In today’s fast-paced global marketplace, sourcing the best handheld air compressor can pose a significant challenge for B2B buyers, especially those operating in diverse regions like Africa, South America, the Middle East, and Europe. With a myriad of options available, each tailored for specific applications—from automotive maintenance to industrial uses—making the right choice is critical. This guide provides a comprehensive overview of the various types of handheld air compressors, their applications, and the key factors to consider when sourcing them.

Navigating the complexities of supplier vetting, cost considerations, and regional availability can be daunting. This guide empowers international B2B buyers by equipping them with actionable insights and strategic approaches. It addresses common pain points, such as ensuring product reliability and performance, understanding warranty and service options, and evaluating supplier credibility. By offering detailed comparisons of leading models and their features, this resource aims to streamline the purchasing process, enabling businesses to invest wisely in equipment that enhances operational efficiency and productivity.

Whether you are in Nigeria, Brazil, or any other global market, this guide serves as a valuable tool for making informed purchasing decisions, ultimately contributing to the success of your operations and the satisfaction of your clients. Embrace the opportunity to navigate the global market with confidence, ensuring that you select the best handheld air compressor to meet your specific needs.

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Cordless Tire Inflators | Battery-operated, portable, often with built-in gauges | Automotive maintenance, roadside assistance | Pros: High portability, quick inflation. Cons: Limited battery life, may require recharging. |

| 12V Electric Compressors | Plugs into vehicle power outlet, suitable for larger tires | Fleet maintenance, construction | Pros: Continuous power, can handle larger tires. Cons: Less portable, requires vehicle access. |

| Compact Handheld Compressors | Small size, lightweight, often USB rechargeable | Personal use, small workshops | Pros: Extremely portable, ideal for light tasks. Cons: Limited power and capabilities. |

| Heavy-Duty Air Compressors | High PSI capabilities, rugged construction | Industrial applications, construction sites | Pros: Can inflate larger tires and tools, durable. Cons: Bulky, less suitable for casual use. |

| Multi-Purpose Inflators | Versatile with multiple attachments for various inflatables | Sports equipment, recreational vehicles | Pros: Versatile, can inflate various items. Cons: May lack power for heavy-duty tasks. |

Cordless tire inflators are designed for maximum portability, typically powered by rechargeable batteries. They are ideal for B2B applications in automotive maintenance and roadside assistance, allowing technicians to easily carry them to service locations. When considering a purchase, businesses should evaluate battery life, inflation speed, and the ability to inflate multiple tires on a single charge. These inflators often come with built-in pressure gauges for accuracy and convenience.

12V electric compressors are designed to connect directly to a vehicle’s power outlet, providing a continuous power source for inflating larger tires. They are commonly used in fleet maintenance and construction, where quick access to air pressure is critical. Buyers should consider the hose length, maximum PSI, and overall durability when selecting a model, as these factors directly affect usability in demanding environments. While they offer robust performance, they may be less portable than cordless options.

Compact handheld compressors are lightweight and often USB rechargeable, making them perfect for personal use or small workshops. Their small size allows them to fit into tight spaces, making them a convenient choice for light tasks. Businesses should focus on inflation speed and the types of attachments included when purchasing these units. While they excel in portability, their limited power may not meet the needs of more demanding applications.

Heavy-duty air compressors are built to handle high PSI requirements and are constructed from rugged materials. They are suitable for industrial applications and construction sites where durability and performance are paramount. When choosing a heavy-duty compressor, businesses should assess the compressor’s size, weight, and power capabilities. Although they offer superior inflation capabilities, their bulkiness may limit their use in less demanding environments.

Multi-purpose inflators come with various attachments, allowing them to inflate everything from sports equipment to recreational vehicles. They are particularly useful in settings where different types of inflatables are frequently used, such as sports facilities or rental services. Buyers should look for models with quick inflation times and adaptability to various inflation tasks. While they provide great versatility, their power may fall short for heavy-duty applications, making it essential to match the tool to the specific needs of the business.

| Industry/Sector | Specific Application of best hand held air compressor | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Repair | Tire inflation and maintenance | Enhances vehicle safety and reduces downtime | Look for models with high PSI capacity and portability |

| Construction | Operating pneumatic tools | Increases efficiency in tool operation | Ensure compatibility with various pneumatic tools |

| Agriculture | Inflating agricultural equipment | Improves operational readiness of equipment | Consider durability and battery life for field use |

| Logistics and Transport | Emergency tire repairs on vehicles | Minimizes disruptions and delays in transport | Focus on compact size and multi-use capabilities |

| Outdoor Recreation | Inflating sports and recreational gear | Facilitates quick setup and enhances user experience | Seek lightweight models with multiple nozzle options |

In the automotive repair sector, the best hand held air compressors are essential for tire inflation and maintenance. These compressors enable mechanics to quickly inflate tires to the recommended PSI, ensuring vehicle safety and optimal performance. The ability to perform quick repairs minimizes vehicle downtime, which is crucial for businesses operating in fast-paced environments. When sourcing, buyers should prioritize models that provide high PSI capacity and portability, allowing for easy maneuverability in a busy workshop or roadside assistance scenario.

In construction, hand held air compressors are often employed to operate pneumatic tools such as nail guns and paint sprayers. This application significantly increases the efficiency of work processes, allowing for faster completion of tasks like framing or finishing. Furthermore, these compressors can be used for quick inflation of air mattresses or other equipment on-site. Buyers in this sector should ensure that the compressors are compatible with various pneumatic tools and have robust power output to handle the demands of a construction environment.

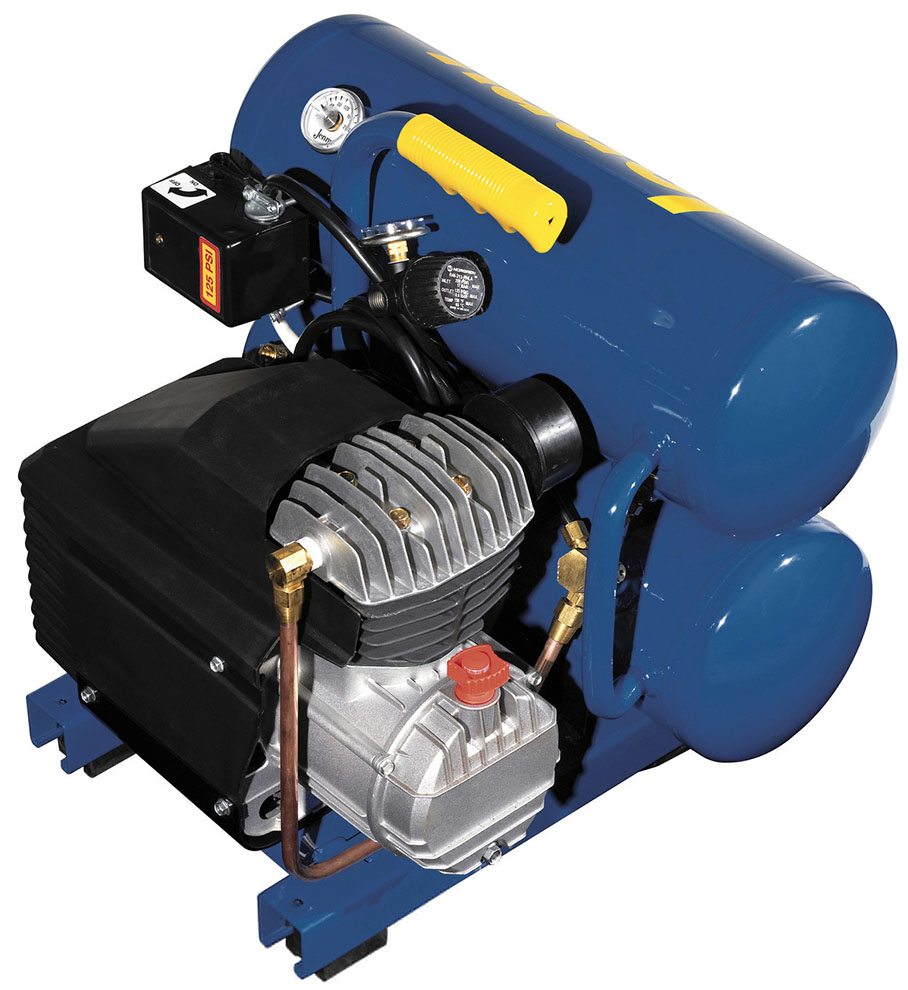

Illustrative image related to best hand held air compressor

In agriculture, hand held air compressors are used to inflate tires on tractors and other machinery, ensuring that equipment is operational and ready for use. This is especially important in regions where agricultural activities are seasonal, and downtime can lead to significant financial losses. By investing in reliable compressors, farmers can ensure that their equipment is always ready for action. Buyers should focus on models with high durability and long battery life to withstand the rigors of field use, particularly in remote areas.

For logistics and transport businesses, hand held air compressors are invaluable for emergency tire repairs on vehicles. Quick inflation of tires can minimize delays in deliveries, thereby enhancing customer satisfaction. In regions with challenging road conditions, having a reliable compressor can mean the difference between meeting deadlines and facing costly delays. When sourcing compressors, companies should look for compact models that offer multi-use capabilities to address various inflation needs on the go.

In the outdoor recreation industry, hand held air compressors are used to inflate sports and recreational gear, such as inflatable boats, rafts, and air mattresses. The convenience of having a portable compressor allows users to quickly set up their equipment, enhancing the overall experience. For international buyers, particularly in regions with diverse outdoor activities, sourcing lightweight models with multiple nozzle options is essential to accommodate various gear types. This versatility ensures that users can enjoy their recreational activities without unnecessary delays.

Illustrative image related to best hand held air compressor

The Problem: B2B buyers often face challenges with hand-held air compressors when trying to inflate various types of tires, such as those on trucks, SUVs, and light vehicles. Many compressors struggle with high-pressure requirements or fail to deliver consistent performance across different tire sizes. This inconsistency can lead to frustration and operational downtime, particularly in industries that rely heavily on vehicle fleets for logistics and transportation.

The Solution: To mitigate this issue, buyers should prioritize sourcing air compressors that are specifically designed to handle a range of tire pressures. Look for models that offer adjustable pressure settings and have a maximum PSI rating that comfortably exceeds the highest requirement of the tires used in your fleet. Additionally, consider units with robust construction and built-in features like digital pressure gauges for precise monitoring. Testing different models in real-world scenarios before committing to a purchase can also help ensure that the selected compressor meets performance expectations across various applications.

The Problem: In many B2B contexts, such as construction or agriculture, professionals often find themselves in remote locations where access to power sources is limited. Hand-held air compressors that rely solely on battery power may run out of charge before all tasks are completed, leading to delays and inefficiencies. This limitation can be particularly problematic when dealing with multiple vehicles or equipment that require inflation throughout the day.

The Solution: When selecting a hand-held air compressor for field use, opt for models that offer dual power options, such as a rechargeable battery and a connection for a vehicle’s 12V outlet. This versatility allows users to recharge the compressor while on the move, ensuring that they can complete their tasks without interruption. Additionally, consider the capacity of the battery and the time required for a full charge, as well as how many tires or tasks can be completed on a single charge. Conducting a thorough assessment of your operational needs will guide the selection of a compressor that provides sufficient power and reliability in the field.

The Problem: B2B buyers frequently encounter issues with the complexity of operating and maintaining hand-held air compressors. Employees may struggle with understanding how to use the device correctly, leading to errors such as over-inflation or under-inflation. Furthermore, inadequate maintenance can result in equipment failure, which disrupts workflow and increases costs.

The Solution: To address operational complexity, businesses should invest in hand-held air compressors that feature user-friendly designs and clear operational instructions. Look for models with automatic shut-off features that prevent over-inflation, and those that include visual indicators for pressure levels. Providing training for employees on how to operate the equipment and perform routine maintenance can significantly enhance efficiency and reduce the likelihood of errors. Additionally, consider establishing a regular maintenance schedule and documenting best practices to ensure long-term reliability and performance of the compressors. This proactive approach not only extends the lifespan of the equipment but also promotes a culture of safety and competence among staff.

When selecting materials for handheld air compressors, it’s essential to consider their properties, advantages, and limitations. This analysis focuses on four common materials: aluminum, steel, plastic, and rubber. Each material has unique characteristics that affect performance, durability, and suitability for various applications.

Aluminum is a popular choice for handheld air compressor housings and components due to its lightweight nature and excellent corrosion resistance. With a temperature rating of up to 150°C and pressure ratings that can exceed 200 psi, aluminum can handle a wide range of operating conditions.

Pros: Aluminum’s lightweight property makes it easy to transport, which is crucial for handheld devices. Its resistance to corrosion ensures longevity, especially in humid or saline environments, making it suitable for international markets like Africa and South America.

Cons: While aluminum is durable, it can be more expensive than other materials and may require specialized manufacturing techniques, increasing production costs. Additionally, it may not withstand impacts as well as steel.

Impact on Application: Aluminum is compatible with various media, including air and non-corrosive gases, making it versatile for different applications.

Steel is often used in the construction of the compressor’s frame and internal components due to its high strength and durability. It can withstand higher pressures (up to 300 psi) and has a temperature rating of around 200°C.

Pros: Steel’s robustness makes it ideal for heavy-duty applications, especially in regions where equipment may face harsh conditions. Its lower cost compared to aluminum makes it a budget-friendly option for manufacturers.

Cons: Steel is heavier than aluminum, which can affect the portability of handheld compressors. It is also prone to rust if not properly coated or maintained, particularly in humid climates.

Illustrative image related to best hand held air compressor

Impact on Application: Steel is suitable for applications requiring high pressure and durability, but buyers must consider the need for protective coatings to prevent corrosion, especially in tropical regions.

Plastic is commonly used for non-structural components and casings in handheld air compressors. It has a temperature rating of up to 70°C and can handle pressures of around 100 psi.

Pros: The lightweight nature of plastic contributes to the overall portability of the compressor. Additionally, it can be molded into complex shapes, allowing for innovative designs and features.

Cons: Plastic generally has lower durability and pressure resistance compared to metals, which may limit its use in high-demand applications. It can also be susceptible to UV degradation if exposed to sunlight for extended periods.

Illustrative image related to best hand held air compressor

Impact on Application: While plastic is suitable for lightweight applications, buyers in regions with extreme temperatures or UV exposure should consider the long-term viability of plastic components.

Rubber is primarily used for seals, gaskets, and hoses in handheld air compressors due to its flexibility and excellent sealing properties. It can withstand temperatures ranging from -30°C to 100°C and pressures up to 150 psi.

Pros: Rubber’s flexibility allows for effective sealing, preventing air leaks and improving efficiency. It is also relatively inexpensive and easy to manufacture.

Cons: Over time, rubber can degrade due to exposure to heat, ozone, and UV light, which may require regular replacement. Its limited temperature range can also be a drawback in extreme conditions.

Impact on Application: Rubber is essential for ensuring airtight seals in compressors, but buyers should be aware of the environmental conditions that may affect its longevity.

| Material | Typical Use Case for best hand held air compressor | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Compressor housings and components | Lightweight and corrosion-resistant | Higher cost and impact sensitivity | Medium |

| Steel | Frame and internal components | High strength and durability | Heavier and prone to rust | Low |

| Plastic | Non-structural components and casings | Lightweight and moldable | Lower durability and UV sensitivity | Low |

| Rubber | Seals, gaskets, and hoses | Excellent sealing properties | Degradation over time and limited temperature range | Low |

By carefully considering these materials, international B2B buyers can make informed decisions that align with their specific needs and regional conditions, ensuring optimal performance and longevity of handheld air compressors.

Manufacturing a handheld air compressor involves several critical stages, each of which contributes to the overall quality and functionality of the final product. The primary stages include material preparation, forming, assembly, and finishing.

The manufacturing process begins with material selection, where manufacturers typically choose high-grade metals and plastics that can withstand pressure and wear. Common materials include aluminum for lightweight components, high-strength steel for structural parts, and durable polymers for housings.

Illustrative image related to best hand held air compressor

Once the materials are selected, they undergo rigorous quality checks to ensure they meet predefined specifications. This may involve measuring dimensions, checking for defects, and assessing material properties like tensile strength and corrosion resistance.

The forming stage is where the selected materials are shaped into components. Techniques such as stamping, machining, and molding are commonly employed. For instance, aluminum housings may be stamped from sheets using precision dies, while plastic components may be created through injection molding.

Advanced techniques, like CNC (Computer Numerical Control) machining, are often used for critical parts, ensuring high precision and repeatability. This stage is crucial for ensuring that all components fit together seamlessly during assembly.

Illustrative image related to best hand held air compressor

The assembly stage involves combining the various components to create a fully functional handheld air compressor. This process can be manual or automated, depending on the scale of production.

Automated assembly lines are becoming increasingly popular, utilizing robotics to ensure consistent quality and efficiency. Workers may perform final adjustments, install electronic components, and conduct preliminary tests to ensure the compressor operates correctly.

Finishing is the last stage in the manufacturing process, where the product is polished and prepared for packaging. This may include painting, anodizing, or applying protective coatings to enhance durability and aesthetic appeal.

Quality checks are performed again during this stage to identify any surface defects or assembly issues. The final product is then packaged according to international shipping standards, ensuring it arrives intact to B2B buyers across the globe.

Quality assurance is paramount in the manufacturing of handheld air compressors. International standards, such as ISO 9001, provide a framework for quality management systems, ensuring that manufacturers consistently meet customer and regulatory requirements.

Illustrative image related to best hand held air compressor

Additionally, industry-specific standards like CE marking for European markets and API (American Petroleum Institute) standards for compressors used in the oil and gas sector may also apply. These certifications not only enhance product credibility but also ensure compliance with safety and environmental regulations.

Quality control (QC) is integrated throughout the manufacturing process, with several checkpoints to ensure product integrity. Key QC checkpoints include:

Various testing methods are employed to validate the performance and safety of handheld air compressors. Common methods include:

For international B2B buyers, verifying supplier quality control is essential to ensure product reliability. Here are several methods to consider:

Illustrative image related to best hand held air compressor

International buyers, especially from regions like Africa, South America, the Middle East, and Europe, should be aware of specific quality control nuances:

By understanding these manufacturing processes and quality assurance practices, B2B buyers can make informed decisions when sourcing handheld air compressors, ensuring they invest in reliable and high-quality products that meet their operational needs.

The following guide serves as a comprehensive checklist for B2B buyers seeking to procure the best handheld air compressors. This step-by-step approach will ensure that you select a product that meets your operational needs while also aligning with your budget and quality standards.

Establishing clear technical specifications is essential before initiating the procurement process. Consider factors such as the required PSI (pounds per square inch), tank size, and power source (battery-operated vs. corded). These specifications will dictate the performance and suitability of the air compressor for your specific applications, such as tire inflation or powering pneumatic tools.

Understanding the specific applications for which the handheld air compressor will be used is critical. Will it be primarily for inflating tires, operating tools, or other purposes? This assessment will help you determine the necessary features, such as portability, weight, and additional functionalities like built-in pressure gauges or LED lights, which enhance usability in various conditions.

Illustrative image related to best hand held air compressor

Before making a purchase, conduct thorough research on potential brands and their reputations in the market. Look for customer reviews, expert opinions, and ratings from reliable sources. A brand with a solid reputation often indicates better quality and customer support, which can be invaluable for maintenance and service down the line.

Engaging with multiple suppliers allows for a more informed decision. Request detailed company profiles, including their experience, certifications, and case studies that demonstrate successful deliveries in similar markets. Moreover, seek references from other businesses, particularly those operating within your region, to gain insights into the supplier’s reliability and service quality.

Ensure that the products comply with relevant international standards and regulations, particularly if you are sourcing from different countries. Certifications such as ISO or CE mark can provide assurance of product quality and safety. This step is particularly important for industries requiring strict adherence to safety and operational guidelines.

Before finalizing your order, request product demonstrations or samples, if possible. This allows you to evaluate the compressor’s performance firsthand, ensuring it meets your expectations in real-world scenarios. Pay attention to ease of use, noise levels, and overall functionality during the demonstration.

Finally, assess the after-sales support and warranty terms offered by the supplier. A strong warranty and reliable customer service can provide peace of mind, especially in case of defects or operational issues. Ensure that the warranty covers essential components and that support is readily available to address any concerns post-purchase.

By following this checklist, B2B buyers can make informed decisions when sourcing handheld air compressors, ultimately leading to enhanced operational efficiency and reduced downtime.

When sourcing hand held air compressors, understanding the cost structure is essential for B2B buyers. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margins.

Illustrative image related to best hand held air compressor

Materials: The selection of high-quality components such as motors, hoses, and pressure gauges significantly impacts the overall cost. Variability in material prices can be influenced by market demand and availability, affecting your sourcing strategy.

Labor: Labor costs can vary widely based on the region of production. Countries with lower labor costs can offer competitive pricing, but it is crucial to consider the skill level and training of the workforce, which can affect the quality of the product.

Manufacturing Overhead: This includes expenses related to factory maintenance, utilities, and indirect labor. Higher overhead costs in developed regions may lead to increased prices, while manufacturers in emerging markets may offer more cost-effective solutions.

Tooling: The initial investment in tooling for manufacturing specific compressor models can be substantial. Custom designs often require more sophisticated tooling, which can raise the upfront costs but may lead to better product differentiation.

Quality Control: Stringent QC processes ensure that the compressors meet safety and performance standards. While implementing robust QC can increase costs, it ultimately protects your investment by reducing the risk of defective products.

Logistics: Shipping and handling costs are crucial, especially for international buyers. Factors such as distance, shipping method, and Incoterms can affect the total logistics costs significantly.

Margin: Suppliers typically apply a profit margin that varies based on market dynamics and competition. Understanding the competitive landscape can help you negotiate better prices.

Several factors can influence the pricing of hand held air compressors.

Volume/MOQ: The minimum order quantity (MOQ) can greatly affect pricing. Bulk orders typically attract discounts, allowing buyers to reduce per-unit costs.

Specifications and Customization: Custom specifications or additional features can lead to higher prices. It’s essential to evaluate whether the added features justify the cost or if standard models suffice.

Materials and Quality Certifications: Compressors made from premium materials or those that comply with international quality standards (like ISO certifications) may command higher prices. These certifications can also be critical for compliance in specific markets.

Supplier Factors: The reputation and reliability of the supplier can impact pricing. Established suppliers may offer higher quality and better service but at a premium price.

Incoterms: The chosen Incoterms (International Commercial Terms) will define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs, which can significantly affect total costs.

When sourcing hand held air compressors, particularly from diverse regions such as Africa, South America, the Middle East, and Europe, consider the following tips:

Negotiate Based on Total Cost of Ownership (TCO): Instead of focusing solely on the initial purchase price, consider the TCO, which includes maintenance, operational costs, and potential downtime. This perspective can reveal the true value of a compressor.

Be Aware of Pricing Nuances: Different regions may have varying pricing structures due to local market conditions, tariffs, and taxes. Familiarize yourself with these factors to enhance your negotiation strategy.

Establish Long-term Relationships: Building a long-term relationship with suppliers can lead to better pricing and terms over time. Suppliers may offer loyalty discounts or favorable payment terms to repeat customers.

Request Multiple Quotes: Gathering quotes from several suppliers can provide leverage in negotiations. It also helps in understanding the market rate for the specific models you are interested in.

Evaluate Payment Terms: Flexible payment terms can significantly affect cash flow. Negotiating favorable terms can allow for better financial management and investment in other areas of your business.

Navigating the complexities of sourcing hand held air compressors requires a thorough understanding of cost components, price influencers, and negotiation strategies. International B2B buyers should consider these factors carefully to ensure they make informed purchasing decisions that align with their operational needs and budget constraints. Always remember that prices may vary, and it’s prudent to seek multiple quotes to ensure you are getting the best deal.

In the realm of portable air solutions, the best hand held air compressor serves as a popular option for various industries, particularly in automotive maintenance and construction. However, B2B buyers should consider alternative technologies and methods that can also meet their air compression needs effectively. This analysis compares the hand held air compressor with two viable alternatives: portable tire inflators and electric air pumps.

| Comparison Aspect | Best Hand Held Air Compressor | Portable Tire Inflator | Electric Air Pump |

|---|---|---|---|

| Performance | High PSI, suitable for multiple tasks | Moderate PSI, quick tire inflation | High PSI, versatile applications |

| Cost | Mid-range ($50-$150) | Low-cost ($30-$90) | Mid-range ($50-$120) |

| Ease of Implementation | Requires some technical skill | User-friendly, minimal setup | Simple plug-and-use design |

| Maintenance | Regular checks for wear | Low maintenance, battery replacement needed | Minimal, depends on usage |

| Best Use Case | General air compression needs | Tire inflation for vehicles | Inflating various items (e.g., air mattresses, sports equipment) |

Portable Tire Inflator

Portable tire inflators are specifically designed for quick and efficient tire inflation. They are compact and lightweight, making them ideal for automotive applications. The key advantage of these devices is their ease of use; most models require minimal setup, often just plugging into a vehicle’s 12V outlet. However, their performance is limited to lower pressures (usually around 100-150 PSI), which may not be suitable for heavy-duty applications. Additionally, while they are budget-friendly, their reliance on batteries or vehicle power can restrict usability in remote locations.

Electric Air Pump

Electric air pumps are versatile tools that can cater to a wide range of inflation needs, from tires to recreational items like inflatable boats and air mattresses. They offer high PSI capabilities and can often inflate multiple items in one go. The ease of use is another plus, as they typically operate with a simple plug-and-play mechanism. However, the initial cost can be on the higher side, and they may require a power source, which limits mobility compared to hand held air compressors. Maintenance is generally low, but the longevity depends on the frequency of use.

When deciding between the best hand held air compressor and its alternatives, B2B buyers should assess their specific operational requirements. If the primary need is for quick and efficient tire inflation, a portable tire inflator may be the best fit. However, for businesses that require a versatile solution capable of handling various air compression tasks, an electric air pump could prove more beneficial. Ultimately, the choice hinges on factors such as performance, cost, ease of use, and the particular applications that are most relevant to your industry. By aligning these factors with your operational needs, you can select the most suitable air compression solution for your business.

When evaluating handheld air compressors, several technical specifications are critical for ensuring optimal performance and suitability for various applications. Understanding these properties can significantly impact purchasing decisions for B2B buyers.

Maximum Pressure (PSI)

– Definition: The maximum pressure an air compressor can deliver, measured in pounds per square inch (PSI).

– Importance: Different applications require varying pressure levels. For example, inflating tires for heavy-duty vehicles typically demands higher PSI (up to 80 PSI), making it essential for buyers to choose compressors that meet specific operational needs.

Airflow Rate (CFM)

– Definition: The airflow rate, measured in cubic feet per minute (CFM), indicates how much air the compressor can deliver within a minute.

– Importance: A higher CFM rating allows for quicker inflation and efficient operation of air tools. For B2B buyers, understanding the required CFM for specific tasks can help in selecting a compressor that minimizes downtime and maximizes productivity.

Duty Cycle

– Definition: The duty cycle represents the ratio of operational time to rest time, often expressed as a percentage (e.g., 50% duty cycle means the compressor can run for 5 minutes and needs 5 minutes to cool down).

– Importance: A higher duty cycle is essential for continuous operations. Businesses that require frequent or prolonged use of compressors should prioritize models with a higher duty cycle to avoid overheating and ensure reliability.

Weight and Portability

– Definition: The weight of the compressor affects its portability and ease of use.

– Importance: For B2B applications where compressors need to be transported frequently, lighter models are preferable. Buyers should consider the balance between weight and functionality to ensure that the compressor meets their mobility needs without compromising performance.

Power Source

– Definition: The type of power source used by the compressor, which can be electric, battery-operated, or gas-powered.

– Importance: The choice of power source affects versatility and operational efficiency. Battery-operated models offer portability for remote locations, while electric compressors provide consistent power for stationary applications. Understanding the power requirements for specific tasks is crucial for informed purchasing.

Familiarity with industry jargon can streamline the purchasing process and improve communication with suppliers.

OEM (Original Equipment Manufacturer)

– Definition: Refers to companies that produce parts and equipment that may be marketed by another manufacturer.

– Importance: Understanding OEM relationships is vital for sourcing quality parts and ensuring compatibility with existing systems, particularly for businesses looking to integrate new compressors with existing equipment.

MOQ (Minimum Order Quantity)

– Definition: The smallest number of units a supplier is willing to sell.

– Importance: Knowing the MOQ helps buyers assess the feasibility of bulk purchases and negotiate effectively. For companies requiring multiple units for a fleet, being aware of MOQs can lead to cost savings.

RFQ (Request for Quotation)

– Definition: A document sent to suppliers to request pricing and terms for a specific quantity of goods.

– Importance: Submitting an RFQ can help businesses compare prices and terms from different suppliers, ensuring they receive the best deal for their air compressor needs.

Incoterms (International Commercial Terms)

– Definition: A series of pre-defined commercial terms published by the International Chamber of Commerce, outlining the responsibilities of buyers and sellers in international transactions.

– Importance: Understanding Incoterms is crucial for B2B buyers engaged in cross-border purchases. Clear knowledge of these terms ensures that responsibilities regarding shipping, insurance, and tariffs are well-defined, reducing potential misunderstandings.

Warranty and Service Agreements

– Definition: Documents that outline the terms of service, maintenance, and support provided by the manufacturer or supplier.

– Importance: Knowing the warranty terms can significantly impact the long-term costs associated with equipment maintenance and repairs. Buyers should seek comprehensive service agreements to ensure operational continuity.

By grasping these technical specifications and trade terms, B2B buyers can make informed decisions, optimize their procurement strategies, and enhance their operational efficiencies when selecting the best handheld air compressors.

Illustrative image related to best hand held air compressor

The global handheld air compressor market is witnessing significant growth, driven by rising demand in automotive, construction, and DIY sectors. Factors such as urbanization, increased vehicle ownership, and the growing trend of home improvement projects are fueling the need for portable air solutions. In regions like Africa, South America, and the Middle East, the surge in infrastructure development and automotive maintenance is particularly notable. International B2B buyers must stay attuned to emerging technologies, such as battery-powered compressors with enhanced efficiency, compact designs, and integrated smart features. These innovations not only improve functionality but also cater to the growing consumer preference for user-friendly and versatile tools.

Moreover, the market is shifting towards e-commerce platforms for sourcing, enabling buyers to access a broader range of products and competitive pricing. This trend is essential for businesses in developing regions, where traditional distribution channels may be limited. Collaboration with local suppliers who understand regional market nuances can also provide a competitive edge. Additionally, the trend of bundling products with accessories—such as tire inflators, adapters, and storage solutions—can enhance value propositions for B2B buyers, ensuring they meet diverse customer needs while maintaining operational efficiency.

The environmental impact of manufacturing processes and product lifecycle is an increasingly critical concern for businesses sourcing handheld air compressors. The industry is witnessing a shift towards sustainable practices, emphasizing the need for ethical sourcing and reduced carbon footprints. International buyers should prioritize suppliers that implement environmentally friendly production methods, such as using recycled materials and minimizing waste.

Illustrative image related to best hand held air compressor

Certifications like ISO 14001 (Environmental Management) and products made with sustainable materials can signal a commitment to environmental responsibility. Additionally, the demand for energy-efficient models that consume less power during operation is rising, which not only appeals to eco-conscious consumers but also helps businesses reduce operational costs.

Ethical supply chains are also becoming a focal point, with businesses encouraged to source components from manufacturers that adhere to fair labor practices. This alignment not only mitigates risks associated with unethical practices but also enhances brand reputation in a market increasingly driven by corporate social responsibility. By investing in sustainable and ethical sourcing, B2B buyers can differentiate their offerings in a competitive landscape while contributing positively to the environment and society.

The handheld air compressor has evolved significantly since its inception, transitioning from bulky, stationary units to compact, portable designs that cater to a variety of applications. Initially developed for industrial use, these devices have gained popularity among consumers, thanks to advancements in technology and materials. The introduction of battery-operated models marked a turning point, allowing users to operate compressors without the constraints of cords and outlets.

As the market matured, manufacturers began integrating smart technologies, such as pressure sensors and automatic shut-off features, enhancing user convenience and safety. Today, the focus is not only on performance but also on sustainability, with a growing emphasis on energy efficiency and eco-friendly materials. This evolution reflects the changing needs of consumers and businesses alike, emphasizing versatility and user-friendliness in an increasingly competitive market. For international B2B buyers, understanding this evolution is crucial for making informed sourcing decisions that align with current trends and consumer expectations.

1. How do I choose the right hand-held air compressor for my business needs?

Selecting the right hand-held air compressor involves evaluating your specific requirements, such as the types of tasks you’ll perform (e.g., inflating tires, powering pneumatic tools), desired pressure levels, and portability. Consider the compressor’s PSI (pounds per square inch) rating, duty cycle, and whether it operates on battery or direct power. It’s also crucial to assess the compressor’s size and weight for ease of transport. Gathering feedback from users in similar industries can also provide valuable insights.

2. What is the best hand-held air compressor for heavy-duty applications?

For heavy-duty applications, compressors like the Viair 88P are highly recommended due to their robust construction and ability to deliver high pressures quickly, making them suitable for larger tires and demanding tasks. Look for models with a high PSI rating (120 PSI or more) and those designed for frequent use. It’s essential to evaluate product specifications to ensure they align with the specific requirements of your operations, especially if you’re in industries like construction or automotive.

3. How can I verify the quality and reliability of a hand-held air compressor supplier?

To verify the quality and reliability of a supplier, conduct thorough background checks, including assessing their business history, customer reviews, and industry certifications. Request samples of their products to evaluate performance and durability firsthand. Engage with references from other businesses that have purchased from them to gather insights about their experiences. Additionally, consider suppliers that offer warranties and after-sales support, which can indicate confidence in their products.

4. What is the typical minimum order quantity (MOQ) for hand-held air compressors?

The minimum order quantity (MOQ) for hand-held air compressors can vary significantly depending on the supplier and the model you choose. Generally, MOQs can range from 10 to 100 units. It’s advisable to discuss your specific needs with potential suppliers and inquire if they offer flexibility for smaller orders, especially if you are a new business or testing a new market. Suppliers may be more accommodating for long-term partnerships.

5. What payment terms should I expect when purchasing hand-held air compressors internationally?

Payment terms can vary by supplier and region, but common practices include advance payments, letters of credit, or payment upon delivery. Many suppliers may require a deposit (20-30%) upfront, with the balance due upon shipment or delivery. It’s essential to clarify payment terms in advance to ensure they align with your financial processes. Additionally, consider using secure payment methods to protect your transaction.

6. How do I handle logistics for international shipping of hand-held air compressors?

Handling logistics for international shipping involves selecting a reliable freight forwarder or shipping company experienced in transporting industrial equipment. Discuss shipping options, including air freight for urgent needs and sea freight for cost-effective solutions. Ensure compliance with local regulations and customs requirements in your destination country to avoid delays. Additionally, consider insurance for your shipment to safeguard against potential losses during transit.

7. What certifications should I look for in hand-held air compressors?

When sourcing hand-held air compressors, look for certifications that demonstrate compliance with safety and performance standards, such as CE marking in Europe, UL certification in the U.S., or ISO certifications for manufacturing quality. These certifications not only assure product safety but also indicate adherence to industry regulations. Ensure that the supplier provides documentation for these certifications to validate their claims.

8. How can I customize hand-held air compressors for my specific business needs?

Many suppliers offer customization options for hand-held air compressors, including branding, specific pressure settings, and additional features such as built-in lights or USB ports. To initiate the customization process, communicate your requirements clearly with the supplier and request details on available options and associated costs. Ensure that you discuss lead times for customized products, as these may differ from standard offerings.

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Looking for a handheld air compressor that is rechargeable and has high power, specifically for use as a duster rather than for inflating tires. The user is trying to replace compressed air cans and needs a product that can perform similarly to those duster cans.

Domain: automoblog.com

Registered: 2004 (21 years)

Introduction: Best Portable Air Compressors: 1. Ryobi ONE+ – Overall Rating: 4.3, Power Source: Lithium battery, Weight: 4 pounds, Inflation Speed: 3.0, Ease of Use: 5.0, Portability: 5.0. Pros: Lightweight, compact, battery powered, easy to operate. Cons: Batteries and charger sold separately, slower inflation speed. Customer Rating: 4.5/5 from around 500 ratings. 2. Kobalt Portable Air Compressor – Overall Ra…

Domain: cartalk.com

Registered: 1995 (30 years)

Introduction: Best Portable Tire Inflators:

1. **AstroAI Tire Inflator Portable Air Compressor**

– Type: 12-Volt Plug-In

– Price: $40.49 ($31.98 at Amazon)

– Pros: Durable, easy to use, multiple connections, digital pressure gauge, compact storage.

– Cons: Power cable can be a hassle to use and store.

2. **EMSON Bullseye Pro Digital Tire Inflator**

– Type: Battery-Operated

– Pric…

In conclusion, selecting the best handheld air compressor is crucial for optimizing operational efficiency and ensuring effective maintenance across various industries. International B2B buyers should focus on key attributes such as portability, power options, inflation speed, and accuracy when evaluating products. The right compressor can enhance productivity, reduce downtime, and ultimately lead to significant cost savings.

Strategic sourcing plays a pivotal role in this process. By partnering with reputable suppliers and leveraging bulk purchasing agreements, businesses can secure high-quality equipment at competitive prices. Additionally, considering local availability and support can greatly benefit companies operating in diverse markets such as Africa, South America, the Middle East, and Europe.

As the demand for reliable and efficient air compressors continues to rise, now is the time for B2B buyers to reassess their sourcing strategies. Embrace innovation and prioritize quality in your procurement decisions to stay ahead in the competitive landscape. Equip your operations with the best tools available, and ensure you are prepared for the challenges of tomorrow.

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.