Navigating the complexities of sourcing the right air pump for your business needs can be daunting, especially for international B2B buyers in diverse regions such as Africa, South America, the Middle East, and Europe. As businesses expand globally, understanding the various types of air pumps available—ranging from compact models for travel to heavy-duty pumps for industrial applications—becomes crucial. This guide aims to equip you with the knowledge necessary to make informed purchasing decisions, addressing key challenges such as identifying reliable suppliers, understanding cost implications, and evaluating product specifications.

Throughout this comprehensive resource, we will explore different air pump categories, their specific applications across industries, and essential criteria for supplier vetting to ensure quality and reliability. From portable electric pumps ideal for outdoor activities to powerful inflators suited for commercial use, we delve into each option’s unique features and benefits. Additionally, we provide insights into pricing structures, shipping logistics, and best practices for negotiating terms with manufacturers.

By the end of this guide, international B2B buyers will have a clearer understanding of the air pump market, empowering them to select the right products that meet their operational needs while ensuring cost-effectiveness and quality. Whether you are based in Nigeria, Saudi Arabia, or anywhere in between, our actionable insights will help you navigate the global air pump market with confidence.

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Portable Electric Air Pump | USB rechargeable, compact design, multi-functional | E-commerce, outdoor equipment, automotive | Pros: Portable, quick inflation; Cons: Battery life may vary. |

| Manual Air Pump | Hand-operated, lightweight, often less expensive | Camping, sports equipment, emergency kits | Pros: No power source needed; Cons: Labor-intensive, slower. |

| High-Volume Electric Air Pump | High PSI output, fast inflation, often bulky | Industrial applications, large inflatables | Pros: Efficient for heavy-duty tasks; Cons: Less portable. |

| Dual-Function Air Pump | Capable of both inflating and deflating | Travel gear, air mattresses, inflatable toys | Pros: Versatile; Cons: May lack power compared to specialized pumps. |

| Solar-Powered Air Pump | Eco-friendly, operates on solar energy | Remote locations, eco-conscious businesses | Pros: Sustainable; Cons: Dependent on sunlight availability. |

Portable electric air pumps are designed for convenience and efficiency. They are typically USB rechargeable, allowing for multiple uses on a single charge, making them ideal for businesses involved in e-commerce or outdoor equipment sales. Their compact size enhances portability, enabling easy storage and transport. B2B buyers should consider battery life, charging speed, and compatibility with various inflatable products when selecting these pumps for their operations.

Manual air pumps are a cost-effective solution for businesses that require basic inflation capabilities without the need for electricity. These pumps are lightweight and easy to use, making them suitable for camping gear, sports equipment, or emergency kits. However, their labor-intensive nature and slower inflation speed can be a drawback for businesses with high-volume needs. Buyers should evaluate the trade-offs between cost and efficiency based on their specific applications.

Illustrative image related to air pum

High-volume electric air pumps are built for heavy-duty applications requiring significant air pressure output, such as inflating large inflatables or industrial equipment. While they offer rapid inflation and high PSI capabilities, their bulkiness can limit portability. Businesses in sectors like construction or event management should consider these pumps for their efficiency, but must also factor in storage and transport logistics.

Dual-function air pumps, capable of both inflating and deflating, provide versatility for businesses dealing with various inflatable products. They are especially beneficial for travel gear and air mattress retailers. While they offer multi-use functionality, buyers should note that they may not perform as efficiently as dedicated pumps for specific tasks. Assessing the range of inflatables that need to be serviced can guide purchasing decisions.

Solar-powered air pumps present a sustainable option for businesses operating in remote areas or focusing on eco-friendliness. These pumps utilize solar energy, reducing dependency on traditional power sources. However, their effectiveness is contingent on sunlight availability, which can limit their utility in certain regions. B2B buyers should assess the environmental impact and energy needs of their operations when considering this type of pump.

Illustrative image related to air pum

| Industry/Sector | Specific Application of air pum | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Tire inflation and maintenance for vehicles | Ensures optimal tire pressure, improving fuel efficiency and safety | Compatibility with various tire types; portability; power source options |

| Outdoor Recreation | Inflating camping gear (sleeping pads, air mattresses) | Enhances user experience by providing quick and easy inflation | Lightweight design; rechargeable battery; durability for outdoor use |

| Manufacturing | Air-powered tools and machinery | Increases operational efficiency and reduces manual labor | Air pressure compatibility; maintenance support; energy efficiency |

| Shipping and Logistics | Packaging and compression for cargo | Maximizes shipping space, reducing transportation costs | Size and power specifications; ease of use; reliability in diverse environments |

| Hospitality and Events | Inflating event decorations and furniture | Provides quick setup and breakdown for events, saving time | Portability; multiple nozzle attachments for versatility; durability for frequent use |

In the automotive sector, air pumps are essential for tire inflation and maintenance. Proper tire pressure is crucial for vehicle safety and fuel efficiency, impacting operational costs for fleet operators and individual car owners alike. Air pumps designed for automotive use often feature compatibility with various tire sizes and types, ensuring that businesses can maintain their vehicles effectively. For international buyers, particularly in regions like Africa and the Middle East, sourcing durable and portable air pumps that can withstand diverse environmental conditions is critical.

In outdoor recreation, air pumps are widely used to inflate camping gear such as sleeping pads, air mattresses, and inflatable boats. These devices enhance the user experience by providing a quick and efficient way to inflate equipment, allowing users to focus on enjoying their activities rather than struggling with manual inflation. Buyers from South America and Europe should consider the weight and portability of air pumps, as well as battery life, to ensure they are suitable for travel and outdoor use, especially in remote areas.

Within manufacturing, air pumps are utilized to power various tools and machinery, contributing to increased efficiency and reduced manual labor. These pumps facilitate the operation of air-powered tools, which are commonly used in assembly lines and fabrication processes. Businesses looking to source air pumps for manufacturing must consider factors such as air pressure compatibility and energy efficiency, as these elements directly impact productivity and operational costs. For international buyers, understanding the local availability of maintenance support is also vital.

In the shipping and logistics industry, air pumps are essential for packaging and compressing cargo, maximizing shipping space and reducing transportation costs. By utilizing air pumps to remove excess air from packaging, businesses can optimize the volume of goods transported, leading to significant cost savings. Buyers in this sector should prioritize the size and power specifications of air pumps to ensure they meet the demands of various cargo types. Additionally, reliability in different environmental conditions is crucial for international operations.

In the hospitality and events sector, air pumps are invaluable for inflating decorations and furniture, facilitating quick setup and breakdown processes. This efficiency saves time and enhances the overall event experience for both organizers and attendees. When sourcing air pumps for this application, businesses should look for portability, multiple nozzle attachments for versatility, and durability to withstand frequent use. Understanding the specific requirements of various event setups can help buyers make informed purchasing decisions, especially in diverse markets across Europe and Africa.

The Problem:

B2B buyers often face challenges when sourcing air pumps that can efficiently serve multiple purposes. For instance, companies in the logistics and travel sectors require pumps that not only inflate items like air mattresses and inflatable products but also deflate them for compact storage. Buyers may find themselves with a limited range of products that can either inflate or deflate but not both, leading to inefficiencies and increased operational costs.

The Solution:

To address this pain point, it is crucial for buyers to look for air pumps designed with dual functionality—both inflation and deflation capabilities. When sourcing air pumps, prioritize models that feature powerful suction mechanisms for quick deflation while also providing robust inflation options. For example, models like the Airback® Compact Air Pump, which can handle both tasks efficiently, are ideal. Additionally, consider the pump’s portability and battery life; a USB-C rechargeable option can offer up to 20 uses per charge, making it an excellent choice for businesses involved in travel or outdoor events. When specifying products, ensure they are compatible with various inflatable types to maximize versatility.

The Problem:

In industries where time is critical, such as event planning and emergency services, the reliability of air pumps can significantly impact operations. Buyers may encounter pumps that fail to perform under pressure, either losing charge quickly or not providing sufficient airflow, leading to delays and potential losses. This inconsistency can be especially troublesome in high-stakes environments where equipment must be ready at a moment’s notice.

Illustrative image related to air pum

The Solution:

To mitigate reliability issues, buyers should conduct thorough research on the durability and performance metrics of air pumps before purchasing. Look for products with high user ratings and reviews that specifically mention performance under load. Selecting air pumps made from durable materials can also enhance longevity. Additionally, consider models with built-in battery indicators and fast charging capabilities, ensuring that the pump can be ready for use whenever required. A well-structured maintenance plan, including regular testing of equipment before critical usage, can further enhance reliability.

The Problem:

Many B2B buyers lack the technical knowledge to understand the specifications that impact the performance of air pumps, leading to poor purchasing decisions. For example, choosing a pump that does not meet the PSI requirements for specific applications, such as inflating high-pressure air mattresses or vehicle tires, can result in damage or inadequate performance. This lack of understanding can create operational inefficiencies and unnecessary costs.

The Solution:

To overcome this knowledge gap, buyers should invest time in understanding the key specifications of air pumps, including maximum pressure (PSI), volume capacity (L/min), and compatibility with different types of valves. Engaging with suppliers who provide detailed product descriptions and technical support can also enhance decision-making. Furthermore, consider conducting a needs assessment to determine the specific applications and pressures required for your operations. Many reputable suppliers offer guidance on selecting the right air pump based on your unique needs, ensuring that you make informed choices that align with your operational requirements.

When selecting materials for air pumps, it is essential to consider their properties, advantages, and limitations. This analysis focuses on four common materials: plastic, aluminum, stainless steel, and rubber. Each material has unique characteristics that can significantly impact the performance and suitability of air pumps in various applications.

Plastic, particularly high-density polyethylene (HDPE) and polypropylene (PP), is widely used in air pump manufacturing due to its lightweight nature and resistance to corrosion. These materials can withstand moderate temperature and pressure ratings, making them suitable for various applications, including inflatables and small air compressors.

Pros:

– Lightweight and easy to mold, which simplifies manufacturing processes.

– Cost-effective, making it an attractive option for budget-conscious buyers.

– Resistant to moisture and many chemicals, enhancing durability.

Cons:

– Limited temperature and pressure resistance compared to metals, which may restrict its use in high-performance applications.

– Can be less durable over time, especially under UV exposure or extreme temperatures.

Impact on Application:

Plastic is ideal for applications involving low-pressure inflatables but may not be suitable for high-pressure systems. International buyers should ensure compliance with local regulations regarding material safety and environmental impact.

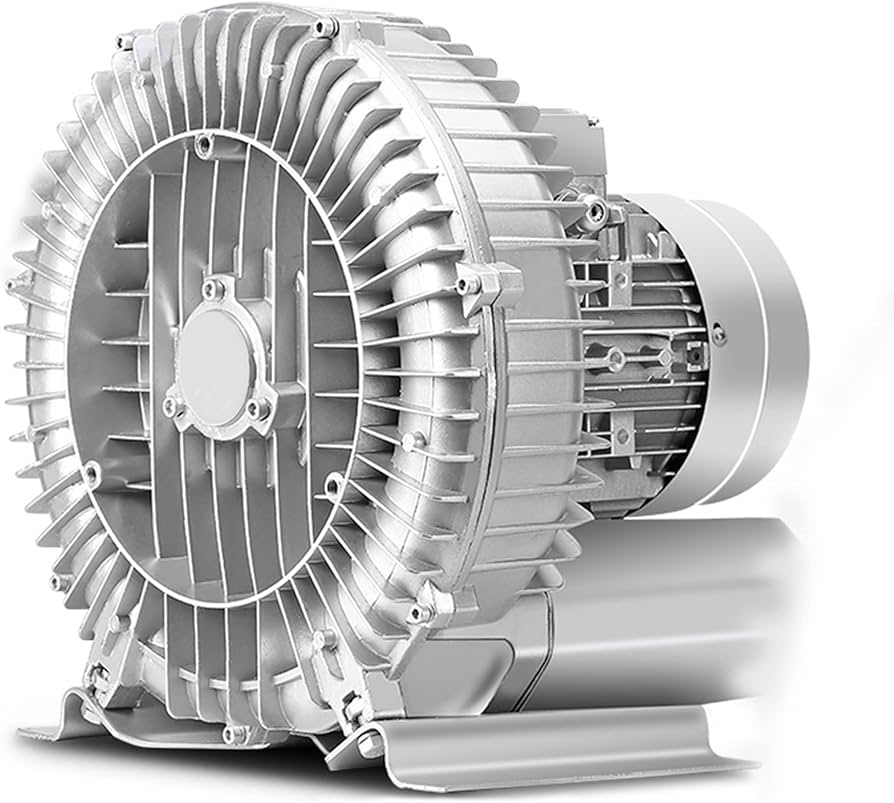

Aluminum is a popular choice for air pump components due to its excellent strength-to-weight ratio and corrosion resistance. It is commonly used in portable air pumps and those designed for high-pressure applications.

Pros:

– Lightweight yet strong, making it suitable for portable designs.

– Excellent corrosion resistance, especially when anodized, which extends the product’s lifespan.

– Good thermal conductivity, which helps dissipate heat in high-performance applications.

Cons:

– Higher cost compared to plastics, which may deter some buyers.

– Requires more complex manufacturing processes, such as machining and welding.

Impact on Application:

Aluminum is well-suited for high-pressure applications and is compatible with various media. Buyers in regions like Europe may prefer aluminum for its recyclability and compliance with environmental standards.

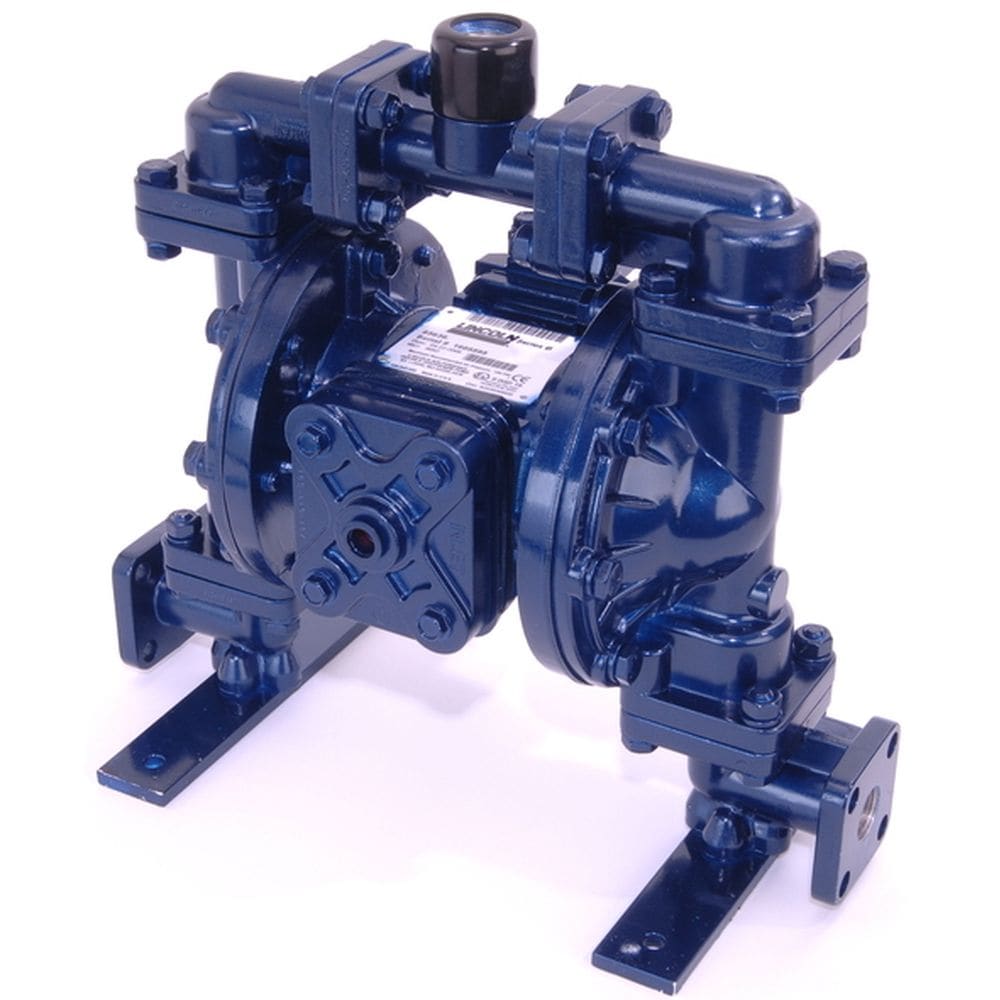

Stainless steel is renowned for its exceptional durability and resistance to corrosion, making it an excellent choice for air pumps used in harsh environments. It is commonly found in industrial applications where reliability is paramount.

Illustrative image related to air pum

Pros:

– High strength and durability, ensuring long-term performance.

– Excellent resistance to corrosion and oxidation, making it suitable for various media.

– Can withstand high temperatures and pressures, expanding its application range.

Cons:

– Typically more expensive than plastic and aluminum, which can affect pricing strategies.

– Heavier than other materials, which may impact portability.

Impact on Application:

Stainless steel is ideal for applications requiring high durability and resistance to aggressive media. International buyers should be aware of compliance with standards such as ASTM and DIN, which govern material specifications.

Rubber is often used in seals and gaskets within air pumps due to its excellent elasticity and ability to create airtight seals. Common types include nitrile rubber and silicone, each offering different properties.

Pros:

– Excellent flexibility and resilience, ensuring effective sealing.

– Good resistance to wear and tear, enhancing longevity.

– Can operate effectively across a range of temperatures.

Illustrative image related to air pum

Cons:

– Limited resistance to certain chemicals, which can degrade rubber over time.

– May require periodic replacement, increasing maintenance costs.

Impact on Application:

Rubber is crucial for ensuring airtight seals in air pumps, particularly in inflatable products. Buyers should consider local availability and compliance with safety standards to ensure product reliability.

| Material | Typical Use Case for air pum | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Plastic | Low-pressure inflatables | Lightweight and cost-effective | Limited temperature/pressure resistance | Low |

| Aluminum | Portable air pumps | Excellent strength-to-weight ratio | Higher cost and complex manufacturing | Medium |

| Stainless Steel | Industrial air pumps | High durability and corrosion resistance | Heavier and more expensive | High |

| Rubber | Seals and gaskets | Excellent sealing properties | Limited chemical resistance | Medium |

This strategic material selection guide provides B2B buyers with essential insights into the properties, advantages, and limitations of materials used in air pump manufacturing. Understanding these factors can help ensure the right choice for specific applications and compliance with international standards.

The manufacturing process of air pumps typically involves several key stages: material preparation, forming, assembly, and finishing. Each stage plays a crucial role in ensuring the final product meets quality standards and customer expectations.

The manufacturing journey begins with material selection. Air pumps are often made from durable, lightweight materials such as high-density polyethylene (HDPE), polypropylene, or aluminum for casing, while rubber or silicone may be used for seals and valves. Suppliers must ensure that these materials meet specific industry standards for safety and performance. This stage includes sourcing raw materials, conducting preliminary quality checks, and preparing them for the next phase.

In the forming stage, manufacturers utilize various techniques such as injection molding, blow molding, or die-casting to shape the materials into the required components. For example, injection molding is commonly used for producing the pump’s casing, while blow molding is often utilized for creating air chambers. Precision is critical in this phase, as any defects can compromise the pump’s functionality.

Once components are formed, they move to the assembly stage. This involves integrating different parts, such as motors, valves, and hoses, into a cohesive unit. Automated assembly lines are increasingly common, enhancing efficiency and reducing human error. However, manual assembly may still be employed for more complex air pumps, particularly those requiring specialized expertise.

The finishing stage includes processes like painting, coating, and quality polishing, which not only enhance the aesthetic appeal but also protect the product from environmental factors. This stage may also involve the installation of labels and user manuals. A thorough inspection is conducted to ensure that each air pump meets the required specifications before it is packaged and shipped.

Quality assurance (QA) is vital in the air pump manufacturing process. Several international standards govern the quality of air pumps, with ISO 9001 being one of the most recognized. This standard focuses on ensuring consistent quality in products and services, which is crucial for B2B buyers looking for reliable suppliers.

In addition to ISO 9001, air pump manufacturers may seek industry-specific certifications such as CE (Conformité Européenne) for compliance with European health, safety, and environmental protection standards, or API (American Petroleum Institute) standards for pumps used in the oil and gas industry. These certifications help buyers assess the compliance and reliability of the products they are considering.

Quality control (QC) is implemented at various checkpoints throughout the manufacturing process:

Incoming Quality Control (IQC): This stage involves inspecting raw materials before they are used in production. Ensuring the materials meet specified standards is critical to maintaining the quality of the final product.

In-Process Quality Control (IPQC): During the manufacturing process, ongoing checks are conducted to monitor the quality of work in progress. This includes measurements of component tolerances and functionality tests of assemblies.

Final Quality Control (FQC): Before products are shipped, a comprehensive inspection is performed. This includes functional testing, pressure tests, and aesthetic checks to ensure each air pump meets established quality standards.

Various testing methods are employed to ensure air pumps function correctly and meet safety standards. Common tests include:

For B2B buyers, verifying a supplier’s quality control practices is essential to mitigating risks. Here are some actionable steps:

Supplier Audits: Conduct on-site audits to assess the manufacturing processes and quality control measures in place. This provides firsthand insight into their operations.

Request Quality Reports: Ask suppliers for detailed quality control reports, including results from IQC, IPQC, and FQC stages. This documentation can reveal the effectiveness of their QC processes.

Third-Party Inspections: Engage third-party inspection services to independently verify the quality and compliance of the products before shipment. This adds an additional layer of assurance.

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, must consider specific nuances when dealing with quality control:

Regulatory Compliance: Different countries have unique regulations concerning product safety and quality. Understanding these regulations is crucial for compliance and market acceptance.

Supply Chain Transparency: Buyers should seek suppliers who offer transparency throughout the supply chain, ensuring that every component is sourced and manufactured in compliance with relevant standards.

Cultural Considerations: Effective communication with suppliers regarding quality expectations may require cultural sensitivity, especially when dealing with suppliers from diverse regions.

In conclusion, understanding the manufacturing processes and quality assurance protocols for air pumps is essential for B2B buyers. By focusing on material preparation, forming techniques, assembly methods, and rigorous quality control measures, buyers can make informed decisions, ensuring they select reliable suppliers that meet their specific needs and standards.

In the competitive landscape of B2B procurement, sourcing the right air pump can significantly impact your operations, whether for inflating products, facilitating logistics, or ensuring customer satisfaction. This guide serves as a comprehensive checklist to help international buyers make informed decisions when procuring air pumps, specifically tailored for diverse markets across Africa, South America, the Middle East, and Europe.

Understanding your technical requirements is crucial before starting the procurement process. Determine the type of air pump needed—manual, electric, or portable—and the specific features that will best serve your application, such as pressure capacity, power source, and portability. Consider your end-use scenarios, such as whether the pump will be used for inflating air mattresses, compression bags, or other inflatables.

Conduct thorough research to identify potential suppliers. Utilize online platforms, industry trade shows, and local business directories to compile a list of manufacturers and distributors. Pay attention to suppliers with a proven track record in your region, as they are more likely to understand local regulations and market demands.

Before committing to a supplier, it’s crucial to vet them thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Look for suppliers that have experience with international shipping, as this can simplify logistics and reduce lead times.

Illustrative image related to air pum

Ensure that potential suppliers hold relevant certifications and comply with international quality standards. This step is essential for verifying product quality and safety, particularly if you are sourcing for markets with stringent regulations.

Request detailed quotes from multiple suppliers to compare pricing and payment terms. Understand the total cost of ownership, including shipping, taxes, and potential tariffs, which can significantly affect your budget. Look for transparency in pricing and inquire about discounts for bulk orders.

Before finalizing a large order, request samples to assess the product quality firsthand. Testing the air pumps in real-world scenarios helps ensure they meet your specifications and performance expectations.

Once you’ve selected a supplier, discuss logistics and delivery options. Ensure that the supplier can meet your delivery timelines and that you understand the shipping process, including customs clearance if importing.

By following this checklist, B2B buyers can ensure they make informed decisions when sourcing air pumps, ultimately leading to enhanced operational efficiency and customer satisfaction.

When sourcing air pumps, particularly for international B2B transactions, understanding the cost structure and pricing dynamics is crucial. This analysis delves into the various cost components, influential pricing factors, and offers practical tips for buyers in regions such as Africa, South America, the Middle East, and Europe.

Materials: The primary materials in air pump production include plastics, metals, and electronic components for electric models. The choice of materials significantly impacts the durability and functionality of the pump, influencing overall costs.

Labor: Labor costs vary widely by region. In countries with lower labor costs, such as those in parts of Asia, manufacturers can produce air pumps more economically. Conversely, labor costs in Europe or North America are typically higher, affecting pricing strategies.

Manufacturing Overhead: This encompasses costs related to factory operations, including utilities, equipment maintenance, and administrative expenses. Efficient manufacturing processes can reduce these costs, allowing suppliers to offer more competitive pricing.

Tooling: The initial investment in tooling is significant, particularly for custom air pump designs. This cost can be amortized over large production runs, so higher volume orders can benefit from lower per-unit tooling costs.

Quality Control (QC): Ensuring that air pumps meet international quality standards involves additional costs. This includes testing and certification fees, which are critical for establishing credibility in markets with stringent regulations.

Logistics: Shipping costs, including freight, insurance, and customs duties, must be factored into the total cost. Depending on the Incoterms agreed upon, these costs can vary significantly, affecting the final price to the buyer.

Margin: Suppliers typically mark up costs to ensure profitability. Understanding the margins in your specific market can help in negotiations and sourcing decisions.

Volume and Minimum Order Quantity (MOQ): Suppliers often offer tiered pricing based on order volume. Larger orders can lead to significant discounts, making it essential for buyers to assess their needs carefully.

Specifications and Customization: Custom features or specific technical specifications can increase costs. Buyers should weigh the benefits of customization against the additional expenses.

Material Quality and Certifications: Higher-quality materials and certifications (e.g., CE, ISO) can enhance product reliability but will also raise costs. Buyers must evaluate the trade-offs between price and quality.

Supplier Factors: The reputation and reliability of suppliers can influence pricing. Established suppliers may charge a premium due to their proven track record, while emerging manufacturers might offer lower prices to gain market entry.

Incoterms: Understanding the Incoterms used in your agreements is vital. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can significantly impact the total landed cost of the air pumps.

Negotiate Wisely: Leverage volume commitments to negotiate better pricing. Building long-term relationships with suppliers can also lead to favorable terms.

Assess Total Cost of Ownership (TCO): Consider not just the purchase price but also the total cost over the product’s lifecycle, including maintenance, energy consumption, and potential downtime.

Be Aware of Pricing Nuances: International buyers should be mindful of currency fluctuations and tariffs that can affect pricing. Establishing contracts in stable currencies or using forward contracts can mitigate risks.

Research Local Market Conditions: Understanding the local market dynamics in regions like Nigeria or Saudi Arabia can provide insights into pricing trends and competitive offerings, allowing for more informed sourcing decisions.

In conclusion, a comprehensive understanding of the cost structure and pricing influencers when sourcing air pumps can empower B2B buyers to make informed decisions. By considering the outlined components and strategies, buyers can enhance their procurement efficiency and achieve better value from their investments.

When considering solutions for inflation and deflation tasks, it’s essential to evaluate various alternatives to air pumps. This analysis will help B2B buyers identify the best option for their specific applications, particularly in regions like Africa, South America, the Middle East, and Europe, where diverse needs and resources may influence purchasing decisions.

| Comparison Aspect | Air Pum | Portable Electric Air Pump | Manual Foot Pump |

|---|---|---|---|

| Performance | High suction power; versatile use | Quick inflation; multiple uses | Moderate performance; labor-intensive |

| Cost | €39.00 | $76.00 | $29.99 |

| Ease of Implementation | Simple setup; rechargeable battery | User-friendly; portable | Requires physical effort |

| Maintenance | Minimal; durable design | Low; battery life dependent | Low; mechanical parts may wear |

| Best Use Case | Travel and compact storage | Biking and outdoor activities | Casual use, low-pressure items |

The portable electric air pump is a strong alternative to air pumps, especially for users who require quick and efficient inflation, such as cyclists or outdoor enthusiasts. With a maximum pressure of 150 PSI and a rechargeable battery, it can inflate various items, from tires to air mattresses. However, its higher price point at $76.00 and reliance on battery life can be a drawback for some buyers. This pump excels in scenarios where speed and convenience are paramount, making it ideal for those who are frequently on the move.

Manual foot pumps present a more budget-friendly option, typically priced around $29.99. They are simple mechanical devices that require no power source, making them a reliable choice in remote areas or for occasional use. However, they demand physical effort, which can be inconvenient, especially when inflating larger items. While they are less efficient than electric pumps in terms of speed and effort, they are suitable for casual users who need to inflate items like pool floats or air mattresses without the need for advanced technology.

When selecting between an air pump and its alternatives, B2B buyers should consider their specific use cases, budget constraints, and operational environments. For businesses focused on travel and efficiency, the air pump’s portability and powerful suction make it an excellent choice. Conversely, for those in need of a cost-effective solution that requires minimal maintenance, a manual foot pump may suffice. The portable electric air pump serves well for those prioritizing speed and versatility, particularly in active settings. Ultimately, assessing the unique requirements of your operations will guide you toward the most suitable inflation solution.

Understanding the technical specifications of air pumps is crucial for B2B buyers to ensure they select the right equipment for their needs. Here are some essential properties to consider:

Air pumps are typically made from various materials, including high-grade plastics and metals. The material affects durability, weight, and resistance to environmental factors. For example, a lightweight plastic may be ideal for portable air pumps, while a robust metal construction could be necessary for industrial applications. Selecting the right material can ensure longevity and performance, especially in harsh conditions.

Illustrative image related to air pum

The pressure rating, usually measured in PSI (pounds per square inch), indicates the maximum pressure the pump can handle. Higher pressure ratings are essential for applications requiring rapid inflation or for inflatables that demand significant air pressure. Understanding the pressure requirements of your products will help you choose a pump that meets operational needs without risking damage.

The flow rate measures how quickly an air pump can inflate or deflate an object, expressed in liters per minute (L/min). A higher flow rate means quicker inflation, which is critical in commercial settings where time is of the essence. Buyers should consider their specific use cases to balance speed and efficiency effectively.

Air pumps can be powered by various sources, including manual operation, batteries, or direct electrical connections. Battery-powered pumps offer portability and convenience, while electric models may provide higher performance for larger applications. Buyers should assess their operational environment to determine the most suitable power source.

Illustrative image related to air pum

Dimensions and weight are significant factors, especially for air pumps intended for travel or outdoor use. Compact and lightweight designs enhance portability, making it easier for users to transport the pump to various locations. B2B buyers should consider their logistical requirements when selecting an air pump.

Durability refers to the pump’s ability to withstand frequent use and environmental stressors. A robust build will often be accompanied by warranty options that indicate the manufacturer’s confidence in the product. Buyers should prioritize durability to minimize replacement costs and downtime.

Familiarity with industry terminology can streamline the purchasing process for B2B buyers. Here are several common trade terms you should know:

OEM refers to companies that produce components or products that are used in another company’s final product. In the air pump sector, understanding OEM relationships can help buyers source high-quality parts for manufacturing or maintenance.

MOQ indicates the smallest number of units a supplier is willing to sell. Understanding MOQ is vital for budgeting and inventory management, particularly for businesses looking to place bulk orders without overcommitting to excess stock.

Illustrative image related to air pum

An RFQ is a document sent to suppliers requesting pricing and terms for a specific quantity of goods. This is a crucial step in procurement, allowing buyers to compare offers and negotiate better terms.

Incoterms are standardized international shipping and freight terms that define the responsibilities of buyers and sellers. Familiarity with these terms is essential for managing shipping logistics and ensuring compliance with international trade regulations.

Lead time refers to the duration from placing an order to receiving the goods. Understanding lead times is critical for supply chain management, helping businesses to plan inventory and avoid stockouts.

This term encompasses the services provided after a purchase, including installation, maintenance, and repairs. Strong after-sales support can enhance customer satisfaction and ensure optimal product performance over time.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions, ensuring they select the right air pump for their specific applications and operational needs.

The global air pump market is currently experiencing robust growth, driven by several key factors. The rising demand for portable and rechargeable air pumps, particularly in sectors like outdoor recreation, automotive, and home improvement, is notable. As consumers and businesses alike seek convenience and efficiency, products such as compact electric air pumps that offer both inflation and deflation capabilities are gaining traction. Moreover, the growing popularity of electric vehicles and e-bikes has further fueled the demand for specialized air pumps capable of servicing these innovations.

Emerging technologies are also reshaping the market landscape. The incorporation of smart features, such as Bluetooth connectivity for pressure monitoring and automated inflation, is becoming increasingly common. B2B buyers from regions like Africa and South America are particularly interested in sourcing high-quality products that can withstand varying climatic conditions and usage scenarios. Additionally, as global supply chains continue to adapt post-pandemic, buyers are prioritizing suppliers who can offer reliability, fast shipping, and responsive customer service.

Sustainability is becoming an essential consideration for B2B buyers in the air pump sector. Environmental impact is a growing concern, as companies are increasingly held accountable for their carbon footprints. Buyers are now actively seeking suppliers that prioritize eco-friendly practices, such as utilizing recyclable materials in product design and manufacturing processes.

The importance of ethical supply chains cannot be overstated. Buyers are demanding transparency regarding the sourcing of materials and labor conditions. Certifications like ISO 14001 for environmental management and Fair Trade certifications are becoming critical factors in supplier selection. Products that incorporate ‘green’ materials not only appeal to environmentally conscious consumers but also align with regulatory requirements in many regions, including Europe and the Middle East.

As international buyers look to establish long-term partnerships, aligning with suppliers who prioritize sustainability can enhance brand reputation and customer loyalty, making it a strategic advantage in competitive markets.

The air pump industry has evolved significantly over the last few decades. Initially, air pumps were predominantly manual, requiring considerable effort to operate. However, with advancements in technology, electric and battery-operated pumps have become prevalent, offering enhanced efficiency and user convenience.

The introduction of portable air pumps has transformed consumer expectations, particularly in the outdoor and recreational sectors. Over the years, the market has seen a shift from basic functionality to multi-use devices capable of servicing various applications, including automotive, sports, and camping gear.

This evolution is crucial for B2B buyers, as understanding the historical context can provide insights into current product offerings and future innovations. Buyers should be aware of ongoing trends, such as the integration of smart technologies and sustainable practices, to make informed sourcing decisions that align with market demands.

How do I choose the right air pump for my business needs?

Choosing the right air pump depends on the intended applications. For instance, if you need a pump for inflating products like air mattresses or sports equipment, consider a model that offers both inflation and deflation functionalities. Evaluate the pump’s portability, battery life, and ease of use, especially for frequent travel. Additionally, assess the compatibility with your existing products and ensure that it meets the required PSI levels for your applications.

What features should I look for in a portable air pump?

When sourcing a portable air pump, prioritize features such as a rechargeable battery, lightweight design, and compact size for ease of transport. Look for multi-use capabilities, like inflation and deflation, and ensure it can handle various tasks, from inflating air mattresses to compressing packing materials. Durability is also crucial; choose a pump made from high-quality materials that can withstand regular use, especially if your business involves extensive travel.

What are the typical minimum order quantities (MOQs) for air pumps?

Minimum order quantities can vary significantly based on the manufacturer and the type of air pump. Generally, MOQs for air pumps range from 50 to 500 units for wholesale buyers. It’s essential to communicate your needs with suppliers to negotiate MOQs that align with your business requirements. Some manufacturers may offer flexibility on MOQs for first-time buyers or larger orders, so always inquire about potential discounts for bulk purchases.

How can I vet suppliers for air pumps effectively?

To vet suppliers, start by researching their business reputation through reviews and testimonials from other B2B buyers. Request references and case studies to gauge their reliability. Verify their compliance with international quality standards and certifications relevant to your market. Engaging in direct communication to discuss your specific requirements will also help you assess their responsiveness and customer service. Consider ordering samples to evaluate product quality before committing to larger purchases.

What payment terms should I expect when sourcing air pumps internationally?

Payment terms can vary by supplier and region. Common options include upfront payment, a 30% deposit with the balance due upon shipment, or letter of credit arrangements. It’s crucial to negotiate terms that suit your cash flow needs while also ensuring supplier trustworthiness. Be aware of any currency exchange implications and additional fees related to international transactions. Establishing clear terms in a contract can help protect both parties.

What quality assurance practices should I consider when sourcing air pumps?

When sourcing air pumps, ensure that your supplier follows strict quality assurance practices. Request documentation of their quality control processes, including testing for safety and performance standards. Ask about warranties or guarantees that protect your investment. Conducting factory visits or third-party inspections can further ensure the product meets your specifications. Establishing a clear return policy can also safeguard against defective items.

How do logistics and shipping impact my air pump sourcing?

Logistics and shipping can significantly affect the total cost and lead time of your air pump orders. Evaluate shipping options such as air freight for faster delivery versus sea freight for cost savings. Understand the import regulations and customs duties in your country to avoid unexpected costs. Collaborate with reliable logistics partners who can provide tracking and timely updates throughout the shipping process to ensure smooth delivery.

What are the best practices for negotiating with air pump suppliers?

Effective negotiation with suppliers requires preparation and clarity. Research market prices and understand your budget constraints to set realistic expectations. Clearly communicate your needs and volume requirements to leverage better pricing. Building a relationship based on trust can also lead to favorable terms, such as discounts for future orders or flexible payment options. Be open to compromise while ensuring that both parties feel valued in the transaction.

Domain: airback.store

Registered: 2023 (2 years)

Introduction: {“name”:”Air Pump”,”brand”:”Airback”,”regular_price”:”€79,00″,”sale_price”:”€39,00″,”rating”:”4.4 / 5.0 (15 reviews)”,”features”:[“Rechargeable USB-C Battery (up to 20 uses on a single charge)”,”Inflates & Deflates (one device for both packing compression and air inflatables)”,”Ultra-Portable (fits easily in a pocket or bag)”,”Powerful Suction (quickly compresses Airback® bags)”,”Multi-Use (works …

Domain: tumbltrak.com

Registered: 1998 (27 years)

Introduction: Tumbl Trak Electric Air Pumps

– Types: Standard Electric Air Pump, Deluxe Electric Air Pump, Replacement Hose (for Orange Deluxe Pump), Replacement Nozzle (for Orange Deluxe Pump)

– Standard Electric Air Pump Specifications:

– Voltage: 120 volt

– Power: 500 watt

– Pressure: 2.2 PSI

– Function: Inflator and Deflator

– Adapters: 2 Tapered Adapters (3/16in. OD and 7/8in. OD)

– Deluxe Electr…

Domain: airhead.com

Registered: 1995 (30 years)

Introduction: {“products”:[{“name”:”12 Volt Towable Air Pump”,”price”:”$84.99″},{“name”:”120 Volt Towable Tube Super Air Pump”,”price”:”$108.99″},{“name”:”120 Volt Towable Tube Air Pump I”,”price”:”$84.99″},{“name”:”12 Volt Clips Pool Float Air Pump”,”price”:”$84.99″},{“name”:”Rechargable Pool Float Air Pump”,”price”:”$47.99″},{“name”:”12 Volt Pool Float Air Pump”,”price”:”$29.99″},{“name”:”120 Volt Electric Ai…

Domain: lectricebikes.com

Registered: 2018 (7 years)

Introduction: Portable Electric Air Pump

– Price: $76.00 (Regular price: $89.00, Save $13)

– Rating: 4.9 out of 5 stars (based on 266 reviews)

– Ships Within: 1 Week

– Size: Roughly the size of a water bottle

– Functions: Inflates tires, tire pressure meter, flashlight

– Compatibility: All Lectric eBike Models, most standard bicycles or eBikes

– What’s in the box: Automobile Power Cord, USB Charging Cord, Bicyc…

As international B2B buyers navigate the air pump market, strategic sourcing emerges as a critical component in optimizing procurement processes. Understanding the diverse applications of air pumps—from inflation to deflation—allows businesses to select products that align with their specific needs, whether for consumer goods, travel accessories, or industrial applications. The advantages of sourcing high-quality, versatile pumps cannot be overstated; they enhance operational efficiency and improve customer satisfaction by ensuring reliable performance.

Moreover, with the increasing emphasis on sustainability, buyers should prioritize suppliers who demonstrate a commitment to environmentally friendly practices, such as using rechargeable batteries and durable materials. This not only reduces the carbon footprint but also resonates with the growing consumer demand for eco-conscious products.

Looking ahead, the air pump market is poised for innovation, driven by technological advancements and changing consumer behaviors. B2B buyers in regions like Africa, South America, the Middle East, and Europe should remain proactive in their sourcing strategies, leveraging market insights to capitalize on emerging trends. By fostering strong supplier relationships and continually assessing market dynamics, businesses can ensure they remain competitive and responsive to their customers’ evolving needs. Take action now to secure your supply chain and position your business for future success in the air pump industry.

Illustrative image related to air pum

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.