In the dynamic landscape of international cycling markets, understanding how to inflate bike tires efficiently is crucial for B2B buyers aiming to enhance customer satisfaction and safety. Proper tire inflation not only ensures optimal performance but also extends the lifespan of bicycles, making it a significant concern for suppliers in regions like Africa, South America, the Middle East, and Europe, including Saudi Arabia and Nigeria. This guide offers a comprehensive exploration of tire inflation, covering various types of valves, suitable pump options, and recommended inflation pressures tailored to different bike types and riding conditions.

B2B buyers will gain insights into the nuances of tire inflation, including how to identify valve types, the importance of selecting the right pump, and the implications of improper inflation on ride quality and safety. Additionally, this guide addresses key factors in supplier vetting, cost considerations, and maintenance practices. By equipping decision-makers with actionable information, this resource empowers them to make informed purchasing decisions that can elevate their product offerings and meet the diverse needs of their clientele. Embrace the opportunity to enhance your business’s reputation by mastering the essentials of bike tire inflation and ensuring that your customers enjoy a safe and enjoyable riding experience.

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Track Pump | Large, stable base; pressure gauge; high volume | Bike shops, rental companies | Pros: Fast inflation; easy to use. Cons: Bulky for transport. |

| Mini Pump | Compact design; lightweight; often hose-attached | Retailers, mobile repair services | Pros: Portable; ideal for on-the-go repairs. Cons: Slower inflation rate. |

| CO2 Inflator | Uses compressed CO2 cartridges; rapid inflation | Emergency repair kits, cycling events | Pros: Quick inflation; small size. Cons: Limited to single-use cartridges. |

| Electric Pump | Automated inflation; adjustable pressure settings | Large-scale bike manufacturers | Pros: Effortless use; consistent pressure. Cons: Requires power source; heavier. |

| Tubeless Pump | Designed for tubeless setups; specific valve types | High-end bike retailers | Pros: Seamless inflation for tubeless tires. Cons: Requires specialized knowledge for setup. |

Track pumps are essential tools for any bike shop or rental company due to their efficiency in inflating tires quickly and accurately. With a large base for stability and a pressure gauge for precision, these pumps allow for high-volume air transfer, making them ideal for workshop environments. B2B buyers should consider the durability and compatibility of the pump with various valve types, as well as its ease of use to enhance customer service.

Mini pumps are designed for portability, making them an excellent choice for retailers and mobile repair services. Their lightweight construction allows cyclists to easily carry them during rides, ensuring they can address any flat tires on the go. When purchasing mini pumps, businesses should look for models with a hose attachment to minimize valve damage during inflation. This versatility can lead to increased customer satisfaction and repeat business.

CO2 inflators are a game-changer for emergency tire repairs, particularly in competitive cycling events where time is crucial. These devices use compressed carbon dioxide cartridges to provide rapid inflation, allowing riders to get back on the road swiftly. B2B buyers need to assess the availability of compatible cartridges and the cost-effectiveness of using CO2 inflators compared to traditional pumps. While they are incredibly convenient, businesses should ensure customers understand their limitations, such as the need for multiple cartridges for prolonged use.

Electric pumps automate the inflation process, making them suitable for large-scale bike manufacturers and service centers. These pumps often feature adjustable pressure settings, ensuring consistent inflation across various tire types. While they provide ease of use, B2B buyers must consider the necessity of a power source and the additional weight these pumps bring compared to manual options. Investing in electric pumps can streamline operations and enhance productivity in high-volume environments.

Tubeless pumps are specifically designed for tubeless tire systems, which are increasingly popular among high-end bike retailers. These pumps facilitate seamless inflation directly to the tire rim, eliminating the need for inner tubes. When purchasing tubeless pumps, businesses should evaluate the pump’s compatibility with different tubeless valve types and the ease of use for both staff and customers. Proper knowledge and training on tubeless systems can significantly enhance the customer experience and reduce service time in retail settings.

| Industry/Sector | Specific Application of how to inflate bike tires | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Bicycle Manufacturing | Quality Control in Production | Ensures consistent performance and safety standards | Reliable inflation tools and equipment for production lines |

| Retail & Distribution | Customer Service in Bike Shops | Enhances customer experience and satisfaction | Diverse pump types and compatibility with various valves |

| Logistics & Delivery | Fleet Maintenance for Delivery Bikes | Reduces downtime and enhances operational efficiency | Durable pumps suitable for frequent use and easy transport |

| Tourism & Recreation | Equipment Rental Services | Increases customer satisfaction and repeat business | Portable inflation solutions for diverse bike types |

| Sports Organizations | Event Preparation for Cycling Competitions | Ensures optimal performance and safety for athletes | High-quality pumps with precise pressure gauges |

In bicycle manufacturing, the process of inflating bike tires is critical during quality control stages. Ensuring that each tire is inflated to the correct pressure is vital for maintaining safety and performance standards. Manufacturers often require specialized pumps that can handle various valve types and provide accurate pressure readings. For international buyers, sourcing reliable inflation equipment that meets production demands while adhering to regional standards is essential to avoid production delays.

Illustrative image related to how to inflate bike tires

In retail and distribution, bike shops must provide tire inflation services to enhance customer satisfaction. Offering a quick and efficient tire inflation service can significantly improve the customer experience, encouraging repeat visits. Shops need to stock a range of pumps that cater to different valve types, ensuring compatibility with various bike models. International buyers should consider the diversity of bike types in their region when sourcing pumps to meet customer needs effectively.

For logistics companies using delivery bikes, maintaining proper tire pressure is crucial for operational efficiency. Regular tire inflation prevents breakdowns and minimizes downtime, ensuring timely deliveries. Businesses require durable, portable pumps that can withstand frequent use and provide reliable performance. When sourcing these tools, international buyers should focus on the availability of service and support in their region to ensure long-term usability.

In the tourism and recreation sector, businesses that rent bikes must ensure their equipment is in optimal condition. Properly inflated tires enhance the riding experience, leading to higher customer satisfaction and loyalty. Rental services need portable and easy-to-use inflation solutions that cater to various bike types. Buyers in this sector should prioritize sourcing pumps that are lightweight and efficient, suitable for both in-shop use and outdoor settings.

Sports organizations hosting cycling events rely on precise tire inflation for athlete performance and safety. Ensuring that all participating bikes are inflated to the correct pressure can prevent mishaps during competitions. Organizations often need high-quality pumps equipped with accurate pressure gauges to meet specific requirements. Buyers in this sector should consider sourcing pumps that can handle high volumes and provide quick inflation, ensuring readiness for events.

The Problem: One of the most common challenges faced by B2B buyers is the incompatibility between the bike pump and the various valve types, such as Presta and Schrader. Buyers often find themselves with a pump that doesn’t fit the valve type on their bicycles, leading to frustration and wasted time. In regions where different bike models are prevalent, such as Africa and South America, this issue can be exacerbated by varying local standards and practices. Additionally, the lack of knowledge regarding the valve types can lead to purchasing incorrect pumps, resulting in further costs and delays in operations.

The Solution: To effectively address this challenge, B2B buyers should prioritize sourcing pumps that are versatile and can accommodate both Presta and Schrader valves. When selecting pumps, it is crucial to ensure they come with an adaptable head or include an easy-to-use conversion kit. Buyers should also invest in training their staff on identifying valve types and selecting the correct equipment. Furthermore, maintaining an inventory of valve adaptors can serve as a practical solution for businesses operating in diverse markets. This proactive approach not only streamlines the inflation process but also enhances operational efficiency.

The Problem: Many B2B buyers struggle with maintaining the correct tire pressure, which is vital for optimal bike performance. Running tires either over-inflated or under-inflated can lead to poor ride quality, increased risk of punctures, and ultimately, dissatisfied customers. In regions with varying climates, such as the Middle East and Europe, temperature fluctuations can also impact tire pressure, further complicating management efforts. This inconsistency can result in a negative perception of the bikes being sold or serviced.

The Solution: To combat incorrect tire pressure management, B2B buyers should implement a systematic approach to regularly check and maintain tire pressures. This can include investing in high-quality digital tire pressure gauges that provide accurate readings. Additionally, establishing a routine for checking tire pressures before bike rentals or sales can ensure that all bikes are in optimal condition. Buyers can also educate their customers about the importance of proper tire maintenance and offer guidance on how to check tire pressure effectively. Creating an instructional guide or video can further enhance customer engagement and satisfaction.

The Problem: In many emerging markets, access to reliable pumping equipment can be a significant barrier for businesses dealing with bike maintenance and sales. Limited infrastructure, combined with economic constraints, can hinder the ability to obtain quality pumps, leading to inefficiencies in service delivery. This issue is particularly relevant in regions like Nigeria and parts of South America, where local markets may not stock the necessary equipment, forcing businesses to rely on subpar tools that compromise service quality.

The Solution: To overcome this challenge, B2B buyers should establish partnerships with reliable suppliers that specialize in high-quality bike maintenance equipment. By creating bulk purchasing agreements, businesses can ensure consistent access to the necessary pumping equipment at competitive prices. Additionally, exploring local manufacturing options for pumps may provide a sustainable solution that reduces dependency on international supply chains. Encouraging local workshops or training sessions on bike maintenance can also foster community engagement while enhancing the skill set of local technicians. By addressing these logistical challenges, businesses can improve their service offerings and ultimately drive customer satisfaction.

When selecting materials for inflating bike tires, it is essential to consider the properties and performance characteristics that directly affect usability, durability, and cost. This analysis focuses on four common materials: rubber, aluminum, plastic, and steel. Each material has unique properties that influence its suitability for different applications in the bike tire inflation process.

Rubber is the most commonly used material in the construction of inner tubes and tire seals. Its primary properties include excellent elasticity, temperature resistance, and the ability to maintain air pressure. Rubber can withstand a wide range of temperatures, making it suitable for various climates, from the heat of the Middle East to the cooler regions of Europe.

Pros: Rubber is highly durable and resistant to punctures, providing a long service life. It is also relatively low-cost, making it an economical choice for manufacturers.

Cons: The main limitation of rubber is its susceptibility to degradation from UV exposure and ozone, which can lead to cracks over time. This necessitates regular inspections and replacements.

Impact on Application: Rubber’s compatibility with air and its ability to form airtight seals make it ideal for use in inner tubes.

Considerations for International Buyers: Buyers in regions like Africa and South America should ensure that the rubber used meets local compliance standards, such as ASTM or ISO, to guarantee quality and performance.

Illustrative image related to how to inflate bike tires

Aluminum is frequently used in the construction of bike pumps due to its lightweight and corrosion-resistant properties. It can withstand high pressures, making it suitable for both track and mini-pumps.

Pros: Aluminum is durable and lightweight, which enhances the portability of mini-pumps. It also has a good strength-to-weight ratio and is resistant to rust, making it ideal for outdoor use.

Cons: The primary disadvantage is cost; aluminum is more expensive than plastic and may not be as cost-effective for budget-conscious manufacturers.

Impact on Application: Aluminum pumps can handle higher pressures, making them suitable for both road and mountain biking applications.

Considerations for International Buyers: Buyers should look for aluminum products that comply with relevant standards, such as DIN or JIS, to ensure quality assurance in their markets.

Plastic is often used in pump heads and adapters due to its lightweight and versatile nature. Various types of plastics can be engineered to provide adequate strength and flexibility.

Pros: Plastic components are generally low-cost and can be molded into complex shapes, which is advantageous for pump designs. They are also resistant to corrosion and lightweight.

Cons: Plastic may not be as durable as metal options and can become brittle over time, especially under UV exposure. This can lead to cracking and failure.

Impact on Application: Plastic is suitable for non-pressurized components, such as pump heads, but is not recommended for high-pressure applications.

Considerations for International Buyers: Buyers should verify that the plastics used are compliant with safety and environmental regulations in their respective countries.

Steel is commonly used in the construction of pump cylinders and other high-stress components due to its strength and durability. It can withstand significant pressure without deforming.

Illustrative image related to how to inflate bike tires

Pros: Steel is incredibly durable and can handle high pressures, making it ideal for track pumps. It is also resistant to wear and tear.

Cons: The main drawback of steel is its weight, which can make pumps less portable. Additionally, steel is prone to rust if not properly coated.

Impact on Application: Steel is well-suited for high-pressure applications, but its weight may limit its use in portable mini-pumps.

Considerations for International Buyers: Buyers should ensure that steel components are treated for corrosion resistance and meet international standards for safety and performance.

| Material | Typical Use Case for how to inflate bike tires | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Rubber | Inner tubes and tire seals | Excellent elasticity and durability | Susceptible to UV degradation | Low |

| Aluminum | Pump construction (track and mini-pumps) | Lightweight and corrosion-resistant | Higher cost than plastic | Med |

| Plastic | Pump heads and adapters | Low-cost and versatile | Less durable than metals | Low |

| Steel | Pump cylinders and high-stress components | High strength and durability | Heavier and prone to rust | Med |

This comprehensive analysis of materials provides B2B buyers with actionable insights to make informed decisions regarding the selection of components for bike tire inflation. Understanding the properties, advantages, and limitations of each material will facilitate better procurement strategies tailored to specific regional needs.

The manufacturing process for devices used in inflating bike tires involves several critical stages: material preparation, forming, assembly, and finishing. Each stage contributes to the overall functionality and quality of the product.

Material Preparation

The first step involves selecting high-quality materials such as durable plastics for pump bodies, rubber for seals, and metals for components like valves and levers. Suppliers often conduct preliminary quality checks on these materials to ensure they meet specific standards. For instance, rubber must be flexible yet strong enough to withstand repeated use without degrading.

Forming

In this phase, materials are shaped into the desired components. This might involve injection molding for plastic parts, machining for metal components, or extrusion for hoses. Advanced manufacturing techniques such as CNC machining ensure precision in the creation of parts, particularly in pump heads and valve systems. The use of CAD software allows for the simulation of designs, which can help in identifying potential issues before production.

Assembly

After forming, the components are assembled into final products. This stage often includes the installation of pressure gauges, seals, and valve heads. Automated assembly lines may be employed to enhance efficiency and reduce human error. For high-quality pumps, attention to detail is crucial, as any misalignment can lead to air leaks or operational failures.

Finishing

Finally, the finishing stage involves quality checks, surface treatment, and packaging. Products may undergo painting or coating for aesthetic and protective purposes. This stage also includes final inspections to ensure that each unit meets the established specifications before being shipped to customers.

Quality assurance (QA) in the manufacturing of bike tire inflation devices is critical for ensuring reliability and safety. Adhering to international standards and implementing robust quality control measures can significantly enhance product quality.

International Standards

Compliance with international standards such as ISO 9001 is vital for manufacturers aiming to establish a global market presence. ISO 9001 focuses on quality management systems and helps companies consistently meet customer and regulatory requirements. Additionally, industry-specific certifications such as CE mark for European markets or API for specific technical standards can enhance a product’s credibility.

Quality Control Checkpoints

Quality control processes typically incorporate several checkpoints:

Incoming Quality Control (IQC): This involves inspecting raw materials and components before they enter the production process. Ensuring that only high-quality materials are used lays the foundation for the final product’s integrity.

In-Process Quality Control (IPQC): Continuous monitoring during the manufacturing process helps identify defects early. This may include checking dimensions, functionality, and assembly accuracy.

Final Quality Control (FQC): Before products are packaged, a thorough inspection is conducted to verify that they meet all specifications and standards. This often involves functional tests, pressure tests, and visual inspections.

For international B2B buyers, particularly from diverse regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is crucial for ensuring product reliability.

Supplier Audits

Conducting supplier audits is one of the most effective ways to assess a manufacturer’s quality assurance practices. These audits should evaluate compliance with international standards, the effectiveness of quality control measures, and the overall manufacturing environment. Audits can be conducted in-person or through third-party services to provide an unbiased perspective.

Quality Assurance Reports

Requesting detailed quality assurance reports from suppliers can provide insights into their QC processes. These reports should include information on testing methods, results, and any corrective actions taken in response to identified issues. Regular updates on quality metrics can indicate a supplier’s commitment to maintaining high standards.

Third-Party Inspections

Engaging third-party inspection services can add an extra layer of verification. These organizations can conduct independent assessments of the manufacturing facility and the quality control processes in place. This approach is particularly beneficial for buyers unfamiliar with local manufacturing practices, ensuring that products meet international quality standards before shipment.

Navigating quality control nuances is essential for international B2B buyers, especially when dealing with suppliers from different regions. Understanding local regulations, cultural differences, and logistical challenges can aid in establishing effective partnerships.

Cultural Considerations

Different regions may have varying attitudes towards quality and compliance. For instance, manufacturers in Europe may have more stringent quality controls compared to those in emerging markets. B2B buyers should be aware of these differences and set clear expectations regarding quality standards from the outset.

Logistical Challenges

Transporting products across borders can introduce risks related to quality degradation. It’s vital to discuss packaging and shipping methods with suppliers to minimize potential damage during transit. Additionally, incorporating inspection points at various stages of the supply chain can help maintain quality consistency.

Regulatory Compliance

Buyers must ensure that products comply with the regulatory requirements of their respective markets. For instance, products sold in Europe must adhere to CE marking standards, while those in the U.S. may need to meet specific safety regulations. Collaborating with suppliers who have experience in navigating these regulations can streamline the compliance process.

By understanding the manufacturing processes and quality assurance measures relevant to bike tire inflation devices, B2B buyers can make informed decisions that enhance their procurement strategies and ensure product reliability in their markets.

This guide provides a comprehensive checklist for B2B buyers interested in procuring the necessary equipment and expertise for inflating bike tires. Understanding the proper procedures and equipment ensures optimal performance, safety, and longevity of bicycles, which is crucial for businesses in the cycling industry, particularly in regions like Africa, South America, the Middle East, and Europe.

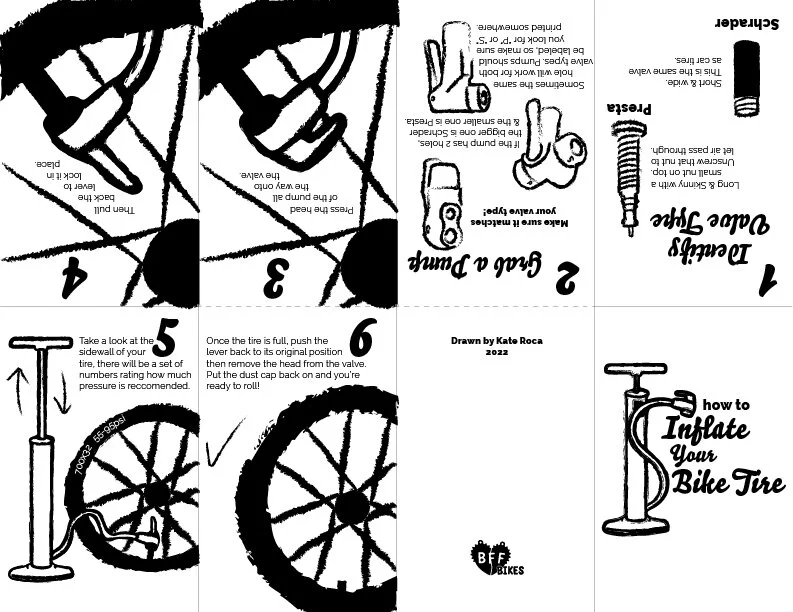

Before purchasing pumps or accessories, it’s essential to recognize the valve types commonly found in bicycles: Schrader, Presta, and Dunlop. Each valve type requires specific pump heads or adaptors, so confirming compatibility can prevent delays and additional costs.

Selecting the appropriate pump is critical for efficient tire inflation. B2B buyers should consider both a floor pump for workshop use and a portable mini-pump for on-the-go repairs.

Assess potential suppliers by reviewing their product range, technical expertise, and support services. This step is vital to ensure they can provide the necessary equipment and knowledge for effective tire inflation.

It’s imperative to ensure that the equipment you source meets industry standards and certifications. High-quality pumps and tools lead to better performance and customer satisfaction.

Understanding the pricing structure and payment terms can significantly impact procurement decisions. Transparent pricing helps in budgeting and financial planning.

Consider the after-sales support and training provided by suppliers, as this can enhance the effective use of the equipment. Proper training ensures that your team can efficiently inflate tires, reducing the risk of damage.

Stay informed about new technologies and trends in tire inflation methods and equipment. This knowledge can provide a competitive edge in the market.

By following this checklist, B2B buyers can effectively procure the necessary equipment and knowledge for inflating bike tires, ensuring enhanced performance and customer satisfaction in their operations.

When sourcing bike tire inflation solutions, understanding the cost structure is crucial for B2B buyers. The primary cost components include:

Materials: The type of materials used in pumps, valves, and accessories significantly influences costs. For example, high-quality rubber and durable plastics may lead to higher initial costs but can offer better longevity and reliability.

Labor: Labor costs vary by region and can significantly impact the overall pricing. Countries with lower labor costs may offer more competitive pricing but might compromise on quality or consistency.

Manufacturing Overhead: This includes costs related to facilities, utilities, and equipment. Suppliers with advanced manufacturing technologies may charge higher prices due to their increased efficiency and lower defect rates.

Tooling: Custom tooling for specific products or specifications can increase initial costs. If a buyer requires specialized designs, this can lead to additional tooling fees.

Quality Control (QC): Investments in quality assurance processes can lead to higher upfront costs but can reduce the risk of defects and returns, ultimately affecting the Total Cost of Ownership (TCO).

Logistics: Shipping costs can vary widely depending on the destination and shipping methods. International buyers must factor in customs duties and taxes, which can add to the overall price.

Margin: Suppliers will typically include a profit margin in their pricing, which can vary based on market demand, competition, and the perceived value of the product.

Several factors can influence pricing for bike tire inflation equipment:

Volume/MOQ (Minimum Order Quantity): Suppliers often provide discounts for bulk orders. Understanding the MOQ can help buyers negotiate better pricing and manage inventory more efficiently.

Specifications and Customization: Custom solutions tailored to specific needs may incur additional costs. Buyers should evaluate whether the benefits of customization justify the increased expenses.

Materials and Quality Certifications: Higher-quality materials and certifications (e.g., ISO, CE) can lead to increased costs but often translate to better performance and reliability, critical for B2B applications.

Supplier Factors: The reputation and reliability of the supplier can significantly impact pricing. Established suppliers may charge more due to their track record of quality and service.

Incoterms: Understanding Incoterms is essential for international transactions. They dictate responsibilities for shipping, insurance, and tariffs, which can affect the total landed cost.

B2B buyers can adopt several strategies to enhance cost-efficiency when sourcing bike tire inflation solutions:

Negotiation: Effective negotiation can lead to reduced prices and better terms. Buyers should be prepared to discuss quantities, pricing, and payment terms to reach a mutually beneficial agreement.

Total Cost of Ownership (TCO): Buyers should consider not just the purchase price but the TCO, which includes maintenance, durability, and operational costs. Investing in quality products may reduce long-term expenses.

Pricing Nuances for International B2B Buyers: Buyers in regions like Africa, South America, the Middle East, and Europe should be aware of regional pricing dynamics. Currency fluctuations, import tariffs, and local market conditions can affect costs.

Research and Benchmarking: Conducting thorough market research to understand prevailing prices and trends can empower buyers during negotiations and decision-making processes.

Prices and cost structures can vary significantly based on market conditions, supplier relationships, and geographical factors. This analysis serves as a guideline, and buyers are encouraged to conduct specific research to obtain accurate pricing information tailored to their needs.

When it comes to maintaining optimal performance for bicycles, inflating tires is crucial. While traditional methods of inflating bike tires have been widely adopted, there are several alternative solutions available that may better suit the needs of various users, especially in diverse markets such as Africa, South America, the Middle East, and Europe. This analysis aims to compare the conventional method of inflating bike tires with two alternative solutions: CO2 inflators and electric tire pumps.

| Comparison Aspect | How To Inflate Bike Tires | CO2 Inflators | Electric Tire Pumps |

|---|---|---|---|

| Performance | Reliable, requires manual effort for precise inflation. | Fast inflation but may not hold air long-term. | Consistent pressure, easy to use. |

| Cost | Moderate (pumps range from $20-$100). | Low initial cost (cartridges are cheap, but need frequent replacement). | Higher initial investment ($50-$200). |

| Ease of Implementation | Requires manual operation and knowledge of valve types. | Simple operation; requires no special skills. | User-friendly, often just a button push. |

| Maintenance | Low, requires occasional checks and repairs. | Minimal, but cartridges need replacing. | Moderate; may require battery changes or charging. |

| Best Use Case | General cycling, long-term use. | Emergency situations, portable use. | Regular cycling, home use, or professional settings. |

CO2 inflators are a popular choice among cyclists, particularly for those who seek a quick and portable solution for flat tires. They work by utilizing compressed CO2 cartridges to inflate tires rapidly. The primary advantage of CO2 inflators is their speed; they can inflate a tire in seconds, making them ideal for emergency situations on the road. However, they are less suitable for long-term use as the inflation may not hold for extended periods, necessitating the purchase of new cartridges frequently. Additionally, users must be cautious with the cartridges, as improper handling can lead to waste.

Illustrative image related to how to inflate bike tires

Electric tire pumps offer a modern alternative for inflating bike tires with minimal effort. These devices are designed for ease of use—often requiring just the push of a button to achieve the desired tire pressure. Electric pumps can provide a consistent inflation experience and are especially beneficial for users who may struggle with manual pumping. However, they come with a higher initial investment and may require charging or battery replacements over time. Additionally, their portability can be limited compared to CO2 inflators, making them more suited for home or garage use rather than on-the-go cycling.

When selecting the appropriate tire inflation method, B2B buyers should consider their specific needs, including the type of cycling activity, frequency of use, and budget. For businesses focused on regular maintenance and performance, traditional pumps or electric tire pumps may offer the best long-term value. Conversely, for emergency scenarios or portable solutions, CO2 inflators can be advantageous. Understanding these alternatives will help buyers make informed decisions that align with their operational goals and enhance overall cycling performance.

When considering how to inflate bike tires effectively, several technical properties come into play that can significantly impact performance and safety. Understanding these specifications is crucial for B2B buyers, particularly those in the cycling industry looking to optimize product offerings.

Valve Type Compatibility

– Definition: Bike tires typically use one of three valve types: Presta, Schrader, or Dunlop. Each type has different dimensions and mechanisms for inflation.

– B2B Importance: Offering products compatible with multiple valve types can enhance customer satisfaction and reduce returns. Companies should ensure pumps or adapters are designed to accommodate the prevalent valve types in their target markets.

Pressure Rating (PSI)

– Definition: PSI (pounds per square inch) measures the air pressure in the tire. Each tire has a specified minimum and maximum PSI range indicated on its sidewall.

– B2B Importance: Maintaining optimal tire pressure is vital for safety and performance. Buyers should prioritize products that include clear pressure gauges or recommend specific pressure ranges for different riding conditions.

Material Grade of Inner Tubes

– Definition: The material grade refers to the quality of rubber or synthetic material used in the inner tube, which affects durability and puncture resistance.

– B2B Importance: Sourcing high-grade materials can improve product longevity and customer satisfaction, particularly in regions with challenging terrains. Buyers should evaluate suppliers based on the quality of materials used in their inner tubes.

Pump Efficiency

– Definition: This refers to the amount of air a pump can deliver per stroke, typically measured in liters or cubic centimeters.

– B2B Importance: Efficient pumps can save time and effort, making them more appealing to consumers. Buyers should assess the efficiency ratings of various pumps, particularly for track versus mini pumps, to cater to different customer needs.

Size and Weight of Pumps

– Definition: The dimensions and weight of a pump can influence its portability and usability.

– B2B Importance: Lightweight and compact designs are essential for products aimed at cyclists who need pumps for on-the-go repairs. Buyers should consider the target demographic’s preferences when sourcing pumps.

Understanding industry jargon is crucial for effective communication and negotiation in the B2B space. Here are several key terms relevant to bike tire inflation.

OEM (Original Equipment Manufacturer)

– Definition: An OEM is a company that produces parts or equipment that may be marketed by another manufacturer.

– Relevance: B2B buyers often seek OEM partnerships to ensure they are sourcing high-quality components that meet industry standards.

MOQ (Minimum Order Quantity)

– Definition: MOQ refers to the smallest quantity of a product that a supplier is willing to sell.

– Relevance: Understanding MOQ is vital for budget management and inventory planning. Buyers should negotiate MOQs that align with their sales forecasts to avoid excess stock.

RFQ (Request for Quotation)

– Definition: An RFQ is a document sent to suppliers requesting pricing for specific products or services.

– Relevance: Utilizing RFQs allows buyers to compare prices and terms from multiple suppliers, ensuring they secure the best deal for their needs.

Incoterms (International Commercial Terms)

– Definition: These are standardized trade terms that define the responsibilities of buyers and sellers in international transactions.

– Relevance: Familiarity with Incoterms can help buyers avoid misunderstandings regarding shipping, insurance, and delivery obligations, particularly when dealing with international suppliers.

SKU (Stock Keeping Unit)

– Definition: An SKU is a unique identifier for each distinct product and service that can be purchased.

– Relevance: Accurate SKU management helps streamline inventory processes and improve order fulfillment, which is crucial for companies selling bike-related products.

By understanding these technical properties and trade terms, B2B buyers in the cycling industry can make informed decisions that enhance product offerings and optimize operational efficiency.

The global bike tire inflation sector is experiencing significant shifts driven by various factors. One of the primary drivers is the increasing popularity of cycling as a sustainable mode of transportation and recreational activity, particularly in urban areas across Africa, South America, the Middle East, and Europe. This shift is further fueled by government initiatives promoting cycling to reduce carbon footprints and alleviate traffic congestion. As more consumers embrace cycling, the demand for effective tire inflation solutions is expected to rise.

Emerging technologies are also reshaping the sourcing landscape. The introduction of smart pumps equipped with digital pressure gauges and app connectivity is gaining traction among both consumers and B2B buyers. These innovations enhance user experience by providing real-time data on tire pressure, thus promoting optimal performance and safety. Furthermore, advancements in materials used for tire pumps, such as lightweight composites and durable plastics, are enhancing product longevity and performance.

International B2B buyers, particularly in regions like Saudi Arabia and Nigeria, should be aware of local market dynamics that may influence sourcing decisions. Factors such as import tariffs, local manufacturing capabilities, and distribution networks can significantly impact pricing and availability. Establishing relationships with local suppliers can also facilitate smoother logistics and reduce lead times, ultimately benefiting the bottom line.

Sustainability is increasingly becoming a focal point for B2B buyers in the bike tire inflation market. The environmental impact of manufacturing processes and the materials used in pumps and valves is under scrutiny. B2B buyers are encouraged to prioritize suppliers that demonstrate a commitment to sustainable practices, including the use of recycled materials and eco-friendly production methods.

The importance of ethical sourcing cannot be overstated. Buyers should look for suppliers who are transparent about their supply chains and who adhere to fair labor practices. Certifications such as ISO 14001 for environmental management and Fair Trade certification can serve as indicators of a supplier’s commitment to sustainability and ethical sourcing.

Illustrative image related to how to inflate bike tires

Moreover, the integration of ‘green’ materials in product offerings is gaining traction. Manufacturers are increasingly exploring biodegradable plastics and other environmentally friendly materials for pump components. By aligning procurement strategies with sustainability goals, B2B buyers not only contribute to environmental preservation but also enhance their brand reputation among eco-conscious consumers.

The evolution of bike tire inflation technology has been marked by significant advancements that have improved convenience and efficiency. Initially, manual pumps dominated the market, requiring physical effort to inflate tires. However, with the rise of cycling as a popular activity, the demand for faster and more efficient inflation solutions led to the development of track pumps and mini pumps, which offered enhanced performance and portability.

In recent years, the introduction of CO2 inflators has revolutionized the sector, providing cyclists with a quick and efficient way to inflate tires in emergency situations. These devices utilize compressed carbon dioxide cartridges to deliver rapid inflation, making them popular among competitive cyclists and casual riders alike.

As technology continues to advance, the future of bike tire inflation may see even more innovations, such as automated inflation systems that can self-adjust tire pressure based on real-time data collected during rides. This evolution not only enhances user experience but also aligns with the growing trend of smart technology integration in cycling gear.

In summary, B2B buyers in the bike tire inflation sector must stay informed about market dynamics, sustainability practices, and technological advancements to make strategic sourcing decisions that align with their business goals and consumer demands.

How do I solve issues with my bike tires losing air?

To address air loss in bike tires, first inspect for punctures or leaks in the inner tube. If the tire is consistently losing air, it may be necessary to replace the inner tube or check the valve for damage. Additionally, ensure that the tire is properly seated on the rim, as improper seating can lead to air loss. Regularly checking and maintaining appropriate tire pressure can also help mitigate this issue, enhancing the overall riding experience.

What is the best pump type for inflating bike tires?

The ideal pump for inflating bike tires depends on the bike’s valve type. A track pump is highly recommended for home use due to its efficiency and pressure gauge, allowing for quick inflation. For on-the-go repairs, a mini pump is essential as it is portable and lightweight. Ensure that the pump is compatible with both Presta and Schrader valves to cater to various bike models, thus maximizing utility and convenience for your operations.

How can I determine the correct tire pressure for my bikes?

To find the correct tire pressure, refer to the specifications printed on the tire’s sidewall. This typically includes a range of acceptable pressures measured in PSI. Factors such as rider weight, terrain type, and tire width can influence the optimal pressure. It is advisable to conduct trial and error adjustments within the manufacturer’s guidelines to optimize performance, comfort, and safety for cyclists, ensuring a better riding experience.

What are the key factors to consider when sourcing bike pumps for resale?

When sourcing bike pumps, consider factors such as compatibility with various valve types, durability, ease of use, and price competitiveness. It’s crucial to evaluate the supplier’s manufacturing capabilities, quality assurance processes, and after-sales support. Additionally, assess the supplier’s ability to provide customization options, such as branding or specific features, which can enhance market appeal and meet local preferences in your target regions.

How do I vet suppliers for bike tire inflating equipment?

To effectively vet suppliers, start by researching their reputation in the industry. Look for reviews, testimonials, and case studies from other businesses. Request samples to evaluate product quality and assess their manufacturing processes and compliance with international standards. Establish communication to gauge responsiveness and support capabilities, ensuring they align with your operational needs and expectations in regions such as Africa, South America, and the Middle East.

What is the minimum order quantity (MOQ) for bike tire inflating products?

The MOQ for bike tire inflating products can vary significantly by supplier and product type. Some manufacturers may have a low MOQ, allowing for smaller test orders, while others might require larger quantities to reduce production costs. When negotiating, consider your market demand and potential sales volume to determine a feasible MOQ. Establish clear communication with suppliers to understand their terms and flexibility regarding order sizes.

What payment terms are commonly accepted in international trade for bike equipment?

Payment terms in international trade typically include options such as advance payment, letter of credit, or net payment terms (e.g., 30 days after shipment). It’s essential to negotiate terms that protect both parties, ensuring timely payments while maintaining cash flow. Familiarize yourself with the supplier’s preferred payment methods and any additional fees associated with currency exchange or international transactions, particularly when dealing with suppliers from diverse regions.

How can I ensure quality assurance in bike tire inflating products?

To ensure quality assurance, establish clear specifications and standards before placing orders. Request detailed product documentation, including certifications and test reports, from your suppliers. Implement quality control measures such as third-party inspections or audits during production and prior to shipping. Building a solid relationship with suppliers and maintaining open communication can also facilitate ongoing quality checks and improvements, ensuring that the products meet your standards consistently.

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Presta valve, bike pump, adapter for Presta valve, air compressor, inner tube with Presta valve.

Domain: bikeradar.com

Registered: 2006 (19 years)

Introduction: Track pump: A home essential with a long flexible hose, large camber for quick air transfer, base for weight support, and typically features a pressure gauge. Mini pump: Recommended to have a hose for easier use.

Domain: wikihow.com

Registered: 2004 (21 years)

Introduction: The article provides a guide on how to inflate bike tires, detailing three methods based on valve types: Schrader, Presta, and Woods. Key points include: 1. Identify the valve type: Schrader (American valve, wider, found on cars and cheaper bikes) or Presta (French valve, narrower, found on high-end bikes). 2. Check the recommended PSI printed on the tire’s side. 3. Use a compatible pump: gas stat…

Domain: bikeforums.net

Registered: 2001 (24 years)

Introduction: Presta valve, air compressor, adapter for Presta valve, hand pump option, tire inflating process includes unscrewing the Presta valve to inflate, using an adapter to connect to a standard air compressor, and ensuring the valve is securely closed after inflation.

Domain: bicycles.stackexchange.com

Registered: 2009 (16 years)

Introduction: Road bike: Takara Kabuto Single Speed Road Bike; Air pump: Topeak Pocket Rocket Master Blaster; Valve type: Schrader; PSI measurement: Required PSI is stamped on the side of the tire; Pump usage: Remove valve cap, insert valve into Schrader port, lift lever to lock, pump until tire feels firm, measure pressure with gauge, adjust as necessary.

Domain: schwinnbikes.com

Registered: 2003 (22 years)

Introduction: 1. Recommended Inflation Pressure: Every tire has a maximum inflation recommendation (usually in PSI or bars) labeled on the side of the tire. 2. Valve Types: Presta valves (found on higher-end and road bikes) and Schrader valves (used on cars and many bike tires). 3. Pump Types: A good floor pump is recommended for home use, while a small hand pump or carbon dioxide inflator is suggested for on-t…

In summary, the ability to effectively inflate bike tires is crucial for ensuring optimal performance and rider safety. B2B buyers should prioritize sourcing quality pumps compatible with various valve types, as well as gauge accuracy for precise pressure management. Investing in a range of pumps—track pumps for home use and portable mini-pumps for on-the-go repairs—can significantly enhance the cycling experience for customers.

Strategic sourcing not only improves product availability but also fosters relationships with suppliers that understand the specific needs of the diverse markets in Africa, South America, the Middle East, and Europe. As cycling continues to grow in popularity across these regions, the demand for high-quality inflation solutions will also rise.

Illustrative image related to how to inflate bike tires

Looking ahead, businesses should consider the evolving technologies in tire inflation, such as CO2 inflators and digital pressure gauges, to stay ahead in the competitive market. By aligning with innovative suppliers and focusing on quality, international B2B buyers can ensure they meet the needs of their customers while enhancing their operational efficiency. Embrace these insights and take proactive steps towards sourcing the best solutions for bike tire inflation today.

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.