In the dynamic landscape of logistics and transportation, sourcing effective tire inflation systems for trailers presents a significant challenge for international B2B buyers. Improper tire inflation not only jeopardizes safety but can lead to increased fuel consumption, reduced tire lifespan, and operational downtime. As businesses strive to maintain efficiency, understanding the nuances of tire inflation technology becomes essential. This guide comprehensively explores various types of tire inflation systems, their applications, and the critical factors for supplier vetting and cost considerations.

With a focus on the unique needs of buyers from Africa, South America, the Middle East, and Europe—particularly in regions like Germany and Brazil—this resource empowers decision-makers to make informed purchasing choices. From industry-proven solutions like the Halo Tire Inflator, known for its rugged durability and easy installation, to advanced systems like Hendrickson’s TIREMAAX, which continuously maintains optimal tire pressure, the guide covers a spectrum of options tailored to diverse operational demands.

Through detailed insights and actionable advice, this guide aims to equip B2B buyers with the knowledge required to navigate the complexities of the tire inflation market, ensuring that they can enhance fleet performance and reduce total cost of ownership effectively. By leveraging this information, businesses can secure reliable partnerships and optimize their trailer operations in an increasingly competitive global market.

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Automatic Tire Inflation Systems | Continuous monitoring and automatic adjustment of tire pressure | Fleet management, long-haul trucking | Pros: Increases tire life, reduces downtime; Cons: Higher initial investment. |

| Manual Tire Inflation Kits | Portable kits requiring manual operation for inflation/deflation | Small to medium-sized fleets, off-road applications | Pros: Lower cost, easy to use; Cons: Labor-intensive, less efficient. |

| Modular Tire Inflation Systems | Modular designs allowing inflation of multiple tires simultaneously | Off-road vehicles, trailers with multiple axles | Pros: Efficient for multiple tires, versatile; Cons: May require additional setup time. |

| Predictive Tire Management Systems | Advanced monitoring with data analytics for tire health | Large fleets, logistics companies | Pros: Prevents tire failures, data-driven insights; Cons: Complex technology, requires training. |

| Centralized Tire Inflation Systems | Integrated systems that manage tire pressure across multiple vehicles | Transport companies, large fleet operators | Pros: Streamlined maintenance, reduces manual checks; Cons: Installation complexity, potential maintenance costs. |

Automatic tire inflation systems are designed for continuous monitoring and automatic adjustment of tire pressure. These systems are particularly beneficial for fleet management and long-haul trucking, where tire performance directly impacts fuel efficiency and safety. The key advantage of such systems lies in their ability to extend tire life and minimize downtime due to tire-related issues. However, the initial investment can be higher, which may deter some smaller operations.

Manual tire inflation kits are portable solutions that require operators to manually inflate or deflate tires. These kits are ideal for small to medium-sized fleets and off-road applications where cost is a primary concern. While they are easy to use and have a lower upfront cost, they can be labor-intensive and less efficient compared to automated systems, potentially leading to inconsistent tire pressure management.

Modular tire inflation systems allow for the simultaneous inflation of multiple tires, making them well-suited for off-road vehicles and trailers with multiple axles. These systems provide efficiency and versatility, enabling quick adjustments in various conditions. However, they may require additional setup time, which could be a drawback for operations needing rapid deployment.

Predictive tire management systems use advanced monitoring and data analytics to assess tire health and performance. These systems are particularly valuable for large fleets and logistics companies, as they can prevent tire failures and provide data-driven insights for maintenance planning. While they offer significant advantages, the complexity of the technology may necessitate training and could pose a challenge for some operators.

Centralized tire inflation systems integrate tire pressure management across multiple vehicles, making them ideal for transport companies and large fleet operators. These systems streamline maintenance processes and reduce the need for manual checks, enhancing operational efficiency. However, their installation can be complex and may involve additional maintenance costs, which should be considered in the overall budgeting for tire management solutions.

| Industry/Sector | Specific Application of tire inflation system for trailers | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Logistics and Freight | Automated tire pressure management in long-haul trucking | Reduces fuel costs and extends tire lifespan, minimizing downtime due to tire failures. | Ensure compatibility with diverse fleet vehicles and ease of installation. |

| Agriculture | Tire inflation systems for agricultural trailers | Enhances operational efficiency by ensuring optimal tire pressure for heavy loads, reducing wear and tear. | Look for systems that can withstand harsh environmental conditions and heavy-duty use. |

| Construction | Tire inflation for construction equipment trailers | Improves safety and productivity by maintaining proper tire pressure, reducing the risk of blowouts. | Consider systems that allow for quick adjustments on job sites with minimal downtime. |

| Mining | Tire inflation systems for mining haulage trucks | Increases operational uptime and reduces maintenance costs by preventing tire-related breakdowns in rugged terrains. | Seek robust systems that can handle extreme conditions and heavy loads typical in mining operations. |

| Recreational Vehicles | Tire inflation systems for off-road trailers | Offers convenience and safety for recreational activities by ensuring optimal tire pressure during adventures. | Focus on portable systems that are easy to use and store, with reliable performance in varied terrains. |

In the logistics and freight sector, tire inflation systems are crucial for long-haul trucking operations. These automated systems continuously monitor and adjust tire pressure, addressing one of the most significant maintenance challenges: improper inflation. By ensuring that tires are optimally inflated, businesses can significantly reduce fuel costs, enhance tire longevity, and minimize downtime due to tire failures. International buyers should prioritize systems that are compatible with various fleet vehicles and emphasize ease of installation to streamline operations.

Illustrative image related to tire inflation system for trailers

In agriculture, tire inflation systems are applied to trailers transporting heavy loads, such as equipment and produce. These systems help maintain optimal tire pressure, which is vital for improving operational efficiency and reducing wear and tear on tires. Properly inflated tires enhance traction and stability, crucial for navigating uneven terrain. Buyers in this sector should consider systems that are durable enough to withstand harsh environmental conditions and heavy-duty usage, ensuring reliable performance throughout the farming season.

In construction, tire inflation systems are utilized for trailers that transport equipment and materials to job sites. Maintaining proper tire pressure is essential for safety and productivity, as under-inflated tires can lead to blowouts and accidents, causing costly delays. These systems allow for quick adjustments, ensuring that tires are always at optimal pressure regardless of the load. Buyers should look for systems that offer robust performance and the ability to make adjustments with minimal downtime, particularly in dynamic job site conditions.

In the mining industry, tire inflation systems are vital for haulage trucks that operate in extreme conditions. These systems prevent tire-related breakdowns by ensuring that tires are properly inflated, which is crucial for maximizing operational uptime and reducing maintenance costs. Given the rugged terrain and heavy loads typical in mining, it is essential for buyers to seek robust tire inflation solutions that can withstand harsh environments and provide reliable performance over time.

For recreational vehicle owners, tire inflation systems are essential for maintaining the safety and performance of off-road trailers. These systems allow users to quickly inflate or deflate tires according to the terrain, ensuring optimal traction and handling during adventures. Convenience is a significant factor, so buyers should focus on portable systems that are easy to use and store, providing reliable performance in varied conditions. This flexibility enhances the overall recreational experience, making it a worthwhile investment for enthusiasts.

Illustrative image related to tire inflation system for trailers

The Problem:

Many B2B buyers, particularly those managing fleets in regions with extreme climates, face the ongoing challenge of maintaining consistent tire pressure across trailers. Fluctuations in temperature can lead to tire under-inflation or over-inflation, which not only compromises safety but also negatively impacts fuel efficiency and tire longevity. This inconsistency often results in increased maintenance costs and can lead to unexpected breakdowns, causing disruptions in operations and additional logistical challenges.

The Solution:

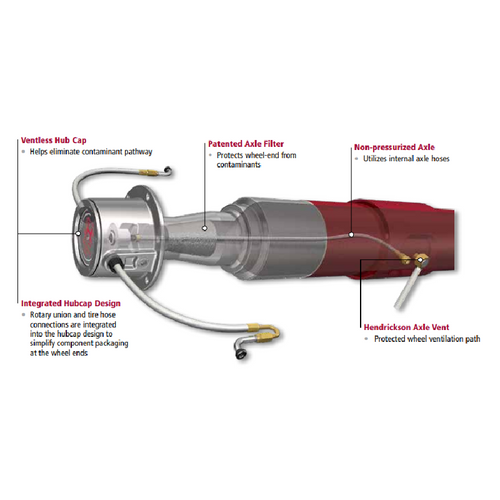

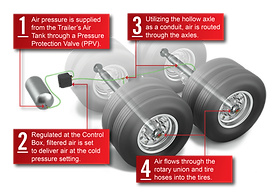

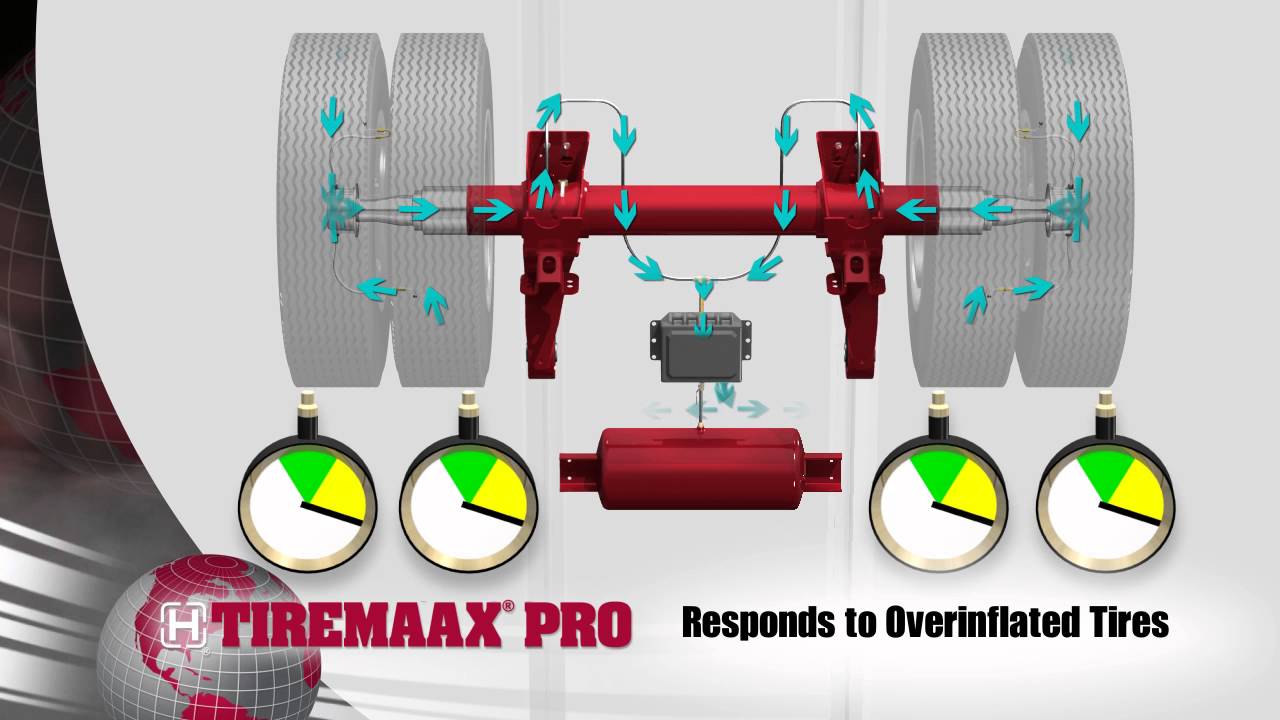

Investing in an advanced tire inflation system, such as the TIREMAAX CP or PRO from Hendrickson, can effectively address these issues. These systems utilize patented technology to automatically monitor and adjust tire pressure, ensuring that tires remain consistently inflated regardless of external conditions. When sourcing these systems, buyers should look for options that offer easy installation and minimal maintenance requirements. For instance, the TIREMAAX systems can be integrated with various suspension types, which makes them versatile across different fleet configurations. Regular monitoring and maintenance of the system itself will ensure its longevity and effectiveness, ultimately leading to reduced fuel costs and extended tire life.

The Problem:

In many operations, particularly those involving off-road trailers, manual tire inflation can be a tedious and time-consuming task. Buyers often find themselves dealing with multiple tires needing inflation, leading to increased downtime and labor costs. This inefficiency is particularly pronounced when trailers are used in remote areas where quick access to inflation equipment is limited, making it essential for operators to streamline their tire maintenance processes.

The Solution:

To overcome this challenge, adopting a modular tire inflation system, such as the MORRFlate 6 Tire Modular Trailer Kit, can significantly enhance efficiency. This kit allows users to inflate or deflate multiple tires simultaneously, drastically reducing the time spent on maintenance. When selecting a system, B2B buyers should consider features like detachable leads, which provide flexibility for use with various trailer configurations. Investing in a system that comes with a lifetime warranty on hoses and is designed for durability will ensure that the solution is not only effective but also cost-efficient in the long run. Training staff on the use of these systems can further optimize their deployment, ensuring that all team members are capable of performing tire maintenance quickly and effectively.

The Problem:

B2B buyers often encounter significant costs associated with tire failures, which can stem from improper inflation. These failures can lead to costly repairs, increased downtime, and even potential safety hazards. The financial implications are particularly concerning for companies operating in regions where rapid response to breakdowns is challenging, such as remote areas in Africa or South America. The loss of productivity due to tire-related issues can severely impact overall profitability and operational efficiency.

The Solution:

Implementing an automatic tire inflation system like the Halo Tire Inflator can mitigate the risk of tire failures caused by improper inflation. This system is designed for rugged environments and can be installed in just a few minutes without specialized tools, making it accessible for various operational settings. B2B buyers should prioritize systems that offer predictive tire management features, which not only maintain optimal pressure but also provide real-time monitoring and alerts for potential issues. By investing in these proactive solutions, companies can significantly reduce maintenance costs, prevent unexpected breakdowns, and enhance overall fleet reliability. Additionally, buyers should conduct a cost-benefit analysis to evaluate the potential savings from reduced tire replacements and enhanced fuel efficiency, reinforcing the value of investing in quality tire inflation systems.

When selecting materials for tire inflation systems in trailers, it’s crucial to consider their properties, advantages, disadvantages, and how they align with international standards. Below, we analyze four common materials used in these systems: rubber, aluminum, stainless steel, and composite plastics.

Illustrative image related to tire inflation system for trailers

Rubber is a widely used material in tire inflation systems due to its excellent elasticity and ability to create airtight seals. It typically has a high-temperature rating and can withstand pressures of up to 150 PSI, making it suitable for various tire inflation applications.

Pros: Rubber is durable and offers good resistance to wear and tear, making it ideal for environments where flexibility is required. It is also cost-effective and easy to manufacture.

Cons: However, rubber can degrade over time when exposed to UV light and ozone, leading to potential failures. It may require regular inspections and replacements, increasing long-term maintenance costs.

Impact on Application: Rubber is compatible with air and nitrogen but may not perform well with certain chemicals, which could be a consideration for specific applications.

International Considerations: Buyers in regions like Africa and South America should ensure that the rubber meets local standards for durability and safety. Compliance with ASTM D2000 or similar standards is often expected.

Illustrative image related to tire inflation system for trailers

Aluminum is another popular choice due to its lightweight nature and excellent corrosion resistance. It can handle high-pressure applications, typically rated for pressures up to 250 PSI.

Pros: Aluminum components are strong yet lightweight, which can improve fuel efficiency in trailers. They also have good thermal conductivity, which can be beneficial in dissipating heat generated during tire inflation.

Cons: The primary drawback is the cost; aluminum is generally more expensive than rubber. Additionally, while it resists corrosion, it can be susceptible to scratching and denting under harsh conditions.

Impact on Application: Aluminum is suitable for air and nitrogen but may not be compatible with certain aggressive chemicals, which could lead to corrosion over time.

Illustrative image related to tire inflation system for trailers

International Considerations: Buyers from Europe, especially Germany, may prefer aluminum due to its lightweight properties and compliance with EU standards for vehicle components.

Stainless steel is known for its exceptional strength and corrosion resistance, making it a premium choice for tire inflation systems.

Pros: It can withstand high pressures (up to 500 PSI) and extreme temperatures, ensuring durability in harsh environments. Its resistance to rust and corrosion makes it ideal for regions with high humidity or salt exposure.

Cons: The main disadvantage is its higher cost compared to rubber and aluminum. Additionally, stainless steel components can be heavier, which may affect the overall weight of the trailer.

Illustrative image related to tire inflation system for trailers

Impact on Application: Stainless steel is compatible with air and nitrogen and can handle various chemical exposures without degrading.

International Considerations: Compliance with standards like ASTM A240 is essential for international buyers, particularly in the Middle East, where climate conditions can be harsh.

Composite plastics are increasingly used in tire inflation systems due to their versatility and lightweight properties.

Pros: They are resistant to corrosion and can be engineered to handle specific pressures and temperatures, making them suitable for a variety of applications. They are also generally less expensive than metals.

Illustrative image related to tire inflation system for trailers

Cons: However, composite plastics may not offer the same level of durability as metals and can be prone to cracking under extreme conditions.

Impact on Application: Composite materials are compatible with air and nitrogen but may not be suitable for all chemical environments.

International Considerations: Buyers should ensure that composite materials meet relevant standards, such as DIN EN ISO 9001, especially in European markets.

| Material | Typical Use Case for tire inflation system for trailers | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Rubber | Seals and hoses in inflation systems | Cost-effective, flexible | Degrades under UV exposure | Low |

| Aluminum | Structural components and fittings | Lightweight, corrosion-resistant | Higher cost, susceptible to scratching | Medium |

| Stainless Steel | High-pressure applications and durable fittings | Exceptional strength and corrosion resistance | Higher weight, higher cost | High |

| Composite Plastics | Lightweight fittings and components | Versatile, lightweight | Less durable, potential for cracking | Medium |

This analysis provides B2B buyers with essential insights into material selection for tire inflation systems, helping them make informed decisions that align with their operational needs and regional standards.

Illustrative image related to tire inflation system for trailers

The manufacturing process for tire inflation systems, particularly those designed for trailers, involves several critical stages. Each stage is integral to ensuring the final product meets durability and performance standards required in various operational environments.

The first stage involves sourcing high-quality materials that can withstand the rigors of road and environmental conditions. Typically, materials used include high-strength polymers, aluminum, and steel. These materials are selected for their lightweight properties, corrosion resistance, and ability to handle high pressures.

Once sourced, materials undergo rigorous quality checks to verify that they meet specifications. This includes tensile strength tests and chemical composition analyses. After passing these checks, the materials are cut, shaped, and treated as necessary to prepare them for the next stage.

The forming process varies based on the component being manufactured. Techniques such as injection molding, extrusion, and machining are commonly employed. For instance, polymer components might be produced through injection molding, while metal parts may require machining or forging.

Illustrative image related to tire inflation system for trailers

During this stage, precision is paramount. Advanced CNC (Computer Numerical Control) machines ensure that components are formed to exact specifications, which is crucial for the assembly of tire inflation systems that must fit seamlessly with trailer hubs and valves.

Assembly involves integrating the various components into a cohesive unit. This can be done using automated assembly lines or manual processes, depending on the complexity of the system. Key techniques include:

During assembly, workers or machines conduct real-time inspections to identify defects or misalignments that could affect the system’s performance.

The finishing stage focuses on enhancing the product’s durability and appearance. This can involve processes such as:

Quality assurance is a critical aspect of the manufacturing process for tire inflation systems. Compliance with international standards ensures that products are safe, reliable, and effective.

Illustrative image related to tire inflation system for trailers

Quality control (QC) is implemented at various stages of the manufacturing process to ensure that each product meets the required standards.

Incoming Quality Control (IQC): This initial stage checks the quality of raw materials upon arrival. Materials must meet predetermined specifications before they are used in production.

In-Process Quality Control (IPQC): Throughout the manufacturing process, random samples are taken to ensure that components are being produced within acceptable tolerances. This includes checking dimensions and performing functional tests.

Final Quality Control (FQC): Before products leave the manufacturing facility, they undergo a comprehensive inspection. This includes functional testing under simulated operating conditions to ensure reliability and performance.

For international buyers, especially those from regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality assurance practices is essential for mitigating risks.

Supplier Audits: Conducting audits of potential suppliers helps assess their manufacturing processes, quality control measures, and compliance with international standards. This can be done in person or through third-party inspection services.

Quality Reports: Requesting detailed quality reports from suppliers can provide insights into their manufacturing processes and quality control results. This includes data on defect rates, testing outcomes, and corrective actions taken for any quality issues.

Third-Party Inspections: Engaging third-party inspection agencies can provide an unbiased assessment of the supplier’s capabilities and adherence to quality standards. This is particularly useful for buyers unfamiliar with local suppliers.

For B2B buyers, particularly those in diverse regions, understanding the nuances of quality certifications is vital.

Europe: CE marking is essential for products sold in the EU, and buyers should ensure that suppliers can provide this certification. Manufacturers often undergo rigorous testing to comply with EU regulations.

Africa and South America: Buyers should look for ISO certifications and local compliance certifications, which may vary by country. Familiarity with local regulations can aid in verifying supplier compliance.

Middle East: The region may have specific certifications that align with local standards. It’s crucial for buyers to understand these requirements to ensure that products meet local regulatory demands.

In conclusion, thorough knowledge of the manufacturing processes and quality assurance practices surrounding tire inflation systems for trailers empowers B2B buyers to make informed purchasing decisions. By focusing on compliance with international standards, understanding quality control measures, and verifying supplier capabilities, businesses can secure reliable products that enhance operational efficiency.

To assist B2B buyers in sourcing tire inflation systems for trailers, this guide provides a structured checklist to streamline the procurement process. These systems are essential for maintaining optimal tire pressure, reducing operational costs, and enhancing safety during transport.

Understanding your specific requirements is critical. Determine the types of trailers you operate, the expected tire sizes, and the environmental conditions in which the systems will function. Consider factors like pressure range, compatibility with existing trailer systems, and whether you need automatic or manual inflation capabilities.

Different tire inflation systems come with varying technologies and features. Research systems such as automatic tire pressure control, manual kits, and modular options that allow simultaneous inflation of multiple tires. Assess how these technologies align with your operational needs.

Thoroughly vet potential suppliers before making a commitment. Request detailed company profiles, including their manufacturing processes, quality certifications, and customer service practices. Reviewing case studies and references from similar industries can provide insights into their reliability.

Given the harsh conditions that trailers often operate in, prioritize durability in your selection process. Look for systems that have been tested for extended mileage and demonstrate rugged construction. Additionally, consider the maintenance requirements of the systems to ensure long-term functionality.

Understanding the financial implications of your investment is vital. Calculate the potential savings from improved fuel efficiency, reduced tire wear, and minimized downtime due to tire failures. Many suppliers provide ROI calculators to help you assess the financial benefits of their systems.

Before finalizing your purchase, request product demonstrations or samples to evaluate performance. This hands-on experience will help you understand the ease of installation and operation. Additionally, it allows you to assess compatibility with your existing equipment.

Once you’ve selected a supplier and product, negotiate terms that align with your budget and needs. Discuss warranties, support services, and delivery timelines. Ensure all agreements are documented to protect your interests throughout the procurement process.

By following this checklist, B2B buyers can make informed decisions when sourcing tire inflation systems for trailers, ultimately enhancing their operational efficiency and safety on the road.

When evaluating the cost structure of tire inflation systems for trailers, several key components play a crucial role in determining the overall price. These include:

Materials: The choice of materials significantly impacts cost. Systems made from high-grade materials that withstand harsh environments will naturally be more expensive. For example, components like hoses, valves, and electronic systems should be durable and resistant to wear.

Labor: Labor costs can vary based on the region of production and the complexity of the manufacturing process. Skilled labor is necessary for quality control and assembly, which can add to the overall cost.

Manufacturing Overhead: This includes costs related to factory operation, utilities, and indirect labor. Efficient manufacturing processes can help in reducing these overheads.

Tooling: The initial investment in tooling can be substantial, particularly for customized or specialized systems. This is a one-time cost but should be factored into the price for buyers looking for bespoke solutions.

Quality Control (QC): Implementing rigorous QC processes ensures that the products meet industry standards, which can raise costs but ultimately leads to reduced failures and longer product life.

Logistics: Transportation and shipping costs are critical, especially for international buyers. The distance to the end user and the mode of transportation can greatly influence the final price.

Margin: Suppliers will add a margin to cover their costs and profit, which can vary widely depending on market conditions and competitive landscape.

Several factors can influence the pricing of tire inflation systems, particularly for international buyers:

Volume/MOQ: Purchasing in bulk or meeting minimum order quantities (MOQs) can lead to significant discounts. Buyers should consider their needs carefully to optimize costs.

Specifications and Customization: Tailored solutions with specific features or configurations will generally incur higher costs. Buyers should weigh the benefits of customization against their budget constraints.

Materials and Quality Certifications: Higher-quality materials and systems that meet international safety and performance certifications may command premium prices. Buyers should assess the long-term benefits of investing in higher-quality systems.

Supplier Factors: The reputation and reliability of the supplier can affect pricing. Established brands may charge more due to their proven track record, while emerging suppliers might offer lower prices to gain market share.

Incoterms: Understanding the terms of sale (Incoterms) is vital for international purchases. These terms dictate who is responsible for shipping, insurance, and tariffs, impacting the total cost.

To maximize cost efficiency when sourcing tire inflation systems, buyers should consider the following strategies:

Negotiation: Always engage in negotiations to obtain the best possible price. Presenting data on competitor pricing or showcasing the potential for repeat business can strengthen your position.

Total Cost of Ownership (TCO): Evaluate the TCO rather than just the initial purchase price. Consider factors such as maintenance, fuel savings from improved tire performance, and the longevity of the system.

Pricing Nuances for International Buyers: Be aware of currency fluctuations, import duties, and local taxes that may apply. These can significantly impact the final cost and should be factored into any financial analysis.

Market Research: Conduct thorough research on suppliers in different regions. Markets in Africa, South America, the Middle East, and Europe may have varying price structures due to local economic conditions.

Long-term Relationships: Building strong relationships with suppliers can lead to better pricing, exclusive deals, and priority service, ultimately enhancing the purchasing experience.

Navigating the cost and pricing landscape of tire inflation systems for trailers requires a comprehensive understanding of the various cost components, pricing influencers, and negotiation strategies. By employing these insights, international B2B buyers can make informed decisions that not only meet their operational needs but also ensure a favorable return on investment. Always remember to account for the total cost of ownership in your evaluations, as this will provide a clearer picture of the financial implications over time.

When evaluating solutions for maintaining optimal tire pressure in trailers, it is essential to consider various alternatives to traditional tire inflation systems. Each solution offers unique benefits and drawbacks, which can significantly impact operational efficiency, maintenance costs, and overall performance. Below, we provide a comparative analysis of the tire inflation system for trailers against two viable alternatives: manual tire inflation and portable tire inflators.

| Comparison Aspect | Tire Inflation System For Trailers | Manual Tire Inflation | Portable Tire Inflators |

|---|---|---|---|

| Performance | Automatically maintains tire pressure, reducing downtime and tire wear. | Inconsistent pressure maintenance, relies on user accuracy. | Provides quick inflation but requires manual operation for each tire. |

| Cost | Higher initial investment but offers long-term savings through reduced fuel consumption and tire replacement costs. | Minimal upfront cost but can lead to higher long-term expenses due to inefficiencies. | Moderate cost, often one-time purchase, but may require additional accessories. |

| Ease of Implementation | Quick installation (5-10 minutes), no specialized tools needed. | Simple to implement but labor-intensive and time-consuming. | Easy to use but may require additional setup time for multiple tires. |

| Maintenance | Low maintenance with durable components designed for longevity. | Requires regular checks and manual adjustments. | Requires monitoring and maintenance of the inflator and hoses. |

| Best Use Case | Ideal for fleets needing consistent tire pressure management to enhance efficiency. | Suitable for occasional users or small operations with limited tire management needs. | Best for emergency situations or off-road applications where quick inflation is necessary. |

Manual tire inflation is the most traditional method, involving the use of a pressure gauge and an air compressor. The primary advantage is the low initial cost, making it accessible for small businesses or individual operators. However, this method is labor-intensive and can lead to inconsistent tire pressure management, resulting in increased tire wear and reduced fuel efficiency over time. Additionally, it requires regular checks, which can be time-consuming and prone to human error.

Portable tire inflators provide a middle ground between manual inflation and automated systems. They are easy to transport and can quickly inflate tires in emergency situations or when on the go. While they are moderately priced and convenient for individual or occasional use, they still require manual operation for each tire, which can be cumbersome when managing multiple trailers. Moreover, the effectiveness of these inflators can vary, and they may not maintain tire pressure consistently without ongoing user intervention.

Selecting the appropriate tire inflation system for trailers hinges on understanding your specific operational needs. If you operate a large fleet or require consistent tire pressure management to maximize efficiency, investing in a dedicated tire inflation system is likely to yield significant long-term savings. Conversely, if your operations are smaller or less frequent, manual inflation or portable inflators may suffice. Ultimately, the decision should reflect a balance between initial investment, maintenance capabilities, and the operational demands of your fleet. By carefully assessing these factors, B2B buyers can make informed decisions that enhance their operational efficiency and reduce overall costs.

When considering tire inflation systems for trailers, several critical technical properties stand out, each contributing to performance, durability, and cost-effectiveness. Understanding these specifications is essential for B2B buyers aiming to make informed purchasing decisions.

The material grade of components used in tire inflation systems is paramount. High-quality materials, such as aluminum or high-strength polymers, enhance durability and resistance to environmental factors like corrosion and wear. For instance, systems made from aerospace-grade aluminum can withstand harsh road conditions and extend the lifespan of the equipment, reducing the need for frequent replacements.

The pressure range defines the operational limits of the tire inflation system. Most systems are designed to operate within specific PSI (pounds per square inch) settings, typically ranging from 70 to 120 PSI. Understanding the required pressure range is critical, as it directly impacts tire performance, fuel efficiency, and safety. Systems that maintain optimal tire pressure can lead to significant savings in fuel and maintenance costs.

Flow rate refers to the speed at which air can be pumped into or released from the tires. A higher flow rate allows for quicker inflation and deflation, which is essential for fleets that need to minimize downtime. Systems with adjustable flow rates provide flexibility for various tire sizes and conditions, making them suitable for diverse applications.

Ease of installation is another critical property. Systems that can be installed within 5-10 minutes without specialized tools are highly desirable for fleet operators. Quick installation reduces labor costs and minimizes the operational disruption during maintenance, making it a crucial factor in the purchasing decision.

The maintenance requirements of tire inflation systems can greatly influence their long-term cost-effectiveness. Systems designed to be maintenance-free or requiring minimal upkeep are preferred as they reduce operational disruptions and costs associated with regular servicing.

Many manufacturers conduct extensive durability testing, such as lab tests for a million miles or road tests for several billion miles. This information is vital for B2B buyers to assess the reliability of the product in challenging environments. A proven track record of durability can lead to reduced long-term costs and increased trust in the product.

Understanding industry terminology is crucial for effective communication and negotiation in the B2B landscape. Below are some common trade terms relevant to tire inflation systems:

Illustrative image related to tire inflation system for trailers

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. In tire inflation systems, purchasing OEM parts ensures compatibility and quality, as these components are specifically designed for the system.

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is significant for B2B buyers as it affects inventory management and cash flow. Understanding the MOQ helps businesses plan their purchases more effectively.

An RFQ is a document sent to suppliers asking for pricing and terms for specific products or services. Issuing an RFQ can help buyers compare options and negotiate better deals, ensuring they receive competitive pricing for tire inflation systems.

Incoterms are internationally recognized rules that define the responsibilities of buyers and sellers in international transactions. Understanding these terms is essential for B2B buyers to clarify shipping, insurance, and liability aspects when importing tire inflation systems from various regions.

TPMS refers to a system that monitors tire pressure and alerts the driver when it falls below a certain threshold. This technology is increasingly integrated into tire inflation systems, providing an added layer of safety and efficiency.

Illustrative image related to tire inflation system for trailers

ROI is a performance measure used to evaluate the efficiency of an investment. For tire inflation systems, calculating the ROI can help businesses understand the financial benefits of investing in such systems, considering factors like fuel savings and reduced tire maintenance costs.

By familiarizing themselves with these technical properties and trade terms, B2B buyers can make more informed decisions when selecting tire inflation systems for trailers, ultimately leading to improved operational efficiency and cost savings.

The tire inflation system for trailers has gained significant traction globally, driven by the increasing awareness of the cost implications of improper tire maintenance. Key trends include the adoption of automated tire pressure control systems, which not only enhance fuel efficiency but also prolong tire life. For instance, systems like TIREMAAX from Hendrickson and the Halo Tire Inflator by Aperia Technologies exemplify cutting-edge technology that continuously monitors and adjusts tire pressure, reducing the risk of tire failure and downtime.

B2B buyers from regions such as Africa, South America, the Middle East, and Europe are increasingly prioritizing these advanced solutions to mitigate operational costs associated with fleet management. The emergence of modular kits, like the MORRFlate system, also highlights a trend towards more versatile and user-friendly products that facilitate simultaneous inflation and deflation of multiple tires, appealing to off-road and utility vehicle markets. Furthermore, the trend towards digitalization in fleet management is paving the way for predictive maintenance solutions, enabling buyers to make data-driven decisions regarding tire health and replacement schedules.

The environmental impact of tire inflation systems cannot be overlooked, especially as companies globally strive to reduce their carbon footprint. Improperly inflated tires contribute significantly to fuel inefficiency, which in turn leads to higher greenhouse gas emissions. B2B buyers are increasingly seeking suppliers who demonstrate a commitment to sustainability through the use of eco-friendly materials and practices.

Ethical sourcing is becoming paramount, with buyers demanding transparency in the supply chain. Certifications such as ISO 14001 for environmental management and materials labeled as recycled or sustainably sourced are gaining importance. Suppliers that can provide evidence of sustainable practices are more likely to appeal to conscientious buyers. Additionally, innovations in materials that enhance durability and reduce waste are increasingly sought after, aligning with the industry’s shift toward sustainability.

The evolution of tire inflation systems for trailers has been marked by significant technological advancements. Initially, manual tire inflation methods dominated the market, often leading to inefficiencies and increased wear on tires. The introduction of automatic tire pressure monitoring systems (TPMS) in the early 2000s marked a turning point, allowing for real-time monitoring and adjustment of tire pressure.

As the industry progressed, innovations such as modular tire inflation kits emerged, catering to both on-road and off-road applications. Today, the focus is on integrating smart technology, including predictive analytics and IoT capabilities, into tire inflation systems, enabling fleet operators to optimize their maintenance schedules and improve overall operational efficiency. This evolution not only reflects the changing demands of the market but also underscores the importance of technological adaptation in a competitive landscape.

Navigating the tire inflation system market requires B2B buyers to stay informed about key trends, sustainability practices, and the historical context of the products they source. By understanding these dynamics, companies can make informed decisions that align with their operational goals and contribute to a more sustainable future.

1. How do I solve tire pressure issues in trailers?

To effectively solve tire pressure issues in trailers, investing in a reliable tire inflation system is essential. These systems, such as automatic tire pressure control solutions, continuously monitor and maintain optimal tire pressure, reducing the risk of under-inflation or over-inflation. Key features to look for include durability, ease of installation, and compatibility with your trailer’s specifications. Regularly checking tire pressure manually can also help, but an automated system provides a more efficient and reliable solution to minimize downtime and maintenance costs.

2. What is the best tire inflation system for reducing fuel consumption?

The best tire inflation systems for reducing fuel consumption are those that maintain optimal tire pressure consistently. Systems like Hendrickson’s TIREMAAX® use advanced technology to automatically adjust tire pressure, ensuring that tires are neither under-inflated nor over-inflated. This not only enhances fuel efficiency but also prolongs tire life and minimizes the risk of blowouts. When choosing a system, consider factors such as compatibility with your trailer type, ease of installation, and proven performance in similar operational conditions.

3. How can I verify the reliability of a tire inflation system supplier?

To verify the reliability of a tire inflation system supplier, conduct thorough research on their reputation and experience in the industry. Look for customer reviews, case studies, and testimonials from previous clients. It’s also beneficial to check their certifications and compliance with international quality standards. Establishing direct communication with the supplier can help clarify their support services, warranty terms, and product guarantees. Consider visiting their facilities or requesting product demonstrations to assess their capabilities firsthand.

4. Are there customization options available for tire inflation systems?

Yes, many manufacturers offer customization options for tire inflation systems to meet specific operational needs. This can include adjustments in tire pressure settings, system configurations tailored to unique trailer designs, or enhancements for specific environmental conditions. When discussing customization, provide detailed information about your trailer specifications and operational requirements to ensure the supplier can deliver a tailored solution. It’s important to confirm any additional costs or lead times associated with custom orders.

5. What is the minimum order quantity (MOQ) for tire inflation systems?

Minimum order quantities (MOQs) for tire inflation systems can vary significantly by supplier and product type. Typically, larger suppliers may have higher MOQs due to manufacturing constraints, while smaller manufacturers might accommodate smaller orders. It’s advisable to inquire directly with the supplier about their MOQ, as some may offer flexibility for first-time buyers or bulk purchases. Understanding MOQ is crucial for planning your budget and inventory needs effectively.

6. What payment terms should I expect when purchasing tire inflation systems?

Payment terms for tire inflation systems can vary based on the supplier’s policies and the nature of your order. Common terms may include a partial upfront payment with the balance due upon delivery or a net 30 or 60 days agreement. Always clarify payment options, including credit terms, discounts for early payment, and accepted payment methods (e.g., bank transfer, credit card). Establishing clear payment terms upfront helps avoid misunderstandings and ensures a smoother transaction process.

7. How do I ensure quality assurance for tire inflation systems?

To ensure quality assurance for tire inflation systems, look for suppliers who adhere to recognized industry standards and certifications, such as ISO or CE marks. Inquire about their quality control processes, including testing protocols and warranty policies. Request documentation regarding the system’s performance metrics and durability tests. Additionally, establishing a clear return and service policy will help ensure that any issues encountered post-purchase are addressed promptly and effectively.

8. What logistics considerations should I keep in mind when sourcing tire inflation systems internationally?

When sourcing tire inflation systems internationally, consider logistics factors such as shipping costs, lead times, and customs regulations in your country. Collaborate with suppliers to understand their shipping options, including freight methods and delivery timelines. It’s also critical to factor in potential duties and taxes that may apply. Establishing a reliable logistics partner can streamline the process and help mitigate risks associated with international shipping, ensuring timely delivery and compliance with local regulations.

Domain: shop.aperiatech.com

Registered: 2010 (15 years)

Introduction: Product Name: Halo Tire Inflator

Price: $600.00

Limited Time Offer: 22% Off with code “22” at checkout

Features:

– Only Tire Management Platform for all wheel positions

– Over 100 billion industry proven miles

– Extends tire life, improves fuel economy, maximizes uptime, enhances safety

Included in Each Kit: All Halos, Brackets, and necessary Hoses for full vehicle installation

Note: Each Halo ar…

Domain: hendrickson-intl.com

Registered: 1997 (28 years)

Introduction: Hendrickson TIREMAAX Tire Pressure Control Systems are designed to address improper tire inflation, which can significantly reduce fuel economy and tire life. The product lineup includes TIREMAAX CP, PRO, and PRO-LB systems, utilizing advanced patented technology to maintain proper tire pressure. Key features include:

– Compatibility with Hendrickson integrated air suspension systems and non-integ…

Domain: morrflate.com

Registered: 2019 (6 years)

Introduction: Morrflate Trailer Kit is designed for inflating multiple tires simultaneously. It includes a durable air hose and multiple tire inflation connectors. The kit is suitable for trailers, RVs, and other vehicles with multiple tires. It features a compact design for easy storage and transport. The product is built for efficiency and convenience, making tire inflation quick and hassle-free.

Domain: cummins.com

Registered: 1990 (35 years)

Introduction: The Meritor Tire Inflation System (MTIS) is designed to automatically maintain optimal tire pressure, enhancing tire life and improving fuel efficiency. It features a centralized inflation system that allows for easy monitoring and maintenance. The system is compatible with various tire sizes and can be integrated into different vehicle types. Key benefits include reduced tire wear, improved safet…

Domain: parts.ectts.com

Registered: 1999 (26 years)

Introduction: TIREMAXX Tire Inflation Kit 19.5 | Hendrickson

– Price: $799.00

– SKU: 15392

– Weight: 0.00 LBS

– Shipping: Free Shipping

– Features:

– Designed for 19.5 in. wheels

– Enhances tire life

– Reduces maintenance

– Conserves fuel

– Trims labor costs

– Automatic tire inflation system

– Draws from trailer air supply

– Simple mechanical design (no pressure switches, electronics, or transd…

Domain: anythingtruck.com

Registered: 2000 (25 years)

Introduction: [{‘name’: ‘Meritor 31314-21 Tire Inflation System Stator and Filter’, ‘part_number’: ‘650-3131421’, ‘price’: ‘$23.57 USD’, ‘rating’: ‘5 out of 5’, ‘recommendation’: ‘Would recommend this product.’}, {‘name’: ‘Meritor 31317-03 Tire Inflation System Thru Tee, Dual Wheels, 3.5″ Long’, ‘part_number’: ‘650-3131703’, ‘price’: ‘$68.60 USD’, ‘rating’: ‘Not Yet Rated’}, {‘name’: ‘Meritor 31317-03-S Tire In…

Domain: veriha.com

Registered: 1998 (27 years)

Introduction: Modern trailers equipped with auto inflation systems are designed to maintain tire pressure, reducing the risk of blowouts and improving fuel efficiency. The system features two distinct air hoses extending from the axle hubs to the inflation valves on each tire, using air from the trailer’s air tank, activating at a minimum of 80 psi. A pressure monitor box regulates the system and includes an On…

Domain: utilitytrailer.com

Registered: 1996 (29 years)

Introduction: Tire inflation systems are designed to maintain optimum tire pressure, which helps increase fuel economy, improve safety, and maximize tire life. Recommended systems are available for selection.

In the rapidly evolving market for tire inflation systems for trailers, strategic sourcing has emerged as a critical component for businesses aiming to enhance operational efficiency and reduce costs. The insights drawn from industry leaders highlight the substantial benefits of investing in advanced tire inflation technologies, such as improved fuel economy, extended tire life, and minimized downtime due to tire failures.

By leveraging innovative solutions like the TIREMAAX® and Halo Tire Inflator, companies can achieve remarkable ROI through reduced maintenance expenses and enhanced fleet performance. Furthermore, the ease of installation and the durability of these systems make them an attractive option for businesses operating in challenging environments.

As international B2B buyers from regions such as Africa, South America, the Middle East, and Europe explore their sourcing options, it is imperative to prioritize suppliers that offer proven technologies and robust support. Embracing these advanced tire inflation systems not only represents a sound investment but also positions businesses to thrive in a competitive landscape.

Looking ahead, the demand for reliable tire management solutions will only grow. Now is the time to engage with leading suppliers and explore how these systems can elevate your fleet’s performance and sustainability.

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

Illustrative image related to tire inflation system for trailers

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.