In the fast-paced world of industrial operations, sourcing reliable locking air chucks with gauge can pose significant challenges for B2B buyers. The need for precision, durability, and ease of use is paramount, especially when dealing with high-volume tire inflation across diverse markets. This guide serves as a comprehensive resource, meticulously detailing the various types of locking air chucks, their specific applications, and essential factors to consider when selecting a supplier.

From understanding the nuances of open flow versus closed flow options to evaluating the material quality and design features that enhance performance, this guide equips international buyers from regions such as Africa, South America, the Middle East, and Europe—including key markets like Germany and Vietnam—with the insights necessary to make informed purchasing decisions.

Moreover, we delve into critical aspects such as cost considerations, supplier vetting processes, and the latest innovations in locking air chuck technology. By addressing these key areas, this guide empowers buyers to navigate the complexities of the global market confidently, ensuring they select products that not only meet their operational needs but also enhance efficiency and safety in their tire inflation processes.

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

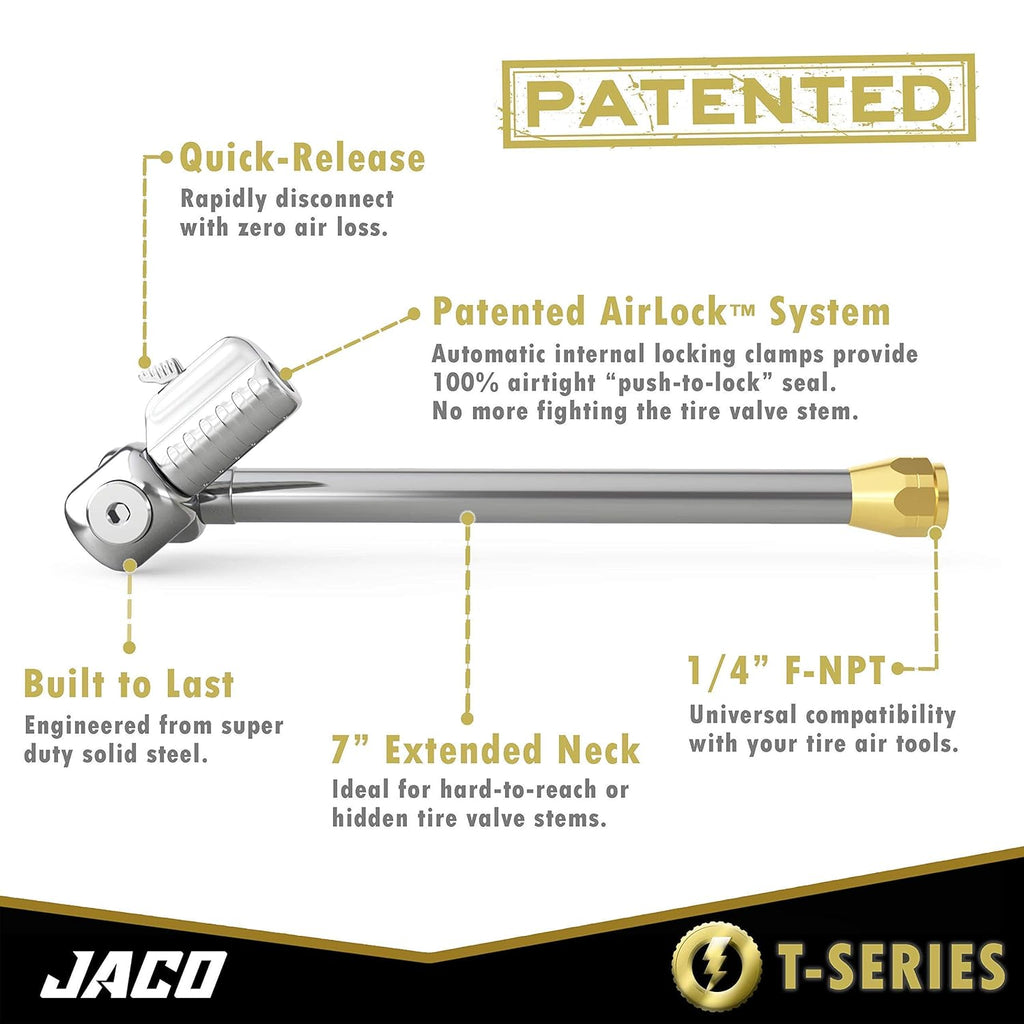

| Push-to-Lock Air Chuck | Patented nozzle for instant airtight seal; zero air loss quick-release | Tire shops, automotive service | Pros: Easy to use, minimal air loss. Cons: May require specific inflator compatibility. |

| 360° Swivel Air Chuck | Flexible head design; eliminates airline tension | Fleet maintenance, logistics | Pros: Enhanced maneuverability, reduces wear on hoses. Cons: Slightly higher cost. |

| Dually Tire Air Chuck | Extended neck for hard-to-reach valves; dual swivel heads | Heavy-duty vehicles, trucks | Pros: Ideal for difficult access, secure connection. Cons: Bulkier design may be cumbersome. |

| Digital Gauge Air Chuck | Integrated digital pressure gauge; precise readings | Construction, industrial vehicles | Pros: Accurate pressure readings, reduces over-inflation risk. Cons: Requires battery maintenance. |

| Self-Locking Air Chuck | Automatic locking mechanism; rapid disconnect | Tire maintenance, automotive shops | Pros: Quick and secure attachment, user-friendly. Cons: Potentially more complex mechanism. |

Push-to-lock air chucks are designed for efficiency, featuring a patented nozzle that provides an instant, airtight seal on tire valve stems. This design minimizes air loss during inflation, making it particularly valuable for tire shops and automotive service centers. When selecting this type, buyers should consider compatibility with their inflators and the chuck’s durability, as frequent use can lead to wear.

The 360° swivel air chuck is characterized by its flexible head, which allows for easy access to valve stems in tight spaces. This design is particularly beneficial for fleet maintenance and logistics operations where quick and efficient tire inflation is essential. Buyers should look for sturdy materials that can withstand heavy use and consider the chuck’s weight, as a lighter design can reduce fatigue during extended use.

Illustrative image related to locking air chuck with gauge

Dually tire air chucks feature an extended neck and dual swivel heads, making them perfect for reaching valve stems on heavy-duty vehicles and trucks. Their design ensures a secure connection even in challenging positions, which is crucial for professionals in transportation and logistics. Buyers should assess the chuck’s reach and compatibility with their existing tools to ensure optimal performance.

Digital gauge air chucks integrate a digital pressure gauge for precise inflation readings, reducing the risk of over-inflation—a common issue in construction and industrial applications. This feature is particularly advantageous for businesses that prioritize safety and efficiency. Buyers should consider battery life and ease of reading the gauge when selecting this option, as these factors can impact usability in busy environments.

Self-locking air chucks utilize an automatic locking mechanism that secures the connection to the valve stem, allowing for rapid inflation and deflation. This user-friendly feature is ideal for tire maintenance in automotive shops where speed and efficiency are paramount. When choosing this type, buyers should evaluate the chuck’s locking mechanism for reliability and the ease of use to ensure it meets their operational needs.

Illustrative image related to locking air chuck with gauge

| Industry/Sector | Specific Application of locking air chuck with gauge | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Repair | Tire inflation and pressure monitoring for vehicles | Ensures optimal tire performance, safety, and fuel efficiency | Reliability, ease of use, compatibility with various tire valves |

| Agriculture | Tire maintenance for heavy machinery and farming equipment | Reduces downtime and enhances operational efficiency | Durability for harsh conditions, ability to handle high pressures |

| Logistics & Transportation | Regular tire checks for fleet vehicles | Increases fleet safety and reduces tire-related incidents | Quick connect features, minimal air loss during inflation |

| Manufacturing | Air pressure maintenance in pneumatic tools | Enhances tool efficiency and extends lifespan | Compatibility with existing pneumatic systems, ease of operation |

| Construction | Tire inflation for heavy construction vehicles | Improves safety and efficiency on job sites | Portability, rugged design, and ease of use in various environments |

In the automotive repair industry, locking air chucks with gauges are essential for tire inflation and pressure monitoring. This equipment ensures that tires are inflated to the correct pressure, which is crucial for vehicle safety, performance, and fuel efficiency. For international buyers, especially from regions like Africa and South America, sourcing durable and reliable air chucks is vital due to varying environmental conditions and the need for consistent performance. Buyers should consider compatibility with different tire valve types and the ease of use in high-volume tire service environments.

In agriculture, locking air chucks with gauges are used for maintaining the tire pressure of heavy machinery such as tractors and harvesters. Proper tire inflation is crucial for maximizing traction and minimizing soil compaction, which can lead to better crop yields. For buyers in the Middle East and Europe, sourcing equipment that can withstand harsh outdoor conditions and high-pressure requirements is essential. Additionally, the ability to rapidly connect and disconnect without air loss is a significant advantage in maintaining operational efficiency during busy farming seasons.

In logistics and transportation, regular tire checks using locking air chucks with gauges are critical for fleet vehicles. This practice helps in preventing tire blowouts and other safety issues, thereby reducing the risk of accidents and associated costs. For international buyers, particularly in regions like Africa and Europe, it is important to source air chucks that offer quick connection features and minimize air loss during inflation. Ensuring that the equipment is robust enough to handle the demands of a busy fleet environment is also a key consideration.

Illustrative image related to locking air chuck with gauge

Manufacturing facilities utilize locking air chucks with gauges to maintain air pressure in pneumatic tools and machinery. Proper air pressure ensures that tools operate efficiently, reducing wear and tear, which extends their lifespan. For B2B buyers, especially in industrial sectors across Europe and South America, it is crucial to select chucks that are compatible with existing pneumatic systems and provide ease of operation. Additionally, sourcing durable products that can withstand the rigors of a manufacturing environment is essential for maintaining productivity.

On construction sites, locking air chucks with gauges are used for tire inflation of heavy construction vehicles like bulldozers and excavators. Ensuring that these vehicles have the correct tire pressure is vital for safety and operational efficiency. Buyers from the Middle East and Africa should focus on sourcing portable and rugged designs that can withstand tough job site conditions. The ability to quickly and easily inflate tires without losing air is also a significant benefit, enhancing productivity on-site.

The Problem: Many B2B buyers, particularly those in tire maintenance and automotive services, face challenges with achieving a reliable, airtight seal when using locking air chucks with gauges. This issue is particularly common in environments with varied tire valve types, such as those seen in trucks, buses, and heavy machinery. An inadequate seal can lead to air loss during inflation, resulting in wasted time and resources, not to mention potential safety hazards if tires are not inflated to the correct pressure.

The Solution: To address this problem, buyers should prioritize investing in high-quality locking air chucks that feature advanced sealing technologies, such as push-to-lock mechanisms and zero air loss quick-release buttons. For instance, products like the Lightning™ Series air chucks are designed to provide a 100% airtight seal with their patented locking systems. When sourcing these tools, it’s crucial to consider compatibility with various tire valve types (like Presta and Schrader) and ensure the chuck’s material is durable enough for heavy use. Additionally, training staff on the proper technique for attaching and detaching the chuck can help minimize air loss. Regular maintenance of the chucks, including cleaning and checking for wear, will also prolong their lifespan and reliability.

Illustrative image related to locking air chuck with gauge

The Problem: Another common pain point for B2B buyers is the incompatibility of locking air chucks with their existing tire inflators and gauges. This issue can cause significant downtime, as teams may need to find adapters or even purchase new equipment to make everything work together. Compatibility issues can also arise with different pressure ratings and flow types, complicating operations in a busy workshop environment.

The Solution: To mitigate compatibility issues, buyers should conduct a thorough inventory of their existing equipment before making a purchase. When selecting locking air chucks, opting for models that come with universal fittings (like 1/4″ NPT) can enhance compatibility across various tools and systems. Additionally, suppliers like LockNLube offer adapters specifically designed to bridge gaps between different valve types and inflator systems. Buyers should also consider a comprehensive tire inflator kit that includes various chucks and adapters to ensure they have the right tools for any job. Establishing a relationship with a reliable supplier who can provide ongoing support and product recommendations can further streamline operations.

The Problem: The inefficiency of the tire inflation process can be a significant concern for businesses that rely on quick turnaround times, such as transportation companies or automotive service centers. Traditional air chucks may require manual adjustments and can lead to frustration when dealing with hard-to-reach valves, especially on dual wheels or heavy-duty vehicles. This inefficiency can result in increased labor costs and slower service times, impacting overall productivity.

The Solution: To improve the efficiency of the tire inflation process, buyers should invest in locking air chucks designed for ease of use and access. Chucks with a 360° swivel head or extended necks, like the Lightning™ T Dually Tire Air Chuck, allow for better maneuverability and easier attachment to valves in tight spaces. Additionally, utilizing a tire inflator with an integrated gauge can streamline the process by eliminating the need to switch between tools. Buyers should also implement standardized procedures for tire inflation, including pre-inflation checks and a set routine for using locking air chucks, to reduce time spent on each tire. Finally, consider training employees on the best practices for tire inflation to enhance speed and accuracy, thereby improving overall operational efficiency.

Illustrative image related to locking air chuck with gauge

When selecting locking air chucks with gauges, the choice of material significantly impacts product performance, durability, and overall suitability for various applications. Below, we analyze four common materials used in the manufacturing of these components, focusing on their properties, advantages, disadvantages, and considerations for international B2B buyers.

Key Properties: Brass is known for its excellent corrosion resistance and ability to withstand high pressures, making it suitable for air chuck applications. It typically has a maximum pressure rating of around 145 PSI.

Pros & Cons: Brass is durable and offers good thermal conductivity, which can be beneficial in high-temperature applications. However, it can be more expensive than other materials and may require more complex manufacturing processes, which can increase lead times.

Impact on Application: Brass is compatible with a wide range of media, including air and gases, making it versatile. However, it may not be suitable for corrosive environments unless specifically treated.

Considerations for International Buyers: Compliance with ASTM standards is crucial for buyers in regions like Europe and the Middle East. Buyers should also consider the availability of brass in their local markets, as sourcing may vary.

Illustrative image related to locking air chuck with gauge

Key Properties: Aluminum alloys are lightweight yet strong, offering good resistance to corrosion and thermal expansion. They typically perform well under moderate pressure conditions.

Pros & Cons: The primary advantage of aluminum is its lightweight nature, which reduces fatigue during use. However, it may not be as durable as brass under extreme conditions, and its cost can vary based on alloy composition.

Impact on Application: Aluminum is suitable for air applications but may not be compatible with certain chemicals or high-temperature environments. This restricts its use in specialized applications.

Considerations for International Buyers: Buyers should ensure that the aluminum alloy meets relevant international standards such as DIN or JIS. Additionally, the recyclability of aluminum may appeal to environmentally conscious buyers.

Key Properties: Chrome-plated zinc alloys provide a balance of strength and corrosion resistance, typically rated for moderate pressure applications. The chrome plating enhances surface durability.

Pros & Cons: This material is cost-effective and offers a good aesthetic finish. However, the plating can wear off over time, potentially exposing the zinc to corrosion.

Impact on Application: Suitable for general air applications, chrome-plated zinc is effective in environments where aesthetics are important. However, it may not be the best choice for high-pressure or corrosive environments.

Considerations for International Buyers: Compliance with local regulations regarding zinc usage is essential, especially in regions with strict environmental laws. Buyers should also consider the potential for wear and plan for replacement cycles accordingly.

Key Properties: Stainless steel is renowned for its exceptional strength, corrosion resistance, and ability to withstand extreme temperatures and pressures.

Illustrative image related to locking air chuck with gauge

Pros & Cons: While stainless steel offers superior durability, it is generally more expensive and can be heavier than other materials, which may affect usability in certain applications.

Impact on Application: Ideal for high-pressure and corrosive environments, stainless steel is compatible with a wide range of media, including aggressive chemicals.

Considerations for International Buyers: Buyers must ensure that the stainless steel meets international standards such as ASTM A276. Its higher cost may be justified in applications requiring longevity and reliability.

| Material | Typical Use Case for locking air chuck with gauge | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Brass | General air applications, high-pressure systems | Excellent corrosion resistance | Higher cost, complex manufacturing | High |

| Aluminum Alloy | Lightweight applications, moderate pressure | Lightweight, good thermal expansion | Less durable under extreme conditions | Medium |

| Chrome-Plated Zinc Alloy | General air applications, aesthetic finishes | Cost-effective, good aesthetic finish | Plating wear can lead to corrosion | Low |

| Stainless Steel | High-pressure, corrosive environments | Exceptional strength and durability | Higher cost, heavier weight | High |

By carefully considering these materials and their properties, B2B buyers can make informed decisions that align with their operational needs and regional compliance requirements.

Illustrative image related to locking air chuck with gauge

The manufacturing and quality assurance processes for locking air chucks with gauges are crucial for ensuring that these tools meet the demands of professional users across various industries, including automotive, aviation, and heavy machinery. Understanding these processes can help B2B buyers make informed decisions when sourcing these products.

The manufacturing process begins with material selection, which is critical for durability and performance. Common materials used include chrome-plated zinc alloy, brass, and aluminum alloys. These materials are chosen for their strength, resistance to corrosion, and ability to withstand high pressure. The initial stage involves cutting raw materials into manageable sizes, followed by surface treatment to enhance their properties, such as applying protective coatings or finishes.

Once the materials are prepared, the next phase is forming. This typically involves techniques such as die casting, machining, and forging. For instance, die casting is often used for zinc alloys to create complex shapes with high precision. Machining may be employed to achieve the exact dimensions required for internal components, ensuring that the locking mechanism functions correctly. Forging is another method that enhances the strength of components through deformation, making them more resilient under pressure.

After forming, the components are assembled. This stage is critical, as it involves fitting various parts, such as the locking mechanism, gauge, and nozzle. Automated assembly systems may be employed to enhance efficiency, but skilled technicians also play a vital role in ensuring that parts fit together seamlessly. The assembly process often includes the installation of seals and gaskets to prevent air leaks, which is essential for the chuck’s performance.

The final stage in the manufacturing process is finishing, which can include polishing, painting, or applying additional protective coatings. This not only improves the appearance of the locking air chuck but also increases its resistance to wear and corrosion. Quality control checks are typically integrated into this stage to ensure that each product meets the required specifications before it is packaged for shipping.

Quality assurance is paramount in the production of locking air chucks, and adhering to international standards such as ISO 9001 is crucial. This standard outlines the requirements for a quality management system and ensures that manufacturers consistently meet customer and regulatory requirements. B2B buyers can look for suppliers that have ISO 9001 certification as a sign of commitment to quality.

In addition to ISO 9001, industry-specific certifications such as CE marking and API (American Petroleum Institute) standards may also apply. CE marking indicates compliance with European health, safety, and environmental protection standards, which is particularly relevant for buyers in Europe. API standards are important for products used in the oil and gas industry, ensuring that they can withstand the rigorous demands of that sector.

The first checkpoint in quality control is Incoming Quality Control (IQC), where raw materials are inspected upon arrival at the manufacturing facility. This ensures that only high-quality materials are used in production, which is critical for the performance and safety of the final product.

In-Process Quality Control (IPQC) involves monitoring the manufacturing process at various stages. This includes verifying dimensions during machining and ensuring that assembly techniques meet specified standards. Regular checks help identify any deviations from the desired quality early in the production process, reducing waste and rework.

Illustrative image related to locking air chuck with gauge

Final Quality Control (FQC) is the last line of defense before products are shipped to customers. This stage involves rigorous testing of the finished locking air chucks. Common tests include pressure tests to verify that there are no leaks, functional tests to ensure that the locking mechanism works correctly, and visual inspections for any defects in finish or assembly.

B2B buyers should conduct supplier audits to assess the manufacturing and quality assurance processes in place. This includes examining the facility, reviewing quality management documentation, and interviewing key personnel. An audit can provide insights into the supplier’s adherence to international standards and their commitment to continuous improvement.

Buyers should also request quality assurance reports that detail the outcomes of IQC, IPQC, and FQC processes. These reports can provide reassurance that the products meet specified standards and highlight any corrective actions taken in the event of non-conformance.

Engaging third-party inspection services can offer an unbiased assessment of the supplier’s quality assurance processes. These services can conduct independent testing and verification of products, ensuring that they meet both international and industry-specific standards.

Illustrative image related to locking air chuck with gauge

International buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, should be aware of potential variations in quality standards and regulations. It is essential to understand the specific certifications required in the buyer’s region and ensure that the supplier can comply. Additionally, language barriers and cultural differences may affect communication; hence, establishing clear channels and protocols for quality assurance discussions is vital for successful partnerships.

In conclusion, understanding the manufacturing processes and quality assurance protocols for locking air chucks with gauges is essential for B2B buyers. By focusing on material selection, forming techniques, assembly processes, and rigorous quality control measures, buyers can ensure they source reliable and high-performing products that meet their operational needs.

When sourcing a locking air chuck with a gauge, it’s essential to follow a structured approach to ensure you procure a product that meets your specific operational needs. This guide will assist B2B buyers in making informed decisions, particularly in the diverse markets of Africa, South America, the Middle East, and Europe.

Before reaching out to suppliers, clearly outline your technical requirements for the locking air chuck with gauge. Consider factors such as pressure ratings, compatibility with existing equipment, and specific features like swivel heads or automatic locking mechanisms. This clarity will streamline your procurement process and help suppliers provide tailored solutions.

Conduct thorough research to identify potential suppliers who specialize in locking air chucks with gauges. Look for manufacturers or distributors with a strong reputation in your target market. Utilize online platforms, industry forums, and trade shows to gather insights about their offerings and reliability.

Assess the manufacturing capabilities of your shortlisted suppliers. Consider their production capacity, technology used, and quality control processes. This step is vital to ensure that the supplier can meet your demand and maintain quality.

It’s crucial to ensure that your chosen supplier holds relevant certifications, such as ISO 9001 for quality management systems. This verification not only reflects their commitment to quality but also minimizes risks associated with product defects.

Once you have selected a few potential suppliers, request detailed quotations that outline pricing, payment terms, and delivery schedules. Compare these offers to ensure you are getting the best value without compromising quality.

Reliable after-sales support is essential for any B2B procurement. Evaluate the supplier’s policies regarding warranties, returns, and technical support. A strong after-sales service can significantly enhance your operational efficiency.

Illustrative image related to locking air chuck with gauge

After thorough evaluation and comparison, make your final purchasing decision based on all gathered information. Ensure that all aspects, including product quality, supplier reliability, and support services, align with your business needs.

By following these steps, B2B buyers can confidently source locking air chucks with gauges that enhance their operational efficiency and ensure long-term satisfaction.

When sourcing locking air chucks with gauges, understanding the cost structure is crucial for international B2B buyers. The primary components include:

Materials: The choice of materials significantly affects pricing. Common materials like chrome-plated zinc alloy and aluminum alloy are prevalent due to their durability and lightweight properties. Higher-quality materials, such as brass for specific applications, can increase costs but offer better performance and longevity.

Labor: Labor costs vary by region and manufacturing practices. Countries with lower labor costs may offer more competitive pricing, but this can also impact quality. Consideration should be given to the skill level of labor, especially in precision manufacturing environments.

Manufacturing Overhead: Overhead includes utilities, rent, and equipment maintenance. Factories with advanced technology might have higher upfront costs but can achieve efficiencies that lower overall pricing in the long run.

Tooling: Initial tooling costs can be significant, particularly for customized or specialized designs. Buyers should assess whether the supplier has existing tools or if new tooling is necessary, as this can impact the initial order cost.

Quality Control (QC): Rigorous QC processes ensure product reliability. Suppliers that invest in quality assurance may charge higher prices, but this often results in reduced failure rates and lower total cost of ownership.

Logistics: Shipping costs, particularly for international orders, can be substantial. Factors such as distance, shipping method, and Incoterms can greatly affect the final price. Understanding logistics is vital to calculate the total landed cost.

Margin: Supplier margins can vary widely. While lower margins might attract buyers, they may also indicate lower quality or service levels. Evaluate the overall value proposition rather than focusing solely on price.

Various factors influence the pricing of locking air chucks with gauges:

Volume/MOQ: Bulk purchasing often leads to better pricing. Suppliers typically offer discounts for larger orders, which can significantly reduce the cost per unit.

Specifications/Customization: Custom designs or specific features (like a locking mechanism or gauge type) can increase costs. Buyers should clarify their needs early in the process to avoid unexpected expenses.

Materials and Quality Certifications: Higher-quality materials and compliance with international standards (like ISO certifications) can drive up costs. Buyers must balance quality with budget constraints to ensure optimal procurement.

Supplier Factors: The reputation and reliability of suppliers play a crucial role. Established suppliers with a history of quality may charge higher prices but can provide assurance regarding product performance.

Incoterms: Understanding Incoterms is essential for international transactions. They dictate responsibilities for shipping, insurance, and tariffs, which can significantly affect overall pricing.

To maximize cost-efficiency when sourcing locking air chucks with gauges, consider the following strategies:

Leverage Negotiation Skills: Engage in discussions with multiple suppliers to compare offers. Highlighting competitive quotes can incentivize suppliers to provide better pricing.

Evaluate Total Cost of Ownership: Consider not just the purchase price but also factors like durability, maintenance, and operational efficiency. A higher upfront cost can be justified by lower long-term expenses.

Understand Regional Market Dynamics: Familiarize yourself with the specific market conditions in your region (e.g., Africa, South America, Europe). Local economic factors, tariffs, and import regulations can influence pricing.

Explore Alternative Suppliers: Diversifying your supplier base can mitigate risks and enhance bargaining power. Investigate suppliers from emerging markets that may offer competitive pricing without compromising quality.

Stay Informed on Pricing Trends: Monitor market trends and pricing shifts. Understanding when to buy and how global economic conditions affect material costs can lead to more strategic purchasing decisions.

In conclusion, a comprehensive understanding of the cost structure, price influencers, and negotiation strategies is essential for B2B buyers sourcing locking air chucks with gauges. By considering these factors, businesses can make informed decisions that align with their operational needs and budget constraints, ultimately leading to successful procurement outcomes.

In the realm of tire inflation and maintenance, locking air chucks with integrated gauges have become a popular choice due to their efficiency and reliability. However, various alternative solutions also exist, each with its own set of advantages and potential drawbacks. This analysis aims to compare locking air chucks with gauges against two viable alternatives: traditional tire inflators and digital tire inflators. Understanding these options will help B2B buyers make informed decisions tailored to their specific operational needs.

| Comparison Aspect | Locking Air Chuck With Gauge | Traditional Tire Inflator | Digital Tire Inflator |

|---|---|---|---|

| Performance | High; maintains airtight seal | Moderate; prone to air loss | High; precise pressure readings |

| Cost | Moderate (varies by brand) | Low to moderate | Higher (advanced features) |

| Ease of Implementation | Easy; compatible with most hoses | Easy; basic setup | Moderate; may require training |

| Maintenance | Low; durable materials | Low; simple mechanics | Moderate; requires battery or charging |

| Best Use Case | Professional tire shops, fleets | General household use | Commercial applications, precision tasks |

Traditional tire inflators are manual devices that utilize a nozzle to connect to the tire valve. They are typically low-cost and easy to implement, making them accessible for general use in households and small workshops. However, they may suffer from air loss during disconnection, leading to inefficiencies. While they are suitable for occasional use, their performance may not meet the demands of professional environments where precision and reliability are critical.

Digital tire inflators represent a more advanced solution, equipped with digital displays that provide precise pressure readings. They are ideal for commercial applications where accuracy is paramount, such as in tire shops or service centers. Although they come at a higher price point and may require some training for optimal use, their ability to minimize human error and ensure accurate inflation makes them a valuable investment. However, they may require more maintenance due to their electronic components and the need for batteries or charging.

Selecting the right tire inflation solution hinges on understanding the specific requirements of your operations. Locking air chucks with gauges offer a reliable, efficient option for tire maintenance, particularly in professional settings where performance is crucial. However, if cost is a primary concern and the application is less demanding, traditional tire inflators may suffice. For those requiring precision and advanced features, digital tire inflators can enhance operational efficiency despite their higher cost. B2B buyers should evaluate their unique needs, budget constraints, and the expected frequency of use to make the most informed choice.

Illustrative image related to locking air chuck with gauge

Understanding the technical specifications of locking air chucks with gauges is vital for B2B buyers seeking reliability and performance in tire inflation equipment. Here are some key properties to consider:

Material Composition

The most common materials used in manufacturing locking air chucks are brass, aluminum alloy, and chrome-plated zinc. Brass offers excellent corrosion resistance and durability, making it suitable for high-pressure applications. Aluminum is lightweight and resistant to rust, ideal for portable tools. Chrome-plated zinc provides strength and aesthetic appeal but may not be as durable under extreme conditions. Selecting the right material impacts the longevity and reliability of the air chuck, which is crucial for businesses that depend on consistent performance.

Thread Size and Type

Most locking air chucks are designed with a 1/4″ NPT (National Pipe Thread) fitting, which is a standard in the industry. Understanding thread size and type is essential when ensuring compatibility with existing air hoses and inflators. Incorrect sizing can lead to leaks or inefficient inflation processes, impacting operational efficiency.

Flow Rate

The flow rate, often measured in cubic feet per minute (CFM), indicates how quickly air can be delivered to the tire. For businesses, a higher flow rate can significantly reduce inflation times, improving productivity, especially in tire shops or service stations. Assessing the flow rate helps buyers choose products that align with their operational needs.

Pressure Rating

Locking air chucks typically have a maximum pressure rating, often around 145 PSI. This specification is crucial for businesses dealing with heavy-duty vehicles or high-performance applications. A chuck rated for higher pressure ensures safety and reliability, reducing the risk of equipment failure during operation.

Locking Mechanism

The locking mechanism is a critical feature that ensures a secure connection to the tire valve. Various designs, such as push-to-lock or automatic locking systems, provide different levels of ease and reliability. For B2B buyers, understanding the locking mechanism can influence the speed and efficiency of tire inflation, which is particularly important in high-volume environments.

Gauge Accuracy

An integrated gauge should provide precise pressure readings. Accuracy in tire pressure is vital for vehicle safety, fuel efficiency, and tire longevity. A reliable gauge minimizes the risk of under- or over-inflation, which can lead to increased operational costs and safety hazards.

Familiarity with industry jargon is essential for effective communication and negotiation in B2B transactions. Here are some common terms associated with locking air chucks:

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts and equipment that may be marketed by another manufacturer. Understanding OEM can help buyers identify quality standards and compatibility of replacement parts with existing equipment.

MOQ (Minimum Order Quantity)

MOQ indicates the smallest number of units a supplier is willing to sell. Buyers should consider MOQ when planning inventory purchases, as it impacts cash flow and storage capacity.

RFQ (Request for Quotation)

An RFQ is a document sent by buyers to suppliers to request pricing and terms for specific products. This process is crucial for cost comparison and negotiation, ensuring buyers secure the best possible deal.

Incoterms (International Commercial Terms)

These are a set of rules that define the responsibilities of buyers and sellers in international trade. Understanding Incoterms is essential for B2B transactions involving shipping and logistics, as they determine who bears the risk and costs at various stages of the supply chain.

Lead Time

Lead time refers to the amount of time it takes from placing an order to receiving the product. It’s an important consideration for businesses to ensure timely delivery and operational efficiency.

Warranty

A warranty is a guarantee provided by the manufacturer regarding the condition of the product and the commitment to repair or replace it if necessary. Understanding warranty terms can protect buyers from defects and ensure long-term reliability of the equipment.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions that enhance operational efficiency and product reliability in their tire inflation processes.

The locking air chuck with gauge sector is witnessing significant growth driven by various global factors, including increasing automotive production and a growing focus on tire maintenance. As vehicle manufacturers ramp up production in regions like Africa and South America, the demand for reliable tire inflation solutions is surging. Key trends influencing this market include the adoption of advanced materials and technologies, such as durable aluminum and brass alloys, which enhance product longevity and performance. Additionally, innovations like quick-release mechanisms and 360° swivel heads are becoming standard, as they facilitate ease of use and minimize air loss during inflation.

International B2B buyers are also increasingly focused on sourcing products that meet stringent quality and safety standards. This is particularly true in Europe, where regulations around product safety and environmental impact are tightening. Emerging markets in the Middle East and Asia, including Vietnam, are also adapting to these standards, creating a demand for high-quality, certified products. Furthermore, the integration of digital technologies into tire maintenance processes is transforming the industry. Digital gauges and smart inflators equipped with locking air chucks are gaining popularity, as they provide accurate measurements and enhance user experience.

The environmental impact of manufacturing processes is a critical consideration for B2B buyers in the locking air chuck sector. As awareness of climate change and resource depletion grows, the demand for sustainable and ethically sourced products is rising. Buyers are increasingly prioritizing suppliers who adhere to sustainable practices, such as reducing waste and utilizing eco-friendly materials in their products. Certifications like ISO 14001 for environmental management systems and adherence to REACH regulations for chemical safety are becoming essential for suppliers aiming to attract international clients.

Illustrative image related to locking air chuck with gauge

Incorporating sustainable materials, such as recycled metals and biodegradable packaging, can significantly enhance a company’s reputation and marketability. Suppliers who can demonstrate their commitment to sustainability not only contribute to environmental conservation but also appeal to a growing segment of eco-conscious buyers. This trend is particularly pronounced in Europe, where consumers and businesses alike are pushing for greater transparency in supply chains and product sourcing. As a result, ethical sourcing is not just a compliance issue; it has become a competitive advantage in the global marketplace.

The locking air chuck with gauge has evolved significantly since its inception. Initially designed as simple mechanical devices for tire inflation, modern locking air chucks now integrate advanced engineering and materials to enhance performance and user convenience. The introduction of features like push-to-lock nozzles and quick-release functions has transformed the user experience, allowing for faster and more efficient tire inflation. As automotive technology has advanced, so too has the locking air chuck, adapting to meet the needs of both commercial and consumer markets. Today, these tools are essential in various sectors, including automotive repair, transportation, and agriculture, reflecting their critical role in tire maintenance and safety.

How do I choose the right locking air chuck with gauge for my business?

Selecting the appropriate locking air chuck involves considering your specific applications and operational needs. Evaluate the type of vehicles or equipment you will be servicing, as different models cater to various valve types, such as Schrader or Presta. Look for features like a 360° swivel head for ease of use, a quick-release button to minimize air loss, and durability materials like chrome-plated zinc or aluminum alloy. Additionally, ensure the chuck can handle the required pressure ratings for your operations.

What are the advantages of using a locking air chuck with gauge?

Locking air chucks with gauges offer numerous benefits for tire inflation and maintenance. They provide a secure, airtight connection to prevent air loss during inflation, which enhances efficiency. The built-in gauge allows for real-time pressure monitoring, ensuring optimal tire pressure is maintained, which can lead to improved fuel efficiency and tire longevity. Moreover, their user-friendly designs, such as push-to-lock mechanisms, streamline operations and reduce the risk of errors in pressure settings.

What should I consider when vetting suppliers for locking air chucks?

When evaluating suppliers, prioritize those with a proven track record in manufacturing high-quality tools. Check for certifications that validate their compliance with international quality standards. Assess their customer reviews and case studies to gauge reliability and service levels. Request samples to evaluate product quality firsthand, and inquire about their warranty policies and after-sales support. Finally, consider their capacity for fulfilling large orders and their ability to customize products to meet your specific requirements.

What are the minimum order quantities (MOQ) for locking air chucks?

Minimum order quantities can vary widely among suppliers, often influenced by production capabilities and material availability. Typically, MOQs range from 50 to 500 units. For large-scale operations, negotiating lower MOQs may be possible, especially if you establish a long-term partnership. Always discuss potential bulk pricing discounts with suppliers to maximize your investment. Understanding MOQs is crucial for budgeting and ensuring you have adequate inventory for your business needs.

What payment terms should I expect when sourcing locking air chucks internationally?

Payment terms can vary based on the supplier’s policies and your negotiation outcomes. Common terms include a 30% deposit upfront with the balance due upon shipment, or net 30/60 days after delivery. For international transactions, consider using secure payment methods like letters of credit or escrow services to mitigate risks. Always clarify currency exchange rates and any additional banking fees that may apply. Establishing clear payment terms upfront will help avoid misunderstandings and ensure a smooth transaction process.

How can I ensure quality assurance when importing locking air chucks?

To maintain high quality standards, request detailed product specifications and certifications from your suppliers. Implement a quality control process that includes pre-shipment inspections and random sampling of products. Collaborating with third-party inspection agencies can provide an unbiased assessment of product quality before shipment. Additionally, ensure that suppliers are willing to adhere to your quality standards and are open to feedback and adjustments based on inspection results.

What logistics considerations should I keep in mind when sourcing locking air chucks?

Logistics play a crucial role in ensuring timely delivery and minimizing costs. Consider the shipping methods available (air, sea, or land) and their associated costs and transit times. Evaluate the supplier’s location and how it impacts shipping efficiency. Additionally, be aware of customs regulations and duties in your importing country, as these can affect delivery timelines and overall expenses. Establishing a reliable logistics partner can streamline the shipping process and provide real-time tracking updates.

Can locking air chucks be customized to meet specific needs?

Many suppliers offer customization options for locking air chucks, allowing you to tailor features such as size, design, and gauge specifications to suit your applications. Customization can enhance usability for specific vehicle types or operational environments. Discuss your requirements with potential suppliers and inquire about their design capabilities. Keep in mind that customization may affect lead times and pricing, so factor this into your planning and budgeting processes.

Domain: jacosuperiorproducts.com

Registered: 2014 (11 years)

Introduction: Lightning™ Locking Tire Air Chucks:

1. Lightning™ S Tire Air Chuck – 1/4″ NPT (Open Flow)

– Price: $16.99 (originally $29.99)

– Features: Chrome-plated zinc alloy, patented “push-to-lock” nozzle, quick-release button for zero air loss.

2. Lightning™ S2 Tire Air Chuck – 1/4″ NPT (Open/Closed Flow)

– Price: $19.99 (originally $24.95)

– Features: Compact design, enhanced grip, 360° swiv…

Domain: locknlube.com

Registered: 2013 (12 years)

Introduction: [{‘name’: ‘LockNFlate® Air Chuck’, ‘sizes’: ‘4 Sizes’, ‘price’: ‘$39.99’}, {‘name’: ‘LockNFlate Retractable Air Hose Reel’, ‘size’: ’50\’ x 3/8″‘, ‘price’: ‘$179.99’}, {‘name’: ‘LockNFlate Tire Inflator Adapter’, ‘type’: ‘1/4 NPT (m) to Schrader Valve (m)’, ‘price’: ‘$10.99’}, {‘name’: ‘LockNFlate® XL for Large Bore Tire Valves’, ‘sizes’: ‘2 Sizes’, ‘price’: ‘$49.99’}, {‘name’: ‘LockNFlate Straigh…

Domain: shop.exceltiregauge.com

Registered: 2004 (21 years)

Introduction: {“product_name”: “Lock-on Open End Chuck”, “brand”: “Excel Tire Gauge”, “sale_price”: “$18.60”, “msrp”: “”, “description”: “The Excel Lock-on Open End chuck fits most tire pressure gauge and inflators, but is designed specifically for use with Excel Air Machines Equipment. The brass chuck design inflates tires easily, even on heavy-duty work vehicles thanks to a 145 PSI maximum pressure rating. Th…

Domain: hoseshop.com

Registered: 2003 (22 years)

Introduction: {“Product Name”: “Locking Air Chuck”, “Part Number”: “CH09”, “Price”: “$12.68”, “Availability”: “In Stock”, “Description”: “The locking air chuck features a tang that engages the tire valve, allowing air to flow only when the tire valve is engaged. It provides a tight seal that is disengaged by pressing the trigger. The 90-degree design offers easier attachment and a secure seal compared to straig…

In conclusion, the strategic sourcing of locking air chucks with gauges offers substantial benefits for international B2B buyers, particularly in Africa, South America, the Middle East, and Europe. By prioritizing quality, reliability, and innovation, businesses can enhance their tire maintenance operations while minimizing downtime. The variety of options available—from rugged aluminum designs to advanced features such as 360° swivel heads and zero air loss mechanisms—ensures that buyers can find products tailored to their specific needs.

Investing in high-quality locking air chucks not only guarantees a secure and efficient tire inflation process but also supports long-term operational efficiency and safety. As the demand for reliable tire maintenance tools continues to grow, buyers are encouraged to evaluate suppliers based on product quality, technological advancements, and customer service.

Looking ahead, the evolution of air chuck technology presents an opportunity for businesses to streamline their operations and reduce costs. Engaging with trusted suppliers who emphasize innovation and performance will empower companies to stay competitive in a rapidly changing marketplace. Now is the time for international buyers to leverage these insights and make informed purchasing decisions that will drive future success.

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.