In the rapidly evolving automotive industry, sourcing reliable air compressors for vehicles has become a pivotal challenge for B2B buyers, especially in regions like Africa, South America, the Middle East, and Europe. With diverse applications ranging from inflating tires to powering pneumatic tools, the demand for high-performance, durable air compressors is on the rise. This comprehensive guide aims to demystify the global market for vehicle air compressors by exploring various types, their applications, and essential factors for supplier vetting.

International buyers face unique challenges, including navigating different regulatory standards, varying market dynamics, and the need for robust after-sales support. By addressing these concerns, this guide empowers B2B purchasers to make informed decisions, ensuring they select the right equipment that meets both operational needs and budgetary constraints.

Moreover, we will delve into cost considerations, maintenance tips, and market trends that can influence purchasing strategies. Whether you are sourcing for a fleet of commercial vehicles or for specialized applications, understanding the nuances of air compressor technology will enhance your competitive edge. This guide serves as your strategic resource, equipping you with the insights necessary to thrive in the global marketplace for air compressors designed for vehicles.

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Portable Air Compressors | Compact, lightweight, often battery-operated | Automotive repair, mobile workshops, emergency kits | Pros: Easy to transport, versatile. Cons: Limited power and capacity compared to mounted options. |

| Onboard Air Compressors | Permanently installed, higher output, 12V or 24V | Off-road vehicles, fleet vehicles, heavy-duty trucks | Pros: High performance, always ready to use. Cons: More expensive, requires installation. |

| Brushless Air Compressors | Enhanced efficiency, quieter operation, longer lifespan | Automotive applications, industrial use, construction | Pros: Energy-efficient, low maintenance. Cons: Higher initial cost. |

| Tank Air Compressors | Larger capacity, can store air for high-demand tasks | Workshops, garages, heavy machinery, tire shops | Pros: Continuous air supply, suitable for heavy-duty tasks. Cons: Bulky, requires more space. |

| Dual Motor Compressors | Increased air output, often dual-purpose | Off-road vehicles, commercial vehicles, service fleets | Pros: Fast inflation, suitable for various applications. Cons: Higher weight and cost. |

Portable air compressors are designed for mobility, making them ideal for automotive repairs, mobile workshops, and emergency kits. Their lightweight nature allows easy transport, which is essential for businesses that require flexibility in operations. However, buyers should consider that these compressors typically offer limited power and capacity compared to mounted alternatives, which may affect their effectiveness in high-demand scenarios.

Onboard air compressors are permanently installed systems that provide higher output, typically operating on 12V or 24V. They are particularly beneficial for off-road vehicles and fleets that require consistent air pressure for tires or tools. The convenience of having an always-ready air supply is a significant advantage; however, businesses should weigh the initial investment and installation costs against the long-term benefits of enhanced vehicle performance.

Brushless air compressors stand out due to their energy efficiency and quieter operation, making them suitable for various automotive and industrial applications. Their longer lifespan and lower maintenance needs can lead to reduced operational costs over time. Buyers should be prepared for a higher initial purchase price, which is often justified by the long-term savings and efficiency gains.

Tank air compressors are characterized by their larger capacity, allowing them to store air for high-demand tasks in workshops, garages, and tire shops. This continuous air supply is crucial for heavy-duty applications, ensuring that tools and machinery operate without interruption. However, their bulkiness can be a drawback, requiring adequate space for installation and operation.

Dual motor compressors provide increased air output and versatility, often catering to both inflation and powering tools. This dual-purpose functionality makes them highly sought after in off-road vehicles and commercial fleets. While they offer fast inflation and adaptability, buyers should consider the additional weight and cost associated with these systems to ensure they align with their operational requirements.

| Industry/Sector | Specific Application of air compressor for vehicle | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Repair | Tire inflation and maintenance for service vehicles | Ensures optimal vehicle performance and safety | Reliability, ease of use, and maintenance requirements |

| Construction | Powering pneumatic tools for vehicle maintenance | Increases efficiency and reduces downtime | Portable options, power capacity, and durability |

| Agriculture | Inflating tires for farm machinery and vehicles | Enhances mobility and operational efficiency | Compatibility with various tire sizes and ruggedness |

| Off-Road and Recreational Vehicles | Tire pressure adjustments for off-road vehicles | Improves traction and performance in diverse terrains | Compact design, pressure monitoring, and ease of transport |

| Logistics and Transportation | Emergency tire repair for delivery vehicles | Minimizes delays and enhances service reliability | Quick inflation capabilities and portable design |

In automotive repair settings, air compressors are essential for tire inflation and maintenance. They enable technicians to quickly inflate tires to the recommended pressure, ensuring vehicles operate safely and efficiently. The ability to adjust tire pressure can also enhance fuel efficiency and prolong tire life. For international buyers in regions like Africa and Europe, sourcing reliable compressors that withstand varying climate conditions and provide consistent performance is crucial. Additionally, ease of use and maintenance are significant considerations to ensure minimal downtime in busy repair shops.

In the construction sector, air compressors are vital for powering pneumatic tools used in vehicle maintenance, such as impact wrenches and nail guns. This capability allows for efficient and effective repairs or modifications on-site, reducing overall downtime and increasing productivity. For B2B buyers, especially in South America and the Middle East, selecting a compressor that offers robust power and portability is essential. The equipment must also be durable enough to withstand harsh working environments, ensuring longevity and reliability.

Agricultural operations often rely on air compressors to inflate tires for farm machinery and vehicles, ensuring they can navigate various terrains effectively. Proper tire inflation enhances mobility and operational efficiency, which is critical during busy planting and harvesting seasons. Buyers from regions like Africa, where agricultural activities are pivotal, should consider compressors that are versatile and compatible with a range of tire sizes. Additionally, the ability to operate in rugged conditions is a key factor in sourcing decisions.

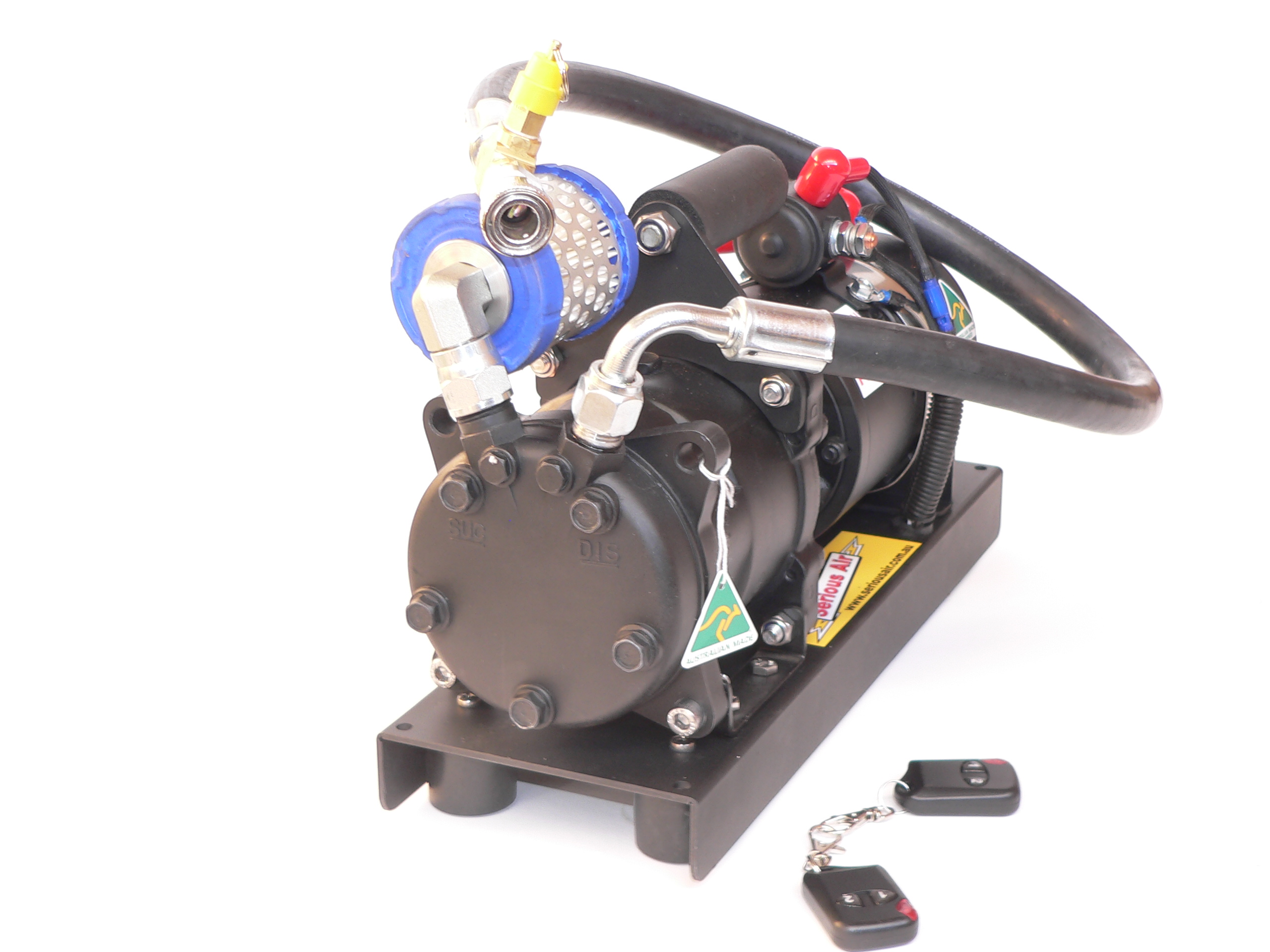

Illustrative image related to air compressor for vehicle

For off-road enthusiasts, air compressors are indispensable for adjusting tire pressures based on terrain. Lowering tire pressure can significantly improve traction on sand or rocky surfaces, while inflating them back to road levels is essential for highway driving. International buyers from regions with diverse landscapes, such as the Middle East, should prioritize compressors that are compact, easy to transport, and equipped with pressure monitoring features. These factors ensure that users can adapt quickly to changing conditions while enjoying their recreational activities.

In the logistics and transportation industry, air compressors serve a critical role in emergency tire repairs for delivery vehicles. Quick inflation capabilities can significantly minimize delays and enhance service reliability, which is crucial in competitive markets. B2B buyers in Europe and South America should focus on sourcing portable and efficient compressors that can be easily stored in vehicles. Reliability and speed of service are paramount, making the choice of compressor a significant investment for maintaining operational efficiency.

The Problem: B2B buyers often face confusion when selecting the appropriate air compressor for their vehicles, particularly when considering factors such as power requirements, portability, and application. This challenge is exacerbated by the wide variety of models available, each with unique features and specifications. Buyers may struggle to understand which compressor is best suited for their specific needs, leading to potential over-investment in features that won’t be utilized or, conversely, under-investment in capabilities that are crucial for their operations.

The Solution: To effectively address this issue, buyers should begin by thoroughly assessing their operational requirements. It is essential to evaluate the types of tasks the compressor will support—whether inflating tires, powering air tools, or providing on-the-go air for various applications. Once requirements are defined, buyers should consult manufacturer specifications, focusing on motor power (measured in horsepower), air delivery rate (CFM), and duty cycle. Engaging with suppliers who offer comprehensive guidance and technical support can also be beneficial. Requesting a demonstration or trial period can help in making an informed decision. Additionally, considering a compressor with modular capabilities can provide flexibility for future needs.

Illustrative image related to air compressor for vehicle

The Problem: Many businesses operate in demanding environments—such as construction sites, mining operations, or agricultural settings—where equipment reliability is paramount. B2B buyers may worry that standard air compressors will fail under extreme conditions, leading to downtime, increased costs, and safety risks. Factors such as dust, moisture, and temperature fluctuations can significantly impact the performance and longevity of air compressors.

The Solution: To mitigate reliability concerns, it is crucial to invest in industrial-grade air compressors specifically designed for harsh conditions. Buyers should look for features such as weather-resistant casings, robust motors, and efficient cooling systems. Furthermore, sourcing compressors that undergo rigorous testing for durability and have proven performance in similar environments is advisable. Regular maintenance schedules should also be established, including routine checks of hoses, filters, and electrical components, to ensure optimal performance. Partnering with a reputable supplier who provides support and spare parts can enhance the longevity and reliability of the investment.

The Problem: Air compressors, like any mechanical equipment, require regular maintenance and can experience failures that necessitate repairs. B2B buyers often lack detailed knowledge about the maintenance needs of their compressors, which can lead to operational disruptions and unexpected costs. This uncertainty can be particularly pronounced in regions where access to technical support and spare parts may be limited.

The Solution: To tackle maintenance and repair challenges, businesses should prioritize training for their personnel on proper compressor upkeep. This includes understanding how to monitor oil levels, replace filters, and check for leaks. Buyers should also consider purchasing compressors that come with comprehensive manuals and online resources for troubleshooting common issues. Additionally, establishing a relationship with a local distributor or service provider can facilitate quick access to replacement parts and expert advice. Implementing a proactive maintenance schedule, based on the manufacturer’s guidelines, can prevent most issues before they arise, ensuring uninterrupted operations. Regular training sessions can also keep the team updated on best practices and new technologies in compressor maintenance.

When selecting materials for air compressors in vehicles, several options stand out due to their unique properties and suitability for various applications. Understanding these materials can help international B2B buyers make informed decisions that align with their operational needs and regional standards.

Aluminum is a popular choice for air compressor components due to its lightweight nature and excellent thermal conductivity. It typically has a temperature rating up to 150°C (302°F) and can withstand pressures of around 200 psi, making it suitable for many automotive applications.

Pros: Aluminum is highly resistant to corrosion, especially when anodized, which extends the lifespan of the compressor. Its lightweight characteristic also enhances fuel efficiency in vehicles.

Cons: While it has good strength, aluminum may not be as durable under extreme conditions compared to steel. Additionally, manufacturing processes for aluminum can be more complex and costly.

For international buyers, particularly in regions like Africa and the Middle East, compliance with local standards such as ASTM can be critical. Buyers should also consider the availability of aluminum in their region, as supply chain issues can affect costs.

Steel, particularly stainless steel, is another common material used in air compressors due to its high strength and durability. It can handle high temperatures (up to 300°C or 572°F) and pressures exceeding 300 psi, making it ideal for heavy-duty applications.

Pros: Steel’s robustness makes it suitable for high-stress environments, and its resistance to wear and tear is superior to that of aluminum.

Cons: Steel is heavier, which can negatively impact vehicle performance and fuel efficiency. It is also more susceptible to corrosion unless treated, which can lead to higher maintenance costs.

Buyers from Europe, such as Germany, may prefer steel due to its compliance with stringent manufacturing standards. However, they should be aware of the potential for increased shipping costs due to weight.

Plastic materials, particularly high-density polyethylene (HDPE) and polycarbonate, are increasingly used in air compressors for non-structural components. These plastics can withstand temperatures up to 100°C (212°F) and moderate pressure levels.

Pros: Plastics are lightweight and resistant to corrosion, making them ideal for components that require flexibility and reduced weight. They are also cost-effective and easy to mold into complex shapes.

Cons: The main limitation is their lower strength compared to metals, which may lead to failure under high-stress conditions. They also have a limited temperature and pressure threshold.

Illustrative image related to air compressor for vehicle

For buyers in South America, where cost-effective solutions are often prioritized, the use of plastic can significantly reduce overall costs. However, they must ensure that the plastics used meet local compliance standards.

Composite materials, such as carbon fiber reinforced polymers, are becoming more common in high-performance air compressors. These materials can handle temperatures up to 200°C (392°F) and pressures around 250 psi.

Pros: Composites offer a unique combination of lightweight and high strength, making them ideal for advanced applications. They also provide excellent resistance to corrosion and fatigue.

Illustrative image related to air compressor for vehicle

Cons: The primary downside is the high cost of composites and the complexity involved in their manufacturing processes. This can lead to higher initial investments for B2B buyers.

In regions like Europe, where innovation and high performance are valued, composites can be an attractive option despite their cost. Buyers should evaluate the long-term benefits versus initial expenditures.

| Material | Typical Use Case for air compressor for vehicle | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Lightweight components in portable compressors | Excellent corrosion resistance | Less durable under extreme conditions | Medium |

| Steel | Heavy-duty applications in onboard compressors | High strength and durability | Heavier, potential corrosion issues | High |

| Plastic | Non-structural components in cost-effective models | Lightweight and cost-effective | Lower strength and temperature limits | Low |

| Composite | High-performance applications in advanced models | Lightweight with high strength | High cost and manufacturing complexity | High |

This strategic material selection guide provides B2B buyers with actionable insights to navigate their purchasing decisions effectively, ensuring compliance with regional standards while optimizing performance and cost.

The manufacturing process of air compressors for vehicles involves several critical stages, each designed to ensure the final product meets rigorous performance and safety standards. The main stages include material preparation, forming, assembly, and finishing.

Material preparation is the first step in the manufacturing process. High-quality materials, such as aluminum, steel, and durable plastics, are selected based on the required specifications for strength and weight. Suppliers typically conduct thorough evaluations to ensure that materials meet international standards, which is particularly important for B2B buyers in regions like Africa and South America, where material quality can vary significantly.

Once materials are sourced, they undergo processes like cutting, machining, and surface treatment to prepare them for assembly. These processes often involve CNC (Computer Numerical Control) machines for precision, ensuring that every component fits perfectly together, which is crucial for optimizing airflow and efficiency in the final product.

Forming is the next stage, where prepared materials are shaped into specific components. Various techniques are employed in this stage, including stamping, forging, and extrusion.

The choice of technique depends on the design requirements and the intended application of the compressor, with manufacturers often opting for methods that maximize strength while minimizing weight.

The assembly stage is where individual components come together to form a complete air compressor. This process typically involves manual labor and automated systems working in tandem. Skilled technicians assemble the compressor according to predefined specifications, ensuring that each part is installed correctly and securely.

During assembly, manufacturers often incorporate quality checks to ensure that components align correctly, which is essential for maintaining efficiency and performance. For B2B buyers, understanding the assembly techniques can provide insight into the manufacturer’s attention to detail and commitment to quality.

Finishing is the final stage of manufacturing, where the assembled air compressor undergoes treatments to enhance its durability and appearance. Common finishing techniques include powder coating, painting, and surface polishing. These processes not only improve the aesthetic appeal of the product but also provide a protective layer against corrosion and wear, which is particularly important in rugged environments.

Furthermore, manufacturers often conduct additional quality assurance measures during this stage, such as leak testing and pressure testing, to confirm that the compressor can operate safely and efficiently under expected conditions.

Illustrative image related to air compressor for vehicle

Quality assurance (QA) is a critical component of the manufacturing process for air compressors. Manufacturers must adhere to various international standards to ensure product reliability and safety.

One of the most recognized international quality standards is ISO 9001, which outlines criteria for a quality management system. Compliance with ISO 9001 indicates that a manufacturer has established processes to ensure consistent quality in their products and services.

In addition, industry-specific certifications such as CE (Conformité Européenne) for products sold in Europe and API (American Petroleum Institute) standards for compressors used in oil and gas applications are crucial. B2B buyers should verify that potential suppliers possess these certifications, as they reflect adherence to safety and performance benchmarks.

Quality control (QC) involves several checkpoints throughout the manufacturing process, including:

B2B buyers should inquire about the QC processes employed by suppliers to gain confidence in their product reliability.

To ensure that a supplier maintains high-quality standards, B2B buyers can employ several strategies:

Conducting supplier audits is one of the most effective methods for verifying a manufacturer’s QC processes. Audits can be performed by the buyer or by third-party inspection agencies, which provide an unbiased assessment of the supplier’s practices and compliance with international standards.

Additionally, reviewing QC reports and certifications can provide insights into the supplier’s quality management system. Buyers should request documentation that outlines the supplier’s adherence to relevant standards and any results from previous audits.

Third-party inspections involve independent organizations assessing the manufacturing process and final products to ensure compliance with specified standards. These inspections can cover various aspects, including material quality, assembly practices, and final product testing.

For B2B buyers, especially in regions like Africa and the Middle East, utilizing third-party inspection services can mitigate risks associated with sourcing products from international suppliers.

Illustrative image related to air compressor for vehicle

B2B buyers from diverse regions must be aware of specific nuances when it comes to quality control. These may include variations in local regulations, differing standards of material quality, and the potential for language barriers in communication. Buyers should prioritize establishing clear expectations with suppliers and consider engaging local experts who understand regional compliance requirements.

By understanding the manufacturing processes and quality assurance measures for air compressors, international B2B buyers can make informed purchasing decisions that align with their operational needs and standards.

When sourcing an air compressor for vehicles, it is essential to approach the process systematically. This checklist will guide you through the critical steps to ensure you select a product that meets your operational needs, complies with industry standards, and offers good value for your investment.

Understanding your specific requirements is the first step in the sourcing process. Determine the intended use of the air compressor—whether for inflating tires, powering pneumatic tools, or other applications.

– Pressure Requirements: Identify the necessary PSI (pounds per square inch) for your applications.

– Power Source: Decide between portable 12V compressors or more powerful onboard systems based on your vehicle type and usage context.

Conduct thorough market research to identify available air compressor models that fit your specifications. This step helps you understand the variety of options available in the market and compare features.

– Brands and Models: Look for reputable brands known for reliability and performance, such as ARB or VIAIR.

– Features Comparison: Assess features like airflow rates, motor types (brushless or traditional), and additional functionalities such as built-in gauges.

Before committing to a supplier, it’s crucial to vet them thoroughly. This ensures that you are partnering with a reliable source that can meet your needs.

– Supplier Background: Request company profiles, certifications, and case studies relevant to your industry.

– Customer Feedback: Seek references from other businesses that have purchased similar products to gauge supplier reliability and product performance.

Illustrative image related to air compressor for vehicle

Ensure that the air compressors comply with relevant local and international standards. Compliance not only guarantees product quality but also reduces potential legal and operational risks.

– Certification Checks: Look for certifications such as ISO, CE, or UL that verify safety and performance standards.

– Warranty and Support: Confirm the warranty terms and the availability of after-sales support to address any operational issues.

Analyze the pricing structure of the compressors while factoring in total cost of ownership. A lower initial price may not always equate to better value.

– Long-term Costs: Consider maintenance, energy consumption, and potential repair costs over the compressor’s lifespan.

– Bulk Purchase Discounts: Inquire about pricing for bulk orders, which can significantly reduce per-unit costs.

Before finalizing the purchase, negotiate the terms to ensure favorable conditions for your business.

– Payment Terms: Discuss payment options, including any financing available for larger purchases.

– Delivery and Logistics: Confirm lead times and shipping methods to ensure timely delivery of the compressors.

Illustrative image related to air compressor for vehicle

Once the air compressors are sourced, plan for their installation and any necessary training for your team.

– Installation Guidelines: Ensure the supplier provides clear installation instructions or offers installation services.

– Operational Training: Arrange for training sessions for your staff on how to operate and maintain the compressors effectively, ensuring optimal performance and safety.

By following this step-by-step checklist, B2B buyers can streamline the procurement process for air compressors, ensuring that they make informed decisions that align with their operational needs and budget constraints.

When sourcing air compressors for vehicles, understanding the cost structure is crucial for B2B buyers. Key components include:

Materials: The quality and type of materials used significantly affect costs. For example, durable components such as high-grade aluminum or stainless steel are preferred for performance under extreme conditions, but they come at a higher price.

Labor: Skilled labor is required for assembly and quality assurance processes. Labor costs can vary significantly depending on the country of production, with regions like Europe typically having higher wages compared to countries in Africa or South America.

Manufacturing Overhead: This includes costs related to utilities, facility maintenance, and administrative expenses. Effective management of these overheads can lead to cost savings.

Tooling: The initial investment in tooling is substantial, especially for custom designs. Buyers should consider whether they need standard models or custom solutions, as this will influence the tooling costs.

Quality Control (QC): Rigorous testing and quality assurance processes are essential, especially for products intended for rugged environments. This may add to the overall cost but ensures reliability and longevity.

Logistics: Transportation costs can vary based on the shipping method, distance, and whether the product is shipped via air or sea. Incoterms will also dictate who bears these costs, impacting the total price.

Margin: Suppliers typically add a margin to cover risks and ensure profitability. This margin can vary widely based on supplier reputation and market demand.

Several factors influence the pricing of air compressors, particularly for international buyers:

Volume and Minimum Order Quantity (MOQ): Bulk purchases often lead to significant discounts. Suppliers may offer lower prices per unit for larger orders, making it essential for buyers to assess their needs accurately.

Specifications and Customization: Customized products usually incur higher costs due to the additional design and manufacturing processes involved. Buyers must weigh the benefits of customization against the potential price increase.

Materials and Quality Certifications: High-quality components and certifications (such as ISO or CE) can increase initial costs but may lead to lower Total Cost of Ownership (TCO) due to reduced maintenance and replacement needs.

Supplier Factors: The reputation and reliability of the supplier can significantly influence pricing. Established suppliers may charge a premium for their products, while emerging suppliers might offer competitive pricing to gain market share.

Incoterms: Understanding shipping terms is vital. For example, “FOB” (Free on Board) means the buyer takes responsibility once the goods are on board the shipping vessel, affecting the total landed cost.

Effective negotiation can lead to cost efficiencies. Here are some strategies:

Research Market Prices: Knowing the average market price for similar products can empower buyers during negotiations. This information helps in assessing whether the offered prices are competitive.

Focus on Total Cost of Ownership (TCO): Highlighting the long-term savings from a quality product can justify a higher initial price, making suppliers more willing to negotiate on other aspects like payment terms.

Build Relationships: Establishing long-term relationships with suppliers can lead to better pricing and terms over time. Consistent communication and trust can result in better support and pricing flexibility.

Be Prepared for Compromise: Understand your limits and be ready to make concessions, whether on price, payment terms, or delivery schedules, to reach a mutually beneficial agreement.

Consider Local Suppliers: For buyers in Africa or South America, sourcing from local suppliers may reduce shipping costs and lead times, providing a competitive advantage.

In summary, B2B buyers of air compressors for vehicles need to thoroughly understand the cost components and pricing influencers that affect their purchasing decisions. By strategically negotiating and considering the Total Cost of Ownership, buyers can make informed choices that align with their operational needs and budget constraints. Always remember to seek multiple quotes and maintain an adaptable approach to sourcing to ensure the best possible outcome.

In the automotive industry, air compressors play a critical role in ensuring optimal vehicle performance, especially for off-road and utility applications. However, several alternative solutions exist that can achieve similar outcomes. This analysis will compare air compressors for vehicles against two notable alternatives: portable inflators and CO2 inflators. By understanding these options, B2B buyers can make informed decisions tailored to their operational needs.

| Comparison Aspect | Air Compressor For Vehicle | Portable Inflator | CO2 Inflator |

|---|---|---|---|

| Performance | High output, suitable for multiple applications | Moderate output, good for tires only | High output, rapid inflation |

| Cost | $250 – $1,379 depending on model | $30 – $150 | $100 – $300 |

| Ease of Implementation | Requires installation for onboard models | Plug-and-play, very user-friendly | Requires CO2 cartridges, slightly complex |

| Maintenance | Regular checks, parts available | Minimal maintenance | Cartridge replacement needed |

| Best Use Case | Off-road adventures, heavy-duty tasks | Quick tire inflation, light use | Racing, quick tire inflation |

Portable inflators are compact devices designed primarily for inflating tires and small items like sports equipment. Their primary advantage lies in their ease of use; they typically plug into a vehicle’s power outlet and require minimal setup. Additionally, they are cost-effective, making them an attractive option for businesses with limited budgets. However, their performance is generally lower than that of vehicle-mounted air compressors, and they may not be suitable for heavy-duty applications or multiple simultaneous uses. This limits their effectiveness in high-demand scenarios, such as off-road expeditions or professional automotive services.

CO2 inflators utilize compressed carbon dioxide to quickly inflate tires. They are particularly popular among racers and outdoor enthusiasts due to their rapid inflation capabilities. The speed of CO2 inflators makes them ideal for situations where time is of the essence, such as during a race or an emergency. However, they come with the drawback of needing replacement cartridges, which can add to long-term costs and create waste. Additionally, while they are effective for tire inflation, they lack the versatility of air compressors, which can also power tools and other devices.

When selecting an air compression solution, B2B buyers must consider their specific operational requirements. For heavy-duty applications, such as off-road driving or professional automotive services, an air compressor for vehicles is often the best choice due to its performance, versatility, and ability to handle multiple tasks simultaneously. Conversely, if the primary need is for quick tire inflation or light use, portable inflators or CO2 inflators may be sufficient and more cost-effective. Ultimately, understanding the unique demands of your operations will guide you in choosing the right solution that balances performance, cost, and ease of use.

Illustrative image related to air compressor for vehicle

Understanding the technical properties of air compressors is vital for B2B buyers in the automotive industry. Here are some critical specifications that influence performance, reliability, and suitability for various applications:

Pressure Rating (PSI)

The pressure rating, measured in pounds per square inch (PSI), indicates the maximum air pressure the compressor can generate. A higher PSI allows for faster inflation and the capability to power pneumatic tools. For off-road vehicles or commercial fleets, selecting a compressor with an adequate PSI rating ensures that tires can be efficiently inflated and tools can operate effectively.

Airflow Rate (CFM)

The airflow rate, expressed in cubic feet per minute (CFM), measures how much air the compressor can deliver within a minute. For B2B buyers, a higher CFM rating translates to quicker inflation times and the ability to support multiple tools simultaneously. This is crucial for businesses that require efficiency and productivity in their operations.

Duty Cycle

The duty cycle indicates the percentage of time a compressor can operate continuously within a given period without overheating. For example, a duty cycle of 50% means the compressor can run for 5 minutes and must rest for 5 minutes. Understanding the duty cycle helps buyers select a compressor that matches their workload and prevents overheating, enhancing longevity and performance.

Power Source (Voltage)

The power source, typically available in 12V or 24V configurations for vehicle-mounted compressors, defines compatibility with vehicle electrical systems. Buyers must consider the power availability of their vehicles to ensure seamless operation. A mismatch could lead to performance issues or even damage to the compressor.

Material and Build Quality

The materials used in the compressor’s construction, such as aluminum or reinforced plastic, affect durability and weight. For B2B purchasers, selecting a compressor made from high-quality materials ensures reliability in harsh environments, reducing the need for frequent replacements and maintenance.

Size and Weight

The physical dimensions and weight of the compressor are crucial for installation and mobility. A compact, lightweight design is preferable for portable applications, while a more substantial unit may be necessary for heavy-duty tasks. Buyers should assess the intended use to ensure the right balance between performance and portability.

Familiarity with trade terminology is essential for effective communication in the B2B landscape. Here are some common terms that buyers should know:

OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. Understanding OEM relationships is crucial for buyers looking for compatible parts or replacements that meet the original specifications, ensuring the reliability of their air compressor systems.

MOQ (Minimum Order Quantity)

MOQ signifies the smallest number of units a supplier is willing to sell. B2B buyers need to be aware of MOQs when sourcing air compressors, as these quantities can affect inventory management and overall costs. Negotiating lower MOQs can help smaller businesses manage their cash flow more effectively.

RFQ (Request for Quotation)

An RFQ is a formal process where buyers request price quotes from suppliers for specific products or services. Utilizing RFQs enables buyers to compare prices, terms, and specifications across multiple suppliers, ensuring they make informed purchasing decisions.

Incoterms (International Commercial Terms)

Incoterms are internationally recognized rules that define the responsibilities of buyers and sellers in shipping goods. Familiarity with Incoterms helps buyers understand shipping costs, risks, and delivery responsibilities, which is essential for international transactions involving air compressors.

Warranty Period

The warranty period indicates how long the manufacturer guarantees the product against defects. Understanding the warranty terms is vital for B2B buyers to assess the long-term value and reliability of their investment in air compressors.

Aftermarket Support

Aftermarket support refers to services provided after the sale, including maintenance, repairs, and spare parts availability. Ensuring robust aftermarket support is critical for B2B buyers to maintain the operational efficiency of their air compressors over time.

By grasping these technical properties and trade terms, B2B buyers can make more informed decisions when sourcing air compressors for vehicles, ensuring that their investments meet operational needs and deliver long-term value.

The global air compressor market for vehicles is witnessing significant transformation driven by technological advancements and changing consumer demands. One of the primary drivers is the rising need for efficient and versatile air compressor systems that can accommodate various applications, from tire inflation to powering pneumatic tools. Emerging technologies such as brushless motors and smart cooling systems are enhancing performance and energy efficiency, thereby catering to eco-conscious consumers and businesses alike.

In regions like Africa and South America, where off-road and utility vehicle markets are expanding, the demand for portable and onboard air compressors is growing. These markets are characterized by a rising number of adventure and recreational vehicle users, pushing manufacturers to innovate products that are compact, durable, and easy to use. In Europe and the Middle East, regulatory frameworks emphasizing energy efficiency and emissions reductions are prompting buyers to seek compressors with advanced features that minimize environmental impact.

Additionally, the trend towards digitalization is reshaping sourcing strategies, with international buyers increasingly leveraging online platforms for procurement, allowing for better price comparisons and access to a wider range of products. As competition intensifies, suppliers who can offer robust customer support, warranty services, and readily available spare parts will gain a competitive edge in this dynamic landscape.

Sustainability is becoming a cornerstone of purchasing decisions in the air compressor market. Businesses are increasingly aware of the environmental impact of their operations and are prioritizing suppliers who adopt sustainable practices. This encompasses everything from the materials used in manufacturing to the energy efficiency of the compressors themselves. For instance, compressors that utilize eco-friendly refrigerants and are built from recyclable materials are becoming increasingly sought after.

Moreover, the importance of ethical sourcing cannot be overstated. Buyers are looking for manufacturers who demonstrate transparency in their supply chains, ensuring that materials are sourced responsibly and labor practices meet ethical standards. Certifications such as ISO 14001 for environmental management and other ‘green’ labels can provide assurance of a supplier’s commitment to sustainability.

Illustrative image related to air compressor for vehicle

For international B2B buyers, especially those in regions like Africa and South America, selecting suppliers with robust sustainability practices can enhance brand reputation and appeal to a growing segment of environmentally conscious consumers. This shift not only addresses regulatory pressures but also aligns with global sustainability goals, making it a strategic imperative for modern businesses.

The evolution of air compressors for vehicles can be traced back to the early 20th century when they were primarily used in industrial settings. As the automotive industry expanded, so did the applications of air compressors, which began to include tire inflation and powering tools. Over the decades, advancements in technology have led to the development of portable and onboard compressors, making them accessible to a wider range of consumers, including those in off-road and recreational sectors.

The introduction of electric and hybrid vehicles has further propelled innovation in this space, with manufacturers developing compressors that cater specifically to these newer vehicle types. Today’s air compressors are not only more efficient but also offer enhanced features such as smart technology integration, allowing users to monitor performance and energy consumption effectively. As the market continues to evolve, the focus on sustainability and technology will likely drive the next wave of innovations in the air compressor sector.

Illustrative image related to air compressor for vehicle

How do I determine the right air compressor for my vehicle fleet?

Selecting the right air compressor depends on several factors, including the type of vehicles in your fleet, the intended use (inflating tires, powering tools, etc.), and the required pressure and airflow. Assess the compressor’s specifications, such as CFM (Cubic Feet per Minute) and PSI (Pounds per Square Inch), to ensure it meets your operational needs. Additionally, consider whether a portable or mounted compressor is more suitable for your applications. Consulting with manufacturers or suppliers can also provide insights based on your specific requirements.

What is the best air compressor for off-road vehicles?

For off-road vehicles, a high-performance, portable air compressor is often recommended. Look for models with robust construction, capable of withstanding extreme conditions, and offering features like quick inflation and deflation capabilities. Compressors with dual motors or brushless technology tend to provide more efficiency and longevity. Brands recognized for their reliability in off-road conditions, such as ARB or VIAIR, typically offer a range of options suited for rugged terrains.

What are the key factors to consider when vetting air compressor suppliers?

When vetting suppliers, prioritize their experience in the air compressor market and their reputation for quality. Request references or case studies from similar businesses to gauge their reliability. Additionally, consider their compliance with international standards and certifications, such as ISO. Evaluate their customer service responsiveness and technical support capabilities, as these will be vital for ongoing maintenance and troubleshooting.

What customization options are available for air compressors?

Many manufacturers offer customization options for air compressors, including modifications for specific pressure requirements, size adaptations, or the addition of specialized features like built-in gauges or unique mounting systems. Discuss your specific needs with potential suppliers to explore available customizations. Keep in mind that customized solutions may have longer lead times and could influence pricing.

What are the minimum order quantities (MOQs) for purchasing air compressors?

Minimum order quantities can vary significantly among suppliers. Some manufacturers may require a minimum order of five to ten units, while others might be flexible for smaller orders, especially for new customers or trial purchases. It’s essential to clarify MOQs during negotiations, as this can impact your procurement strategy and cash flow. Ensure that you also inquire about pricing breaks for larger orders.

What payment terms should I expect when sourcing air compressors internationally?

Payment terms for international purchases can vary widely, often influenced by the supplier’s policies and your relationship with them. Common terms include upfront payment, a partial deposit with the balance due upon shipment, or net 30/60/90 days after delivery. It’s crucial to discuss and agree on payment terms before finalizing any contracts to ensure clarity and avoid potential disputes.

How do I ensure quality assurance for air compressors during international shipping?

To ensure quality assurance, request that suppliers provide detailed product specifications, including performance metrics and compliance certifications. Implement an inspection process, either through third-party services or by negotiating quality checks before shipment. Establish clear return policies and warranties, allowing for recourse if the delivered products do not meet agreed-upon standards.

What logistics considerations should I keep in mind when importing air compressors?

When importing air compressors, consider the shipping method (air vs. sea), which can significantly affect delivery times and costs. Ensure that you understand customs regulations and duties applicable to your region, as these can add to overall expenses. Collaborate with logistics partners experienced in handling heavy equipment to navigate importation smoothly. Lastly, track shipments closely to mitigate delays and ensure timely delivery.

Domain: store.arbusa.com

Registered: 1998 (27 years)

Introduction: Portable & Vehicle Mounted Air Compressor Systems by ARB 4×4 USA. Key features include: durable, high-performance compressors for tires, tools, and Air Lockers; new Brushless Compressors with 50% more output, smart cooling, and quick-release mounts for unmatched airflow in a compact design. Product categories include Mounted Compressors, Portable Compressors, and Brushless Compressors. Notable pro…

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Looking for a good air compressor primarily to use for car tires. Recommendations include: 1. Viair 88p – recommended for inflating tires and comes with a tire plug kit. 2. Milwaukee M18 – highly rated, especially if you already use Milwaukee batteries for tools. 3. California Air Tools – known for being oil-free and quiet, with an 8-gallon model mentioned as easy to carry.

Domain: facebook.com

Registered: 1997 (28 years)

Introduction: small portable air compressors/tire inflators

In the ever-evolving landscape of vehicle air compressors, strategic sourcing emerges as a critical element for B2B buyers aiming to enhance operational efficiency and performance. The diverse offerings in the market, from portable to mounted compressors, provide opportunities for businesses to select solutions that best fit their specific needs, whether for off-road adventures or everyday utility. Key factors such as durability, ease of maintenance, and performance under extreme conditions should guide procurement decisions.

International buyers from regions like Africa, South America, the Middle East, and Europe must prioritize partnerships with reputable suppliers who offer quality assurance and reliable after-sales support. This approach not only ensures access to high-performance products but also fosters long-term relationships that can lead to advantageous pricing and product innovation.

Looking ahead, the demand for air compressors will likely continue to grow as industries recognize their versatility and essential role in vehicle maintenance and performance enhancement. By leveraging strategic sourcing, businesses can position themselves to capitalize on emerging trends and technologies in the air compressor market. Engage with trusted suppliers today to secure the best solutions that will empower your operations for tomorrow’s challenges.

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

Illustrative image related to air compressor for vehicle

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.