In today’s dynamic global marketplace, sourcing the right wheel air compressor can be a daunting task for international B2B buyers, especially with the diverse range of products and suppliers available. The challenge lies not only in identifying the most suitable type of compressor for specific applications—be it for automotive, industrial, or recreational use—but also in navigating the complexities of supplier reliability and cost-effectiveness. This comprehensive guide aims to equip decision-makers from regions such as Africa, South America, the Middle East, and Europe—including key markets like Nigeria and Germany—with the insights necessary to make informed purchasing decisions.

Throughout this guide, we will explore various types of wheel air compressors, their applications across different industries, and criteria for effectively vetting suppliers. Additionally, we will delve into cost considerations, market trends, and best practices for integration into existing operations. By synthesizing critical information and actionable strategies, this resource empowers B2B buyers to streamline their sourcing processes and secure the best value for their investments. Whether you’re looking to enhance operational efficiency or ensure compliance with regional standards, understanding the nuances of the wheel air compressor market is essential for fostering long-term success and competitiveness in your business endeavors.

| Tipo Nombre | Principales rasgos distintivos | Aplicaciones B2B principales | Breves pros y contras para los compradores |

|---|---|---|---|

| Portable Tire Inflators | Compact, lightweight, often battery-operated | Automotive repair, roadside assistance | Pros: Easy to transport, quick inflation. Contras: Limited power, not suitable for heavy-duty tasks. |

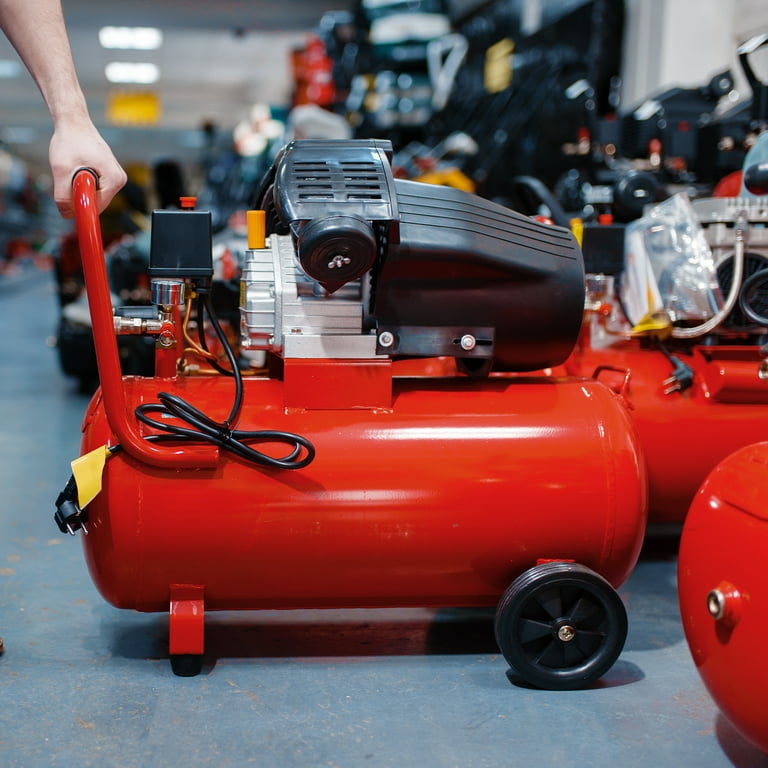

| Electric Wheel Compressors | High power output, suitable for continuous use | Manufacturing, construction | Pros: Powerful, can run multiple tools. Contras: Requires electricity, less portable. |

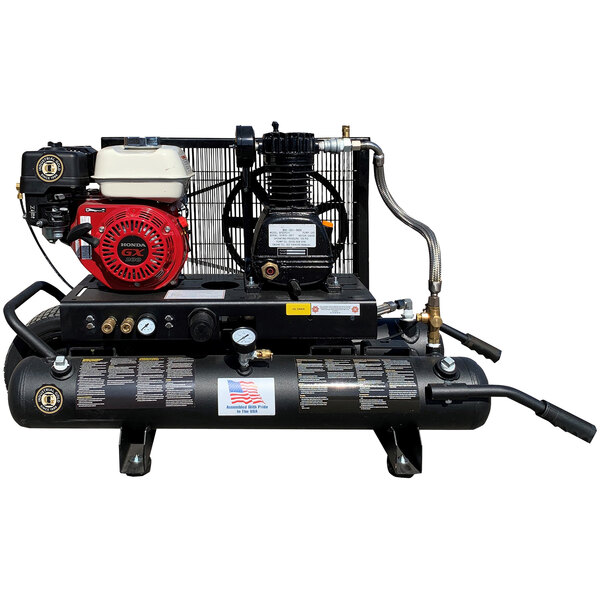

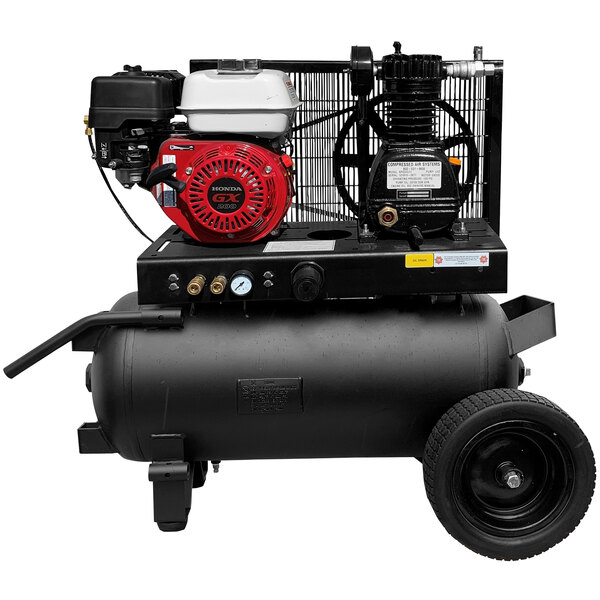

| Gas-Powered Compressors | Operated by gasoline engines, high mobility | Remote job sites, off-road vehicles | Pros: High mobility, powerful in remote areas. Contras: Maintenance-intensive, noise and emissions. |

| Heavy-Duty Air Compressors | Large tanks, high CFM output, robust construction | Industrial applications, heavy machinery | Pros: Suitable for demanding tasks, consistent performance. Contras: Expensive, requires significant space. |

| Multi-Function Compressors | Versatile, often includes additional features | Various sectors, DIY projects | Pros: Multi-purpose, space-saving. Contras: Complexity may deter some users, can be pricier. |

Portable tire inflators are designed for quick and efficient tire inflation, making them ideal for automotive repair businesses and roadside assistance services. Their compact size allows them to be easily transported in vehicles or stored in tight spaces. B2B buyers should consider their power source—battery-operated models provide convenience for mobile applications, while those that plug into a vehicle’s power outlet offer reliability. However, these inflators generally have limited power and may not be suitable for heavy-duty inflation tasks.

Electric wheel compressors are characterized by their high power output, making them suitable for continuous use in manufacturing and construction environments. These compressors can operate multiple pneumatic tools simultaneously, providing a reliable air supply for various applications. B2B buyers should evaluate their power requirements and ensure that the compressor can handle the necessary air demands. While they are efficient and powerful, electric compressors require a stable electricity supply, which may limit their use in remote locations.

Gas-powered compressors are favored for their mobility and ability to operate in remote job sites without the need for electrical outlets. These compressors are typically equipped with gasoline engines, allowing them to provide a high output of compressed air. They are particularly useful for off-road vehicles and construction sites where electricity is not readily available. However, B2B buyers should be aware of the maintenance needs associated with gas engines, as well as the noise and emissions they produce, which could impact worksite regulations.

Heavy-duty air compressors are designed for demanding industrial applications, featuring large tanks and high CFM (cubic feet per minute) output. They are ideal for powering heavy machinery and tools in manufacturing settings. Businesses involved in construction or heavy-duty repairs will benefit from their consistent performance and reliability. However, these compressors can be expensive and require significant space, making them a considerable investment for B2B buyers. Evaluating the specific air demands of the intended applications is crucial when selecting a heavy-duty compressor.

Multi-function compressors offer versatility by incorporating various features such as tire inflation, air tools operation, and even inflation for sports equipment. This makes them suitable for a wide range of sectors, including automotive, DIY projects, and general maintenance tasks. B2B buyers appreciate the space-saving design, as these compressors can replace multiple single-function tools. However, the complexity of some models may deter users unfamiliar with their operation, and the initial investment can be higher than standard models.

| Industria/Sector | Specific Application of Wheel Air Compressor | Valor/beneficio para la empresa | Consideraciones clave para el aprovisionamiento de esta aplicación |

|---|---|---|---|

| Reparación de automóviles | Tire inflation for vehicle servicing | Enhances service efficiency and customer satisfaction | Look for portability, PSI capacity, and durability |

| Construcción | Powering pneumatic tools for construction tasks | Increases productivity and reduces downtime | Ensure compatibility with tools and adequate air flow |

| Agricultura | Inflating agricultural equipment tires | Ensures optimal performance and reduces equipment wear | Evaluate tire size compatibility and ruggedness |

| Transportation & Logistics | Maintenance of fleet vehicles | Improves fleet reliability and reduces operational costs | Consider power source options and ease of transport |

| Fabricación | Operating air-powered machinery | Enhances production efficiency and operational safety | Focus on pressure ratings and energy efficiency |

In the automotive repair industry, wheel air compressors are essential for tire inflation during vehicle servicing. They provide quick and reliable inflation, ensuring that vehicles are road-ready in minimal time. By enhancing service efficiency, these compressors contribute to increased customer satisfaction. For buyers in regions like Nigeria or Germany, it is crucial to assess the compressor’s portability and PSI capacity to meet diverse vehicle requirements.

In construction, wheel air compressors power pneumatic tools such as nail guns and drills, significantly boosting productivity on job sites. By providing a consistent air supply, these compressors help reduce downtime and enhance the overall efficiency of construction operations. Buyers should consider the compressor’s compatibility with various tools and its air flow capacity to ensure optimal performance, especially in demanding environments found in South America and the Middle East.

Agricultural businesses utilize wheel air compressors for inflating tires on tractors and other equipment, which is vital for maintaining optimal performance in the field. Proper tire pressure minimizes equipment wear and enhances fuel efficiency. Buyers in the agricultural sector should focus on the compressor’s ruggedness and compatibility with tire sizes commonly used in their operations, particularly in regions with challenging terrains like parts of Africa.

In the transportation and logistics sector, maintaining fleet vehicles is crucial for operational reliability. Wheel air compressors enable quick tire inflation, ensuring that vehicles are always ready for the road, which helps to reduce operational costs associated with downtime. Buyers should evaluate the compressor’s power source options and portability to facilitate easy use across various locations, especially in extensive logistics operations in Europe.

Manufacturing facilities leverage wheel air compressors to operate air-powered machinery, improving production efficiency and ensuring operational safety. These compressors are integral to maintaining consistent performance levels in manufacturing processes. When sourcing, businesses should prioritize pressure ratings and energy efficiency to align with their operational needs, particularly in competitive markets across Africa and Europe.

El problema: B2B buyers often face the challenge of selecting the right wheel air compressor that aligns with their operational requirements. With numerous models available, each boasting different features and capacities, it can be overwhelming to determine which compressor will best serve specific applications, such as inflating tires for heavy machinery or powering pneumatic tools. This confusion can lead to purchasing equipment that is either underpowered or overly complex for the intended use, resulting in wasted resources and time.

Illustrative image related to wheel air compressor

La solución: To effectively select the right wheel air compressor, buyers should begin by clearly defining their usage requirements. This includes understanding the maximum pressure (PSI) needed and the volume of air (CFM) required for their applications. It is advisable to consult with manufacturers or suppliers who can provide insights based on industry standards and user reviews. Additionally, leveraging product comparison tools on supplier websites can help narrow down options. Finally, consider investing in a compressor with adjustable settings and multiple attachments, as this can enhance versatility and ensure that the equipment can adapt to various tasks as business needs evolve.

El problema: Many B2B buyers experience inconsistent performance with their wheel air compressors, particularly in demanding environments such as construction sites or remote locations. Factors such as fluctuations in power supply, environmental conditions, and improper maintenance can lead to unreliable performance, resulting in downtime and decreased productivity. This inconsistency can be especially frustrating for businesses that rely on timely and efficient operations.

La solución: To mitigate performance issues, it is crucial to invest in high-quality compressors designed for specific environments. Buyers should look for compressors that feature robust construction and reliable performance ratings. Additionally, implementing a regular maintenance schedule can significantly enhance the longevity and reliability of the equipment. This includes routine checks on oil levels, air filters, and hose connections. Training staff on proper usage and maintenance techniques can further reduce the risk of performance issues, ensuring that the compressor operates efficiently even under challenging conditions.

El problema: Portability is a common concern for B2B buyers, particularly those who require wheel air compressors for fieldwork or remote locations. Many compressors are bulky and heavy, making them difficult to transport and set up quickly. This can lead to inefficiencies, especially in industries where time is critical, such as emergency services or mobile repair units.

Illustrative image related to wheel air compressor

La solución: Buyers should prioritize compact and lightweight models that are specifically designed for portability without compromising on power. Opting for compressors with built-in wheels and ergonomic handles can facilitate easier transport. Additionally, consider battery-operated or dual-power models that offer flexibility for use in locations without direct power sources. Investing in a durable carrying case can also protect the compressor during transport while making it easier to organize necessary accessories. By choosing the right portable solution, businesses can enhance their operational efficiency and responsiveness in the field.

When selecting materials for wheel air compressors, it is crucial to consider their properties, performance, and suitability for specific applications. Below are analyses of four common materials used in the manufacturing of wheel air compressors, focusing on their key properties, advantages, disadvantages, and considerations for international B2B buyers.

Aluminum is widely used in the construction of wheel air compressors due to its lightweight nature and excellent corrosion resistance. It typically has a temperature rating of up to 150°C (302°F) and can withstand moderate pressure levels, making it suitable for various applications.

Pros: Aluminum is durable and has a high strength-to-weight ratio, which enhances portability. It is also resistant to rust and corrosion, making it ideal for humid or coastal environments.

Illustrative image related to wheel air compressor

Contras: While it is generally cost-effective, aluminum can be more expensive than some steel options. Additionally, it may not handle extreme pressure as well as heavier metals.

Impacto en la aplicación: Aluminum’s compatibility with various media, including air and non-corrosive gases, makes it a versatile choice. However, users must ensure that the aluminum components are not subjected to high-pressure applications beyond their ratings.

Consideraciones para compradores internacionales: Compliance with international standards such as ASTM and DIN is crucial. Buyers from regions like Europe may prefer aluminum for its lightweight properties, while those in Africa and South America might weigh cost considerations more heavily.

Illustrative image related to wheel air compressor

Steel is another common material used in wheel air compressors, known for its strength and durability. It can withstand high pressures, often rated up to 250 PSI or more, depending on the alloy used.

Pros: Steel is highly durable and can handle extreme conditions, making it suitable for industrial applications. Its lower cost compared to aluminum makes it an attractive option for budget-conscious buyers.

Contras: Steel is heavier than aluminum, which may impact portability. It is also prone to rust and corrosion if not properly coated or treated, necessitating additional maintenance.

Impacto en la aplicación: Steel’s ability to withstand high pressures makes it ideal for heavy-duty applications. However, its susceptibility to corrosion means that it may not be suitable for environments with high humidity or exposure to corrosive substances.

Illustrative image related to wheel air compressor

Consideraciones para compradores internacionales: Buyers in the Middle East and Africa should consider the environmental conditions when selecting steel. Compliance with local standards such as JIS for Japan or ASTM for the U.S. is also essential.

Composite materials, often a blend of plastics and fibers, are increasingly being used in wheel air compressors for their lightweight and corrosion-resistant properties. They can typically handle temperatures up to 100°C (212°F) and moderate pressures.

Pros: Composites offer excellent corrosion resistance and are lightweight, enhancing portability. They can also be molded into complex shapes, providing design flexibility.

Contras: The initial cost of composite materials can be higher than metals, and they may not be suitable for high-pressure applications. Their long-term durability under stress is also a consideration.

Impacto en la aplicación: Composites are ideal for applications where weight reduction is critical, such as portable compressors. However, they should not be used in environments with extreme temperatures or pressures.

Consideraciones para compradores internacionales: Buyers in Europe may favor composites for their innovative design and lightweight properties, while those in developing regions might find the cost prohibitive. Compliance with relevant safety standards is also necessary.

Illustrative image related to wheel air compressor

Brass is often used in fittings and connectors within wheel air compressors due to its excellent corrosion resistance and good mechanical properties. It typically operates well under moderate pressure and temperature conditions.

Pros: Brass is highly resistant to corrosion and wear, making it ideal for fittings that are frequently connected and disconnected. It also has good machinability.

Contras: Brass can be more expensive than steel and aluminum, and it may not be suitable for high-pressure applications.

Illustrative image related to wheel air compressor

Impacto en la aplicación: Brass is ideal for air connections and fittings, ensuring a reliable seal. However, it should be evaluated for compatibility with specific media, especially in industrial applications.

Consideraciones para compradores internacionales: Buyers should ensure that brass components meet international standards, especially in regions like Germany where compliance is strictly enforced.

| Material | Typical Use Case for Wheel Air Compressor | Ventajas clave | Principales desventajas/limitaciones | Coste relativo (Bajo/Medio/Alto) |

|---|---|---|---|---|

| Aluminio | Portable compressors | Ligero y resistente a la corrosión | Higher cost than steel | Medio |

| Acero | Industrial compressors | High durability and pressure rating | Prone to rust and corrosion | Bajo |

| Compuesto | Lightweight portable units | Excellent corrosion resistance | Higher initial cost | Alta |

| Brass | Connectors and fittings | Corrosion-resistant and durable | Not suitable for high pressures | Medio |

This comprehensive analysis provides B2B buyers with actionable insights into material selection for wheel air compressors, ensuring they make informed decisions tailored to their specific needs and regional considerations.

The manufacturing of wheel air compressors involves several crucial stages that ensure the final product meets high standards of performance and reliability.

The first step in the manufacturing process is the careful selection and preparation of materials. Common materials include high-grade aluminum or steel for the compressor body, plastic for the housing, and rubber for seals and hoses. These materials are chosen for their durability and resistance to corrosion, which is critical for the longevity of the compressor, especially in varying climates encountered in regions like Africa and South America.

Illustrative image related to wheel air compressor

Once the materials are prepared, they undergo forming processes. This typically includes stamping, casting, or machining, depending on the component. For example, the cylinder may be machined to precise specifications to ensure optimal performance. Advanced techniques such as CNC machining provide high accuracy, which is vital for components that must fit together seamlessly.

After forming, components are often treated to enhance their strength and resistance to wear. This may involve heat treatment or surface coating, which can help in reducing friction and increasing the lifespan of the air compressor.

The assembly of wheel air compressors is a meticulous process, where various components are brought together. Automated assembly lines are increasingly common, as they improve efficiency and consistency. However, skilled technicians often perform critical assembly tasks to ensure quality.

In this stage, components such as the motor, air tank, pressure regulator, and controls are integrated. Attention to detail is paramount; for instance, proper alignment of the motor and compressor unit is essential to prevent operational issues.

The final stage in the manufacturing process involves finishing touches. This includes painting or powder coating the compressor body to enhance aesthetics and provide additional protection against environmental factors. Quality checks are conducted at this stage to ensure that the compressor not only looks good but also functions correctly.

Illustrative image related to wheel air compressor

Quality assurance is critical in the manufacturing of wheel air compressors. International standards such as ISO 9001 play a significant role in ensuring that manufacturers maintain consistent quality throughout their processes. This standard emphasizes a process-oriented approach and requires companies to demonstrate their ability to provide products that meet customer and regulatory requirements.

In addition to ISO 9001, specific industry certifications can enhance the credibility of a manufacturer. For instance, CE marking signifies compliance with EU safety, health, and environmental protection standards, which is especially important for buyers in Europe. Similarly, certifications from the American Petroleum Institute (API) may be relevant for compressors designed for industrial applications, ensuring they meet rigorous performance and safety standards.

Quality control (QC) checkpoints are integral to ensuring the reliability and safety of wheel air compressors.

Control de calidad entrante (IQC): This initial checkpoint involves inspecting raw materials and components upon arrival at the manufacturing facility. The goal is to verify that they meet specified standards before being used in production.

Control de calidad durante el proceso (IPQC): During manufacturing, regular inspections are conducted to monitor compliance with specifications. This includes checking dimensions, assembly accuracy, and functionality of components.

Control de calidad final (CCF): Before the compressors are shipped, a thorough inspection is performed. This includes functional tests, pressure testing, and safety checks to ensure that each unit operates correctly and meets performance standards.

Testing methods for wheel air compressors may include:

For international buyers, especially those from regions like Africa and the Middle East, verifying a supplier’s quality control measures is crucial.

Illustrative image related to wheel air compressor

Conduct Audits: Regular audits can help ensure that suppliers adhere to their stated quality assurance processes. Buyers can conduct these audits themselves or hire third-party services for an unbiased evaluation.

Solicitar informes de calidad: Suppliers should provide documentation detailing their quality control processes, inspection results, and any certifications they hold. This transparency is vital for building trust.

Engage Third-Party Inspectors: Utilizing third-party inspection services can help buyers verify compliance with international standards and industry-specific certifications. These services can provide an objective assessment of the manufacturer’s quality control practices.

B2B buyers from diverse regions may encounter unique challenges regarding quality control. For example:

Regulatory Differences: Different countries have varying regulations regarding product safety and quality. Buyers should be familiar with the specific standards applicable to their markets, such as CE in Europe or ANSI in the United States.

Consideraciones culturales: Communication barriers can arise, impacting the effectiveness of quality control measures. Establishing clear lines of communication and ensuring mutual understanding of quality expectations is crucial.

Logistical Challenges: The shipping and handling of wheel air compressors can impact their quality. Buyers should consider how their suppliers manage logistics to prevent damage during transport.

In conclusion, understanding the manufacturing processes and quality assurance protocols for wheel air compressors is vital for B2B buyers. By focusing on the manufacturing stages, relevant certifications, quality control checkpoints, and verification methods, buyers can make informed decisions that ensure they procure reliable and high-quality products for their markets.

When procuring a wheel air compressor, especially for international markets such as Africa, South America, the Middle East, and Europe, it’s essential to follow a systematic approach. This guide provides a step-by-step checklist to ensure you make informed decisions, maximize your investment, and secure reliable suppliers.

Establishing clear technical specifications is crucial for selecting the right wheel air compressor for your needs. Consider factors such as pressure capacity (measured in PSI), tank size, and whether you need a portable or stationary model. These details will not only guide your search but also ensure that the compressor meets your operational requirements.

Understanding the regional market dynamics is vital. Investigate common applications, preferred brands, and specific regional regulations or certifications required for air compressors. This knowledge will help you identify products that are not only compliant but also in demand, giving you a competitive edge.

Illustrative image related to wheel air compressor

Before committing to any supplier, thorough vetting is essential. Request company profiles, product catalogs, and references from businesses within your industry or region. Look for suppliers who have a proven track record of reliability and quality, as this can significantly reduce risks associated with procurement.

Once you have shortlisted potential suppliers, request samples of the wheel air compressors you are considering. Testing the compressors firsthand allows you to assess quality, performance, and suitability for your specific applications. Pay attention to the ease of use, noise levels, and durability during your evaluation.

Pricing structures can vary significantly among suppliers. Analyze quotes carefully, considering not just the upfront costs but also long-term operational expenses, including maintenance and energy consumption. Additionally, negotiate payment terms that align with your cash flow and financial planning.

Reliable after-sales support can be a game-changer, especially in international transactions. Inquire about warranty terms, availability of spare parts, and the supplier’s responsiveness to service requests. A strong support system can enhance your operational efficiency and reduce downtime.

Finally, ensure you have a clear understanding of the logistics involved in getting the compressor to your location. Discuss shipping options, delivery timelines, and any associated costs with your supplier. Effective logistics planning will help you avoid unexpected delays and additional expenses.

By following this comprehensive checklist, you can navigate the procurement process for wheel air compressors with confidence, ensuring that you choose a product that meets your operational needs while fostering a successful supplier relationship.

When sourcing wheel air compressors, understanding the cost structure is essential for making informed purchasing decisions. The primary cost components include:

Illustrative image related to wheel air compressor

Materiales: The quality of materials significantly influences the cost. High-grade metals, durable plastics, and advanced electronic components can increase the unit price. For instance, compressors designed for heavy-duty applications often utilize robust materials that can withstand higher pressures and longer usage.

Trabajo: Labor costs vary based on the region of manufacturing and the complexity of the assembly process. Skilled labor is often required for quality assurance and assembly, especially for complex models with advanced features like digital controls or multiple pressure settings.

Gastos generales de fabricación: This includes costs associated with factory operations, utilities, and administrative expenses. Efficient manufacturing processes can help reduce these costs, making it vital to evaluate suppliers’ production capabilities.

Herramientas: Initial tooling costs can be significant, especially for custom designs. The complexity of the compressor design directly affects tooling costs, which can be amortized over larger production runs.

Control de calidad: Implementing rigorous QC measures ensures product reliability but adds to the overall cost. Certifications such as ISO or CE can also impact pricing, as they require compliance with specific standards.

Logística: Shipping costs can vary widely depending on the destination, mode of transportation, and packaging requirements. International buyers should consider freight costs, customs duties, and insurance when calculating total expenses.

Margen: Suppliers typically mark up their costs to include profit margins. These margins can vary based on market competition and the supplier’s position in the supply chain.

Several factors influence pricing beyond the basic cost structure:

Volumen/MOQ: Bulk purchases often come with significant discounts. Understanding Minimum Order Quantities (MOQ) can help buyers negotiate better prices.

Especificaciones y personalización: Custom specifications such as size, power capacity, and additional features (like built-in pressure gauges) can increase costs. Buyers should clearly define their requirements to avoid unexpected charges.

Materiales y certificaciones de calidad: Higher quality or specialized materials (e.g., corrosion-resistant components) can raise the price. Additionally, products with recognized certifications may command higher prices due to perceived reliability.

Factores del proveedor: The reputation and reliability of suppliers can influence pricing. Established brands may offer premium prices due to their track record of quality and service.

Incoterms: Understanding shipping terms is crucial for international buyers. Incoterms dictate who bears the risk and costs during transit, affecting the overall landed cost of the product.

To optimize purchasing outcomes, B2B buyers should consider the following strategies:

Effective Negotiation: Engage in open discussions with suppliers about pricing structures and be prepared to negotiate based on the total cost of ownership rather than just the initial price.

Cost-Efficiency Analysis: Conduct a total cost of ownership analysis that includes maintenance, operational costs, and potential downtime. This approach helps in justifying higher upfront costs if the compressor offers long-term savings.

Matización de precios para compradores internacionales: Buyers from Africa, South America, the Middle East, and Europe should be aware of currency fluctuations, tariffs, and local market conditions that could affect pricing. Establishing relationships with multiple suppliers can provide leverage in negotiations.

Seek Long-Term Partnerships: Building long-term relationships with suppliers can lead to better pricing, improved service, and access to exclusive deals or new product lines.

Manténgase informado sobre las tendencias del mercado: Regularly researching market trends and competitor pricing can provide insights into fair pricing and emerging technologies that may offer better value.

While indicative prices for wheel air compressors can vary widely, understanding the cost structure and price influencers allows international B2B buyers to make informed sourcing decisions. By employing strategic negotiation and being aware of the total cost implications, buyers can optimize their procurement processes and secure better deals.

When considering air compression solutions, it is essential to evaluate various alternatives to determine the best fit for your operational needs. Wheel air compressors, designed for mobility and efficiency, can be compared against other popular options in the market, including portable tire inflators and stationary air compressors. This analysis will provide insights into their performance, cost, ease of implementation, maintenance, and optimal use cases.

| Aspecto comparativo | Wheel Air Compressor | Inflador de neumáticos portátil | Stationary Air Compressor |

|---|---|---|---|

| Rendimiento | High PSI, suitable for heavy-duty tasks | Moderate PSI, ideal for quick tire inflation | Very high PSI, suitable for industrial applications |

| Coste | Mid-range investment, durable | Low-cost, budget-friendly | High initial investment, but long-term value |

| Facilidad de aplicación | Requires setup, but mobile | Plug-and-play, very easy to use | Requires installation and space |

| Mantenimiento | Moderate, periodic checks needed | Low, minimal upkeep | High, regular maintenance required |

| El mejor caso de uso | Off-road vehicles, heavy machinery | Personal vehicles, emergency use | Industrial settings, workshops |

Portable tire inflators are compact and designed for ease of use, making them an excellent choice for emergency situations or personal vehicles. Their affordability and lightweight design allow for convenient storage in cars. However, they typically offer lower PSI compared to wheel air compressors, which may limit their effectiveness for larger tires or heavy-duty applications. Additionally, while they are great for quick fixes, they lack the durability and high performance required for more extensive operations.

Stationary air compressors are powerful and suitable for industrial applications, providing very high PSI levels ideal for powering various air tools and equipment. They are generally more durable and can handle continuous use. However, they come with a high upfront cost and require a dedicated space for installation. Maintenance demands are also higher, requiring regular servicing to ensure optimal performance. For businesses focused on extensive air compression needs, they offer significant long-term value, but they may not be the best fit for smaller operations or those needing mobility.

Choosing the right air compression solution depends on your specific operational requirements. If your primary need involves heavy-duty tasks and mobility, a wheel air compressor may be the most effective option. For quick tire inflation or emergency situations, a portable tire inflator provides a cost-effective and convenient solution. In contrast, if your operations require continuous and powerful air supply, investing in a stationary air compressor could yield the best long-term benefits. Assessing your business needs, budget, and operational environment will guide you in selecting the most suitable air compression technology.

Understanding the essential specifications of a wheel air compressor is crucial for B2B buyers seeking reliability and efficiency. Here are some critical technical properties to consider:

Presión nominal (PSI)

The pressure rating, measured in pounds per square inch (PSI), indicates the maximum pressure the compressor can generate. Higher PSI ratings are essential for applications requiring rapid inflation or for inflating larger tires. For instance, heavy-duty models may reach 150 PSI, suitable for trucks and RVs. Choosing the right pressure ensures that the compressor meets operational needs without risking damage to the tires or equipment.

CFM (Cubic Feet per Minute)

CFM measures the volume of air delivered by the compressor and is vital for determining the compressor’s efficiency. A higher CFM rating means quicker inflation times and the ability to power pneumatic tools. For businesses, selecting a compressor with an appropriate CFM rating can significantly impact productivity, especially in high-demand environments like automotive workshops.

Motor Power (HP)

The motor power, typically rated in horsepower (HP), indicates the compressor’s capability to perform under load. A higher HP rating often correlates with increased efficiency and performance. For B2B buyers, understanding the motor power helps in assessing the compressor’s suitability for specific tasks, ensuring that it can handle the required workloads without overheating or failing.

Tank Size

The tank size, measured in gallons, affects the compressor’s ability to store compressed air for immediate use. Larger tanks allow for extended use without the need for constant recharging, which can be beneficial in industrial settings. Buyers should consider their specific air consumption needs to ensure that the selected tank size matches their operational requirements.

Portability Features

Portability is often a critical factor for wheel air compressors, especially in sectors like construction or automotive services. Features such as wheel design, weight, and handle ergonomics contribute to ease of transport. A lightweight and compact model can enhance convenience, allowing for quick deployment in various work environments.

Familiarity with industry terminology can facilitate smoother transactions and communications in the B2B landscape. Here are some common terms you should know:

Illustrative image related to wheel air compressor

OEM (fabricante de equipos originales)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. Understanding OEM relationships is crucial for buyers seeking quality replacement parts or accessories that meet specific compatibility standards.

MOQ (Cantidad mínima de pedido)

MOQ indicates the smallest number of units a supplier is willing to sell. This term is particularly important for B2B buyers as it impacts inventory management and cost efficiency. Suppliers may set MOQs to ensure profitability on smaller orders, so understanding this can aid in negotiating better terms.

RFQ (solicitud de presupuesto)

An RFQ is a formal document issued by buyers to solicit pricing and terms from suppliers. Providing detailed specifications in an RFQ can lead to more accurate quotes, enabling buyers to compare offers effectively. This process is essential for informed purchasing decisions.

Incoterms (Términos comerciales internacionales)

Incoterms define the responsibilities of buyers and sellers in international shipping transactions. They clarify who bears the costs and risks at each stage of transport. Familiarity with these terms can help businesses avoid misunderstandings and ensure smooth logistics.

Periodo de garantía

The warranty period specifies the duration during which the manufacturer is liable for repairs or replacements. Understanding warranty terms is critical for B2B buyers to assess product reliability and plan for potential future costs.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions regarding wheel air compressors, ensuring they select the right equipment for their operational needs while navigating the complexities of international procurement.

The global wheel air compressor market is experiencing significant growth driven by several factors. First, the increasing demand for portable and efficient tire inflation solutions across various industries, including automotive, construction, and recreational vehicles, is a primary driver. In regions like Africa and South America, where vehicle ownership is rising, the need for reliable air compressors is becoming more pronounced. Additionally, the Middle East and Europe are witnessing a surge in off-road and recreational vehicle usage, further bolstering the market.

Emerging B2B technology trends are also shaping sourcing strategies. The integration of smart technologies, such as IoT-enabled compressors that offer real-time monitoring and predictive maintenance, is gaining traction. This trend not only enhances operational efficiency but also enables businesses to make data-driven decisions regarding maintenance and usage. Furthermore, the rise of e-commerce platforms is simplifying the procurement process, allowing international buyers to access a wider range of products and suppliers than ever before.

With the growing emphasis on operational efficiency and cost-effectiveness, many businesses are exploring innovative sourcing strategies. Collaborative partnerships with manufacturers and suppliers are becoming essential for securing quality products at competitive prices. Buyers from diverse regions are increasingly prioritizing suppliers who can demonstrate reliability, quality assurance, and timely delivery, ensuring that their operations remain uninterrupted.

Sustainability is an imperative consideration for international B2B buyers in the wheel air compressor sector. The environmental impact of manufacturing and disposing of air compressors can be significant, prompting businesses to seek sustainable alternatives. Ethical sourcing practices, which include assessing suppliers for their environmental policies and commitment to reducing carbon footprints, are becoming a priority.

Illustrative image related to wheel air compressor

Buyers should look for suppliers who offer products made from recycled materials or those that use eco-friendly manufacturing processes. Certifications such as ISO 14001 for environmental management systems can indicate a supplier’s commitment to sustainability. Moreover, choosing wheel air compressors that are energy-efficient not only reduces operational costs but also aligns with global sustainability goals.

Additionally, the demand for transparency in supply chains is increasing. B2B buyers are more inclined to partner with manufacturers who can provide detailed insights into their sourcing practices, materials used, and overall environmental impact. This trend not only fosters trust but also enhances a company’s reputation in the marketplace, making it a crucial factor in supplier selection.

The evolution of wheel air compressors can be traced back to the early 20th century, when the need for efficient tire inflation solutions emerged alongside the rise of the automotive industry. Initially, air compressors were bulky and primarily used in industrial settings. Over the decades, technological advancements led to the development of portable and lightweight models, making them accessible for personal and commercial use.

The introduction of electric and battery-operated compressors in the late 20th century marked a significant turning point, allowing users to inflate tires without the need for a power outlet. Today, the market continues to innovate, focusing on enhancing performance, portability, and user-friendliness. As consumer preferences evolve, the wheel air compressor sector is adapting to meet the demands of a more diverse and environmentally conscious market.

1. How do I solve issues with wheel air compressor performance?

To resolve performance issues with wheel air compressors, start by checking the power supply and ensuring proper voltage levels. Inspect the air filter for blockages, as a clogged filter can reduce efficiency. Regular maintenance, including lubrication of moving parts and checking for air leaks, is crucial. If problems persist, consult the manufacturer’s troubleshooting guide or contact customer support for professional assistance.

2. What is the best wheel air compressor for industrial applications?

The best wheel air compressor for industrial applications typically features high CFM (Cubic Feet per Minute) ratings, robust construction, and a reliable power source. Look for models that can handle continuous use and have a tank capacity suited for your needs. Brands known for durability and efficiency in industrial settings include VIAIR and AstroAI. Always consider specific requirements like PSI ratings and noise levels based on your operational environment.

3. How can I vet suppliers of wheel air compressors for quality assurance?

To vet suppliers, start by researching their reputation through online reviews and industry feedback. Request certifications that prove compliance with international standards, such as ISO or CE certifications. Conduct a factory visit if possible, or utilize third-party inspection services to assess manufacturing practices. Additionally, ask for samples or references from existing clients to evaluate product quality firsthand.

4. What customization options are available for wheel air compressors?

Many manufacturers offer customization options for wheel air compressors, including modifications to size, power ratings, and additional features such as built-in gauges or multi-functional uses. Discuss your specific needs with potential suppliers and inquire about the feasibility and costs associated with customizations. This can help ensure that the compressor meets your unique operational requirements.

5. What are the typical minimum order quantities (MOQ) for wheel air compressors?

Minimum order quantities (MOQ) for wheel air compressors vary by supplier and can range from a few units to hundreds, depending on the manufacturer’s policies. For bulk orders, suppliers may offer better pricing or flexible terms. Always clarify the MOQ during initial discussions to ensure it aligns with your purchasing capabilities and project needs.

6. What payment terms should I expect when sourcing from international suppliers?

Payment terms can differ significantly based on the supplier and country of origin. Common terms include 30% deposit upfront and the remaining balance before shipment. Some suppliers may offer letters of credit or payment through escrow services for added security. Be sure to negotiate terms that are favorable for your cash flow while ensuring the supplier feels secure.

7. How can I ensure timely logistics and delivery of wheel air compressors?

To ensure timely logistics and delivery, establish clear communication with your supplier regarding shipping methods and timelines. Utilize freight forwarders familiar with international shipping regulations and customs procedures. Track shipments actively and discuss contingency plans for potential delays. Building strong relationships with logistics partners can also help mitigate risks associated with international shipping.

8. What quality assurance processes should be in place for wheel air compressors?

Quality assurance processes should include thorough testing of compressors before shipment, including pressure tests and performance evaluations. Request documentation of quality control measures, such as inspections during various production stages. Consider implementing a quality assurance agreement that outlines expectations for product performance and defect resolution, ensuring accountability from the supplier.

Dominio: fanttik.com

Matriculado: 2020 (5 años)

Introducción: 2X Faster Electric Tire Inflators, various models including X9 Ace, X9 Pro, X8 APEX, X9 APEX, X9 Classic, X9 Ultra, X10 Cross. Prices range from $48.99 to $199.97 with discounts up to 50%. Ratings of 4.8 for several models. Black Friday Sale from 11.20-12.1.

Dominio: lowes.com

Matriculado: 1995 (30 años)

Introducción: This company, Lowe’s – Air Inflators, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

In conclusion, the strategic sourcing of wheel air compressors presents significant opportunities for international B2B buyers, particularly in emerging markets such as Africa, South America, the Middle East, and established economies in Europe. As demand for reliable and efficient tire inflation solutions continues to rise, understanding the diverse product offerings—from compact portable models to robust industrial units—is essential for making informed procurement decisions.

Investing in high-quality air compressors not only enhances operational efficiency but also fosters customer satisfaction through reliable performance. Buyers should prioritize suppliers who demonstrate a commitment to innovation, quality assurance, and responsive customer service. Leveraging partnerships with reputable manufacturers can lead to advantageous pricing structures and supply chain efficiencies.

Looking ahead, the evolution of technology in air compressor systems promises to deliver even more efficient and versatile solutions. B2B buyers are encouraged to stay abreast of market trends and technological advancements to position themselves strategically in a competitive landscape. By embracing these insights, businesses can ensure they are well-equipped to meet the demands of their customers while driving sustainable growth in their respective markets.

La información facilitada en esta guía, incluido el contenido relativo a fabricantes, especificaciones técnicas y análisis de mercado, tiene únicamente fines informativos y educativos. No constituye asesoramiento profesional en materia de adquisiciones, asesoramiento financiero ni asesoramiento jurídico.

Aunque hemos hecho todo lo posible por garantizar la exactitud y actualidad de la información, no nos hacemos responsables de posibles errores, omisiones o información obsoleta. Las condiciones del mercado, los detalles de las empresas y las normas técnicas están sujetos a cambios.

Los compradores B2B deben llevar a cabo su propia diligencia debida independiente y exhaustiva antes de tomar cualquier decisión de compra. Esto incluye ponerse en contacto directamente con los proveedores, verificar las certificaciones, solicitar muestras y buscar asesoramiento profesional. El riesgo de confiar en la información contenida en esta guía es responsabilidad exclusiva del lector.