. However, compressed air is susceptible to pressure loss due to temperature fluctuations, which can affect vehicle performance and safety. B2B buyers should consider the environmental conditions in which their vehicles operate, as frequent pressure checks may be necessary to maintain optimal tire performance.

Nitrogen inflation offers a distinct advantage for fleet operators and high-performance vehicle owners. By using nitrogen, businesses can experience reduced tire pressure loss over time, leading to improved fuel efficiency and extended tire lifespan. Additionally, nitrogen is less prone to moisture, which can prevent internal corrosion. While the initial investment in nitrogen filling equipment may be higher, the long-term savings and enhanced safety can justify the cost for companies managing large fleets or specialized vehicles.

Illustrative image related to tire pressure air

Air infused with sealants or other additives is ideal for businesses operating in challenging environments, such as construction or off-road sectors. This type of inflation reduces the risk of punctures and enhances tire durability, which can be crucial for minimizing downtime. While this option may require specialized maintenance equipment, the benefits of increased safety and reduced repair costs make it a compelling choice for businesses prioritizing operational efficiency.

Helium is a specialized choice primarily utilized in racing and aerospace applications. Its lightweight properties can reduce rolling resistance, potentially improving vehicle performance. However, helium’s high cost and limited availability make it impractical for most B2B applications. Companies considering helium inflation should assess whether the performance benefits outweigh the challenges associated with sourcing and managing this type of inflation.

CO2 is increasingly used in specialized tire inflation systems, particularly in racing environments. It provides stable pressure over time and can offer environmental benefits due to its reduced carbon footprint compared to traditional air. However, the limited availability of CO2 systems and the need for specialized equipment can pose challenges for widespread adoption. B2B buyers should evaluate the specific requirements of their operations to determine if CO2 is a viable option for their tire inflation needs.

| Industria/Sector | Specific Application of tire pressure air | Valor/beneficio para la empresa | Consideraciones clave para el aprovisionamiento de esta aplicación |

|---|---|---|---|

| Automotive Manufacturing | Inflating tires during assembly | Enhances production efficiency and ensures safety | Quality control standards, availability of equipment |

| Logistics & Transportation | Regular tire pressure checks for fleets | Reduces fuel costs and improves vehicle safety | Consistency in supply, reliability of pressure gauges |

| Agricultura | Tire inflation for agricultural machinery | Optimizes performance and minimizes soil compaction | Durability of inflation equipment, local climate impact |

| Mining | Tire pressure management for heavy vehicles | Increases operational safety and tire lifespan | Resistance to harsh environments, service availability |

| Construcción | Tire inflation for construction vehicles | Ensures optimal performance and safety on-site | Compliance with safety regulations, equipment compatibility |

In automotive manufacturing, tire pressure air is essential during the assembly process. Tires must be inflated to specific pressures to ensure safety and performance standards are met. Proper inflation enhances production efficiency by reducing the risk of defects and ensuring that vehicles operate as intended. For international buyers, sourcing high-quality inflation systems that comply with safety regulations is crucial, as any failure in tire performance can lead to significant liability issues.

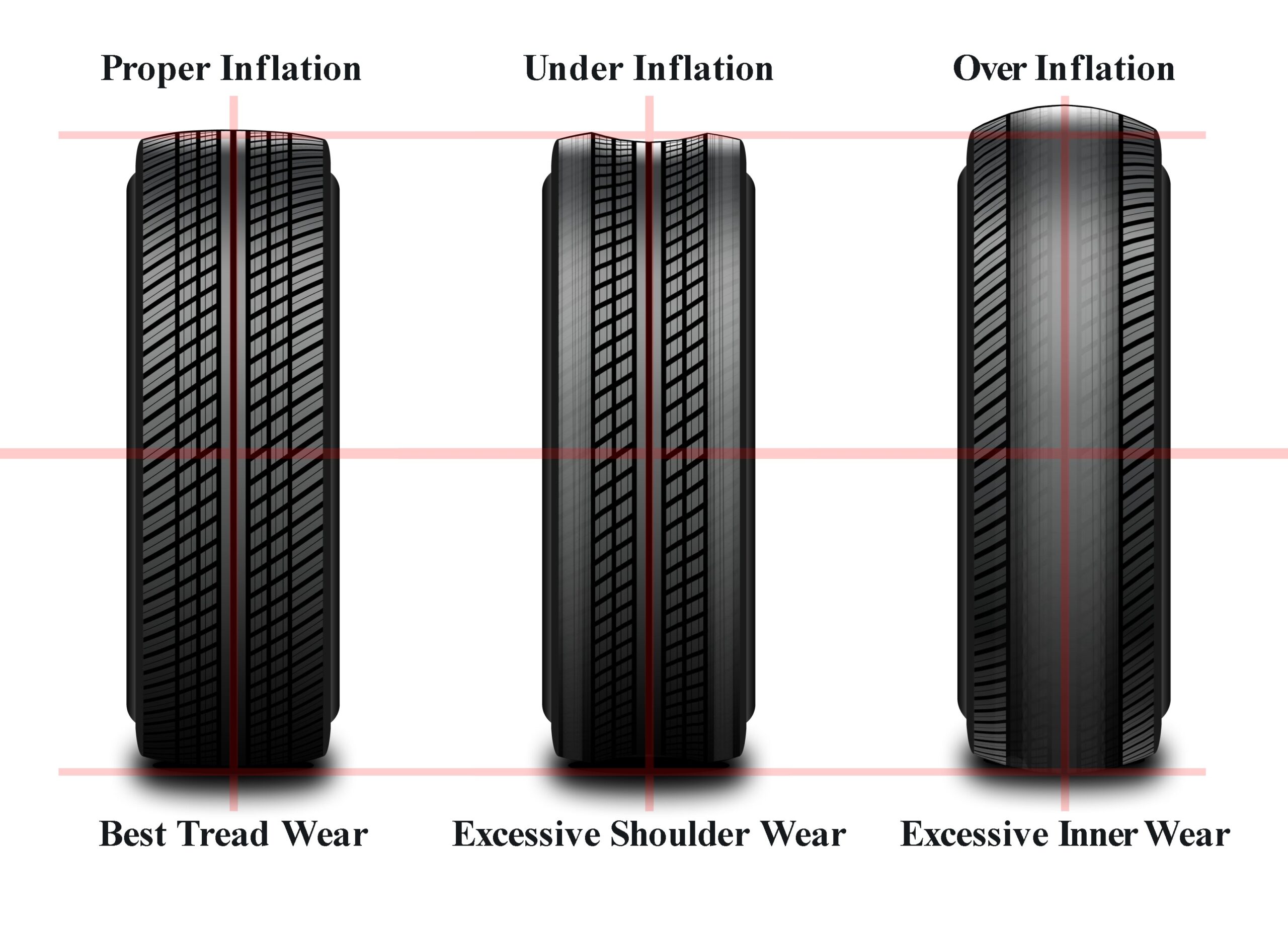

In the logistics and transportation sector, regular tire pressure checks are vital for fleet management. Maintaining optimal tire pressure significantly reduces fuel consumption, as under-inflated tires increase rolling resistance. This practice not only enhances vehicle safety but also extends tire life, leading to lower operational costs. B2B buyers in this sector should consider the reliability and accuracy of tire pressure monitoring systems to ensure consistent performance across diverse geographical regions.

Agricultural machinery relies heavily on tire pressure management to optimize performance. Properly inflated tires reduce soil compaction, which is critical for crop health and yield. This application is particularly relevant in regions with varied soil types and farming practices, such as Africa and South America. Buyers must prioritize durable inflation solutions that can withstand harsh agricultural environments and consider the impact of local climate conditions on tire performance.

In the mining industry, effective tire pressure management for heavy vehicles is crucial for operational safety. Over-inflated or under-inflated tires can lead to blowouts, posing risks to personnel and equipment. Maintaining the correct tire pressure enhances vehicle stability and reduces downtime. Buyers should focus on sourcing robust tire inflation systems that can operate in extreme conditions, ensuring reliability and compliance with industry safety standards.

For construction vehicles, tire inflation is vital to ensure optimal performance and safety on job sites. Properly inflated tires can handle varying terrains and loads, which is common in construction environments. This application emphasizes the importance of sourcing equipment that meets safety regulations and can adapt to different vehicle types and conditions. Buyers should also consider the service availability of tire inflation systems to minimize operational disruptions.

El problema: For companies operating vehicle fleets, maintaining optimal tire pressure is critical for safety, fuel efficiency, and overall vehicle performance. However, fluctuations in tire pressure due to temperature changes, wear and tear, or slow leaks can lead to inconsistent performance across different vehicles. This inconsistency can result in increased operational costs, reduced safety, and potentially higher liability in case of accidents.

La solución: To effectively manage tire pressure across a fleet, companies should invest in a centralized tire pressure monitoring system (TPMS). This system provides real-time data on tire pressures for all vehicles, allowing fleet managers to monitor and address issues proactively. Implementing a regular maintenance schedule, including monthly tire pressure checks and a visual inspection of tires for signs of wear, can further enhance tire performance. Additionally, educating drivers about the importance of checking tire pressure before long trips can ensure that all vehicles are operating safely and efficiently.

Illustrative image related to tire pressure air

El problema: B2B buyers often face confusion regarding the recommended tire pressure for different vehicles, especially when managing a diverse fleet with varying makes and models. Each vehicle may have its unique specifications, leading to potential overinflation or underinflation, which can compromise safety and tire longevity.

La solución: To mitigate this issue, companies should create a comprehensive tire pressure reference guide that outlines the recommended PSI for each vehicle model within the fleet. This guide can be displayed prominently in the maintenance area or distributed digitally to all drivers. Furthermore, investing in tire inflators equipped with automatic pressure adjustment features can help ensure that tires are inflated to the correct specifications without manual guesswork. Regular training sessions for maintenance staff on how to read tire pressure labels and adjust accordingly will also enhance overall tire care and vehicle safety.

El problema: In regions with extreme weather fluctuations, such as high heat in the summer or freezing temperatures in winter, maintaining optimal tire pressure becomes a significant challenge. These conditions can cause tire pressure to drop or rise unexpectedly, leading to safety hazards and increased wear on tires, which is particularly concerning for businesses reliant on timely deliveries or transportation services.

La solución: To effectively manage tire pressure in varying climates, companies should adopt a proactive approach by utilizing climate-responsive tire pressure management solutions. These include using tire pressure gauges that account for temperature variations and automatic tire inflation systems that adjust pressure as needed. Additionally, educating drivers about the impact of weather on tire pressure and encouraging them to check their tires more frequently during extreme weather can significantly enhance safety. Establishing a seasonal tire check protocol will also allow businesses to prepare their vehicles for the demands of each season, ensuring that tire performance remains consistent year-round.

When it comes to tire pressure air, the selection of materials is crucial for ensuring optimal performance, durability, and safety. Below, we analyze four common materials used in tire pressure applications, focusing on their properties, advantages, disadvantages, and considerations for international B2B buyers.

Compressed Air

Compressed air is the most common medium used for inflating tires. It is readily available, easy to use, and can be generated from various sources.

Nitrogen

Nitrogen is increasingly used in tire inflation due to its properties that provide more stable pressure over time.

Carbon Dioxide (CO2)

While less common than air or nitrogen, CO2 is sometimes used for tire inflation, especially in specific industrial applications.

Illustrative image related to tire pressure air

Helium

Helium is occasionally used in specialized tire applications, particularly in racing or high-performance scenarios.

| Material | Typical Use Case for tire pressure air | Ventajas clave | Principales desventajas/limitaciones | Coste relativo (Bajo/Medio/Alto) |

|---|---|---|---|---|

| Compressed Air | General vehicle tire inflation | Readily available and low cost | Pressure fluctuations due to temperature changes | Bajo |

| Nitrogen | High-performance and heavy-duty vehicles | Maintains pressure longer, enhancing fuel efficiency | Higher initial cost and less availability | Med |

| Carbon Dioxide (CO2) | Industrial applications | Lower cost and availability | Increased tire wear if not monitored | Bajo |

| Helium | Racing and high-performance tires | Reduces weight for better performance | High cost and limited accessibility | Alta |

This analysis provides B2B buyers with critical insights into material selection for tire pressure air, enabling informed decisions tailored to their specific market needs and conditions.

The manufacturing process for tire pressure air, while seemingly straightforward, involves several key stages to ensure the final product meets industry standards and customer expectations. The main stages of manufacturing include material preparation, forming, assembly, and finishing.

The initial stage in the manufacturing of tire pressure air involves the selection and preparation of raw materials. For tire pressure air, this primarily includes compressed air, which must be free from contaminants and moisture. Manufacturers often utilize advanced filtration systems to ensure the air quality meets strict standards.

In addition to filtration, the air is typically subjected to drying processes, such as desiccant drying or refrigeration, to remove moisture. This is crucial, as moisture can lead to tire degradation and safety issues. Quality control begins at this stage, with tests performed to ensure that the air meets purity specifications before moving on to the next phase.

Illustrative image related to tire pressure air

The forming stage is primarily focused on the compression of the prepared air into storage tanks or cylinders. This process requires specialized equipment capable of maintaining the integrity of the air while ensuring that it is compressed to the correct pressure levels.

Manufacturers may employ techniques such as multi-stage compression, which gradually increases the pressure while minimizing heat generation, thus preserving the quality of the air. Additionally, advanced monitoring systems are used to track pressure levels throughout the compression process, ensuring adherence to safety standards.

Once the air is compressed, it is transferred to storage containers or dispensing systems. This assembly stage involves connecting various components, such as valves, gauges, and hoses, which are essential for delivering the air to the end user.

Quality assurance during assembly is vital; manufacturers typically implement rigorous checks to confirm that all connections are leak-proof and that the dispensing mechanisms function correctly. This is especially important for B2B buyers, as any failure in the system could lead to operational disruptions.

The finishing stage involves thorough testing and certification of the compressed air systems. This includes pressure testing to ensure that the storage vessels can withstand operational pressures without failure.

Illustrative image related to tire pressure air

Additionally, manufacturers often apply surface treatments to components to enhance durability and corrosion resistance. Final inspections are conducted to verify that all systems comply with international standards, ensuring that the product is ready for distribution.

Quality assurance (QA) is a critical component of the tire pressure air manufacturing process. It encompasses several international standards and industry-specific certifications, which help maintain product integrity and safety.

ISO 9001 is one of the most recognized international standards for quality management systems. It sets out criteria for a quality management system and is based on several quality management principles, including a strong customer focus, the involvement of top management, and a process-based approach.

For tire pressure air, compliance with ISO 9001 ensures that manufacturers maintain high standards throughout their production processes. Additionally, other certifications like CE marking or API standards may apply, depending on the specific applications and regions served.

Quality control checkpoints are strategically implemented throughout the manufacturing process to ensure consistent product quality. These checkpoints include:

Control de calidad entrante (IQC): This involves inspecting raw materials and components before they enter the production line. Tests for air purity and moisture content are crucial at this stage.

Control de calidad durante el proceso (IPQC): Continuous monitoring during the manufacturing process ensures that all stages meet the required specifications. This includes checking pressure levels during compression and verifying the integrity of assembled components.

Control de calidad final (CCF): At the end of production, comprehensive testing is conducted to ensure that the final product meets all safety and quality standards. This includes pressure testing and functionality assessments.

For international B2B buyers, particularly from diverse regions such as Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control measures is essential. Here are some actionable strategies:

Conducting supplier audits is a fundamental way to assess a manufacturer’s quality assurance practices. Buyers can schedule regular audits to evaluate compliance with international standards and internal quality management protocols. This includes reviewing documentation, testing results, and inspecting production facilities.

Requesting detailed quality reports and certifications from suppliers is crucial. These documents should outline compliance with relevant standards, results from quality tests, and evidence of adherence to safety regulations. Certifications such as ISO 9001 or CE can provide assurance of the supplier’s commitment to quality.

Engaging third-party inspection services can provide an unbiased assessment of a supplier’s quality control processes. These independent organizations can conduct thorough evaluations of manufacturing practices and product quality, ensuring that buyers receive compliant and reliable products.

In conclusion, understanding the manufacturing processes and quality assurance measures for tire pressure air is vital for B2B buyers. By focusing on the key stages of manufacturing, relevant international standards, and effective verification methods, buyers can make informed decisions that enhance their operational efficiency and safety. Investing in quality not only fosters trust in supplier relationships but also contributes to long-term business success across diverse markets.

In the ever-evolving automotive industry, ensuring the optimal performance of vehicles through proper tire maintenance is paramount. This guide serves as a practical checklist for B2B buyers looking to procure tire pressure air effectively, ensuring that their operations run smoothly and safely.

Before initiating your procurement process, it’s essential to establish clear technical specifications for tire pressure air. This includes understanding the pressure requirements specific to the vehicles in your fleet, which typically range between 28 to 36 PSI. Knowing these parameters helps in selecting the right products that meet the operational needs of your vehicles.

Thorough research on potential suppliers is critical to ensure you find a reliable source for tire pressure air. Investigate suppliers who specialize in automotive products, particularly those with a focus on tire maintenance solutions.

Ensure that your chosen suppliers hold the necessary certifications and comply with international quality standards. This step is vital for maintaining safety and performance standards in your tire management operations.

Before finalizing your order, request samples of the tire pressure air to evaluate its quality. This step allows you to test the product in real-world conditions and assess its performance against your specifications.

Engage in negotiations with your shortlisted suppliers to secure the best pricing and terms. This not only affects your cost but also the overall value you receive from the partnership.

Once you have procured tire pressure air, implement a quality assurance process to monitor its usage and effectiveness. This step ensures that you maintain optimal tire pressure across your fleet, contributing to safety and efficiency.

Illustrative image related to tire pressure air

Building a long-term relationship with your suppliers can lead to better service, pricing, and product availability. Engage in regular communication and feedback to foster a partnership that benefits both parties.

By following these steps, B2B buyers can effectively procure tire pressure air that meets their operational needs, ensuring the safety and performance of their fleet.

When sourcing tire pressure air for B2B applications, understanding the cost structure is essential for effective budgeting and negotiations. The primary cost components include:

Materiales: The primary material cost involves the air itself, which may vary based on purity and any additional components (e.g., nitrogen for specialized applications). Suppliers might charge more for high-purity air that meets specific industrial standards.

Trabajo: Labor costs can vary significantly based on the region. In areas with lower labor costs, such as parts of Africa and South America, suppliers may offer more competitive pricing. However, labor costs in Europe and the Middle East can be higher, impacting the overall pricing structure.

Gastos generales de fabricación: This includes costs related to the facilities, equipment maintenance, and utilities involved in the production of tire pressure air. Efficient operations can lead to lower overhead costs, which can be passed on to buyers.

Herramientas: Specialized equipment for producing and packaging tire pressure air can incur significant costs. Suppliers often amortize these costs over large production runs, which means that bulk orders can result in lower per-unit pricing.

Control de calidad: Rigorous quality assurance processes ensure that the air meets safety and performance standards. This can add to the cost but is essential for maintaining product integrity, particularly in regions with stringent regulations.

Logística: Transportation and storage costs can vary widely based on the distance from the supplier to the buyer and the mode of transport used. International shipping may involve additional fees, tariffs, and customs duties.

Margen: Supplier profit margins can vary based on market competition, quality, and service levels. Buyers should be aware that premium suppliers may charge higher margins for specialized services.

Several factors can influence the pricing of tire pressure air, including:

Volumen/MOQ: Larger orders often come with discounts due to economies of scale. Understanding the minimum order quantity (MOQ) is crucial for negotiating favorable pricing.

Especificaciones y personalización: Custom formulations or specific delivery requirements can increase costs. Buyers should clearly define their needs to avoid unexpected expenses.

Calidad del material y certificaciones: Higher quality or certified air may command a premium price. Buyers in highly regulated markets should prioritize suppliers who can provide the necessary certifications.

Factores del proveedor: The reliability and reputation of the supplier can significantly impact pricing. Established suppliers may offer better service but at a higher cost. Evaluating multiple suppliers can help in finding the right balance of cost and quality.

Incoterms: Understanding the agreed terms of shipping and responsibility can help manage total costs. Different Incoterms can affect who bears the cost of shipping, insurance, and duties.

International B2B buyers, particularly in Africa, South America, the Middle East, and Europe, should consider several strategies to enhance cost-efficiency:

Negociar las condiciones: Engage suppliers in discussions about pricing, especially when placing larger orders. Don’t hesitate to ask for discounts based on volume or long-term partnerships.

Evaluar el coste total de propiedad (TCO): Beyond the initial purchase price, consider the long-term implications of sourcing decisions. This includes maintenance costs, reliability, and potential downtime associated with inferior products.

Understand Pricing Nuances in Different Regions: Be aware of regional pricing differences and factors that could influence costs, such as local economic conditions and supply chain logistics.

Realizar estudios de mercado: Regularly review market prices and trends to stay informed. Understanding the market landscape can empower buyers during negotiations.

Prices for tire pressure air can vary widely based on numerous factors outlined above. The figures presented are indicative and should not be considered as fixed or binding. Buyers are encouraged to conduct thorough research and obtain multiple quotes to ensure they secure the best pricing tailored to their specific needs.

In the pursuit of optimal tire performance and safety, businesses often explore alternatives to traditional tire pressure air solutions. Understanding various methods and technologies can help international B2B buyers make informed decisions that align with their operational needs.

| Aspecto comparativo | Tire Pressure Air | Nitrogen Inflation | Tire Pressure Monitoring Systems (TPMS) |

|---|---|---|---|

| Rendimiento | Standard air improves handling, fuel economy, and tire longevity when maintained | Nitrogen maintains tire pressure longer, reduces oxidation, and improves fuel efficiency | Provides real-time pressure readings, alerts for low pressure, enhances safety |

| Coste | Low initial cost for air filling; ongoing costs for maintenance | Higher initial cost for nitrogen filling and equipment | Moderate cost for installation and potential ongoing monitoring fees |

| Facilidad de aplicación | Easily available at service stations; minimal equipment needed | Requires specialized equipment for filling and monitoring | Integration may require professional installation; user training needed |

| Mantenimiento | Frequent checks needed; susceptible to pressure changes due to temperature | Less frequent checks required; stable pressure over time | Requires periodic battery replacement; needs calibration |

| El mejor caso de uso | General use for passenger and commercial vehicles | Ideal for high-performance vehicles, long-haul trucking, and extreme conditions | Suitable for safety-conscious fleets or vehicles operating in variable conditions |

Nitrogen inflation is an alternative that offers significant advantages over traditional air. One of the primary benefits is that nitrogen molecules are larger than oxygen molecules, which reduces the rate of pressure loss in tires. This characteristic enhances tire longevity and fuel efficiency, making it particularly appealing for businesses with high operational demands, such as logistics and transportation companies. However, the initial cost of nitrogen filling and the need for specialized equipment can be a barrier for some businesses. Additionally, while nitrogen requires less frequent checks, it does not eliminate the need for regular maintenance entirely.

A Tire Pressure Monitoring System (TPMS) provides a modern solution for maintaining optimal tire pressure. By offering real-time monitoring, TPMS alerts drivers to any significant drop in tire pressure, which can prevent accidents and enhance safety. This technology is particularly beneficial for fleets operating in diverse environments, where tire conditions can change rapidly. However, the installation of TPMS can involve upfront costs, and businesses may need to invest in staff training to ensure effective use. Regular maintenance of the system is also essential, as sensors may require battery replacements or recalibration.

When selecting the appropriate tire pressure solution, B2B buyers should consider their specific operational needs, vehicle types, and budget constraints. For businesses that prioritize cost-effectiveness and ease of implementation, traditional tire pressure air may suffice. Conversely, companies focused on performance, safety, and long-term cost savings might benefit from investing in nitrogen inflation or TPMS. Assessing the nature of vehicle usage, environmental factors, and maintenance capabilities will further guide buyers in making a choice that enhances their tire management strategy and overall operational efficiency.

Understanding the technical properties of tire pressure air is crucial for B2B buyers in the automotive sector. Here are key specifications that impact performance, safety, and efficiency.

Pressure Range (PSI)

– Definition: Tire pressure is typically measured in pounds per square inch (PSI). The recommended range for most vehicles lies between 28 and 36 PSI.

– Importance: Maintaining the correct PSI ensures optimal vehicle handling, fuel efficiency, and tire longevity. Low or high pressure can lead to uneven tire wear, reduced traction, and increased risk of blowouts.

Temperature Stability

– Definition: Tire pressure can fluctuate with temperature changes, expanding in heat and contracting in cold conditions.

– Importance: Understanding this property helps businesses plan for seasonal changes. For instance, tires may need to be inflated more during colder months to compensate for pressure drops, affecting inventory and supply chain strategies.

Composición del material

– Definition: The air used in tires can be standard compressed air or nitrogen. Nitrogen is often preferred for performance vehicles due to its lower permeability and moisture content.

– Importance: Choosing the right material affects tire performance and maintenance schedules. For B2B buyers, understanding the material composition helps make informed decisions about tire quality and longevity.

Volume Tolerance

– Definition: This refers to the ability of a tire to maintain its shape and pressure under various load conditions.

– Importance: Proper volume tolerance ensures safety and performance under different weights and driving conditions. Businesses must be aware of this when selecting tires for commercial vehicles that frequently carry heavy loads.

Inflation Techniques

– Definition: The method used to inflate tires, which can include manual pumps, compressors, or automated systems.

– Importance: Efficient inflation techniques can reduce labor costs and improve turnaround times for tire maintenance. B2B buyers should consider the technologies that offer the best efficiency for their operations.

Understanding industry jargon is essential for effective communication and negotiation in the tire supply chain.

OEM (fabricante de equipos originales)

– Definition: Refers to companies that manufacture products that are sold under another company’s brand.

– Importance: B2B buyers often seek OEM tires to ensure compatibility and performance, making this term vital for procurement discussions.

MOQ (Cantidad mínima de pedido)

– Definition: The smallest quantity of a product that a supplier is willing to sell.

– Importance: Knowing the MOQ helps businesses manage inventory and cash flow. It’s crucial for negotiating bulk purchases and understanding supplier constraints.

RFQ (solicitud de presupuesto)

– Definition: A document sent to suppliers asking for a quote on specific products or services.

– Importance: An RFQ is essential for price comparisons and securing favorable terms. B2B buyers should be adept at crafting RFQs to streamline procurement processes.

Incoterms (Términos comerciales internacionales)

– Definition: A set of rules published by the International Chamber of Commerce that define the responsibilities of sellers and buyers in international transactions.

– Importance: Familiarity with Incoterms helps B2B buyers understand shipping costs, risks, and obligations, facilitating smoother international trade agreements.

TPMS (Tire Pressure Monitoring System)

– Definition: An electronic system that monitors the air pressure inside the tires and alerts the driver when levels are low.

– Importance: TPMS enhances safety and can be a selling point for tire products. Buyers should consider the integration of TPMS in their vehicle fleets for optimal performance.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions that enhance operational efficiency and product performance in their tire-related purchases.

The tire pressure air sector is experiencing significant shifts influenced by various global drivers, making it essential for international B2B buyers to stay informed. One primary driver is the increasing emphasis on vehicle safety and performance. Proper tire inflation is critical for fuel efficiency, handling, and tire longevity, prompting manufacturers to innovate in tire pressure management technologies. This includes advancements in Tire Pressure Monitoring Systems (TPMS), which are becoming standard in vehicles worldwide, thereby enhancing the demand for tire pressure air products.

Illustrative image related to tire pressure air

Emerging trends in sourcing include the integration of IoT technologies and smart sensors that provide real-time monitoring of tire pressure, appealing to tech-savvy markets in regions like Europe and South America. This shift towards smart technology is also driven by the growing concerns over fuel economy and environmental impact, as under-inflated tires can lead to increased fuel consumption and higher emissions.

For B2B buyers, understanding these dynamics is crucial. The market is moving towards more reliable and efficient tire pressure solutions, with a focus on reducing maintenance costs and enhancing vehicle performance. Buyers from Africa and the Middle East should be particularly aware of the variations in climate, which can affect tire performance and pressure, necessitating tailored solutions for different environments.

As the global marketplace evolves, sustainability and ethical sourcing are becoming paramount in the tire pressure air sector. The environmental impact of tire production and disposal is significant, prompting businesses to seek more sustainable alternatives. B2B buyers are increasingly prioritizing suppliers that utilize eco-friendly materials and manufacturing processes. This includes the use of recycled materials in tire pressure management products and innovations in production that minimize waste.

Illustrative image related to tire pressure air

Moreover, ethical supply chains are gaining attention as consumers demand transparency. Buyers are encouraged to partner with manufacturers who adhere to stringent labor practices and environmental regulations. Certifications like ISO 14001 for environmental management systems and the Global Recycling Standard can help buyers identify responsible suppliers.

The push for sustainability extends to product development, where “green” certifications are becoming essential. Buyers are looking for products that not only meet performance standards but also align with their corporate social responsibility goals. By sourcing from suppliers committed to sustainability, businesses can enhance their brand reputation while contributing to a more sustainable future.

The tire pressure air sector has evolved significantly over the decades. Initially, tire inflation was a manual process reliant on basic gauges and hand pumps. With the advent of technology, the introduction of TPMS in the early 2000s marked a turning point. This technology provided real-time monitoring of tire pressure, enhancing safety and efficiency.

As consumer expectations and regulatory standards have risen, manufacturers have responded by developing more sophisticated tire pressure solutions, including digital inflators and automated systems. These innovations not only improve safety but also cater to the growing demand for convenience among consumers.

Today, the sector stands at the intersection of technology and sustainability, where the focus is not just on performance but also on minimizing environmental impact. This evolution underscores the importance for B2B buyers to choose partners that are aligned with modern market demands, ensuring they remain competitive in a rapidly changing landscape.

How do I solve inconsistent tire pressure across my fleet?

To address inconsistent tire pressure in your fleet, implement a regular maintenance schedule that includes tire pressure checks. Utilize tire pressure monitoring systems (TPMS) to receive real-time alerts about tire conditions. Additionally, train your staff on how to check and adjust tire pressure accurately, accounting for temperature fluctuations and load variations. Consider investing in automatic tire inflation systems for larger fleets, which can help maintain optimal pressure and improve safety and fuel efficiency.

What is the best tire pressure air solution for commercial vehicles?

The best tire pressure air solution for commercial vehicles typically involves using high-quality compressed air systems that ensure consistent pressure and purity. Look for suppliers that offer specialized tire inflation equipment designed for commercial fleets, which may include digital pressure gauges and automatic inflation systems. Ensure that the solution you choose is compatible with the tire specifications of your vehicles and meets local regulatory standards.

How can I vet suppliers for tire pressure air products?

To vet suppliers for tire pressure air products, assess their reputation through industry reviews and client testimonials. Verify their certifications and compliance with international quality standards, such as ISO 9001. Request samples or trial products to evaluate performance and reliability. Additionally, consider their logistical capabilities and responsiveness to inquiries, which can indicate their commitment to customer service.

What is the minimum order quantity (MOQ) for tire pressure air products?

The minimum order quantity for tire pressure air products varies by supplier and product type. Many manufacturers set MOQs based on production costs and shipping considerations. When negotiating with suppliers, inquire about flexible MOQ options, especially if you’re looking for customization or trial orders. Establishing a good relationship with your supplier may also allow for lower MOQs or more favorable terms.

What payment terms should I expect when sourcing tire pressure air?

Payment terms for sourcing tire pressure air products can differ significantly among suppliers. Common arrangements include partial upfront payments with the balance due upon delivery, or net 30/60 days after invoice. Always clarify payment methods accepted (e.g., bank transfer, credit card, or letters of credit) and ensure they align with your financial processes. Negotiating favorable terms can help manage cash flow and reduce financial risk.

How does temperature affect tire pressure and air quality?

Temperature has a significant impact on tire pressure; for every 10-degree Fahrenheit change, tire pressure can vary by approximately 1 psi. This fluctuation can lead to under-inflation or over-inflation, affecting tire performance and safety. Additionally, the quality of the air used for inflation matters. Ensure that the air is free from moisture and contaminants, as this can lead to tire degradation and inconsistent pressure levels.

What quality assurance measures should I implement when sourcing tire pressure air?

Implementing quality assurance measures involves establishing clear specifications for the air quality, pressure consistency, and performance standards. Request documentation from suppliers that outlines their quality control processes and any third-party testing certifications. Regularly audit your suppliers and perform random checks on delivered products to ensure they meet your standards. Building a strong QA framework will help mitigate risks associated with tire performance.

What logistics considerations should I keep in mind when importing tire pressure air products?

When importing tire pressure air products, consider factors such as shipping methods, customs regulations, and lead times. Evaluate the reliability of your logistics partners and their experience with handling similar products. Additionally, be aware of potential tariffs and duties that may apply to your imports, and ensure that your suppliers can provide necessary documentation for customs clearance. Planning for these logistics elements will streamline the import process and minimize delays.

Dominio: pirelli.com

Matriculado: 1995 (30 años)

Introducción: Recommended tire pressure is established by the car manufacturer and typically falls between 28 and 36 PSI. The correct pressure can be found in the car’s operator manual or on a sticker inside the driver’s door. It is important to check tire pressure when the tires are cold. Maximum tire pressure is stated on the tire sidewall and should not be used for everyday driving as it can impair handling …

Dominio: cars.com

Inscrito: 1998 (27 años)

Introducción: Recommended tire pressures are typically found on a sticker inside the driver-side door, in the glove box, or on the inside of the fuel-filler door. The recommended pressure is a cold inflation pressure, meaning it should be checked when the vehicle has been sitting. Some vehicles have different pressures for front and rear tires, and higher pressures may be listed for heavy loads. Spare tires sho…

Dominio: continental-tires.com

Matriculado: 2000 (25 años)

Introducción: Tire pressure is crucial for vehicle safety and performance. It is recommended to check tire pressure once a month, ideally when the tires are cold. Use a reliable tire pressure gauge to measure the PSI (pounds per square inch) of each tire and compare it to the vehicle handbook for the recommended pressure. Adjust the pressure as needed, considering the vehicle’s load. Underinflated tires can lea…

In summary, strategic sourcing for tire pressure air is essential for optimizing fleet performance and ensuring safety. Proper tire inflation not only enhances fuel efficiency but also extends tire life, reducing overall operational costs. B2B buyers must prioritize sourcing high-quality tire pressure monitoring systems and reliable air inflation solutions that cater to specific vehicle needs across diverse markets in Africa, South America, the Middle East, and Europe.

As tire pressure can fluctuate due to temperature and usage, implementing a proactive maintenance strategy is crucial. This includes regular checks and adjustments based on environmental conditions, which can prevent costly downtime and improve vehicle handling. By leveraging strategic sourcing, businesses can secure favorable pricing and quality assurance, ultimately leading to enhanced operational efficiency.

Looking ahead, international buyers should seek partnerships with suppliers that offer innovative solutions in tire pressure management. Investing in advanced technology and consistent supply chains will not only meet current demands but also prepare for future advancements in automotive safety and efficiency. Engage with trusted providers to elevate your fleet’s performance and ensure safety on the roads.

La información facilitada en esta guía, incluido el contenido relativo a fabricantes, especificaciones técnicas y análisis de mercado, tiene únicamente fines informativos y educativos. No constituye asesoramiento profesional en materia de adquisiciones, asesoramiento financiero ni asesoramiento jurídico.

Aunque hemos hecho todo lo posible por garantizar la exactitud y actualidad de la información, no nos hacemos responsables de posibles errores, omisiones o información obsoleta. Las condiciones del mercado, los detalles de las empresas y las normas técnicas están sujetos a cambios.

Los compradores B2B deben llevar a cabo su propia diligencia debida independiente y exhaustiva antes de tomar cualquier decisión de compra. Esto incluye ponerse en contacto directamente con los proveedores, verificar las certificaciones, solicitar muestras y buscar asesoramiento profesional. El riesgo de confiar en la información contenida en esta guía es responsabilidad exclusiva del lector.

Illustrative image related to tire pressure air