Navigating the complexities of sourcing compressor air gauges can present significant challenges for international B2B buyers, particularly in regions such as Africa, South America, the Middle East, and Europe. The need for precise measurement tools in various applications—from automotive maintenance to industrial manufacturing—underscores the importance of selecting the right air gauge. With a multitude of options available, buyers often struggle with identifying the best products that meet their specific requirements while ensuring compatibility and reliability.

This comprehensive guide aims to simplify the procurement process by providing valuable insights into the different types of compressor air gauges, their applications, and critical factors to consider when selecting a supplier. We delve into essential topics such as gauge specifications, industry standards, and best practices for supplier vetting, ensuring that buyers are well-equipped to make informed decisions. Additionally, the guide covers cost considerations and potential pitfalls to avoid, empowering businesses to optimize their purchasing strategies effectively.

For B2B buyers in diverse markets, including Vietnam and Saudi Arabia, understanding these dynamics is crucial. By leveraging the knowledge contained within this guide, businesses can enhance operational efficiency, minimize downtime, and ultimately drive profitability through informed sourcing of high-quality compressor air gauges.

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Analog Pressure Gauge | Mechanical dial with a needle; no electronic components | General industrial use, automotive | Pros: Simple, cost-effective. Cons: Less precise, harder to read in low light. |

| Digital Pressure Gauge | Electronic display; often includes backlighting and high accuracy | Automotive, manufacturing, and HVAC | Pros: High accuracy, easy to read. Cons: Requires batteries, may be more expensive. |

| Tank Pressure Gauge | Measures pressure inside the compressor tank | Compressor monitoring and maintenance | Pros: Essential for operation, indicates tank status. Cons: Limited to tank pressure only. |

| Regulator Gauge | Installed on compressor regulators to control output pressure | Pneumatic tools, spray equipment | Pros: Essential for maintaining desired pressure. Cons: Can be less durable under high stress. |

| Multi-Function Gauge | Combines multiple measurements (pressure, temperature, etc.) | Diverse applications in complex systems | Pros: Versatile, space-saving. Cons: Can be complex to set up and read. |

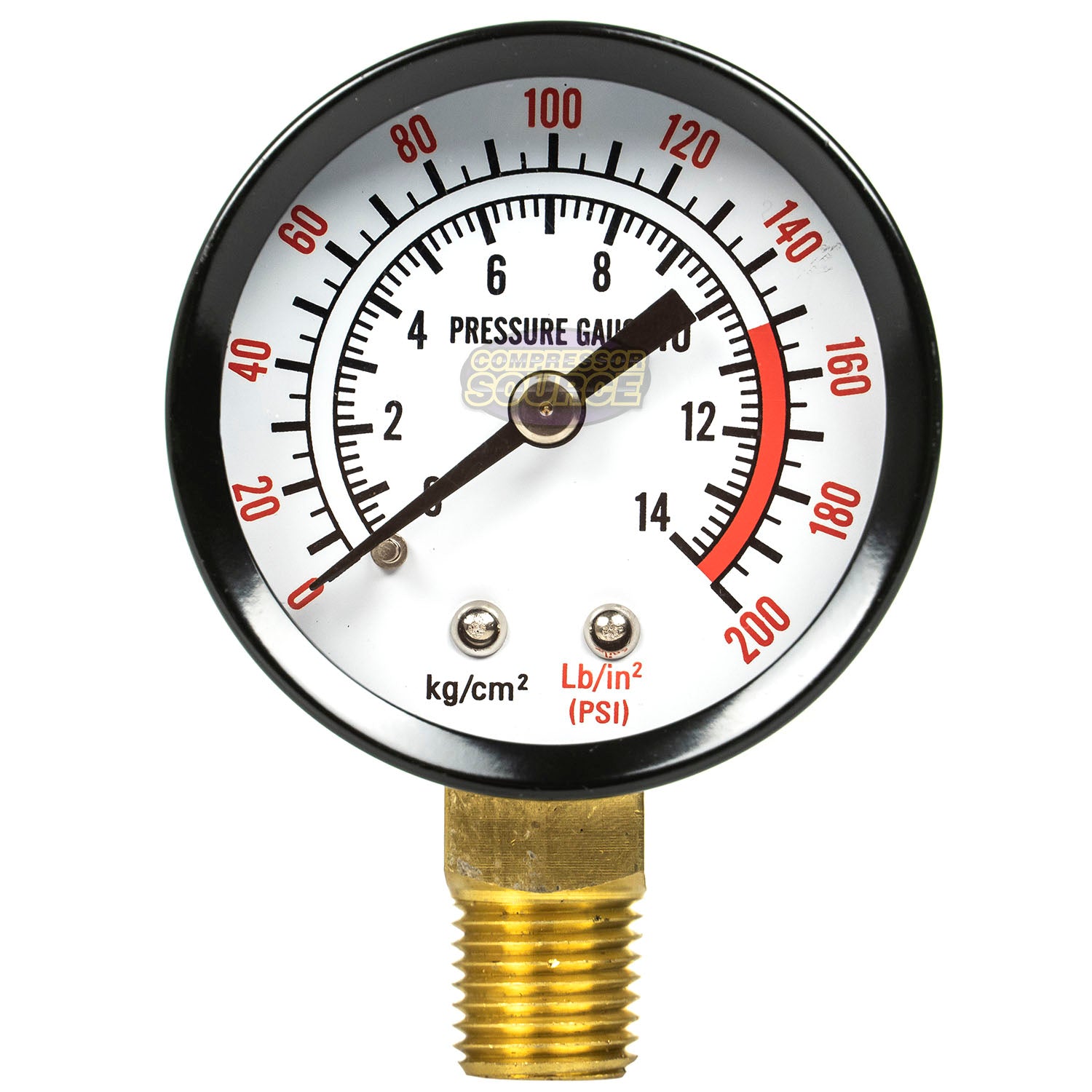

Analog pressure gauges are mechanical devices that utilize a dial and needle to display pressure readings. They are typically more affordable and straightforward, making them a common choice for various industrial applications, including automotive and general manufacturing. However, their reliance on mechanical parts can lead to less precision compared to digital alternatives. B2B buyers should consider the environment in which these gauges will be used, as they can be difficult to read in low-light conditions.

Digital pressure gauges offer a significant upgrade in accuracy and ease of use. Featuring electronic displays, many digital gauges come equipped with backlighting, allowing for visibility in various lighting conditions. These gauges are ideal for industries requiring precise measurements, such as automotive and HVAC. While they may come at a higher cost and require battery replacements, their accuracy and user-friendly nature make them a worthwhile investment for B2B buyers focused on efficiency and reliability.

Tank pressure gauges are essential for monitoring the internal pressure of air compressor tanks. By providing real-time data on tank status, these gauges help ensure safe and efficient operation. They are particularly useful in maintenance settings where monitoring tank pressure is crucial for operational safety. However, their functionality is limited to tank pressure alone, so B2B buyers should assess whether additional gauges are needed to monitor other system parameters.

Regulator gauges are specifically designed to monitor and control the output pressure of air compressors. They are often integrated into pneumatic systems, ensuring that tools and equipment receive the appropriate pressure levels. While essential for maintaining operational efficiency, these gauges may be less durable under high-stress conditions. Buyers should evaluate the compatibility of regulator gauges with their existing systems to ensure optimal performance.

Multi-function gauges combine various measurement capabilities, such as pressure and temperature, into a single unit. This versatility makes them ideal for complex systems that require monitoring multiple parameters simultaneously. While they save space and reduce the need for multiple devices, their complexity can pose challenges in terms of installation and readability. B2B buyers should weigh the benefits of having a consolidated measurement solution against the potential learning curve associated with more advanced features.

| Industry/Sector | Specific Application of Compressor Air Gauge | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Manufacturing | Tire pressure monitoring for assembly line vehicles | Ensures safety and performance of vehicles | Accuracy, compatibility with existing systems, durability |

| Construction | Monitoring air pressure for pneumatic tools and equipment | Enhances operational efficiency and safety | PSI range, ruggedness for harsh environments, calibration |

| Oil & Gas | Monitoring air pressure in drilling operations | Prevents equipment failure and enhances safety | High-pressure capacity, resistance to corrosive environments |

| Food and Beverage Processing | Ensuring proper air pressure in packaging machinery | Maintains product integrity and quality | Compliance with health regulations, precision measurement |

| HVAC Systems | Monitoring pressure in air conditioning and heating systems | Improves energy efficiency and system longevity | Temperature tolerance, integration with existing HVAC systems |

In automotive manufacturing, compressor air gauges are essential for monitoring tire pressure during vehicle assembly. Proper tire inflation is critical for vehicle safety and performance. By ensuring that tires are inflated to the recommended pressure, manufacturers can prevent potential safety hazards and enhance fuel efficiency. B2B buyers in this sector should consider gauges that offer high accuracy and compatibility with existing systems, especially when sourcing internationally from regions like Europe or the Middle East, where regulatory standards may vary.

Illustrative image related to compressor air gauge

In the construction industry, compressor air gauges are used to monitor air pressure for pneumatic tools and heavy equipment. Accurate pressure readings are vital for ensuring that tools operate efficiently and safely. Under-inflated tools can lead to performance issues and increased wear, while over-inflation poses safety risks. Buyers should prioritize gauges that are rugged and can withstand harsh environments, with a suitable PSI range for the tools being used, particularly in developing regions such as Africa and South America.

In the oil and gas sector, compressor air gauges monitor air pressure in drilling operations. Maintaining the correct pressure is crucial for preventing equipment failure and ensuring the safety of operations. High-pressure gauges are necessary for this application, and they must also be resistant to corrosive environments often encountered in oil extraction. International buyers should ensure that the gauges meet stringent safety standards and are capable of operating effectively in extreme conditions.

Within the food and beverage processing industry, compressor air gauges ensure that air pressure in packaging machinery is maintained correctly. This precision is vital for preserving product integrity and quality, as improper air pressure can lead to packaging failures. Buyers in this sector should focus on sourcing gauges that comply with health regulations and provide precise measurements to avoid contamination risks, especially when sourcing from regions with varying compliance standards, such as South America and Africa.

In HVAC systems, compressor air gauges are used to monitor pressure levels in air conditioning and heating systems. Accurate readings help improve energy efficiency and extend the lifespan of the equipment. For B2B buyers, it is essential to consider the temperature tolerance of the gauges and their ability to integrate seamlessly with existing HVAC systems. This is particularly important for international buyers in regions with diverse climate conditions, such as the Middle East and Europe, where HVAC systems face varying operational challenges.

The Problem: Many B2B buyers experience frustration when their compressor air gauges provide inaccurate pressure readings. This often stems from poorly calibrated gauges or damage sustained during transport or handling. Inaccurate readings can lead to over-inflation or under-inflation of pneumatic tools, resulting in equipment malfunction or premature wear. This not only disrupts operations but can also lead to costly repairs and delays in production schedules, impacting the bottom line.

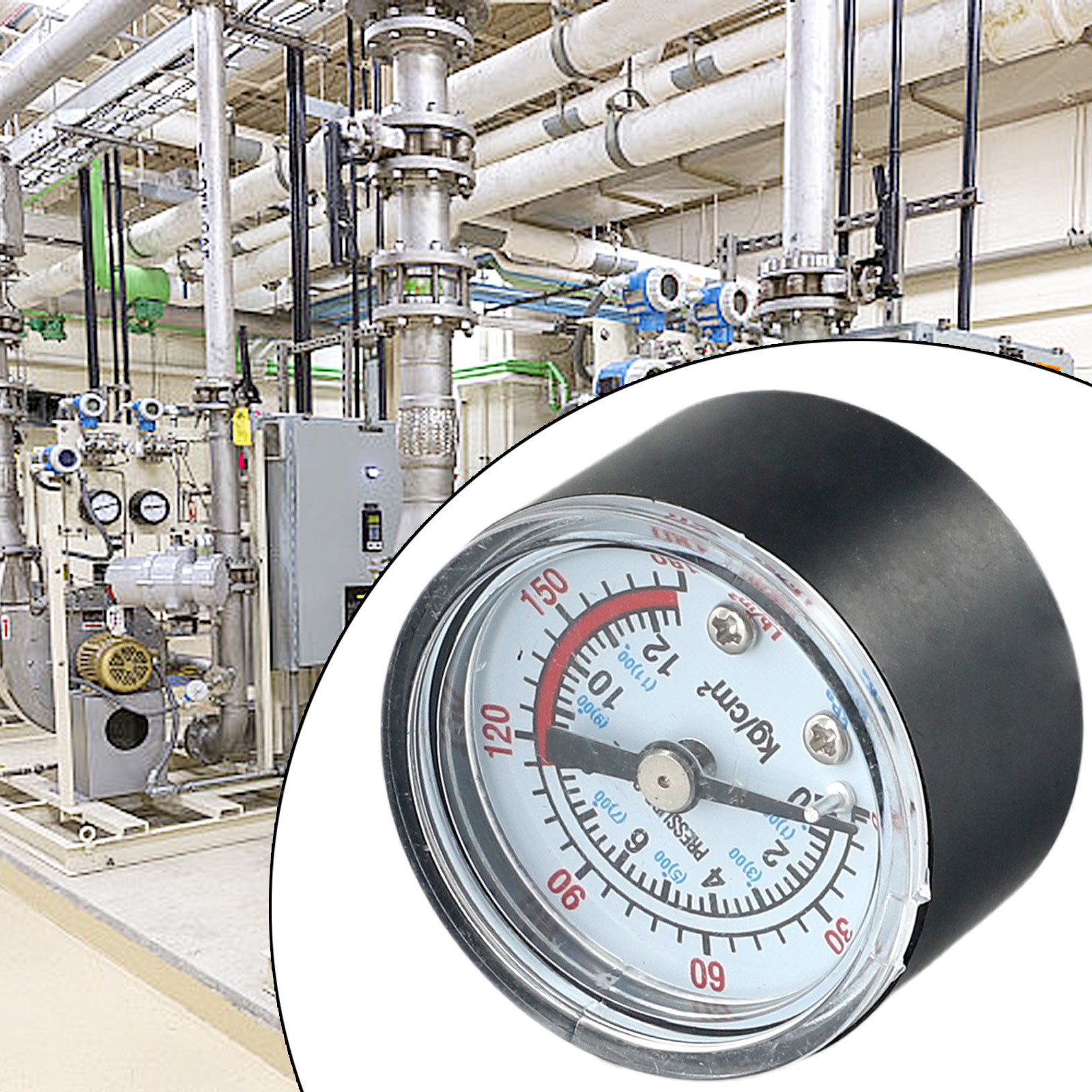

Illustrative image related to compressor air gauge

The Solution: To mitigate the risk of inaccurate readings, B2B buyers should prioritize sourcing high-quality, reliable compressor air gauges that come with calibration certificates. When selecting gauges, look for models that offer a wide range of pressure settings and are built with durable materials to withstand harsh working environments. Regular maintenance is crucial; implement a routine check-up schedule to calibrate gauges according to manufacturer specifications. This ensures that readings remain accurate and helps in preventing equipment damage. Additionally, consider investing in digital gauges with auto-calibration features, which can greatly enhance reliability and ease of use.

The Problem: Compatibility issues are a common pain point for businesses that rely on compressor air gauges. B2B buyers often find that the gauges they purchase do not fit their existing systems, leading to wasted time and resources. This can be particularly problematic in regions where specific gauge standards vary, causing delays in installation and increased costs due to the need for adapters or replacements.

The Solution: Before purchasing a compressor air gauge, it is essential for buyers to thoroughly assess the specifications of their current systems. Buyers should take note of the thread sizes, pressure ranges, and mounting styles required for compatibility. Partnering with suppliers that offer a wide range of gauges and accessories can simplify the sourcing process. Moreover, consider seeking suppliers who provide consultation services to help identify the best products for your existing systems. By ensuring compatibility upfront, businesses can avoid the headaches associated with installation delays and additional expenses.

Illustrative image related to compressor air gauge

The Problem: Many B2B buyers encounter difficulties in understanding how to properly read and utilize their compressor air gauges. This knowledge gap can lead to improper usage, resulting in inefficiencies in operations and potential safety hazards. Misinterpretation of gauge readings can also compromise the performance of pneumatic tools, leading to suboptimal results and increased operational costs.

The Solution: To address this issue, companies should invest in training programs for their staff, focusing on the functionality of air gauges and how to interpret their readings accurately. Comprehensive training should include practical demonstrations and detailed explanations of the different types of gauges and their respective uses. Additionally, suppliers can provide resources such as user manuals, instructional videos, and on-site training sessions to enhance user understanding. By fostering a knowledgeable workforce, businesses can ensure that compressor air gauges are used correctly, maximizing efficiency and safety in their operations.

When selecting materials for compressor air gauges, it is essential to consider their performance characteristics, durability, and suitability for specific applications. Here, we analyze four common materials used in the construction of compressor air gauges: brass, stainless steel, plastic, and aluminum.

Brass is a popular choice for compressor air gauges due to its excellent corrosion resistance and good mechanical properties. It can withstand high pressures, typically rated up to 300 PSI, making it suitable for most air compressor applications.

Pros: Brass offers durability and a good balance between cost and performance. It is relatively easy to machine and can be produced in various shapes and sizes.

Illustrative image related to compressor air gauge

Cons: However, brass can be susceptible to dezincification, especially in harsh environments, which can lead to structural failure over time. Additionally, its higher cost compared to plastic may deter some buyers.

Impact on Application: Brass is compatible with a wide range of media, including air, oil, and water, making it versatile for different compressor systems.

Considerations for International Buyers: Buyers from regions like Africa and South America should ensure compliance with local standards for brass components, such as ASTM B16 or JIS H3250, to avoid issues with quality and safety.

Stainless steel is another common material, known for its exceptional strength and resistance to corrosion and high temperatures. It can handle pressures well above 300 PSI, making it ideal for industrial applications.

Pros: The durability of stainless steel ensures a long lifespan, reducing the frequency of replacements. It also has a sleek appearance, which can be a selling point for high-end applications.

Cons: The primary drawback is its cost, as stainless steel is generally more expensive than both brass and plastic. Additionally, it can be more challenging to machine, leading to increased manufacturing complexity.

Impact on Application: Stainless steel is compatible with various media, including aggressive fluids, making it suitable for diverse applications in sectors such as oil and gas.

Considerations for International Buyers: Buyers in the Middle East and Europe should check for compliance with standards like DIN 17440 for stainless steel, ensuring that the materials meet local regulations.

Plastic gauges are often used in low-pressure applications due to their lightweight and cost-effective nature. They can typically handle pressures up to 150 PSI, making them suitable for smaller compressors.

Pros: The primary advantage of plastic is its low cost and ease of manufacturing. It is also resistant to corrosion from moisture, making it ideal for environments where metal gauges might rust.

Cons: However, plastic is less durable than metal alternatives and can become brittle over time, particularly when exposed to UV light or extreme temperatures.

Impact on Application: Plastic gauges are best suited for air-only applications, as they may not withstand the chemical properties of oils or other fluids.

Considerations for International Buyers: Buyers should ensure that the plastic materials used comply with relevant safety standards, such as ASTM D638, especially in regions with stringent regulations like Europe.

Illustrative image related to compressor air gauge

Aluminum is a lightweight and corrosion-resistant material that is increasingly being used for compressor air gauges. It can handle moderate pressures, typically up to 200 PSI.

Pros: The lightweight nature of aluminum makes it easy to install and transport. It also offers good thermal conductivity, which can be beneficial in certain applications.

Cons: However, aluminum can be less durable than brass or stainless steel and may not perform well in high-pressure environments. Additionally, it can be more expensive than plastic, which may limit its use in budget-sensitive projects.

Impact on Application: Aluminum is suitable for air applications but may not be ideal for environments with high humidity or exposure to corrosive substances.

Illustrative image related to compressor air gauge

Considerations for International Buyers: Buyers should verify that aluminum components meet standards such as ASTM B221 to ensure quality and reliability, particularly in regions like Africa where material standards may vary.

| Material | Typical Use Case for Compressor Air Gauge | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Brass | General-purpose air gauges | Good corrosion resistance | Susceptible to dezincification | Medium |

| Stainless Steel | High-pressure industrial applications | Exceptional strength and durability | Higher cost and machining complexity | High |

| Plastic | Low-pressure applications | Low cost and lightweight | Less durable, can become brittle | Low |

| Aluminum | Moderate-pressure applications | Lightweight and corrosion-resistant | Less durable than metals | Medium |

This strategic material selection guide provides valuable insights for international B2B buyers, ensuring that they can make informed decisions based on performance, cost, and compliance with local standards.

The manufacturing process for compressor air gauges involves several critical stages that ensure the final product meets quality and performance standards. These stages include material preparation, forming, assembly, and finishing.

Material Preparation: The manufacturing process begins with the selection of high-quality materials, typically involving brass or stainless steel for the gauge body and other components. The materials are inspected for purity and structural integrity to prevent defects during production. Suppliers often adhere to international material standards, which is crucial for ensuring reliability, especially for international B2B buyers.

Forming: Once materials are prepared, the next stage is forming. Techniques such as machining, casting, or stamping are utilized to create the various components of the gauge. Machining is particularly popular for precision parts, allowing for tight tolerances that are essential for accurate pressure readings. For instance, the gauge housing and the pressure diaphragm are often machined to ensure they can withstand the pressures they will encounter in operation.

Assembly: After forming, the components are assembled. This may involve manual or automated processes, depending on the scale of production. Each component, such as the dial, needle, and casing, must be carefully aligned and secured to ensure proper functionality. During this stage, manufacturers may use torque specifications to guarantee that each part is securely attached without risking damage.

Finishing: The final stage involves finishing processes, which can include polishing, coating, or painting to enhance durability and aesthetic appeal. For instance, a rubber casing may be added for shock resistance, while a backlight feature can be integrated for visibility in low-light conditions. These finishing touches not only improve the product’s functionality but also enhance its marketability.

Quality assurance (QA) is an integral part of the manufacturing process, ensuring that each compressor air gauge meets both industry standards and customer expectations.

Adherence to International Standards: Compliance with international quality standards, such as ISO 9001, is essential for manufacturers targeting global markets. ISO 9001 provides a framework for consistent quality management, focusing on customer satisfaction and continuous improvement. Additionally, industry-specific certifications like CE (Conformité Européenne) for the European market and API (American Petroleum Institute) standards may apply depending on the gauge’s intended application.

Quality Control Checkpoints: Quality control (QC) is often divided into several checkpoints throughout the manufacturing process:

– Incoming Quality Control (IQC): This initial checkpoint involves inspecting raw materials and components upon arrival to ensure they meet specified standards.

– In-Process Quality Control (IPQC): Throughout the manufacturing process, periodic inspections are conducted to identify defects early. This includes monitoring dimensions and testing the functionality of components before assembly.

– Final Quality Control (FQC): Once the gauges are assembled, they undergo final inspections, which typically include pressure testing to verify accuracy and performance under expected conditions. This final step is crucial for ensuring that the products are ready for distribution.

Common Testing Methods: Manufacturers employ various testing methods to ensure quality. These may include:

– Pressure Testing: Gauges are subjected to high-pressure conditions to validate their performance and safety.

– Calibration Testing: Ensuring that the gauge accurately reads pressure is paramount. Calibration against known standards is performed to confirm precision.

– Durability Testing: This involves simulating real-world conditions to assess the gauge’s robustness and longevity.

For B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is essential for ensuring product reliability and compliance with local standards.

Supplier Audits: Conducting audits of potential suppliers can provide insight into their manufacturing processes and quality assurance practices. This can involve visiting the production facility to assess equipment, processes, and the overall quality culture within the organization.

Quality Reports: Requesting detailed quality reports from suppliers can help buyers understand their QC processes. This may include documentation of test results, compliance certifications, and any corrective actions taken in response to quality issues.

Third-Party Inspections: Engaging third-party inspection agencies can offer an independent verification of the supplier’s quality practices. These agencies can perform random inspections during manufacturing and provide unbiased reports on compliance with industry standards.

International B2B buyers must navigate various nuances regarding quality control and certification, especially when sourcing products like compressor air gauges from different regions.

Local Standards and Regulations: Each region may have specific standards that products must meet. For instance, European buyers may require CE marking, while buyers in the Middle East might adhere to GSO standards. Understanding these requirements is crucial for compliance and market entry.

Import Regulations: Buyers should be aware of import regulations that could affect product quality and safety. This includes tariffs, inspections, and documentation required upon arrival in the destination country.

Cultural and Communication Considerations: Establishing clear communication with suppliers is vital. Language barriers and differing business practices can impact the understanding of quality expectations. B2B buyers should ensure that all quality standards are explicitly stated in contracts and agreements.

In conclusion, the manufacturing processes and quality assurance measures for compressor air gauges are vital for ensuring product reliability and customer satisfaction. By understanding these processes and actively engaging in supplier verification, B2B buyers can make informed decisions that enhance their operational efficiency and product performance.

Navigating the procurement of compressor air gauges requires a strategic approach, particularly for international B2B buyers. This checklist is designed to guide you through the essential steps to ensure that you select the right product that meets your operational needs and compliance standards while also considering regional market dynamics.

Before you begin sourcing, clearly outline the technical requirements for the compressor air gauge. Consider factors such as the pressure range (e.g., 0-300 PSI), connection types (e.g., 1/8″ or 1/4″ threads), and whether you need features like backlighting or auto shut-off. This clarity will help you filter options effectively and avoid purchasing gauges that do not meet your needs.

Illustrative image related to compressor air gauge

Start by compiling a list of potential suppliers. Look for companies with a solid reputation in the industry, preferably those with experience in your target region (e.g., Africa, South America, the Middle East, or Europe). Utilize online platforms, trade shows, and industry referrals to gather information.

Ensure that potential suppliers hold relevant certifications that demonstrate compliance with international quality standards. Look for certifications such as ISO 9001 or specific regional compliance marks, which can indicate a commitment to quality and safety.

Before making a purchase, request detailed product specifications and samples if possible. Evaluate the durability, accuracy, and reliability of the gauges. Consider features like:

Gather pricing information from multiple suppliers to ensure competitive pricing. Beyond just the cost per unit, consider additional factors such as shipping fees, bulk order discounts, and warranty offerings.

After-sales support is critical for ensuring the longevity of your investment. Inquire about the supplier’s warranty policies and the availability of technical support.

Once you have selected a supplier, finalize your order and establish a clear timeline for delivery. Maintain open communication with the supplier throughout the shipping process to address any potential delays or issues.

Following this checklist will help streamline your sourcing process for compressor air gauges and ensure that you make informed purchasing decisions that align with your business objectives.

Illustrative image related to compressor air gauge

When sourcing compressor air gauges, understanding the cost structure is crucial for B2B buyers. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margin.

Materials: The choice of materials significantly impacts costs. High-quality brass and stainless steel are common for durable gauges, while lower-cost plastics may be used in budget models. The selection of materials should align with the intended application and desired lifespan of the gauge.

Labor and Manufacturing Overhead: Labor costs vary by region. For instance, manufacturing in Southeast Asia might offer lower labor costs compared to Europe. Overhead includes utilities, maintenance, and factory operations, which can also fluctuate based on location.

Tooling: Customization or specialized designs often require unique tooling, which can increase initial costs. Buyers should consider whether the added expense is justified by the anticipated benefits of tailored features.

Quality Control: Implementing stringent QC processes can increase costs but ensures product reliability and adherence to certifications. For international buyers, products that comply with recognized standards (e.g., ISO, CE) may have higher upfront costs but lower total ownership costs.

Logistics: Shipping, customs duties, and insurance must be factored into the total cost. International logistics can be complex and costly, especially for bulk orders. Understanding Incoterms can help buyers clarify who is responsible for shipping and risk at various stages.

Margin: Suppliers will add a profit margin to cover their costs and risks. This margin can vary widely based on supplier reputation, market demand, and the buyer’s negotiation skills.

Several factors influence the pricing of compressor air gauges, making it essential for B2B buyers to be aware of these nuances.

Volume/MOQ: Minimum order quantities (MOQ) can significantly affect pricing. Larger orders typically lead to lower per-unit costs due to economies of scale. Buyers should evaluate their needs carefully to optimize order sizes.

Specifications and Customization: Custom specifications, such as pressure ranges or specialized fittings, can drive up costs. Buyers should balance the need for customization against their budget constraints.

Material Quality and Certifications: High-quality materials and certifications enhance reliability but come at a premium. Buyers should assess the long-term benefits against initial costs.

Supplier Factors: The supplier’s location, reputation, and market conditions can impact pricing. Engaging with multiple suppliers can provide leverage in negotiations.

Incoterms and Shipping Terms: Understanding Incoterms is vital for pricing negotiations. Terms such as FOB (Free on Board) or CIF (Cost, Insurance, and Freight) dictate who bears shipping costs and risks, influencing the overall budget.

B2B buyers should adopt several strategies to enhance cost-efficiency when sourcing compressor air gauges.

Illustrative image related to compressor air gauge

Negotiate Effectively: Leverage volume purchases and long-term relationships to negotiate better terms. Suppliers may offer discounts for larger orders or repeat business.

Consider Total Cost of Ownership (TCO): Evaluate not just the initial purchase price but also the long-term costs associated with maintenance, downtime, and replacement. Investing in higher-quality gauges may reduce TCO.

Be Aware of Pricing Nuances for International Buyers: For buyers in Africa, South America, the Middle East, and Europe, currency fluctuations, import tariffs, and local regulations can affect overall pricing. Staying informed about these factors can lead to more advantageous purchasing decisions.

Research and Compare Suppliers: Invest time in researching potential suppliers and comparing their offerings. This not only helps in finding the best price but also ensures you partner with reliable manufacturers.

In conclusion, a comprehensive understanding of cost components and pricing influencers can empower international B2B buyers to make informed sourcing decisions regarding compressor air gauges. By focusing on negotiation, TCO, and supplier evaluation, buyers can enhance their purchasing effectiveness while minimizing costs.

In the realm of industrial and commercial applications, the accuracy of pressure measurement is critical for ensuring optimal performance and safety. While compressor air gauges are widely used, several alternative technologies and methods can also serve the purpose of monitoring and regulating air pressure. This analysis compares compressor air gauges with two alternatives: digital pressure sensors and mechanical pressure switches.

| Comparison Aspect | Compressor Air Gauge | Digital Pressure Sensor | Mechanical Pressure Switch |

|---|---|---|---|

| Performance | Accurate, with readings in PSI | High precision, real-time data | Reliable for threshold activation |

| Cost | Low to moderate (approx. $10 – $340) | Moderate to high (approx. $50 – $500) | Low (approx. $20 – $100) |

| Ease of Implementation | Simple installation, user-friendly | Requires calibration and setup | Easy to install, minimal setup |

| Maintenance | Low maintenance, occasional recalibration | Requires periodic calibration | Minimal, generally robust |

| Best Use Case | General pressure monitoring | Automated systems, data logging | Safety applications, on/off control |

Digital pressure sensors provide a high level of accuracy and can offer real-time data monitoring, making them ideal for automated systems where precise pressure readings are essential. They often feature digital displays and can integrate with software for data analysis, which can enhance operational efficiency. However, they come with a higher initial cost and may require more sophisticated installation and calibration processes. This complexity might deter smaller operations or those with limited technical expertise.

Illustrative image related to compressor air gauge

Mechanical pressure switches are a cost-effective alternative that activates or deactivates equipment based on preset pressure levels. They are particularly valuable in safety applications, where maintaining specific pressure thresholds is critical. Their simplicity and reliability make them easy to install and maintain. However, they do not provide continuous pressure readings and are less suitable for applications requiring precise pressure management or monitoring over time.

When selecting the right pressure measurement solution, B2B buyers should assess their specific operational needs and budget constraints. Compressor air gauges are excellent for straightforward pressure monitoring, while digital pressure sensors are better suited for automated systems that demand high accuracy and real-time data. Mechanical pressure switches can be a practical choice for safety-critical applications where cost and reliability are paramount. Ultimately, the decision should align with the intended application, required precision, and available resources to ensure optimal performance and safety in the operational environment.

Understanding the technical properties of compressor air gauges is crucial for B2B buyers looking to invest in reliable and accurate equipment. Here are some essential specifications to consider:

Pressure Range: The pressure range indicates the minimum and maximum pressure the gauge can measure, typically expressed in pounds per square inch (PSI) or bars. For instance, a gauge with a range of 0-300 PSI is suitable for a variety of applications. Selecting a gauge with an appropriate pressure range ensures that it can handle the operational demands of your specific air compression tasks.

Material Grade: The materials used in the construction of the gauge significantly impact its durability and accuracy. Common materials include brass, stainless steel, and high-grade plastic. Brass is often preferred for its corrosion resistance and strength. Choosing high-quality materials is vital for long-term performance, especially in harsh environments typical in many industrial applications.

Mounting Type: Gauges can be mounted in different ways, such as back mount, bottom mount, or side mount. The mounting type affects installation flexibility and accessibility for reading the gauge. A gauge that fits seamlessly into your existing setup can reduce installation costs and downtime, making it a critical consideration.

Accuracy and Tolerance: Accuracy refers to how closely a gauge’s reading matches the actual pressure, while tolerance indicates the permissible deviation from this reading. For instance, a gauge with a tolerance of ±1 PSI is more precise than one with ±2 PSI. Accuracy is essential for operational efficiency, as inaccurate readings can lead to over- or under-inflation, potentially damaging equipment or affecting safety.

Size and Display Type: The physical size of the gauge and its display type (analog vs. digital) can affect usability. Digital gauges often provide easier readability, especially in low-light conditions, and can offer features like backlighting and auto shut-off. Choosing the right size ensures compatibility with your equipment, while the display type can enhance operational efficiency.

Calibration Requirements: Regular calibration is necessary to maintain the accuracy of air gauges. Understanding the calibration intervals and processes can help you ensure that your equipment remains reliable over time. This aspect is particularly important for industries where precision is critical, such as automotive or manufacturing.

Familiarity with industry jargon can enhance communication and decision-making. Here are some key terms to know:

OEM (Original Equipment Manufacturer): This term refers to companies that produce components or products that are used in another company’s end product. When purchasing gauges, understanding whether they are OEM parts can help ensure compatibility and quality, especially in large-scale operations.

MOQ (Minimum Order Quantity): MOQ defines the smallest number of units a supplier is willing to sell. Knowing the MOQ is essential for budgeting and inventory management, particularly for businesses that may not need large quantities at once.

RFQ (Request for Quotation): An RFQ is a document sent to suppliers to solicit price quotes for specific products. Issuing an RFQ can streamline the procurement process, allowing for better comparisons and negotiations with multiple suppliers.

Incoterms (International Commercial Terms): These are a series of pre-defined commercial terms published by the International Chamber of Commerce (ICC). They clarify the responsibilities of buyers and sellers in international transactions. Understanding Incoterms can help mitigate risks associated with shipping, insurance, and delivery.

Calibration Certificate: This document verifies that a gauge has been tested and calibrated to meet specific standards. Having a calibration certificate ensures that the equipment will perform accurately, which is crucial for compliance and operational efficiency.

Lead Time: Lead time refers to the period between placing an order and receiving it. Understanding lead times is vital for inventory planning and ensuring that operations run smoothly without unnecessary delays.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions when procuring compressor air gauges, ultimately enhancing operational efficiency and product reliability.

The compressor air gauge market is experiencing a dynamic shift driven by the increasing demand for precision in industrial applications. Key drivers include the growth of manufacturing sectors across Africa, South America, the Middle East, and Europe, particularly in countries like Vietnam and Saudi Arabia. As industries evolve, the need for accurate pressure monitoring is paramount for operational efficiency and safety. Digital gauges, which offer enhanced accuracy and features such as backlighting and auto shut-off, are becoming increasingly popular among B2B buyers. Additionally, the integration of IoT technologies in air compressors is paving the way for smart gauges that can provide real-time data analytics, further enhancing operational decision-making.

Emerging trends in sourcing highlight the importance of reliability and compatibility. Buyers are increasingly seeking gauges that can fit a variety of compressor models, ensuring ease of installation and maintenance. The rise of e-commerce platforms is also transforming how B2B buyers source these products, allowing for more competitive pricing and greater access to international brands. Furthermore, companies are prioritizing suppliers that can offer quick shipping and responsive customer service, as downtime in industrial applications can be costly.

Sustainability is becoming a critical factor in the procurement strategies of B2B buyers in the compressor air gauge sector. The environmental impact of manufacturing processes is under scrutiny, prompting companies to seek out suppliers committed to sustainable practices. This includes the use of recycled materials in gauge production and the implementation of energy-efficient manufacturing techniques.

Ethical sourcing is equally important, as buyers look to ensure that their supply chains are free from exploitation and harmful practices. Certifications such as ISO 14001 (Environmental Management) and adherence to RoHS (Restriction of Hazardous Substances) regulations are increasingly being demanded by buyers as a sign of a supplier’s commitment to environmental responsibility. These certifications not only enhance brand reputation but also align with the growing consumer preference for sustainable products.

Moreover, the use of ‘green’ materials in the production of compressor air gauges, such as biodegradable plastics and non-toxic metals, is gaining traction. B2B buyers are encouraged to engage with suppliers who can demonstrate their commitment to sustainability through transparent reporting and certifications, ensuring that their procurement strategies are not just cost-effective but also environmentally responsible.

The evolution of compressor air gauges dates back to the early industrial revolution when the need for accurate pressure measurement became essential for safe and efficient operations. Initially, these gauges were analog, employing mechanical systems to display pressure levels. Over the decades, advancements in technology led to the introduction of digital gauges, which offered improved accuracy and user-friendly features.

The late 20th century saw the incorporation of electronic components, allowing for more sophisticated monitoring systems that could integrate with other industrial technologies. As industries have become increasingly automated, the demand for high-performance air gauges has surged, leading to innovations that cater to the unique needs of various sectors. Today, the compressor air gauge market is characterized by a blend of traditional craftsmanship and cutting-edge technology, making it essential for B2B buyers to understand both historical and modern advancements in order to make informed sourcing decisions.

How do I ensure the accuracy of compressor air gauges?

To ensure the accuracy of compressor air gauges, regularly calibrate them according to manufacturer specifications. Consider using a certified calibration service if available in your region. Additionally, inspect the gauge for any signs of damage or wear, as physical defects can affect performance. Utilizing high-quality gauges with precise increments, such as those that measure to 0.5 psi, will also enhance accuracy. Finally, always verify the gauge reading against a known standard when possible to confirm its reliability.

What is the best type of compressor air gauge for industrial applications?

For industrial applications, digital gauges are often the best choice due to their enhanced accuracy and ease of use. Look for models with features like backlighting, auto-on/off functions, and compatibility with various fittings (e.g., 1/8″ or 1/4″ threads). Gauges with a wider pressure range, such as 0-300 psi, are ideal for diverse environments. Ensure that the gauge can withstand the operating conditions of your facility, including temperature fluctuations and potential exposure to harsh chemicals.

What should I consider when sourcing compressor air gauges from international suppliers?

When sourcing compressor air gauges internationally, evaluate the supplier’s reputation and reliability by checking reviews and references. Ensure compliance with international quality standards and certifications, such as ISO or CE marks. Assess their ability to provide after-sales support, including warranty terms and customer service responsiveness. Additionally, consider the supplier’s experience with your specific regional requirements, as regulations and standards may vary significantly across countries.

What are typical payment terms when purchasing compressor air gauges internationally?

Payment terms can vary widely by supplier and region, but common practices include payment in advance, letters of credit, or payment upon delivery. For larger orders, consider negotiating installment payments based on shipment milestones. Always clarify the currency of the transaction and any associated fees. Ensure you understand the terms regarding returns and refunds in case of defective products to avoid disputes later on.

How can I customize compressor air gauges for my specific needs?

Customization options for compressor air gauges may include specific pressure ranges, dial colors, or branding with your company logo. Discuss your requirements directly with the supplier, as many manufacturers offer bespoke solutions. Be prepared to meet minimum order quantities (MOQs) for customized products, which can vary significantly. Providing detailed specifications will help the supplier create a gauge that meets your operational needs effectively.

What is the minimum order quantity (MOQ) for compressor air gauges?

The MOQ for compressor air gauges typically depends on the supplier and the type of gauge you are ordering. Standard gauges may have an MOQ as low as 10-50 units, while customized gauges may require larger orders, often ranging from 100 to 500 units. Always inquire about the MOQ before finalizing your order to ensure it aligns with your procurement strategy and budget. Understanding the MOQ can also aid in planning inventory and managing cash flow.

What quality assurance processes should I expect from suppliers of compressor air gauges?

Reputable suppliers should have robust quality assurance (QA) processes in place, including testing each batch of gauges for accuracy and durability. Ask about their QA certifications, such as ISO 9001, which indicates a commitment to quality management. Inquire about the testing methods used, such as pressure calibration and environmental testing. Understanding their QA processes will give you confidence in the reliability of the gauges you purchase.

How do logistics and shipping affect the sourcing of compressor air gauges?

Logistics and shipping are critical factors when sourcing compressor air gauges internationally. Consider the shipping methods available, such as air freight for faster delivery or sea freight for cost savings. Understand the lead times involved, including manufacturing and transit times, to ensure timely delivery for your operations. Additionally, be aware of customs regulations and potential tariffs in your country, as these can impact the overall cost and delivery schedule of your order.

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: 1. Milton Standard Air Pressure Gauge and Inflator – Recommended for reliability.

2. Jaco Flow Pro – Digital gauge, noted for accuracy and performance.

3. Sealey SA302 Tyre Inflator – Comes with gauge, includes various air chucks and adapters for different tire types.

In today’s competitive landscape, the strategic sourcing of compressor air gauges is essential for businesses seeking to optimize operational efficiency and ensure accurate performance monitoring. High-quality gauges, like those offered by leading manufacturers, not only enhance precision in pressure readings but also contribute to the longevity of equipment. By investing in reliable gauges, companies can reduce maintenance costs and improve the overall reliability of their compressed air systems.

Furthermore, understanding the specifications and compatibility of different gauges is crucial for making informed purchasing decisions. International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should focus on suppliers that provide comprehensive support and diverse product offerings. This approach not only ensures better alignment with specific operational needs but also fosters stronger supplier relationships.

Illustrative image related to compressor air gauge

As industries worldwide continue to evolve, the demand for precision and efficiency will only increase. Now is the time for businesses to reassess their sourcing strategies for compressor air gauges. By prioritizing quality and reliability, international buyers can position themselves for success in a rapidly changing market. Explore your options today and secure the tools necessary for sustained growth and operational excellence.

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.