In the rapidly evolving landscape of transportation logistics, sourcing reliable air pumps for truck tires is a critical challenge for international B2B buyers. With the demand for efficient and durable inflators rising across diverse markets, including Africa, South America, the Middle East, and Europe, understanding the nuances of product selection becomes paramount. This comprehensive guide delves into the various types of air pumps available, their specific applications, and essential criteria for supplier vetting, ensuring that decision-makers can confidently navigate their purchasing journey.

The guide explores the latest technological advancements in tire inflators, offering insights into performance metrics such as pressure capabilities, portability, and additional features that enhance usability. Additionally, it provides a detailed overview of cost considerations, enabling buyers to balance quality with budgetary constraints. By addressing common pain points such as product reliability and supplier trustworthiness, this resource empowers B2B purchasers to make informed decisions that align with their operational needs and market demands.

Whether you are seeking to enhance your fleet’s efficiency or ensure the safety of your vehicles, this guide serves as an essential tool for sourcing the right air pumps for truck tires. Leverage our insights to optimize your procurement strategy and secure a competitive edge in your respective market.

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Portable Air Compressors | Compact, battery-operated, suitable for on-the-go use | Small fleets, maintenance services | Pros: Easy to transport, versatile; Cons: Limited power for larger tires. |

| Heavy-Duty Air Compressors | High PSI output, designed for large tires | Heavy-duty trucking, construction | Pros: Fast inflation, durable; Cons: Bulky, may require electrical outlet. |

| Cordless Tire Inflators | Rechargeable, often lightweight and compact | Emergency roadside assistance | Pros: Convenient, no cords; Cons: Battery life may limit usage. |

| Dual-Power Inflators | Can operate on both battery and AC power | Workshops, garages | Pros: Versatile power options; Cons: Heavier, more complex. |

| Digital Tire Inflators | Equipped with digital pressure gauges for accuracy | Fleet management, automotive repair | Pros: Precise readings, easy to use; Cons: May be more expensive. |

Portable air compressors are designed for convenience and ease of use, making them ideal for small fleets or maintenance services that require quick tire inflation. Their compact size allows for easy transport, typically fitting within a toolbox or vehicle compartment. However, while they are versatile, they may lack the power needed for larger truck tires, limiting their effectiveness in heavy-duty applications.

Heavy-duty air compressors are specifically engineered to handle high PSI outputs, making them suitable for inflating larger tires found on trucks and construction equipment. They are often used in environments where rapid inflation is necessary, such as in trucking or construction sites. While they offer durability and speed, their bulkiness and reliance on electrical outlets can be a disadvantage for mobile applications.

Cordless tire inflators provide the ultimate convenience for emergency roadside assistance, allowing users to easily inflate tires without being tethered to a power source. Their lightweight and compact design make them easy to store in vehicles. However, potential buyers should consider battery life, as prolonged use may require recharging, which can limit their utility during extensive operations.

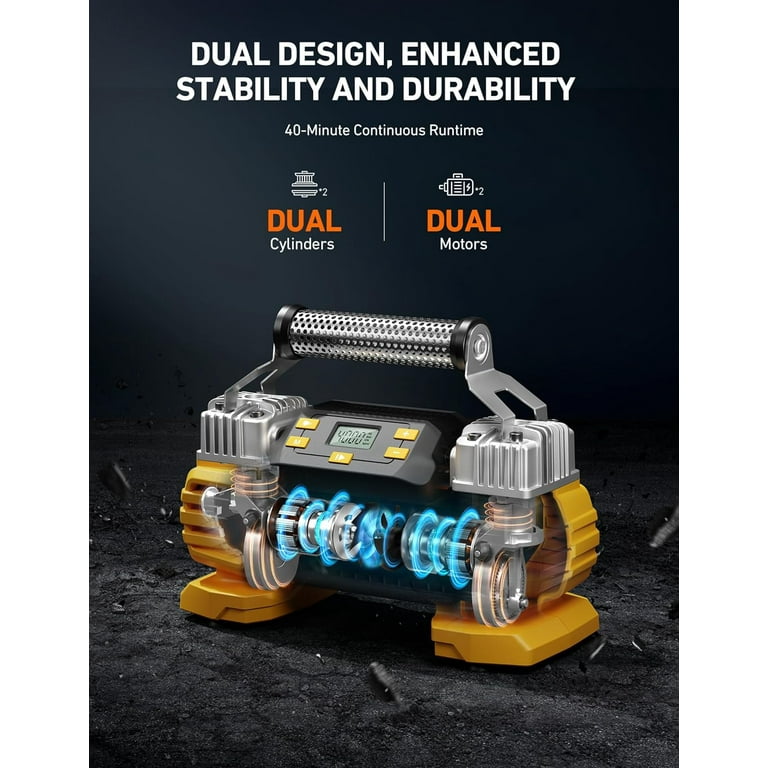

Illustrative image related to air pump for truck tires

Dual-power inflators are versatile tools that can operate on both battery and AC power, making them suitable for workshops and garages. This feature allows for flexibility in usage, accommodating both mobile and stationary applications. While they provide the benefits of both power sources, they tend to be heavier and more complex, which may not be ideal for all users.

Digital tire inflators are equipped with advanced pressure gauges that provide precise readings, ensuring that tires are inflated to the correct specifications. This accuracy is essential for fleet management and automotive repair settings, where maintaining optimal tire pressure can enhance vehicle performance and safety. Although they may come at a higher cost, the benefits of ease of use and precision make them a worthwhile investment for serious buyers.

| Industry/Sector | Specific Application of air pump for truck tires | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Logistics and Transportation | Regular tire maintenance for fleets | Improved fuel efficiency and reduced downtime | Capacity to inflate high-pressure tires, durability, and portability |

| Construction | Tire inflation for heavy machinery and trucks | Enhanced safety and productivity on job sites | Compatibility with various tire sizes, robust design for rugged environments |

| Agriculture | Inflation of tires on agricultural vehicles | Increased operational efficiency and reduced tire wear | Ability to handle different tire pressures, ease of use in remote areas |

| Mining | Tire inflation for mining trucks and equipment | Minimization of tire-related failures and accidents | High PSI capability, ruggedness, and reliability under extreme conditions |

| Emergency Services | Quick inflation for rescue and emergency vehicles | Timely response and operational readiness | Speed of inflation, battery-powered options for mobility, and compact design |

In the logistics and transportation sector, air pumps for truck tires are essential for maintaining the optimal pressure of fleet vehicles. Regular tire maintenance ensures better fuel efficiency and minimizes downtime due to flat tires. Buyers in this sector should prioritize inflators that can handle high tire pressures and offer portability, making it easier for drivers to maintain tire health on the go, especially in regions with limited access to service stations.

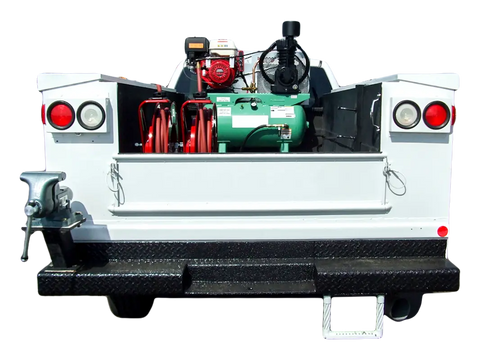

In construction, tire inflation is critical for heavy machinery and trucks that operate on job sites. Properly inflated tires enhance safety and productivity, reducing the risk of accidents and equipment failure. Businesses should seek air pumps that can accommodate a range of tire sizes and pressures, as well as those built to withstand harsh environmental conditions typical of construction sites.

Illustrative image related to air pump for truck tires

The agriculture industry relies heavily on vehicles for various tasks, from transporting goods to fieldwork. Air pumps are used to inflate tires on agricultural machinery, ensuring operational efficiency and reducing wear on tires. Buyers in this sector need inflators that are user-friendly and capable of handling different tire pressures, as many agricultural vehicles operate in remote areas where access to traditional service is limited.

In mining, the use of air pumps for inflating tires on trucks and heavy equipment is vital for safety and efficiency. Proper tire inflation minimizes the risk of tire-related failures that can lead to costly downtime and accidents in hazardous environments. Companies should focus on sourcing pumps with high PSI capabilities and robust designs to withstand the extreme conditions often found in mining operations.

Emergency services rely on quick and efficient tire inflation for their vehicles, which are critical for timely responses to emergencies. Air pumps that can rapidly inflate tires help maintain operational readiness and ensure that emergency vehicles are always prepared. Key considerations for sourcing include the speed of inflation, battery-powered options for mobility, and compact designs that facilitate easy storage in vehicles.

The Problem: Many B2B buyers face challenges with maintaining consistent tire pressure across their fleet of trucks. Inaccurate readings can lead to under-inflated or over-inflated tires, which not only affect vehicle performance but can also increase fuel consumption and reduce tire lifespan. This inconsistency is particularly problematic for companies operating in regions with fluctuating temperatures, as tire pressure can vary significantly with temperature changes.

The Solution: To tackle this issue, B2B buyers should invest in high-quality tire inflators equipped with digital pressure gauges that provide accurate readings. Look for models that allow for presetting the desired tire pressure, which can automatically shut off once the target is reached. Additionally, consider incorporating regular maintenance routines that include checking tire pressure at consistent intervals, particularly before long journeys or after extreme weather changes. This proactive approach not only enhances operational efficiency but also extends the life of the tires, ultimately saving costs for the business.

Illustrative image related to air pump for truck tires

The Problem: Many international businesses operate in diverse terrains where access to power sources can be limited. Buyers often find themselves in situations where traditional air pumps are impractical due to their size or reliance on a constant power supply. This can lead to downtime when trucks are unable to operate due to flat tires, affecting delivery schedules and customer satisfaction.

The Solution: Investing in portable, battery-operated air pumps designed specifically for truck tires can alleviate this pain point. Buyers should seek out inflators that offer a robust battery life, capable of inflating multiple tires on a single charge. Models like the AstroAI Cordless Tire Inflator provide flexibility and convenience. In addition, opting for units with a lightweight design and carrying cases can enhance mobility. Establishing a protocol for ensuring these portable pumps are always available in vehicles can minimize downtime and ensure continuous operations.

The Problem: Selecting the appropriate air pump can be daunting for B2B buyers managing a fleet of trucks, especially when dealing with varying tire sizes and inflation requirements. Many inflators on the market are designed for standard vehicles and may not meet the high-pressure needs of heavy-duty trucks. This mismatch can lead to inefficiencies and frustration during inflation tasks.

The Solution: To overcome this challenge, buyers should conduct thorough research and testing before making a purchase. Focus on inflators that specify their compatibility with heavy-duty tires and can achieve higher PSI levels, such as the Viair 88P. It’s crucial to evaluate the inflator’s performance through hands-on testing to ensure it meets the demands of the fleet. Additionally, consider the inflator’s duty cycle and whether it can handle continuous use without overheating. Establishing a standardized selection process that includes feedback from drivers can help ensure that the chosen equipment meets operational needs effectively. By prioritizing heavy-duty specifications, businesses can streamline their tire maintenance processes and enhance overall fleet reliability.

When selecting materials for air pumps designed for truck tires, B2B buyers must consider various factors that influence performance, durability, and compliance with international standards. Below is an analysis of common materials used in the manufacturing of these pumps, focusing on their properties, advantages, disadvantages, and specific considerations for international markets.

Illustrative image related to air pump for truck tires

Aluminum is a widely used material in air pump construction due to its favorable properties. It boasts a high strength-to-weight ratio, making it lightweight yet durable. Aluminum can withstand temperatures up to 150°C (302°F) and pressures exceeding 100 psi, which is essential for tire inflation. Additionally, it exhibits good corrosion resistance, particularly when anodized, which enhances its longevity in various environments.

Pros and Cons:

The primary advantage of aluminum is its lightweight nature, which improves portability. It is also relatively cost-effective compared to other metals. However, aluminum can be prone to denting and scratching, which may affect aesthetics and functionality over time. Manufacturing processes for aluminum can be more complex, requiring specialized equipment and techniques.

Impact on Application:

Aluminum is compatible with air and nitrogen, making it suitable for inflating truck tires. However, it may not be the best choice for applications involving aggressive chemicals or extreme temperatures.

Steel, particularly stainless steel, is another common material used in air pump construction. It offers excellent strength and durability, withstanding high pressures and temperatures up to 300°C (572°F). Stainless steel is also resistant to corrosion, making it ideal for harsh environments.

Pros and Cons:

The key advantage of steel is its robustness and resistance to wear and tear, ensuring a longer lifespan for the pump. However, steel is heavier than aluminum, which may reduce portability. The cost of stainless steel is generally higher than aluminum, and the manufacturing process can be more complex due to the need for welding and finishing.

Illustrative image related to air pump for truck tires

Impact on Application:

Steel is suitable for heavy-duty applications, including commercial trucks operating in diverse climates. It is compatible with various gases and can handle high-pressure requirements effectively.

Plastic materials, particularly high-density polyethylene (HDPE) and polycarbonate, are increasingly being used in air pump designs. They are lightweight and can be molded into complex shapes, offering design flexibility. Plastics typically have a temperature rating of around 80°C (176°F) and can handle moderate pressures.

Pros and Cons:

The main advantage of plastic is its lightweight nature and resistance to corrosion, making it ideal for portable applications. However, plastics may not withstand high pressures as effectively as metals, which can limit their use in heavy-duty applications. Additionally, plastics can degrade under UV exposure, which may be a concern in sunny regions.

Impact on Application:

Plastic air pumps are suitable for light-duty applications and are often used in consumer-grade products. They may not be ideal for heavy-duty truck tire inflation but are excellent for personal vehicles or recreational use.

Illustrative image related to air pump for truck tires

Rubber is commonly used for seals, hoses, and gaskets in air pumps due to its flexibility and excellent sealing properties. It can withstand temperatures ranging from -40°C to 100°C (-40°F to 212°F) and is resistant to many chemicals.

Pros and Cons:

Rubber’s primary advantage is its ability to create airtight seals, preventing air leaks during inflation. However, rubber can degrade over time due to exposure to ozone and UV light, necessitating regular inspections and replacements. The cost of rubber components is typically low, but they may require more frequent maintenance.

Impact on Application:

Rubber components are essential for ensuring the efficiency and reliability of air pumps, particularly in environments with varying temperatures and humidity levels.

| Material | Typical Use Case for air pump for truck tires | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Lightweight portable air pumps | High strength-to-weight ratio | Prone to dents and scratches | Medium |

| Steel | Heavy-duty commercial air pumps | Excellent durability and strength | Heavier and more expensive | High |

| Plastic | Consumer-grade air pumps | Lightweight and corrosion-resistant | Limited pressure tolerance | Low |

| Rubber | Seals and hoses in air pumps | Creates airtight seals | Degrades over time with exposure | Low |

This analysis provides B2B buyers with critical insights into material selection for air pumps, helping them make informed decisions that align with their operational needs and regional compliance requirements.

Manufacturing air pumps for truck tires involves several distinct stages, each critical to ensuring the final product meets performance and safety standards. The primary stages include material preparation, forming, assembly, and finishing.

Illustrative image related to air pump for truck tires

The process begins with the careful selection and preparation of raw materials. High-quality metals, plastics, and rubber are typically chosen for their durability and performance characteristics. Suppliers must ensure that these materials comply with international standards, such as ISO 9001, which dictates quality management systems. Pre-manufacturing testing is often conducted to assess the materials’ tensile strength, flexibility, and resistance to wear and tear.

Once the materials are prepared, the next stage is forming. This can involve techniques such as injection molding for plastic components and stamping or machining for metal parts. For instance, the casing of the air pump might be molded into shape, while the internal mechanisms, such as pistons and valves, may be precision-machined. Advanced technologies like CNC machining are increasingly used to enhance accuracy and reduce production times.

After forming, the assembly stage combines all components into a finished product. This stage often utilizes automated assembly lines to enhance efficiency. Each component, from the motor to the pressure gauge, is meticulously integrated. Attention to detail is critical here, as improper assembly can lead to failures in performance or safety.

The finishing stage includes surface treatments, painting, and final quality checks. Components may undergo processes such as anodizing or powder coating to enhance durability and resistance to environmental factors. Final assembly often includes the installation of additional features like digital pressure gauges, LED lights, and power adapters, which are increasingly expected by consumers.

Quality assurance is crucial in the manufacturing of air pumps for truck tires, ensuring that products not only meet regulatory standards but also perform reliably in various conditions.

International standards such as ISO 9001 are fundamental in establishing a framework for quality management systems. For air pumps, additional certifications may be required depending on the target market. For example, CE marking is crucial for products sold in Europe, indicating compliance with health and safety standards, while API (American Petroleum Institute) certifications may be relevant for pumps used in conjunction with oil and gas applications.

Quality control (QC) checkpoints throughout the manufacturing process include:

Incoming Quality Control (IQC): This step ensures that all raw materials meet specified standards before production begins. This can involve visual inspections and material testing.

In-Process Quality Control (IPQC): During manufacturing, operators conduct regular checks to ensure that components are being produced correctly. This may involve measurements of component dimensions and functional tests of mechanisms.

Final Quality Control (FQC): Before products are packaged and shipped, a final inspection is performed. This includes functionality tests, pressure tests, and visual inspections to ensure the product is defect-free.

For B2B buyers, especially those operating in diverse international markets, verifying a supplier’s quality control practices is essential. Here are some effective strategies:

Conducting thorough audits is a critical step in verifying a supplier’s QC processes. Buyers should request access to quality management system documentation, including ISO certifications, and review inspection reports. On-site audits provide the opportunity to assess the manufacturing environment and observe quality control practices in action.

Engaging third-party inspection services can enhance confidence in product quality. These services can perform independent evaluations at various stages of the manufacturing process, providing unbiased reports on compliance with specified standards.

Illustrative image related to air pump for truck tires

Testing methods for air pumps typically include:

Pressure Testing: Verifying that the pump can withstand its rated pressure and ensuring there are no leaks.

Performance Testing: Assessing the pump’s efficiency and speed in inflating tires under different conditions.

Durability Testing: Simulating prolonged use to ensure that the pump can operate effectively over time without failure.

International buyers must navigate specific nuances when sourcing air pumps from manufacturers. For instance, regulations may differ significantly between markets in Africa, South America, the Middle East, and Europe. Buyers should familiarize themselves with local compliance requirements and ensure that their suppliers can meet these standards.

Cultural differences can also play a role in quality expectations. For example, European buyers may place a higher emphasis on environmental sustainability and compliance, while Middle Eastern buyers might prioritize durability and performance in extreme conditions. Understanding these differences can help buyers communicate their needs effectively and select suppliers that align with their expectations.

In summary, the manufacturing processes and quality assurance practices for air pumps for truck tires are multifaceted and require careful consideration from B2B buyers. By understanding these processes and implementing robust verification strategies, buyers can ensure they procure high-quality products that meet their operational needs.

When sourcing air pumps for truck tires, it’s essential to follow a structured approach to ensure that you select the right equipment that meets your operational needs. This guide will help international B2B buyers navigate the procurement process effectively.

Illustrative image related to air pump for truck tires

Before beginning your search, clearly outline the technical specifications required for the air pump. Consider factors such as maximum pressure (psi), power source (battery-operated, 12V plug-in, or AC), and size/weight for portability. This step is crucial because different trucks may require different pump capabilities, and knowing your specifications will streamline your search.

Investigate the various types of air pumps available in the market. Look for products that cater specifically to truck tires, as they often have different requirements compared to standard car tire inflators. Evaluate brands that are well-regarded in the industry for reliability and performance.

Conduct thorough evaluations of potential suppliers to ensure they meet your business needs. Request company profiles, product catalogs, and references from businesses in similar industries. This step is vital to assess the credibility and reliability of suppliers before making a commitment.

Ensure that the air pumps comply with international quality and safety standards, especially if you are importing equipment. This is particularly important for buyers in regions with strict regulations, such as Europe or the Middle East. Compliance not only guarantees product safety but also minimizes potential legal issues.

Before finalizing your order, ask for samples or conduct product testing with a small batch. This allows you to evaluate performance firsthand and ensure that the product meets your specifications. Testing can reveal issues such as inflation speed and accuracy, which are critical for operational efficiency.

Once you have identified potential suppliers and evaluated their products, initiate negotiations regarding pricing, bulk discounts, and payment terms. This step is crucial for optimizing your budget and ensuring that you get the best value for your investment.

After negotiations, finalize your procurement plan, including quantities, delivery schedules, and payment arrangements. Document everything to ensure clarity and accountability on both sides. A well-structured procurement plan helps maintain smooth operations and strengthens supplier relationships.

Illustrative image related to air pump for truck tires

By following these steps, B2B buyers can effectively source high-quality air pumps for truck tires, ensuring operational efficiency and cost-effectiveness in their procurement strategy.

When sourcing air pumps for truck tires, understanding the cost structure is crucial for B2B buyers. The primary cost components include:

Materials: The choice of materials directly impacts the overall cost. High-quality metals and durable plastics typically increase the price but offer better performance and longevity.

Labor: Labor costs can vary significantly based on the region of production. Skilled labor in developed countries may drive costs up compared to emerging markets where labor is more affordable.

Manufacturing Overhead: This includes utilities, rent, and salaries associated with production facilities. Economies of scale can significantly reduce these costs, making it beneficial for buyers to consider larger volume orders.

Tooling: Initial costs for molds and machinery can be substantial, particularly for customized or specialized inflators. These costs are usually amortized over the production run.

Quality Control (QC): Investing in robust QC processes ensures product reliability and compliance with industry standards, which can elevate costs but reduce long-term liabilities.

Logistics: Shipping, warehousing, and handling costs must be factored in, especially for international shipments where duties and tariffs can add to the total cost.

Margin: Suppliers typically mark up prices to account for their profit margins. Understanding the market dynamics can help buyers negotiate better terms.

Several factors can affect the pricing of air pumps for truck tires:

Volume/MOQ: Suppliers often provide discounts for larger orders due to reduced handling and setup costs. Buyers should negotiate for better rates based on their purchasing power.

Specifications and Customization: Customized features such as higher PSI capabilities or specific connectors may increase the base price. Buyers should assess whether these features are necessary for their operations.

Materials: The use of premium materials can enhance durability but will also raise the cost. Balancing quality and price is vital for long-term savings.

Quality and Certifications: Products that meet international quality standards (e.g., ISO certifications) may come at a premium but can ensure safety and reliability, which is critical for heavy-duty applications.

Supplier Factors: The reputation, reliability, and location of the supplier can influence pricing. Established suppliers may charge more due to perceived quality, while newer entrants might offer competitive pricing to gain market share.

Incoterms: Understanding shipping terms (e.g., FOB, CIF) is essential. These terms dictate who bears the risk and costs at different stages of transportation, impacting the overall cost structure.

For B2B buyers, particularly those in diverse markets like Africa, South America, the Middle East, and Europe, here are actionable tips:

Illustrative image related to air pump for truck tires

Negotiate Bulk Discounts: Leverage your purchasing volume to negotiate better pricing. Suppliers are often willing to provide price breaks for larger orders.

Assess Total Cost of Ownership (TCO): Beyond the initial purchase price, consider maintenance, operational efficiency, and longevity. A higher upfront cost may result in lower TCO if the product lasts longer or requires less maintenance.

Understand Pricing Nuances in International Markets: Currency fluctuations, import duties, and local market conditions can impact final costs. Buyers should factor these into their budget and pricing negotiations.

Consider Local Suppliers: Sourcing from local manufacturers may reduce shipping costs and lead times, making it an attractive option for businesses looking to minimize expenses.

Evaluate Supplier Reliability: Opt for suppliers with proven track records and positive reviews. This can save costs associated with product returns, warranty claims, and downtime due to equipment failure.

Prices mentioned are indicative and subject to change based on market conditions, supplier negotiations, and specific product features. Always conduct thorough research and consult multiple suppliers to obtain accurate quotes tailored to your needs.

In the realm of tire maintenance, air pumps for truck tires serve a crucial function by ensuring optimal tire pressure for safety and efficiency. However, there are various alternative solutions available that may offer different advantages depending on the specific needs of businesses. This section will explore these alternatives, comparing their performance, costs, ease of implementation, maintenance requirements, and best use cases.

| Comparison Aspect | Air Pump For Truck Tires | Portable Air Compressor | Nitrogen Inflation System |

|---|---|---|---|

| Performance | Quickly inflates tires to high pressures (up to 160 psi) | Versatile for multiple vehicle types; typically slower | Maintains tire pressure longer, reduces tire wear |

| Cost | Moderate (approx. $40 – $100) | Moderate to high (approx. $50 – $300) | High initial setup (approx. $1,000 – $2,000) |

| Ease of Implementation | Simple plug-and-play operation | Requires some setup and space | Needs specialized equipment and trained personnel |

| Maintenance | Low maintenance, occasional checks needed | Moderate; depends on usage frequency | Low once installed, but requires periodic checks |

| Best Use Case | Ideal for roadside assistance and personal use | Suitable for workshops and heavy-duty applications | Best for fleet operations focused on long-term tire health |

Portable air compressors offer a versatile solution for inflating tires, applicable not only to trucks but also to various vehicle types. They are generally lightweight and can be easily transported. However, they typically inflate tires at a slower rate compared to dedicated air pumps and require a power source, which can limit their usability in remote locations. Their cost can vary significantly based on capacity and brand, making them a flexible option for businesses of different sizes.

Nitrogen inflation systems represent a premium alternative designed primarily for fleet operators looking to maximize tire longevity and performance. By filling tires with nitrogen instead of regular air, these systems help maintain tire pressure more effectively and reduce oxidation, leading to longer tire life. However, the initial investment is substantial, and the equipment requires trained personnel for operation. This solution is best suited for larger operations that can justify the upfront costs through savings on tire replacements and fuel efficiency.

When selecting the most suitable tire inflation solution, B2B buyers should carefully assess their specific operational needs and budget constraints. For businesses that require quick, on-the-go solutions, an air pump for truck tires or a portable air compressor may be the most practical choice. Conversely, those managing larger fleets might find that the long-term benefits of a nitrogen inflation system outweigh the initial costs. Ultimately, understanding the distinct advantages and limitations of each option will enable buyers to make informed decisions that align with their operational goals and financial strategies.

Understanding the technical specifications and terminology associated with air pumps for truck tires is vital for B2B buyers aiming to make informed purchasing decisions. Here’s an overview of essential properties and trade terms relevant to this industry.

Maximum Pressure (PSI)

Maximum pressure, measured in pounds per square inch (PSI), indicates the highest air pressure the pump can deliver. For truck tires, which often require higher pressure (up to 80 PSI or more), selecting a pump with adequate maximum pressure is crucial. This ensures that the pump can inflate tires effectively, promoting safety and performance on the road.

Duty Cycle

The duty cycle refers to the amount of time a pump can operate continuously before needing a cooldown period. For instance, a 25% duty cycle means the pump can run for 15 minutes but should rest for 45 minutes. Understanding the duty cycle is essential for buyers who need to inflate multiple tires in one go, as it impacts the pump’s efficiency and usability in high-demand scenarios.

Flow Rate (CFM)

The flow rate, often measured in cubic feet per minute (CFM), indicates how quickly the pump can deliver air. A higher flow rate means faster inflation, which is especially beneficial for businesses that rely on quick turnaround times for vehicle maintenance. Buyers should consider the flow rate to ensure it meets their operational needs.

Power Source

Air pumps can be powered by electricity, batteries, or vehicle power (12V). Knowing the power source is vital for ensuring compatibility with existing equipment and operational settings. For example, battery-powered pumps offer portability, while those that connect to a vehicle’s power supply may be more suitable for on-site repairs.

Material Grade

The material grade of the pump components affects durability and performance. Pumps made from high-grade metals or reinforced plastics can withstand the rigors of frequent use and harsh environments. This is particularly important for B2B buyers in regions with challenging climates or rough terrain, as it impacts the longevity and reliability of the pump.

Hose Length

The length of the hose affects the pump’s reach and versatility. A longer hose allows easier access to tires without needing to reposition the pump frequently. This feature is particularly beneficial for fleets or workshops where multiple vehicles are serviced in one location.

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. Understanding OEM relationships can help buyers identify reliable suppliers and ensure they are getting quality products that meet specific standards.

MOQ (Minimum Order Quantity)

MOQ denotes the smallest order size a supplier is willing to accept. This term is crucial for B2B buyers, as it affects inventory management and cost efficiency. Buyers should negotiate MOQs to align with their purchasing power and operational needs.

RFQ (Request for Quotation)

An RFQ is a formal document used by buyers to solicit price quotes from suppliers for specific products. Using an RFQ helps ensure that buyers receive competitive pricing and clear terms, facilitating informed decision-making.

Incoterms (International Commercial Terms)

Incoterms are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Familiarity with these terms helps B2B buyers understand shipping costs, risk management, and delivery responsibilities, which are vital for smooth international trade.

Tire Pressure Monitoring System (TPMS)

While not specific to pumps, TPMS refers to a system that alerts drivers when tire pressure is too low. Understanding TPMS can enhance the purchasing decision for air pumps, as compatibility with these systems may be a selling point.

Warranty Period

The warranty period indicates the time frame during which the manufacturer guarantees the product against defects. A robust warranty reflects confidence in the product’s quality and can be a decisive factor for buyers considering long-term investments.

By understanding these essential technical properties and trade terms, B2B buyers can make informed decisions when selecting air pumps for truck tires, ensuring they meet operational requirements and industry standards.

The air pump market for truck tires is witnessing robust growth, driven by the increasing demand for efficient and reliable tire maintenance solutions across various sectors. Key global drivers include the expanding logistics and transportation industries, particularly in regions like Africa and South America, where the growth of e-commerce and trade necessitates a dependable fleet. Additionally, rising fuel prices and a growing emphasis on vehicle maintenance are prompting fleet operators to invest in high-quality air pumps that ensure optimal tire performance and longevity.

Illustrative image related to air pump for truck tires

Emerging B2B tech trends are reshaping sourcing strategies. The integration of smart technology into tire inflators, such as digital pressure gauges and automated shut-off features, enhances usability and efficiency. Furthermore, the rise of e-commerce platforms is transforming traditional procurement processes, allowing international buyers from the Middle East and Europe to access a wider range of products and suppliers. This shift is particularly significant in markets like Saudi Arabia and Brazil, where digital transformation is rapidly advancing.

In terms of market dynamics, competition is intensifying as manufacturers innovate to differentiate their products. Companies are increasingly focusing on developing portable, lightweight, and multi-functional inflators that cater to diverse customer needs. This trend is crucial for B2B buyers looking for solutions that offer both performance and convenience, particularly in remote or challenging environments.

Sustainability is becoming a pivotal consideration for B2B buyers in the air pump for truck tires sector. The environmental impact of manufacturing processes and product lifecycle is under scrutiny, prompting companies to adopt sustainable practices. Buyers are increasingly favoring suppliers who demonstrate a commitment to reducing their carbon footprint, whether through energy-efficient manufacturing or the use of recycled materials.

Ethical sourcing is equally important, as consumers and businesses alike demand transparency in supply chains. B2B buyers can leverage this trend by seeking partnerships with manufacturers that uphold ethical labor practices and environmental standards. Certifications such as ISO 14001 (Environmental Management) and other ‘green’ certifications can serve as indicators of a supplier’s commitment to sustainability.

Moreover, the use of eco-friendly materials in the production of air pumps—such as recycled plastics and biodegradable components—can enhance a company’s brand reputation and appeal to environmentally conscious consumers. By prioritizing sustainability and ethical sourcing, B2B buyers not only contribute to a healthier planet but also align their operations with the values of their customers and stakeholders.

Illustrative image related to air pump for truck tires

The evolution of the air pump for truck tires has been marked by significant technological advancements and shifts in consumer preferences. Initially, tire inflators were primarily manual or basic mechanical devices, often lacking accuracy and efficiency. However, as the automotive industry progressed, so did the demand for more sophisticated solutions. The introduction of electric and portable air pumps revolutionized the market, allowing for quicker and more convenient tire inflation.

In recent years, the focus has shifted toward smart technology, with modern inflators featuring digital displays, programmable settings, and automatic shut-off functions. These innovations cater to the needs of busy fleet operators who require reliable and efficient tire maintenance solutions. The ongoing trend towards sustainability has further prompted manufacturers to explore eco-friendly materials and processes, ensuring that the air pump sector not only meets operational demands but also aligns with global environmental goals.

As the market continues to evolve, B2B buyers must stay informed about technological advancements and emerging trends to make strategic sourcing decisions that enhance their operational efficiency and sustainability initiatives.

How do I choose the right air pump for truck tires?

Selecting the appropriate air pump for truck tires involves considering several factors, such as the pump’s maximum pressure, power source, and portability. For heavy-duty trucks, look for pumps that can inflate to at least 80 PSI and can handle larger tire sizes. Evaluate features like built-in pressure gauges for accuracy, quick inflation times, and additional functionalities, such as USB ports or built-in lights. Ensure the pump is compatible with your fleet’s specific tire requirements and check for ease of use, especially in remote locations.

What is the best air pump for heavy-duty trucks?

For heavy-duty trucks, the Viair 88P is often recommended due to its ability to efficiently inflate larger tires and its rugged construction. It can inflate a flat tire from zero to 35 PSI in under seven minutes, making it a reliable choice for commercial use. Other options include the AstroAI Cordless Tire Inflator, which offers portability and ease of use. Always consider the specific tire sizes in your fleet and choose a pump that meets those needs effectively.

What should I look for in a supplier of air pumps for truck tires?

When vetting suppliers for air pumps, prioritize factors such as product quality, certifications, and compliance with international standards. Evaluate their manufacturing capabilities, lead times, and whether they offer customization options to meet specific needs. Request samples to assess product performance and reliability. Additionally, inquire about their after-sales support and warranty terms to ensure they can address any issues post-purchase.

What is the minimum order quantity (MOQ) for purchasing air pumps?

The MOQ for air pumps can vary significantly depending on the supplier and the specific model. Typically, for B2B transactions, the MOQ can range from 50 to 200 units. It’s important to discuss your requirements with potential suppliers to negotiate terms that fit your business needs. Some suppliers may offer lower MOQs for first-time orders or during promotional periods.

What payment terms should I expect when sourcing air pumps internationally?

Payment terms for international purchases can vary widely. Common options include letters of credit, wire transfers, or payment through platforms like PayPal. Many suppliers require a deposit upfront (often 30%) with the balance due before shipping. It’s crucial to negotiate favorable terms, especially regarding payment timelines and currency, to mitigate financial risk and ensure smooth transactions.

How can I ensure quality control when sourcing air pumps?

To ensure quality control, establish clear specifications with your supplier regarding materials, performance standards, and testing protocols. Request samples before placing a bulk order and consider conducting third-party inspections during production and pre-shipment. Additionally, inquire about the supplier’s quality assurance processes and certifications, such as ISO standards, to ensure their commitment to delivering high-quality products.

What logistics considerations should I keep in mind when importing air pumps?

Logistics plays a critical role in the timely delivery of air pumps. Consider factors such as shipping methods (air freight vs. sea freight), customs regulations, and import duties specific to your country. Work with a reliable freight forwarder to navigate these complexities and ensure that all paperwork is in order. Additionally, account for lead times and potential delays, especially during peak shipping seasons.

Are there customization options available for air pumps?

Many suppliers offer customization options for air pumps, such as branding, specific pressure settings, or additional features tailored to your requirements. Discuss your needs with potential suppliers to determine the extent of customization they can provide. Keep in mind that customization may affect lead times and pricing, so factor these into your decision-making process to ensure alignment with your business strategy.

Could not verify enough suppliers for air pump for truck tires to create a list at this time.

As the demand for reliable air pumps for truck tires continues to rise, strategic sourcing plays a pivotal role in ensuring businesses can meet their operational needs efficiently. Understanding the various types of air pumps—from portable inflators to heavy-duty compressors—enables B2B buyers to select the right equipment tailored to their specific requirements. Factors such as inflation speed, portability, and power options are essential for maintaining tire health and ensuring vehicles remain roadworthy, which ultimately impacts profitability.

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should prioritize partnerships with reputable suppliers that offer quality products with robust warranties and customer support. Emphasizing local sourcing can also lead to reduced lead times and shipping costs, enhancing supply chain resilience.

Illustrative image related to air pump for truck tires

Looking ahead, the evolution of air pump technology will likely bring even more innovative solutions to the market. Now is the time for B2B buyers to capitalize on these advancements and secure the best equipment to maintain their fleets. Engage with suppliers, assess your needs, and invest in high-quality air pumps that will contribute to your operational efficiency and sustainability goals.

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

Illustrative image related to air pump for truck tires

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.