In the fast-paced world of automotive maintenance, sourcing reliable tire inflator hose replacements can pose a significant challenge for B2B buyers across diverse global markets. Whether you are operating in the bustling streets of Lagos, the vibrant cities of Brazil, or the industrial hubs of Europe, ensuring that your tire inflators are equipped with high-quality hoses is essential for optimal performance and customer satisfaction. This guide serves as a comprehensive resource for international buyers, detailing the various types of tire inflator hoses, their applications, and essential considerations for supplier vetting.

The landscape of tire inflator hose replacement is not only about understanding the technical specifications but also about navigating the complexities of global supply chains, pricing models, and quality assurance. By providing insights into material durability, compatibility with different inflator models, and the latest innovations in hose technology, this guide equips B2B buyers with the knowledge needed to make informed purchasing decisions.

Furthermore, we delve into cost analysis, helping businesses assess the long-term value of investments in quality replacements versus cheaper alternatives. With a focus on markets in Africa, South America, the Middle East, and Europe, this guide empowers buyers to streamline their procurement processes, ensuring they can meet the demands of their customers while maintaining operational efficiency. As you navigate the global market for tire inflator hose replacements, let this guide be your trusted companion in achieving excellence in your supply chain management.

| Tipo Nombre | Principales rasgos distintivos | Aplicaciones B2B principales | Breves pros y contras para los compradores |

|---|---|---|---|

| Standard Inflator Hose | Typically made from rubber or PVC; 1/4″ to 1/2″ diameter | Automotive repair shops, tire service centers | Pros: Cost-effective, widely available. Contras: May wear out faster than premium options. |

| Heavy-Duty Inflator Hose | Reinforced materials for enhanced durability | Industrial applications, fleet maintenance | Pros: Long-lasting, withstands high pressures. Contras: Mayor inversión inicial. |

| Inflator Hose with Adapters | Includes various connectors for compatibility | Mobile repair services, diverse vehicle types | Pros: Versatile, easy to use with different vehicles. Contras: May require additional adapters. |

| Coiled Inflator Hose | Space-saving design, retracts when not in use | Workshops with limited space, mobile units | Pros: Reduces clutter, easy to store. Contras: Can tangle if not properly managed. |

| Digital Inflator Hose | Integrated pressure gauge and automatic shut-off | High-end service centers, luxury vehicle maintenance | Pros: Accurate readings, reduces over-inflation risk. Contras: More expensive, requires power source. |

Standard inflator hoses are commonly made from rubber or PVC and typically have diameters ranging from 1/4″ to 1/2″. These hoses are ideal for general automotive use and are prevalent in automotive repair shops and tire service centers. When purchasing, buyers should consider the hose’s pressure rating and compatibility with existing inflator systems. While they are cost-effective and widely available, their lifespan may be shorter compared to more robust options.

Heavy-duty inflator hoses are constructed from reinforced materials designed to withstand higher pressures and harsher conditions. They are suitable for industrial applications and fleet maintenance, where durability is paramount. Buyers should evaluate the hose’s pressure tolerance and the environments in which it will be used. Although these hoses come with a higher price tag, their longevity and reliability can lead to lower overall costs over time.

Inflator hoses with adapters are designed to accommodate various connectors, making them versatile for different vehicle types. This feature is particularly beneficial for mobile repair services that encounter diverse vehicles. When purchasing, businesses should assess the range of adapters included and their ease of use. While these hoses offer great flexibility, the need for additional adapters may complicate the setup for some users.

Illustrative image related to tire inflator hose replacement

Coiled inflator hoses are designed to save space and retract when not in use, making them ideal for workshops with limited storage. Their compact nature can enhance mobility for service providers. Buyers should consider the hose’s length and how it manages tangling, as improper handling can lead to issues. Although they help reduce clutter, users must ensure proper storage to avoid tangling.

Digital inflator hoses come equipped with integrated pressure gauges and often feature automatic shut-off capabilities, providing accurate inflation and reducing the risk of over-inflation. These hoses are commonly used in high-end service centers and for luxury vehicle maintenance. Buyers should look for features like battery life and ease of reading the gauge. While they offer significant advantages in accuracy and safety, the cost and dependency on a power source can be potential drawbacks.

| Industria/Sector | Specific Application of Tire Inflator Hose Replacement | Valor/beneficio para la empresa | Consideraciones clave para el aprovisionamiento de esta aplicación |

|---|---|---|---|

| Talleres de reparación de automóviles | Replacement of inflator hoses for tire servicing | Ensures efficient tire inflation, reducing customer wait times | Quality standards, compatibility with various tire inflators, and local availability |

| Transportation & Logistics | Maintenance of fleet vehicles’ tire inflators | Enhances fleet safety and reduces downtime due to tire issues | Durability under heavy use, adaptability to various vehicle types, and cost-effectiveness |

| Manufacturing & Warehousing | Use in tire inflation for handling equipment | Increases operational efficiency and reduces equipment failure risks | Performance reliability, resistance to wear and tear, and compliance with industry regulations |

| Roadside Assistance Services | Quick hose replacements for emergency tire repairs | Improves service response time and customer satisfaction | Ease of installation, versatility for different tire types, and availability of replacement parts |

| Venta al por menor y comercio electrónico | Selling replacement hoses for consumer tire inflators | Expands product offerings and meets customer DIY needs | Competitive pricing, product variety, and supplier reliability |

In automotive repair shops, tire inflator hose replacements are crucial for maintaining efficient tire servicing operations. When a hose becomes worn or damaged, it can lead to air leaks, making it difficult to inflate tires properly. By replacing these hoses, shops can ensure quick and reliable service, minimizing customer wait times and enhancing overall satisfaction. Buyers in this sector should consider compatibility with various inflator models and the quality of materials to ensure longevity and performance.

In the transportation and logistics industry, maintaining the inflators used on fleet vehicles is essential for safety and operational efficiency. A reliable inflator hose ensures that tires are adequately inflated, reducing the risk of blowouts and improving fuel efficiency. For international buyers, especially in regions like Africa and South America, sourcing durable hoses that can withstand diverse environmental conditions is vital. Cost-effectiveness and adaptability to different vehicle types are also key considerations.

Manufacturing and warehousing operations often rely on tire inflators for handling equipment such as forklifts and pallet jacks. A dependable inflator hose ensures that these vehicles operate smoothly, reducing the likelihood of downtime due to tire-related issues. Buyers should focus on sourcing hoses that are resistant to wear and tear, as well as those that comply with industry safety regulations. This not only enhances equipment reliability but also supports overall operational efficiency.

For roadside assistance services, the ability to quickly replace tire inflator hoses can significantly improve service response times. When a hose fails, having a reliable replacement on hand allows technicians to provide timely assistance to stranded motorists, enhancing customer satisfaction. B2B buyers in this sector should prioritize ease of installation and versatility, ensuring that hoses can accommodate various tire types and valve configurations.

Retailers and e-commerce businesses can expand their product offerings by including tire inflator hose replacements. This caters to consumers who prefer DIY tire maintenance and emergency preparedness. By sourcing a variety of hoses at competitive prices, retailers can attract a broader customer base. Reliability of suppliers and the availability of replacement parts are critical factors that can influence purchasing decisions in this sector, ensuring that customers receive quality products that meet their needs.

Illustrative image related to tire inflator hose replacement

El problema: B2B buyers, particularly in regions like Africa and South America, often encounter challenges when sourcing compatible tire inflator hose replacements. Different brands and models have varying specifications, leading to confusion about which hoses will work with their existing inflators. This can result in costly downtime, as businesses may purchase incorrect parts, leading to delays in service or repair operations.

La solución: To effectively source the correct tire inflator hose replacements, buyers should maintain a comprehensive inventory of their current equipment specifications, including brand, model, and size. When seeking replacements, it’s beneficial to partner with suppliers who offer a wide range of products and can provide compatibility information. Utilizing online platforms that allow for side-by-side comparisons of hose specifications can streamline the selection process. Additionally, consider investing in universal hose adapters that can enhance compatibility across different inflators, thus reducing the risk of mismatched parts.

El problema: One common issue faced by B2B buyers is the poor quality of replacement hoses available in the market. Many low-cost options may seem appealing initially but can lead to frequent failures, leaks, or reduced inflation efficiency. This not only impacts operational efficiency but can also harm the reputation of businesses that rely on reliable tire maintenance services.

La solución: To mitigate the risk of poor-quality hoses, buyers should prioritize sourcing from reputable manufacturers known for their durability and performance standards. Look for hoses that meet industry certifications and specifications, which often indicate higher quality. It’s also advisable to read reviews and seek recommendations from other businesses in the industry. Investing in hoses made from robust materials, such as reinforced rubber or thermoplastic, can provide long-term value despite a higher upfront cost. Establishing long-term relationships with trusted suppliers can also lead to better product guarantees and support.

El problema: Many businesses struggle with the installation and maintenance of tire inflator hoses, which can be complex and time-consuming, especially for staff who may not have specialized training. Complicated connections or the need for specific tools can lead to errors, resulting in inefficient operations and increased labor costs.

La solución: To simplify installation and maintenance, B2B buyers should seek tire inflator hoses designed for ease of use. Look for hoses with quick-connect fittings or standardized connectors that require minimal tools for attachment. Providing staff with training sessions or instructional materials on proper installation techniques can significantly reduce errors and improve efficiency. Additionally, consider implementing a regular maintenance schedule that includes checking connections and hoses for wear and tear. This proactive approach can help identify potential issues before they lead to downtime, ultimately enhancing operational reliability.

When selecting materials for tire inflator hose replacements, it is crucial to consider various factors that affect performance, durability, and cost. The following analysis outlines four common materials used in tire inflator hoses, providing insights into their properties, advantages, disadvantages, and specific considerations for international B2B buyers.

Rubber is one of the most widely used materials for tire inflator hoses due to its excellent flexibility and resilience. It typically has a temperature rating of -40°F to 212°F and can handle pressures up to 300 PSI. Rubber hoses are generally resistant to abrasion and provide a good seal against air leaks.

Pros: Rubber hoses are durable and can withstand harsh environmental conditions, making them suitable for various applications. They are also relatively inexpensive to manufacture, which can lead to lower costs for end-users.

Contras: However, rubber can degrade over time due to exposure to UV light and ozone, which may limit its lifespan. Additionally, rubber hoses may not be suitable for high-temperature applications beyond their rated limits.

Impacto en la aplicación: Rubber hoses are compatible with air and various gases, making them versatile for tire inflators. However, they may not be suitable for corrosive media.

Illustrative image related to tire inflator hose replacement

Consideraciones para compradores internacionales: Compliance with international standards like ASTM and DIN is essential. Buyers in regions like Africa and South America should ensure that the rubber used meets local regulations regarding material safety and environmental impact.

Polyvinyl Chloride (PVC) is another popular material for tire inflator hoses. It offers a temperature range of -10°F to 150°F and can handle pressures up to 200 PSI. PVC is known for its excellent chemical resistance and is lightweight, making it easy to handle.

Pros: The primary advantage of PVC hoses is their resistance to a wide range of chemicals, which makes them suitable for various applications. They are also less expensive than rubber hoses.

Contras: On the downside, PVC hoses are less flexible than rubber, which can make them more challenging to work with in tight spaces. They may also become brittle over time, especially in cold conditions.

Impacto en la aplicación: PVC hoses are ideal for air and non-corrosive gases but may not be suitable for high-pressure applications.

Illustrative image related to tire inflator hose replacement

Consideraciones para compradores internacionales: Buyers should be aware of the specific chemical compatibility of PVC with the media used in their applications. Compliance with local and international standards is crucial, particularly in Europe, where regulations on plastic materials are stringent.

Nylon hoses are known for their high strength and durability, with a temperature rating of -40°F to 200°F and a pressure capacity of up to 300 PSI. Nylon is also resistant to abrasion and has excellent tensile strength.

Pros: The key advantage of nylon is its ability to withstand high pressures and mechanical stress, making it suitable for heavy-duty applications. It is also lightweight and flexible.

Contras: However, nylon hoses can be more expensive than rubber or PVC options. They may also absorb moisture, which can lead to swelling and reduced performance over time.

Impacto en la aplicación: Nylon hoses are compatible with air and various gases, making them versatile. However, they may not be suitable for applications involving corrosive substances.

Consideraciones para compradores internacionales: Buyers should ensure that nylon hoses comply with relevant standards and regulations in their regions, especially in the Middle East, where temperature fluctuations can affect performance.

Silicone is a high-performance material with a temperature range of -100°F to 500°F and a pressure rating of up to 150 PSI. It is known for its excellent flexibility and resistance to extreme temperatures and environmental conditions.

Illustrative image related to tire inflator hose replacement

Pros: Silicone hoses are highly durable and can maintain their integrity in extreme conditions. They are also resistant to UV light and ozone, which enhances their lifespan.

Contras: The primary drawback is the higher cost of silicone compared to other materials. Additionally, silicone hoses may not be suitable for high-pressure applications.

Impacto en la aplicación: Silicone hoses are ideal for air and non-corrosive gases but may not be the best choice for applications requiring high pressure.

Consideraciones para compradores internacionales: Buyers should ensure that silicone hoses meet international standards for safety and performance, particularly in Europe, where product quality is closely monitored.

| Material | Typical Use Case for tire inflator hose replacement | Ventajas clave | Principales desventajas/limitaciones | Coste relativo (Bajo/Medio/Alto) |

|---|---|---|---|---|

| Goma | General-purpose tire inflators | Excellent flexibility and durability | Degrades under UV exposure | Bajo |

| PVC | Lightweight inflators for non-corrosive gases | Good chemical resistance | Less flexible, can become brittle | Bajo |

| Nylon | Heavy-duty applications requiring high pressure | Alta resistencia y durabilidad | More expensive, moisture absorption | Med |

| Silicone | Extreme temperature applications | Excellent temperature resistance | Higher cost, limited high-pressure use | Alta |

This comprehensive analysis of materials for tire inflator hose replacements provides valuable insights for B2B buyers, enabling them to make informed decisions based on performance, cost, and compliance with international standards.

The manufacturing process for tire inflator hoses involves several critical stages designed to ensure durability and performance.

The first stage is material preparation, where high-quality rubber, thermoplastics, or a combination of both are sourced. The choice of material directly impacts the hose’s flexibility, resistance to wear, and ability to withstand high pressure. Suppliers often use reinforced materials that can endure the stresses of inflation and deflation cycles. Additionally, sourcing materials from reputable suppliers with established quality standards is crucial for ensuring reliability.

Illustrative image related to tire inflator hose replacement

In the forming stage, the prepared materials are shaped into the required hose dimensions. Techniques such as extrusion are commonly employed, where heated material is forced through a die to create a continuous length of hose. This process allows for precise control over the diameter and wall thickness, which are critical for performance. Manufacturers may also use molding techniques for specific components, such as connectors and fittings, ensuring that they fit securely and maintain an airtight seal.

Following forming, the assembly stage involves connecting various components, including the hose itself, fittings, and any additional adapters. This stage is critical because improper assembly can lead to leaks or failures during use. Manufacturers often utilize automated machinery for consistent assembly, although manual checks are essential for quality assurance. The compatibility of different hose ends with tire valve stems is a key consideration, particularly with the variety of valve types used globally.

Finally, the finishing process involves testing the assembled hoses for leaks and pressure resistance, as well as applying any surface treatments. This might include applying a protective coating to enhance durability against environmental factors such as UV exposure and ozone degradation. Proper finishing ensures that the hoses meet both aesthetic and functional standards, appealing to B2B buyers looking for reliable, long-lasting products.

Quality assurance (QA) is a vital aspect of manufacturing tire inflator hoses, ensuring that products meet international standards and customer expectations.

Many manufacturers adhere to internationally recognized standards such as ISO 9001, which outlines a framework for quality management systems. Compliance with ISO standards is an indicator of a manufacturer’s commitment to quality and continual improvement. Additionally, industry-specific certifications, such as CE marking for products sold in Europe and API standards for automotive products, can further assure buyers of the product’s reliability and safety.

Quality control (QC) typically involves several checkpoints throughout the manufacturing process:

Control de calidad entrante (IQC): This initial checkpoint assesses raw materials and components before they enter production. Ensuring that materials meet specified standards helps prevent defects later in the process.

Control de calidad durante el proceso (IPQC): During manufacturing, IPQC is conducted at various stages to monitor processes and detect any deviations from quality standards. This may include checking dimensions, pressure tests, and visual inspections.

Control de calidad final (CCF): After assembly, FQC involves comprehensive testing of the finished product. This includes pressure testing and leak detection to ensure that the hoses perform as expected under real-world conditions.

Testing methods for tire inflator hoses can include:

Hydrostatic Testing: This method involves filling the hose with water and pressurizing it to check for leaks.

Burst Testing: Hoses are subjected to high pressure until they fail, allowing manufacturers to determine their maximum working pressure.

Flexibility Tests: These tests assess how well the hose performs under bending and twisting, ensuring it can withstand usage without cracking or kinking.

For B2B buyers, especially those in regions such as Africa, South America, the Middle East, and Europe, verifying supplier quality control practices is essential to ensure product reliability.

Conduct Audits: Buyers should perform regular audits of their suppliers to assess compliance with quality standards. This can include reviewing documentation, observing production processes, and checking for adherence to safety protocols.

Solicitar informes de calidad: Suppliers should provide detailed quality reports that outline testing results, compliance with international standards, and any corrective actions taken in response to past issues.

Utilize Third-Party Inspection Services: Engaging third-party inspection agencies can provide an unbiased assessment of a supplier’s quality control processes. These agencies can perform inspections at various stages of production, ensuring that quality is maintained.

Establish Long-term Relationships: Building strong relationships with suppliers can facilitate better communication regarding quality expectations and improvements. Long-term partnerships often lead to better understanding and cooperation on quality initiatives.

B2B buyers in different regions face unique challenges regarding quality control. For instance, buyers from Africa or South America may encounter suppliers who are less familiar with international standards. It is crucial for these buyers to:

Communicate Clearly: Ensure that quality expectations are clearly communicated and documented to avoid misunderstandings.

Be Aware of Local Regulations: Understand any local regulations that may affect product quality and safety standards, as these can vary significantly by region.

Leverage Technology: Utilize technology for real-time monitoring of production processes and quality checks, especially when dealing with suppliers in different time zones or regions.

In conclusion, a thorough understanding of the manufacturing processes and robust quality assurance measures is essential for B2B buyers seeking reliable tire inflator hose replacements. By prioritizing quality at every stage, from material selection to final testing, manufacturers can meet the rigorous demands of the global market. Buyers must also take proactive steps to verify and validate supplier quality control practices to ensure they are getting the best products for their needs.

To ensure a successful procurement process for tire inflator hose replacement, this guide offers a structured checklist tailored for B2B buyers. By following these steps, you can streamline your sourcing process and make informed decisions that align with your operational needs.

Understanding the technical requirements of the tire inflator hose is fundamental. This includes the diameter, material, and pressure rating necessary for your specific applications. Clearly defined specifications will help you avoid costly mistakes and ensure compatibility with existing equipment.

Finding trustworthy suppliers is critical for maintaining quality and reliability. Research potential suppliers in your target regions—Africa, South America, the Middle East, and Europe—to ensure they can meet your sourcing needs.

Before finalizing any agreements, verify that your suppliers hold relevant certifications. This step ensures compliance with safety and quality standards, which is particularly important in the automotive sector.

Illustrative image related to tire inflator hose replacement

Before making a bulk purchase, request samples to assess the quality of the hoses. This step is vital to verify that the products meet your specifications and performance expectations.

Once you’ve selected potential suppliers, engage in negotiations regarding pricing, delivery terms, and payment conditions. This step can significantly impact your overall procurement costs.

Implementing a quality assurance process ensures ongoing compliance with your specifications. This step helps mitigate risks associated with defective products.

Illustrative image related to tire inflator hose replacement

After the initial procurement, continuously review your supply chain for efficiency and effectiveness. Look for opportunities to optimize processes and relationships with suppliers.

By following this comprehensive checklist, B2B buyers can navigate the tire inflator hose replacement procurement process with confidence, ensuring they source quality products that meet their operational needs.

When sourcing tire inflator hose replacements, it is essential to understand the various cost components that contribute to the overall pricing. These components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margins.

Materiales: The choice of materials significantly impacts cost. High-quality rubber or thermoplastic elastomers are typically used for durability, but these materials come at a premium. Low-cost alternatives may save money initially but can lead to frequent replacements, ultimately increasing the total cost of ownership.

Trabajo: Labor costs vary based on the region and the complexity of the manufacturing process. In markets with lower wage rates, such as some countries in Africa or South America, labor costs may be less, but this could be offset by the need for skilled labor for quality assurance and precision in production.

Gastos generales de fabricación: This includes indirect costs related to production, such as utilities, rent, and salaries of support staff. A higher manufacturing overhead can indicate a more sophisticated manufacturing process, which may justify a higher price due to improved quality and reliability.

Herramientas: The initial investment in tooling can be significant, especially for custom or specialized hose designs. Buyers should inquire about tooling costs and whether they will be amortized over a certain production volume to understand their long-term cost implications.

Control de calidad: Implementing rigorous QC processes ensures product reliability but adds to the overall cost. Certifications (e.g., ISO standards) that demonstrate compliance with international quality benchmarks may also influence pricing.

Logística: Shipping costs can vary widely based on distance, shipping method, and Incoterms. International buyers must consider the additional costs associated with customs duties, taxes, and potential delays in transit.

Margen: Suppliers typically mark up prices to maintain profitability. Understanding the expected margin in your market can help in negotiations.

Several factors can influence pricing when sourcing tire inflator hoses, particularly for international B2B buyers:

Volumen y cantidad mínima de pedido (MOQ): Larger orders often lead to lower per-unit costs due to economies of scale. Negotiating favorable MOQs can help in achieving better pricing.

Especificaciones y personalización: Customized hoses that meet specific performance criteria or certifications may incur higher costs. Buyers should balance the need for customization with budget constraints.

Calidad del material y certificaciones: Higher-quality materials and certifications can justify a higher price point. Buyers should evaluate the long-term benefits of investing in quality against the risk of frequent replacements.

Factores del proveedor: The reliability, reputation, and geographic location of suppliers can significantly impact pricing. Suppliers in regions with established manufacturing capabilities may offer more competitive prices due to lower operational costs.

Incoterms: Understanding Incoterms is crucial for managing logistics costs. Buyers should ensure clarity on responsibilities for shipping, insurance, and tariffs to avoid unexpected expenses.

Negociar las condiciones: Always negotiate payment terms, lead times, and delivery schedules. Flexibility on both sides can lead to cost savings and better relationships.

Evaluar el coste total de propiedad (TCO): Consider not just the upfront cost but the long-term implications of the product’s lifespan, maintenance, and performance. A higher initial investment may lead to lower overall costs.

Seek Multiple Quotes: Obtaining quotes from various suppliers can provide leverage in negotiations and help identify the market price range.

Entender los matices de los precios en los mercados internacionales: Different regions may have unique pricing structures influenced by local demand, supply chain logistics, and economic conditions. For example, buyers in Nigeria or Brazil should be aware of currency fluctuations and import duties that could affect final pricing.

Realizar estudios de mercado: Staying informed about trends, emerging suppliers, and innovations in tire inflator technology can provide insights that enhance negotiation power.

Prices discussed in this analysis are indicative and subject to change based on market conditions, supplier negotiations, and other factors. Buyers should conduct thorough research and due diligence when making sourcing decisions.

In the realm of tire maintenance, the importance of reliable inflation tools cannot be overstated. While tire inflator hose replacement is a common solution for maintaining proper tire pressure, several alternatives exist that may better suit specific needs and preferences. This analysis delves into how tire inflator hose replacement compares to other viable options, helping B2B buyers make informed decisions.

| Aspecto comparativo | Tire Inflator Hose Replacement | Compresor de aire portátil | Tire Sealant |

|---|---|---|---|

| Rendimiento | Restores original functionality, ensuring proper tire inflation. | Provides quick inflation; may vary in power. | Seals punctures, maintaining air pressure without inflating. |

| Coste | Moderate cost for hose and installation. | Varies widely; generally higher upfront cost. | Low-cost solution for minor repairs. |

| Facilidad de aplicación | Requires mechanical skill for installation. | User-friendly; plug-and-play operation. | Simple application; no tools needed. |

| Mantenimiento | Periodic checks required; hoses may wear over time. | Requires maintenance; check for leaks and battery life. | Minimal maintenance; single-use or limited applications. |

| El mejor caso de uso | Ideal for long-term tire maintenance in fleets or workshops. | Best for on-the-go inflation needs, especially for individual users. | Suitable for emergency situations or temporary fixes. |

Portable air compressors are a popular alternative for tire inflation. They provide quick inflation and are often compact enough to fit in a vehicle’s trunk. However, their performance can vary significantly between models. While some compressors can inflate tires quickly, others may struggle with larger tires or require frequent recharging. Additionally, the initial investment can be higher than simply replacing a hose. They are ideal for users who prioritize convenience and speed, especially in emergency situations.

Tire sealants are a practical solution for minor tire punctures, providing a quick fix without the need for immediate inflation. They work by sealing small holes as air escapes, allowing drivers to continue their journey with minimal interruption. However, sealants are not a substitute for proper tire maintenance and should only be used as a temporary fix. Their effectiveness diminishes with larger punctures, and they may require professional repair afterward. This option is particularly beneficial for emergency scenarios where time is of the essence.

When considering the best solution for tire maintenance, B2B buyers must evaluate their specific needs. Tire inflator hose replacement is an excellent choice for businesses that require reliable, long-term performance, particularly in fleet management or workshops. Conversely, portable air compressors offer convenience for businesses that need quick inflation solutions for individual users or emergency situations. Tire sealants serve as a temporary fix but should not be relied upon for long-term maintenance. By analyzing performance, cost, ease of implementation, and maintenance needs, buyers can choose the right solution that aligns with their operational goals and budget constraints.

When considering tire inflator hose replacement, understanding the essential technical properties and industry-specific terminology is crucial for making informed purchasing decisions. Here’s a breakdown of the key specifications and trade terms relevant to this component.

Calidad del material

Tire inflator hoses are typically made from durable materials such as rubber, PVC, or polyurethane. The material grade affects the hose’s flexibility, resistance to abrasion, and longevity under various environmental conditions. For B2B buyers, selecting the right material ensures that the hoses can withstand the rigors of frequent use and the potential exposure to oils, chemicals, or extreme temperatures.

Pressure Rating

This specification indicates the maximum pressure the hose can safely handle, often measured in PSI (pounds per square inch). A higher pressure rating is essential for commercial applications where inflating larger tires or operating under high-pressure conditions is necessary. Understanding the pressure requirements helps prevent hose failure during operation, ensuring safety and efficiency.

Diameter

The inner diameter of the hose impacts the airflow and inflation speed. Common sizes include 1/4 inch and 3/8 inch. Selecting the appropriate diameter is vital for achieving optimal performance, especially in high-demand scenarios. A larger diameter can facilitate faster inflation, which is beneficial for businesses that prioritize efficiency.

Temperature Range

Tire inflator hoses must perform effectively across a range of temperatures. The specified temperature range indicates the environments in which the hose can function without degrading. For B2B buyers, this property is critical when operating in regions with extreme climates, ensuring that the hoses maintain their integrity and performance.

Connector Type

The type of connector—such as twist-on or press-on—affects the ease of use and compatibility with various tire valves. Understanding connector types is essential for ensuring that the replacement hoses can be used with existing inflators and tire systems without requiring additional adapters or modifications.

OEM (fabricante de equipos originales)

This term refers to products made by the original manufacturer of the equipment. In the context of tire inflator hoses, OEM parts are designed to meet the specifications of the original device, ensuring compatibility and performance. B2B buyers often prefer OEM parts to maintain the quality and reliability of their equipment.

MOQ (Cantidad mínima de pedido)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is essential for businesses to manage inventory and cost-effectiveness. Buyers should negotiate MOQs based on their operational needs to avoid overstocking or understocking situations.

RFQ (solicitud de presupuesto)

An RFQ is a document sent to suppliers requesting pricing and terms for specific products. This term is crucial in B2B transactions as it helps businesses obtain competitive pricing and negotiate terms effectively. Including detailed specifications in an RFQ can lead to more accurate and favorable responses.

Incoterms (Términos comerciales internacionales)

These are standardized terms used in international trade to define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with Incoterms helps B2B buyers understand shipping costs and liabilities, facilitating smoother transactions across borders.

Plazos de entrega

Lead time refers to the time it takes from placing an order to receiving the goods. For tire inflator hoses, understanding lead times is crucial for inventory management and ensuring that businesses can meet customer demands without interruption.

By comprehensively understanding these technical properties and trade terms, B2B buyers can make informed decisions that align with their operational needs and enhance their procurement strategies.

The tire inflator hose replacement market is shaped by various global drivers that influence both supply and demand. A significant factor is the rising vehicle ownership in emerging markets such as Africa and South America, where countries like Nigeria and Brazil are witnessing increased automobile usage. This trend is driving demand for reliable tire maintenance products, including inflator hoses. Furthermore, the shift towards e-commerce platforms has made it easier for B2B buyers to source quality products from international suppliers, resulting in more competitive pricing and expanded product options.

Another crucial trend is the incorporation of advanced materials and technologies in the production of tire inflator hoses. Manufacturers are increasingly adopting durable and flexible materials that withstand harsh conditions, which is particularly relevant for buyers in regions with varied climates. Additionally, innovations such as quick-connect fittings are becoming standard, enhancing user convenience and efficiency during inflation. As a result, international buyers are encouraged to consider suppliers who emphasize technological advancements in their offerings.

Moreover, fluctuating raw material costs and supply chain disruptions due to global events have created a volatile market environment. Buyers must remain vigilant in evaluating suppliers based on their ability to maintain consistent quality and pricing. By leveraging data analytics and market research, businesses can make informed sourcing decisions that align with their operational needs.

Illustrative image related to tire inflator hose replacement

Sustainability and ethical sourcing are increasingly critical for B2B buyers in the tire inflator hose replacement sector. The environmental impact of products is a growing concern, prompting buyers to seek out suppliers who prioritize eco-friendly materials and manufacturing processes. For instance, the use of recycled plastics and biodegradable materials in the production of inflator hoses can significantly reduce waste and carbon footprints.

Furthermore, ethical supply chains are becoming a priority as buyers recognize the importance of fair labor practices and responsible sourcing. Suppliers who can demonstrate compliance with international labor standards and possess relevant certifications, such as ISO 14001 for environmental management, are likely to gain a competitive edge. Buyers in regions like Europe, where regulatory frameworks are stringent, are particularly focused on sourcing from companies that uphold these standards.

Additionally, the demand for ‘green’ certifications is on the rise, as businesses strive to enhance their brand reputation by aligning with sustainable practices. Suppliers that can provide transparent information about their sourcing and manufacturing processes are better positioned to meet the expectations of conscientious buyers. Emphasizing sustainability not only helps in compliance with regulations but also appeals to a growing consumer base that values eco-friendly products.

The tire inflator hose replacement market has undergone significant evolution over the past few decades. Initially, tire inflators were basic devices with limited functionality, primarily aimed at providing emergency solutions for flat tires. As automotive technology advanced, so did the design and materials used in inflator hoses. The introduction of high-pressure hoses and quick-release connectors has greatly improved usability and efficiency.

Illustrative image related to tire inflator hose replacement

In recent years, the market has seen an influx of portable and battery-operated inflators, catering to the increasing demand for convenience among consumers. With the rise of e-commerce, buyers can now easily access a wide range of products from global suppliers, allowing for better price comparisons and product selection. This shift has led to increased competition, driving innovation and improvements in product quality.

Today, the focus on sustainability and ethical sourcing is reshaping the market landscape. As buyers become more discerning, they are looking for suppliers who not only offer high-quality products but also adhere to sustainable practices. This evolution indicates a promising future for the tire inflator hose replacement sector, where technological advancements and ethical considerations go hand in hand.

How do I solve a leak in my tire inflator hose?

To address a leak in your tire inflator hose, first, identify the source of the leak by visually inspecting the hose for cracks or holes. If the damage is minor, consider using a hose repair kit that typically includes patches and adhesives designed for rubber or plastic materials. For more significant damage, replacing the entire hose may be necessary. Ensure compatibility with your inflator model and check for quality assurance certifications to guarantee durability and performance. If sourcing from international suppliers, confirm their return policy in case the replacement does not meet expectations.

What is the best tire inflator hose replacement for high-pressure applications?

For high-pressure applications, choose a tire inflator hose made from reinforced materials such as rubber or thermoplastic. These hoses should have a higher PSI rating, typically above 150 PSI, to ensure safety and efficiency. Brands known for quality, like Viair and Slime, often provide durable options. When sourcing, verify that the hose features high-quality fittings that can withstand repeated connections without failure. Additionally, inquire about certifications that ensure compliance with international standards, especially if you are importing from regions with varying regulations.

What customization options are available for tire inflator hoses?

Many suppliers offer customization options for tire inflator hoses, including length, diameter, and connector types. Custom lengths can help fit specific applications, especially in commercial settings where standard sizes may not suffice. Furthermore, you can request branding options, such as printed logos or colors, to align with your company’s branding strategy. When negotiating with suppliers, ensure they can accommodate your customization requests without significantly increasing lead times or costs, and confirm any minimum order quantities (MOQs) that may apply.

What are the minimum order quantities (MOQs) for tire inflator hose replacements?

Minimum order quantities (MOQs) for tire inflator hose replacements can vary widely among suppliers, often depending on the type and customization of the hose. Typically, standard hoses may have an MOQ of 100 to 500 units, while customized options could require higher quantities. When sourcing, it’s advisable to discuss MOQs upfront to understand your purchasing commitments. If your needs are lower than the MOQ, consider consolidating orders with other products or finding a supplier willing to negotiate terms based on your business relationship.

What payment terms should I expect when sourcing tire inflator hoses internationally?

Payment terms for international sourcing can vary significantly. Common practices include upfront payment, deposits, or payment upon delivery. Letter of Credit (LC) is often used for larger transactions to secure both parties. It’s crucial to clarify payment terms with your supplier to avoid misunderstandings. Additionally, consider the implications of currency exchange rates and transaction fees. If you’re working with suppliers from Africa, South America, the Middle East, or Europe, ensure you understand their preferred payment methods and any potential risks involved.

How do I vet suppliers for tire inflator hose replacements?

Vetting suppliers for tire inflator hose replacements involves several steps. Start by researching their reputation through online reviews, industry forums, and trade references. Request samples to assess product quality before placing a bulk order. Additionally, check for relevant certifications that indicate compliance with international quality standards, such as ISO or CE. Engaging in direct communication can also provide insights into their customer service and responsiveness. Attend trade shows or industry exhibitions to meet suppliers in person and build relationships that may lead to better deals.

What logistics considerations should I keep in mind when importing tire inflator hoses?

Logistics considerations for importing tire inflator hoses include shipping methods, customs regulations, and delivery timelines. Decide whether to use air freight for faster delivery or sea freight for cost-effectiveness. Familiarize yourself with the customs duties and tariffs applicable to your product category in your country. It’s advisable to work with a freight forwarder who understands the nuances of international shipping and can navigate customs clearance efficiently. Additionally, ensure your supplier provides the necessary documentation, such as invoices and certificates of origin, to facilitate smooth customs processing.

How can I ensure quality assurance for tire inflator hose replacements?

To ensure quality assurance for tire inflator hose replacements, establish clear specifications and standards before placing orders. Request certifications that validate the product’s compliance with international quality standards. Implement a quality control process that includes inspecting samples upon arrival and conducting regular audits on suppliers. Additionally, consider establishing a return policy for defective products and maintaining open communication with your supplier regarding any quality issues. Building a long-term relationship with reliable suppliers can also enhance the consistency of quality you receive.

Dominio: reddit.com

Matriculado: 2005 (20 años)

Introducción: Portable air compressor with a hose that can develop a rip, making it unable to inflate. The hose is attached to the air pump, possibly in a crimped manner. Users suggest that instead of replacing the hose, it may be easier to repair it by cutting out the torn section and using barbed fittings and hose clamps. Alternatively, the hose could potentially be unscrewed and replaced with a new one by lo…

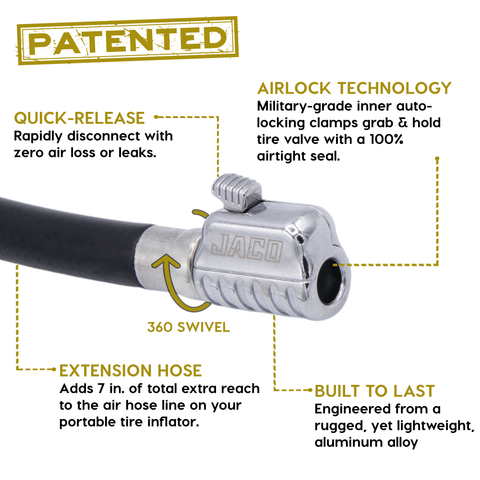

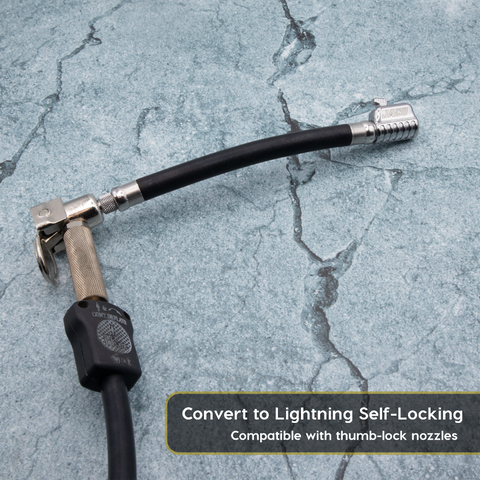

Dominio: jacosuperiorproducts.com

Registrado: 2014 (11 años)

Introducción: Tire Inflator Hose Extension Nozzle, Extra 15% Off Orders Over $50 (Ends 11/30) – Use Code: BF2025, 100% Free Shipping on All Orders in the USA, JACO Superior Products, Customer Testimonials highlight product quality and customer service.

Dominio: airhead.com

Matriculado: 1995 (30 años)

Introducción: {“product_name”: “Towable Air Pump Hose Replacement”, “price”: “$12.99”, “item_number”: “AHP-120HP-HOSE”, “description”: “Air Pump Hose Replacement and Adaptors for AHP-120HP Pump”, “warning”: “WARNING: This product can expose you to chemicals including Vinyl chloride, which is known to the State of California to cause cancer, and Di-n-hexyl Phthalate (DnHP), which is known to the State of Califor…

In conclusion, the strategic sourcing of tire inflator hose replacements offers significant advantages for international B2B buyers, particularly in emerging markets like Africa, South America, the Middle East, and Europe. By leveraging reliable suppliers and understanding product specifications, businesses can ensure they are equipped with high-quality components that enhance operational efficiency and customer satisfaction.

Investing in the right inflator hose solutions not only reduces downtime but also contributes to long-term cost savings through improved durability and performance. Buyers should prioritize partnerships with manufacturers that provide comprehensive support, including technical assistance and after-sales service, to navigate the complexities of sourcing in diverse markets.

Looking ahead, the demand for tire inflator hose replacements is expected to grow alongside the automotive industry. Now is the time for businesses to assess their sourcing strategies and align with suppliers that can meet future needs. By taking proactive steps today, international buyers can position themselves for success and capitalize on emerging opportunities in the global marketplace. Embrace this chance to strengthen your supply chain and drive your business forward.

La información facilitada en esta guía, incluido el contenido relativo a fabricantes, especificaciones técnicas y análisis de mercado, tiene únicamente fines informativos y educativos. No constituye asesoramiento profesional en materia de adquisiciones, asesoramiento financiero ni asesoramiento jurídico.

Aunque hemos hecho todo lo posible por garantizar la exactitud y actualidad de la información, no nos hacemos responsables de posibles errores, omisiones o información obsoleta. Las condiciones del mercado, los detalles de las empresas y las normas técnicas están sujetos a cambios.

Los compradores B2B deben llevar a cabo su propia diligencia debida independiente y exhaustiva antes de tomar cualquier decisión de compra. Esto incluye ponerse en contacto directamente con los proveedores, verificar las certificaciones, solicitar muestras y buscar asesoramiento profesional. El riesgo de confiar en la información contenida en esta guía es responsabilidad exclusiva del lector.