Inflating tires with nitrogen is becoming an increasingly strategic choice for businesses across the globe, particularly in industries where tire performance is critical. As international B2B buyers grapple with the challenges of sourcing reliable tire inflation solutions, understanding the benefits of nitrogen over traditional air fills is essential. This guide delves into the nuances of how to inflate tires with nitrogen, providing insights into various applications, supplier vetting, and cost considerations that cater to the unique needs of markets in Africa, South America, the Middle East, and Europe, including countries like Brazil and Germany.

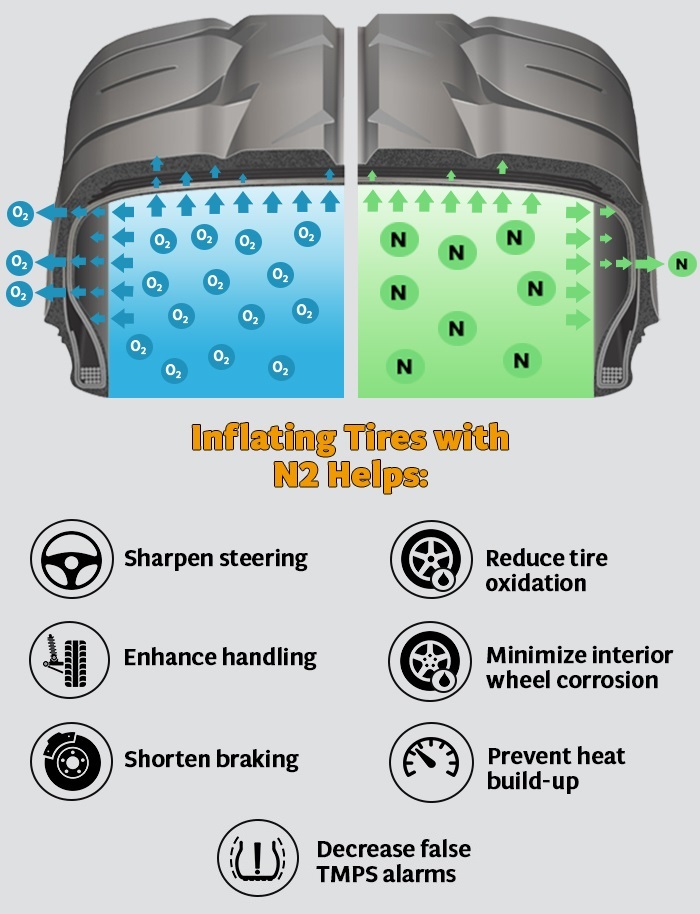

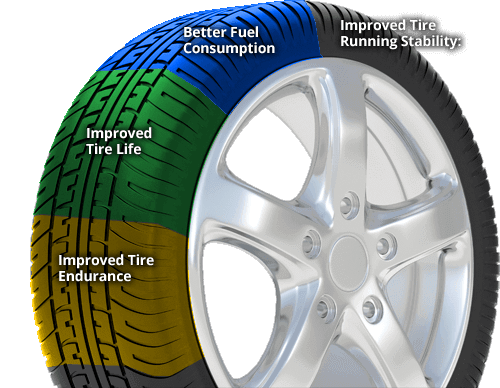

The comprehensive nature of this guide empowers buyers by offering a holistic view of nitrogen tire inflation. From exploring the types of nitrogen filling equipment available to assessing the operational advantages, such as reduced pressure loss and moisture-free environments, this resource equips decision-makers with the knowledge to make informed purchasing decisions. Moreover, it highlights the importance of vetting suppliers to ensure quality and reliability in a competitive market. By leveraging this guide, international buyers can optimize their tire management strategies, enhance operational efficiency, and ultimately improve their bottom line.

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Commercial Nitrogen Filling | Utilizes industrial-grade nitrogen systems for tire inflation. | Fleet management, logistics, and transportation companies. | Pros: Consistent tire pressure, reduced maintenance. Cons: Initial setup costs can be high. |

| DIY Home Nitrogen Filling | Portable kits for filling tires with nitrogen at home. | Small businesses with limited vehicle fleets. | Pros: Cost-effective for small operations. Cons: Requires technical know-how and safety precautions. |

| Mobile Nitrogen Services | On-site nitrogen filling services for vehicles. | Automotive repair shops, racing teams, and service stations. | Pros: Convenience and immediate service. Cons: Ongoing service costs may add up. |

| Hybrid Air-Nitrogen Systems | Combines nitrogen with dry air for inflation. | Racing teams and high-performance vehicle operators. | Pros: Improved pressure stability with lower moisture content. Cons: Complexity in setup and operation. |

| Nitrogen Purging Systems | Removes moisture from tires before filling with nitrogen. | Automotive manufacturers and high-end service centers. | Pros: Optimal tire performance and longevity. Cons: Higher investment and maintenance requirements. |

Commercial nitrogen filling systems are designed for high-volume tire inflation, utilizing industrial-grade nitrogen generation or storage tanks. These systems are typically installed in fleet management and transportation companies where consistent tire pressure is crucial for safety and efficiency. The primary consideration for B2B buyers is the initial setup cost, which can be significant but is often offset by reduced maintenance and fuel savings from improved tire performance.

DIY home nitrogen filling involves using portable kits that allow businesses to fill tires with nitrogen independently. This method is suitable for small businesses with limited vehicle fleets that seek to save on costs associated with commercial nitrogen filling services. Buyers should consider the technical know-how required for safe operation and the cost of tank refills, which can come from local welding supply stores.

Mobile nitrogen services provide on-site tire inflation, making them ideal for automotive repair shops, racing teams, and service stations. This convenience allows businesses to maintain optimal tire pressure without the need for a permanent installation. While the service is beneficial, businesses should be aware that ongoing costs may accumulate, making it essential to evaluate the frequency of use against potential expenses.

Illustrative image related to how to inflate tires with nitrogen

Hybrid air-nitrogen systems combine nitrogen with dry air to enhance tire performance, particularly in high-performance applications such as racing. These systems reduce moisture content, which can lead to improved pressure stability and tire longevity. B2B buyers must consider the complexity of setup and operation, as well as the potential benefits of enhanced tire performance, especially in demanding environments.

Nitrogen purging systems are designed to remove moisture from tires before filling them with nitrogen, ensuring optimal performance and longevity. These systems are particularly valuable for automotive manufacturers and high-end service centers that prioritize tire quality. While the investment and maintenance costs are higher, the long-term benefits of improved tire performance can justify the expense, making it a worthwhile consideration for serious buyers.

| Industry/Sector | Specific Application of how to inflate tires with nitrogen | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Manufacturing | Filling tires for vehicles during production | Improved tire longevity and reduced maintenance costs | Reliable nitrogen supply, equipment for filling, training for staff |

| Aviation | Nitrogen filling for aircraft tires | Enhanced safety through stable tire pressure and reduced risk of blowouts | Compliance with aviation standards, specialized filling equipment |

| Transportation & Logistics | Nitrogen inflation for fleet vehicles | Decreased downtime due to fewer tire-related issues | Bulk nitrogen sourcing, regular monitoring and maintenance protocols |

| Mining and Heavy Machinery | Inflating tires for heavy equipment | Increased operational efficiency and reduced tire wear | Durable tire solutions, availability of nitrogen filling stations on-site |

| Motorsport | Nitrogen filling for racing tires | Consistent tire performance under varying temperature conditions | Specialized equipment, rapid filling solutions, and training for technicians |

In the automotive manufacturing sector, nitrogen is increasingly used to fill tires during vehicle production. This application provides improved tire longevity and reduces maintenance costs for manufacturers. Buyers in this sector should consider the reliability of nitrogen supply, the necessary equipment for filling, and the training of staff to handle nitrogen filling processes efficiently.

In aviation, nitrogen inflation of aircraft tires is critical for safety. The stable pressure provided by nitrogen minimizes the risk of blowouts, which is paramount in this industry. Buyers must ensure compliance with strict aviation standards, acquire specialized filling equipment, and maintain regular inspections to guarantee tire integrity.

For the transportation and logistics industry, filling fleet vehicles’ tires with nitrogen can significantly decrease downtime related to tire maintenance. The reduced frequency of tire refills leads to lower operational costs. Buyers should focus on sourcing bulk nitrogen reliably and implementing regular monitoring and maintenance protocols to ensure optimal tire performance across their fleet.

In mining and heavy machinery, nitrogen inflation is essential for the tires of heavy equipment used in harsh environments. This practice increases operational efficiency and reduces tire wear, which is crucial for minimizing costs in resource extraction. Buyers need to consider durable tire solutions and the availability of nitrogen filling stations on-site to support continuous operations.

Lastly, in the motorsport industry, nitrogen is preferred for racing tires due to its ability to maintain consistent pressure despite temperature fluctuations. This consistency is vital for performance and safety during races. Buyers should invest in specialized equipment for quick nitrogen filling and ensure their technicians are trained to handle these processes effectively, optimizing tire performance on the track.

The Problem: For B2B buyers, particularly those in industries reliant on vehicle fleets, the cost of switching to nitrogen tire inflation can be daunting. Many are hesitant to invest in nitrogen systems due to the initial setup costs associated with purchasing tanks, regulators, and filling equipment. Additionally, there is uncertainty regarding the long-term savings versus traditional compressed air. This financial concern can lead to delays in decision-making or a reluctance to adopt nitrogen inflation altogether, impacting operational efficiency.

The Solution: To effectively manage costs while transitioning to nitrogen inflation, buyers should first conduct a thorough cost-benefit analysis. Evaluate the current expenses related to tire maintenance, including frequent refills and potential tire wear due to pressure fluctuations. Then, compare these figures against the expected savings from longer-lasting tire pressure stability with nitrogen. Sourcing nitrogen from local welding supply companies or gas distributors can also mitigate costs. Consider negotiating bulk purchase agreements or using nitrogen generators that produce nitrogen on-site, which can significantly lower ongoing costs. Additionally, businesses should educate their teams on the advantages of nitrogen to justify the initial investment, reinforcing the long-term savings and safety benefits of nitrogen-filled tires.

The Problem: Many B2B buyers may lack the technical know-how regarding the proper procedures for inflating tires with nitrogen. This can lead to improper inflation techniques that negate the benefits of nitrogen use. For instance, if tires are not purged of air properly before filling, the remaining oxygen can still lead to pressure fluctuations and moisture issues, undermining the advantages of nitrogen.

Illustrative image related to how to inflate tires with nitrogen

The Solution: To overcome this challenge, businesses should invest in training programs for staff involved in tire maintenance. This training should cover the importance of completely deflating tires and purging them of air before filling with nitrogen. Providing clear, step-by-step protocols for the inflation process will enhance adherence to best practices. Additionally, acquiring equipment with dual valve systems allows for more efficient purging and filling processes. Consider collaborating with suppliers who offer technical support or workshops on nitrogen tire inflation, ensuring that all personnel are well-versed in the necessary procedures. This investment in education will ensure that the benefits of nitrogen are fully realized, leading to safer and more efficient operations.

The Problem: In regions such as Africa and South America, where environmental regulations are becoming increasingly stringent, B2B buyers may face scrutiny regarding the environmental impact of using nitrogen for tire inflation. Concerns about the carbon footprint associated with transporting nitrogen tanks or the energy consumption of nitrogen generation systems can create hesitance in adopting this technology.

The Solution: To alleviate these environmental concerns, businesses should focus on sustainable practices associated with nitrogen usage. First, investigate local sources for nitrogen to minimize transportation-related emissions. If using nitrogen generation systems, consider investing in energy-efficient models powered by renewable energy sources. Additionally, companies can implement a comprehensive sustainability plan that includes reducing overall tire waste by extending tire life through proper inflation practices. Sharing these initiatives with stakeholders can enhance corporate social responsibility efforts and improve brand reputation. Engaging with environmental consultants can further guide businesses in aligning their nitrogen usage with best practices in sustainability, ensuring compliance with regulations while also contributing to broader environmental goals.

Illustrative image related to how to inflate tires with nitrogen

When considering the inflation of tires with nitrogen, several materials play crucial roles in the process. Each material has distinct properties, advantages, and disadvantages that can impact performance and suitability for various applications. Below, we analyze four common materials used in nitrogen tire inflation systems: aluminum, steel, rubber, and composite materials.

Key Properties: Aluminum is lightweight and resistant to corrosion, making it an ideal choice for components such as nitrogen tanks and valves. It can withstand high pressures, typically rated up to 3000 psi, which is suitable for tire inflation.

Pros & Cons: The main advantage of aluminum is its low weight, which reduces the overall system weight, enhancing portability. However, aluminum can be more expensive than steel and may require specific manufacturing processes, such as anodizing, to enhance its corrosion resistance.

Impact on Application: Aluminum’s compatibility with nitrogen makes it suitable for high-performance applications, such as motorsports. However, it may not be as durable as steel under extreme conditions.

Considerations for International Buyers: Compliance with international standards like ASTM and DIN is critical. Buyers in regions such as Europe and South America should ensure that the aluminum used meets local regulations regarding pressure vessels.

Illustrative image related to how to inflate tires with nitrogen

Key Properties: Steel is known for its strength and durability. It can handle high pressures (up to 5000 psi) and is resistant to wear and tear, making it a reliable choice for nitrogen tanks and fittings.

Pros & Cons: The primary advantage of steel is its robustness and longevity. However, steel is heavier than aluminum, which can be a drawback in portable applications. Additionally, steel is prone to corrosion if not properly treated, necessitating regular maintenance.

Impact on Application: Steel is often used in industrial applications where durability is paramount. Its weight may limit its use in consumer applications but is ideal for stationary systems.

Considerations for International Buyers: Steel components must comply with various international standards, including JIS and ASTM. Buyers should also consider the availability of maintenance services to prevent corrosion.

Key Properties: Rubber is primarily used for seals and gaskets in nitrogen inflation systems. It is flexible and can withstand a range of temperatures and pressures.

Illustrative image related to how to inflate tires with nitrogen

Pros & Cons: Rubber’s flexibility allows for a tight seal, preventing nitrogen leakage. However, it can degrade over time, especially when exposed to extreme temperatures or chemicals, necessitating regular replacement.

Impact on Application: Rubber is essential for ensuring airtight seals in tire valves. Its performance can directly affect the longevity of nitrogen-filled tires.

Considerations for International Buyers: Buyers should ensure that rubber components meet relevant standards for temperature and chemical resistance, especially in regions with extreme weather conditions, such as Africa and the Middle East.

Illustrative image related to how to inflate tires with nitrogen

Key Properties: Composite materials, often made from a combination of polymers and fibers, offer high strength-to-weight ratios and excellent resistance to environmental factors.

Pros & Cons: The main advantage of composites is their lightweight nature and resistance to corrosion. However, they can be more expensive to manufacture and may not be as readily available in some regions.

Impact on Application: Composites are increasingly used in high-performance applications where weight savings are critical, such as in racing and aerospace.

Considerations for International Buyers: International buyers should assess the availability and cost of composite materials in their regions, as well as compliance with local safety standards.

| Material | Typical Use Case for how to inflate tires with nitrogen | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Nitrogen tanks and valves | Lightweight and corrosion-resistant | Higher cost than steel | Medium |

| Steel | Industrial nitrogen tanks and fittings | High strength and durability | Heavier and prone to corrosion | Low |

| Rubber | Seals and gaskets for valves | Flexible and airtight | Degrades over time | Low |

| Composite | High-performance nitrogen tanks | Lightweight and corrosion-resistant | Higher manufacturing costs | High |

This strategic material selection guide emphasizes the importance of choosing the right materials for nitrogen tire inflation systems, considering performance, durability, and international compliance standards. By understanding the properties and implications of each material, B2B buyers can make informed decisions that align with their operational needs and regional regulations.

Illustrative image related to how to inflate tires with nitrogen

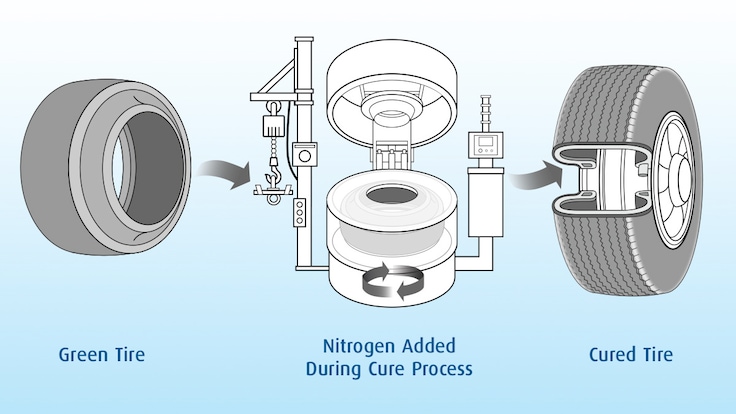

The manufacturing process for nitrogen tire inflation systems involves several key stages that ensure both efficiency and quality. The main stages include material preparation, forming, assembly, and finishing.

Material Preparation: This initial stage involves sourcing high-quality materials, including nitrogen tanks, valves, hoses, and other components. Suppliers are typically vetted based on their ability to meet international standards. In regions like Africa and South America, it is essential to consider local suppliers who can provide materials that comply with international quality standards.

Forming: During this stage, the raw materials are shaped into components that will be used in the inflation systems. This may involve processes such as machining, welding, and molding. Advanced techniques like computer numerical control (CNC) machining are often employed to ensure precision and consistency in the components produced.

Assembly: Once the individual components are formed, they are assembled into complete systems. This stage often utilizes automated assembly lines to enhance efficiency and reduce human error. Quality checks are integral at this point, ensuring that each system functions properly before moving on to the next stage.

Finishing: The final stage involves testing and preparing the systems for shipment. This includes surface treatments, painting, and final inspections. The systems are then packaged securely for transportation, ensuring they reach international buyers in optimal condition.

Quality control (QC) is a crucial aspect of the manufacturing process, particularly in industries where safety and performance are paramount. For nitrogen tire inflation systems, several international standards and industry-specific guidelines govern QC practices.

International Standards Compliance: Manufacturers typically adhere to ISO 9001, which outlines the requirements for a quality management system (QMS). Compliance with this standard indicates that the manufacturer consistently provides products that meet customer and regulatory requirements.

Industry-Specific Standards: In addition to ISO 9001, industry-specific certifications such as CE marking for the European market and API standards for oil and gas applications are often required. These certifications ensure that the products meet safety and performance standards specific to the industry.

QC Checkpoints: The QC process usually involves several key checkpoints:

– Incoming Quality Control (IQC): This initial checkpoint assesses the quality of raw materials and components before they enter the production line.

– In-Process Quality Control (IPQC): Continuous monitoring during the manufacturing process helps identify any deviations from quality standards.

– Final Quality Control (FQC): This final assessment ensures that the completed systems meet all specifications and quality standards before shipment.

Common Testing Methods: Various testing methods are employed to verify the quality of nitrogen tire inflation systems. These may include pressure tests, leak tests, and performance evaluations under simulated operating conditions.

For international B2B buyers, particularly those from diverse regions such as Africa, South America, the Middle East, and Europe, verifying supplier QC practices is essential to ensure product reliability and compliance.

Supplier Audits: Conducting audits of potential suppliers can provide valuable insights into their manufacturing processes and QC practices. Buyers should look for suppliers who are open to third-party audits as an indication of their commitment to transparency and quality.

Quality Reports: Requesting quality reports and certifications can help buyers assess whether suppliers meet international standards. These documents should detail the supplier’s adherence to relevant standards and the results of any internal quality assessments.

Third-Party Inspections: Engaging third-party inspection services can provide an additional layer of assurance. These independent agencies can conduct inspections and testing at various stages of the manufacturing process, providing unbiased evaluations of the supplier’s QC practices.

Navigating the complexities of quality control in international trade can be challenging, especially for buyers from regions like Brazil and Germany, where regulatory environments may differ significantly.

Illustrative image related to how to inflate tires with nitrogen

Understanding Regional Standards: Buyers should familiarize themselves with the specific quality standards applicable in their target markets. For example, while ISO certifications are widely recognized, additional regional certifications may be required for compliance in certain countries.

Cultural Considerations: Understanding cultural differences in business practices can also impact quality assurance. Buyers should consider how communication styles, negotiation practices, and expectations around quality may vary across different regions.

Logistics and Supply Chain Management: Ensuring that suppliers have robust logistics and supply chain management systems can significantly impact the quality of products received. Buyers should inquire about the supplier’s capabilities in managing inventory, transportation, and delivery timelines.

Building Long-Term Relationships: Establishing strong relationships with suppliers can facilitate better communication and collaboration on quality issues. Long-term partnerships often lead to improved product quality and consistency, benefiting both parties.

The manufacturing processes and quality assurance practices for nitrogen tire inflation systems are integral to ensuring that these products meet the demands of international B2B buyers. By understanding the stages of manufacturing, the importance of quality control, and how to verify supplier practices, businesses can make informed decisions that enhance their operational efficiency and product reliability. As the market for nitrogen tire inflation continues to grow, these insights will be vital for companies looking to thrive in a competitive landscape.

Inflating tires with nitrogen offers distinct advantages over traditional air filling, including improved pressure retention and reduced moisture content. This practical sourcing guide outlines the essential steps B2B buyers should follow to procure the necessary equipment and services for nitrogen tire inflation. Whether you operate in automotive services, logistics, or fleet management, understanding this process will enhance your operational efficiency and product reliability.

Before sourcing nitrogen inflation solutions, it’s essential to evaluate your specific requirements. Consider the volume of tires you inflate, the types of vehicles in your fleet, and whether you need mobile or stationary systems. Understanding these factors will help you tailor your procurement strategy to meet operational demands effectively.

Investigate the types of nitrogen inflation equipment available on the market. Options range from portable nitrogen generators to large-scale filling stations. Each option has its own set of benefits and limitations based on your operational scale.

Ensure that potential suppliers comply with industry standards and possess the necessary certifications. This is crucial for maintaining safety and operational integrity when dealing with pressurized gases.

Conduct thorough evaluations of suppliers to ascertain their reliability and capability. Request detailed company profiles, customer testimonials, and case studies relevant to your industry.

Gather quotes from multiple suppliers to understand the market price for nitrogen inflation equipment and services. Consider not just the initial purchase price but also ongoing maintenance costs and service agreements.

Illustrative image related to how to inflate tires with nitrogen

Choose suppliers that offer comprehensive training for your staff on using nitrogen inflation equipment. This training ensures that your team can operate the equipment safely and efficiently, maximizing the benefits of nitrogen filling.

Once you have selected a supplier and equipment, develop a detailed implementation plan. This should include timelines for installation, staff training, and the transition from traditional air filling to nitrogen inflation.

By following this guide, B2B buyers can effectively navigate the procurement process for nitrogen tire inflation, ensuring they make informed decisions that enhance their operational capabilities.

When considering the costs associated with inflating tires with nitrogen, several key components come into play. These include:

Illustrative image related to how to inflate tires with nitrogen

Materials: The primary material cost involves purchasing nitrogen gas, which is typically sourced from gas suppliers or welding supply companies. The price can vary significantly based on local market rates and the supplier’s pricing strategy. Additional materials may include tire inflation equipment, which can range from basic kits to more sophisticated systems.

Labor: Labor costs are incurred during the setup and operation of nitrogen filling systems. This may include training staff to use the equipment effectively and safely. Depending on the complexity of the system, ongoing maintenance may also require skilled labor.

Manufacturing Overhead: This includes costs related to the infrastructure needed to house the nitrogen filling operation. If a company chooses to invest in on-site nitrogen generation systems, the overhead can increase due to the required equipment and utilities.

Tooling: The tools necessary for tire inflation, such as gauges and regulators, contribute to the overall cost structure. Quality and precision in tooling can directly affect operational efficiency and the reliability of nitrogen fills.

Quality Control (QC): Ensuring the nitrogen filling process meets industry standards involves implementing quality control measures. This might involve periodic inspections of equipment and training staff to maintain consistent inflation pressures.

Logistics: Transporting nitrogen tanks or equipment adds logistical costs. This includes delivery fees from suppliers and potential tariffs or customs duties for international sourcing, which are particularly relevant for buyers in Africa, South America, and the Middle East.

Margin: Suppliers often build a margin into the pricing structure to cover their costs and ensure profitability. This margin can vary based on competition and market demand.

Several factors influence pricing for nitrogen tire inflation services:

Volume/MOQ: Pricing often reflects the volume of nitrogen purchased. Larger orders may qualify for bulk pricing, which is advantageous for businesses looking to reduce costs.

Specifications/Customization: Custom solutions, such as specific nitrogen purity levels or tailored filling systems, can raise costs. Buyers should assess their needs against the benefits of customization.

Materials: The quality of nitrogen and associated equipment can vary, impacting price. Higher-quality materials often yield better performance and longer service life.

Quality/Certifications: Suppliers with recognized certifications may charge a premium. Buyers should weigh the benefits of certified products against potential cost savings from non-certified options.

Supplier Factors: Supplier reputation, reliability, and service quality can influence pricing. Established suppliers may command higher prices due to their proven track record.

Incoterms: The agreed Incoterms can significantly affect costs related to shipping and delivery. Understanding these terms is essential for international buyers to avoid unexpected fees.

For B2B buyers, especially those operating across diverse markets like Africa, South America, and Europe, the following tips can enhance cost-efficiency:

Negotiation: Engage suppliers in discussions about pricing, especially if purchasing in bulk. Suppliers may offer discounts or flexible payment terms to secure larger orders.

Total Cost of Ownership (TCO): Evaluate not just the initial purchase price, but also the TCO, which includes maintenance, operational costs, and potential savings from improved tire longevity and performance.

Pricing Nuances: Be aware of regional pricing differences. For example, costs may vary significantly between European and South American markets due to local economic conditions and supplier competition.

Research Suppliers: Conduct thorough research on suppliers, comparing prices, quality, and service offerings. Look for reviews or case studies that illustrate their reliability.

Consider Alternatives: While nitrogen has benefits, evaluate whether the use of dry air could meet your needs at a lower cost, particularly in less critical applications.

Prices mentioned in this analysis are indicative and can fluctuate based on market conditions, supplier negotiations, and specific buyer requirements. Always consult with multiple suppliers to obtain accurate pricing tailored to your specific needs.

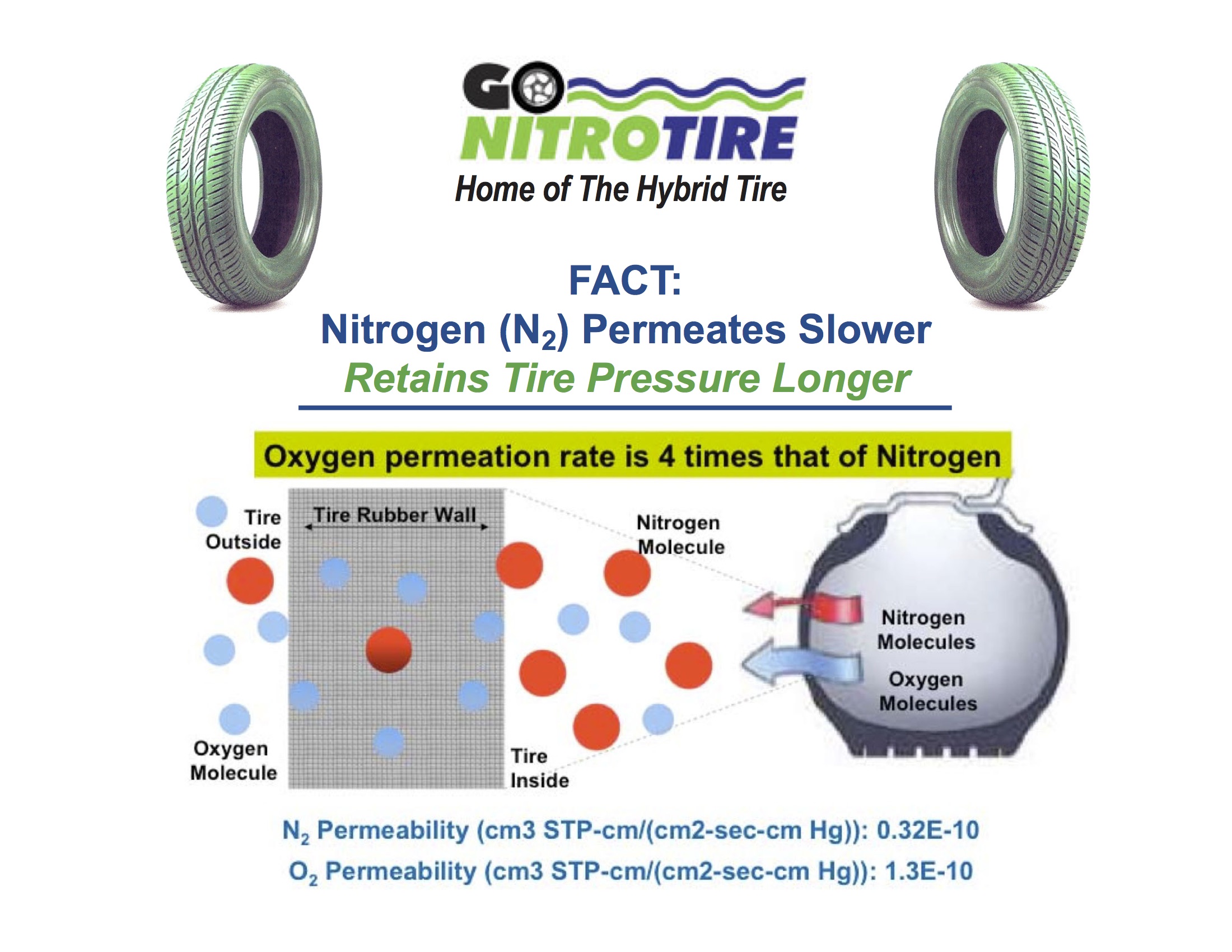

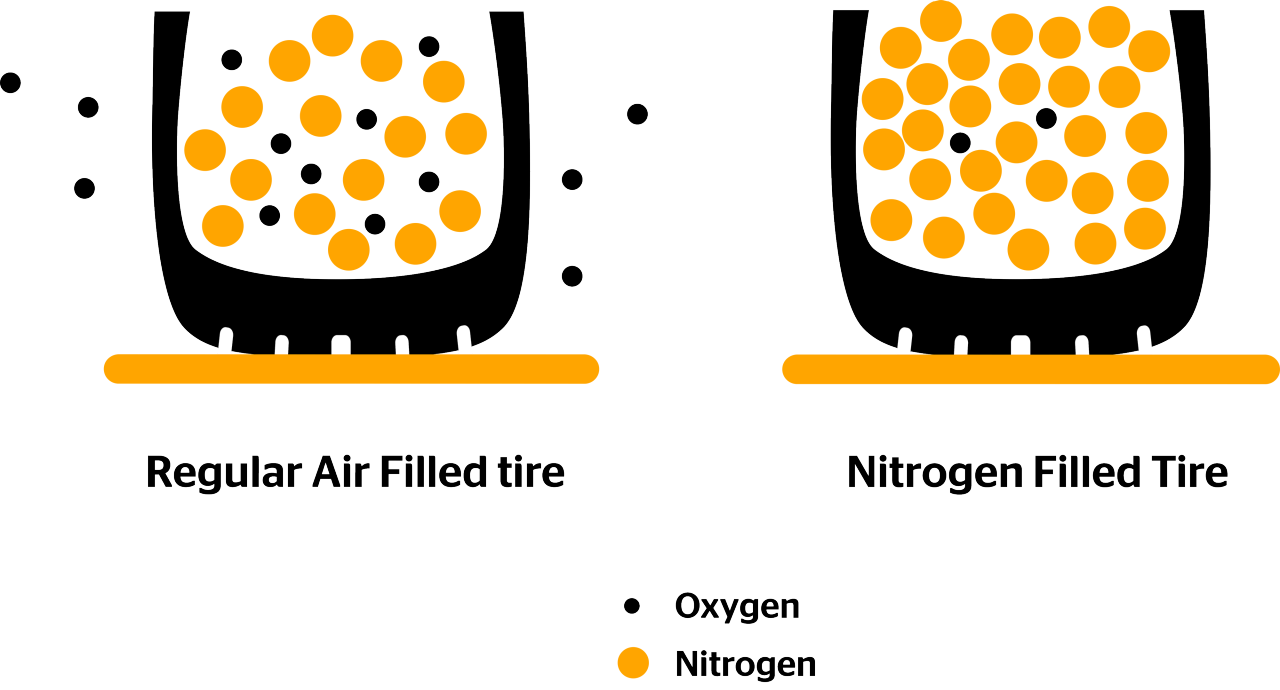

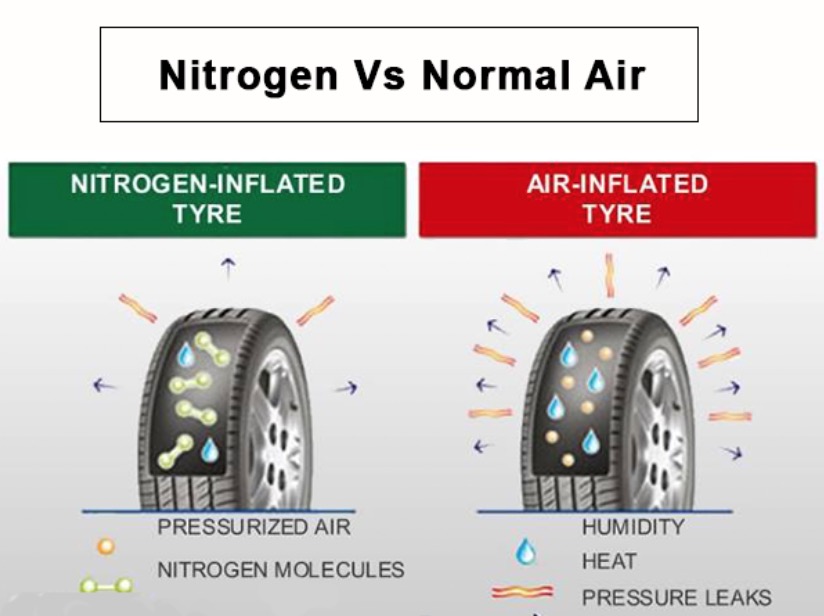

In the realm of tire inflation, nitrogen has gained popularity due to its unique properties, such as reduced moisture content and slower pressure loss compared to conventional air. However, several alternative methods exist that also offer advantages depending on specific operational needs and contexts. This analysis aims to provide a comparative overview of nitrogen inflation against other viable tire inflation solutions to assist B2B buyers in making informed decisions.

Illustrative image related to how to inflate tires with nitrogen

| Comparison Aspect | How To Inflate Tires With Nitrogen | Alternative 1: Compressed Air | Alternative 2: Dry Air Technology |

|---|---|---|---|

| Performance | Slower pressure loss; stable under temperature changes | Faster pressure loss; affected by moisture | Similar stability to nitrogen; moisture-free |

| Cost | Higher initial investment for equipment and nitrogen | Lower cost; readily available | Moderate investment; requires specialized drying equipment |

| Ease of Implementation | Requires specialized equipment and training | Simple; accessible with standard compressors | More complex setup; requires air drying system |

| Maintenance | Minimal; periodic refills needed | Regular checks needed; prone to moisture buildup | Regular maintenance of drying system required |

| Best Use Case | Racing, fleets requiring consistent performance | Everyday vehicles, general use | Professional racing teams, high-performance vehicles |

Compressed air is the most commonly used method for inflating tires. Its primary advantage lies in its availability and cost-effectiveness. Air compressors are widely accessible and relatively inexpensive, making this method suitable for everyday vehicles and general use. However, the presence of moisture in compressed air can lead to pressure fluctuations and quicker tire degradation, especially in humid conditions. For businesses with less stringent performance requirements, using compressed air is a viable and economical solution.

Dry air technology involves using specialized equipment to remove moisture from the air before inflating tires. This method can offer similar performance benefits to nitrogen, as it minimizes the negative impact of moisture on tire pressure stability. The initial investment is moderate, as businesses need to acquire air drying systems, which can be complex and require ongoing maintenance. This solution is particularly suited for professional racing teams or organizations that demand high performance and reliability from their tires but may not be feasible for smaller operations due to cost and complexity.

When selecting a tire inflation method, B2B buyers should consider their specific operational needs, performance requirements, and budget constraints. For businesses involved in high-performance racing or fleets where consistent tire pressure is critical, nitrogen inflation or dry air technology may provide the best long-term benefits. Conversely, for everyday operations or businesses with less demanding performance needs, compressed air remains a practical and cost-effective choice. Ultimately, the right solution will depend on the balance between performance, cost, and ease of implementation tailored to the unique requirements of the buyer’s operations.

When it comes to inflating tires with nitrogen, understanding the essential technical properties is crucial for making informed purchasing decisions. Here are some key specifications that B2B buyers should consider:

Purity Level of Nitrogen (N2)

– Definition: The percentage of nitrogen in the gas mixture. Ideally, nitrogen used for tire inflation should be at least 95% pure.

– Importance: Higher purity levels reduce the moisture content in the tire, leading to more consistent tire pressure over time. This is particularly vital in industries where performance and safety are paramount, such as aviation and motorsports.

Pressure Rating

– Definition: The maximum pressure that a tire can safely handle, usually measured in PSI (pounds per square inch).

– Importance: Knowing the appropriate pressure rating ensures that tires are inflated correctly, preventing blowouts and extending tire life. This information is essential for businesses that rely on transportation or logistics.

Leak Rate

– Definition: The rate at which gas escapes from the tire, typically measured in PSI per month.

– Importance: Nitrogen has a lower leak rate compared to regular air, which means tires will maintain optimal pressure for a longer period. Businesses can benefit from reduced maintenance costs and improved fuel efficiency due to better tire performance.

Temperature Stability

– Definition: The ability of nitrogen to maintain consistent pressure across temperature variations.

– Importance: Tires filled with nitrogen experience less pressure fluctuation with temperature changes. This characteristic is critical for companies operating in regions with extreme weather conditions, ensuring better traction and safety.

Moisture Content

– Definition: The amount of water vapor present in the gas mixture.

– Importance: Low moisture content is essential to prevent tire degradation and maintain consistent pressure. In humid environments, this property becomes even more vital, influencing tire performance and longevity.

Understanding industry jargon can help B2B buyers navigate the procurement process more effectively. Here are some common terms related to nitrogen tire inflation:

OEM (Original Equipment Manufacturer)

– Definition: A company that produces parts and equipment that may be marketed by another manufacturer.

– Relevance: OEMs often have specifications for tire inflation methods that can affect warranty and performance. Understanding this term helps buyers align with manufacturer requirements.

MOQ (Minimum Order Quantity)

– Definition: The smallest quantity of a product that a supplier is willing to sell.

– Relevance: Knowing the MOQ is essential for budget planning and supply chain management, especially for businesses that may not require large volumes of nitrogen at once.

RFQ (Request for Quotation)

– Definition: A standard business process where a company solicits price quotes from suppliers for specific products or services.

– Relevance: An RFQ can help businesses obtain competitive pricing for nitrogen filling services, ensuring they make cost-effective decisions.

Incoterms (International Commercial Terms)

– Definition: A set of predefined international trade terms published by the International Chamber of Commerce (ICC).

– Relevance: Understanding Incoterms helps buyers clarify shipping responsibilities and costs, crucial for international transactions involving nitrogen tanks or filling services.

Tire Pressure Monitoring System (TPMS)

– Definition: An electronic system that monitors the air pressure inside the tires.

– Relevance: TPMS can alert businesses to tire pressure issues, making it easier to manage tire maintenance and safety effectively.

By familiarizing themselves with these technical properties and trade terms, B2B buyers can make better decisions regarding nitrogen tire inflation, ultimately enhancing their operational efficiency and safety.

The market for nitrogen tire inflation is experiencing notable growth, driven by increasing awareness of the benefits associated with nitrogen over traditional air filling. One of the primary global drivers is the automotive sector’s push for improved fuel efficiency and tire longevity. Nitrogen’s lower permeability compared to air helps maintain tire pressure for longer periods, which can result in enhanced fuel efficiency and reduced tire wear. This trend is particularly relevant for commercial fleets and high-performance vehicles, where operational costs are closely monitored.

In terms of B2B technology and sourcing trends, the market is seeing a rise in the availability of portable nitrogen generation units. These systems allow businesses to produce nitrogen on-site, reducing dependency on external suppliers and potentially lowering costs. Additionally, e-commerce platforms are emerging as a vital channel for buyers in regions like Africa and South America, facilitating access to nitrogen filling equipment and maintenance services. Buyers are increasingly looking for suppliers who can provide comprehensive solutions, including training on nitrogen filling techniques and equipment maintenance.

Illustrative image related to how to inflate tires with nitrogen

The dynamics of the nitrogen tire inflation market are also shaped by regional considerations. In Europe, for example, stringent regulations on emissions and fuel consumption are accelerating the adoption of nitrogen filling. Conversely, in emerging markets, the focus remains on cost-effectiveness, prompting suppliers to emphasize the long-term savings associated with nitrogen use. International B2B buyers are advised to stay informed about local regulations and the unique market conditions in their respective regions to make informed sourcing decisions.

The environmental impact of nitrogen tire inflation is a growing concern among B2B buyers. While nitrogen itself is inert and does not contribute to pollution, the sustainability of the supply chain plays a critical role in minimizing the overall carbon footprint. Suppliers that prioritize sustainable practices, such as using renewable energy sources for nitrogen generation and employing eco-friendly materials for tire maintenance products, are gaining traction in the market.

Ethical sourcing is becoming increasingly important, with buyers looking for suppliers who can demonstrate a commitment to responsible practices. This includes transparency in the supply chain and adherence to international standards for environmental sustainability. Companies that hold certifications such as ISO 14001 for environmental management systems can enhance their credibility and attract environmentally conscious buyers.

In addition, the trend towards green certifications is influencing product development in the nitrogen tire inflation sector. Suppliers are innovating by developing nitrogen generation systems that are more energy-efficient and reduce waste. These advancements not only contribute to sustainability but also align with the growing consumer demand for environmentally friendly products and practices.

The use of nitrogen for tire inflation dates back to the early 20th century, primarily in aviation and motorsport applications where performance and safety are paramount. Initially, nitrogen was favored due to its non-flammable nature and minimal moisture content, which helps in maintaining tire pressure under extreme conditions. Over the decades, the benefits of nitrogen filling have been recognized in the automotive sector, leading to its adoption in consumer vehicles and commercial fleets.

In recent years, the proliferation of nitrogen filling stations and the development of portable nitrogen generation units have made it easier for B2B buyers to access this technology. As awareness of the advantages of nitrogen over traditional air filling continues to grow, the market is expected to evolve further, with more suppliers entering the fray and offering innovative solutions tailored to the needs of international buyers. This historical context underscores the importance of nitrogen tire inflation as a vital component of modern automotive and fleet management practices.

How do I choose the right nitrogen filling equipment for my business?

Selecting the appropriate nitrogen filling equipment involves assessing your specific business needs, such as tire types, volume, and inflation frequency. Look for equipment that offers efficiency, reliability, and scalability. Consider options with built-in pressure regulators and moisture filters to ensure optimal tire performance. Research suppliers that provide comprehensive support and maintenance services, as well as favorable warranty terms. Comparing different brands and models, along with customer reviews, can also help you make an informed decision.

What are the benefits of using nitrogen over air for tire inflation?

Using nitrogen for tire inflation offers several advantages, including reduced pressure loss over time, improved tire life, and enhanced fuel efficiency. Nitrogen is less reactive than oxygen, minimizing oxidation and degrading of the tire rubber. Additionally, nitrogen-filled tires maintain more consistent pressure under varying temperature conditions, which is crucial for businesses operating in regions with extreme climate fluctuations. This stability can lead to better handling and safety, especially for commercial fleets.

How do I verify the quality of nitrogen supplied by my vendor?

To ensure the quality of nitrogen from your vendor, request documentation of purity levels, ideally 95% or higher, which can be verified through third-party testing. Assess the vendor’s certifications, such as ISO or industry-specific standards, to confirm adherence to quality protocols. Additionally, inquire about their nitrogen production process, including any filtration systems used to remove moisture and contaminants. Regular quality audits and feedback from other B2B clients can further help gauge supplier reliability.

What are the typical minimum order quantities (MOQ) for nitrogen filling equipment?

Minimum order quantities for nitrogen filling equipment can vary significantly based on the supplier and the type of equipment. Some manufacturers may offer MOQ as low as one unit for specialized equipment, while others might require larger bulk purchases to ensure cost-effectiveness. It’s essential to discuss your specific needs with suppliers and negotiate terms that align with your business operations. Additionally, consider suppliers that offer flexible options or trial periods to reduce upfront commitments.

What payment terms should I expect when sourcing nitrogen filling solutions?

Payment terms for nitrogen filling solutions can differ by supplier and region. Common practices include net 30, net 60, or payment upon delivery. Some suppliers may also offer discounts for early payments or bulk orders. It’s crucial to establish clear terms upfront, including any deposit requirements and financing options. Investigate suppliers that provide transparent pricing structures and are open to negotiations, especially if you plan to establish a long-term partnership.

How do I ensure compliance with international trade regulations when importing nitrogen equipment?

To ensure compliance with international trade regulations, first familiarize yourself with the import laws of your country and the exporting country. This includes understanding tariffs, customs duties, and safety standards applicable to nitrogen filling equipment. Collaborate with experienced customs brokers who can assist in navigating complex regulations. Additionally, ensure that your supplier provides all necessary documentation, such as certificates of origin and compliance, to facilitate smooth customs clearance.

What logistics considerations should I keep in mind when importing nitrogen equipment?

When importing nitrogen equipment, consider logistics factors such as shipping methods, timelines, and costs. Evaluate whether air freight or sea freight is more suitable based on your urgency and budget. Ensure that the equipment is packed securely to prevent damage during transit. Additionally, plan for potential delays by establishing buffer periods in your supply chain. Collaborating with reliable freight forwarders can streamline the logistics process and help manage any challenges that arise.

How can I customize nitrogen filling solutions for my specific business needs?

Customization of nitrogen filling solutions can often be achieved through discussions with suppliers about your specific requirements, such as equipment size, pressure range, and integration with existing systems. Many manufacturers offer bespoke solutions that can include additional features like automated filling systems or mobile units. Engage with the supplier early in the procurement process to explore available options and ensure that the final product aligns with your operational goals and technical specifications.

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Costco offers nitrogen inflation for tires; some garages and quick lube places also provide this service. Regular air can be used to inflate nitrogen-filled tires, but it will dilute the nitrogen. The cost mentioned is $19.99 per tire for premium regular air.

Domain: grassrootsmotorsports.com

Registered: 1999 (26 years)

Introduction: Filling tires with nitrogen can help maintain consistent pressure during temperature fluctuations, as nitrogen has no moisture content and pressure increases predictably with temperature. Nitrogen is less reactive than oxygen, which may benefit the rubber inside the tire. While nitrogen can reduce the rate of pressure loss compared to air, the difference is marginal. Some users suggest that using …

Domain: study.com

Registered: 1995 (30 years)

Introduction: Nitrogen in tires is a filling option that offers several benefits over regular air. The average cost for filling tires with nitrogen ranges from five to ten dollars per tire. Nitrogen-filled tires should contain at least 95% nitrogen to maximize benefits, although mixing with regular air is permissible. Key advantages include reduced tire pressure changes, improved fuel economy, decreased rolling…

Domain: garagejournal.com

Registered: 2006 (19 years)

Introduction: Nitrogen for tire inflation at home involves using a setup with a tank, regulator, and hose to fill tires without returning to a tire center. Some users express skepticism about the benefits of nitrogen over regular air, noting that air is already 80% nitrogen. Benefits mentioned include reduced water vapor, thermal stability, fewer leaks, inhibiting rust inside wheels, and potentially better gas …

Domain: mechanics.stackexchange.com

Registered: 2009 (16 years)

Introduction: Filling nitrogen tires with regular air is safe and will not cause the car to blow up. The main benefits of nitrogen filling include: 1. Lesser variation in pressure with tire temperature changes. 2. Reduced chances of corrosion to the valves and rims due to the absence of oxygen and moisture. If switching back to pure nitrogen, all air must be purged, which can be costly. Regular air is 78% nitro…

In conclusion, incorporating nitrogen into tire inflation processes presents several strategic advantages for businesses, particularly those operating in regions with fluctuating temperatures and humidity levels. The stability of nitrogen-filled tires minimizes pressure variations, leading to improved fuel efficiency, enhanced tire lifespan, and ultimately lower operational costs. Additionally, nitrogen’s reduced permeability compared to air translates into less frequent refilling, which can be particularly beneficial for fleets and high-usage vehicles.

Strategic sourcing is vital in optimizing the procurement of nitrogen filling equipment and services. International buyers should seek reliable suppliers that offer quality nitrogen inflation systems and support tailored to their specific operational needs. Establishing partnerships with local welding supply companies can also streamline the supply chain and reduce costs associated with nitrogen tank refills.

Looking ahead, businesses in Africa, South America, the Middle East, and Europe should actively explore the integration of nitrogen tire inflation into their operations. By investing in this technology, companies can not only improve their fleet performance but also align with global sustainability goals. Engage with suppliers now to ensure your organization remains competitive in an evolving market that increasingly values efficiency and cost-effectiveness.

Illustrative image related to how to inflate tires with nitrogen

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.