In today’s global market, sourcing reliable and accessible air for tires can be a significant challenge for international B2B buyers. Whether operating in bustling urban centers or remote regions, businesses must navigate an array of options to ensure their vehicles are well-maintained and operational. This guide on “where to get air for tires near me” offers a comprehensive overview of available resources, ranging from gas stations and tire shops to bike repair stations and portable air compressors.

The guide delves into various types of air supply options, their applications across different vehicle types, and how to effectively vet suppliers to guarantee quality service. Additionally, it provides insights into cost considerations and regional variations, particularly for buyers in Africa, South America, the Middle East, and Europe, including specific countries like Germany and Saudi Arabia. By equipping decision-makers with actionable information, this resource empowers businesses to make informed purchasing decisions, ultimately enhancing operational efficiency and reducing maintenance costs.

Navigating the complexities of sourcing tire air becomes easier with a structured approach, allowing companies to maintain their fleet’s performance and safety standards without incurring unnecessary expenses.

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Gas Stations | Often provide air for free; accessible locations | Fleet maintenance, logistics companies | Pros: Convenient; often free. Cons: Availability may vary; not all stations offer air. |

| Tire Shops | Specialized in tire services; may offer free air | Tire retailers, automotive service providers | Pros: Expertise in tire care; additional services available. Cons: May charge for air; limited locations. |

| Portable Air Compressors | Personal devices for on-the-go inflation | Transportation companies, individual fleet owners | Pros: Always available; portable. Cons: Initial investment; requires maintenance. |

| Bike Repair Stations | Focused on bicycles; often provide air for free | Cycling shops, delivery services using bikes | Pros: Free service; community-oriented. Cons: Limited to bicycles; not suitable for vehicles. |

| Supermarkets & Membership Clubs | Some locations offer air as part of membership benefits | Retail businesses, membership-based services | Pros: Free or low-cost; accessible. Cons: May require membership; limited to specific locations. |

Gas stations are among the most common locations where businesses and individuals can find free air for tires. They are typically easily accessible and widespread, making them a convenient option for fleet maintenance and logistics companies. However, the availability of air services can vary by location, so businesses should verify beforehand. While most gas stations offer this service for free, some may charge a nominal fee, which could impact operational costs for businesses reliant on frequent tire maintenance.

Tire shops are specialized establishments that not only provide air for tires but also offer a range of tire-related services. This makes them an excellent choice for businesses involved in automotive services or those managing fleets. The expertise found at tire shops can help ensure that tires are properly maintained, which is crucial for safety and efficiency. However, it’s essential to note that some tire shops may charge for air services, which could affect the overall budget for tire upkeep.

Portable air compressors are an increasingly popular choice for businesses that require tire inflation on-the-go. These devices can be kept in vehicles or used at various locations, ensuring that tire pressure can be managed without relying on external services. For transportation companies and fleet owners, having an air compressor can significantly reduce downtime and improve efficiency. However, buyers should consider the initial investment and the need for regular maintenance to ensure optimal performance.

Illustrative image related to where to get air for tires near me

Bike repair stations often provide free air for bicycle tires, making them a valuable resource for businesses that utilize bikes for deliveries or transport. These stations are typically community-oriented, encouraging local engagement and support. While they are excellent for bicycles, businesses focused on automotive services will find them unsuitable for their needs. Nonetheless, they serve as a cost-effective solution for companies with a cycling component in their logistics.

Some supermarkets and membership clubs offer air services as a value-added benefit for customers. This can be particularly advantageous for businesses that are part of membership programs, as they can access air at no additional cost. The convenience of these locations often makes them appealing for regular tire maintenance. However, businesses should be aware that such services might be limited to specific locations and may require membership, potentially complicating access for some users.

| Industry/Sector | Specific Application of where to get air for tires near me | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Transportation and Logistics | Routine maintenance at fleet service stations | Reduces downtime by ensuring tire integrity and safety | Proximity to service locations and reliability of air supply |

| Automotive Repair Shops | Quick tire inflation services for customers | Enhances customer satisfaction and retention | Accessibility and efficiency of air supply infrastructure |

| Bicycle Retail and Repair | Providing air for customer bicycles | Increases foot traffic and potential sales | Availability of air pumps and maintenance of equipment |

| Construction Equipment Rental | Ensuring proper tire pressure for heavy machinery | Improves safety and operational efficiency | Consistency in air supply and suitable equipment for large tires |

| Agriculture | Maintaining tire pressure for farm vehicles | Enhances productivity and reduces tire-related accidents | Access to air sources in rural areas and equipment compatibility |

In the transportation and logistics sector, maintaining the proper tire pressure of fleet vehicles is crucial for safety and efficiency. Access to air for tires near service stations minimizes downtime, ensuring that vehicles remain operational and safe on the road. Businesses should consider the proximity of air supply locations and the reliability of service providers to maintain their fleets effectively. This is especially relevant for international buyers who may need to coordinate maintenance across various regions.

Automotive repair shops can enhance customer satisfaction by providing free or low-cost tire inflation services. This added convenience encourages customers to return for additional services, fostering loyalty. For repair shops, it’s essential to source air supply from reliable providers and ensure that the infrastructure is efficient. International buyers should also consider local regulations regarding tire maintenance services, which may vary significantly between regions.

Illustrative image related to where to get air for tires near me

Bicycle retailers and repair shops can attract more customers by offering air inflation services for bicycles. This service not only increases foot traffic but also creates opportunities for upselling related products like tires and maintenance tools. Retailers should focus on the availability of air pumps and the maintenance of equipment to provide consistent service. For international buyers, understanding local cycling trends and demand is critical in tailoring their offerings.

In the construction industry, maintaining tire pressure in heavy machinery is vital for safety and operational efficiency. Access to reliable air sources ensures that equipment remains in optimal working condition, reducing the risk of accidents and costly downtime. When sourcing air supply options, businesses should consider the consistency and availability of service, particularly in remote construction sites. International buyers must also take into account the compatibility of air inflation equipment with various machinery types.

Farm vehicles require regular tire maintenance to ensure productivity and safety in agricultural operations. Access to air for tires can help farmers prevent accidents caused by under-inflated tires, which can lead to machinery malfunctions. When sourcing air supply, farmers should prioritize accessibility in rural areas and ensure that the equipment used is suitable for larger agricultural tires. International buyers should also be aware of specific agricultural practices in their region to meet local needs effectively.

The Problem: For B2B buyers managing fleets, ensuring all vehicles are properly inflated is crucial for safety and efficiency. However, finding reliable locations to get air for tires can be a daunting task. Many gas stations and tire shops may not consistently provide free air, and it can be time-consuming to identify which locations are actually equipped to assist. This inconsistency can lead to delays in operations, increased maintenance costs, and potential safety hazards if tires are under-inflated.

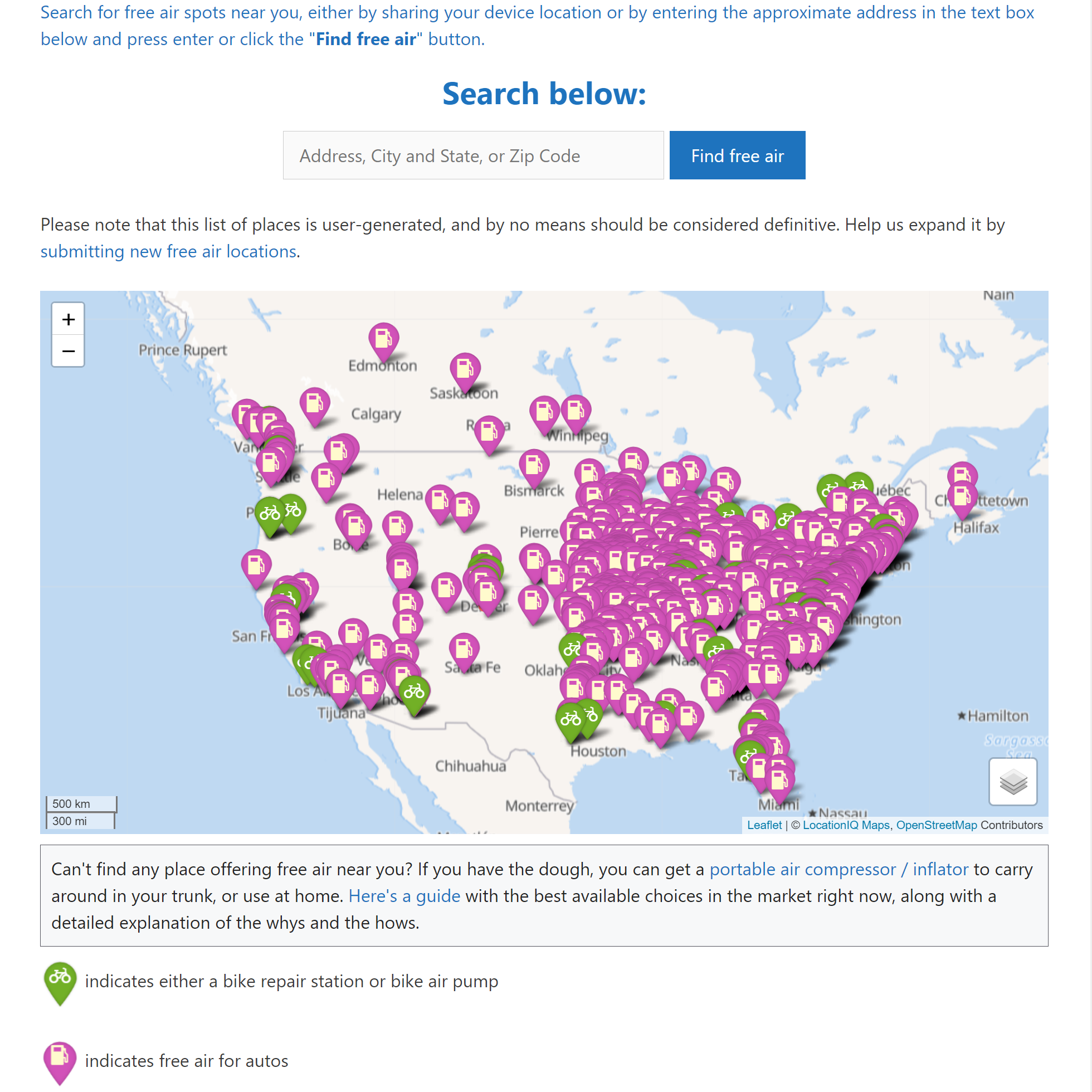

The Solution: To streamline the process, B2B buyers should utilize crowd-sourced platforms that aggregate data on locations offering free air. Websites like FreeAirPump.com provide an interactive map that shows nearby options, helping fleet managers quickly identify the most convenient and reliable air sources. Additionally, integrating this information into a mobile app or fleet management software can automate notifications when vehicles are in proximity to air sources. Regularly updating the fleet with portable air compressors can also serve as a backup, ensuring that drivers are never caught without a way to maintain tire pressure, thus reducing downtime and enhancing fleet safety.

The Problem: B2B buyers, especially in logistics and transportation, face the challenge of managing operational costs. Paying for air to inflate tires—ranging from $0.75 to $5.00 per fill—can accumulate significantly over time, particularly for businesses with large fleets or high tire maintenance needs. This expense can strain budgets, especially for small to medium enterprises where every penny counts.

The Solution: To mitigate these costs, businesses can adopt a proactive approach by establishing partnerships with local tire shops or gas stations that offer free air as a promotional service. Negotiating agreements can ensure that employees have access to free air without incurring additional charges. Furthermore, incorporating tire pressure monitoring systems (TPMS) into the fleet can provide real-time data on tire pressure, reducing the frequency of air top-ups and extending the lifespan of tires. Educating drivers on the importance of regular tire maintenance can also foster a culture of cost efficiency and safety.

The Problem: In various regions, the quality of air supplied at gas stations or service stations can vary widely. Some locations may have outdated or malfunctioning equipment, leading to insufficient tire inflation. This inconsistency can result in reduced vehicle performance, increased wear and tear on tires, and ultimately, safety risks for drivers. For B2B buyers, ensuring that their vehicles are equipped with well-inflated tires is a non-negotiable aspect of fleet management.

The Solution: B2B buyers should develop a vetting process for air supply locations, focusing on those that have proven reliability and quality. Using the aforementioned crowd-sourced maps, they can identify and maintain a list of preferred locations with consistently good reviews. Establishing relationships with local tire shops can also ensure access to well-maintained air pumps, and companies can encourage employees to report on air quality and pump functionality. Additionally, investing in high-quality portable air compressors ensures that businesses have a dependable alternative for tire inflation, safeguarding against the unpredictability of public air supply services.

When considering where to get air for tires, the materials used in air supply systems play a crucial role in performance, durability, and overall cost-effectiveness. Here, we analyze four common materials used in tire inflation systems, focusing on their properties, advantages, disadvantages, and considerations for international B2B buyers.

Rubber is a widely used material in tire inflation systems, particularly in hoses and seals. Its key properties include excellent elasticity, temperature resistance (typically up to 120°C), and good pressure ratings (up to 300 psi). Rubber is also resistant to abrasion, making it suitable for environments where wear and tear are common.

Illustrative image related to where to get air for tires near me

Pros: Rubber is cost-effective, lightweight, and offers good flexibility, which is essential for easy handling. It can also be molded into various shapes, providing versatility in design.

Cons: However, rubber can degrade over time due to exposure to ozone and UV light, leading to potential leaks. It may also have limited chemical resistance, which can be a concern in certain environments.

Impact on Application: Rubber is compatible with air and is often used in portable air compressors and tire inflators. Its flexibility allows for easy connection to various tire types.

Illustrative image related to where to get air for tires near me

Considerations for International Buyers: Buyers should ensure that the rubber meets international standards such as ASTM D2000 or DIN 7863, particularly in regions like Europe and the Middle East, where compliance is critical.

Aluminum is another popular choice for air supply systems, particularly in fittings and connectors. It boasts a high strength-to-weight ratio, excellent corrosion resistance, and can withstand high pressures (up to 1500 psi).

Pros: Aluminum is lightweight and resistant to corrosion, making it ideal for outdoor applications. Its durability ensures a longer lifespan, reducing the need for frequent replacements.

Illustrative image related to where to get air for tires near me

Cons: The primary drawback of aluminum is its cost compared to rubber. Additionally, it can be prone to galling when threaded, which may complicate assembly.

Impact on Application: Aluminum is often used in high-pressure air systems, ensuring safe and efficient tire inflation.

Considerations for International Buyers: Compliance with standards such as ASTM B221 for aluminum extrusions is essential, especially in regions like Germany and Saudi Arabia, where quality assurance is paramount.

Stainless steel is commonly used for valves and fittings in tire inflation systems due to its exceptional corrosion resistance and strength. It can handle high temperatures and pressures (up to 3000 psi), making it suitable for demanding environments.

Pros: The durability of stainless steel significantly extends the lifespan of components, reducing maintenance costs. Its resistance to corrosion ensures reliability in various climates.

Cons: The main downside is the higher cost of stainless steel compared to rubber and aluminum. Its weight may also be a consideration for portable applications.

Impact on Application: Stainless steel components are ideal for commercial tire inflation systems, where reliability and performance are critical.

Illustrative image related to where to get air for tires near me

Considerations for International Buyers: Buyers should look for compliance with standards like ASTM A240 or JIS G4303 to ensure quality, particularly in regions with stringent regulations.

Polyvinyl Chloride (PVC) is often utilized in air hoses due to its lightweight and flexible nature. It performs well under moderate pressure (up to 150 psi) and is resistant to a variety of chemicals.

Pros: PVC is generally more affordable than rubber and aluminum, making it a cost-effective option for many applications. Its flexibility allows for easy maneuverability.

Illustrative image related to where to get air for tires near me

Cons: However, PVC has lower temperature resistance (up to 60°C) and can become brittle over time, especially when exposed to UV light.

Impact on Application: PVC is suitable for low-pressure tire inflation systems and is often used in consumer-grade air compressors.

Considerations for International Buyers: Compliance with standards such as ASTM D1784 is important, especially in regions where safety regulations are strict.

Illustrative image related to where to get air for tires near me

| Material | Typical Use Case for where to get air for tires near me | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Rubber | Hoses and seals for portable air compressors | Cost-effective and flexible | Degrades over time | Low |

| Aluminum | Fittings and connectors in high-pressure systems | Lightweight and corrosion-resistant | Higher cost, prone to galling | Medium |

| Stainless Steel | Valves and fittings in commercial tire inflation systems | Exceptional durability | Higher cost, heavier | High |

| PVC | Low-pressure air hoses for consumer-grade compressors | Affordable and flexible | Lower temperature resistance | Low |

This strategic material selection guide provides essential insights for B2B buyers looking to optimize their tire inflation systems. Understanding the properties and implications of each material can lead to more informed purchasing decisions, ensuring compliance and performance across diverse international markets.

The manufacturing of tire air supply systems, such as air pumps and compressors, involves several critical stages to ensure efficiency and reliability. The primary stages include material preparation, forming, assembly, and finishing.

Material Preparation: This initial phase involves selecting high-quality materials, such as metals, plastics, and rubber components. Manufacturers often choose materials based on their durability, resistance to wear, and performance under pressure. For instance, the casing of an air compressor might be made from aluminum for lightweight strength, while rubber components are selected for their flexibility and sealing capabilities.

Forming: During the forming stage, raw materials are shaped into parts using various techniques, including casting, machining, and molding. For example, metal parts may be machined to precise specifications, while plastic components can be produced through injection molding. The choice of forming technique affects the overall quality and performance of the end product.

Assembly: Once the individual components are formed, they are assembled into final products. This stage often requires skilled labor and precision tools to ensure that all parts fit together perfectly. Effective assembly processes are crucial for minimizing leaks in air pumps and ensuring the longevity of the equipment.

Finishing: The final stage involves applying coatings, treatments, or surface finishes to enhance the product’s appearance and functionality. This may include rust-proofing for metal parts or applying anti-slip surfaces to handles. Quality finishes not only improve aesthetics but also contribute to the product’s durability in various environmental conditions.

Key manufacturing techniques are employed to enhance the performance and reliability of tire air supply equipment. These techniques include:

Precision Engineering: Utilizing advanced machining and manufacturing technologies ensures that components are produced with high accuracy. This is particularly important for parts that require tight tolerances, as even minor discrepancies can lead to performance failures.

Automated Assembly Lines: The use of automated systems in assembly processes increases efficiency and consistency. Automated lines can reduce human error and improve production speed, crucial for meeting large-scale demands.

Quality Control Integration: Incorporating quality control measures throughout the manufacturing process helps in identifying defects early. Techniques like Statistical Process Control (SPC) allow manufacturers to monitor production and maintain high-quality standards.

Quality assurance (QA) plays a vital role in ensuring that tire air supply systems meet international and industry-specific standards. Key components of a robust QA system include:

Relevant International Standards: Adhering to ISO 9001 standards is crucial for manufacturers. This certification indicates that the organization has a robust quality management system in place, focusing on customer satisfaction and continuous improvement.

Industry-Specific Certifications: For products sold in European markets, CE marking ensures compliance with safety, health, and environmental protection standards. Similarly, in other regions, manufacturers may seek certifications from organizations like the American Petroleum Institute (API) for equipment used in oil and gas.

Quality control is an ongoing process that involves multiple checkpoints throughout the manufacturing stages:

Incoming Quality Control (IQC): This initial checkpoint assesses the quality of raw materials before they enter production. Inspectors verify that materials meet specified standards, thereby preventing defects from arising in later stages.

In-Process Quality Control (IPQC): During the manufacturing process, periodic inspections are conducted to ensure that components are being produced according to specifications. This includes monitoring machine performance and verifying that assembly procedures are followed correctly.

Final Quality Control (FQC): After assembly, final inspections are performed to evaluate the overall functionality and safety of the tire air supply systems. This may involve pressure testing to ensure that air pumps do not leak and perform effectively under real-world conditions.

Testing methods play a crucial role in verifying the reliability and safety of tire air supply systems:

Pressure Testing: This is a common method used to ensure that air compressors and pumps can handle the required pressure without leaking. Manufacturers often use water or air to test the integrity of the seals and joints.

Durability Testing: Products are subjected to stress tests that simulate real-world usage to assess their longevity and performance under various conditions. This may include temperature variations and prolonged operation cycles.

Performance Testing: Evaluating the efficiency of air pumps involves measuring the time taken to inflate a tire to a specified pressure. This helps manufacturers identify any performance issues that need addressing.

For international B2B buyers, especially those from Africa, South America, the Middle East, and Europe, verifying supplier quality control standards is essential. Here are several strategies to consider:

Supplier Audits: Conducting on-site audits allows buyers to assess a supplier’s manufacturing processes and quality control measures firsthand. This provides insights into their operational capabilities and adherence to quality standards.

Quality Reports: Requesting detailed quality reports can help buyers understand how a supplier monitors and controls quality throughout the manufacturing process. These reports may include data on defect rates, testing results, and compliance with international standards.

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased evaluation of a supplier’s quality control practices. These inspections often include comprehensive assessments of manufacturing facilities, processes, and product quality.

Navigating quality control and certification can be particularly challenging for international buyers:

Understanding Regional Regulations: Different countries have varying requirements for product certifications. Buyers should familiarize themselves with local regulations to ensure compliance and avoid potential market entry issues.

Language and Documentation Barriers: Language differences can complicate the verification of quality standards and certifications. Buyers should ensure that documentation is available in a language they understand and that they can seek clarification on any ambiguous terms.

Cultural Considerations: Understanding the business culture of suppliers in different regions can facilitate smoother negotiations and ensure that quality expectations are clearly communicated.

By focusing on these aspects of manufacturing processes and quality assurance, B2B buyers can make informed decisions when sourcing tire air supply systems, ensuring they receive reliable and high-quality products that meet their operational needs.

Illustrative image related to where to get air for tires near me

This guide provides a systematic approach for B2B buyers seeking reliable sources for tire inflation air. Understanding where to access air for tires can enhance operational efficiency, reduce costs, and ensure the safety of vehicles in various industries. Here’s a step-by-step checklist to streamline your sourcing process.

Knowing the specific regions where you need air for tires is essential. Different areas may have varying availability of services, especially in international markets like Africa, South America, the Middle East, and Europe.

– Research Local Regulations: Some countries have laws requiring free air at certain establishments, which can influence your sourcing decisions.

– Consider Logistics: Understanding the local infrastructure can help you find the most accessible locations.

Leverage online platforms that provide maps or databases of locations offering free air for tires. Websites such as FreeAirPump.com allow users to search for nearby spots based on their location.

– Crowdsourced Information: These platforms often have user-generated content, which means they are regularly updated with new locations.

– Check User Feedback: Look for reviews or ratings of these locations to ensure quality service.

Conduct a thorough assessment of local tire shops and gas stations that typically provide air for free or at a minimal cost.

– Contact Multiple Establishments: Not all locations advertise this service; a phone call can confirm availability.

– Inquire About Additional Services: Some shops may offer tire pressure checks or maintenance services, which can be beneficial.

If local options are limited, consider investing in portable air compressors or inflators. This can serve as a backup solution for tire inflation needs.

– Assess Features and Reliability: Look for products that are durable and suited for your specific vehicle types.

– Evaluate Costs vs. Benefits: Weigh the initial investment against the potential savings from not having to pay for air at service stations.

Illustrative image related to where to get air for tires near me

Building relationships with local businesses can provide insights and recommendations on where to access air for tires effectively.

– Join Local Trade Associations: Many regions have automotive or transportation associations that can offer valuable information.

– Attend Industry Events: Networking at trade shows or conferences can lead to discovering reliable air sources or suppliers.

Before finalizing your preferred locations, ensure they meet the required quality standards and compliance regulations.

– Check Equipment Maintenance: Regular maintenance of air pumps is crucial for accurate tire inflation.

– Ask About Certifications: Valid certifications can indicate a commitment to service quality and safety standards.

Once you’ve compiled a list of reliable air sources, create a document that can be shared with your team or other stakeholders.

– Create an Easy Reference Guide: Include addresses, contact information, and services offered.

– Encourage Team Feedback: Regular updates from team members can help keep the information current and relevant.

By following this checklist, B2B buyers can efficiently identify and secure dependable sources for tire inflation air, ensuring operational effectiveness and safety in their vehicle management.

When analyzing the cost structure for sourcing air for tires, several components come into play. Firstly, materials are minimal since the primary product is compressed air; however, the infrastructure required to generate and store this air, such as compressors and storage tanks, can be significant. Labor costs will vary based on the location and type of service provider, as tire shops and gas stations may employ different pricing strategies depending on their operational costs and labor laws.

Manufacturing overhead includes expenses related to maintenance and operational costs of air compressors and associated equipment. This can impact the pricing strategy of businesses offering free air services, as the costs must be absorbed into their overall service pricing. Tooling and quality control (QC) measures are less relevant in this context, but ensuring that air compressors function effectively and safely is essential for customer satisfaction and compliance with local regulations.

Illustrative image related to where to get air for tires near me

Logistics plays a crucial role in the pricing structure for air services. The cost of transporting air compressors and other equipment to various locations can affect the overall pricing strategy. Moreover, businesses must consider their margins when pricing services; those offering free air often recoup costs through other services or products sold, such as tires and automotive repairs.

Several factors influence the pricing of air services. Volume and Minimum Order Quantity (MOQ) are significant; businesses offering air services may see lower costs per unit when operating at scale. For instance, tire shops that frequently refill air may negotiate better terms with suppliers of air compressor equipment.

Specifications and customization can also impact costs. High-quality air compressors with advanced features may command a premium price, while more basic models will be cheaper but may not offer the same reliability.

Quality and certifications of the equipment used can influence pricing as well. Providers with certified equipment may charge more due to the assurance of quality and safety, appealing to businesses concerned with compliance and customer satisfaction.

Supplier factors such as reliability, reputation, and service support can also affect pricing. Companies that establish a strong relationship with suppliers may benefit from better pricing or terms. Finally, Incoterms can influence pricing for international transactions, particularly for B2B buyers from regions like Africa, South America, the Middle East, and Europe. Understanding these terms is crucial for managing costs and ensuring that buyers are not caught off-guard by unexpected fees.

B2B buyers should consider several strategies to enhance cost-efficiency when sourcing air for tires. Negotiation is key; engaging suppliers to discuss bulk purchasing or long-term contracts can yield more favorable pricing.

It’s important to evaluate the Total Cost of Ownership (TCO), which includes not just the initial purchase price of air services but also maintenance, operational costs, and potential downtime.

Buyers should also be aware of pricing nuances specific to international markets. For instance, different regions may have varying regulatory requirements that can affect the cost of sourcing air services. Understanding these local dynamics can provide a competitive edge in negotiations.

In conclusion, while the cost of sourcing air for tires may appear straightforward, several underlying factors and strategies can significantly influence pricing for B2B buyers. By understanding these components, businesses can make informed decisions that optimize their operational costs and enhance profitability.

In the quest for effective tire maintenance, businesses must consider various methods for inflating tires beyond simply locating air sources nearby. While finding free air for tires is a convenient solution, alternative options such as portable air compressors and tire inflators can offer distinct advantages. This section compares the traditional approach of sourcing air for tires with other viable solutions, helping B2B buyers make informed decisions based on their operational needs.

| Comparison Aspect | Where To Get Air For Tires Near Me | Portable Air Compressor | Tire Inflator App |

|---|---|---|---|

| Performance | Generally reliable; depends on location availability | High; portable and can be used anywhere | Moderate; relies on user accuracy and device compatibility |

| Cost | Free or minimal charges at some locations | Initial investment (typically $30-$150) | Free to download; may require in-app purchases |

| Ease of Implementation | Simple; find a location and fill tires | Requires purchase, setup, and learning | Easy to download and set up, but requires compatible equipment |

| Maintenance | Minimal; depends on the location’s upkeep | Regular maintenance of the compressor needed | Low; mainly software updates |

| Best Use Case | Quick, spontaneous inflation needs | Frequent travelers or fleet managers | Data-driven tire management for tech-savvy users |

Portable air compressors are compact devices that allow users to inflate tires anywhere and at any time. The primary advantage is their independence from external sources; users can inflate tires on the go, which is particularly useful for businesses with mobile operations or fleets. However, the initial investment can be significant, and proper maintenance is required to ensure longevity and efficiency. Additionally, users must be familiar with operating the device, which may require some training.

Tire inflator apps are digital solutions that help users monitor tire pressure and locate nearby air sources. These apps often feature GPS functionality to provide directions to the nearest inflation points. While the app itself may be free or low-cost, the effectiveness hinges on the user having compatible devices and understanding how to interpret the data presented. This method is best suited for tech-savvy individuals or businesses looking to integrate tire maintenance into a broader digital management system. However, it may not provide immediate solutions in urgent situations.

Illustrative image related to where to get air for tires near me

For B2B buyers, the choice between finding air for tires nearby and investing in alternative solutions should be guided by specific operational needs. If immediate access to air is crucial and frequent, a portable air compressor may provide the best value, especially for businesses with a mobile workforce. Conversely, for companies focused on data management and efficiency, a tire inflator app may enhance overall tire maintenance strategies. Ultimately, understanding the unique requirements of your business will help determine the most suitable tire inflation method.

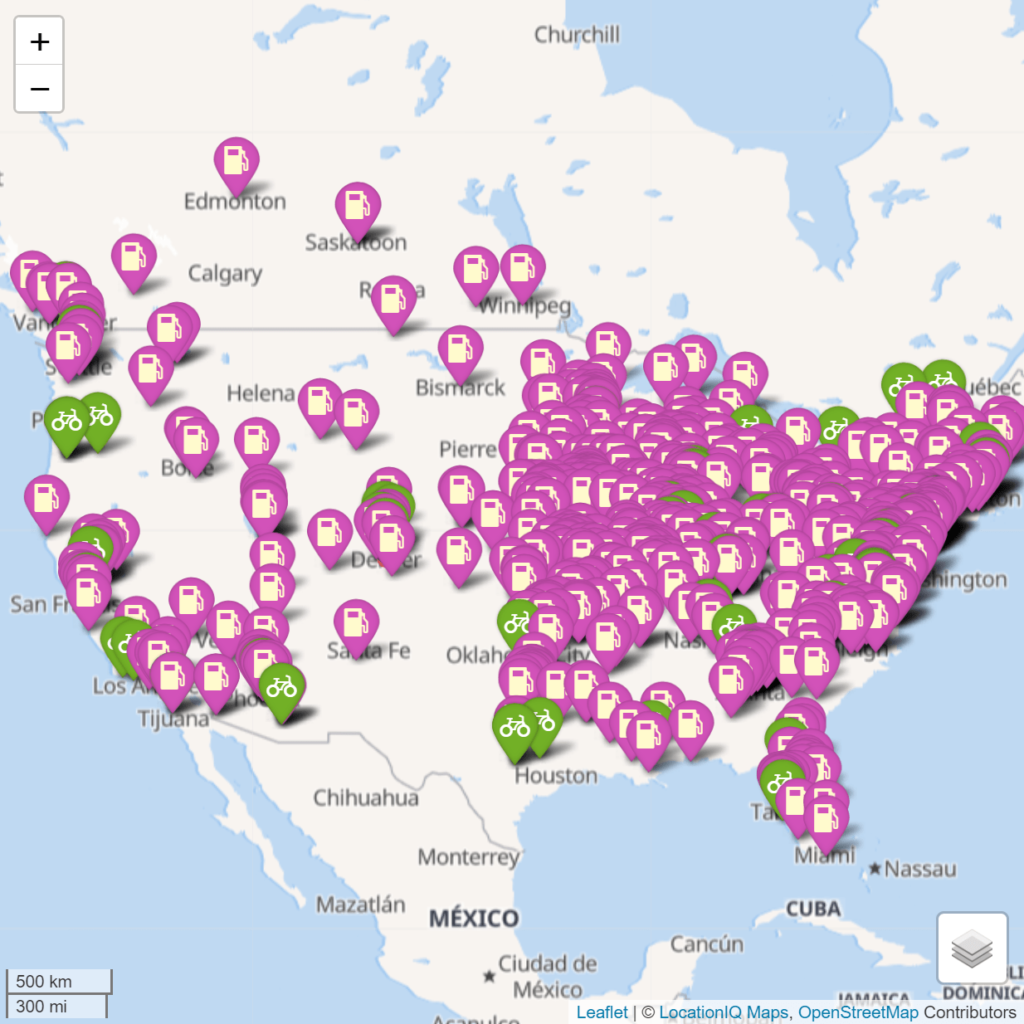

When sourcing air for tires, understanding the essential technical properties is crucial for B2B buyers. Here are some critical specifications to consider:

Air Pressure Rating (PSI)

The air pressure rating, measured in pounds per square inch (PSI), indicates the maximum pressure that a tire can safely handle. For commercial vehicles, maintaining the correct PSI is vital for optimal performance and safety. B2B buyers should ensure that the air supply equipment can deliver air at the required PSI to meet vehicle specifications.

Compressor Flow Rate (CFM)

The flow rate, measured in cubic feet per minute (CFM), determines how quickly an air compressor can fill a tire. A higher CFM rating means faster inflation times, which is essential for service centers with high customer turnover. Buyers should assess their operational needs to select an air supply system that matches their desired efficiency.

Durability and Material Quality

The materials used in air supply systems, such as rubber hoses and metal fittings, must withstand high pressure and frequent use. Buyers should look for equipment made from high-grade materials to minimize wear and tear, thus reducing maintenance costs and downtime.

Temperature Tolerance

Air compressors and associated equipment should operate effectively under varying environmental conditions. Understanding the temperature tolerance is vital, especially for businesses in regions with extreme weather. Equipment that can function across a broad temperature range will ensure reliability and longevity.

Noise Level (Decibels)

The noise produced by air compressors can affect the working environment, particularly in enclosed spaces. Noise levels, measured in decibels (dB), should be considered when selecting equipment, as lower noise levels can enhance workplace comfort and compliance with local regulations.

Energy Efficiency Rating

As businesses strive to reduce operating costs, the energy efficiency of air supply systems becomes increasingly important. Equipment with a high energy efficiency rating not only lowers energy bills but also aligns with sustainability goals. Buyers should consider this factor when evaluating long-term operational costs.

Understanding industry jargon is essential for effective communication and negotiations in the B2B landscape. Here are some common terms:

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of tire maintenance, B2B buyers may deal with OEMs for high-quality air supply systems that meet specific vehicle requirements.

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. For businesses looking to maintain a steady supply of air equipment, understanding the MOQ helps in budgeting and inventory planning.

RFQ (Request for Quotation)

An RFQ is a formal request for pricing information from suppliers. When sourcing air supply systems, B2B buyers can issue an RFQ to multiple vendors to compare prices and terms, ensuring they make informed purchasing decisions.

Incoterms (International Commercial Terms)

Incoterms are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Familiarity with these terms helps B2B buyers understand shipping costs, insurance, and delivery responsibilities when sourcing air supply equipment from global suppliers.

Aftermarket

This term refers to parts and equipment sold after the original sale of the vehicle. B2B buyers often explore aftermarket options for air supply systems that may offer cost savings or enhanced features compared to OEM products.

Service Level Agreement (SLA)

An SLA is a contract that outlines the expected level of service between a provider and a customer. For businesses relying on air supply services, having a clear SLA ensures accountability and sets expectations for service delivery.

By grasping these specifications and trade terms, B2B buyers can make informed decisions when sourcing air for tires, ensuring their operations run smoothly and efficiently.

The market for tire inflation services, including where to get air for tires, is increasingly influenced by several global drivers, including technological advancements, consumer behavior shifts, and economic factors. One significant trend is the rising demand for convenience, prompting service providers to adopt user-friendly technologies such as mobile apps that help consumers locate nearby air stations quickly. In regions like Africa and South America, where vehicle ownership is on the rise, the need for accessible tire maintenance services is becoming critical.

Moreover, the integration of IoT (Internet of Things) technology in vehicles is reshaping how tire pressure is monitored and maintained. Smart sensors can alert drivers when tire pressure drops, enhancing safety and efficiency. This trend is particularly relevant for fleet operators in the Middle East and Europe, where operational costs are closely scrutinized. B2B buyers are increasingly looking for partnerships with companies that offer not just air but comprehensive tire management solutions, including pressure monitoring and maintenance services.

Additionally, the ongoing global push towards sustainability is influencing sourcing trends. Companies are exploring eco-friendly solutions, such as portable air compressors powered by renewable energy sources. This shift is particularly pertinent for buyers in Germany, where sustainability is a key market driver. As a result, suppliers that can provide a mix of traditional services alongside innovative, eco-conscious options are likely to thrive.

The environmental impact of tire maintenance and inflation is a growing concern for B2B buyers. Traditional methods of tire inflation can lead to the waste of compressed air and energy, contributing to carbon emissions. As a response, businesses are increasingly prioritizing sustainability in their sourcing strategies. This includes seeking suppliers who use ‘green’ materials and processes in their air inflation services.

Furthermore, ethical sourcing is becoming essential in the tire service industry. Companies that adhere to ethical supply chain practices not only enhance their brand reputation but also align with the values of environmentally-conscious consumers. Certifications such as ISO 14001 (Environmental Management) and other green certifications provide assurance to buyers regarding the sustainability of their partners.

Illustrative image related to where to get air for tires near me

In markets like Africa and South America, where resource scarcity can impact operational efficiencies, ethical sourcing becomes even more critical. B2B buyers are encouraged to evaluate their suppliers based on their commitment to sustainability, ensuring that they contribute positively to local economies and ecosystems. By prioritizing suppliers with a strong environmental and ethical track record, businesses can mitigate risks and enhance their competitive edge in the marketplace.

The concept of providing air for tires has evolved significantly over the past few decades. Originally, tire inflation services were primarily offered at gas stations and tire shops as a basic customer service. However, as vehicle technology advanced and consumer expectations shifted, the demand for more convenient and accessible options grew. The rise of mobile technology has further transformed the landscape, enabling users to locate air stations through apps and online platforms easily.

Today, the industry is witnessing a blend of traditional service models with innovative solutions that cater to the needs of a modern, eco-conscious consumer base. This evolution reflects broader trends in automotive care, with a focus on efficiency, convenience, and sustainability, shaping the future of tire inflation services and offering B2B buyers a myriad of sourcing opportunities.

How do I locate places offering free air for tires in my area?

To find free air for tires, utilize online tools like crowdsourced maps available on platforms such as FreeAirPump.com. These databases allow users to enter their location to find nearby gas stations, tire shops, and bike repair stations that offer free air. Additionally, consider using local community forums or social media groups, as they can provide up-to-date recommendations from residents. Always verify the location beforehand, as the availability can change frequently.

What are the best tire service providers for businesses in Europe?

In Europe, some reputable tire service providers include Euromaster, ATS Euromaster, and Kwik Fit. These companies offer comprehensive tire services including inflation, pressure checks, and emergency assistance. For B2B buyers, it’s essential to assess the service network, availability of free air, and overall customer service reputation before committing. Look for providers that can accommodate fleet vehicles to ensure efficiency.

What should I consider when sourcing air compressors for my business?

When sourcing air compressors, consider factors such as capacity, portability, and energy efficiency. Evaluate the specific needs of your business, including the volume of tires you service and the types of vehicles. Ensure that the compressors are compliant with local regulations and come with adequate warranties. Supplier reputation and customer reviews can provide insights into reliability and after-sales support.

How do I vet suppliers for tire air services in Africa?

To vet suppliers for tire air services in Africa, start by researching their industry reputation through online reviews and ratings. Request references from past clients and check their compliance with local regulations. It’s also crucial to visit their facilities, if possible, to assess their service quality and reliability. Establishing clear communication and understanding their payment terms and service agreements can also aid in building a trustworthy relationship.

What are the typical payment terms for tire service contracts?

Payment terms for tire service contracts can vary widely, typically ranging from net 30 to net 60 days. Some suppliers may offer discounts for early payment, while others might require upfront payments, especially for larger orders or services. It’s important to clarify these terms during negotiations and ensure they align with your company’s cash flow management practices.

What logistics considerations should I keep in mind for tire air services?

Logistics for tire air services include ensuring timely delivery of air compressors or inflators, as well as the availability of service personnel when required. Evaluate the supplier’s distribution network, including their ability to service remote areas if necessary. Additionally, consider the lead times for service requests and whether the supplier can meet your operational demands efficiently.

Are there customization options for air compressor systems?

Many suppliers offer customization options for air compressor systems to better suit your business needs. This can include adjustments in capacity, additional features such as built-in filtration systems, or specialized attachments for different types of vehicles. Discuss your specific requirements with potential suppliers to explore available options and ensure that the system meets your operational needs.

How can I ensure quality assurance in tire air services?

To ensure quality assurance in tire air services, establish clear service level agreements (SLAs) with your suppliers. Regularly monitor service performance against these SLAs and solicit feedback from your team to identify any issues. Additionally, consider conducting periodic audits of the service locations and equipment to ensure compliance with quality standards. Working with certified suppliers can also enhance the reliability of the services provided.

Domain: freeairpump.com

Registered: 2012 (13 years)

Introduction: Map of places that provide free air for tires, with over 12,000 locations in the U.S. User-generated content, updated weekly. Search for free air spots by device location or address. Offers information on portable air compressors and inflators. Lists common places offering free air: tire shops, car repair stations, bike shops, and specific gas station chains (e.g., Co-op, Family Express, Getgo, Hy…

Domain: yelp.com

Registered: 2003 (22 years)

Introduction: This company, Omar Discount Tires – Gas Stations with Air Pumps, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Domain: firestonecompleteautocare.com

Registered: 2004 (21 years)

Introduction: This company, Firestone – Local Auto Care Services, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Domain: freeairnear.me

Registered: 2023 (2 years)

Introduction: Free air pumps for tires are available at 219 locations across 127 cities in New York. Of these, 196 businesses provide free air for cars and bikes, while 23 locations offer free air for bicycles only. Notably, 138 gas stations in New York also offer free air for tires, including chains such as Stewart’s, Byrne Dairy, Sunoco, Mobil, and others. However, gas stations are not legally required to pro…

The need for accessible and affordable tire air is critical for businesses operating in diverse international markets. As we’ve explored, numerous gas stations, tire shops, and dedicated air stations provide free or low-cost air services, presenting an excellent opportunity for cost-saving measures in fleet management and logistics. By strategically sourcing air for tires, companies can enhance operational efficiency, reduce overhead costs, and ensure the safety of their vehicles.

Illustrative image related to where to get air for tires near me

For B2B buyers in Africa, South America, the Middle East, and Europe, understanding local resources and regulations surrounding tire air access is paramount. Establishing relationships with local tire service providers and gas stations can foster goodwill, potentially leading to additional services and discounts. Furthermore, leveraging technology—such as user-generated maps—can streamline the process of locating nearby air sources, ensuring your fleet is always road-ready.

Looking ahead, the emphasis on sustainability and cost-effectiveness will continue to shape sourcing strategies. As you navigate the complexities of tire maintenance, consider incorporating portable air compressors into your toolkit for added convenience. Stay proactive in sourcing air for tires; it’s not just about filling tires—it’s about fueling your business’s success.

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

Illustrative image related to where to get air for tires near me

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.