In today’s fast-paced automotive landscape, sourcing the right cordless tire inflator with battery and charger can be a pivotal challenge for businesses aiming to maintain operational efficiency. With the increasing reliance on battery-powered tools, the demand for reliable and portable tire inflators is on the rise, particularly in regions such as Africa, South America, the Middle East, and Europe. This guide delves deep into the global market dynamics, providing a comprehensive overview of the various types of cordless tire inflators available, their applications, and the essential factors to consider when making a purchasing decision.

As international B2B buyers navigate this competitive landscape, understanding the nuances of supplier vetting, cost analysis, and product specifications becomes critical. This guide equips decision-makers with actionable insights to identify high-quality products that meet their operational needs while ensuring cost-effectiveness. By exploring key features like battery life, pressure capabilities, and additional functionalities, buyers can make informed choices that enhance their service offerings and customer satisfaction.

Whether you’re in Brazil looking for a compact solution for urban mobility or in Germany seeking high-performance inflators for heavy-duty vehicles, this guide serves as a valuable resource. It empowers businesses to streamline their procurement processes and optimize their investments in tire maintenance tools, ultimately leading to improved efficiency and profitability.

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Battery-Powered Inflator | Compact design, typically 12V or 20V, suitable for light use | Automotive repair shops, roadside assistance | Pros: Portable, easy to use, quick inflation. Cons: Limited battery life for heavy-duty use. |

| High-Pressure Inflator | Higher PSI capabilities (up to 160 PSI), robust construction | Trucking, heavy machinery maintenance | Pros: Suitable for larger vehicles, durable. Cons: Heavier, more expensive. |

| Multi-Function Inflator | Includes additional features (USB charging, built-in light) | Emergency services, outdoor recreation | Pros: Versatile, can inflate various items. Cons: May be bulkier, higher maintenance. |

| Ultra-Compact Inflator | Small size, lightweight, often rechargeable via USB | Personal vehicle owners, small businesses | Pros: Highly portable, ideal for limited storage. Cons: Slower inflation speed. |

| Professional Grade Inflator | Designed for frequent use, higher durability and performance | Fleet management, tire service centers | Pros: Fast inflation, long-lasting. Cons: Higher upfront cost, requires training for use. |

Standard battery-powered inflators are designed for convenience and ease of use, typically operating on 12V or 20V batteries. These inflators are ideal for light to moderate tire inflation tasks, making them a popular choice for automotive repair shops and roadside assistance teams. When purchasing, B2B buyers should consider the battery life and charging time, as these factors directly impact operational efficiency.

High-pressure inflators are engineered to handle demanding tasks, capable of inflating tires to pressures exceeding 160 PSI. This makes them suitable for larger vehicles such as trucks and heavy machinery, which require higher air pressure for optimal performance. B2B buyers should evaluate the inflator’s construction quality and ease of transport, as these units can be heavier and may come at a premium price.

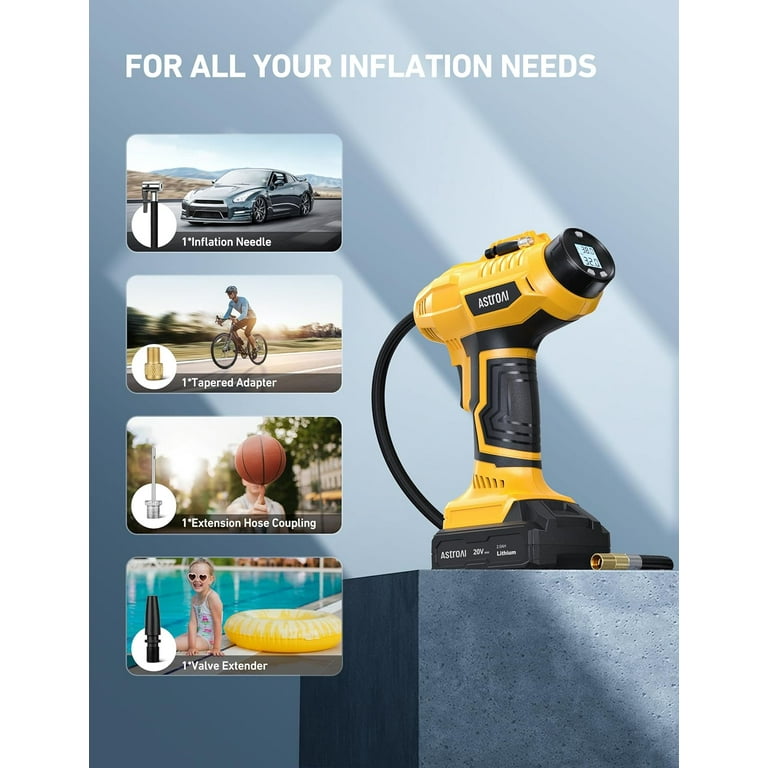

Illustrative image related to cordless tire inflator with battery and charger

Multi-function inflators are versatile tools that often come equipped with additional features such as USB charging ports and built-in lights. These functionalities make them particularly useful for emergency services and outdoor recreation businesses where versatility is key. Buyers should assess the durability and ease of use of these inflators, as well as their battery life, to ensure they meet the varied needs of their operations.

Ultra-compact inflators are designed for portability, making them ideal for personal vehicle owners and small businesses with limited storage space. These inflators are often rechargeable via USB and can easily fit in glove compartments. However, buyers should be aware that while these models are convenient, they may have slower inflation speeds and limited power, making them less suitable for larger tires or frequent use.

Professional-grade inflators are built for high performance and frequent use, making them a strong choice for fleet management and tire service centers. These units typically offer rapid inflation times and enhanced durability, ensuring they can handle the rigors of daily operations. B2B buyers must consider the initial investment and the potential need for operator training to maximize the efficiency and safety of these inflators in a professional setting.

| Industry/Sector | Specific Application of cordless tire inflator with battery and charger | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Repair | Quick tire inflation for roadside assistance services. | Reduces downtime for vehicles, enhancing service efficiency. | Durability, battery life, portability, and charging options. |

| Logistics and Transport | Routine tire maintenance for fleet vehicles. | Ensures optimal tire pressure, improving fuel efficiency. | Compatibility with various tire types, ease of use, and reliability. |

| Agriculture | Inflation of ATV and tractor tires on-site. | Minimizes delays during critical farming operations. | Rugged design, battery capacity, and availability of accessories. |

| Recreational Vehicles | Tire inflation for RVs and trailers during travel. | Enhances safety and convenience for long-distance trips. | Compact size, multi-functionality, and charging flexibility. |

| Manufacturing | Use in production lines for machinery and equipment tire maintenance. | Prevents equipment downtime, ensuring continuous operations. | Power output, pressure accuracy, and ease of integration into existing workflows. |

In the automotive repair industry, cordless tire inflators with battery and charger are essential tools for roadside assistance services. These inflators provide quick tire inflation, allowing technicians to address flat tires on-site, significantly reducing vehicle downtime. For international buyers, particularly in regions with varying terrain and climate conditions, it is crucial to select inflators that are durable and reliable. Features such as long battery life and fast inflation rates are key considerations to enhance service efficiency.

In logistics and transport, maintaining the right tire pressure is vital for fleet vehicles. Cordless tire inflators allow fleet managers to conduct routine tire maintenance quickly and efficiently, preventing issues that can lead to increased fuel consumption and tire wear. Buyers in this sector should focus on inflators that are compatible with various tire types and have robust performance to handle daily use. The ability to recharge using vehicle power outlets adds to the practicality of these tools, especially for long-haul operations.

Illustrative image related to cordless tire inflator with battery and charger

Agricultural operations often rely on ATVs and tractors, which require regular tire maintenance to avoid delays during planting and harvesting seasons. Cordless tire inflators enable farmers to inflate tires on-site, ensuring that equipment is always ready for use. When sourcing these tools, agricultural businesses should prioritize rugged designs that withstand outdoor conditions and have sufficient battery capacity to handle multiple inflation tasks in a single charge, thereby minimizing operational interruptions.

For owners of RVs and trailers, having a reliable cordless tire inflator is crucial for ensuring safety during long trips. These inflators allow users to quickly check and adjust tire pressure, preventing blowouts and enhancing overall travel safety. International buyers should look for compact models that are easy to store and transport. Multi-functionality, such as the ability to inflate recreational equipment like kayaks and air mattresses, adds further value to these inflators, making them a versatile addition to any travel kit.

In manufacturing, maintaining machinery and equipment in optimal condition is vital for productivity. Cordless tire inflators are employed to keep tires of forklifts and other machinery properly inflated, thus preventing unexpected downtime. When sourcing inflators for manufacturing applications, businesses should consider power output and pressure accuracy to ensure they meet the demands of industrial environments. Additionally, ease of integration into existing workflows can streamline maintenance processes, contributing to overall operational efficiency.

The Problem: Many B2B buyers in sectors like transportation and logistics face challenges with the inconsistent performance of cordless tire inflators due to unreliable battery life. When operators rely on these tools for quick tire maintenance, a depleted battery can lead to delays and inefficient operations, particularly in remote areas where access to power outlets is limited. This can result in increased downtime, affecting overall productivity and potentially leading to safety hazards if tires are not adequately inflated.

Illustrative image related to cordless tire inflator with battery and charger

The Solution: To mitigate this issue, businesses should prioritize sourcing high-quality cordless tire inflators with robust battery performance. When evaluating options, look for models that include lithium-ion batteries with a high amp-hour (Ah) rating, which provide longer usage times and quicker recharge cycles. Additionally, consider inflators that offer dual power sources—such as both battery and 12-volt car adapter capabilities—ensuring that inflation can continue even if the battery runs low. It’s also wise to implement a regular maintenance schedule for the inflators, including periodic checks of battery health, to ensure optimal performance when needed.

The Problem: Another common pain point for B2B buyers is the challenge of accurately monitoring tire pressure, especially when using cordless tire inflators that may not feature built-in pressure gauges. In industries such as construction and transportation, maintaining the correct tire pressure is crucial for safety and efficiency. Inaccurate readings can lead to over-inflation or under-inflation, increasing the risk of tire blowouts or uneven wear.

The Solution: To address this concern, businesses should consider investing in cordless tire inflators that come equipped with digital pressure gauges that provide real-time readings. Look for models that allow users to set desired pressure levels, automatically shutting off once the target pressure is reached. Additionally, integrating tire pressure monitoring systems (TPMS) into the fleet can help track tire pressure continuously and alert operators to any deviations before they become critical. Training staff on proper usage and the importance of tire maintenance can further enhance safety and operational efficiency.

The Problem: B2B buyers often report challenges with the portability of cordless tire inflators, especially in industries requiring frequent mobility, such as road service and emergency response. Inflators that are too bulky or lack efficient carrying solutions can hinder swift deployment, leading to delayed responses in critical situations.

The Solution: When selecting cordless tire inflators, buyers should prioritize compact and lightweight models that are designed for easy transport. Look for inflators that come with carrying cases or integrated handles for seamless mobility. Additionally, consider investing in models that offer multiple inflation accessories, enabling versatility for various applications, such as inflating sports equipment or recreational vehicles. Finally, implementing a strategic inventory management system that places inflators in easily accessible locations can ensure that teams can quickly retrieve and deploy them when needed, enhancing responsiveness and operational efficiency.

By addressing these common pain points with actionable solutions, B2B buyers can significantly enhance their tire maintenance processes, leading to improved safety, efficiency, and productivity across their operations.

When selecting materials for cordless tire inflators, manufacturers must consider factors such as performance, durability, cost, and compliance with international standards. Below, we analyze four common materials used in these devices, focusing on their properties, advantages, disadvantages, and implications for international B2B buyers.

Key Properties: Plastics, particularly high-density polyethylene (HDPE) and polycarbonate, are often used for housing and components due to their lightweight nature and good impact resistance. They typically have a temperature rating of up to 80°C and can withstand moderate pressures.

Pros & Cons: Plastics are generally cost-effective and easy to mold, which simplifies manufacturing processes. However, they may not offer the same level of durability as metals, especially in high-stress environments. Additionally, certain plastics can degrade under UV exposure or extreme temperatures, affecting long-term performance.

Illustrative image related to cordless tire inflator with battery and charger

Impact on Application: Plastics are suitable for non-structural components and housings, but they may not be ideal for parts exposed to high pressures or extreme temperatures, where metal alternatives might be necessary.

Considerations for International Buyers: Buyers in regions like Africa and South America should ensure that the plastics used comply with local regulations regarding environmental impact and safety standards. In Europe, adherence to REACH regulations is crucial.

Key Properties: Aluminum is lightweight yet strong, with excellent corrosion resistance and a temperature rating that can exceed 150°C. It is often used for structural components and housings.

Pros & Cons: The main advantage of aluminum is its strength-to-weight ratio, which enhances the durability of the inflator while keeping it portable. However, aluminum can be more expensive than plastics, and its manufacturing processes can be complex, requiring specialized equipment.

Impact on Application: Aluminum is well-suited for components that require both strength and lightweight characteristics, making it ideal for high-pressure applications in tire inflation.

Illustrative image related to cordless tire inflator with battery and charger

Considerations for International Buyers: Buyers should verify that aluminum components meet international standards like ASTM or DIN for quality assurance. Additionally, understanding the local recycling capabilities for aluminum can be beneficial for sustainability practices.

Key Properties: Steel, particularly stainless steel, is known for its high tensile strength and excellent corrosion resistance, with temperature ratings often exceeding 200°C.

Pros & Cons: Steel offers superior durability and longevity, making it ideal for high-stress components. However, its weight can be a disadvantage in portable applications, and it is generally more expensive than both plastics and aluminum.

Impact on Application: Steel is typically used for high-pressure hoses and fittings, where strength and reliability are paramount. Its robustness makes it suitable for heavy-duty inflators designed for trucks and SUVs.

Considerations for International Buyers: Compliance with international standards for steel quality is essential. Buyers should also consider the implications of steel tariffs in certain regions, which can affect overall costs.

Illustrative image related to cordless tire inflator with battery and charger

Key Properties: Rubber is flexible and has excellent sealing properties, making it ideal for gaskets and seals. It can withstand a wide temperature range, typically from -40°C to 120°C.

Pros & Cons: The flexibility of rubber allows for effective sealing, which is crucial for maintaining pressure in inflators. However, rubber can degrade over time due to exposure to ozone or UV light, which can limit its lifespan.

Impact on Application: Rubber components are essential for ensuring airtight seals in the inflator, preventing air loss during use. This is critical for maintaining performance and efficiency.

Considerations for International Buyers: Buyers should ensure that rubber materials meet relevant international standards for durability and safety. Additionally, understanding the local climate and its effects on rubber longevity is important for product reliability.

| Material | Typical Use Case for cordless tire inflator with battery and charger | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Plastic | Housing and non-structural components | Lightweight and cost-effective | Limited durability under stress | Low |

| Aluminum | Structural components and housings | High strength-to-weight ratio | More expensive and complex to manufacture | Medium |

| Steel | High-pressure hoses and fittings | Superior durability and longevity | Heavier and generally more costly | High |

| Rubber | Seals and gaskets | Excellent sealing properties | Degrades over time with exposure | Medium |

This analysis provides a comprehensive overview of the materials commonly used in cordless tire inflators, highlighting their properties and considerations for international B2B buyers. By understanding these factors, buyers can make informed decisions that align with their operational needs and regional standards.

Illustrative image related to cordless tire inflator with battery and charger

The manufacturing of cordless tire inflators with a battery and charger involves several critical stages, each designed to ensure the final product meets quality and performance standards. The main stages include material preparation, forming, assembly, and finishing.

Material preparation is the first step in the manufacturing process. This phase involves sourcing high-quality raw materials such as durable plastics for the casing, metal components for the motor, and lithium-ion batteries. Suppliers should be vetted to ensure they comply with international standards such as ISO 9001, which emphasizes quality management systems.

In addition to standard materials, manufacturers often opt for components that meet specific industry certifications. For example, the battery must comply with safety standards such as UN 38.3 for lithium batteries, particularly important for international shipping.

Once materials are prepared, the forming stage begins. This typically includes molding plastic parts using injection molding techniques and stamping metal components. The manufacturing process often involves advanced technologies such as CNC machining for precision parts, ensuring that each component fits perfectly and functions as intended.

Additionally, forming processes may require the use of die-casting for the aluminum or magnesium parts that provide structural integrity. Utilizing automated machinery enhances efficiency and reduces human error, which is crucial for maintaining high production standards.

Illustrative image related to cordless tire inflator with battery and charger

The assembly stage combines all the components into a finished product. This involves several sub-steps, such as:

Manufacturers often employ assembly line techniques to optimize efficiency. Use of robotics and automation can further streamline this process, enhancing speed while maintaining consistency in quality.

Finishing processes are essential for both aesthetic and functional aspects of the product. This includes painting, labeling, and applying protective coatings to enhance durability.

Quality control checkpoints often occur during this stage to ensure that the product not only meets design specifications but is also visually appealing and ready for the consumer market. For instance, any surface imperfections or misalignments must be addressed before the product can move to final packaging.

Illustrative image related to cordless tire inflator with battery and charger

Quality assurance (QA) is a critical component of the manufacturing process, ensuring that the cordless tire inflators meet both regulatory standards and customer expectations.

For manufacturers targeting international markets, compliance with standards such as ISO 9001 is crucial. This standard focuses on quality management systems, emphasizing continuous improvement and customer satisfaction. Additionally, specific certifications like CE (Conformité Européenne) for products sold in Europe and API (American Petroleum Institute) standards for oil-related products are often necessary.

These standards ensure that products are not only safe but also environmentally friendly, which is increasingly important to B2B buyers globally.

Quality control is typically implemented at various checkpoints during the manufacturing process:

These checkpoints help to mitigate risks associated with defective products reaching the market, ultimately protecting the brand’s reputation.

B2B buyers can take several steps to ensure their suppliers adhere to high-quality standards:

Supplier Audits: Conducting regular audits of manufacturing facilities can provide insights into the quality control processes in place. Buyers should look for documentation of compliance with international standards.

Quality Assurance Reports: Requesting detailed QA reports from suppliers can help buyers understand the testing methodologies and outcomes, ensuring transparency in the manufacturing process.

Third-Party Inspections: Engaging third-party inspection agencies can provide an impartial assessment of the manufacturing processes and product quality. This is particularly important for international buyers who may not have direct access to the manufacturing facilities.

When dealing with suppliers from regions such as Africa, South America, the Middle East, and Europe, it’s essential for buyers to understand regional differences in quality standards and regulations.

For instance, the regulatory landscape may vary significantly across these regions, impacting product certifications and quality expectations. Buyers should familiarize themselves with local regulations and standards to ensure compliance and avoid potential legal issues.

Furthermore, cultural differences may affect communication and negotiation styles, so establishing clear expectations and maintaining open lines of communication can help mitigate misunderstandings.

In conclusion, the manufacturing and quality assurance processes for cordless tire inflators with battery and charger are multifaceted and require careful attention to detail. By understanding these processes, B2B buyers can make informed decisions and select suppliers that meet their quality standards, ultimately ensuring the reliability and performance of their products in the marketplace.

When sourcing cordless tire inflators equipped with batteries and chargers, it’s essential to follow a structured approach. This guide provides a step-by-step checklist tailored for B2B buyers, ensuring you make informed decisions that align with your operational needs and market demands.

Illustrative image related to cordless tire inflator with battery and charger

Establishing clear technical specifications is foundational to your sourcing process. Consider factors such as maximum pressure capacity (measured in psi), battery life, and charging time. These specifications will help you narrow down options that meet the performance requirements of your target market.

Understanding market trends in regions such as Africa, South America, the Middle East, and Europe is crucial. Analyze consumer preferences, such as the desire for compact designs or multifunctional features like built-in lights or USB ports.

Thoroughly vet potential suppliers to ensure reliability and quality. Request detailed company profiles, product catalogs, and references from previous clients, especially those within your industry.

Before finalizing your order, request product samples for testing. This step is critical for assessing the inflator’s functionality, durability, and ease of use in real-world scenarios.

Illustrative image related to cordless tire inflator with battery and charger

Once you have identified suitable suppliers, engage in negotiations to secure favorable pricing and terms. Consider the total cost of ownership, which includes shipping, tariffs, and warranty conditions.

Assess the after-sales support offered by your suppliers. Reliable customer service and warranty options can significantly impact your long-term satisfaction with the product.

Plan the logistics of importing the inflators into your target markets. Consider the most efficient shipping methods and distribution channels to ensure timely delivery.

By following this checklist, you can streamline the procurement process for cordless tire inflators, ensuring you select products that meet your business needs while maximizing efficiency and profitability.

Illustrative image related to cordless tire inflator with battery and charger

When sourcing cordless tire inflators equipped with batteries and chargers, understanding the cost structure is essential for B2B buyers. The primary cost components include:

Materials: The choice of materials significantly impacts the overall cost. High-quality plastics and metals for the casing, durable lithium-ion batteries, and reliable inflation mechanisms can raise costs but enhance product longevity and performance.

Labor: Labor costs can vary based on the manufacturing location. Regions with higher labor costs, such as parts of Europe, may lead to increased pricing compared to lower-cost regions like Southeast Asia.

Manufacturing Overhead: This includes costs related to factory maintenance, utilities, and other operational expenses. Efficient manufacturing processes can reduce these overheads, leading to lower prices for buyers.

Tooling: Initial tooling costs for molds and specialized machinery can be substantial, especially for custom designs. These costs are often amortized over larger production runs, so higher volume orders can benefit from reduced per-unit costs.

Quality Control (QC): Implementing rigorous QC measures is crucial for ensuring product reliability. While this adds to the cost, it can prevent costly returns and warranty claims, thus benefiting buyers in the long run.

Logistics: Shipping and handling costs can vary based on the location of the supplier and the destination. International shipping, customs fees, and the choice of Incoterms can significantly affect the total landed cost.

Margin: Suppliers typically add a margin to cover their costs and ensure profitability. Understanding standard margins in the industry can help buyers negotiate better deals.

Several factors influence pricing, particularly for international buyers:

Volume and Minimum Order Quantity (MOQ): Larger orders can often secure better pricing due to economies of scale. Buyers should negotiate MOQs that align with their needs to avoid excess inventory.

Specifications and Customization: Custom features or specifications can increase costs. Buyers should assess whether these customizations provide sufficient value to justify the additional expense.

Material Quality and Certifications: Products that meet specific certifications (like CE or ISO) may command higher prices. However, these certifications can enhance marketability and trust in the product.

Supplier Factors: The reputation and reliability of suppliers play a crucial role in pricing. Established suppliers with a history of quality may charge more, but the risk of failure or subpar products is typically lower.

Incoterms: Understanding Incoterms is vital for cost management. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can shift responsibilities and costs between the buyer and supplier, affecting total costs.

Negotiate Wisely: Leverage volume purchases or long-term contracts to negotiate better prices. Establishing a relationship with suppliers can lead to more favorable terms.

Focus on Cost-Efficiency: Consider the Total Cost of Ownership (TCO), which includes purchase price, maintenance, and operational costs. A higher initial price might be justified by lower long-term costs due to better quality or efficiency.

Understand Pricing Nuances for International Buyers: Buyers from regions like Africa or South America should be aware of currency fluctuations, tariffs, and import regulations that could impact overall costs.

Request Samples: Before committing to a large order, request samples to assess quality. This can help avoid costly mistakes and ensure that the product meets expectations.

Evaluate Multiple Suppliers: Conducting thorough market research to compare prices and offerings from different suppliers can provide leverage during negotiations.

Prices for cordless tire inflators can fluctuate based on market conditions, material costs, and supplier pricing strategies. It is advisable for buyers to conduct their own due diligence and obtain up-to-date quotes to ensure competitive sourcing decisions.

In the landscape of tire inflation, the cordless tire inflator with battery and charger stands out for its convenience and portability. However, businesses may consider alternative solutions based on their unique needs, cost constraints, and operational environments. This section explores two viable alternatives: traditional AC-powered tire inflators and manual hand pumps, comparing their performance, cost, ease of implementation, maintenance, and best use cases.

Illustrative image related to cordless tire inflator with battery and charger

| Comparison Aspect | Cordless Tire Inflator With Battery And Charger | AC-Powered Tire Inflator | Manual Hand Pump |

|---|---|---|---|

| Performance | High PSI capability, fast inflation times | High PSI, continuous use | Low PSI, labor-intensive |

| Cost | Moderate ($40-$100) | Low to moderate ($30-$80) | Very low ($10-$30) |

| Ease of Implementation | Easy, plug-and-play with included charger | Requires access to power | Requires manual effort |

| Maintenance | Low, battery checks needed | Low, regular cleaning needed | Low, simple mechanical upkeep |

| Best Use Case | Roadside assistance, personal vehicles | Workshops, service centers | Emergency kits, bicycles |

AC-powered tire inflators are often chosen for their robust performance and ability to maintain high pressure for extended periods. They can inflate tires quickly and are suitable for businesses that operate from a fixed location, such as auto repair shops or service centers. The primary advantages include consistent power supply and the capability to inflate multiple tires in a single session without battery constraints. However, they require access to an electrical outlet, which limits their portability and usability in roadside or remote situations.

Manual hand pumps present an economical alternative, especially for businesses looking to minimize costs. These pumps are lightweight, portable, and require no power source, making them ideal for emergency kits or use on bicycles. While they are highly cost-effective, the trade-off is significant labor intensity and slower inflation times. Manual pumps are best for low-pressure applications or infrequent use, but they may not be practical for larger vehicles or heavy-duty applications where efficiency is a priority.

When evaluating tire inflation solutions, B2B buyers should consider their specific operational needs, budget, and the environments in which they operate. The cordless tire inflator with battery and charger offers a balance of performance and portability, making it suitable for various applications, especially in dynamic environments. In contrast, AC-powered inflators are ideal for fixed locations where high-volume usage is expected, while manual pumps serve well in low-cost scenarios or for infrequent use. By aligning the choice with operational demands and budget constraints, buyers can ensure they select the most effective tire inflation solution for their needs.

Understanding the essential technical specifications of cordless tire inflators is crucial for B2B buyers aiming to make informed purchasing decisions. Here are some key properties to consider:

Illustrative image related to cordless tire inflator with battery and charger

Maximum Pressure (PSI)

– The maximum pressure, measured in pounds per square inch (PSI), indicates the highest inflation pressure the inflator can achieve. A typical range for tire inflators is between 80 to 160 PSI.

– B2B Importance: Selecting an inflator with appropriate PSI is vital for compatibility with various vehicle types, especially for trucks and SUVs that require higher pressures.

Battery Capacity (Ah)

– Measured in ampere-hours (Ah), battery capacity determines how long the inflator can operate before needing a recharge. A higher Ah rating indicates a longer usage time.

– B2B Importance: For businesses that require frequent tire maintenance, choosing an inflator with a robust battery capacity can enhance operational efficiency and reduce downtime.

Power Source Options

– Cordless tire inflators typically feature multiple power sources, including rechargeable batteries and 12-volt adapters for vehicle charging. This versatility allows for use in various scenarios.

– B2B Importance: Having multiple power options ensures that the inflator can be used in remote locations without access to standard power sources, catering to diverse operational environments.

Duty Cycle

– The duty cycle refers to the recommended operational time versus the resting time. For example, a 20-minute duty cycle means the inflator can run for 20 minutes before needing a cooldown period.

– B2B Importance: Understanding the duty cycle is essential for businesses that require continuous operation, as it helps prevent overheating and prolongs the tool’s lifespan.

Weight and Portability

– The weight of the inflator affects its portability. Lightweight models (typically under 5 lbs) are easier to transport and store.

– B2B Importance: For companies that require mobile solutions, especially in the automotive service sector, choosing a lightweight inflator can enhance usability and convenience.

Pressure Gauge Accuracy

– The accuracy of the built-in pressure gauge is critical for ensuring that tires are inflated to the correct pressure. Digital gauges tend to offer higher precision compared to analog versions.

– B2B Importance: Accurate gauges minimize the risk of under- or over-inflation, which can lead to increased tire wear and safety hazards.

Familiarity with industry terminology is essential for effective communication and negotiations in B2B environments. Here are some key terms to know:

OEM (Original Equipment Manufacturer)

– An OEM is a company that produces parts and equipment that may be marketed by another manufacturer. In the context of tire inflators, it refers to manufacturers who produce the inflators for various brands.

– Relevance: Knowing the OEM helps buyers assess product quality and compatibility with existing equipment.

MOQ (Minimum Order Quantity)

– MOQ is the smallest quantity of a product that a supplier is willing to sell. For inflators, MOQs can vary significantly based on the supplier and product specifications.

– Relevance: Understanding MOQ helps businesses manage inventory and budget constraints effectively.

RFQ (Request for Quotation)

– An RFQ is a document sent to suppliers requesting pricing and availability for specific products or services. It is essential in the procurement process.

– Relevance: Using RFQs can streamline purchasing and ensure competitive pricing from multiple suppliers.

Incoterms (International Commercial Terms)

– Incoterms are a series of pre-defined commercial terms published by the International Chamber of Commerce (ICC) that clarify the responsibilities of buyers and sellers in international trade.

– Relevance: Understanding Incoterms is crucial for B2B buyers to navigate shipping, insurance, and delivery responsibilities effectively.

Warranty and Service Agreements

– These are guarantees provided by manufacturers regarding the performance and longevity of their products. They may also include terms for repairs or replacements.

– Relevance: Knowing warranty terms helps buyers assess the long-term value and reliability of their investment in inflators.

Lead Time

– Lead time refers to the time taken from placing an order to receiving the product. This can vary based on supplier capabilities and logistics.

– Relevance: Understanding lead times is vital for businesses to plan inventory and manage customer expectations effectively.

By grasping these technical properties and trade terms, B2B buyers can make more informed decisions regarding cordless tire inflators, ensuring they choose products that meet their operational needs and market demands.

The global market for cordless tire inflators is experiencing notable growth driven by several factors, including the increasing demand for convenience and portability in automotive maintenance tools. As consumers and businesses alike prioritize ease of use, the cordless design, which eliminates the need for external power sources, is becoming increasingly popular. In regions such as Africa, South America, the Middle East, and Europe, the rise in vehicle ownership, coupled with a growing emphasis on road safety, has spurred demand for reliable tire maintenance solutions. Additionally, the trend towards battery-powered tools is bolstered by advancements in battery technology, leading to more efficient and powerful inflators capable of handling a variety of tire pressures.

Emerging trends in the B2B sector include the integration of smart technology into tire inflators. Features like digital pressure gauges, automatic shut-off functions, and even app connectivity for monitoring tire health are becoming standard. Furthermore, the shift towards e-commerce platforms for sourcing these products is gaining traction, allowing international buyers to access a broader range of options and competitive pricing. As a result, B2B buyers must stay informed about the latest technological advancements and market offerings to ensure they make strategic purchasing decisions.

Illustrative image related to cordless tire inflator with battery and charger

Sustainability is increasingly becoming a pivotal factor in the sourcing of cordless tire inflators. As global awareness of environmental issues rises, B2B buyers are seeking products that not only meet performance standards but also align with eco-friendly practices. This includes sourcing inflators made from recyclable materials and employing manufacturing processes that minimize carbon footprints. Additionally, products with certifications such as Energy Star or those that utilize renewable energy sources for battery charging are gaining favor among environmentally conscious buyers.

Ethical sourcing practices are also crucial, particularly as consumers demand transparency from brands. Companies that demonstrate a commitment to ethical supply chains—such as ensuring fair labor practices and responsible material sourcing—are more likely to gain trust and loyalty from B2B clients. This trend is particularly relevant in regions where regulatory frameworks regarding environmental and labor standards are evolving, thus prompting international buyers to prioritize suppliers who can guarantee compliance with these standards.

The evolution of cordless tire inflators can be traced back to the development of portable air compressors in the late 20th century. Initially, these devices were bulky and primarily powered by AC outlets. However, with advancements in battery technology and a growing demand for portable solutions, the market saw the introduction of battery-operated inflators in the early 2000s. This shift allowed users to inflate tires without the constraints of cords, enhancing convenience and usability.

By the 2010s, manufacturers began incorporating smart technology into these tools, improving their functionality and appeal. The emergence of high-capacity lithium-ion batteries further revolutionized the market, enabling longer usage times and faster inflation rates. Today, the cordless tire inflator market is characterized by a diverse range of products catering to various consumer needs, from compact models designed for personal use to heavy-duty options suited for commercial applications. As the market continues to evolve, the focus on innovation, sustainability, and user-friendly features remains paramount for B2B buyers looking to make informed purchasing decisions.

Illustrative image related to cordless tire inflator with battery and charger

How do I choose the right cordless tire inflator for my business needs?

When selecting a cordless tire inflator, consider the intended use and frequency of operation. Look for features such as maximum PSI, battery life, and additional functionalities like built-in pressure gauges and adapters for various inflatables. Assess the inflator’s portability and weight, especially if it will be used in remote locations. Additionally, review customer feedback and performance tests to ensure the product meets your standards for reliability and efficiency.

What are the benefits of using a cordless tire inflator with a battery and charger?

Cordless tire inflators offer unmatched convenience, allowing users to inflate tires without being tethered to a power source. This mobility is particularly advantageous in areas with limited electrical access, making them suitable for various applications, from automotive to recreational use. Furthermore, the inclusion of a rechargeable battery reduces long-term operational costs and enhances ease of use, as they can quickly recharge between uses, ensuring readiness when needed.

What should I consider when vetting suppliers for cordless tire inflators?

When evaluating suppliers, prioritize those with a proven track record in manufacturing high-quality inflators. Request samples to assess the product’s performance and durability. Investigate the supplier’s compliance with international standards and certifications, especially if exporting to regions with strict regulations. Additionally, consider their production capacity, lead times, and customer service responsiveness to ensure they can meet your business demands consistently.

What is the typical minimum order quantity (MOQ) for cordless tire inflators?

MOQs can vary significantly among suppliers, often ranging from 100 to 500 units for bulk orders. Factors influencing MOQ include the supplier’s production capabilities, the complexity of the product, and your negotiation leverage. It’s advisable to communicate your needs clearly and discuss potential flexibility on MOQs, especially if you are willing to establish a long-term partnership that may lead to better pricing and terms.

What payment terms are common for international purchases of cordless tire inflators?

Typical payment terms for international purchases include a deposit (often 30-50%) upon order confirmation, with the balance due before shipment or upon delivery. Some suppliers may offer letters of credit or escrow services for added security. It’s essential to establish clear payment terms in your contract to avoid misunderstandings, and consider discussing options for extended payment terms if you’re placing a large order.

How can I ensure quality assurance for cordless tire inflators?

To ensure quality, request detailed specifications and testing reports from suppliers. Implement a quality assurance process that includes pre-shipment inspections to verify that inflators meet your standards. Additionally, consider establishing a third-party inspection service to assess product quality before shipment, especially for large orders. Building a strong relationship with your supplier can also facilitate better communication regarding quality expectations.

What logistics considerations should I keep in mind when importing cordless tire inflators?

When importing, consider shipping methods (air vs. sea), as they affect cost and delivery time. Understand the customs regulations in your country and ensure all necessary documentation is in order to avoid delays. Partnering with a reliable freight forwarder can simplify the logistics process, helping to navigate import duties and tariffs. Additionally, factor in storage and distribution needs upon arrival to ensure a smooth transition to market.

Are there customization options available for cordless tire inflators?

Many suppliers offer customization options, such as branding with your company logo, specific color choices, or tailored packaging. Discuss your requirements early in the negotiation process to understand what is feasible and any associated costs. Customization can enhance brand visibility and meet unique market demands, making your product more appealing to customers in diverse regions. Always request samples of customized products to ensure they align with your expectations.

Domain: automoblog.com

Registered: 2004 (21 years)

Introduction: Best Portable Tire Inflators for 2025: 1. Slime Cordless Tire Inflator – Easy to use and stow. 2. 20V Avid Power Cordless Tire Inflator – Drill-style design and carrying case. 3. Fanttik X8 Apex – Overall good quality and functionality, features a flashlight and USB outlet. 4. DeWalt 20V MAX Tire Inflator – Robust and powerful with four memory settings. 5. Milwaukee M18 Cordless Tire Inflator – Du…

Domain: sharperimage.com

Registered: 1995 (30 years)

Introduction: Cordless Auto Stop Tire Inflator by Sharper Image

Domain: bestbuy.com

Registered: 1994 (31 years)

Introduction: Cordless Tire Inflators are portable devices designed for convenience and efficiency in maintaining tire pressure. They are ideal for cars, bikes, and inflatables, allowing users to inflate tires without cords or power outlets. Key products include: 1. HiBoy – 2 in 1 Tire Inflator: Portable air compressor with vacuum function, 150PSI, 5000mAh battery, rated 4.6/5 stars. 2. Fanttik – X8 APEX: Porta…

In the rapidly evolving market for cordless tire inflators with battery and charger, strategic sourcing remains paramount for B2B buyers seeking to optimize their procurement processes. Key takeaways emphasize the importance of evaluating product performance, battery efficiency, and additional features such as built-in pressure gauges and portability. By prioritizing these factors, businesses can ensure they select inflators that not only meet operational demands but also enhance customer satisfaction through reliable performance.

Investing in high-quality cordless tire inflators can lead to improved efficiency and reduced downtime, particularly for businesses in sectors like automotive services and logistics. With the global demand for portable and reliable tire inflation solutions increasing, especially in regions like Africa, South America, the Middle East, and Europe, now is the opportune time to reassess sourcing strategies.

As the market continues to innovate, international buyers are encouraged to stay informed about emerging trends and technologies that can further enhance their product offerings. By leveraging strategic partnerships and focusing on quality, businesses can position themselves for success in this competitive landscape. Embrace the future of tire inflation solutions and explore new sourcing opportunities today.

Illustrative image related to cordless tire inflator with battery and charger

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.