Navigating the complexities of sourcing inflatable tires in today’s global market presents unique challenges for B2B buyers, particularly those operating in diverse regions such as Africa, South America, the Middle East, and Europe. With varying terrain and climatic conditions, selecting the right type of inflatable tires can significantly impact operational efficiency and safety. This comprehensive guide delves into the myriad types of inflatable tires available, their specific applications—from automotive to industrial uses—and crucial factors for vetting suppliers.

Understanding pricing structures and total cost of ownership is essential for making informed purchasing decisions, especially for businesses in emerging markets like Nigeria and Brazil, where budget constraints are often a reality. Additionally, the guide offers insights into logistics and import regulations that can affect the procurement process.

By empowering international B2B buyers with actionable insights and expert recommendations, this guide serves as a valuable resource for navigating the inflatable tire landscape. Buyers will gain the knowledge needed to make strategic decisions that enhance product performance and overall business success. Whether you’re looking to enhance your vehicle’s performance or streamline your production processes, the right inflatable tires can make all the difference.

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Inflatable Tires | Typically made from rubber or PVC, designed for general use. | Automotive, bicycles, light trucks | Pros: Versatile, cost-effective. Cons: Limited performance on rough terrains. |

| Heavy-Duty Inflatable Tires | Reinforced materials for enhanced durability and load capacity. | Construction, heavy machinery | Pros: High load-bearing capacity. Cons: Heavier and more expensive. |

| Specialty Inflatable Tires | Custom designs for specific applications (e.g., RC vehicles). | Hobbyist markets, specialized vehicles | Pros: Tailored performance. Cons: May require longer lead times for orders. |

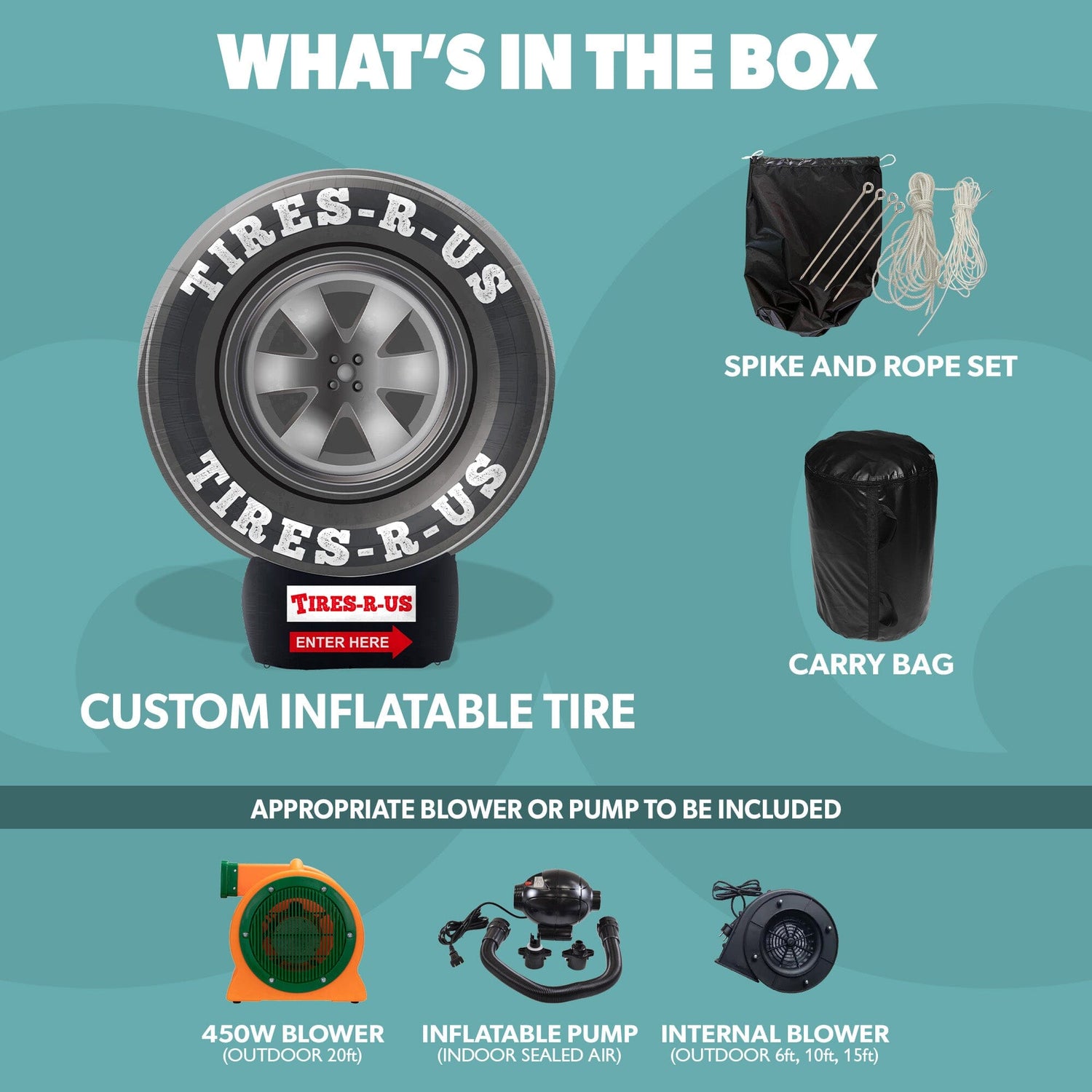

| Giant Advertising Inflatable Tires | Large, eye-catching designs for promotional use. | Marketing, events, trade shows | Pros: High visibility, customizable. Cons: Requires storage space, logistics for transport. |

| Adjustable Inflatable Tires | Features adjustable pressure for varied terrain performance. | Aviation, recreational vehicles | Pros: Customizable comfort and performance. Cons: Maintenance of air pressure needed. |

Standard inflatable tires are commonly utilized in various automotive and recreational applications. Made from durable rubber or PVC, these tires are designed for everyday use in vehicles such as cars, bicycles, and light trucks. They offer a balance of performance and cost-effectiveness, making them an attractive option for B2B buyers looking for reliable solutions. However, their performance may be limited on rough or uneven terrains, which is an important consideration for buyers operating in more challenging environments.

Illustrative image related to inflatable tires

Heavy-duty inflatable tires are engineered for superior durability and load capacity, making them ideal for use in construction and heavy machinery. These tires often feature reinforced materials to withstand harsh conditions and heavy weights. While they offer significant advantages in terms of strength and longevity, they tend to be heavier and more expensive than standard options. B2B buyers in industries requiring robust solutions should weigh the initial investment against the long-term benefits of reduced wear and tear.

Specialty inflatable tires are designed for niche markets, such as remote-controlled vehicles or specific industrial applications. These tires can be customized to meet precise performance requirements, offering tailored solutions for hobbyists and specialized vehicles. While they provide unique advantages in terms of performance, buyers should be aware that these products may involve longer lead times for production and delivery. Understanding the specific needs of the application is crucial for making informed purchasing decisions.

Giant advertising inflatable tires serve as powerful marketing tools, designed to capture attention at events, trade shows, and dealerships. Their large size and customizable features allow brands to create visually striking displays that enhance visibility. While they offer significant promotional advantages, buyers must consider the logistics of transport and storage, as well as the potential need for ongoing maintenance. These inflatables can provide a high return on investment when effectively integrated into marketing strategies.

Illustrative image related to inflatable tires

Adjustable inflatable tires feature innovative designs that allow users to modify air pressure according to terrain conditions. This adaptability makes them suitable for aviation and recreational vehicles, where performance can vary significantly based on the environment. Buyers should consider the ease of maintenance and the need for ongoing pressure adjustments, as these factors can affect the overall user experience. Investing in adjustable tires can lead to improved comfort and safety during operation, making them a valuable choice for B2B buyers in relevant industries.

| Industry/Sector | Specific Application of Inflatable Tires | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Custom Advertising at Dealerships | Enhances brand visibility and attracts customers | Ensure durability and weather resistance of materials |

| Aerospace | RC Aircraft Landing Gear | Provides shock absorption on rough terrain | Look for adjustable air pressure options for performance |

| Manufacturing | Robotics and STEM Projects | Lightweight solutions for mobility in projects | Consider compatibility with various robotics systems |

| Construction | Equipment Transport on Rough Terrain | Reduces damage to equipment and improves mobility | Assess tire durability under heavy loads and rough use |

| Event Marketing | Promotional Displays at Trade Shows | Creates memorable brand experiences | Customization options for branding and visibility |

In the automotive sector, inflatable tires serve as striking promotional tools at dealerships and trade shows. Their large size and customizable designs draw attention and create a memorable brand presence. By enhancing visibility, businesses can attract more foot traffic and potential customers. When sourcing inflatable tires for advertising, businesses should focus on the quality of materials to ensure durability and resistance to outdoor elements, especially in regions with varying climates, such as Africa and South America.

In the aerospace industry, inflatable tires are commonly utilized in remote-controlled (RC) aircraft, especially those designed for rugged terrain. These tires provide essential shock absorption during landings on uneven surfaces, allowing for smoother operations in challenging environments. Buyers in this sector should prioritize adjustable air pressure features, enabling customization for different landing conditions. This is particularly relevant for international markets where terrain conditions can vary significantly.

Inflatable tires are increasingly utilized in robotics and STEM projects, where lightweight and flexible mobility solutions are essential. They enable robots to navigate various terrains without causing damage, thus enhancing the overall efficiency of operations. When sourcing inflatable tires for these applications, businesses should ensure compatibility with the specific designs and weight requirements of their robotic systems. This is crucial for manufacturers in emerging markets like Nigeria and Brazil, where innovation in technology is rapidly expanding.

Illustrative image related to inflatable tires

In construction, inflatable tires are vital for transporting equipment across rough terrains, minimizing damage to both the equipment and the surfaces being traversed. Their ability to absorb shocks and provide stability is invaluable in challenging environments. Buyers should evaluate the load-bearing capacity and durability of these tires, especially in regions where construction sites may present extreme conditions. This consideration is particularly important for construction firms operating in the Middle East, where terrain can be unpredictable.

Inflatable tires are increasingly used in event marketing, especially at trade shows and community events, where they serve as eye-catching displays that promote brand engagement. Their versatility allows for easy setup and transport, making them an attractive option for businesses looking to create impactful marketing experiences. When sourcing these promotional tools, companies should focus on customization options that align with their branding needs, ensuring that their inflatable displays resonate with diverse audiences across Europe and beyond.

The Problem: B2B buyers often face challenges with maintaining optimal air pressure in inflatable tires when operating in varied terrains. For instance, a logistics company managing a fleet of delivery vehicles might encounter fluctuating tire performance due to inconsistent air pressure. This can lead to increased fuel consumption, reduced load capacity, and potentially hazardous driving conditions, particularly in regions with uneven or rough roads typical in parts of Africa and South America.

The Solution: To address this issue, B2B buyers should invest in high-quality inflatable tires equipped with positive-seal air valves, which minimize air leakage. It is critical to develop a regular maintenance schedule that includes checking air pressure before each trip. Buyers should also consider inflatable tires that allow for adjustable firmness—sourcing tires that can be tailored to specific terrains. For example, softer inflation can provide better shock absorption on rough roads, while firmer inflation can enhance efficiency on smoother surfaces. Additionally, incorporating tire pressure monitoring systems (TPMS) can help ensure that air pressure remains optimal, enhancing safety and performance across diverse operating conditions.

The Problem: Companies operating in extreme environments, such as construction sites or rural areas with rough terrain, often struggle with the durability of inflatable tires. These tires can suffer from punctures, tears, or other forms of damage, leading to costly downtimes and delays. For instance, a construction firm in the Middle East may find that its inflatable tires are not holding up against the abrasive surfaces and extreme temperatures, resulting in frequent replacements and added operational costs.

The Solution: To combat durability issues, B2B buyers should prioritize sourcing inflatable tires made from high-quality, puncture-resistant materials. It is advisable to conduct thorough research and select suppliers who offer tires specifically designed for rugged applications. Buyers should also consider integrating a tire management program that includes regular inspections and assessments of tire condition, enabling timely repairs or replacements before major failures occur. Investing in tires that feature reinforced sidewalls and superior tread designs can further enhance durability, ensuring that the tires can withstand harsh environmental conditions without compromising performance.

The Problem: Many businesses struggle with the initial investment and ongoing costs associated with inflatable tires. For example, a transportation company in Brazil might be hesitant to switch to inflatable tires due to concerns over their cost-effectiveness compared to traditional solid tires. This hesitation is compounded by fears of the tires not delivering long-term value, especially in terms of maintenance and replacement frequency.

The Solution: To ensure a cost-effective transition to inflatable tires, B2B buyers should conduct a comprehensive total cost of ownership (TCO) analysis. This analysis should compare the long-term costs associated with both inflatable and solid tires, taking into account factors such as fuel efficiency, maintenance, and replacement frequency. Additionally, buyers should look for suppliers that provide warranties and support services, which can mitigate risks associated with the initial investment. Leveraging bulk purchasing agreements or long-term contracts can also reduce costs significantly. By emphasizing the benefits of improved fuel efficiency, reduced maintenance, and enhanced ride quality, companies can justify the switch to inflatable tires as a strategic move towards long-term savings and operational efficiency.

Inflatable tires are engineered using various materials, each offering unique properties that affect performance, durability, and suitability for specific applications. Understanding these materials is crucial for B2B buyers looking to make informed purchasing decisions.

Illustrative image related to inflatable tires

Natural Rubber

Natural rubber is a widely used material for inflatable tires due to its excellent elasticity and resilience. It can withstand a wide range of temperatures and pressures, making it suitable for various environments. However, natural rubber is susceptible to UV degradation and ozone, which can lead to cracking over time. This material is often favored for applications requiring high flexibility and shock absorption.

Pros: High elasticity, good shock absorption, and excellent grip.

Cons: Vulnerable to UV and ozone degradation, limited lifespan in harsh environments.

Impact on Application: Best for indoor or controlled environments; less suitable for prolonged outdoor use without protective coatings.

Considerations for Buyers: Compliance with ASTM standards is essential, particularly in regions with stringent safety regulations. Buyers in Africa and South America should consider the availability of protective additives to enhance UV resistance.

Synthetic Rubber (e.g., SBR, EPDM)

Synthetic rubber, such as Styrene-Butadiene Rubber (SBR) and Ethylene Propylene Diene Monomer (EPDM), is engineered to provide enhanced durability and resistance to environmental factors. SBR is commonly used for its balance of performance and cost, while EPDM offers superior weather resistance and longevity.

Pros: Enhanced durability, better resistance to UV and ozone, and customizable properties.

Cons: Generally higher production costs and may require more complex manufacturing processes.

Impact on Application: Ideal for outdoor applications and environments with fluctuating temperatures.

Considerations for Buyers: Ensure that the synthetic rubber meets international standards such as DIN and JIS, especially for buyers in Europe and the Middle East, where compliance is critical.

Thermoplastic Elastomers (TPEs)

TPEs combine the properties of rubber with the processability of plastics, making them an attractive option for inflatable tires. They offer excellent flexibility, chemical resistance, and can be easily molded into complex shapes. TPEs are also recyclable, aligning with sustainability goals.

Pros: Good flexibility, chemical resistance, and ease of manufacturing.

Cons: Generally lower temperature resistance compared to traditional rubber materials.

Impact on Application: Suitable for a wide range of applications, including those requiring chemical compatibility.

Considerations for Buyers: TPEs may not meet certain high-temperature applications, so buyers should assess their specific needs. In regions like Nigeria and Brazil, where temperature fluctuations are common, this factor is particularly relevant.

Polyvinyl Chloride (PVC)

PVC is often used for inflatable tires in applications where cost-effectiveness is a priority. It is resistant to moisture and chemicals, making it suitable for various environments. However, PVC is less flexible than rubber materials, which can impact performance in high-stress applications.

Pros: Cost-effective, moisture-resistant, and easy to manufacture.

Cons: Limited flexibility and durability compared to rubber materials.

Impact on Application: Best for low-stress applications or temporary uses.

Considerations for Buyers: Ensure compliance with local regulations regarding plastic materials, particularly in Europe, where environmental standards are stringent.

| Material | Typical Use Case for inflatable tires | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Natural Rubber | Indoor applications and recreational use | High elasticity and shock absorption | Vulnerable to UV and ozone degradation | Medium |

| Synthetic Rubber (SBR, EPDM) | Outdoor applications and harsh environments | Enhanced durability and weather resistance | Higher production costs and complexity | High |

| Thermoplastic Elastomers (TPEs) | Chemical compatibility and flexible applications | Good flexibility and recyclability | Lower temperature resistance | Medium |

| Polyvinyl Chloride (PVC) | Cost-sensitive and temporary applications | Cost-effective and moisture-resistant | Limited flexibility and durability | Low |

This strategic material selection guide provides essential insights for B2B buyers in diverse regions, helping them choose the right inflatable tire materials based on their specific needs and compliance requirements.

The manufacturing of inflatable tires involves a series of meticulously organized stages, each critical to ensuring the final product meets the high standards required by the market. The primary stages include material preparation, forming, assembly, and finishing.

The first step in producing inflatable tires is the selection and preparation of materials. High-quality rubber compounds, often blended with various additives for durability and flexibility, are essential. These materials undergo rigorous testing to ensure they can withstand different environmental conditions, such as extreme temperatures and varying terrains. Manufacturers often source materials that comply with international standards, ensuring they meet the necessary performance and safety requirements.

Illustrative image related to inflatable tires

Once the materials are prepared, the next stage is forming. This involves molding the rubber into the desired shape for the tire. Techniques such as extrusion and molding are commonly used. In extrusion, rubber is forced through a die to create the tire’s profile, while molding involves placing the rubber in a pre-shaped cavity and applying heat and pressure. This process is crucial for achieving the tire’s structural integrity and performance characteristics.

After forming, the individual components of the inflatable tire, such as the inner tube and outer casing, are assembled. This stage may involve bonding layers of rubber and reinforcing materials to enhance strength and durability. Advanced techniques, such as vulcanization, are employed to chemically bond the rubber, ensuring a robust and flexible end product. The assembly process must be precise, as any misalignment can lead to performance issues or safety hazards.

The final stage of manufacturing is finishing. This includes quality checks and surface treatments to enhance the tire’s appearance and functionality. Tires may be coated with protective layers to resist wear and tear, and additional features, such as tread patterns, are added. This stage also includes final inspections to ensure that the tires meet design specifications and performance standards.

Quality assurance (QA) is a critical aspect of the manufacturing process for inflatable tires. Effective QA measures ensure that the products not only meet industry standards but also exceed customer expectations.

To maintain high-quality production, manufacturers typically adhere to international standards such as ISO 9001, which outlines the requirements for a quality management system. Additionally, industry-specific certifications like CE (Conformité Européenne) and API (American Petroleum Institute) may be relevant, depending on the application of the inflatable tires. These certifications assure buyers that the products comply with safety and performance regulations.

Illustrative image related to inflatable tires

Quality control (QC) is integrated at several key checkpoints throughout the manufacturing process:

Incoming Quality Control (IQC): This initial checkpoint involves inspecting raw materials before they enter the production line. Materials are evaluated for compliance with specifications and performance standards.

In-Process Quality Control (IPQC): During production, continuous monitoring is essential. This includes checking the consistency of material blending, mold temperatures, and dimensional accuracy of the formed components.

Final Quality Control (FQC): Once the tires are assembled, a thorough final inspection is conducted. This includes testing for air retention, structural integrity, and performance under various conditions.

Several testing methods are employed to validate the quality of inflatable tires:

Air Retention Tests: These tests measure the tire’s ability to hold air over time, ensuring that it maintains the desired pressure for optimal performance.

Durability Testing: Tires are subjected to simulated real-world conditions, including extreme temperatures and rough terrains, to assess their longevity and performance.

Visual Inspections: These are conducted to identify any surface defects or inconsistencies that could affect the tire’s performance.

For international B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, verifying supplier quality assurance practices is crucial.

Buyers can request to conduct audits of the manufacturing facilities to assess compliance with established quality standards. These audits can provide insights into the supplier’s production capabilities, quality control measures, and adherence to international standards.

Suppliers should provide comprehensive quality control reports that detail testing results, compliance with standards, and any corrective actions taken. These reports are essential for buyers to evaluate the reliability of the supplier’s quality assurance processes.

Illustrative image related to inflatable tires

Engaging third-party inspection services can provide an unbiased assessment of the supplier’s manufacturing processes and product quality. These services can conduct on-site evaluations and provide detailed reports, which can help buyers make informed decisions.

International B2B buyers face unique challenges regarding quality assurance and compliance.

Buyers must be aware of the specific quality and safety standards applicable in their respective markets. For instance, compliance with EU regulations may differ from standards in Africa or South America. It’s vital for buyers to ensure that suppliers understand and comply with these regional standards to avoid complications during importation.

Different countries have varying import regulations, which can impact the acceptance of products. Buyers should verify that suppliers are equipped to provide necessary documentation, such as certificates of conformity, to facilitate smooth customs clearance.

Illustrative image related to inflatable tires

Establishing strong relationships with suppliers can enhance communication regarding quality assurance practices. Regular engagement can foster transparency and trust, ensuring that quality standards are consistently met throughout the partnership.

In conclusion, the manufacturing processes and quality assurance practices for inflatable tires are complex yet critical to delivering reliable products to the market. B2B buyers must engage actively with suppliers to ensure compliance with quality standards and regulations, ultimately leading to successful business outcomes.

To assist B2B buyers in sourcing inflatable tires effectively, this guide provides a structured checklist aimed at ensuring a smooth procurement process. From defining specifications to evaluating suppliers, each step is designed to help you make informed decisions that align with your business needs.

Before engaging with suppliers, it’s essential to establish clear technical specifications for the inflatable tires you require. Consider the application—are they for RC vehicles, advertising, or industrial use?

– Size and Weight: Determine the necessary diameter, width, and weight capacity based on your intended use.

– Material Requirements: Identify if you need specific materials for durability or environmental resistance, especially if they will be used outdoors.

Illustrative image related to inflatable tires

Conduct thorough research to identify reputable suppliers who specialize in inflatable tires. A well-established supplier can significantly impact your sourcing success.

– Online Directories and Trade Shows: Utilize B2B platforms and attend industry events to gather a list of potential suppliers.

– Supplier Reviews: Look for feedback from other buyers, particularly in your region, to gauge reliability and product quality.

Assess the capabilities of potential suppliers to ensure they can meet your needs. This evaluation process is crucial for minimizing risks associated with quality and delivery.

– Production Capacity: Confirm that the supplier can handle your order volume and meet your deadlines.

– Customization Options: Ensure they can provide customizable features, such as specific designs or branding, if necessary.

Before making a bulk purchase, request samples of the inflatable tires to evaluate their quality and performance. This step can save you from costly mistakes later on.

– Performance Testing: Check for factors such as durability, air retention, and usability on various surfaces.

– Compliance with Standards: Ensure that the samples meet relevant industry standards and safety regulations.

Once you’ve narrowed down your options, initiate negotiations regarding pricing and terms. This step is crucial for establishing a favorable relationship with your supplier.

– Volume Discounts: Inquire about discounts for larger orders or long-term contracts.

– Payment Terms: Discuss payment options and ensure they align with your cash flow management practices.

Ensure that your chosen supplier has the necessary certifications to guarantee the quality and safety of their products. Compliance with international standards is particularly vital for B2B transactions.

– ISO Certifications: Check for ISO or other relevant certifications that indicate adherence to quality management standards.

– Safety Regulations: Verify compliance with local and international safety regulations, especially if the tires will be used in specific industries.

Effective communication with your supplier is key to a successful partnership. Establish a clear communication plan to facilitate ongoing dialogue.

– Regular Updates: Set expectations for updates on production status, shipping timelines, and any potential issues.

– Point of Contact: Designate specific contacts on both sides to streamline communication and resolve any issues promptly.

Following this checklist will empower B2B buyers to navigate the sourcing of inflatable tires efficiently, ensuring they select the right products and suppliers for their specific needs.

When sourcing inflatable tires, understanding the cost structure is essential for effective budgeting and pricing strategies. The primary cost components include:

Materials: The type of materials used significantly impacts the overall cost. High-quality rubber compounds and fabrics that offer durability and performance often lead to higher prices. Suppliers may offer various grades of materials, affecting the tire’s longevity and performance characteristics.

Labor: Labor costs vary depending on the manufacturing location. Regions with lower wage standards may offer reduced labor costs, which can lower the overall price of the product. However, it is crucial to balance labor costs with the quality of craftsmanship.

Manufacturing Overhead: This includes the costs associated with the production facilities, equipment maintenance, and utilities. Efficient manufacturing processes can help reduce overhead costs, which can be passed on to buyers.

Tooling: Custom molds and tooling required for specific tire designs or sizes contribute to initial costs. The more complex the design, the higher the tooling costs, which may be amortized over larger order quantities.

Quality Control (QC): Implementing rigorous QC processes ensures that the inflatable tires meet safety and performance standards. While this adds to the cost, it minimizes the risk of defects and returns, ultimately saving money in the long run.

Logistics: Shipping costs can vary significantly based on distance, shipping methods, and customs duties. For international buyers, understanding these logistics costs is crucial to avoid unexpected expenses.

Margin: Suppliers typically add a profit margin on top of the production costs. This margin can vary based on market competition, supplier reputation, and the uniqueness of the product.

Several factors influence pricing beyond the basic cost components:

Volume/MOQ (Minimum Order Quantity): Suppliers often offer better pricing for larger orders. Understanding the ideal order quantity for your needs can lead to significant savings.

Specifications and Customization: Customized tires with specific features or branding will generally cost more than standard options. Buyers must evaluate whether these additional features justify the higher price.

Material Quality and Certifications: Tires that meet international safety standards or have specific certifications (like ISO) may come at a premium. These certifications can enhance the product’s credibility in the market.

Supplier Factors: The supplier’s reputation, reliability, and customer service can influence pricing. Established suppliers may charge higher prices due to their proven track record and quality assurance.

Incoterms: Understanding Incoterms is crucial for international buyers. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can affect the total landed cost of the products, impacting the overall budget.

For buyers in regions such as Africa, South America, the Middle East, and Europe, effective negotiation is key to securing favorable terms:

Research and Benchmarking: Understanding market rates and competitor pricing helps in negotiating better deals. Consider sourcing quotes from multiple suppliers to establish a baseline.

Focus on Total Cost of Ownership (TCO): Evaluate not just the purchase price but the total cost of ownership, including maintenance, logistics, and potential downtime. This approach can provide leverage in negotiations.

Flexibility on Payment Terms: Offering to pay upfront or accepting longer lead times in exchange for better pricing can be a win-win for both parties.

Long-term Partnerships: Establishing long-term relationships with suppliers can lead to loyalty discounts and better service. Communicate your future needs and growth potential to the supplier.

Cultural Sensitivity: Understanding the cultural context of suppliers can facilitate smoother negotiations. Respect for local customs and practices can foster goodwill and collaboration.

Sourcing inflatable tires requires a comprehensive understanding of the cost components, price influencers, and effective negotiation strategies. By focusing on these areas, international buyers can achieve better pricing and product quality, ultimately enhancing their competitive advantage in the market. Always remember to consider the total cost of ownership and the specific needs of your business when making purchasing decisions.

When evaluating tire solutions for various applications, it’s essential to consider a range of alternatives to inflatable tires. Each option has unique characteristics that can impact performance, cost-effectiveness, and overall suitability for specific use cases. Below, we compare inflatable tires against solid tires and foam-filled tires, two viable alternatives that are commonly used in different industries.

| Comparison Aspect | Inflatable Tires | Solid Tires | Foam-Filled Tires |

|---|---|---|---|

| Performance | Excellent shock absorption; adaptable pressure for varying terrains | Consistent performance; no risk of punctures | Good shock absorption; puncture-resistant |

| Cost | Moderate initial cost; may require ongoing inflation maintenance | Higher upfront cost; long-term durability reduces replacement frequency | Higher initial investment; cost-effective over time due to reduced maintenance |

| Ease of Implementation | Requires inflation equipment; straightforward setup | Easy installation; no special tools needed | More complex installation process; may require specialized tools |

| Maintenance | Regular checks for air pressure; potential for leaks | Minimal maintenance; no air pressure to monitor | Low maintenance; durable and resistant to wear |

| Best Use Case | Ideal for uneven terrains like construction sites or off-road applications | Best for urban environments and paved surfaces | Suitable for heavy-duty applications like forklifts and industrial machinery |

Solid tires are made from durable rubber and offer consistent performance without the risk of punctures. They are ideal for urban environments where the terrain is mostly smooth and predictable. The primary advantage of solid tires is their durability; they can last significantly longer than inflatable tires, which may require replacement due to wear or air loss. However, they lack the shock absorption capabilities of inflatable tires, which can lead to a rougher ride on uneven surfaces.

Illustrative image related to inflatable tires

Foam-filled tires provide a unique solution by combining the benefits of both solid and inflatable tires. They are filled with a solid foam material, making them puncture-resistant while still offering some level of shock absorption. This makes them an excellent choice for heavy-duty applications, such as forklifts and construction vehicles, where durability is paramount. However, the installation process can be more complex, and they typically come with a higher upfront cost than traditional inflatable tires.

When selecting the appropriate tire solution for their needs, B2B buyers should consider the specific application and environment in which the tires will be used. For industries requiring flexibility and adaptability to various terrains, inflatable tires are often the best choice. Solid tires may be more suitable for urban settings where durability and low maintenance are prioritized. Foam-filled tires can be ideal for heavy-duty applications requiring puncture resistance and durability, albeit at a higher initial cost. By carefully weighing the pros and cons of each option, buyers can make informed decisions that align with their operational requirements and budget constraints.

When evaluating inflatable tires for B2B applications, several critical specifications should be considered to ensure optimal performance, durability, and compatibility with various vehicles or equipment. Below are some essential properties that buyers need to understand:

Material Grade

Inflatable tires are typically made from high-quality synthetic rubber or thermoplastic elastomers (TPE). The material grade affects the tire’s durability, flexibility, and resistance to environmental factors like UV light and ozone. For B2B buyers, selecting tires with superior material grades can lead to longer service life and reduced maintenance costs.

Pressure Tolerance

This specification indicates the maximum and minimum air pressure that a tire can safely maintain. Proper pressure tolerance is crucial for performance and safety, as over-inflation or under-inflation can lead to tire failure. Businesses must consider the intended application and operating conditions when selecting tires with the appropriate pressure tolerance to ensure safety and efficiency.

Load Capacity

Load capacity defines how much weight a tire can support without compromising performance or safety. This is particularly important for commercial applications, where tires may be subjected to heavy loads. Understanding load capacity helps businesses select the right tire for their vehicles or machinery, preventing premature wear and potential accidents.

Dimensional Specifications

These include tire diameter, width, and axle compatibility (e.g., axle diameter). Correct dimensions ensure that the tires fit properly on the intended vehicles or equipment. Buyers must verify dimensional specifications to avoid compatibility issues that could lead to operational downtime.

Tread Design

The tread design affects traction, stability, and handling characteristics. Different tread patterns are optimized for various surfaces (e.g., off-road, on-road). B2B buyers should match tread designs to the specific operating environments of their vehicles to enhance performance and safety.

Understanding industry jargon is essential for effective communication and negotiation in the B2B marketplace. Here are several key terms frequently encountered when dealing with inflatable tires:

OEM (Original Equipment Manufacturer)

OEM refers to companies that manufacture products to be sold under another company’s brand. In the tire industry, this term is crucial as it often signifies quality and compatibility, particularly when sourcing tires for specific vehicles or machinery.

MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of products a supplier is willing to sell. Understanding MOQ is vital for buyers to manage inventory levels and cash flow. This term is particularly relevant for international buyers who may need to navigate shipping costs and logistics.

RFQ (Request for Quotation)

An RFQ is a formal process where buyers request pricing and terms from suppliers. This term is essential for B2B negotiations, as it allows buyers to compare offers and make informed purchasing decisions based on price, specifications, and delivery timelines.

Incoterms (International Commercial Terms)

Incoterms are standardized trade terms that define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with Incoterms helps businesses avoid misunderstandings in international transactions and ensures clarity in logistics and financial obligations.

Lead Time

Lead time refers to the time it takes from placing an order until the goods are received. For B2B buyers, understanding lead times is crucial for inventory management and project planning, especially in industries where timely delivery is critical for operational success.

Durability Rating

This rating reflects how well a tire can withstand wear and tear over time. For businesses, selecting tires with a high durability rating can reduce replacement frequency and associated costs, making it an important consideration for long-term operational efficiency.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions when sourcing inflatable tires, ensuring compatibility, performance, and value for their specific applications.

The inflatable tires market is experiencing significant growth driven by various global factors. The increasing demand for lightweight and versatile tire solutions across multiple industries, including automotive, aerospace, and recreational sectors, is a primary market driver. International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, are increasingly looking for innovative products that offer better performance and cost-efficiency. Moreover, advancements in material technology, such as the development of durable synthetic compounds, are enhancing the performance characteristics of inflatable tires, making them more appealing to businesses.

Illustrative image related to inflatable tires

Emerging trends in B2B tech include the integration of IoT and smart technologies into tire management systems. These innovations facilitate real-time monitoring of tire pressure and performance, thus optimizing maintenance schedules and reducing operational costs. Additionally, the rise of e-commerce platforms is reshaping how businesses source inflatable tires, enabling buyers to access a wider range of suppliers and products with ease. The global supply chain dynamics are also shifting, with an emphasis on localized sourcing to mitigate risks associated with international shipping and geopolitical tensions.

Sustainability is becoming a crucial consideration for B2B buyers in the inflatable tires sector. The environmental impact of tire production and disposal is prompting companies to seek eco-friendly alternatives. Sustainable practices, such as using recycled materials and reducing carbon footprints during manufacturing, are gaining traction. Buyers are increasingly favoring suppliers who demonstrate a commitment to sustainability through certifications like ISO 14001 or the Global Recycled Standard (GRS).

Ethical sourcing is equally important, as businesses aim to ensure that their supply chains adhere to fair labor practices and environmental standards. Implementing an ethical sourcing strategy not only enhances brand reputation but also aligns with the growing consumer demand for corporate social responsibility. By prioritizing suppliers who engage in sustainable practices and transparent operations, international buyers can contribute to a more sustainable future while securing high-quality products.

The evolution of inflatable tires can be traced back to the late 19th century when John Boyd Dunlop patented the first practical pneumatic tire in 1887. Initially designed for bicycles, inflatable tires quickly made their way into the automotive industry, revolutionizing transportation by providing better shock absorption and improved ride quality. Over the decades, advancements in materials and manufacturing processes have led to the development of specialized inflatable tires for various applications, including off-road vehicles, aircraft, and recreational vehicles.

Today, the inflatable tires market is characterized by a diverse range of products tailored to meet specific industry needs. The historical context underscores the ongoing innovation within the sector, as manufacturers continually seek to enhance performance, safety, and sustainability, making it essential for B2B buyers to stay informed about the latest advancements and trends.

How do I choose the right inflatable tires for my application?

Selecting the right inflatable tires depends on several factors, including the terrain they will be used on, the load capacity required, and the desired level of shock absorption. Consider the tire’s size, design, and material, as these attributes affect performance. For rough terrains, opt for larger, softer tires that provide better shock absorption. Additionally, assess the compatibility with your equipment, ensuring the tire fits the axle size and weight specifications. Collaborating with experienced suppliers can also help in making informed choices based on your specific needs.

What are the advantages of using inflatable tires over solid tires?

Inflatable tires offer significant benefits compared to solid tires, primarily in terms of shock absorption and traction. Their air-filled design allows them to conform to uneven surfaces, providing a smoother ride and reducing the risk of damage to the vehicle or equipment. This is particularly valuable in industries such as agriculture and construction, where uneven terrains are common. Additionally, inflatable tires can be adjusted for pressure, allowing for customization based on the load and surface type, enhancing performance and safety.

What customization options are available for inflatable tires?

Customization options for inflatable tires can include size, tread pattern, color, and branding elements. Many suppliers offer tailored solutions to meet specific operational requirements, allowing businesses to align the tires with their branding or functional needs. It’s important to discuss your customization needs with potential suppliers to understand the feasibility and costs involved. Some manufacturers may also provide prototypes or samples to ensure that the customized tires meet your expectations before bulk orders are placed.

What is the minimum order quantity (MOQ) for inflatable tires?

The minimum order quantity (MOQ) for inflatable tires can vary significantly based on the manufacturer and the specific product. Typically, MOQs may range from a few dozen to several hundred units, depending on the complexity of the order and the customization required. It’s advisable to communicate your needs with suppliers to negotiate favorable terms, especially if you are looking to test a new product line or are a small business. Some manufacturers might offer lower MOQs for initial orders to build a long-term relationship.

How can I verify the reliability of a supplier for inflatable tires?

To verify a supplier’s reliability, conduct thorough research and due diligence. Look for reviews, testimonials, and case studies from other B2B clients. Request certifications and quality assurance documentation to ensure compliance with international standards. Engaging in direct communication to discuss your needs can also provide insights into their responsiveness and professionalism. Additionally, consider visiting their facility or requesting product samples to assess quality firsthand before finalizing any agreements.

What payment terms are commonly offered by suppliers of inflatable tires?

Payment terms can vary widely among suppliers, but common options include upfront payments, partial payments (e.g., 30% deposit with the balance due upon delivery), and net payment terms (e.g., net 30 or net 60 days). It’s essential to negotiate terms that align with your cash flow and financial policies. Ensure that the terms are clearly documented in the contract to prevent misunderstandings. Also, consider using escrow services for larger transactions to secure both parties during the payment process.

What quality assurance processes should I expect from inflatable tire manufacturers?

Reputable inflatable tire manufacturers should have stringent quality assurance (QA) processes in place. Expect to see testing for durability, performance, and safety standards, which may include pressure testing, load testing, and environmental resistance tests. Ask for details on their QA protocols and any certifications they hold, such as ISO standards. Regular audits and inspections during production can also help ensure that the tires meet the specified requirements, providing peace of mind regarding the product’s reliability.

What logistics considerations should I keep in mind when importing inflatable tires?

When importing inflatable tires, consider logistics factors such as shipping methods, lead times, and customs regulations. Evaluate whether air freight or sea freight is more cost-effective based on your timeline and budget. Understand the import duties and taxes applicable in your country to avoid unexpected costs. Collaborating with a logistics partner experienced in international trade can help streamline the process, ensuring timely delivery and compliance with all legal requirements. Proper planning will mitigate risks associated with delays or damaged goods during transit.

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Inflatable tires are rare in RC crawling due to performance issues. They can make the vehicle bouncy, which is undesirable. Previous options for air-filled tires were not well-received because they did not perform well. Alternatives like Anti-Foams simulate aired down tires while providing sidewall support, are waterproof, simplify tire mounting, and have a long lifespan. Inflated tires require hi…

Domain: dubro.com

Registered: 1996 (29 years)

Introduction: DU-BRO Big Wheels | Inflatable Tundra RC Wheels

Domain: orientaltrading.com

Registered: 1998 (27 years)

Introduction: {“Product Name”: “15” Cars & Trucks Party Inflatable Vinyl Tires – 12 Pc.”, “Item Number”: “#13933694”, “Size”: “15 inches (inflated)”, “Quantity”: “12”, “Material”: “Vinyl”, “Features”: [“Two-in-one party favor: toy and decoration”, “Perfect for car-loving kids and racing parties”, “Durable and easy to inflate”, “Big impact with easy cleanup”], “Warnings”: [“Choking Hazard: Small parts. Not for c…

In summary, the strategic sourcing of inflatable tires presents a significant opportunity for international B2B buyers, particularly in emerging markets such as Africa, South America, the Middle East, and Europe. The versatility of inflatable tires—ranging from robust applications in the automotive sector to innovative uses in marketing and events—underscores their growing importance. Buyers should prioritize partnerships with reliable suppliers who offer customizable solutions, ensuring that product specifications align with local market demands and environmental conditions.

As the global market continues to evolve, leveraging strategic sourcing practices will enhance operational efficiency and cost-effectiveness. Buyers are encouraged to explore diverse sourcing strategies that consider quality, pricing, and supplier reliability to maintain a competitive edge.

Illustrative image related to inflatable tires

Looking ahead, the demand for high-quality inflatable tires is poised to rise, driven by increased mobility and infrastructure development across various regions. By proactively engaging with suppliers and investing in innovative solutions, B2B buyers can position themselves to capitalize on this trend. Take the next step in your sourcing journey—connect with trusted manufacturers and elevate your business’s potential in the dynamic inflatable tire market.

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Illustrative image related to inflatable tires