In an increasingly competitive global market, sourcing free compressed air near me has become a pivotal concern for businesses seeking to optimize operational costs and enhance efficiency. As international B2B buyers from regions such as Africa, South America, the Middle East, and Europe navigate the complexities of supply chains, identifying reliable sources of free air can significantly impact both profitability and sustainability. This comprehensive guide delves into various types of free compressed air sources, their applications in diverse industries, and essential criteria for vetting potential suppliers.

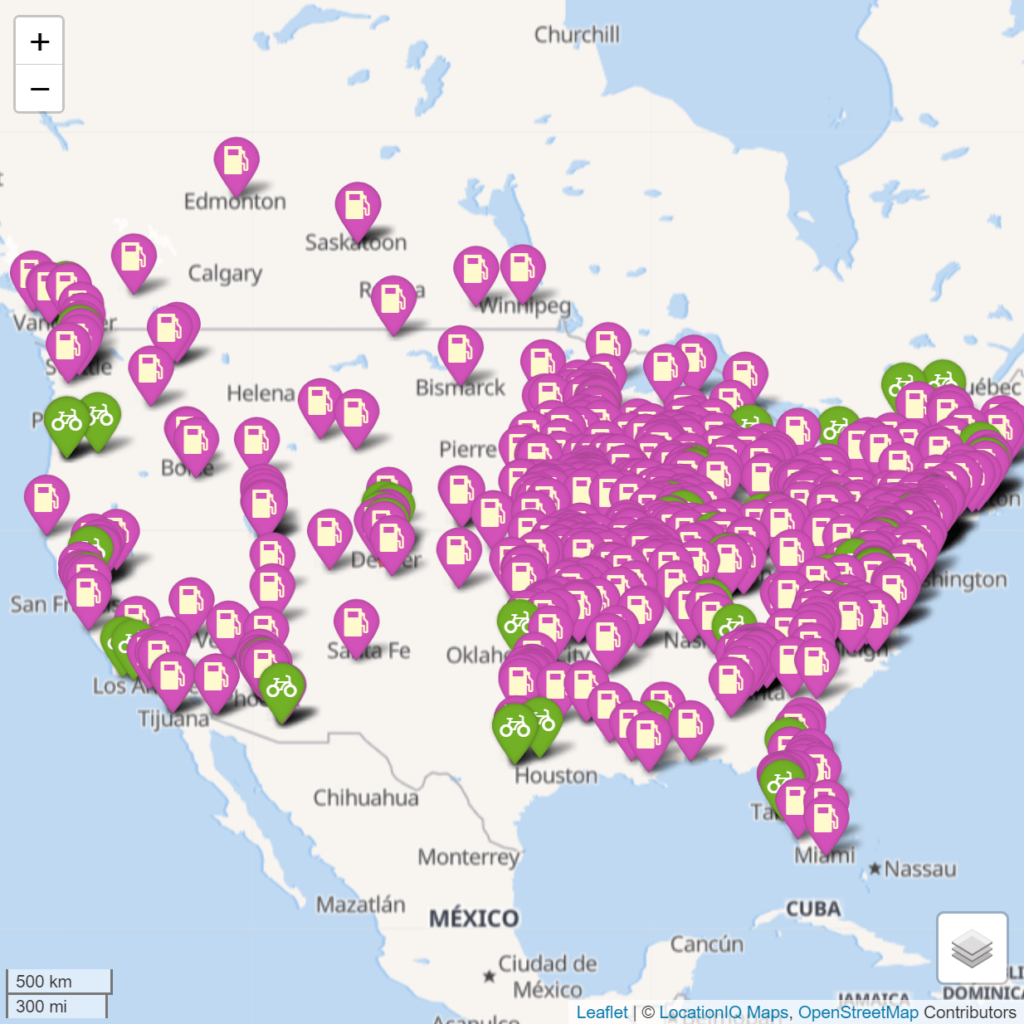

Understanding the nuances of sourcing free compressed air is vital for making informed purchasing decisions. This guide empowers businesses to explore different avenues—ranging from gas stations and tire shops to bike repair stations—where free air services are offered. Additionally, it covers the financial implications, providing insights into cost-saving opportunities and the potential for leveraging these services to enhance customer satisfaction.

By equipping B2B buyers with actionable insights and a thorough understanding of the market landscape, this resource aims to simplify the sourcing process, ensuring that businesses can efficiently locate and utilize free compressed air resources. Whether you are based in Nigeria, Germany, or any other global hub, this guide serves as your roadmap to navigate the intricate web of suppliers, ultimately driving better business outcomes.

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Gas Station Air Pumps | Typically found at fuel stations; often user-operated | Automotive services, fleet management | Pros: Accessible, often free; Cons: May be limited to certain hours, potential maintenance issues. |

| Tire Shop Compressors | Located in tire service centers; usually high-quality | Tire repair, vehicle maintenance | Pros: Reliable, professional-grade equipment; Cons: May require purchase or service fees. |

| Bike Repair Stations | Stand-alone or at bike shops; designed for bicycles | Cycling businesses, recreational services | Pros: Convenient for cyclists; Cons: Limited to bike tires only. |

| Portable Air Compressors | Compact, user-friendly devices for personal use | Small businesses, mobile service units | Pros: Versatile, can be used anywhere; Cons: Initial purchase cost, requires power source. |

| Community Air Stations | Publicly funded or community-supported air stations | Local community services, public works | Pros: Free for public use, promotes community engagement; Cons: Availability may vary, potential for vandalism. |

Gas station air pumps are commonly found in various locations, providing quick access to compressed air for automotive needs. These pumps are typically user-operated, allowing drivers to fill their tires without charge. They are especially valuable for businesses managing fleets, as regular tire maintenance can enhance vehicle efficiency and safety. However, businesses should consider the reliability of these pumps, as they may experience downtime or be unavailable during late hours.

Tire shop compressors are often more robust than standard gas station pumps, offering high-quality compressed air suited for tire repairs and maintenance. These compressors are typically found in professional tire service centers, making them ideal for businesses focused on automotive services. While they can provide a more reliable air supply, businesses may need to factor in potential service fees or membership costs associated with using these facilities.

Bike repair stations cater specifically to the cycling community, offering air for bicycle tires. They can be found in bike shops or as standalone units in public areas. For businesses involved in cycling sales or services, these stations provide an excellent opportunity to attract customers and enhance service offerings. However, their utility is limited to bicycles, which may not be suitable for businesses needing air for larger vehicles.

Portable air compressors are compact devices that can be utilized in various settings, making them a flexible option for businesses. They are particularly useful for small businesses or mobile service units that require on-the-go tire inflation. While these devices offer convenience and versatility, businesses should consider the initial investment and the need for a power source when selecting this option.

Community air stations are often funded by local governments or organizations, providing free air to the public. These stations promote community engagement and can serve as a valuable resource for local businesses looking to foster goodwill. However, businesses should be aware that the availability of these stations can vary, and they may face challenges related to maintenance and potential vandalism.

| Industry/Sector | Specific Application of free compressed air near me | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Repair | Tire inflation and maintenance | Reduces operational costs and enhances customer satisfaction | Proximity to air sources, reliability of equipment, and local regulations |

| Manufacturing | Pneumatic tools and machinery operation | Improves efficiency and reduces production downtime | Availability of compressed air outlets and pressure consistency |

| Transportation | Fleet maintenance for trucks and buses | Lowers maintenance costs and increases vehicle uptime | Accessibility of air stations and air quality standards |

| Construction | Powering pneumatic tools on-site | Increases productivity and reduces tool expenses | Dependability of air supply, local infrastructure, and safety regulations |

| Cycling and Sports | Bicycle tire inflation at events and shops | Enhances customer experience and promotes cycling | Accessibility for cyclists, maintenance of air pumps, and service quality |

In the automotive repair sector, free compressed air is primarily utilized for tire inflation and maintenance. Businesses can offer complimentary air services to customers, enhancing their service portfolio while reducing operational costs associated with purchasing air. This practice not only attracts more customers but also fosters loyalty, as clients appreciate the added value. For international B2B buyers, understanding local regulations and the reliability of air sources is crucial to ensure consistent service delivery.

In manufacturing, free compressed air is essential for operating pneumatic tools and machinery. It facilitates various processes, including assembly lines and material handling, leading to enhanced efficiency and reduced production downtime. Access to reliable air sources can significantly lower operational costs, making it an attractive option for manufacturers. B2B buyers should consider the proximity of air supply stations and the consistency of pressure to meet production demands effectively.

The transportation industry, particularly fleet maintenance for trucks and buses, benefits from free compressed air by lowering maintenance costs and increasing vehicle uptime. Regular tire inflation is critical for safety and efficiency, and having access to complimentary air can streamline operations. For international buyers, it’s important to assess the accessibility of air stations along common routes and ensure compliance with local safety standards.

In the construction industry, free compressed air is often used to power pneumatic tools, which are vital for various tasks such as drilling, nailing, and cutting. Access to free air can significantly increase productivity on job sites while reducing tool expenses, as contractors can rely on local air sources instead of investing in portable compressors. Buyers should evaluate the dependability of air supplies and ensure that local infrastructure can support their operational needs.

Illustrative image related to free compressed air near me

For cycling and sports, free compressed air is invaluable for tire inflation at events and within bike shops. Providing free air services enhances the customer experience, encouraging more people to engage in cycling. This not only fosters community but also promotes a healthier lifestyle. B2B buyers should focus on the accessibility of air stations for cyclists and the maintenance of air pumps to ensure a positive service environment.

The Problem: B2B buyers often face the challenge of finding reliable sources for free compressed air. This inconsistency can be particularly frustrating for businesses reliant on logistics and transport, where maintaining proper tire pressure is crucial for operational efficiency. The challenge is exacerbated in regions where free air services are not uniformly available, leading to unplanned stops, delays, and increased operational costs. For example, a delivery company might find its drivers spending valuable time searching for air stations, which not only affects productivity but also incurs additional fuel costs.

The Solution: To overcome this issue, businesses should leverage user-generated maps and databases that track the availability of free air stations. One effective strategy is to utilize platforms like FreeAirPump.com, which offer crowdsourced information on air stations. Companies can encourage drivers to download the app or bookmark the website, enabling them to quickly locate nearby stations. Additionally, establishing partnerships with local gas stations or tire shops can provide private agreements for air access, ensuring that drivers have reliable air sources on their routes. Regularly updating this information and integrating it into route planning systems can significantly reduce downtime and associated costs.

The Problem: Another significant concern for B2B buyers is the quality of compressed air available at free stations. Not all air pumps deliver air at the necessary pressure or quality, which can lead to improperly inflated tires. This is particularly critical for businesses that operate heavy-duty vehicles, as underinflated tires can lead to increased fuel consumption and decreased safety. A company may find itself facing unexpected maintenance costs or even accidents due to poor tire pressure management.

The Solution: To address this challenge, businesses should implement a standardized checklist for drivers to evaluate air quality at various stations. This checklist can include parameters such as the pressure gauge reading, the presence of visible contaminants, and the operation of the air pump. Additionally, companies can invest in portable tire pressure monitoring systems that allow drivers to measure tire pressure accurately after filling up. Educating drivers on the importance of tire maintenance and proper inflation practices can also foster a culture of safety and efficiency within the organization. Creating a feedback loop where drivers report the quality of air stations can help build a database of reliable locations.

The Problem: Time management is crucial in the B2B sector, particularly in logistics and transportation. Drivers often waste significant time searching for free air stations, leading to inefficiencies and disruptions in schedules. This is especially true in urban areas where gas stations may be scattered or where the availability of free air is not well advertised. For businesses, this translates into lost revenue and strained client relationships due to missed delivery windows.

The Solution: To mitigate this problem, businesses can develop a proactive strategy that incorporates technology. Implementing a mobile app or integrating GPS tracking with a database of free air locations can streamline the process for drivers. By utilizing geolocation services, drivers can receive real-time notifications of nearby air stations as they approach critical points in their routes. Additionally, businesses should consider training sessions for drivers that focus on optimizing route planning and utilizing available resources effectively. Encouraging drivers to share their own tips and experiences regarding air stations can also foster a collaborative environment that enhances overall operational efficiency.

When selecting materials for systems providing free compressed air, particularly for international B2B applications, it’s essential to consider factors such as durability, cost, and compliance with regional standards. Below are analyses of four common materials used in these systems.

Key Properties: Aluminum is lightweight and has excellent corrosion resistance. It can withstand moderate pressures and temperatures, making it suitable for compressed air applications.

Pros & Cons: The durability of aluminum is high, but its cost can be moderate compared to other metals. Manufacturing complexity is relatively low, which allows for easier fabrication into various shapes. However, aluminum may not be suitable for high-pressure applications beyond 200 psi.

Impact on Application: Aluminum is compatible with most media used in compressed air systems, including oil-free air, which is crucial for applications requiring clean air.

Considerations for International Buyers: Buyers in regions like Africa and South America should ensure that aluminum components meet ASTM standards for pressure vessels. In Europe, compliance with DIN standards is critical.

Key Properties: Steel offers high strength and excellent pressure ratings, making it suitable for high-pressure applications. It has good corrosion resistance when treated.

Illustrative image related to free compressed air near me

Pros & Cons: Steel’s durability and strength are significant advantages, especially in heavy-duty applications. However, it is heavier than aluminum and may require more complex manufacturing processes. The cost is generally low to medium, depending on the grade.

Impact on Application: Steel is compatible with various media but may require protective coatings to prevent rust, particularly in humid climates.

Considerations for International Buyers: Compliance with JIS standards is essential for buyers in Japan and other regions. Buyers in the Middle East should consider the impact of high temperatures on steel’s performance.

Illustrative image related to free compressed air near me

Key Properties: Polyethylene is a lightweight, flexible plastic that can handle moderate pressures. It has good chemical resistance and is often used in piping systems.

Pros & Cons: The low cost and ease of manufacturing make polyethylene an attractive option for many applications. However, its pressure rating is lower than metals, which limits its use in high-pressure systems.

Impact on Application: Polyethylene is suitable for transporting compressed air in low-pressure applications and is compatible with various media, including moisture-laden air.

Illustrative image related to free compressed air near me

Considerations for International Buyers: Compliance with local environmental regulations is crucial, especially in regions like Europe, where stringent plastic use regulations exist.

Key Properties: Brass is a corrosion-resistant alloy of copper and zinc, known for its durability and good mechanical properties. It can handle moderate pressures and temperatures.

Pros & Cons: Brass fittings and components are durable and provide excellent sealing properties. However, the cost is higher than aluminum and polyethylene, and manufacturing complexity can be significant.

Impact on Application: Brass is often used in fittings and connectors within compressed air systems, ensuring leak-free performance.

Considerations for International Buyers: Buyers in Germany should ensure that brass components comply with DIN standards, while those in Africa should consider the availability of brass versus alternatives.

| Material | Typical Use Case for free compressed air near me | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Compressed air piping and storage tanks | Excellent corrosion resistance | Limited high-pressure application | Medium |

| Steel | High-pressure air tanks and structural components | High strength and durability | Heavier and more complex to manufacture | Low to Medium |

| Polyethylene | Low-pressure air distribution systems | Lightweight and cost-effective | Limited pressure rating | Low |

| Brass | Fittings and connectors in compressed air systems | Excellent sealing and corrosion resistance | Higher cost and manufacturing complexity | High |

This guide provides a strategic overview of material selection for free compressed air systems, emphasizing key properties, advantages, limitations, and considerations for international buyers. Understanding these factors will enable B2B buyers to make informed decisions that align with their operational needs and compliance requirements.

The production of compressed air systems involves a multi-stage manufacturing process that ensures efficiency, safety, and reliability. Understanding these stages can help B2B buyers identify suppliers who meet quality and performance standards.

The initial stage of manufacturing begins with selecting high-quality materials. Common materials include:

Material selection is crucial, as it directly impacts the longevity and performance of the compressed air system. Suppliers often procure materials from certified vendors, ensuring they meet industry standards.

In the forming stage, raw materials are transformed into specific components through various techniques:

Each forming method is selected based on the desired characteristics of the final product, balancing cost and quality.

The assembly process is where individual components come together to create a complete compressed air system. Key aspects include:

Illustrative image related to free compressed air near me

Effective assembly techniques not only enhance performance but also reduce the likelihood of system failures.

Finishing processes are essential for ensuring the durability and aesthetic quality of compressed air systems. Common techniques include:

Finishing touches not only enhance functionality but also contribute to the overall lifespan of the product.

Quality assurance (QA) is critical in manufacturing compressed air systems to guarantee reliability and compliance with industry standards. B2B buyers should be familiar with the relevant QA measures.

Certifications such as ISO 9001 are vital indicators of a supplier’s commitment to quality management systems. This certification ensures that the manufacturer consistently meets customer and regulatory requirements. Other relevant standards include:

Understanding these certifications helps B2B buyers assess the credibility of potential suppliers.

Quality control (QC) checkpoints are integral to maintaining standards throughout the manufacturing process. Key checkpoints include:

Implementing rigorous QC checkpoints minimizes defects and enhances customer satisfaction.

Testing methods for compressed air systems vary but typically include:

These tests ensure that B2B buyers receive products that meet or exceed expectations.

Verification of a supplier’s quality control measures is essential for B2B buyers. Here are several strategies to ensure compliance and reliability:

Conducting supplier audits is an effective way to assess quality control practices. Key aspects to evaluate during audits include:

Illustrative image related to free compressed air near me

Regular audits help maintain a high standard of quality and compliance.

Requesting quality control reports and certifications from suppliers is vital. Key documents to obtain include:

Having access to these documents allows B2B buyers to make informed decisions.

Engaging third-party inspection services can provide an unbiased assessment of a supplier’s quality control processes. Benefits include:

Utilizing third-party inspections can enhance confidence in the quality of the products being sourced.

When sourcing compressed air systems internationally, B2B buyers must be aware of specific quality control nuances:

Quality standards can vary significantly between regions. For instance, products sold in Europe may require CE marking, while those in the Middle East may need to comply with different regulations. Understanding these regional requirements is crucial to ensure compliance.

Cultural differences can impact communication and expectations regarding quality. B2B buyers should be prepared to navigate these differences, ensuring that quality standards are clearly communicated and understood.

Language barriers can complicate quality assurance processes. It is advisable to engage with suppliers who can provide documentation and support in a language that is comfortable for the buyer, ensuring clarity in specifications and requirements.

By understanding these manufacturing processes and quality assurance measures, B2B buyers can make informed decisions when sourcing compressed air systems, ensuring that they partner with reliable suppliers who meet their needs and expectations.

In the quest for cost-effective solutions, sourcing free compressed air can be a smart move for businesses, especially in regions where transportation and operational costs are crucial. This guide provides a practical checklist for international B2B buyers looking to locate sources of free compressed air, particularly in Africa, South America, the Middle East, and Europe.

Understanding your geographical requirements is the first step in sourcing free compressed air. Knowing where your operations are located will help you pinpoint nearby suppliers. Consider factors such as accessibility, distance from your facility, and any regional regulations that may affect availability.

Before proceeding, it’s essential to familiarize yourself with local laws regarding the provision of free air. Some regions may have legal requirements that mandate gas stations to offer free air, while others may not.

Once you have a list of potential sources, evaluate them based on reliability and service quality. Free air services can vary widely in terms of maintenance and accessibility.

Before relying on a location, it’s prudent to contact the suppliers directly to confirm that they still offer free compressed air. This step helps avoid any inconvenience during procurement.

Leverage online platforms that maintain databases of free air sources. These platforms can provide real-time updates and user-generated content about the availability of air services.

If you encounter challenges in finding free compressed air, explore alternative solutions, such as purchasing portable air compressors. These can serve as a reliable backup for your air needs.

Finally, continuously monitor and assess your sourcing strategy for free compressed air. As your business evolves, so too should your approach to air procurement.

By following this checklist, B2B buyers can effectively navigate the complexities of sourcing free compressed air, optimizing their operational costs while ensuring reliable access to this essential resource.

When analyzing the cost structure associated with sourcing free compressed air, several components come into play, including materials, labor, manufacturing overhead, tooling, quality control, logistics, and margin.

Illustrative image related to free compressed air near me

Materials: The primary material in question is the compressed air itself, which is typically generated through electricity-powered compressors. The cost of electricity can vary significantly based on location, impacting the overall cost structure. Furthermore, the choice of compressor technology (oil-free vs. oil-lubricated) can influence material costs.

Labor: Labor costs involve both the workforce required for operating compressors and maintenance personnel to ensure equipment is functioning efficiently. In regions with lower labor costs, such as parts of Africa and South America, companies may find it beneficial to source services locally to reduce expenses.

Manufacturing Overhead: This includes costs associated with running and maintaining the facility that houses the compressors. Factors such as rent, utilities, and administrative expenses must be factored into the overall cost of providing free air services.

Tooling and Quality Control (QC): Investment in high-quality compressors and regular maintenance is essential to ensure reliability and safety. This includes costs associated with tooling for maintenance and QC processes to monitor air purity and pressure levels.

Logistics: If compressed air is delivered to a centralized location, logistics costs can be significant. This involves transportation and distribution, particularly for regions with limited infrastructure.

Margin: While the service is marketed as “free,” suppliers often incorporate these costs into the pricing of related services, such as tire repairs, or through membership fees at facilities offering free air as a perk.

Several factors influence the pricing of free compressed air, especially for international B2B buyers:

Volume/MOQ: Higher volumes can lead to reduced costs per unit, making it essential for businesses to consider minimum order quantities (MOQ) when negotiating contracts with suppliers.

Specifications and Customization: Specific needs, such as air purity levels or delivery methods, can affect pricing. Custom solutions may incur additional costs, so businesses should clearly define requirements upfront.

Materials and Quality Certifications: The quality of the equipment and air produced can vary. Suppliers offering certified products may charge a premium, but this can enhance reliability and safety, crucial for industries such as automotive or manufacturing.

Supplier Factors: The reputation and reliability of suppliers can significantly influence pricing. Established suppliers with a proven track record may command higher prices, but they often provide better service and support.

Incoterms: Understanding shipping terms is vital for international buyers. Different Incoterms can affect total landed costs, so it’s crucial to negotiate favorable terms that minimize unexpected expenses.

For B2B buyers, particularly in Africa, South America, the Middle East, and Europe, several strategies can enhance cost-efficiency when sourcing free compressed air:

Negotiation: Always negotiate pricing and terms. Leverage volume commitments or long-term contracts to secure better pricing.

Total Cost of Ownership (TCO): Consider the TCO, which includes not just the initial purchase price but also maintenance, operational costs, and potential downtime. This holistic approach can uncover hidden costs.

Pricing Nuances for International Buyers: Be aware of currency fluctuations, tariffs, and local regulations that might affect pricing. Establishing contracts in a stable currency can mitigate risks.

Research Local Alternatives: Exploring local suppliers may reveal competitive pricing, especially in regions with lower operational costs. Additionally, local suppliers may have a better understanding of regional regulations and market dynamics.

Stay Informed: Keep abreast of market trends and technological advancements in compressed air production, as these can impact pricing and service offerings.

The prices and cost structures discussed are indicative and can vary based on numerous factors, including market conditions and supplier negotiations. Always conduct thorough research and consult with industry experts when making sourcing decisions.

In the quest for efficient tire inflation solutions, many businesses and individuals often seek out free compressed air options. However, there are alternative methods available that may better serve specific needs, depending on circumstances such as location, frequency of use, and budget. This analysis will compare ‘free compressed air near me’ against two viable alternatives: portable air compressors and nitrogen inflation systems.

| Comparison Aspect | Free Compressed Air Near Me | Portable Air Compressor | Nitrogen Inflation System |

|---|---|---|---|

| Performance | Sufficient for regular tire inflation | High efficiency, consistent pressure | Improved tire performance and longevity |

| Cost | Free | $30 – $200 (initial investment) | $5 – $10 per tire (service fee) |

| Ease of Implementation | Easy to locate and use | Requires personal investment and setup | Requires specialized equipment and service |

| Maintenance | None | Minimal, occasional checks needed | Regular checks and refills required |

| Best Use Case | Occasional users, budget-conscious | Frequent users, mobile businesses | Performance-focused applications, fleet management |

Portable air compressors are a practical alternative for businesses that require frequent tire inflation. They offer high efficiency and consistent pressure, which is crucial for maintaining optimal tire performance. While the initial investment can range from $30 to $200, the long-term savings can be significant, especially for businesses with a fleet of vehicles. The ease of use is a considerable advantage, as these devices can be used anywhere, eliminating the need to find a nearby air source. However, they require minimal maintenance and may not be as convenient for those who only occasionally need to inflate tires.

Nitrogen inflation systems are designed to enhance tire performance and longevity by reducing pressure loss and heat buildup. This method is particularly beneficial for high-performance vehicles or fleets where tire performance is critical. While the service fee for nitrogen inflation can be $5 to $10 per tire, the benefits may outweigh the costs for businesses focused on performance and safety. However, nitrogen systems require specialized equipment and service, making them less accessible than free air options. Regular checks and refills are also necessary, adding to the long-term commitment.

When evaluating tire inflation solutions, B2B buyers must consider their specific requirements, including frequency of use, budget constraints, and performance goals. Free compressed air services are ideal for occasional users seeking cost-effective solutions, while portable air compressors cater to those who require flexibility and convenience. On the other hand, nitrogen inflation is best suited for businesses prioritizing tire performance and safety. By carefully assessing these alternatives, businesses can make informed decisions that align with their operational needs and financial strategies.

Understanding the technical properties of free compressed air is crucial for B2B buyers looking to optimize operations and reduce costs. Here are some critical specifications and their importance in a business context:

Pressure rating indicates the maximum pressure at which the air can be safely stored and used. This is vital for ensuring that equipment operates efficiently and safely. In industrial settings, operating below the optimal pressure can lead to inefficient performance and increased energy costs.

The flow rate measures the volume of air delivered per unit of time, typically expressed in cubic feet per minute (CFM). A higher flow rate is essential for operations requiring rapid tire inflation or pneumatic tool use. Understanding flow rates helps businesses choose the right air source to meet their operational demands without incurring unnecessary costs.

Illustrative image related to free compressed air near me

Purity level refers to the cleanliness of the compressed air, often measured by the presence of moisture, oil, and particulates. High-purity air is critical in applications where contamination can affect product quality, such as in food processing or pharmaceuticals. Ensuring the right purity level can prevent costly downtime and product recalls.

Temperature range indicates the operational limits of the compressed air system. Air that is too hot can lead to equipment failure and increased wear and tear. Businesses must ensure that the compressed air they utilize remains within the specified temperature range to maintain optimal performance and longevity of their machinery.

Moisture content is a critical property that affects the performance of pneumatic systems. Excess moisture can cause corrosion, freeze-ups, and other operational issues. Understanding moisture levels helps businesses implement proper drying systems, ensuring that their compressed air meets industry standards and reduces maintenance costs.

Familiarizing oneself with industry jargon can facilitate smoother transactions and negotiations. Here are several common trade terms relevant to free compressed air:

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of compressed air systems, understanding OEM relationships can help businesses source reliable components and ensure compatibility with existing systems.

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. For businesses looking to purchase compressed air systems or related components, knowing the MOQ is essential for budgeting and inventory management, especially when evaluating suppliers.

An RFQ is a document issued by a buyer to solicit price quotes from suppliers. In the compressed air market, submitting an RFQ can help businesses compare costs and specifications effectively, ensuring they receive the best value for their investment.

Incoterms are a set of predefined commercial terms published by the International Chamber of Commerce that clarify the responsibilities of buyers and sellers. Understanding these terms is crucial for international transactions involving compressed air systems, as they define who bears the risk and cost at various stages of shipping.

Pneumatics refers to the use of pressurized air to create mechanical motion. This term is fundamental for understanding applications of compressed air in various industries, from manufacturing to automotive services, where pneumatic tools are prevalent.

Illustrative image related to free compressed air near me

By grasping these technical properties and trade terms, B2B buyers can make informed decisions when sourcing free compressed air solutions, ultimately driving efficiency and cost-effectiveness in their operations.

The global demand for free compressed air services is being driven by several factors, including cost-saving measures for businesses and consumers, increased awareness of vehicle maintenance, and the growing popularity of eco-friendly practices. In regions like Africa, South America, the Middle East, and Europe, the trend of offering free air at service stations and tire shops is becoming more prevalent as businesses seek to enhance customer loyalty and attract foot traffic. Many consumers now expect amenities such as free air when visiting gas stations or tire retailers, making it a competitive advantage for businesses.

Emerging technologies, such as mobile applications and geolocation services, are transforming how consumers access free air. These innovations enable users to quickly locate the nearest service points, enhancing convenience and increasing the likelihood of repeat visits. As a result, businesses that integrate these technologies into their customer engagement strategies can significantly improve service accessibility and customer satisfaction.

In addition, environmental considerations are influencing market dynamics. The shift towards sustainable practices is prompting businesses to adopt eco-friendly air compressors that minimize energy consumption and reduce greenhouse gas emissions. International buyers, particularly from regions with stringent environmental regulations, are increasingly prioritizing suppliers who demonstrate a commitment to sustainability.

The importance of sustainability in the free compressed air market cannot be overstated. As environmental concerns continue to grow, businesses are recognizing the need to adopt ethical sourcing practices and reduce their carbon footprints. The environmental impact of traditional air compression methods often includes high energy consumption and reliance on non-renewable resources, prompting a shift toward greener alternatives.

B2B buyers are increasingly seeking suppliers who prioritize sustainability through certifications such as ISO 14001 or Energy Star. These certifications ensure that the products and services offered are aligned with best practices for environmental management. Additionally, the integration of energy-efficient compressors and the use of renewable energy sources in air supply operations are becoming key criteria for procurement decisions.

Moreover, ethical supply chains are essential for establishing trust and credibility in the marketplace. Suppliers that adhere to fair labor practices and demonstrate transparency in their operations are more likely to attract international buyers who value corporate social responsibility. This trend is particularly relevant in regions where consumers are increasingly aware of the ethical implications of their purchasing decisions.

Illustrative image related to free compressed air near me

The evolution of the free compressed air market can be traced back to the early 20th century when air pumps were primarily found in service stations as a courtesy for customers. Initially, these services were offered to build brand loyalty and encourage repeat visits. However, over the years, the landscape has shifted dramatically due to the proliferation of vehicles and the increasing costs associated with vehicle maintenance.

As the automotive industry expanded globally, particularly in regions like Africa and South America, the demand for accessible tire maintenance solutions surged. This led to the establishment of dedicated tire shops and service stations that recognized the need to offer free air as a competitive advantage.

In recent years, the integration of technology has further transformed the market. Crowdsourced platforms and mobile applications have emerged, allowing consumers to locate free air services easily. This shift towards digital solutions reflects changing consumer behaviors and preferences, providing businesses with valuable insights into customer engagement strategies.

In conclusion, the free compressed air market is characterized by dynamic trends influenced by technological advancements, sustainability, and evolving consumer expectations. B2B buyers must remain attuned to these shifts to make informed sourcing decisions that align with their business goals and ethical standards.

How do I find locations that offer free compressed air near me?

To find locations offering free compressed air, utilize online resources such as crowdsourced maps that list gas stations, tire shops, and bike repair stations. Websites like FreeAirPump.com allow you to search by entering your location or using geolocation services. Additionally, local community forums or social media groups can provide insights into newly opened spots or changes in existing services. Always verify the information, as availability can fluctuate.

What are the best sources for free compressed air in my region?

The best sources for free compressed air typically include gas stations, tire repair shops, and dedicated bike repair stations. In regions like Europe and North America, chains such as Costco, Pilot, and various local tire stores often provide complimentary air. In Africa and South America, local auto repair shops or community service stations may also offer free air. It’s advisable to call ahead to confirm availability before visiting.

How can I ensure the quality of free compressed air?

While most locations providing free compressed air maintain acceptable standards, quality can vary. It’s wise to inspect the air pump’s condition and ensure it’s regularly maintained. If possible, check for signs of moisture or contamination in the air, as this can affect tire performance. When in doubt, consider using a portable air compressor for more reliable quality, especially for critical applications in business operations.

What are the international trade regulations for sourcing compressed air equipment?

When sourcing compressed air equipment internationally, you must comply with local regulations regarding imports, customs duties, and safety standards. Each country may have specific requirements for certifications and quality assurance. It’s crucial to work with a reputable supplier familiar with the import process in your region to navigate any legal complexities and ensure compliance with international trade agreements.

How do I vet suppliers for compressed air services?

To effectively vet suppliers, start by researching their reputation through customer reviews and industry ratings. Check their certifications to ensure they meet international quality standards. Additionally, ask for references and case studies showcasing their experience in providing compressed air services. Conducting site visits can also provide insights into their operational capabilities and reliability, which is vital for establishing a long-term partnership.

What are typical payment terms for international B2B transactions involving compressed air?

Payment terms can vary widely based on the supplier and the nature of the agreement. Common practices include upfront payments, partial payments upon order confirmation, and net 30 or net 60 terms after delivery. It’s crucial to negotiate terms that suit both parties while considering factors like currency exchange rates and transaction fees. Establishing clear terms in the contract can prevent misunderstandings and ensure smooth transactions.

What is the minimum order quantity (MOQ) for compressed air equipment?

Minimum order quantities (MOQs) for compressed air equipment can vary significantly depending on the supplier and the type of equipment. Some suppliers may have MOQs as low as one unit, while others may require larger bulk orders. Always inquire about MOQs during the negotiation process to align your purchasing needs with the supplier’s capabilities. This helps in planning your inventory and managing costs effectively.

How can I arrange logistics for importing compressed air equipment?

Arranging logistics for importing compressed air equipment involves several steps. Start by selecting a reliable freight forwarder who understands the complexities of shipping industrial equipment. Coordinate with your supplier to confirm shipping dates and packaging requirements. Additionally, ensure compliance with customs regulations in your country to avoid delays. Consider insurance options to protect your investment during transit, and maintain clear communication with all parties involved to facilitate a smooth import process.

Domain: freeairpump.com

Registered: 2012 (13 years)

Introduction: Map of places that provide free air for tires, with over 12k locations in the U.S. User-generated content, allowing submissions of new free air spots. Offers search functionality by device location or address. Indicates bike repair stations and free air for autos. Lists common places offering free air: tire shops, car repair stations, bike shops, and specific gas station chains (e.g., Co-op, Famil…

Domain: lifehacker.com

Registered: 2004 (21 years)

Introduction: Free air for tires can be found at various locations including gas stations (GATE, GetGo, Holiday Stationstores, Hy-Vee, Kroger, Kum & Go, Kwik Trip, QuickCheck, QuikTrip, Royal Farms, Rutter’s, Sheetz, Stewart’s Shop, Wawa), tire shops (Atlantic Tire and Service, America’s Tire/Discount Tire, Big O Tires, Firestone Complete Auto Care, Goodyear Auto Services, Les Schwab Tire Centers, Just Tires, N…

Domain: yelp.com

Registered: 2003 (22 years)

Introduction: This company, Yelp – Best Free Air in Grand Junction, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Domain: facebook.com

Registered: 1997 (28 years)

Introduction: This company, Facebook – Community Insights, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Domain: protyre.co.uk

Registered: 1999 (26 years)

Introduction: Free air for tyres available at local Protyre garages. Book a free tyre pressure check with qualified fitters. Same day appointments available. Tyre pressure checks include monitoring wear and tread depth. Protyre offers a tyre finder tool for identifying the right tyres at competitive prices. Nationwide garage locator to find nearest Protyre garage.

In an increasingly competitive global market, the ability to strategically source resources like free compressed air can significantly enhance operational efficiency and cost-effectiveness for businesses in various sectors. By identifying local suppliers and leveraging user-generated platforms, international B2B buyers can access a wealth of resources that not only save money but also promote sustainability. The insights gathered from regions such as Africa, South America, the Middle East, and Europe highlight the importance of community-driven initiatives in sourcing free air for automotive and industrial applications.

Furthermore, understanding the geographic distribution of free air sources can aid businesses in making informed decisions about logistics and supply chain management. As the demand for sustainable practices grows, integrating free air sourcing into procurement strategies will not only contribute to cost savings but also align with broader environmental goals.

Looking ahead, B2B buyers are encouraged to actively engage with their communities to identify and share new sources of free compressed air. By collaborating with local businesses and utilizing available resources, companies can enhance their operational capabilities while fostering a culture of resourcefulness and sustainability. Embrace this opportunity to optimize your supply chain and drive your business forward in an eco-conscious manner.

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.