In the fast-evolving landscape of the automotive industry, sourcing reliable solutions for automatic tire pressure management has become a critical challenge for B2B buyers. The efficiency and safety of a vehicle fleet hinge significantly on optimal tire performance, making it essential for companies to invest in advanced tire inflation systems. This guide serves as a comprehensive resource, covering various types of automatic tire pressure technologies, their applications across different vehicle classes, and strategies for effective supplier vetting. Furthermore, it delves into cost considerations and the latest innovations in tire inflation, including smart technologies that adapt to real-time conditions.

International B2B buyers, especially those from Africa, South America, the Middle East, and Europe—regions where transportation logistics are paramount—will find this guide invaluable. By equipping decision-makers with actionable insights, we aim to empower informed purchasing choices that enhance operational efficiency and safety. As fleets increasingly prioritize sustainability and cost-effectiveness, understanding the nuances of automatic tire pressure systems will enable businesses to optimize their investments and stay competitive in the global market. Whether you are looking to improve safety, reduce maintenance costs, or enhance fuel efficiency, this guide will provide the essential information needed to navigate the complexities of sourcing automatic tire pressure solutions.

| Tipo Nombre | Principales rasgos distintivos | Aplicaciones B2B principales | Breves pros y contras para los compradores |

|---|---|---|---|

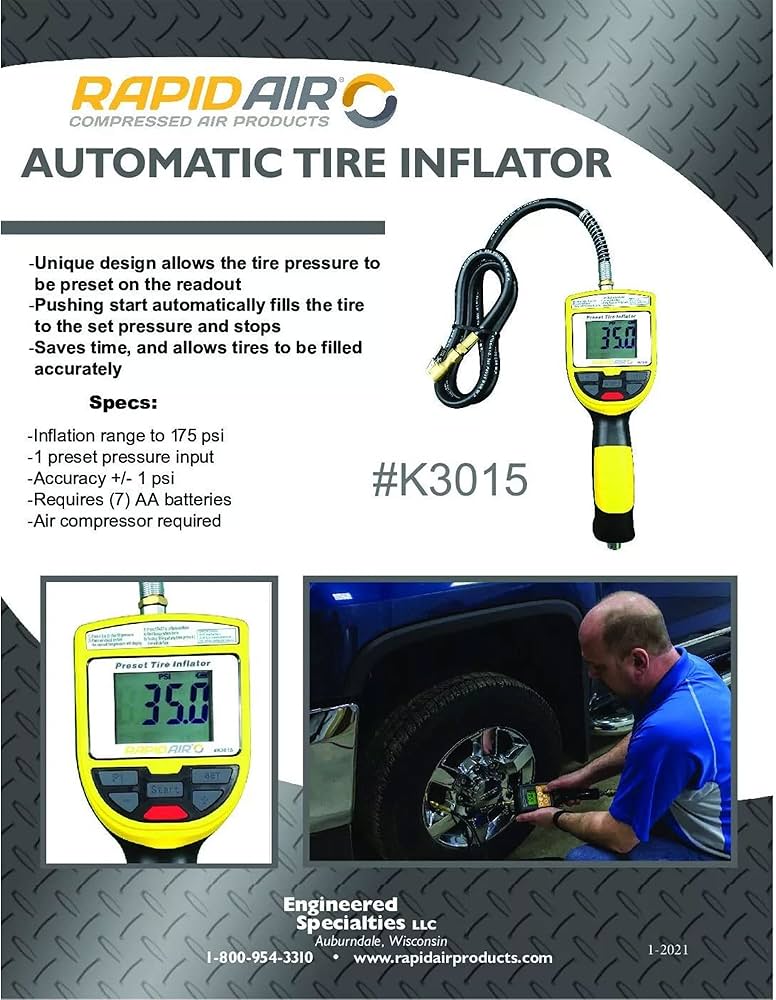

| Automatic Tire Inflators | Connects to compressors, digital gauges, nitrogen compatibility | Fleet maintenance, automotive service centers | Pros: Speedy inflation, accuracy; Contras: Requires compressor setup. |

| Automatic Tire Inflation Systems | Maintains constant pressure, alerts for low pressure, operates while driving | Commercial fleets, logistics companies | Pros: Enhances safety, reduces fuel consumption; Contras: Mayor inversión inicial. |

| Smart Tire Technology | Self-regulating pressure, integrates with vehicle systems | Advanced automotive manufacturers, tech firms | Pros: Minimizes manual checks, real-time data; Contras: Emerging technology, potential reliability concerns. |

| Handheld Automatic Inflators | Portable, easy to use, often battery-operated | Small fleets, emergency services | Pros: Versatile, no compressor needed; Contras: Limited capacity, slower than fixed systems. |

| Integrated Tire Management Systems | Comprehensive monitoring of tire health, predictive analytics | Large transport companies, construction | Pros: Full visibility on tire status, proactive maintenance; Contras: Complex installation, ongoing costs for data services. |

Automatic tire inflators are designed to streamline the tire inflation process, connecting directly to air compressors and featuring digital gauges for precise inflation. Ideal for fleet maintenance and automotive service centers, these inflators can significantly reduce downtime by quickly achieving the desired tire pressure. Buyers should consider the compatibility with existing compressor systems and the potential need for ongoing maintenance.

Automatic tire inflation systems (ATIS) continuously monitor and adjust tire pressure, ensuring optimal performance while driving. These systems are particularly beneficial for commercial fleets and logistics companies, as they enhance safety by reducing blowout risks and improving fuel efficiency. Although they may require a higher initial investment, the long-term savings in fuel and maintenance often justify the cost.

Smart tire technology represents the future of tire management by automatically regulating pressure and providing real-time data to drivers. This technology is well-suited for advanced automotive manufacturers and tech firms looking to integrate innovative solutions into their vehicles. While the benefits include reduced manual checks and enhanced vehicle performance, buyers should be aware of potential reliability issues due to the technology’s emerging status.

Handheld automatic inflators offer a portable solution for tire inflation, making them ideal for small fleets and emergency services. These battery-operated devices are easy to use and do not require a compressor, providing flexibility in various environments. However, buyers should note that their capacity is limited compared to fixed systems, which may impact efficiency during high-demand situations.

Integrated tire management systems offer a holistic approach to tire health monitoring, combining real-time data analytics with predictive maintenance capabilities. These systems are essential for large transport companies and construction firms that rely on heavy machinery. While they provide significant visibility into tire conditions, buyers must consider the complexity of installation and ongoing costs associated with data services, which can affect overall budget planning.

| Industria/Sector | Specific Application of automatic tire pressure | Valor/beneficio para la empresa | Consideraciones clave para el aprovisionamiento de esta aplicación |

|---|---|---|---|

| Transportation & Logistics | Fleet Management Systems for Trucks and Trailers | Enhanced safety, reduced maintenance costs, improved fuel efficiency | Compatibility with various vehicle types, ease of installation, and maintenance requirements |

| Agricultura | Agricultural Equipment Tire Management | Increased productivity, reduced downtime, extended tire life | Durability in harsh environments, adaptability to different tire sizes, and ease of integration with existing systems |

| Mining | Heavy Machinery Tire Pressure Monitoring | Enhanced safety, reduced risk of blowouts, improved operational efficiency | Robustness for extreme conditions, ability to handle varying loads, and real-time monitoring capabilities |

| Construcción | Tire Pressure Systems for Construction Vehicles | Improved safety, reduced fuel consumption, extended tire lifespan | Compliance with industry standards, ease of use, and integration with fleet management software |

| Automotive Manufacturing | Smart Tire Technology Integration | Reduced maintenance costs, improved vehicle performance, enhanced safety | Advanced technology compatibility, supplier reliability, and warranty provisions |

In the transportation and logistics sector, automatic tire pressure systems are integrated into fleet management systems for trucks and trailers. These systems ensure that tire pressure is maintained at optimal levels, enhancing safety and fuel efficiency. By reducing tire wear and the risk of blowouts, companies can minimize maintenance costs and downtime. For international buyers, particularly in regions like Africa and South America, sourcing systems that are compatible with various vehicle types and easy to install is crucial for seamless operations.

Illustrative image related to automatic tire pressure

In agriculture, automatic tire pressure management systems are essential for agricultural equipment, such as tractors and harvesters. These systems help maintain optimal tire pressure, which is critical for maximizing productivity and reducing downtime during critical planting and harvesting periods. Buyers from regions with challenging terrains, like the Middle East, should prioritize systems that are durable, adaptable to different tire sizes, and can withstand harsh environmental conditions.

Mining operations utilize heavy machinery that requires constant monitoring of tire pressure to ensure safety and efficiency. Automatic tire pressure monitoring systems help prevent blowouts and extend tire life, which is vital in high-stakes environments. For buyers in the mining sector, sourcing robust systems capable of handling varying loads and providing real-time monitoring capabilities is essential to maintain operational efficiency and worker safety.

In the construction industry, maintaining proper tire pressure in construction vehicles is critical for safety and fuel efficiency. Automatic tire pressure systems help reduce the risk of accidents and extend the lifespan of tires, ultimately lowering operational costs. Buyers should look for systems that comply with industry standards and offer ease of use, as well as compatibility with fleet management software, to streamline operations.

Automotive manufacturers are increasingly integrating smart tire technology that includes automatic tire pressure monitoring. This technology enhances vehicle performance and reduces maintenance costs by ensuring that tires are always at the correct pressure. For B2B buyers in Europe, sourcing suppliers that offer advanced technology compatibility and reliable warranties is vital to ensure product quality and customer satisfaction.

Illustrative image related to automatic tire pressure

El problema: Many fleet managers face the issue of inconsistent tire pressure, which can lead to increased operational costs. Tires that are not properly inflated often wear unevenly, resulting in more frequent replacements and higher maintenance costs. This issue is particularly acute in regions with varying climates, where temperature fluctuations can affect tire pressure. Additionally, under-inflated tires can decrease fuel efficiency, compounding operational expenses and impacting overall profitability.

La solución: To mitigate this problem, B2B buyers should invest in a reliable automatic tire inflation system (ATIS) that continuously monitors and adjusts tire pressure. When selecting an ATIS, consider features such as real-time monitoring, compatibility with various vehicle types, and the ability to alert drivers about significant pressure changes. Systems like VIGIA or Halo provide excellent options, as they allow for easy installation and integration with existing fleet management systems. Regular training for drivers on how to utilize these systems effectively can further ensure that tire pressure remains optimal, leading to reduced fuel consumption and extended tire life.

El problema: Tire blowouts pose significant safety risks, particularly for commercial vehicles transporting goods across long distances. Fleet operators often experience anxiety regarding the safety of their drivers and the cargo they are transporting. A sudden blowout can lead to serious accidents, costly damages, and legal repercussions. For buyers operating in regions with less reliable road conditions, such as rural areas in Africa or South America, this risk is exacerbated by the likelihood of road debris and potholes.

Illustrative image related to automatic tire pressure

La solución: Implementing an automatic tire pressure monitoring system (TPMS) can greatly enhance safety by alerting drivers to any abnormal pressure changes before they lead to a blowout. Systems that feature an automatic shut-off in the event of rapid air loss, like those offered by VIGIA, help maintain vehicle control and prevent accidents. Furthermore, conducting regular inspections and integrating advanced TPMS with data analytics can help fleet managers anticipate maintenance needs and proactively address tire health, thereby reducing the risk of blowouts and ensuring driver safety.

El problema: Frequent maintenance and downtime for tire issues can disrupt operations and lead to lost revenue, especially for businesses reliant on timely deliveries. Fleet managers often find themselves juggling tire maintenance schedules and facing unexpected breakdowns due to under-inflated or over-inflated tires. This is particularly problematic in regions where tire repair facilities are scarce or where service delays can impact logistics.

La solución: To streamline tire maintenance and reduce downtime, B2B buyers should invest in smart automatic tire pressure systems that not only inflate tires but also provide predictive maintenance alerts. Systems like Continental’s C.A.R.E. technology enable real-time monitoring and automatically adjust tire pressure, significantly reducing the need for manual checks. Buyers should look for solutions that integrate with fleet management software, allowing for centralized monitoring and reporting. This proactive approach ensures that potential tire issues are addressed before they lead to costly downtime, ultimately enhancing operational efficiency and reliability.

When selecting materials for automatic tire pressure systems, it is essential to consider properties that directly impact performance, durability, and cost. Here, we analyze four common materials used in these systems: aluminum, stainless steel, rubber, and composite materials.

Aluminum is widely used in the construction of components such as valves and housings in automatic tire pressure systems due to its lightweight and excellent corrosion resistance. Key properties include a temperature rating of up to 150°C and a pressure rating that can exceed 300 psi.

Pros: Aluminum offers high durability and is relatively easy to machine, making it suitable for high-volume manufacturing. Its lightweight nature contributes to overall vehicle efficiency, particularly in commercial applications.

Contras: While aluminum is cost-effective, it may not withstand extreme conditions as well as some other materials, leading to potential fatigue over time. Additionally, it can be susceptible to galvanic corrosion when in contact with dissimilar metals.

Impacto en la aplicación: Aluminum is compatible with air and nitrogen, making it ideal for tire inflation systems. However, care must be taken to ensure proper sealing to prevent leaks.

Consideraciones para compradores internacionales: Compliance with international standards such as ASTM and DIN is crucial. Buyers in regions like Africa and South America should also consider local corrosion factors, especially in coastal areas.

Illustrative image related to automatic tire pressure

Stainless steel is another common material used in tire pressure systems, particularly for components that require high strength and corrosion resistance. It can withstand temperatures up to 300°C and pressures exceeding 1000 psi.

Pros: Stainless steel offers exceptional durability and resistance to corrosion, making it suitable for harsh environments. It is also highly recyclable, which can be a consideration for eco-conscious companies.

Contras: The primary drawback is its higher cost compared to aluminum. Additionally, stainless steel can be more challenging to machine, potentially increasing manufacturing complexity.

Impacto en la aplicación: Stainless steel is compatible with various gases and can withstand aggressive environments, making it a preferred choice for heavy-duty applications.

Consideraciones para compradores internacionales: Buyers should ensure compliance with JIS standards, particularly in Japan and other Asian markets, and be aware of the higher costs associated with stainless steel components.

Rubber is primarily used in seals and gaskets within automatic tire pressure systems, where flexibility and sealing capability are critical. It can perform well under a temperature range of -40°C to 100°C.

Pros: Rubber provides excellent sealing properties and is cost-effective. Its flexibility allows it to accommodate various shapes and sizes, making it versatile for different applications.

Contras: Rubber can degrade over time due to exposure to UV light and ozone, leading to potential failures in sealing. Its lifespan may also be affected by temperature extremes.

Illustrative image related to automatic tire pressure

Impacto en la aplicación: Rubber is compatible with air and nitrogen but may require specific formulations to enhance its resistance to environmental factors.

Consideraciones para compradores internacionales: Buyers should look for rubber materials that meet ASTM standards for durability and resistance to environmental factors, particularly in regions with extreme weather conditions.

Composite materials are increasingly used in advanced tire pressure systems due to their lightweight and high strength-to-weight ratio. They can operate effectively at temperatures up to 200°C and pressures around 500 psi.

Illustrative image related to automatic tire pressure

Pros: Composites offer excellent resistance to corrosion and fatigue while being lightweight, which enhances fuel efficiency. They can also be molded into complex shapes, providing design flexibility.

Contras: The main limitation is the higher cost of composite materials compared to traditional metals. Additionally, manufacturing processes can be more complex and time-consuming.

Impacto en la aplicación: Composites are suitable for a range of media, including air and nitrogen, and can be tailored for specific applications.

Consideraciones para compradores internacionales: Compliance with international standards is essential, and buyers should consider the availability of composite materials in their local markets, especially in developing regions.

| Material | Typical Use Case for automatic tire pressure | Ventajas clave | Principales desventajas/limitaciones | Coste relativo (Bajo/Medio/Alto) |

|---|---|---|---|---|

| Aluminio | Valves and housings | Ligero y resistente a la corrosión | Susceptible to galvanic corrosion | Medio |

| Acero inoxidable | High-pressure components | Durabilidad excepcional | Higher cost and machining complexity | Alta |

| Goma | Juntas y empaquetaduras | Excellent sealing properties | Se degrada con el tiempo | Bajo |

| Compuesto | Advanced tire pressure systems | Lightweight and design flexibility | Coste más elevado y fabricación más compleja | Alta |

By carefully considering these materials, B2B buyers can make informed decisions that enhance the performance and reliability of automatic tire pressure systems, catering to the specific needs of their markets.

Illustrative image related to automatic tire pressure

The manufacturing process for automatic tire pressure systems involves several critical stages, each integral to ensuring the final product’s reliability and performance.

Preparación del material: The process begins with sourcing high-quality materials that meet industry standards. Common materials include robust plastics for housings, durable metals for internal components, and advanced sensors for pressure monitoring. Suppliers often conduct preliminary inspections to verify that materials comply with international quality standards before proceeding.

Formando: This stage involves shaping the raw materials into specific components. Techniques such as injection molding are used for plastic parts, while metal components may undergo processes like stamping or machining. Precision in forming is crucial, as even minor deviations can affect the system’s performance and durability.

Montaje: The assembly phase combines the formed components into a finished product. This can be done manually or through automated systems, depending on production volume. During assembly, special attention is given to the integration of electronic sensors, pneumatic connections, and software calibration to ensure that the system functions as intended.

Acabado: After assembly, products undergo finishing processes, including painting, coating, or surface treatment to enhance durability and aesthetic appeal. This stage also includes the installation of any necessary wiring and final adjustments to ensure that the product meets all specifications.

Quality control (QC) is essential in the manufacturing of automatic tire pressure systems to guarantee safety, reliability, and performance. Key international standards and industry-specific certifications include:

ISO 9001: This is a widely recognized quality management standard that focuses on meeting customer requirements and ensuring continuous improvement. Manufacturers often adopt ISO 9001 to demonstrate their commitment to quality.

Marcado CE: For products sold in Europe, CE marking signifies compliance with health, safety, and environmental protection standards. It is crucial for B2B buyers in Europe to ensure that their suppliers adhere to these regulations.

Normas API: The American Petroleum Institute (API) sets standards for products used in the oil and gas industries, including tire pressure systems in commercial vehicles. Compliance with API standards can enhance product credibility.

Quality control checkpoints are strategically placed throughout the manufacturing process to ensure that each product meets specified quality standards. Common checkpoints include:

Control de calidad entrante (IQC): This initial phase involves inspecting raw materials and components as they arrive at the manufacturing facility. Quality inspectors verify that all materials meet the required specifications before they are used in production.

Control de calidad durante el proceso (IPQC): During production, regular inspections are conducted to monitor the quality of the manufacturing process. This includes checking dimensions, functionality, and the integrity of assemblies. Any deviations are addressed immediately to prevent defects.

Control de calidad final (CCF): Once the products are assembled, they undergo final inspections to confirm that they meet all performance standards. This may include functional testing of the automatic tire pressure systems under various conditions to ensure reliability.

Testing methods for automatic tire pressure systems vary, but several common techniques are employed to ensure product quality:

Functional Testing: This involves simulating real-world conditions to verify that the tire pressure system operates correctly. Tests may include measuring response times, accuracy of pressure readings, and the effectiveness of inflation mechanisms.

Pruebas de durabilidad: Products are subjected to stress tests, including temperature variations, humidity, and vibration tests to ensure they can withstand extreme conditions without failure.

Electrical Testing: For electronic components, electrical testing is performed to check circuit integrity, sensor accuracy, and power consumption. This helps identify any potential issues that could lead to failure in the field.

B2B buyers must take proactive measures to verify the quality control processes of their suppliers. Here are actionable strategies:

Auditorías de proveedores: Conducting audits of potential suppliers can provide insight into their manufacturing processes and quality control systems. This includes reviewing documentation, observing processes, and assessing compliance with relevant standards.

Solicitud de informes de calidad: Suppliers should provide detailed quality assurance reports that outline their QC processes, inspection results, and any certifications they hold. This documentation can be critical in assessing the supplier’s commitment to quality.

Inspecciones de terceros: Engaging independent third-party inspectors can add an additional layer of assurance. These inspectors can perform unbiased evaluations of the supplier’s facilities and processes, ensuring adherence to international standards.

International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should be aware of specific quality control nuances:

Cumplimiento de la normativa: Different regions may have varying regulations concerning product safety and environmental impact. Buyers must ensure that suppliers comply with local regulations and international standards.

Consideraciones culturales: Understanding cultural differences in business practices can impact the quality control expectations. For example, communication styles and negotiation practices may differ significantly across regions.

Transparencia de la cadena de suministro: Given the complexities of international supply chains, buyers should seek suppliers that offer transparency in their processes. This includes traceability of materials and clarity in their quality control practices.

The manufacturing processes and quality assurance measures for automatic tire pressure systems are intricate and vital for ensuring product reliability and safety. By understanding these processes, B2B buyers can make informed decisions when selecting suppliers, ensuring they choose partners committed to quality and compliance with international standards. Investing in due diligence in quality assurance not only enhances operational efficiency but also contributes to the overall safety and profitability of their fleets.

This guide serves as a comprehensive checklist for B2B buyers looking to procure automatic tire pressure systems. As the demand for efficient fleet management and enhanced safety continues to rise, understanding the key steps in sourcing automatic tire pressure solutions is crucial. This checklist will help you navigate the procurement process effectively, ensuring you select a product that meets your operational needs.

Establishing clear technical specifications is the first step in your sourcing journey. Consider the types of vehicles in your fleet and the specific tire pressure requirements they have. Look for features such as compatibility with nitrogen inflation, digital gauges, and automatic shut-off mechanisms for safety.

Conduct thorough research to identify potential suppliers who specialize in automatic tire pressure systems. Look for companies with a strong reputation in the industry, particularly those that have experience with international markets, especially in regions like Africa, South America, and the Middle East.

Before finalizing any supplier, it’s essential to verify their certifications and compliance with international standards. Certifications can indicate the quality and reliability of the products offered, which is particularly important for safety-critical equipment like tire pressure systems.

Engage suppliers by requesting product demonstrations or trials. This step allows you to evaluate the functionality, ease of installation, and user interface of the systems you’re considering. Observing the product in action can provide insights into its performance and reliability.

Illustrative image related to automatic tire pressure

Collect detailed pricing information from shortlisted suppliers, ensuring that you understand what is included in the cost. Additionally, review warranty options to protect your investment and ensure you have recourse in case of product failures.

After selecting a supplier, inquire about their after-sales support and training programs. Effective training ensures your team can operate the automatic tire pressure systems efficiently, while robust support can help resolve issues swiftly.

Once all evaluations are complete, negotiate and finalize your purchase agreement. Ensure that all terms, including delivery timelines, payment conditions, and service level agreements, are clearly outlined to avoid misunderstandings later.

By following this checklist, B2B buyers can ensure a strategic approach to sourcing automatic tire pressure systems that enhance operational efficiency and safety.

When sourcing automatic tire pressure systems, understanding the cost structure is essential for B2B buyers. The primary cost components include:

Materiales: High-quality materials like durable plastics, metals, and electronic components are crucial for the reliability of tire inflation systems. Advanced features, such as sensors and digital gauges, can increase material costs but significantly enhance product performance.

Trabajo: Labor costs vary based on the region and complexity of manufacturing. Skilled technicians are often needed for assembly and quality control, impacting overall production costs.

Gastos generales de fabricación: This includes costs associated with factory operations, maintenance, utilities, and equipment depreciation. Efficient manufacturing processes can help reduce overhead, which is vital for competitive pricing.

Herramientas: Custom tooling for specialized designs or features can add to initial costs. However, investing in high-quality tooling may lead to long-term savings through improved production efficiency.

Control de calidad: Rigorous QC processes are essential to ensure product reliability and safety. This may involve additional testing phases, which can increase costs but are necessary to meet industry standards.

Logística: Shipping and handling costs can vary significantly based on the destination. Factors such as freight rates, customs duties, and local taxes must be considered in the overall cost structure.

Margen: Suppliers typically add a margin to cover their operational costs and profit. Understanding average margins in the industry can help buyers gauge whether they are getting a fair price.

Several factors influence pricing in the automatic tire pressure market:

Volumen/MOQ: Larger orders often lead to reduced per-unit costs due to economies of scale. Buyers should consider negotiating Minimum Order Quantities (MOQs) that suit their operational needs.

Especificaciones y personalización: Tailoring products to specific requirements (e.g., compatibility with different vehicles) can increase costs. Standardized products may offer better pricing, but buyers must balance this with their operational needs.

Materiales y certificaciones de calidad: Products made with premium materials or those that meet specific certifications (e.g., ISO, CE) tend to be priced higher. Buyers should evaluate whether these certifications are necessary for their markets.

Factores del proveedor: The reliability and reputation of suppliers can significantly impact pricing. Established brands may charge more due to their proven track record, while newer suppliers may offer competitive pricing to gain market share.

Incoterms: Understanding Incoterms is crucial for international sourcing. Different terms can affect the total landed cost, including shipping responsibilities and risk management.

For B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe, the following tips can enhance cost-efficiency:

Negociación: Cultivate strong relationships with suppliers to negotiate better terms. Long-term partnerships can lead to favorable pricing adjustments and improved service levels.

Coste total de propiedad (TCO): Consider not just the purchase price but the entire lifecycle cost of the product, including maintenance, energy consumption, and potential savings from improved fuel efficiency and tire longevity.

Matización de precios para compradores internacionales: Be aware of currency fluctuations, tariffs, and local market conditions that may affect pricing. Engaging with local suppliers can sometimes mitigate these challenges.

Realizar estudios de mercado: Understanding regional pricing trends and competitor offerings can empower buyers during negotiations and sourcing decisions.

In summary, a comprehensive understanding of the cost structure and price influencers in automatic tire pressure systems is vital for B2B buyers. By focusing on key cost components, leveraging negotiation strategies, and considering the total cost of ownership, buyers can make informed decisions that align with their operational goals while ensuring safety and efficiency in their tire management practices.

In the quest for optimal tire management, automatic tire pressure systems have emerged as a leading technology, ensuring consistent pressure and enhancing vehicle safety. However, various alternative solutions exist, each with its unique advantages and drawbacks. Understanding these alternatives can help businesses select the most suitable option for their operational needs.

Illustrative image related to automatic tire pressure

| Aspecto comparativo | Automatic Tire Pressure | Alternative 1: Manual Tire Pressure Checks | Alternative 2: Tire Pressure Monitoring Systems (TPMS) |

|---|---|---|---|

| Rendimiento | Maintains pressure automatically | Relies on human intervention | Alerts driver to pressure changes, but no auto-inflate |

| Coste | Higher initial investment | Low cost, but labor-intensive | Moderate cost with potential savings on maintenance |

| Facilidad de aplicación | Requires professional installation | Simple to implement, no tech needed | Requires some technical knowledge for installation |

| Mantenimiento | Low maintenance once installed | High, requires regular checks | Moderate, periodic sensor checks and battery changes |

| El mejor caso de uso | Commercial fleets and high-utilization vehicles | Small businesses with limited budgets | Mixed-use vehicles needing proactive monitoring |

1. Manual Tire Pressure Checks

Manual tire pressure checks are the most straightforward approach, relying on a handheld gauge to assess tire pressure. While this method incurs minimal costs, it demands regular attention from personnel to ensure tire pressures are within the optimal range. The primary advantage is its simplicity and low initial investment; however, it is labor-intensive and prone to human error, which can lead to inconsistent tire performance and safety risks.

2. Tire Pressure Monitoring Systems (TPMS)

TPMS utilizes sensors to monitor tire pressure and provide alerts to the driver when pressure falls below a predetermined threshold. This technology enhances safety by enabling timely interventions but does not actively inflate the tires. While TPMS can be integrated into most vehicles, its effectiveness is contingent on the driver’s responsiveness to alerts. The moderate cost of TPMS is offset by potential savings from improved fuel efficiency and reduced tire wear, making it an attractive option for businesses seeking a balance between cost and safety.

When selecting a tire management solution, B2B buyers should consider their specific operational requirements, including vehicle type, budget, and maintenance capabilities. Automatic tire pressure systems offer a high-performance solution for fleets where safety and efficiency are paramount, albeit at a higher initial cost. In contrast, manual checks may suit smaller operations with limited budgets, while TPMS provides a middle-ground solution that enhances safety with proactive monitoring. Ultimately, aligning the choice with business goals and operational demands will lead to the most effective tire management strategy.

Automatic tire pressure systems are designed to optimize vehicle performance and safety. Understanding their technical specifications is crucial for B2B buyers who aim to enhance fleet efficiency and reduce operational costs. Here are some essential technical properties:

Pressure Range (psi)

The pressure range of an automatic tire inflator indicates the minimum and maximum air pressure it can handle, typically measured in pounds per square inch (psi). For example, many systems operate within a range of 0-150 psi. A suitable pressure range ensures compatibility with various vehicle types, from passenger cars to heavy-duty trucks. Selecting a system with the appropriate pressure range can prevent over-inflation or under-inflation, both of which can lead to tire damage and safety hazards.

Accuracy and Tolerance

Accuracy refers to how closely the system can measure and maintain the desired tire pressure. Tolerance is the acceptable range of deviation from the target pressure, often expressed in psi. High-accuracy systems (±1 psi) are critical for maintaining optimal tire performance, which can extend tire life and improve fuel efficiency. For B2B buyers, investing in accurate systems can significantly reduce maintenance costs and enhance overall fleet safety.

Calidad del material

The materials used in the construction of automatic tire pressure systems, such as high-grade plastics and metals, determine durability and performance. Systems built with robust materials can withstand harsh environmental conditions and prolonged use, making them more reliable for fleet operations. Understanding material grades helps buyers evaluate long-term value and operational reliability.

Fuente de energía

Automatic tire pressure systems can be powered by various sources, including battery, vehicle power, or pneumatic systems. The choice of power source affects the system’s installation complexity, maintenance needs, and operational costs. Buyers should consider the power source that best fits their operational environment and fleet requirements.

Integration Capability

This refers to the ability of the automatic tire pressure system to interface with existing vehicle telematics and management systems. Systems that offer seamless integration can provide real-time data on tire performance, enhancing decision-making capabilities for fleet managers. A robust integration capability can facilitate better maintenance scheduling and improve overall fleet efficiency.

User Interface

The user interface of the tire pressure system, including digital displays and alerts, is vital for ease of use. An intuitive interface allows drivers and maintenance personnel to quickly assess tire conditions and respond to issues. For B2B buyers, investing in user-friendly systems can enhance operational efficiency and reduce training time for staff.

Understanding industry-specific terminology can help B2B buyers navigate the purchasing process more effectively. Here are some common terms:

OEM (fabricante de equipos originales)

An OEM refers to a company that produces components or systems that are used in another company’s end product. In the context of automatic tire pressure systems, buyers may seek OEM parts to ensure compatibility and quality assurance. Understanding OEM relationships can be crucial for maintaining fleet integrity and performance.

MOQ (Cantidad mínima de pedido)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is essential for buyers to understand when negotiating contracts, as it can impact inventory levels and cash flow. Knowing the MOQ helps buyers plan their purchases according to their operational needs.

RFQ (solicitud de presupuesto)

An RFQ is a document that solicits price quotes from suppliers for specific products or services. B2B buyers use RFQs to compare pricing, terms, and conditions among multiple vendors. Properly drafting an RFQ can lead to better pricing and favorable terms for bulk purchases.

Incoterms

Incoterms are international commercial terms that define the responsibilities of buyers and sellers in the shipping process. Familiarity with these terms, such as FOB (Free On Board) or CIF (Cost, Insurance, and Freight), is crucial for B2B transactions, as they affect shipping costs, risk, and delivery times.

Tire Pressure Monitoring System (TPMS)

TPMS refers to a system that monitors tire pressure and alerts drivers when it falls below a specified threshold. Understanding TPMS is vital for buyers as it relates to safety standards and regulatory compliance in many regions.

Calibration

Calibration is the process of adjusting the tire pressure system to ensure accurate readings. Regular calibration is necessary for maintaining system performance and reliability. Buyers should inquire about calibration services when selecting an automatic tire pressure system to ensure longevity and effectiveness.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions that enhance their fleet’s operational efficiency and safety.

The global automatic tire pressure sector is currently experiencing significant growth, driven by increasing awareness of safety, efficiency, and cost-effectiveness in vehicle maintenance. Key trends include the adoption of advanced technologies such as automatic tire inflation systems (ATIS) and smart tire technologies that monitor and adjust tire pressure in real-time. These innovations are particularly appealing to international B2B buyers in regions like Africa, South America, the Middle East, and Europe, where operational efficiency and fleet safety are paramount.

In emerging markets, the demand for automatic tire pressure solutions is rising due to an expanding automotive sector, coupled with an increased focus on reducing operational costs. For instance, systems like VIGIA and Aperia Technologies’ Halo Tire Inflator enhance tire longevity and fuel efficiency, thereby appealing to fleet operators who prioritize profitability. Furthermore, the integration of IoT (Internet of Things) technologies is facilitating predictive maintenance, allowing fleet managers to address tire issues before they escalate, ultimately reducing downtime and enhancing safety.

Another noteworthy trend is the shift towards sustainability, as companies increasingly seek solutions that not only improve performance but also minimize environmental impact. This evolution in the market dynamics is essential for international buyers who must navigate varying regulations and standards across different regions, particularly in Europe and the Middle East, where stringent environmental policies are becoming the norm.

Sustainability is no longer a buzzword but a critical aspect of B2B purchasing decisions in the automatic tire pressure sector. Buyers are increasingly aware of the environmental impact of their supply chains and are seeking suppliers who prioritize ethical sourcing and sustainable practices. This includes the use of recycled materials in tire manufacturing and the development of products that enhance fuel efficiency, thereby reducing carbon footprints.

For B2B buyers, certifications such as ISO 14001 and environmental product declarations (EPDs) are becoming essential criteria when selecting suppliers. These certifications ensure that the products meet high environmental standards and can provide valuable marketing advantages. Additionally, companies that implement green technologies, such as smart tire systems that automatically adjust tire pressure, not only contribute to sustainability but also offer significant cost savings through improved fuel efficiency and extended tire life.

Moreover, the demand for transparency in supply chains is increasing, prompting suppliers to provide clear information regarding their sourcing practices and the environmental impact of their products. This shift toward ethical sourcing is particularly relevant for buyers from regions like Europe, where consumer preferences are increasingly favoring environmentally responsible products.

The evolution of the automatic tire pressure sector reflects significant technological advancements and changing market demands. Initially, tire pressure monitoring systems (TPMS) were primarily designed to alert drivers when tire pressure dropped below a certain threshold. However, the industry has rapidly progressed towards more sophisticated solutions, such as automatic tire inflation systems that actively maintain optimal pressure levels.

The introduction of smart tire technology represents a pivotal moment in this evolution. These systems not only monitor pressure but also adjust it automatically, thus enhancing vehicle safety and performance. As electric and autonomous vehicles gain traction, the focus on tire technologies that integrate seamlessly with these advancements is set to intensify.

Furthermore, the historical reliance on manual tire maintenance is giving way to automated solutions that enhance operational efficiency and safety. As the market continues to evolve, international B2B buyers are well-positioned to capitalize on these trends, ensuring they remain competitive in an increasingly technology-driven landscape.

Illustrative image related to automatic tire pressure

How do I solve inconsistent tire pressure issues in my fleet?

To address inconsistent tire pressure, consider implementing an automatic tire inflation system (ATIS). These systems maintain optimal tire pressure, reducing the risk of blowouts and enhancing fuel efficiency. When selecting a supplier, look for features such as real-time monitoring, compatibility with various vehicle types, and ease of installation. Additionally, ensure that the system offers alerts for pressure drops and integrates seamlessly with your fleet management technology. Regular maintenance and monitoring will further enhance the system’s effectiveness.

What is the best automatic tire inflation system for commercial vehicles?

The best automatic tire inflation system (ATIS) for commercial vehicles depends on specific fleet needs, such as vehicle type and operational conditions. Popular options include the VIGIA and Halo Tire Inflator, known for their durability, ease of installation, and advanced monitoring features. Assess systems based on criteria like tire longevity, fuel savings, and safety enhancements. It’s advisable to request demonstrations or case studies from suppliers to understand the performance benefits in real-world applications.

What factors should I consider when sourcing automatic tire inflation systems internationally?

When sourcing automatic tire inflation systems internationally, consider factors such as product certifications, local regulations, and supplier reputation. Evaluate the supplier’s experience in your region and their ability to provide localized support and service. Additionally, assess the logistics of shipping, potential tariffs, and delivery timelines. Conduct thorough due diligence by checking references and requesting samples to ensure that the products meet your quality standards.

How can I vet suppliers for automatic tire inflation systems?

To vet suppliers effectively, start by reviewing their industry reputation and customer feedback. Request case studies or testimonials from other businesses in your sector. Verify certifications and compliance with international standards relevant to your region. Conduct an on-site visit if feasible, or utilize video conferencing to assess their facilities and operations. Lastly, consider their after-sales support, warranty policies, and responsiveness to inquiries as indicators of reliability.

What are the minimum order quantities (MOQ) for automatic tire inflation systems?

Minimum order quantities (MOQ) for automatic tire inflation systems can vary widely among suppliers. Some may require a minimum order of a few units, while others may have higher thresholds based on production costs and inventory management. It’s advisable to discuss your specific needs with potential suppliers and negotiate MOQs that align with your purchasing capabilities. Additionally, inquire about bulk order discounts and payment terms to optimize your investment.

What payment terms are typically offered by suppliers of automatic tire inflation systems?

Payment terms offered by suppliers can differ significantly, often influenced by the supplier’s policies and your business relationship. Common terms include upfront payments, net 30, or net 60 days. For international transactions, consider factors like currency exchange rates and payment methods (e.g., wire transfer, letters of credit). Establishing a clear agreement in writing can help mitigate risks and ensure both parties are aligned on payment expectations.

How does quality assurance work for automatic tire inflation systems?

Quality assurance for automatic tire inflation systems typically involves rigorous testing and inspection processes before products are shipped. Suppliers should adhere to international quality standards and certifications relevant to tire safety and performance. Request documentation that outlines their quality control procedures, including any third-party testing or audits. Establishing a clear return policy and warranty terms can further protect your investment and ensure you receive reliable products.

What are the logistics considerations when importing automatic tire inflation systems?

When importing automatic tire inflation systems, consider logistics aspects such as shipping methods, customs regulations, and potential tariffs. Choose a reliable freight forwarder experienced in handling similar products to streamline the process. Ensure that all necessary documentation, including invoices and certificates of origin, is in order to avoid delays. Additionally, plan for warehousing and distribution in your region, taking into account lead times and inventory management strategies.

Dominio: martinsindustries.com

Matriculado: 2005 (20 años)

Introducción: Automatic Tire Inflators for Professionals, available in various types including wall-mounted and handheld. Features include:

– Connects to compressor for accurate inflation/deflation

– Digital gauge

– Nitrogen-inflation compatibility

– Multiple models available:

– Handheld digital tire inflator – Flate Mate Handheld MH-30, Price: $107.72

– Analog Handheld Tire Inflator – Flate Mate Anal…

Dominio: shop.aperiatech.com

Registrado: 2010 (15 años)

Introducción: Product Name: Halo Tire Inflator

Price: $770.00

Limited Time Offer: 22% Off with code “22” at checkout

Características principales:

– Only tire management platform for all wheel positions

– Over 100 billion industry proven miles

– Extends tire life, improves fuel economy, maximizes uptime, enhances safety

– Each kit includes all Halos, Brackets, and necessary Hoses for full vehicle installation

– Each Halo arri…

Dominio: continental-tires.com

Matriculado: 2000 (25 años)

Introducción: Continental C.A.R.E™ technology for smart tires includes features such as: 1. **Connected**: Communicates vital information wirelessly to the car and driver. 2. **Autonomous**: Monitors and adjusts its own air pressure automatically. 3. **Reliable**: Maintains performance under all conditions. 4. **Electrified**: Utilizes self-generated air and electricity to optimize driving performance. 5. **Pre…

Dominio: tireboss.com

Matriculado: 2000 (25 años)

Introducción: Product Name: TIREBOSS 2

Description: The most advanced tire pressure control system in the world, allowing control from the cab with GPS and load sensing autonomous control.

Características principales:

– Touch screen controller

– Smaller control valve, mounts anywhere

– Clean design wheel hardware with auto shut-off valve

– Operator video embedded in controller

– Interactive touch screen display

– GPS speed mo…

Dominio: hendrickson-intl.com

Inscrita: 1997 (28 años)

Introducción: {“product_name”: “TIREMAAX Tire Pressure Control Systems”, “manufacturer”: “Hendrickson”, “key_features”: [“Automatic tire pressure control systems”, “Continuous tire pressure monitoring”, “Prevents tire pressure loss”, “Ventless hubcap and patented axle filter”, “Long-life rotary union (1 million miles)”, “Mechanical controller for maintaining tire pressure”], “benefits”: [“Improves fuel economy”…

Dominio: shop.exceltiregauge.com

Inscrito: 2004 (21 años)

Introducción: {“product_name”: “PNT 4 | AUTOMATIC TIRE INFLATOR”, “sale_price”: “$725.00”, “msrp”: “”, “max_pressure_output_options”: [“80 PSI”, “90 PSI”, “100 PSI”, “110 PSI”, “120 PSI”, “130 PSI”, “140 PSI”], “recommended_for”: [“Tire Shop”, “Dealership”, “Fleet”], “features”: [“Digital Air Machine”, “Hold-on Chuck”, “Chuck Compartment”, “30 ft. Hose”], “warranty”: “2-year Warranty for all parts except chucks…

As the demand for automatic tire pressure management systems continues to rise globally, strategic sourcing presents a significant opportunity for B2B buyers in Africa, South America, the Middle East, and Europe. Investing in advanced tire inflation technologies not only enhances fleet efficiency and safety but also drives down operational costs through improved fuel efficiency and extended tire life. Systems like VIGIA and the Halo Tire Inflator offer reliability and durability, ensuring optimal performance even in challenging environments.

The growing trend towards smart and autonomous tire solutions, as highlighted by innovations from companies like Continental, indicates a future where tires self-regulate pressure, reducing manual interventions and enhancing vehicle performance. For international buyers, sourcing these technologies is not just about procurement; it’s about future-proofing operations against evolving industry standards and consumer expectations.

In conclusion, now is the time to leverage strategic sourcing for automatic tire pressure solutions. By prioritizing quality, reliability, and innovative technology, businesses can enhance their competitive edge and drive sustainable growth. Engage with trusted suppliers to ensure your fleet remains at the forefront of efficiency and safety in an increasingly demanding market.

Illustrative image related to automatic tire pressure

La información facilitada en esta guía, incluido el contenido relativo a fabricantes, especificaciones técnicas y análisis de mercado, tiene únicamente fines informativos y educativos. No constituye asesoramiento profesional en materia de adquisiciones, asesoramiento financiero ni asesoramiento jurídico.

Aunque hemos hecho todo lo posible por garantizar la exactitud y actualidad de la información, no nos hacemos responsables de posibles errores, omisiones o información obsoleta. Las condiciones del mercado, los detalles de las empresas y las normas técnicas están sujetos a cambios.

Los compradores B2B deben llevar a cabo su propia diligencia debida independiente y exhaustiva antes de tomar cualquier decisión de compra. Esto incluye ponerse en contacto directamente con los proveedores, verificar las certificaciones, solicitar muestras y buscar asesoramiento profesional. El riesgo de confiar en la información contenida en esta guía es responsabilidad exclusiva del lector.