In an increasingly competitive global market, sourcing reliable bike tire inflator CO2 solutions can be a daunting task for B2B buyers, especially those operating in diverse regions like Africa, South America, the Middle East, and Europe. With the growing demand for efficient, portable, and user-friendly inflation devices, businesses must navigate a landscape filled with varying product types, quality standards, and supplier capabilities. This guide aims to provide a comprehensive overview of the bike tire inflator CO2 market, covering essential aspects such as product types, applications, supplier vetting processes, and cost considerations.

By delving into the nuances of CO2 inflators, businesses can make informed purchasing decisions that align with their operational needs and customer expectations. The guide will explore the different categories of inflators—from compact models suitable for road cyclists to robust options designed for heavy-duty use—enabling buyers to identify products that best fit their market demands. Furthermore, we will outline strategies for evaluating suppliers, ensuring that international buyers can partner with manufacturers who uphold quality and reliability.

Ultimately, this resource empowers B2B buyers to streamline their sourcing process, mitigate risks associated with subpar products, and enhance their competitive edge in the bicycle accessories market. Whether you’re based in Brazil or Germany, understanding the intricacies of CO2 inflators will enable you to better serve your customers and respond effectively to the evolving demands of the cycling industry.

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Stand-Alone CO2 Inflator | Compact, lightweight, easy to use with one-step operation | Retail bike shops, emergency repair kits | Pros: Fast inflation; Cons: Limited to CO2 cartridges only. |

| Hybrid CO2/Hand Pump | Combination of hand pump and CO2 inflator | Bike rental services, touring companies | Pros: Versatile; Cons: Slightly bulkier. |

| Inline CO2 Inflator | Integrated into multi-tools or pumps | Professional cycling teams, workshops | Pros: Space-saving; Cons: May require practice to use effectively. |

| Cartridge Systems | Utilizes replaceable CO2 cartridges for inflation | Bike manufacturers, wholesalers | Pros: Easy to stock; Cons: Ongoing cost for cartridges. |

| Electric CO2 Pump | Battery-operated for automated inflation | High-end bike shops, tech-focused retailers | Pros: Convenience; Cons: Higher initial investment. |

Stand-alone CO2 inflators are designed for quick and efficient tire inflation, often featuring a simple one-step operation. They are particularly suitable for retail bike shops and emergency repair kits, allowing cyclists to easily manage flat tires without cumbersome manual pumps. B2B buyers should consider the ease of use and the compactness of these inflators, which make them ideal for on-the-go repairs. However, they rely solely on CO2 cartridges, which may necessitate ongoing costs for replacement.

Hybrid CO2/hand pumps combine the functionality of traditional hand pumps with the speed of CO2 inflation. This versatility is particularly beneficial for bike rental services and touring companies that require reliable and efficient tire maintenance solutions. B2B buyers can appreciate the adaptability of these pumps, as they can be used in various scenarios, but they tend to be bulkier than stand-alone inflators, which may be a consideration for space-constrained environments.

Inline CO2 inflators are integrated into multi-tools or bike pumps, offering a space-efficient solution for cyclists. These inflators are commonly used by professional cycling teams and workshops, where efficiency and compactness are paramount. B2B buyers should evaluate the practicality of inline inflators, as they can save space in toolkits. However, they may require users to develop some proficiency to operate effectively, which could be a drawback for less experienced cyclists.

Cartridge systems utilize replaceable CO2 cartridges, making them easy to stock and manage for retailers and manufacturers. They are particularly useful for bike manufacturers and wholesalers who need to ensure that cyclists can quickly address flat tires. While the ease of stocking cartridges is a significant advantage, B2B buyers should also consider the ongoing costs associated with purchasing these cartridges, which can add up over time.

Electric CO2 pumps are battery-operated devices that automate the inflation process, providing a high level of convenience for users. These pumps are ideal for high-end bike shops and tech-focused retailers that want to offer cutting-edge solutions to their customers. While the convenience of electric pumps is a major selling point, B2B buyers should be aware of the higher initial investment required, which may not be suitable for all business models.

| Industry/Sector | Specific Application of bike tire inflator co2 | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Bicycle Retail and Repair | Quick tire inflation services for customers | Enhances customer satisfaction by reducing downtime | Supplier reliability, cartridge availability, pricing |

| Cycling Tours and Rentals | On-the-go inflation for rental bikes during tours | Minimizes disruption and ensures a seamless experience | Compact size, ease of use, compatibility with various valves |

| Sports and Outdoor Events | Providing CO2 inflators as part of race kits or support services | Attracts participants and adds value to event offerings | Lightweight options, durability, and quick inflation speed |

| Emergency Services and NGOs | Use in disaster relief operations for quick tire repairs | Supports efficient mobility in crisis situations | Cost-effectiveness, ease of transport, and reliability |

| E-commerce Platforms | Selling CO2 inflators as part of cycling accessories | Expands product range and attracts niche cycling customers | Competitive pricing, quality assurance, and customer support |

Bicycle retail and repair shops can leverage CO2 inflators to provide rapid tire inflation services to customers. This not only enhances customer satisfaction by minimizing wait times but also encourages repeat business. International buyers should prioritize suppliers with a consistent stock of cartridges and reliable inflators, ensuring they can meet the demands of a busy shop environment.

In the cycling tour and rental sector, CO2 inflators are invaluable for providing on-the-go inflation for rental bikes. This capability minimizes disruptions during tours, ensuring a smooth experience for riders. Buyers in this industry should consider inflators that are compact and easy to use, as well as those compatible with both Presta and Schrader valves to accommodate various bike models.

Sports and outdoor events often include CO2 inflators in race kits or support services, offering quick tire inflation to participants. This feature not only enhances the overall event experience but also attracts more cyclists to participate. When sourcing for such applications, businesses should focus on lightweight and durable inflators that can withstand outdoor conditions and provide rapid inflation.

In emergency services and NGOs, CO2 inflators are crucial for quick tire repairs during disaster relief operations. They facilitate efficient mobility in crisis situations where time is of the essence. Buyers in this sector should prioritize cost-effectiveness, portability, and the reliability of inflators to ensure they can respond effectively during emergencies.

E-commerce platforms can expand their product offerings by including CO2 inflators as part of their cycling accessories. This addition not only attracts niche cycling customers but also enhances the overall shopping experience. For successful sourcing, businesses should consider competitive pricing, quality assurance, and robust customer support to build trust and encourage sales.

The Problem: B2B buyers often face challenges when it comes to sourcing high-quality CO2 cartridges. This issue is particularly pronounced in regions with limited access to reliable suppliers, such as parts of Africa and South America. Buyers may struggle with inconsistent product quality, leading to inflation failures during critical moments. In a business context, this can damage reputations and customer satisfaction, as delays in service can lead to lost sales opportunities.

The Solution: To ensure a steady supply of reliable CO2 cartridges, B2B buyers should establish relationships with multiple reputable manufacturers. Conduct thorough research to identify suppliers with a proven track record of quality and customer service. Look for companies that offer warranties or guarantees on their products, as this can be a strong indicator of reliability. Additionally, consider negotiating bulk purchasing agreements to reduce costs and ensure a consistent supply. Implementing a quality control process upon receiving the products can further mitigate risks; check cartridges for leaks and functionality before distribution.

The Problem: Another common pain point for B2B buyers is the varying inflation speeds and lack of control offered by different CO2 inflators. In a fast-paced business environment, cyclists need to get back on the road quickly, and any delay caused by inefficient equipment can lead to frustration and loss of productivity. Many inflators fail to provide adequate pressure control, resulting in either under-inflated or over-inflated tires, which can compromise safety and performance.

The Solution: When selecting CO2 inflators, prioritize models that feature precise flow control mechanisms. Buyers should look for inflators that allow for gradual release of CO2, enabling users to achieve the desired tire pressure without the risk of over-inflation. Brands such as Lezyne and Muc-Off have models that incorporate these features, making them ideal for professional use. Educate your team on the importance of monitoring tire pressure and practicing with the inflators to ensure they can achieve the best results quickly. Additionally, consider including instructional materials with your products to enhance user experience and efficiency.

The Problem: Increasingly, businesses are facing scrutiny over their environmental impact, including the use of CO2 cartridges for tire inflation. B2B buyers may experience pressure from consumers or regulatory bodies to adopt more sustainable practices. The environmental concerns surrounding the production and disposal of CO2 cartridges can lead to negative perceptions of brands that rely heavily on these products.

The Solution: To address environmental concerns, buyers should consider sourcing CO2 inflators and cartridges that emphasize sustainability. Look for manufacturers that utilize recycled materials or offer refillable options, which can significantly reduce waste. Some brands are innovating with eco-friendly alternatives, such as electric pumps that can minimize reliance on disposable cartridges. Educate your customers about the environmental benefits of these products, and consider marketing them as part of a broader commitment to sustainability. Additionally, you can implement a cartridge recycling program in your business, encouraging customers to return used cartridges for proper disposal or recycling. This proactive approach not only enhances your brand’s reputation but also aligns with the growing consumer demand for environmentally responsible products.

When selecting materials for bike tire CO2 inflators, it is essential to consider factors such as performance, durability, cost, and compliance with international standards. Below is an analysis of some common materials used in the manufacturing of these inflators.

Key Properties: Aluminum is known for its excellent strength-to-weight ratio, making it ideal for portable applications. It can withstand high pressures and has good corrosion resistance, particularly when anodized.

Pros & Cons: The lightweight nature of aluminum enhances the portability of inflators, which is a significant advantage for cyclists. However, it can be more expensive than other materials and may require additional surface treatments to enhance its corrosion resistance.

Impact on Application: Aluminum is compatible with CO2 and does not react with the gas, ensuring reliable performance. It is suitable for high-pressure applications, making it ideal for both road and mountain biking.

Illustrative image related to bike tire inflator co2

Considerations for International Buyers: Buyers should ensure that the aluminum used meets standards such as ASTM B221 for structural aluminum. In regions like Europe, compliance with EN standards is also critical.

Key Properties: Plastics, particularly high-density polyethylene (HDPE) and polycarbonate, offer good chemical resistance and can be molded into complex shapes.

Pros & Cons: The primary advantage of plastic is its low cost and ease of manufacturing. However, plastics may not withstand high pressures as effectively as metals, which can limit their use in certain applications.

Illustrative image related to bike tire inflator co2

Impact on Application: While plastics can be used for non-structural components of CO2 inflators, they may not be suitable for the main body where high pressure is involved. They are more commonly used in parts like grips or protective sleeves.

Considerations for International Buyers: Buyers should look for plastics that comply with relevant safety and environmental regulations, such as REACH in Europe. In regions like South America, understanding local recycling capabilities is also essential.

Key Properties: Stainless steel is known for its exceptional strength and corrosion resistance, especially in humid or salt-laden environments.

Pros & Cons: The durability of stainless steel makes it an excellent choice for high-stress applications, but it is heavier and more expensive than aluminum or plastic. Manufacturing processes can also be more complex due to the material’s toughness.

Illustrative image related to bike tire inflator co2

Impact on Application: Stainless steel can handle high pressures and is compatible with CO2, making it suitable for inflators that require robustness. Its resistance to corrosion ensures longevity, which is critical for outdoor equipment.

Considerations for International Buyers: Compliance with standards such as ASTM A240 for stainless steel is crucial. Buyers in the Middle East should also consider the effects of high temperatures and humidity on material performance.

Key Properties: Composites, often made from a combination of materials like carbon fiber and resin, offer unique properties such as high strength and low weight.

Pros & Cons: Composites can be tailored for specific performance characteristics, making them ideal for advanced applications. However, they can be more expensive and may require specialized manufacturing techniques.

Impact on Application: Composite materials can be used in high-performance inflators where weight is a critical factor, such as in competitive cycling. Their chemical resistance makes them suitable for CO2 applications.

Illustrative image related to bike tire inflator co2

Considerations for International Buyers: Buyers should ensure that composites meet relevant international standards for safety and performance, particularly in markets that emphasize environmental sustainability.

| Material | Typical Use Case for bike tire inflator co2 | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Main body of inflators | Lightweight and strong | Higher cost and potential corrosion | Medium |

| Plastic | Non-structural components | Low cost and easy to manufacture | Limited pressure resistance | Low |

| Stainless Steel | High-stress applications | Excellent durability and corrosion resistance | Heavier and more expensive | High |

| Composite | High-performance inflators | Tailored properties and lightweight | Higher cost and complex manufacturing | High |

This material selection guide provides actionable insights for international B2B buyers, helping them make informed decisions based on performance, cost, and compliance with regional standards.

The manufacturing process for CO2 bike tire inflators typically involves several critical stages, including material preparation, forming, assembly, and finishing. Understanding these stages is crucial for B2B buyers seeking reliable suppliers.

The process begins with the selection of high-quality materials, primarily aluminum, plastic, and rubber. Aluminum is favored for its lightweight and durability, while high-grade plastics are used for components requiring resistance to impact and wear. The preparation phase includes sourcing raw materials from certified suppliers, followed by rigorous inspections to ensure compliance with international quality standards.

In this stage, materials undergo cutting, machining, and surface treatment. For instance, aluminum components may be anodized to enhance corrosion resistance, while plastic parts are often molded using injection techniques to achieve precise dimensions. This meticulous preparation sets the foundation for a robust final product.

Illustrative image related to bike tire inflator co2

Forming involves shaping the prepared materials into components that will make up the inflator. This can include stamping, extruding, or injection molding, depending on the part’s design and function. For example, the housing of the inflator is typically molded from high-quality plastic, while the nozzle may be machined from aluminum.

Once the individual components are formed, the assembly process begins. This stage may involve manual or automated assembly techniques, where parts are fitted together to create the final product. Assembly lines are designed for efficiency, often utilizing jigs and fixtures to ensure accurate alignment. Additionally, components such as valves and CO2 cartridges are integrated into the assembly, requiring precise fitting to ensure proper function.

Finishing processes are crucial for enhancing the aesthetic and functional qualities of CO2 inflators. Techniques such as polishing, painting, or applying protective coatings are commonly employed. For instance, anodizing aluminum parts not only improves appearance but also increases durability and resistance to wear.

Final inspections during the finishing stage are critical. They ensure that all cosmetic and functional specifications are met before the product moves to packaging. This attention to detail is vital, as it impacts both the performance and marketability of the inflators.

Illustrative image related to bike tire inflator co2

Quality assurance (QA) is a cornerstone of the manufacturing process for CO2 bike tire inflators. B2B buyers should seek suppliers who adhere to international standards and maintain rigorous QC checkpoints.

A reputable manufacturer should comply with international quality standards, such as ISO 9001. This certification demonstrates a commitment to quality management systems, ensuring that products consistently meet customer and regulatory requirements.

In addition to ISO standards, specific industry certifications such as CE (Conformité Européenne) for European markets and API (American Petroleum Institute) for certain components may also apply. These certifications indicate compliance with safety and performance regulations, enhancing the credibility of the product.

Quality control is typically structured around several key checkpoints:

Incoming Quality Control (IQC): This initial checkpoint involves inspecting raw materials and components upon arrival at the manufacturing facility. Suppliers should provide certificates of compliance to verify that materials meet specified standards.

In-Process Quality Control (IPQC): During manufacturing, regular inspections are conducted to ensure that processes are being followed correctly and that components are being produced to specification. This may include monitoring critical dimensions and performance characteristics.

Final Quality Control (FQC): At the end of the production line, each finished product undergoes a comprehensive inspection. This includes functional testing of inflators to ensure they operate correctly and safely. Common tests may involve checking for leaks, pressure retention, and compatibility with various valve types.

B2B buyers can employ several strategies to verify the quality control measures of potential suppliers.

Illustrative image related to bike tire inflator co2

Conducting supplier audits is an effective way to assess a manufacturer’s quality assurance processes. Buyers should develop a checklist that includes verification of compliance with international standards, examination of QC documentation, and evaluation of manufacturing capabilities. On-site audits allow buyers to observe processes firsthand, ensuring that suppliers adhere to best practices.

Requesting detailed QC reports from suppliers can provide insights into their quality management systems. These reports should outline the results of inspections and tests conducted at various stages of production. Additionally, engaging third-party inspection services can further validate a supplier’s claims regarding quality and compliance. These independent assessments can help mitigate risks and ensure that products meet the required standards.

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should be aware of specific nuances in quality control. Regulatory requirements may vary significantly between regions, necessitating a thorough understanding of local standards and certifications.

For example, while CE marking is critical for selling in Europe, other regions may prioritize different certifications. Buyers should ensure that suppliers can provide documentation that meets the regulatory requirements of their specific market. This not only ensures compliance but also fosters trust and reliability in the supplier relationship.

Finally, B2B buyers should consider suppliers who embrace continuous improvement methodologies, such as Six Sigma or Total Quality Management (TQM). These approaches demonstrate a commitment to ongoing enhancement of processes and products, which is vital in a competitive market.

By understanding the manufacturing processes and quality assurance practices specific to CO2 bike tire inflators, B2B buyers can make informed decisions that align with their quality expectations and market demands.

Navigating the procurement of bike tire inflators, particularly CO2 models, requires a methodical approach to ensure quality, reliability, and cost-effectiveness. This guide outlines essential steps for B2B buyers, focusing on critical factors that influence sourcing decisions. By following this checklist, you can streamline your purchasing process and secure the best products for your needs.

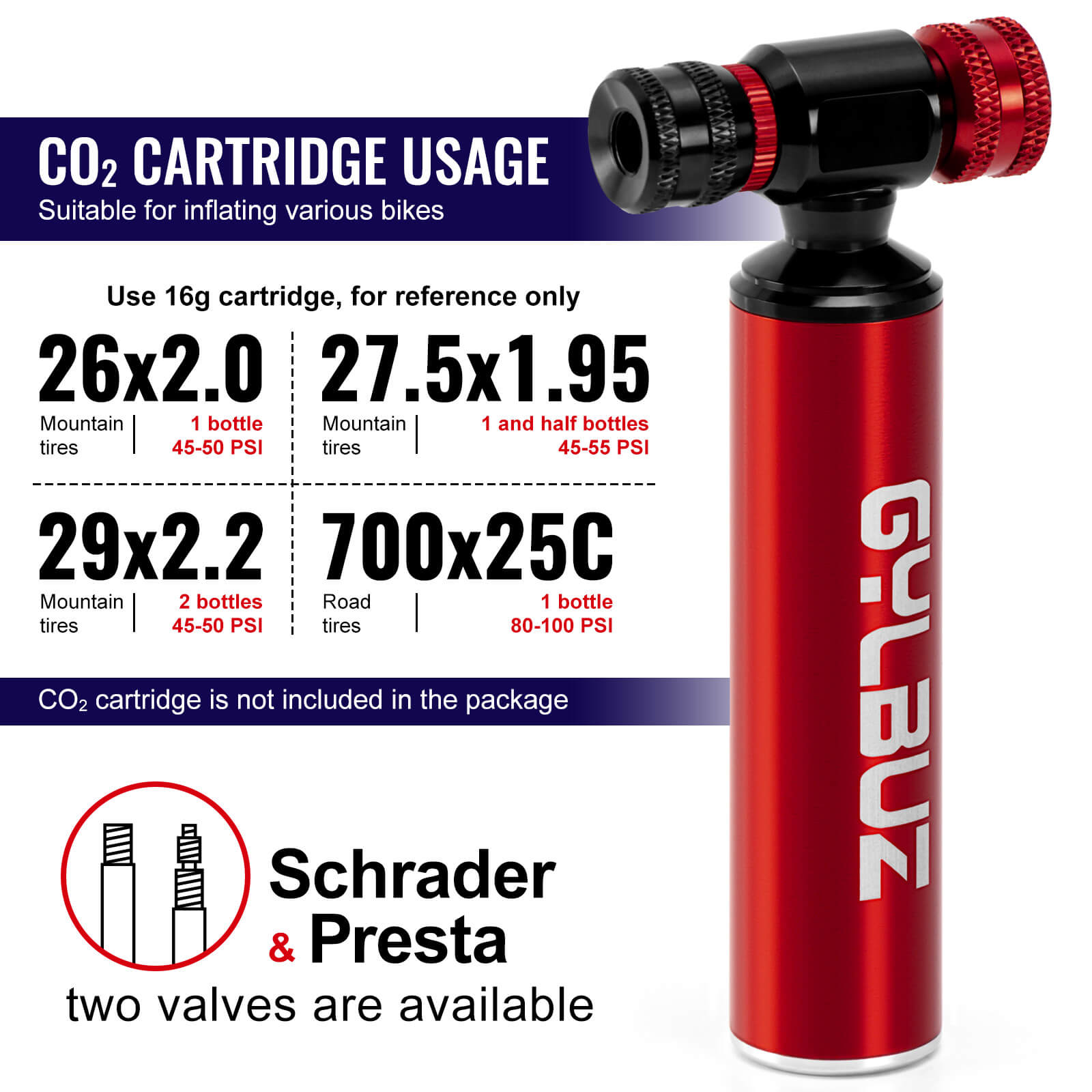

Before engaging with suppliers, clarify the technical requirements for the CO2 inflators you intend to procure. Consider factors such as compatibility with valve types (Presta and Schrader), inflation speed, and the size of CO2 cartridges. Establishing these specifications upfront will help you narrow down potential suppliers who can meet your exact needs.

Stay informed about the latest trends and technological advancements in bike tire inflators. Innovations such as compact designs, dual-function pumps, and adjustable flow controls can enhance user experience. Understanding market trends not only helps in selecting cutting-edge products but also positions your business as a knowledgeable player in the industry.

Thoroughly vet prospective suppliers to ensure they meet your quality and service expectations. Request detailed company profiles, including their manufacturing processes, quality assurance protocols, and any certifications (e.g., ISO). Additionally, seek case studies or references from other businesses in your region that have successfully partnered with them to gauge reliability and customer satisfaction.

Once you have shortlisted suppliers, request samples of their CO2 inflators for evaluation. Testing these products will allow you to assess their performance, durability, and ease of use firsthand. Consider factors such as inflation speed and the ergonomics of the design, as these will directly impact customer satisfaction and return rates.

Collect detailed pricing information from your shortlisted suppliers, ensuring that you understand the total cost of ownership, including shipping and potential tariffs. Compare the value offered by each supplier, factoring in quality and service levels against the price. Additionally, clarify payment terms to ensure they align with your financial planning.

Verify that the products comply with regional safety and environmental regulations relevant to your market. This is particularly important in international trade, where non-compliance can lead to costly fines or shipment delays. Ensure that suppliers can provide documentation to demonstrate adherence to these standards.

Effective communication is vital throughout the procurement process. Establish clear lines of communication with your selected suppliers to discuss order details, timelines, and potential issues that may arise. Regular updates and open dialogue can help prevent misunderstandings and ensure a smooth purchasing experience.

By following these steps, B2B buyers can make informed decisions when sourcing bike tire inflators, ultimately enhancing their product offerings and improving customer satisfaction.

Illustrative image related to bike tire inflator co2

When sourcing bike tire CO2 inflators, understanding the cost structure is crucial for effective budgeting and pricing strategies. The primary cost components include:

Materials: The raw materials used in manufacturing CO2 inflators can significantly affect costs. High-quality aluminum or durable plastic is often preferred for their lightweight and corrosion-resistant properties. Additionally, the type of CO2 cartridges—16g, 20g, or 38g—also influences material costs.

Labor: Labor costs vary by region and the complexity of the manufacturing process. In regions like Europe, where labor costs are higher, it is essential to assess how this will impact overall pricing. Conversely, sourcing from countries with lower labor costs may offer savings.

Manufacturing Overhead: This includes expenses related to the factory’s operation, such as utilities, maintenance, and administration. Efficient production processes can help mitigate these costs.

Tooling: The initial investment in tooling can be substantial, particularly for custom designs or specialized inflators. Buyers should inquire about the amortization of these costs over production runs to understand their impact on unit pricing.

Quality Control (QC): Implementing stringent QC processes ensures product reliability and safety, which is crucial for maintaining market reputation. The costs associated with QC can vary based on the complexity of the testing procedures.

Logistics: Shipping costs are a significant consideration, particularly for international buyers. Factors such as distance, shipping method, and Incoterms will influence logistics expenses.

Margin: Suppliers typically apply a margin to cover their operational costs and profit. Understanding the typical margins in the industry can help buyers negotiate better deals.

Several factors can influence pricing, including:

Volume/MOQ (Minimum Order Quantity): Larger orders often lead to reduced per-unit costs due to economies of scale. Buyers should negotiate MOQs with suppliers to optimize costs.

Specifications and Customization: Customized inflators or those with advanced features (like dual head compatibility or integrated gauges) may command higher prices. Buyers should balance the need for customization against budget constraints.

Materials and Quality Certifications: High-quality materials and certifications (like ISO or CE) can increase costs but also enhance product reliability. Buyers should consider the long-term benefits of investing in quality.

Supplier Factors: The reputation and reliability of suppliers can impact pricing. Established suppliers may charge a premium for their assurance of quality and service.

Incoterms: The chosen Incoterms can affect the total landed cost. Understanding terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) is essential for accurate cost forecasting.

To enhance cost-efficiency and achieve favorable pricing, consider the following strategies:

Negotiate: Leverage volume purchases and long-term agreements to negotiate better prices. Building strong relationships with suppliers can also lead to more favorable terms.

Evaluate Total Cost of Ownership (TCO): Consider not only the initial purchase price but also ongoing costs, such as maintenance, warranty service, and logistics. A slightly higher upfront cost may lead to lower TCO in the long run.

Understand Pricing Nuances for International Buyers: Different regions may have varying pricing structures due to local market conditions, tariffs, and import duties. Buyers from Africa, South America, the Middle East, and Europe should research local regulations and market dynamics to make informed purchasing decisions.

Request Samples: Before committing to large orders, request samples to evaluate quality and ensure the product meets specifications. This can help avoid costly mistakes.

Stay Informed: Regularly monitor market trends and pricing fluctuations to make timely purchasing decisions. Engaging with industry reports and supplier updates can provide insights into potential price changes.

The prices mentioned in this analysis are indicative and may vary based on supplier negotiations, regional economic conditions, and market demand. Always conduct thorough market research and supplier assessments to determine accurate pricing for specific needs.

When it comes to maintaining optimal tire pressure for bicycles, the market offers various solutions beyond CO2 inflators. Each method has its advantages and disadvantages, which can influence purchasing decisions for B2B buyers seeking reliable tire inflation solutions for their operations. The following analysis compares the popular bike tire inflator CO2 with alternatives such as hand pumps and electric pumps, focusing on performance, cost, ease of implementation, maintenance, and best use cases.

| Comparison Aspect | Bike Tire Inflator CO2 | Hand Pump | Electric Pump |

|---|---|---|---|

| Performance | Fast inflation (seconds) | Moderate inflation speed | Fast inflation (seconds) |

| Cost | Moderate (e.g., $15-$40) | Low (e.g., $10-$30) | High (e.g., $50-$200) |

| Ease of Implementation | Simple, requires cartridges | Requires manual effort | Plug-and-play, minimal effort |

| Maintenance | Low (replace cartridges) | Moderate (occasional repairs) | Low (occasional checks) |

| Best Use Case | Racing, emergencies | Everyday commuting, casual rides | Long-distance rides, bike shops |

1. Hand Pumps

Hand pumps are a traditional and widely used method for inflating bicycle tires. Their primary advantage lies in their low cost and independence from external power sources. Hand pumps are portable and lightweight, making them suitable for everyday commuting and casual rides. However, the inflation process is manual and can be physically demanding, requiring more time to achieve the desired tire pressure. Maintenance involves occasional checks for wear and tear, particularly on the hose and valve connections.

2. Electric Pumps

Electric pumps represent a modern alternative, providing rapid tire inflation with minimal effort. They are especially beneficial for long-distance riders or bike shops where efficiency is key. Electric pumps typically require a power source, either through batteries or an electrical outlet, which can limit their portability. While they are often more expensive than both CO2 inflators and hand pumps, they offer convenience and ease of use. Maintenance is generally low, focusing on keeping the pump charged and checking for any electronic malfunctions.

Illustrative image related to bike tire inflator co2

For B2B buyers, selecting the appropriate tire inflation solution depends on specific operational needs and customer preferences. If speed and compactness are critical, particularly in competitive scenarios, CO2 inflators may be the best choice. Conversely, for businesses that prioritize cost and ease of use, hand pumps offer a reliable solution. Electric pumps, while more expensive, provide efficiency and ease, making them ideal for high-volume environments like bike shops or rental services. Ultimately, understanding the unique advantages of each option will enable buyers to make informed decisions that align with their business goals.

When sourcing CO2 bike tire inflators, understanding the technical specifications is crucial for making informed purchasing decisions. Here are some essential properties to consider:

The material used in CO2 inflators typically includes aluminum, plastic, or a combination of both. Aluminum is favored for its durability and lightweight properties, while high-grade plastics can offer corrosion resistance. In B2B terms, selecting the right material impacts the longevity and reliability of the inflator, which can affect customer satisfaction and product returns.

The pressure rating indicates the maximum pressure that the inflator can handle, usually measured in PSI (pounds per square inch). A higher pressure rating means the inflator can service a broader range of tire types, from road bikes to mountain bikes. For B2B buyers, understanding pressure ratings ensures that the product meets the needs of different customer segments and can handle diverse applications.

Most CO2 inflators are designed to work with either Presta or Schrader valves, the two most common types in bicycles. Some models offer dual compatibility, allowing for greater versatility. For international buyers, especially in regions with varying bike standards, ensuring compatibility can reduce the complexity of inventory management and enhance customer satisfaction.

A flow control mechanism allows users to regulate the speed of CO2 release during inflation. This feature is vital for achieving the desired tire pressure without over-inflating. In a B2B context, offering inflators with flow control can differentiate a product line and cater to professional cyclists who require precision.

The weight and compactness of CO2 inflators are critical for cyclists who prioritize portability. Most inflators are designed to fit easily in a jersey pocket or a small bag. For B2B suppliers, marketing lightweight and compact models can attract customers looking for convenience and ease of use, especially in regions where cyclists often travel long distances.

Illustrative image related to bike tire inflator co2

CO2 inflators typically use cartridges of different sizes, such as 16g, 20g, or 25g. The size impacts the volume of air released, with larger cartridges filling tires faster. B2B buyers should be aware of cartridge compatibility to ensure that customers can easily find refills, thus increasing repeat business.

Understanding industry jargon is essential for effective communication and negotiation in B2B transactions. Here are some common terms:

OEM refers to companies that produce parts or products that are used in another company’s end product. In the context of bike tire inflators, this means manufacturers that supply inflators to brands that sell them under their own label. Buyers should consider OEM relationships for reliability and quality assurance.

MOQ is the smallest number of units that a supplier is willing to sell. This term is crucial for B2B buyers as it affects inventory management and cash flow. Understanding MOQ can help businesses negotiate better terms and avoid overstocking.

An RFQ is a formal process where buyers request price quotes from suppliers for specific products. This is particularly useful for B2B buyers looking to compare prices, terms, and delivery options before making a purchasing decision.

Illustrative image related to bike tire inflator co2

Incoterms (International Commercial Terms) are a set of rules that define the responsibilities of buyers and sellers in international transactions. Familiarity with these terms helps B2B buyers understand shipping costs, risks, and responsibilities, ensuring smoother cross-border transactions.

Lead time refers to the amount of time it takes from placing an order to receiving the goods. Understanding lead times is essential for B2B buyers to manage inventory effectively and meet customer demands, especially in regions with longer shipping durations.

By understanding these technical properties and trade terms, B2B buyers can make more informed decisions when sourcing CO2 bike tire inflators, ultimately leading to better customer satisfaction and business success.

Illustrative image related to bike tire inflator co2

The bike tire inflator CO2 market is experiencing substantial growth due to increasing cycling participation globally, particularly in emerging markets across Africa, South America, and the Middle East. Urbanization and the rising trend of eco-friendly transportation are contributing to this uptick. In Europe, especially in cycling-centric countries like Germany, there is a growing demand for efficient, portable inflators that cater to both competitive cyclists and casual riders. The demand for quick and hassle-free inflation solutions is pushing manufacturers to innovate, integrating advanced features such as dual-valve compatibility and enhanced flow control mechanisms.

Emerging technologies, such as smart CO2 inflators that can connect to mobile applications, are beginning to influence purchasing decisions. These tech-forward products appeal to younger, tech-savvy consumers who prioritize convenience and efficiency. Additionally, the rise of e-commerce platforms is reshaping sourcing trends, allowing international B2B buyers to easily access a broader range of products and suppliers, thus enhancing competition and driving down costs.

Moreover, as the cycling community becomes more environmentally conscious, there is a shift towards lightweight, portable inflators that use recyclable materials. This trend is particularly relevant in regions where sustainability is becoming a pivotal part of consumer decision-making processes.

Illustrative image related to bike tire inflator co2

Sustainability is increasingly important in the bike tire inflator CO2 market, influencing both consumer preferences and B2B purchasing decisions. The environmental impact of CO2 cartridges, primarily derived from fossil fuels, raises concerns about their carbon footprint. B2B buyers are now more inclined to source products from manufacturers committed to sustainable practices, including the use of eco-friendly materials and manufacturing processes.

Ethical sourcing is also gaining traction, with buyers preferring suppliers who ensure fair labor practices and transparency throughout their supply chains. Certifications such as ISO 14001 for environmental management and Fair Trade certifications are becoming key indicators of a supplier’s commitment to sustainability and ethical practices. As a result, businesses that prioritize these certifications can differentiate themselves in a competitive market, appealing to environmentally conscious consumers and retailers.

Additionally, the development of biodegradable or recyclable CO2 cartridges is emerging as a viable alternative. These innovations not only meet the growing demand for sustainable products but also align with global efforts to minimize plastic waste, further enhancing brand reputation in the eyes of eco-aware consumers.

Illustrative image related to bike tire inflator co2

The evolution of bike tire inflators, particularly CO2 models, can be traced back to the early 1990s when they began to gain popularity among competitive cyclists. Initially, these inflators offered a quick solution for flat tires but were limited in their usability and effectiveness. Over the years, advancements in materials and design have led to more compact, efficient, and user-friendly products.

The introduction of integrated inflators that combine hand pumps with CO2 capabilities marked a significant turning point, allowing cyclists to carry a single tool for multiple functions. The rise of technology in the 2000s paved the way for smart inflators, enabling features such as pressure monitoring and smartphone connectivity. As cycling continues to grow in popularity, particularly in urban areas, the demand for innovative and sustainable tire inflation solutions will likely shape the future of this sector, making it crucial for B2B buyers to stay ahead of trends and developments.

How do I choose the right CO2 inflator for my business needs?

Selecting the right CO2 inflator involves considering your target market and the types of bikes they use. Evaluate the inflator’s compatibility with various valve types, such as Presta and Schrader, to ensure versatility. Additionally, look for features like flow control, which allows users to adjust the inflation speed, and compactness for easy transport. Assess the durability and materials used in construction, as these factors will influence the product’s longevity and customer satisfaction.

What is the best CO2 inflator for high-volume tires?

For high-volume tires, such as those found on mountain bikes or gravel bikes, a CO2 inflator that delivers a larger volume of gas quickly is essential. Models like the Lezyne Control Drive or the Muc-Off Road Inflator Kit are excellent choices, as they provide efficient inflation with flow control. Additionally, ensure that the inflator is compatible with the appropriate size of CO2 cartridges, typically 25g or larger, to achieve the necessary pressure effectively.

What are the minimum order quantities (MOQs) for CO2 inflators?

MOQs for CO2 inflators can vary significantly depending on the supplier and the specific product line. Typically, MOQs range from 100 to 1,000 units for bulk orders. It’s advisable to negotiate with suppliers, especially if you are looking to test the market or introduce new products. Many manufacturers may offer flexibility on MOQs for repeat orders or long-term partnerships.

What payment terms should I expect when sourcing CO2 inflators internationally?

Payment terms can differ widely among suppliers. Common arrangements include a 30% deposit upfront with the remaining balance due before shipment or upon delivery. Some suppliers may accept letters of credit, which can provide additional security for both parties. Always discuss and clarify payment terms in advance, and consider using escrow services for larger transactions to mitigate risks.

How do I vet suppliers for CO2 inflators?

To vet suppliers effectively, start by reviewing their business credentials, including certifications and compliance with international quality standards. Request product samples to assess quality and functionality. Additionally, check customer reviews and testimonials to gauge reliability and service levels. Visiting the supplier’s facility, if feasible, can provide further insight into their manufacturing processes and capabilities.

What quality assurance measures should I look for in CO2 inflators?

Quality assurance (QA) measures are critical for ensuring the performance and safety of CO2 inflators. Look for suppliers that implement rigorous testing protocols, such as pressure testing and durability assessments. Certifications such as ISO 9001 indicate a commitment to quality management. Ensure that the inflators meet safety standards applicable in your target markets to avoid compliance issues.

What are the logistics considerations when importing CO2 inflators?

Logistics considerations include understanding shipping methods, costs, and delivery timelines. Choose between air freight for faster delivery or sea freight for cost-effectiveness, especially for larger orders. Factor in customs duties and taxes applicable in your region, as these can significantly affect overall costs. Additionally, ensure that your supplier provides proper documentation, including invoices and certificates of origin, to facilitate smooth customs clearance.

How can I customize CO2 inflators for my brand?

Customizing CO2 inflators can enhance brand recognition and customer loyalty. Discuss options with your supplier, which may include custom colors, branding logos, or specific features tailored to your market. Some manufacturers may offer private labeling services, allowing you to sell products under your brand name. Be sure to confirm any additional costs associated with customization and the minimum lead times required for production.

Domain: planetbike.com

Registered: 1997 (28 years)

Introduction: [{‘name’: ‘ALX 2.0 bike floor pump’, ‘price’: ‘$60.00’}, {‘name’: ’20g CO2 replacement cartridges – threaded’, ‘price’: ‘$15.00 – $55.00’}, {‘name’: ‘Red Zeppelin CO2 bike tire inflator’, ‘price’: ‘$20.00’}, {‘name’: ‘Comp 2.0 bike floor pump’, ‘price’: ‘$30.00’}, {‘name’: ‘STX bike floor pump’, ‘price’: ‘$55.00’}, {‘name’: ‘Fresh Air mini pump’, ‘price’: ‘$20.00’}, {‘name’: ‘Shockmate 3.0 bike su…

Domain: ridepdw.com

Registered: 2008 (17 years)

Introduction: Bike Pumps & CO2 Tire Inflators:

1. Timber to Town: Cloud Cap CO2 Inflator – $39.00

2. Shiny Object – from $19.00

3. Tiny Object – $22.00

4. Fatty Object – from $19.00

5. Timber to Town: Cloud Cap Gravel Pump + CO2 Inflator – $89.00

6. Ninja Pump – $35.00

7. 38g CO2 Cartridge – $15.00

8. 16g CO2 Cartridge Packs – from $10.00

9. Leather CO2 Cartridge Sleeve – $5.00

10. Pump Mount – $5.00 …

Domain: ride.lezyne.com

Registered: 2007 (18 years)

Introduction: Lezyne CO2 inflators provide cyclists with instant, reliable tire inflation in seconds, making them ideal for road bikes and mtb. Key products include: PRESSURE DRIVE CFH ($43.99), CLIK™ DRIVE CO2 WITH 20G CARTRIDGE ($37.99), CADDY KIT ($26.39), CONTROL DRIVE CO2 (from $23.99), TWIN KIT (from $23.99), 25G CO2 – 5 PACK ($22.39), REPAIR KIT ($19.99), 20G CO2 – 5 PACK ($15.99), TRIGGER SPEED DRIVE CO…

Domain: tireject.com

Registered: 2009 (16 years)

Introduction: Tire Inflator Tool with 60g CO2 Canisters by TireJect, priced at $34.99. This product includes supersized 60g CO2 cartridges that inflate tires in seconds without the need for electricity or batteries. It is designed for easy use and is compact, making it ideal for off-road or roadside tire inflation. It can inflate various tire sizes: car tires (up to 205/65R15), truck/SUV tires (up to 265/70R17)…

Domain: northtownebikes.com

Registered: 1999 (26 years)

Introduction: [{‘name’: ‘Serfas 12-Gram CO2 Non-Threaded Cartridges’, ‘price’: ‘$12.99’, ‘description’: ‘Compact, non-threaded 12-gram cartridges compatible with CO2 inflators.’}, {‘name’: ‘Planet Bike 25g CO2 Replacement Cartridges – Threaded’, ‘price’: ‘$8.99 – $99.99’, ‘description’: ‘Quick and easy tire repairs; compatible with most inflators; 100% recyclable steel.’}, {‘name’: ‘Genuine Innovations AirChuck…

Domain: genuineinnovations.com

Registered: 2004 (21 years)

Introduction: CO2 inflators consist of two primary parts: the inflator head (nozzle) and the CO2 cartridge. CO2 cartridges are small cans filled with pressurized carbon dioxide gas, easy to store and use for quick tire inflation. There are threaded cartridges that screw into the inflator head and non-threaded cartridges that are pressed into the inflator head. Some inflator heads allow for flow control, enablin…

In conclusion, strategic sourcing of bike tire inflator CO2 products offers significant advantages for international B2B buyers, especially in emerging markets across Africa, South America, the Middle East, and Europe. By focusing on quality, efficiency, and sustainability, businesses can enhance their product offerings and meet the growing demands of cycling enthusiasts. Investing in reliable inflators not only improves customer satisfaction but also strengthens brand loyalty in a competitive market.

Illustrative image related to bike tire inflator co2

Moreover, as the cycling industry evolves with a shift towards eco-friendly solutions, sourcing partners who prioritize sustainable practices will be crucial. Collaborating with manufacturers that offer innovative designs, effective inflation systems, and reliable after-sales support ensures that your business remains competitive and responsive to market trends.

Looking ahead, now is the time to explore partnerships that align with your strategic objectives. Engage with suppliers who can provide high-quality CO2 inflators while also committing to sustainability and customer service. By making informed sourcing decisions today, you position your business to thrive in the dynamic cycling market of tomorrow.

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.