In an increasingly interconnected world, sourcing reliable portable tire inflators presents a unique challenge for international B2B buyers, particularly in regions such as Africa, South America, the Middle East, and Europe. The Project Farm tire inflator stands out as a versatile solution, catering to a variety of applications—from agricultural machinery to personal vehicles. This guide aims to equip buyers with essential insights into the diverse types of inflators available, their specific applications, supplier vetting processes, and cost considerations.

Understanding the landscape of tire inflators is crucial for making informed purchasing decisions that align with operational needs and budget constraints. This comprehensive resource delves into the nuances of tire inflator specifications, highlighting key features such as duty cycles, portability, and power sources. By examining supplier credibility and market trends, buyers can identify the most suitable options for their unique requirements.

Furthermore, this guide empowers international B2B buyers by providing actionable insights and best practices for navigating the complexities of the global market. With a focus on quality, efficiency, and reliability, readers will gain the knowledge necessary to choose the right tire inflator that enhances operational efficiency and minimizes downtime. Whether you are based in Brazil, Vietnam, or beyond, this guide serves as a vital tool in your sourcing strategy, ensuring you make well-informed decisions in a competitive marketplace.

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Portable Battery-Powered Inflators | Compact, cordless, and lightweight; often rechargeable. | Emergency tire inflation, recreational vehicle maintenance. | Pros: Easy to transport, no power outlet needed. Cons: Limited run time and may require frequent recharging. |

| 12V DC Inflators | Designed to connect to a vehicle’s power outlet; typically faster inflation. | Fleet maintenance, roadside assistance. | Pros: Higher pressure output, suitable for larger tires. Cons: Limited to vehicle proximity, may overheat with prolonged use. |

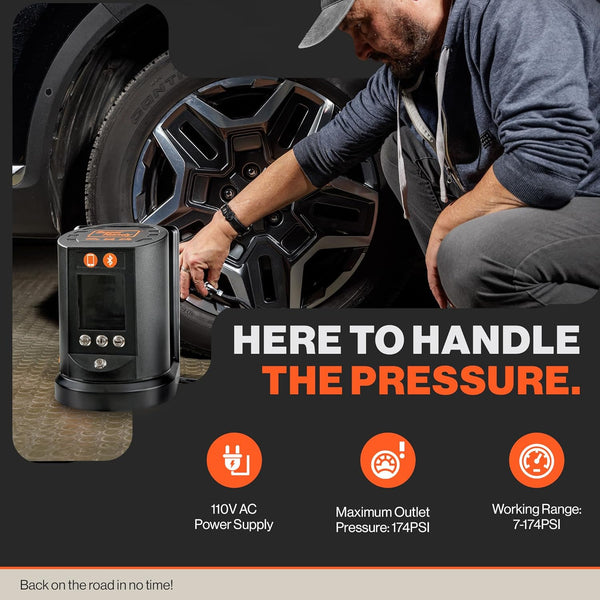

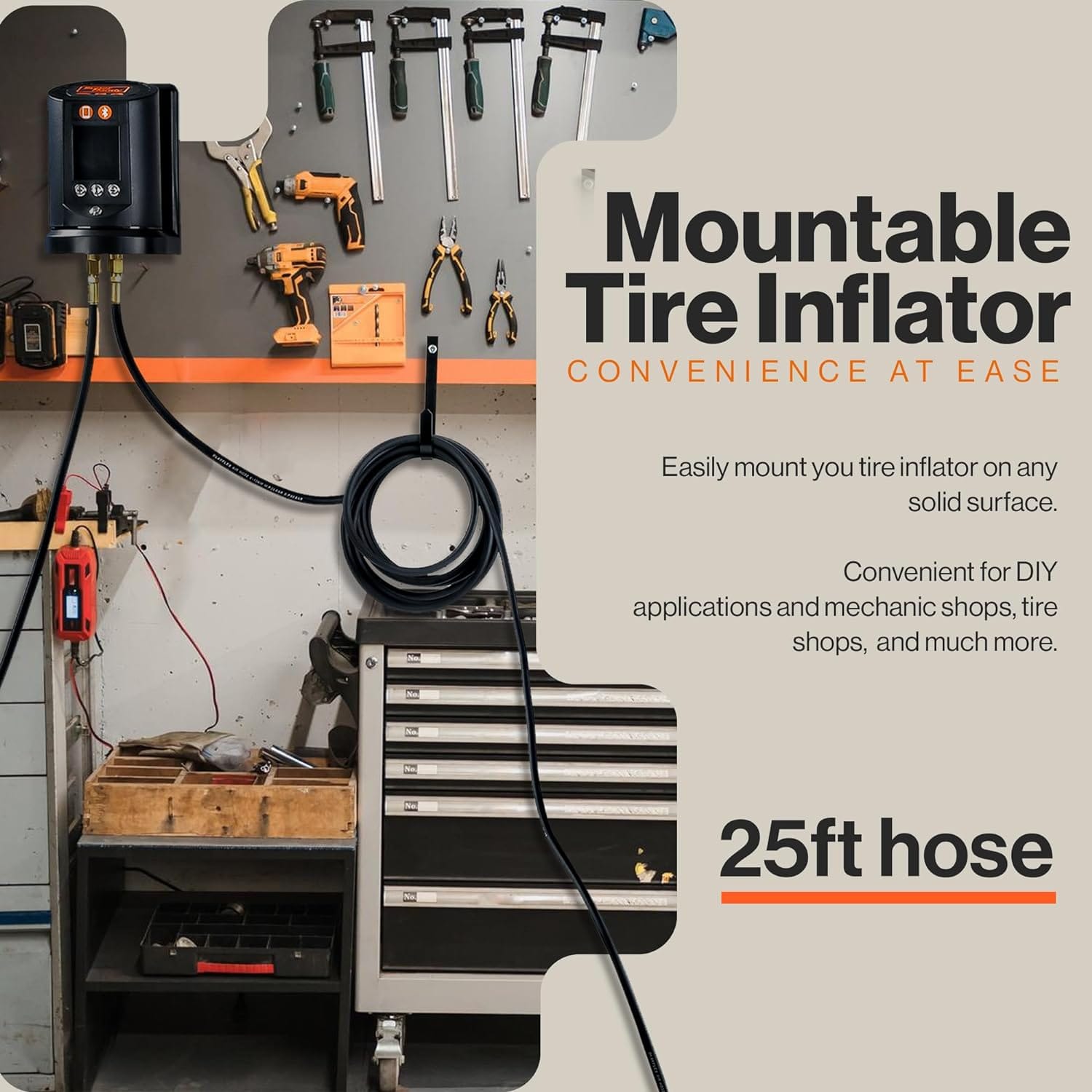

| AC-Powered Compressors | High air volume output, often with larger tanks; suitable for heavy-duty tasks. | Industrial applications, workshops, tire shops. | Pros: Continuous use without duty cycle issues. Cons: Requires a power source and can be bulky. |

| Multi-Function Inflators | Equipped with additional features like deflation, pressure gauges, and LED lights. | Versatile use in automotive, camping, and sports. | Pros: All-in-one functionality, convenient for various tasks. Cons: Can be more expensive and complex to operate. |

| Digital Inflators | Incorporate digital displays for precise pressure readings and automatic shut-off. | Precision tire maintenance, high-performance vehicles. | Pros: Accurate inflation, reduces risk of over-inflation. Cons: May be pricier and dependent on battery life or power source. |

Portable battery-powered inflators are ideal for B2B buyers seeking convenience and mobility. They are compact and lightweight, making them easy to carry in service vehicles or during outdoor activities. These inflators are especially suitable for emergency situations where quick tire inflation is necessary, such as in roadside assistance or recreational vehicle maintenance. However, buyers should consider the limited run time and the need for frequent recharging, which may not suit high-demand environments.

12V DC inflators are designed to connect directly to a vehicle’s power outlet, allowing for faster inflation of tires. They are particularly advantageous for fleet maintenance, where quick response times are essential. These inflators can efficiently inflate larger tires, making them suitable for trucks and vans. However, buyers should be aware of their limitations, such as the risk of overheating with prolonged use and dependence on vehicle proximity.

AC-powered compressors are ideal for heavy-duty applications in industrial settings, workshops, and tire shops. They offer a high air volume output and can operate continuously without the concern of duty cycles, making them suitable for high-demand tasks. B2B buyers should consider the need for a power source and the bulkiness of these units, as they may not be practical for mobile use or in smaller workspaces.

Multi-function inflators provide versatility, featuring additional functions like deflation, pressure gauges, and built-in LED lights. This makes them suitable for a variety of applications, including automotive maintenance, camping, and sports. While they offer convenience, buyers should weigh the benefits against potential higher costs and the complexity of operation, which could be a consideration in environments where simplicity is preferred.

Illustrative image related to project farm tire inflator

Digital inflators are equipped with features that enhance precision, such as digital displays for accurate pressure readings and automatic shut-off functions to prevent over-inflation. These inflators are particularly valuable for precision tire maintenance in high-performance vehicles. However, B2B buyers should consider their higher price point and the dependency on battery life or a power source, which may affect operational efficiency in some settings.

| Industry/Sector | Specific Application of project farm tire inflator | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Agriculture | Inflating tires on agricultural machinery (tractors, harvesters) | Ensures optimal performance and reduces downtime during harvest. | Durability, power supply options, and compatibility with various tire sizes. |

| Construction | Tire inflation for construction vehicles (dump trucks, excavators) | Enhances safety and efficiency by maintaining proper tire pressure. | High PSI capacity, portability, and ease of use in rugged environments. |

| Transportation & Logistics | Quick inflation for delivery and freight vehicles | Minimizes delays in logistics operations due to tire issues. | Rechargeable options, compact design for storage, and reliability. |

| Recreational Vehicles | Tire maintenance for RVs and trailers | Supports safe travel and minimizes the risk of tire blowouts. | Lightweight, battery-powered options for convenience on the road. |

| Emergency Services | Rapid inflation for emergency response vehicles | Ensures readiness and quick response times in critical situations. | High-performance specifications and robust construction for reliability. |

In the agriculture sector, the Project Farm tire inflator is essential for maintaining the tire pressure of various machinery, such as tractors and harvesters. Proper tire inflation is crucial for optimal performance and fuel efficiency, particularly during peak harvest times. By ensuring that equipment operates at the correct tire pressure, farmers can reduce downtime caused by flat tires, ultimately leading to increased productivity. International buyers should focus on the inflator’s durability and power supply compatibility, especially in remote areas where access to electricity may be limited.

The construction industry relies heavily on vehicles like dump trucks and excavators, which require consistent tire pressure for safe operation. The Project Farm tire inflator allows construction managers to quickly address tire inflation needs, preventing potential safety hazards and project delays. With the ability to handle high PSI and portable design, this inflator is ideal for job sites. Buyers in this sector should prioritize inflators that offer robust construction and ease of use, as job site conditions can be demanding.

In the transportation and logistics sector, the Project Farm tire inflator serves as a vital tool for maintaining the tire pressure of delivery and freight vehicles. Timely inflation helps prevent tire blowouts and ensures that vehicles operate efficiently, reducing the risk of delays in delivery schedules. The compact and rechargeable design of the inflator makes it easy to store and use in various locations. When sourcing for this application, businesses should consider the inflator’s reliability and performance under continuous use.

For owners of recreational vehicles (RVs) and trailers, the Project Farm tire inflator provides a convenient solution for tire maintenance during travel. It allows users to quickly inflate tires to the correct pressure, reducing the risk of blowouts and ensuring a safe journey. The lightweight and battery-powered features of the inflator make it an ideal companion for road trips. Buyers should look for options that offer portability and ease of use, particularly for those traveling in remote areas.

Emergency response vehicles require reliable equipment to ensure readiness in critical situations. The Project Farm tire inflator allows for rapid inflation of tires, enabling quick deployment when every second counts. Its high-performance specifications make it suitable for various emergency vehicles, including ambulances and fire trucks. Key sourcing considerations for emergency services include the inflator’s robustness and reliability, ensuring it can withstand the demands of emergency operations.

The Problem: B2B buyers often face challenges with tire inflators that have strict duty cycles, especially in industries where frequent tire inflation is necessary, such as logistics and construction. For instance, if a fleet manager needs to inflate multiple vehicle tires in quick succession, inflators that require downtime to cool can significantly delay operations. This downtime can lead to inefficiencies, increased labor costs, and potentially even safety risks if vehicles are not properly inflated before use.

The Solution: When sourcing a ‘project farm tire inflator,’ it’s crucial to evaluate the duty cycle specifications. Opt for models designed for extended use or those that incorporate advanced cooling technology to minimize downtime. Additionally, consider investing in multiple inflators to ensure that one can be in use while others cool down. To maximize efficiency, train staff on quick setup and operation, allowing them to switch inflators seamlessly. This proactive approach will maintain productivity while ensuring safety compliance.

The Problem: A common pain point for B2B buyers is the challenge of achieving consistent inflation pressure across various types of tires, particularly in industries like agriculture and transportation. Different vehicles require specific pressures, and an inflator that lacks precise pressure control can lead to under-inflated or over-inflated tires. This inconsistency can result in poor vehicle performance, increased tire wear, and higher fuel consumption.

The Solution: To address this issue, look for a ‘project farm tire inflator’ equipped with an integrated pressure gauge and auto shut-off feature. This ensures that once the desired pressure is reached, the inflator automatically stops, preventing over-inflation. Additionally, provide employees with clear guidelines on the appropriate tire pressures for different vehicles in your fleet. Keeping a reference chart readily available can streamline the process and reduce the risk of human error. Regularly calibrating the inflator’s pressure gauge will also help maintain accuracy and reliability.

The Problem: Many businesses operate in remote areas where access to power sources is limited, making traditional inflators impractical. For instance, a construction company working on a site far from urban centers may struggle to inflate tires on heavy machinery without a reliable power supply. This can lead to operational delays and increased transportation costs to bring equipment back to a power source.

The Solution: To combat this challenge, invest in a portable ‘project farm tire inflator’ that runs on battery power or has a dual power source option, allowing it to be charged via a vehicle’s 12V outlet. When selecting an inflator, prioritize models that are compact and lightweight for easy transport. Additionally, consider establishing a battery management plan where spare batteries are charged and ready for use on-site. Training staff on efficient battery management practices will also ensure that inflators are always ready for use, thereby minimizing downtime and keeping projects on schedule.

When selecting materials for a tire inflator, it is crucial to consider their properties, advantages, disadvantages, and how they align with international standards and preferences. Here, we analyze four common materials used in the construction of tire inflators: plastic, aluminum, steel, and rubber.

Plastic, particularly high-density polyethylene (HDPE) and polycarbonate, is widely used in the housing and components of tire inflators. These materials offer excellent corrosion resistance and are lightweight, making them ideal for portable devices. They can withstand a range of temperatures but may not perform well under extreme heat or pressure.

Pros: Plastic is cost-effective and easy to mold into complex shapes, allowing for innovative designs. It is also resistant to rust and corrosion, which is beneficial in humid or wet environments.

Cons: While durable, plastics can become brittle over time, especially when exposed to UV light or extreme temperatures. This limits their long-term viability in harsh conditions.

Impact on Application: Plastic components are suitable for housing and non-pressurized parts of the inflator but may not be ideal for high-pressure applications.

Considerations for International Buyers: Compliance with ASTM and ISO standards is essential. Buyers in regions like Africa and South America should ensure that the plastics used meet local environmental regulations regarding recyclability and safety.

Illustrative image related to project farm tire inflator

Aluminum is commonly used for the body and some internal components of tire inflators due to its excellent strength-to-weight ratio and resistance to corrosion. It can handle higher pressures than plastic, making it suitable for more demanding applications.

Pros: Aluminum is lightweight yet strong, which enhances portability without sacrificing durability. It also dissipates heat effectively, reducing the risk of overheating during prolonged use.

Cons: The manufacturing process for aluminum can be more complex and expensive compared to plastic. Additionally, while it resists corrosion, it is susceptible to scratches and dents.

Impact on Application: Aluminum is well-suited for high-pressure applications and is often used in inflators designed for off-road or heavy-duty use.

Considerations for International Buyers: Buyers should look for compliance with international standards such as DIN and JIS, especially when sourcing from different regions. Understanding local import tariffs on aluminum products is also crucial.

Steel, particularly stainless steel, is utilized in inflators for its robustness and ability to withstand high pressures. It is often found in the compressor components and valves of tire inflators.

Pros: Steel is incredibly durable and can handle extreme conditions, making it ideal for heavy-duty applications. Stainless steel is resistant to rust and corrosion, extending the product’s lifespan.

Cons: The weight of steel can be a disadvantage for portable inflators. Additionally, the cost of stainless steel is higher than that of plastic or aluminum.

Impact on Application: Steel is ideal for high-performance inflators used in commercial or industrial settings where durability and reliability are paramount.

Considerations for International Buyers: Compliance with safety standards and certifications is essential, particularly in regions with stringent regulations. Buyers should also consider the availability of steel in their local markets.

Rubber is primarily used for seals, hoses, and other flexible components in tire inflators. Its elasticity and resilience make it perfect for applications requiring flexibility and durability.

Pros: Rubber provides excellent sealing capabilities, preventing air leaks and ensuring efficient operation. It also withstands a wide range of temperatures and is resistant to wear and tear.

Illustrative image related to project farm tire inflator

Cons: Over time, rubber can degrade due to exposure to oils, UV light, and extreme temperatures. This degradation can lead to failure in seals and hoses.

Impact on Application: Rubber is critical for ensuring airtight connections and is essential for the performance of any tire inflator.

Considerations for International Buyers: Buyers should ensure that the rubber used meets local standards for safety and performance, especially in regions with varying climate conditions.

| Material | Typical Use Case for project farm tire inflator | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Plastic | Housing and non-pressurized components | Lightweight and corrosion-resistant | Can become brittle over time | Low |

| Aluminum | Body and internal components | Strong yet lightweight | More complex manufacturing process | Medium |

| Steel | Compressor components and valves | Extremely durable and high-pressure resistant | Heavier and more expensive | High |

| Rubber | Seals and hoses | Excellent sealing capabilities | Degrades over time with exposure | Medium |

Selecting the right materials for tire inflators is essential for ensuring performance, durability, and compliance with international standards. Understanding the properties, advantages, and limitations of each material will help B2B buyers make informed decisions that align with their specific needs and local market conditions.

Manufacturing a tire inflator involves several critical stages that ensure the final product is reliable and meets the demands of end-users. The primary stages in the production process include material preparation, forming, assembly, and finishing.

The first step in manufacturing a tire inflator is sourcing high-quality materials. This typically includes metals for the housing, plastics for certain components, and rubber for seals. Suppliers must adhere to strict quality standards, ensuring that the materials are durable and capable of withstanding high pressures. B2B buyers should verify that manufacturers use materials compliant with international standards, such as those set by ASTM (American Society for Testing and Materials).

Once materials are prepared, the next stage is forming. This process includes techniques like injection molding for plastic parts and stamping or machining for metal components. Advanced technologies, such as CNC (Computer Numerical Control) machining, allow for precise shaping and consistency in production. This precision is crucial for ensuring that components fit together seamlessly, which is vital for the inflator’s performance.

The assembly phase is where the individual components come together to form the complete tire inflator. This process often involves both manual and automated systems. Skilled workers typically handle critical assembly tasks that require precision, while automated machines may be used for repetitive tasks. It’s essential for manufacturers to maintain a clean and organized workspace during this phase to prevent contamination and ensure product integrity.

Illustrative image related to project farm tire inflator

After assembly, the inflators undergo finishing processes, which may include painting, coating, or applying labels. Finishing not only enhances the aesthetic appeal of the product but also adds protective layers that improve durability. Quality checks during this phase are critical to ensure that the final product meets the desired specifications and is free from defects.

Quality assurance is paramount in the manufacturing of tire inflators, especially when catering to international markets. Manufacturers often adhere to several quality standards to ensure product reliability and safety.

ISO 9001: This is a globally recognized standard for quality management systems (QMS). Compliance with ISO 9001 indicates that a manufacturer has implemented effective processes to enhance customer satisfaction and ensure continuous improvement.

CE Marking: For products sold in the European Economic Area (EEA), CE marking signifies conformity with health, safety, and environmental protection standards. This is crucial for B2B buyers in Europe as it assures compliance with EU regulations.

API Standards: If the inflator is intended for use in the oil and gas industry, compliance with American Petroleum Institute (API) standards may be necessary. These standards ensure that products are safe and reliable for industrial applications.

Quality Control (QC) is integrated throughout the manufacturing process, with specific checkpoints designed to catch defects and ensure consistency.

During the IQC phase, raw materials and components are inspected before they enter the production line. This step is crucial for identifying any issues with materials that could affect the final product’s performance. B2B buyers should inquire about the IQC processes manufacturers have in place and request documentation of material certifications.

IPQC occurs during the manufacturing process and involves continuous monitoring of production to detect defects as they happen. This may include regular inspections of assembly lines and checks on the functionality of components. Implementing IPQC helps minimize waste and reduces the likelihood of defective products reaching the market.

Illustrative image related to project farm tire inflator

FQC is the last line of defense before products are shipped. During this phase, completed tire inflators undergo rigorous testing to verify their performance under various conditions. Common testing methods include pressure tests, durability assessments, and functionality checks. B2B buyers should request detailed FQC reports that outline the testing processes and results.

For international buyers, understanding and verifying the QC processes of potential suppliers is essential to ensure product reliability and compliance with local regulations.

B2B buyers should conduct supplier audits to assess the manufacturing processes and quality control systems in place. This can include on-site visits to manufacturing facilities to observe operations firsthand. Additionally, requesting detailed QC reports, including IQC, IPQC, and FQC data, can provide insights into the supplier’s commitment to quality.

Illustrative image related to project farm tire inflator

Engaging third-party inspection services can offer an unbiased evaluation of a supplier’s manufacturing and QC processes. These inspections can be particularly beneficial for buyers from regions like Africa and South America, where establishing trust and verifying standards may be more challenging. Third-party inspectors can provide certifications and detailed reports that reinforce the credibility of the supplier.

Navigating the landscape of quality certification can be complex for international buyers. Different regions have varying requirements and standards, which can affect the importation and acceptance of products.

For instance, products sold in Europe must meet CE marking requirements, while those intended for the Middle Eastern markets may need to comply with local regulations specific to that region. Buyers should conduct thorough research on the regulations applicable to their target markets and ensure that suppliers can provide the necessary certifications.

Cultural and economic differences can impact the perception of quality and standards. Buyers from Europe may have different expectations compared to those from Africa or South America. It is essential for suppliers to understand these nuances and communicate effectively to establish trust and ensure that products meet the varying expectations of their international clientele.

By comprehensively understanding the manufacturing processes and quality assurance measures associated with project farm tire inflators, B2B buyers can make informed purchasing decisions that align with their operational needs and standards.

Illustrative image related to project farm tire inflator

To ensure a successful procurement process for a “Project Farm Tire Inflator,” B2B buyers should follow a structured approach. This guide provides a step-by-step checklist designed to help you make informed decisions while sourcing tire inflators, particularly relevant for international markets in Africa, South America, the Middle East, and Europe.

Before initiating the procurement process, establish clear technical specifications for the tire inflator. Consider factors such as power source (battery-operated, AC, or DC), maximum pressure output, and duty cycle. Each specification will influence the inflator’s performance and suitability for your needs.

Understanding current market trends and pricing for tire inflators will help you gauge budget expectations. Research various models and their capabilities, noting how they compare in terms of cost and performance.

Illustrative image related to project farm tire inflator

Thoroughly vet suppliers to ensure reliability and quality. Request company profiles, product catalogs, and references from existing clients, especially those in similar industries or regions.

Ensure that the tire inflators comply with industry standards and regulations relevant to your market. Certifications can include ISO, CE, or other relevant safety and quality assurances.

Before finalizing your order, request samples from shortlisted suppliers. Testing the inflators in real-world scenarios will provide valuable insights into their performance and reliability.

Once you have identified a preferred supplier, engage in negotiations to finalize terms and conditions. Discuss pricing, delivery timelines, payment terms, and after-sales support.

After agreement on terms, proceed with the purchase. Post-purchase, continuously monitor the inflators’ performance to ensure they meet your operational needs.

Illustrative image related to project farm tire inflator

By following this checklist, B2B buyers can streamline their procurement process for tire inflators and ensure they select a product that meets their specific requirements effectively.

When sourcing portable tire inflators for agricultural or industrial projects, understanding the comprehensive cost structure and pricing dynamics is crucial for international B2B buyers. This section outlines the key cost components, price influencers, and strategic buyer tips to ensure a successful procurement process.

The cost structure for a project farm tire inflator encompasses several components:

Materials: The primary materials include high-quality plastics, metals, and electronic components. The choice of materials directly impacts durability and performance, which are critical in agricultural settings.

Labor: Labor costs can vary significantly depending on the manufacturing location. Regions with lower labor costs can offer competitive pricing, but it’s essential to consider the trade-off with quality and craftsmanship.

Manufacturing Overhead: This includes costs related to factory operations, utilities, and indirect labor. Efficient manufacturing processes can help reduce these costs.

Tooling: Initial tooling costs for molds and production equipment can be substantial, especially for customized inflators. Buyers should factor in these costs when negotiating prices for unique specifications.

Quality Control (QC): Robust QC processes are essential to ensure product reliability. While this adds to the cost, it minimizes the risk of failures in the field, which can be costly.

Logistics: Shipping costs are particularly relevant for international buyers. Factors such as distance, freight method, and customs duties will influence overall logistics expenses.

Margin: Suppliers will typically add a margin to cover their costs and ensure profitability. Understanding the market landscape can help buyers gauge fair margins for different suppliers.

Several factors can influence the pricing of tire inflators:

Volume and Minimum Order Quantity (MOQ): Larger order volumes often lead to lower per-unit costs. Buyers should consider their anticipated needs to negotiate favorable pricing.

Specifications and Customization: Customized inflators with specific features or branding may incur additional costs. Buyers should weigh the benefits of customization against budget constraints.

Materials and Quality Certifications: High-quality materials and certifications (e.g., ISO, CE) can increase costs but may offer better performance and reliability, reducing long-term maintenance costs.

Supplier Factors: The reputation and reliability of suppliers can impact pricing. Established suppliers may charge more due to their proven track record, while new entrants might offer lower prices to build market share.

Incoterms: Understanding Incoterms is vital for international transactions, as they define responsibilities for shipping, insurance, and tariffs. Clarity on these terms can help avoid unexpected costs.

Negotiation Strategies: Approach negotiations with a clear understanding of your requirements and market prices. Consider leveraging multiple supplier quotes to foster competitive pricing.

Total Cost of Ownership (TCO): Evaluate not just the purchase price but the TCO, which includes maintenance, operational efficiency, and longevity of the inflator. A higher upfront cost may be justified by lower operational costs over time.

Pricing Nuances for International Buyers: Be aware of the impact of currency fluctuations, import tariffs, and local taxes when sourcing from different countries. These factors can significantly alter the final cost.

Long-Term Partnerships: Building relationships with suppliers can lead to better pricing, priority service, and insights into new products. Consider establishing long-term contracts for continuous supply and better rates.

Sourcing project farm tire inflators requires a keen understanding of the cost structure and pricing dynamics. By analyzing the cost components, recognizing price influencers, and employing strategic buyer tips, international B2B buyers can make informed decisions that align with their operational needs and budget constraints. Always remember to verify pricing with suppliers and consider the total cost implications to ensure a successful procurement process.

Illustrative image related to project farm tire inflator

In the realm of tire inflation, businesses often seek efficient, reliable, and cost-effective solutions. While the Project Farm Tire Inflator offers a compelling option, there are various alternatives worth considering that cater to different needs and operational contexts. This analysis provides a comparative overview to help B2B buyers make informed decisions.

| Comparison Aspect | Project Farm Tire Inflator | VIAIR 88P Portable Compressor | DeWalt 20V MAX Cordless Inflator |

|---|---|---|---|

| Performance | Up to 150 PSI; moderate inflation speed | Up to 120 PSI; slower inflation speed | Up to 160 PSI; fast inflation speed |

| Cost | Moderate (typically around $50) | Moderate (approximately $70) | Higher (around $130) |

| Ease of Implementation | Simple setup; lightweight and portable | Requires 12V power source; portable | Battery-operated; versatile charging options |

| Maintenance | Minimal; occasional cleaning | Moderate; check power connections | Minimal; battery care required |

| Best Use Case | General-purpose inflation needs | Emergency tire inflation | Quick inflation for various applications |

The VIAIR 88P is a reliable choice for those who require a portable solution for emergency situations. It operates using a 12V power source, making it suitable for vehicles. The performance is adequate for most passenger vehicles, reaching up to 120 PSI. However, the inflation speed is slower compared to other options, which can be a drawback for businesses needing rapid turnaround times. Additionally, the requirement for a power source limits its versatility compared to battery-operated models.

The DeWalt 20V MAX Cordless Inflator stands out for its high performance, boasting a maximum PSI of 160. This makes it ideal for a wide range of applications, including larger tires and inflatables. Its battery-operated design enhances portability and convenience, allowing users to inflate tires without being tethered to a power source. However, the cost is notably higher, which may not align with every company’s budget constraints. Maintenance is minimal, primarily revolving around battery care, but the investment may be justified by the speed and versatility it offers.

When selecting a tire inflation solution, B2B buyers should consider specific operational needs, including the types of vehicles serviced, inflation frequency, and budget constraints. The Project Farm Tire Inflator is a solid choice for general use, while the VIAIR 88P is ideal for emergency situations where portability is key. Conversely, the DeWalt 20V MAX offers superior performance and convenience at a higher price point, making it suitable for businesses with diverse inflation needs. Ultimately, evaluating these factors will enable businesses to select the most appropriate tire inflator for their unique requirements, ensuring efficiency and reliability in their operations.

In the competitive landscape of B2B purchasing, understanding the technical specifications of tire inflators is vital for making informed decisions. Here are some critical specifications to consider:

Illustrative image related to project farm tire inflator

Pressure Rating (PSI)

The pressure rating, measured in pounds per square inch (PSI), indicates the maximum air pressure the inflator can deliver. A higher PSI rating is essential for inflating larger tires, such as those on agricultural machinery or trucks. For B2B buyers, this specification helps determine if the inflator can meet the specific demands of their fleet or equipment.

Duty Cycle

Duty cycle refers to the operational time a tire inflator can run before needing to cool down. For example, a 10 minutes on and 5 minutes off duty cycle means the inflator can operate for 10 minutes continuously, followed by a 5-minute rest period. This specification is crucial for businesses that require quick, repeated tire inflation, as it impacts productivity and downtime.

Airflow Rate (CFM)

The airflow rate, measured in cubic feet per minute (CFM), indicates how quickly the inflator can fill a tire. A higher CFM rating means faster inflation times, which is beneficial for businesses that need to minimize equipment downtime. Understanding airflow rates allows B2B buyers to choose inflators that optimize their operational efficiency.

Power Source

Tire inflators can be powered by different sources, including 12V car batteries, AC outlets, or rechargeable batteries. Knowing the power source is essential for B2B buyers to ensure compatibility with their operational environment. Battery-powered models offer portability, while AC-powered options typically provide more consistent performance.

Build Material and Durability

The material used in the construction of the inflator affects its durability and longevity. High-quality materials can withstand harsh working conditions, which is particularly important in industries like agriculture and construction. B2B buyers should assess the build quality to ensure they are investing in a reliable product that minimizes replacement costs.

Noise Level (Decibels)

The noise level, measured in decibels (dB), indicates how loud the inflator operates. For businesses operating in noise-sensitive environments, such as urban areas or near residential zones, a quieter model may be necessary. Understanding the noise specifications helps buyers comply with local regulations and maintain a positive relationship with the community.

Familiarity with industry jargon is essential for B2B buyers to navigate procurement effectively. Here are some common terms:

OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts and equipment that may be marketed by another manufacturer. Understanding OEM products is crucial for buyers seeking reliable and compatible inflators for their existing equipment.

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ helps buyers plan their inventory and budget effectively, ensuring they meet supplier requirements while avoiding excess stock.

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers asking for price quotes for specific products. By issuing an RFQ, buyers can compare pricing, terms, and conditions from multiple suppliers, facilitating better decision-making.

Incoterms (International Commercial Terms)

Incoterms are international rules that define the responsibilities of buyers and sellers in international transactions. Familiarity with these terms helps buyers understand shipping responsibilities, costs, and risk management, crucial for cross-border purchases.

Lead Time

Lead time refers to the time it takes from placing an order to receiving the product. Understanding lead times is vital for businesses to manage their supply chain efficiently, particularly in industries with fluctuating demand.

Warranty

A warranty is a guarantee provided by the manufacturer regarding the lifespan and performance of the product. Knowing the warranty terms helps buyers assess the reliability and potential long-term costs associated with the tire inflator.

By grasping these essential technical properties and trade terms, B2B buyers can make informed purchasing decisions that align with their operational needs and budget constraints.

The project farm tire inflator market is witnessing robust growth driven by several global factors. Firstly, the increasing adoption of agricultural mechanization in regions such as Africa and South America is propelling demand for efficient tire maintenance solutions. With the rise of precision farming, operators are increasingly recognizing the importance of maintaining optimal tire pressure for enhanced fuel efficiency and reduced operational costs. Additionally, the growing prevalence of electric and hybrid vehicles in agricultural applications necessitates the availability of portable and efficient inflators.

Illustrative image related to project farm tire inflator

Emerging technologies are also reshaping the market landscape. Innovations in battery technology are leading to the development of lightweight, high-capacity inflators that cater to the needs of modern farming. Furthermore, the integration of smart technology, such as IoT connectivity, allows for real-time monitoring and management of tire pressure, making these inflators indispensable tools for international buyers focused on efficiency and productivity.

International B2B buyers should be aware of regional dynamics that influence sourcing trends. For instance, markets in Europe are increasingly leaning towards eco-friendly products, while buyers in the Middle East may prioritize durability and performance under extreme conditions. Understanding these nuances is crucial for successful procurement strategies.

Sustainability has become a pivotal consideration in the sourcing of project farm tire inflators. Environmental impact assessments are now integral to supplier evaluations, as companies aim to reduce their carbon footprints. Buyers are increasingly seeking inflators made from recycled materials or those that utilize energy-efficient technologies. This shift not only aligns with global sustainability goals but also responds to the growing consumer demand for environmentally responsible products.

Ethical sourcing practices are essential in ensuring that the supply chain is transparent and accountable. Certifications such as ISO 14001 (Environmental Management) and ISO 9001 (Quality Management) are becoming standard requirements for suppliers. These certifications signal a commitment to sustainable practices, which can enhance brand reputation and customer loyalty.

Moreover, the use of ‘green’ materials in the production of tire inflators is gaining traction. Buyers should prioritize manufacturers who invest in environmentally friendly processes and materials, as this will not only meet regulatory requirements but also appeal to a growing segment of environmentally conscious consumers.

The evolution of project farm tire inflators has been marked by significant technological advancements and changing market needs. Initially, inflators were basic mechanical devices that required manual operation and were limited in functionality. However, as agricultural practices evolved, so did the need for more sophisticated inflating solutions.

The introduction of portable, battery-powered inflators revolutionized the market, offering convenience and efficiency for farmers who required quick and easy solutions for tire maintenance. Over the past decade, the incorporation of smart technology has further transformed these devices, allowing for automated pressure adjustments and remote monitoring via mobile applications.

As the agricultural sector continues to embrace innovation, the project farm tire inflator market is poised for further evolution. International B2B buyers must stay informed about these changes to leverage the latest technologies and meet the demands of modern agricultural operations.

Illustrative image related to project farm tire inflator

How do I choose the right tire inflator for my business needs?

Selecting the right tire inflator involves assessing your specific requirements, such as the types of vehicles you service and the frequency of tire inflation. Consider factors like inflator capacity (PSI), duty cycle, and power source (battery or plug-in). For businesses in regions with varying climates, durability against heat or moisture is crucial. Additionally, evaluate the warranty and customer support offered by manufacturers to ensure long-term reliability.

What is the best tire inflator for heavy-duty applications?

For heavy-duty applications, a tire inflator with a high PSI rating and a robust duty cycle is essential. Models from reputable brands like Milwaukee or Dewalt are often preferred, as they provide reliable performance under continuous use. Look for features such as a built-in pressure gauge and the ability to handle larger tires commonly found in trucks and agricultural vehicles. Ensure that the inflator can operate in the conditions typical for your industry.

What should I consider when sourcing tire inflators internationally?

When sourcing tire inflators from international suppliers, consider factors such as compliance with local regulations, import duties, and shipping logistics. It’s also vital to assess the supplier’s reputation and reliability through reviews and certifications. Establish clear communication regarding product specifications, lead times, and after-sales support. Ensure that the supplier can provide documentation for warranty and quality assurance.

How do I vet suppliers for tire inflators?

To effectively vet suppliers, start by researching their business history and reputation in the industry. Look for certifications that indicate quality standards, such as ISO or CE markings. Request references from previous clients and evaluate their feedback on product performance and customer service. It’s also beneficial to conduct a factory visit or request a sample product to assess quality firsthand before committing to larger orders.

What are typical minimum order quantities (MOQs) for tire inflators?

Minimum order quantities (MOQs) for tire inflators can vary widely among suppliers, often ranging from 50 to several hundred units, depending on the manufacturer and product specifications. Some manufacturers may offer lower MOQs for new customers or trial orders. Always negotiate MOQs based on your business needs, and inquire about bulk purchase discounts, which can significantly reduce costs per unit.

What payment terms are common when purchasing from international suppliers?

Payment terms can differ based on the supplier’s policies and your relationship with them. Common arrangements include a deposit upfront (often 30-50%) with the balance due upon shipment or delivery. Some suppliers may offer letters of credit or escrow services for larger orders to secure the transaction. It’s essential to clearly outline payment terms in the contract to avoid misunderstandings.

How can I ensure quality assurance (QA) for my tire inflator order?

To ensure quality assurance, establish specific quality standards and testing protocols with your supplier before production begins. Request samples for testing and consider third-party inspections during manufacturing and prior to shipment. Document all quality expectations in your contract, including return policies for defective units. Continuous communication with the supplier throughout the production process can help address any quality concerns proactively.

What logistics considerations should I keep in mind when importing tire inflators?

When importing tire inflators, consider shipping methods (air vs. sea), costs, and transit times. Ensure that the supplier can provide proper packaging to prevent damage during transit. Familiarize yourself with customs regulations in your country, including tariffs and documentation requirements. Partnering with a reliable freight forwarder can help streamline logistics and ensure compliance with international shipping standards.

Domain: projectfarmreviews.com

Registered: 2023 (2 years)

Introduction: {“Best Performance”:{“Name”:”Milwaukee”,”Price”:”$139″},”Best Value”:{“Kobalt”:{“Price”:”$48″},”Bauer”:{“Price”:”$50″}},”Best Compact”:{“GooLoo”:{“Price”:”$62″}},”Products”:{“Milwaukee”:{“Price”:”$139.00″},”Ridgid”:{“Price”:”$118.00″},”Makita”:{“Price”:”$152.00″},”WORX”:{“Price”:”$70.00″},”DeWalt”:{“Price”:”$129.00″},”Kobalt”:{“Price”:”$48.00″},”Bauer”:{“Price”:”$50.00″},”Ryobi”:{“Price”:”$62.00″}…

Domain: project-farm.com

Registered: 2020 (5 years)

Introduction: Favorite Automotive Products: Seafoam, Techron, Marvel Mystery Oil, Bosch ICON Wiperblades, Amsoil Signature Series Motor Oil, DeWalt Cordless Tire Inflator, CeraKote Ceramic Plastic Trim Restoration, Sylvania Headlight Restoration, WIX car air filter.

Favorite Abrasives: Diablo Flap Disc, Makita Grinding Disc.

Favorite Shop Tools: Rocketsocket Rounded Nut Remover, Milwaukee Impact Driver, Milwa…

The strategic sourcing of portable tire inflators is critical for international B2B buyers aiming to enhance operational efficiency and customer satisfaction. Key takeaways from our analysis highlight the importance of selecting inflators that balance performance with duty cycle considerations, ensuring they meet the diverse needs of various applications—from emergency tire inflation to everyday use. Buyers should prioritize suppliers that offer robust warranties and reliable customer support, as these factors significantly affect long-term satisfaction and value.

As markets in Africa, South America, the Middle East, and Europe continue to evolve, the demand for high-quality, portable tire inflators will only increase. Organizations looking to gain a competitive edge should leverage strategic sourcing to identify innovative products that cater to local preferences and environmental conditions.

Moving forward, we encourage international buyers to engage with manufacturers who demonstrate a commitment to quality, sustainability, and after-sales support. By doing so, businesses can not only streamline their procurement processes but also position themselves for growth in an increasingly competitive landscape. Start exploring your options today to secure the best solutions for your operational needs.

Illustrative image related to project farm tire inflator

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.