In the fast-paced world of international trade, sourcing reliable equipment such as the DEWALT 20V tire inflator can be a daunting task for B2B buyers. The challenge lies not only in identifying a high-quality product that meets diverse operational needs but also in navigating the complexities of supplier relationships across different regions. This guide aims to demystify the process, offering comprehensive insights into the DEWALT 20V tire inflator, including its types, applications, and essential features that cater to various industries—from automotive maintenance in South America to outdoor recreation in Europe.

Throughout this guide, we will explore the multifaceted applications of the DEWALT 20V tire inflator, which range from tire inflation for vehicles to the quick inflation of sporting equipment. We will also delve into best practices for supplier vetting, ensuring that you partner with reputable manufacturers who adhere to international quality standards. Additionally, we will provide a cost analysis to help you make informed purchasing decisions that align with your budgetary constraints.

By equipping you with actionable insights and strategic recommendations, this guide empowers B2B buyers from Africa, the Middle East, and beyond to make confident choices in their sourcing endeavors. Whether you’re in Brazil seeking versatility or in Germany prioritizing efficiency, understanding the global market for the DEWALT 20V tire inflator is crucial to enhancing your operational capabilities.

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Dewalt 20V MAX Corded/Cordless Inflator | Versatile power sources (20V battery, 12V DC, 110V AC), digital gauge, automatic shutoff | Tire inflation, sporting equipment, camping gear, off-roading | Pros: High versatility; Cons: Tool only, battery not included |

| Dewalt 20V MAX Inflator with Accessories | Comes with multiple nozzles and adapters, high-pressure rubber hose | Automotive service centers, outdoor recreation businesses | Pros: Comprehensive accessory kit; Cons: Slightly higher initial cost |

| Dewalt 20V MAX Portable Inflator | Lightweight design, built-in LED light, high-volume inflation mode | Mobile service providers, emergency response teams | Pros: Easy to transport; Cons: Limited to portable applications |

| Dewalt 20V MAX High-Pressure Inflator | Maximum pressure of 160 PSI, robust construction | Industrial applications, heavy-duty vehicles | Pros: Suitable for heavy-duty tasks; Cons: Higher noise level |

| Dewalt 20V MAX Inflator with AC Adapter | Includes AC power adapter, designed for stationary use | Workshops, garages, and maintenance facilities | Pros: Convenient for stationary use; Cons: Less portable than other models |

The Dewalt 20V MAX Corded/Cordless Inflator is designed for versatility, allowing operation via a 20V battery, 12V DC, or 110V AC power sources. This feature is particularly beneficial for businesses that require mobility on job sites or in remote areas. Its digital gauge and automatic shutoff ensure precise inflation, making it ideal for applications such as tire inflation and inflating sporting equipment. When purchasing, consider the need for battery and charger, which are sold separately, impacting the overall cost.

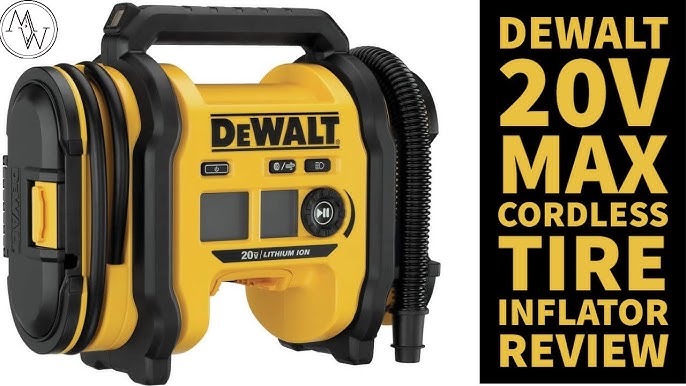

Illustrative image related to dewalt 20v tire inflator

This model stands out for its comprehensive accessory kit, which includes various nozzles and adapters for different inflation needs. It is particularly suitable for automotive service centers and outdoor recreation businesses that require a reliable tool for diverse applications. The high-pressure rubber hose enhances durability, ensuring that the tool can withstand frequent use. Buyers should weigh the initial investment against the potential for increased efficiency in service delivery.

The Dewalt 20V MAX Portable Inflator is lightweight and designed for easy transport, making it a preferred choice for mobile service providers and emergency response teams. Its built-in LED light is a valuable feature for use in low-light conditions. While it excels in portability, buyers should consider its limitations for stationary applications, as it is primarily designed for on-the-go use.

With a maximum pressure of 160 PSI, the Dewalt 20V MAX High-Pressure Inflator is tailored for industrial applications and heavy-duty vehicles. Its robust construction makes it suitable for demanding environments, but potential buyers should be aware of the higher noise levels associated with its operation. This model is ideal for businesses that prioritize power and durability over quiet operation.

This model is designed for stationary use, making it an excellent choice for workshops, garages, and maintenance facilities. The inclusion of an AC power adapter allows for continuous operation without the concern of battery depletion. Buyers should consider how often they will be using the inflator in a fixed location versus needing portability, as this will influence their purchase decision.

| Industry/Sector | Specific Application of Dewalt 20V Tire Inflator | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Services | Tire maintenance and repair for vehicles | Ensures vehicle safety and operational efficiency | Availability of power sources (battery, AC, DC) for flexibility |

| Recreational Equipment | Inflation of sports equipment (e.g., balls, bicycles) | Enhances customer satisfaction and service efficiency | Compatibility with various valve types and ease of use |

| Logistics and Transportation | Inflating truck and trailer tires | Reduces downtime, ensuring timely deliveries | Durability under heavy use and ease of transportation |

| Outdoor and Camping Gear | Inflating camping mattresses and inflatables | Improves customer experience and convenience | Portability and battery life for remote locations |

| Construction and Landscaping | Inflating equipment tires and air mattresses | Increases productivity and reduces equipment failure risks | Robust design for harsh environments and ease of maintenance |

In the automotive sector, the Dewalt 20V tire inflator is essential for tire maintenance and repair. It allows mechanics and service providers to quickly inflate tires to the correct pressure, ensuring vehicle safety and optimal performance. With its automatic shutoff feature, the inflator prevents over-inflation, which can lead to tire failure. For international B2B buyers, especially in regions like Africa and South America, sourcing an inflator that operates on multiple power sources (battery, AC, DC) is crucial to accommodate varying infrastructure conditions.

For businesses in the recreational equipment industry, the Dewalt tire inflator is invaluable for inflating sports gear such as balls and bicycles. Quick inflation capabilities enhance customer satisfaction by allowing users to spend more time enjoying their activities rather than preparing their equipment. B2B buyers should prioritize inflators that are compatible with various valve types to ensure versatility and ease of use in diverse scenarios.

In logistics and transportation, the Dewalt 20V tire inflator is used to maintain truck and trailer tire pressures. Properly inflated tires enhance fuel efficiency and reduce the risk of blowouts, thereby minimizing downtime and ensuring timely deliveries. Businesses should consider the durability of the inflator, as it must withstand rigorous use in demanding environments while maintaining reliability.

Illustrative image related to dewalt 20v tire inflator

For outdoor and camping gear companies, the Dewalt inflator simplifies the process of inflating mattresses and other inflatables. Its portability and battery-powered operation make it ideal for use in remote locations, where access to electricity may be limited. B2B buyers must evaluate battery life and weight for ease of transport, ensuring that their customers can easily carry the inflator on camping trips.

In the construction and landscaping sectors, the Dewalt tire inflator is crucial for maintaining the air pressure of equipment tires and inflating air mattresses used on job sites. This tool increases productivity by reducing the time spent on tire maintenance and minimizing equipment failure risks. Buyers in these industries should focus on the inflator’s robust design, ensuring it can withstand harsh working conditions while remaining easy to maintain.

The Problem: B2B buyers in various industries, such as automotive repair or construction, often operate in environments with limited access to electricity. They may find themselves needing to inflate tires or equipment at job sites where power sources are inconsistent. This can lead to downtime, frustration, and ultimately, loss of productivity. Additionally, in regions with unstable electricity supply, relying solely on AC power can be a significant disadvantage.

The Solution: The DEWALT 20V Tire Inflator offers remarkable versatility by running on three power sources: a 20V MAX battery, 12V DC, or 110V AC. B2B buyers should consider investing in a combination of the 20V MAX battery and the 12V DC power cord to ensure they can operate the inflator in various settings. When selecting the inflator, ensure that the appropriate battery and charger are included in the purchase or ordered separately. This adaptability allows teams to maintain continuous operation regardless of the power availability, ultimately minimizing downtime and enhancing overall efficiency.

Illustrative image related to dewalt 20v tire inflator

The Problem: Accurate tire inflation is crucial for safety and efficiency, particularly for businesses in logistics and transportation. B2B buyers may face challenges with inflators that provide inaccurate pressure readings, leading to under-inflated or over-inflated tires. This not only compromises safety but can also result in increased fuel consumption and wear on vehicles, which affects the bottom line.

The Solution: The DEWALT 20V Tire Inflator features a digital gauge that allows users to set and monitor the desired air pressure accurately. B2B buyers should familiarize their teams with the digital display and the auto-shutoff feature, which stops inflation once the set pressure is reached. To further enhance accuracy, it’s advisable to regularly calibrate the inflator using a known accurate gauge and to train staff on proper usage techniques. This proactive approach will ensure that tire pressures remain within optimal ranges, promoting safety and reducing operational costs.

The Problem: Many B2B buyers require tire inflators that are not only effective but also portable enough to be used in various scenarios, from roadside assistance to on-site repairs. However, some inflators can be bulky and cumbersome, making them impractical for quick and easy transport. This limitation can hinder workflow and responsiveness, especially in industries where time is of the essence.

Illustrative image related to dewalt 20v tire inflator

The Solution: The DEWALT 20V Tire Inflator is designed with portability in mind, weighing only 5.5 lbs and featuring a compact design. Buyers should emphasize the importance of selecting a model with onboard accessory storage to keep all necessary components organized and easily accessible. Additionally, consider equipping teams with a carrying case for enhanced transportability. Training staff on how to efficiently store and set up the inflator can further streamline operations. By prioritizing portability, businesses can enhance their service efficiency, ensuring that they can quickly respond to inflation needs, regardless of the location.

By addressing these common pain points through strategic sourcing and effective utilization of the DEWALT 20V Tire Inflator, B2B buyers can significantly improve operational efficiency and safety across their operations.

When considering the DEWALT 20V tire inflator, material selection is crucial for ensuring performance, durability, and compliance with international standards. Below, we analyze common materials used in the inflator’s construction, focusing on their properties, advantages, disadvantages, and specific considerations for international B2B buyers.

Key Properties: The high-pressure rubber hose is designed to withstand temperatures ranging from -30°C to 70°C and can handle pressures up to 160 PSI. Its flexibility allows for easy maneuverability while maintaining structural integrity under stress.

Pros & Cons: Rubber is known for its excellent durability and resistance to wear and tear. It is also lightweight, making the inflator portable. However, rubber can degrade over time when exposed to UV rays and certain chemicals, which may limit its lifespan in harsh environments.

Impact on Application: The rubber hose is ideal for inflating tires and sports equipment, as it maintains a secure connection to various valve types, including Presta and Schrader.

Considerations for International Buyers: Buyers in regions like Africa and South America should consider the local climate and UV exposure when assessing rubber hose longevity. Compliance with ASTM standards for rubber products is essential for ensuring quality.

Illustrative image related to dewalt 20v tire inflator

Key Properties: The inflator’s housing often utilizes high-impact plastic, which can withstand temperatures from -20°C to 60°C. This material is resistant to corrosion and impacts, making it suitable for rugged use.

Pros & Cons: High-impact plastic is lightweight and cost-effective, which contributes to the overall affordability of the inflator. However, it may not offer the same level of durability as metal components, especially under extreme conditions.

Impact on Application: The plastic housing protects internal components and ensures the inflator remains functional in various environments, from job sites to outdoor recreational areas.

Considerations for International Buyers: Buyers in Europe, particularly Germany, should ensure compliance with EU regulations regarding plastic materials, including RoHS directives. Understanding local preferences for material sustainability can also influence purchasing decisions.

Key Properties: Metal components, such as the threaded chuck and internal fittings, are typically made from stainless steel or aluminum. These materials are corrosion-resistant and can handle high pressures and temperatures.

Pros & Cons: Metal offers superior strength and durability, making it ideal for components that experience significant wear. However, metal parts can increase the overall weight of the inflator and may be more expensive than plastic counterparts.

Impact on Application: The metal fittings ensure a secure connection to inflation valves, enhancing the efficiency of the inflating process and reducing the risk of leaks.

Considerations for International Buyers: Compliance with international standards such as DIN for metal products is crucial. Buyers in the Middle East should also be aware of local corrosion factors, such as humidity and salinity, which can affect metal longevity.

Illustrative image related to dewalt 20v tire inflator

Key Properties: The electronic components, including the digital gauge and automatic shutoff feature, are typically made from a combination of plastics and metals. These components must operate effectively within a temperature range of -10°C to 50°C.

Pros & Cons: Electronic components enhance functionality, providing users with precise pressure readings and automatic inflation shutoff, which improves safety. However, they can be sensitive to extreme temperatures and may require careful handling.

Impact on Application: These features make the inflator user-friendly and efficient, particularly for applications requiring precise air pressure, such as in automotive and sports equipment.

Considerations for International Buyers: Buyers should ensure that electronic components comply with international safety standards and certifications, such as CE marking in Europe and IEC standards in other regions.

| Material | Typical Use Case for dewalt 20v tire inflator | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| High-Pressure Rubber Hose | Tire inflation, sports equipment | Durable and flexible | UV degradation over time | Medium |

| High-Impact Plastic | Housing and protective casing | Lightweight and cost-effective | Less durable than metal | Low |

| Stainless Steel/Aluminum | Threaded chuck and internal fittings | Corrosion-resistant and strong | Increases overall weight | High |

| Electronic Components | Digital gauge and automatic shutoff | Enhances functionality and safety | Sensitive to extreme temperatures | Medium |

This strategic material selection guide provides insights into the properties and considerations of materials used in the DEWALT 20V tire inflator, helping B2B buyers make informed purchasing decisions based on performance, durability, and compliance with international standards.

Illustrative image related to dewalt 20v tire inflator

The manufacturing process of the DEWALT 20V Tire Inflator involves several key stages, ensuring that each unit is produced with precision and reliability. The main stages include material preparation, forming, assembly, and finishing.

Material Preparation

The first stage involves sourcing high-quality materials that meet DEWALT’s stringent specifications. The materials include high-grade plastics for the casing, durable rubber for hoses, and metals for internal components. Suppliers are carefully vetted to ensure that they comply with international quality standards, such as ISO certifications.

Forming

In this stage, raw materials are shaped into components using various techniques. For example, injection molding is commonly used for creating the plastic housing, while metal parts may be produced through stamping or machining. The forming process is designed to create parts that fit together seamlessly, which is crucial for the inflator’s performance.

Illustrative image related to dewalt 20v tire inflator

Assembly

Assembly is a critical phase where all components come together. Skilled technicians utilize automated and manual assembly techniques to ensure precision. The inflator is equipped with features such as a digital gauge, automatic shutoff, and various nozzle attachments, which must be assembled with care to maintain functionality. Quality control checkpoints during assembly allow for immediate identification of any defects.

Finishing

The final stage involves thorough testing and finishing touches. This includes applying protective coatings, labeling, and packaging the inflators. Each unit undergoes rigorous quality checks to ensure that it meets performance standards before it is shipped out.

Quality assurance (QA) is integral to the manufacturing of the DEWALT 20V Tire Inflator, encompassing various international and industry-specific standards to ensure product reliability and safety.

International Standards and Certifications

DEWALT adheres to globally recognized quality management systems such as ISO 9001, which emphasizes continuous improvement and customer satisfaction. Additionally, products may be certified under CE standards for compliance with European health, safety, and environmental protection regulations, ensuring that they can be marketed across European countries.

Quality Control Checkpoints

The QA process includes several checkpoints throughout the manufacturing stages:

Incoming Quality Control (IQC): This step involves inspecting raw materials upon arrival to ensure they meet specifications before production begins. Any subpar materials are rejected or returned.

In-Process Quality Control (IPQC): During assembly, real-time inspections are conducted to verify that components are being assembled correctly. Any deviations from standards are addressed immediately to prevent defects from progressing to the next stage.

Final Quality Control (FQC): Once the inflators are fully assembled, they undergo final testing. This includes checking for functionality, safety features, and performance metrics, such as maximum pressure capacity and noise levels. Only units that pass these tests are approved for packaging and shipment.

To ensure the DEWALT 20V Tire Inflator meets high-performance standards, several testing methods are employed throughout the manufacturing process.

Performance Testing

This includes simulating real-world usage scenarios to verify the inflator’s capabilities. For instance, units are tested for their inflation speed, maximum pressure (up to 160 PSI), and automatic shutoff functionality. This ensures that the inflators can safely and effectively meet user demands.

Durability Testing

The inflators are subjected to stress tests to assess their durability under various conditions. This includes exposure to extreme temperatures, vibrations, and impact scenarios. The goal is to ensure that the product can withstand the rigors of both professional and recreational use.

Illustrative image related to dewalt 20v tire inflator

Safety Testing

Safety is paramount, especially for power tools. The inflators undergo electrical safety tests to prevent malfunctions that could lead to hazards. Compliance with safety standards, such as those set forth by Underwriters Laboratories (UL), is crucial for international distribution.

For B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control practices is vital for ensuring product reliability and compliance with local regulations.

Supplier Audits

Conducting audits of suppliers can provide insight into their manufacturing processes and quality control measures. This includes reviewing their certifications, quality management systems, and past performance records. Regular audits help maintain strong supplier relationships and ensure ongoing compliance with standards.

Quality Reports

Requesting quality reports can offer a snapshot of a supplier’s performance over time. These reports typically include data on defect rates, inspection results, and corrective actions taken. Analyzing this information can help buyers assess the reliability of the inflators they intend to purchase.

Third-Party Inspections

Engaging independent third-party inspection services can provide an unbiased evaluation of the manufacturing process. These services can perform in-depth assessments at various stages, from material sourcing to final assembly, ensuring that products meet both international and local standards.

B2B buyers operating in diverse international markets must navigate various quality control and certification nuances. Understanding these differences is crucial for successful procurement.

Regional Regulations

Different regions may have specific regulations that products must comply with. For example, CE marking is required for products sold in the European Union, while other regions may have their own certification requirements. Familiarizing oneself with these regulations is essential for market entry.

Cultural Considerations

Cultural factors can influence quality expectations. For instance, markets in Europe may prioritize eco-friendliness and sustainability, while buyers in other regions may focus more on cost-effectiveness. Understanding these preferences can help tailor procurement strategies.

Illustrative image related to dewalt 20v tire inflator

Documentation and Compliance

Ensuring that all necessary documentation, such as certificates of compliance and test reports, is in order is vital for smooth customs clearance and market entry. B2B buyers should maintain open lines of communication with suppliers to ensure that they are informed about any changes in compliance requirements.

By understanding the manufacturing processes and quality assurance protocols behind the DEWALT 20V Tire Inflator, B2B buyers can make informed decisions, ensuring they procure reliable and high-quality products suited to their market needs.

This practical sourcing guide aims to assist B2B buyers in effectively procuring the DEWALT 20V tire inflator. With its versatile features and robust design, understanding how to source this product will ensure that you acquire a reliable tool that meets your operational needs and quality standards.

Clearly outline the technical specifications required for your operations. Consider factors such as maximum pressure (up to 160 PSI for the DEWALT model), portability, and power sources (20V MAX battery, 12V DC, or 110V AC). Defining these parameters will help you narrow down options that fit your specific use cases, whether for tire inflation or inflating sporting equipment.

Establish the criteria for your suppliers. This includes their ability to provide authentic DEWALT products, delivery capabilities, and after-sales support. Make sure to consider suppliers that can handle your region’s logistics, especially if you are operating in Africa or South America, where shipping times may vary significantly.

Before committing, thoroughly vet potential suppliers. Request company profiles, case studies, and references from buyers in similar industries or regions. Ensure they have a solid reputation for delivering quality products and responsive customer service, as this will be crucial for ongoing support.

Whenever possible, request samples of the DEWALT 20V tire inflator. This allows you to physically assess the product for quality, performance, and usability. Testing the inflator will help you determine if it meets your operational standards, particularly regarding features like the digital gauge and auto-shutoff functionality.

Once you’ve identified suitable suppliers, engage in negotiations to establish favorable pricing and terms. Consider bulk purchasing options for cost savings, and clarify warranty and return policies to protect your investment. Strong negotiation can lead to better deals, especially when dealing with international suppliers.

Prepare a detailed purchase agreement that outlines all terms, including pricing, delivery timelines, and payment terms. Ensure that both parties sign the agreement to formalize the transaction. This step is critical to mitigate risks associated with international sourcing, especially in regions where legal frameworks may differ.

After procurement, plan for ongoing maintenance and support of the inflator. Establish a relationship with your supplier for future parts, accessories, and servicing needs. This proactive approach will help ensure the longevity and reliability of your DEWALT 20V tire inflator, maintaining optimal performance in your operations.

Illustrative image related to dewalt 20v tire inflator

By following these steps, B2B buyers can confidently source the DEWALT 20V tire inflator, ensuring that they make informed decisions that align with their operational needs.

When sourcing the DeWalt 20V tire inflator, several key cost components come into play. Understanding these can help international B2B buyers make informed decisions.

Materials: The primary materials for the DeWalt 20V tire inflator include high-grade plastics for the body, durable rubber for hoses, and metals for the internal components. The quality of these materials can significantly impact the cost, with higher-grade materials likely leading to increased durability and performance.

Labor: Labor costs vary widely by region. In countries with lower labor costs, manufacturers might achieve a better price point, while those in higher-cost regions may pass on increased labor expenses to buyers. This aspect is crucial for buyers from Africa and South America, where labor costs can differ dramatically from Europe.

Manufacturing Overhead: This includes costs associated with the factory operations, such as utilities, rent, and administrative expenses. Efficient manufacturing processes can help lower these costs, affecting the final price of the inflator.

Tooling: The production of inflators may require specialized tools and machinery, which can be a significant upfront investment for manufacturers. The amortization of these costs over production volume can influence unit pricing, especially for lower-volume orders.

Quality Control (QC): Ensuring that each inflator meets strict quality standards incurs costs. Effective QC processes can enhance the product’s reliability but may also increase the overall price. Buyers should consider the benefits of high QC standards when evaluating cost.

Logistics: Transportation costs can significantly affect the final price, especially for international shipments. Factors such as distance, shipping method, and customs duties must be accounted for, impacting the total cost for buyers in regions like the Middle East and Europe.

Margin: Manufacturers will typically add a markup to cover their profit margins. This margin can vary based on competition, brand reputation, and the perceived value of the product in different markets.

Several price influencers can affect sourcing decisions for the DeWalt 20V tire inflator:

Volume/MOQ: Minimum order quantities (MOQ) play a crucial role. Larger orders can lead to discounts, while smaller orders may incur higher per-unit costs. Buyers should evaluate their needs to find the right balance.

Specifications and Customization: Custom features may increase costs. Buyers should clearly define their requirements to avoid unnecessary expenses, especially when considering specific adaptations for regional markets.

Materials and Quality Certifications: The choice of materials and certifications (e.g., ISO, CE) can influence pricing. Buyers in Europe, for example, may prioritize products with specific certifications, potentially raising costs but ensuring compliance with local regulations.

Supplier Factors: The reliability and reputation of suppliers can impact pricing. Established suppliers may charge more due to brand value, while newer entrants may offer competitive pricing to gain market share.

Incoterms: Understanding Incoterms is essential for calculating total costs. These terms define responsibilities for shipping, insurance, and tariffs, which can significantly influence the final price.

International buyers can employ several strategies to enhance cost efficiency when sourcing the DeWalt 20V tire inflator:

Research and Benchmarking: Conduct thorough market research to compare prices from various suppliers. This information can serve as leverage during negotiations.

Volume Leverage: If possible, consolidate orders to increase volume. Suppliers may be more willing to negotiate favorable terms for larger purchases.

Focus on Total Cost of Ownership (TCO): Assess the long-term costs associated with the inflator, including maintenance and operational expenses. A higher upfront cost may be justified if the product offers superior durability and efficiency.

Be Open to Alternatives: If specific features are not critical, consider alternative models or suppliers that can provide similar performance at a lower cost.

Build Relationships: Establishing a strong relationship with suppliers can lead to better pricing and terms. Regular communication and feedback can foster trust and collaboration.

Understanding the intricate cost structure and pricing influencers of the DeWalt 20V tire inflator is essential for international B2B buyers. By leveraging negotiation strategies and focusing on total cost efficiency, buyers can secure favorable terms that align with their operational needs while ensuring quality and reliability.

When evaluating the best solutions for tire inflation, it’s essential for B2B buyers to consider various alternatives to the Dewalt 20V Tire Inflator. The Dewalt model is recognized for its performance and versatility, but understanding how it compares to other technologies can help buyers make informed decisions tailored to their specific operational needs.

| Comparison Aspect | Dewalt 20V Tire Inflator | Portable Electric Compressor | Manual Foot Pump |

|---|---|---|---|

| Performance | Max pressure of 160 PSI; digital gauge; auto shutoff | Varies; typically around 120 PSI; continuous operation | Limited pressure; requires physical effort |

| Cost | Moderate initial investment; additional batteries may be needed | Generally higher upfront cost | Low initial cost; no ongoing costs |

| Ease of Implementation | Cordless convenience; three power sources | Requires AC outlet; less portable | Highly portable; no setup required |

| Maintenance | Minimal; occasional hose replacement | Moderate; requires regular checks | Very low; manual checks only |

| Best Use Case | On-the-go inflation for vehicles and sports equipment | Workshop or garage settings; frequent use | Emergency use; limited applications |

1. Portable Electric Compressor

Portable electric compressors are often used in workshops and garages where access to power is readily available. They provide continuous air supply and are suitable for a variety of inflation tasks, including tires, sports equipment, and even air mattresses.

Pros: High performance with a steady air supply, faster inflation times, and often more powerful than smaller inflators.

Cons: Typically more expensive upfront, less portable due to size and need for AC power, and can be cumbersome for on-the-go applications.

2. Manual Foot Pump

Manual foot pumps are simple devices that require no electricity and are highly portable. They are commonly used for inflating bicycle tires and sports equipment in emergency situations or where power supply is unavailable.

Pros: Extremely low cost, lightweight, and easy to store. They can be used anywhere without needing a power source.

Cons: Limited inflation pressure, requires physical effort, and can be time-consuming for larger items like car tires.

Illustrative image related to dewalt 20v tire inflator

Choosing the right tire inflation solution depends on the specific needs of your business operations. For those requiring portability and versatility, the Dewalt 20V Tire Inflator stands out due to its multiple power sources and high-pressure capabilities. On the other hand, businesses with a fixed location and higher volume needs might benefit from a portable electric compressor. For occasional use in remote locations, a manual foot pump could suffice. By assessing performance requirements, budget constraints, and intended use cases, B2B buyers can select the most suitable tire inflation technology for their operations.

When considering the purchase of the DEWALT 20V MAX* Corded/Cordless Air Inflator, understanding its technical specifications is crucial for B2B buyers. Here are some key properties that highlight the inflator’s capabilities:

Max Pressure (160 PSI)

The inflator can achieve a maximum pressure of 160 PSI, making it suitable for various applications, including tire inflation for vehicles, bicycles, and sports equipment. For B2B buyers, this is vital as it ensures the tool can handle high-pressure requirements, enhancing its versatility across different sectors.

Power Sources (20V MAX Battery, 12V DC, 110V AC)

This inflator’s ability to operate on multiple power sources provides significant flexibility. Whether on a job site or in a remote location, users can choose the most convenient power option, which is particularly advantageous for businesses involved in mobile operations or those in regions with inconsistent power supply.

Digital Gauge with Auto Shutoff

The integrated digital gauge allows users to set the desired air pressure, while the auto shutoff feature ensures accurate inflation without the risk of over-inflation. This precision is essential for businesses that require consistent performance and safety, reducing the risk of damage to tires or inflatable equipment.

Weight (5.5 lbs) and Portability

Weighing only 5.5 lbs, the inflator is designed for portability, making it easy to transport between job sites or for personal use. For B2B buyers, this feature is crucial as it supports efficiency and ease of use in various environments, from workshops to outdoor settings.

Noise Level (77 dB)

Operating at a noise level of 77 dB, this inflator is relatively quiet compared to traditional air compressors. In industries where noise regulations are strict, such as in urban settings or indoor facilities, this property can be a significant selling point.

Understanding trade terminology is essential for B2B transactions. Here are some commonly used terms that buyers should be familiar with:

Illustrative image related to dewalt 20v tire inflator

OEM (Original Equipment Manufacturer)

This term refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of the DEWALT inflator, knowing if parts are OEM can ensure quality and compatibility, which is crucial for businesses relying on reliable equipment.

MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. For B2B buyers, understanding the MOQ helps in inventory planning and cost management, especially when sourcing tools like the DEWALT inflator for resale or rental.

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers asking for a price quote on specific products. This process is critical for B2B buyers to compare prices and terms across different suppliers to ensure they receive the best deal for products like the DEWALT inflator.

Incoterms (International Commercial Terms)

These are international rules that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms is essential for B2B transactions involving the DEWALT inflator, especially when shipping across borders, as they dictate who bears the risk and costs at various stages of shipping.

Warranty and Service Agreements

Understanding warranty terms, such as the 3-year limited warranty on the DEWALT inflator, is important for B2B buyers. These agreements provide assurance regarding product quality and after-sales support, which are critical factors in long-term purchasing decisions.

By familiarizing themselves with these technical properties and trade terms, B2B buyers can make informed decisions when considering the DEWALT 20V tire inflator, ensuring they meet their operational needs effectively.

The global market for tire inflators, particularly in the B2B sector, is rapidly evolving due to several key drivers. One significant factor is the increasing demand for portable and versatile inflators, spurred by the growth of outdoor and recreational activities across regions such as Africa, South America, the Middle East, and Europe. The Dewalt 20V tire inflator meets this demand with its multi-source power capability—operating on 20V batteries, 12V DC, or 110V AC—making it suitable for diverse applications from automotive maintenance to outdoor sports.

Emerging technologies are also reshaping the landscape of tire inflators. For instance, advancements in digital pressure gauges and automatic shutoff features enhance user experience by providing precise inflation and reducing the risk of over-inflation. B2B buyers are increasingly prioritizing these technological enhancements as they seek reliable and efficient solutions for their operational needs. Additionally, the trend towards e-commerce is transforming sourcing dynamics, allowing international buyers to access competitive pricing and diverse product offerings from suppliers worldwide.

Illustrative image related to dewalt 20v tire inflator

Another notable trend is the rising focus on product durability and maintenance. As businesses seek to minimize operational downtime, inflators like the Dewalt 20V, known for their robust construction and ease of use, are becoming preferred choices. This shift is particularly evident in regions where service networks may be limited, making reliability a top priority for B2B purchasers.

Sustainability is increasingly becoming a critical consideration for B2B buyers in the tire inflator market. With growing awareness of environmental impacts, companies are seeking products that not only perform well but are also produced responsibly. The Dewalt 20V tire inflator, designed with longevity and efficiency in mind, aligns with these sustainability goals.

Incorporating environmentally friendly materials and processes into the manufacturing of inflators is gaining traction. Buyers are looking for products that come with certifications indicating compliance with environmental standards, such as ISO 14001 or Energy Star ratings. These certifications assure purchasers that the product has been made with reduced environmental impact and energy consumption, making them more attractive in the procurement process.

Furthermore, ethical sourcing is becoming paramount as companies strive to ensure that their supply chains are transparent and socially responsible. This includes verifying the origins of materials used in the production of tools like the Dewalt 20V tire inflator. Engaging with suppliers who prioritize ethical labor practices not only enhances a company’s brand reputation but also fosters consumer loyalty, particularly in regions where ethical consumption is increasingly valued.

The Dewalt 20V tire inflator represents a significant evolution in the air inflator market, reflecting the brand’s commitment to innovation and user-centric design. Initially, tire inflators were limited to basic functionality and required manual operation. Over the years, advancements in battery technology and smart features have transformed inflators into versatile tools that cater to a wide range of applications.

With the introduction of the 20V MAX line, Dewalt has positioned itself as a leader in the portable inflator segment. The incorporation of high-pressure and high-volume modes, alongside user-friendly features like digital gauges and automatic shutoff, showcases the brand’s focus on enhancing operational efficiency and safety. This evolution not only meets the demands of modern consumers but also aligns with the broader trend of integrating technology into everyday tools, ensuring that the Dewalt 20V tire inflator remains a relevant choice for B2B buyers today.

How do I ensure the Dewalt 20V tire inflator meets my specific requirements?

To ensure the Dewalt 20V tire inflator meets your specific needs, assess your primary applications, such as tire inflation or deflating sports equipment. Review the inflator’s specifications, including its maximum pressure of 160 PSI, and features like the digital gauge and automatic shutoff for accuracy. Request product samples if possible, and consult with your supplier about any customization options available, such as branding or specific accessory kits tailored to your market.

What is the best power source for using the Dewalt 20V tire inflator in different regions?

The Dewalt 20V tire inflator is versatile, operating on a 20V MAX battery, 12V DC, or 110V AC power sources. In regions like Africa and South America, where power stability may vary, using a rechargeable battery is often the most reliable option. For stationary use, ensure your AC supply matches the inflator’s requirements. Always verify the compatibility of power sources with local electrical standards to avoid equipment damage.

What are the minimum order quantities (MOQs) for purchasing the Dewalt 20V tire inflator?

MOQs for the Dewalt 20V tire inflator can vary by supplier and region. Typically, B2B buyers should expect MOQs to range from 10 to 50 units depending on the distributor’s inventory policies and shipping logistics. It is advisable to discuss your specific needs with your supplier to negotiate favorable terms, especially if you are considering bulk purchases for resale or large-scale projects.

What are the payment terms commonly offered for international purchases of the Dewalt 20V tire inflator?

Payment terms for international purchases often include options like letters of credit, wire transfers, or payment on delivery. Many suppliers may offer net 30 or net 60 terms to established customers. It’s crucial to clarify terms upfront, including currency, payment method, and any additional fees related to currency exchange or international shipping, to avoid misunderstandings during the transaction.

How can I verify the quality assurance processes for the Dewalt 20V tire inflator?

To verify quality assurance processes, request documentation of the manufacturer’s compliance with international standards such as ISO certifications. Inquire about the testing procedures the inflator undergoes, including pressure tests and safety checks. Establishing a relationship with a reputable supplier that provides transparency regarding their QA processes can help ensure you receive a high-quality product that meets your expectations.

What logistics considerations should I keep in mind when importing the Dewalt 20V tire inflator?

When importing the Dewalt 20V tire inflator, consider logistics factors such as shipping methods, customs clearance, and potential tariffs. Discuss with your supplier the most efficient shipping routes and timelines. Also, ensure you are aware of any import regulations specific to your country, including documentation requirements and safety standards that the inflator must meet upon arrival.

Are there customization options available for the Dewalt 20V tire inflator for branding purposes?

Many suppliers offer customization options for the Dewalt 20V tire inflator, including branding with your company logo or specific accessory kits tailored to your market. Discuss your branding needs with your supplier to explore available options, and inquire about any associated costs and lead times for producing customized units. Customization can enhance brand visibility and appeal to local markets.

What warranty and support can I expect when purchasing the Dewalt 20V tire inflator?

The Dewalt 20V tire inflator typically comes with a three-year limited warranty, which covers defects in materials and workmanship. Additionally, buyers can often access one year of free service and a 90-day satisfaction guarantee. Ensure you understand the warranty terms and conditions, including how to claim service and support, as this can be crucial for maintaining your investment and ensuring ongoing customer satisfaction.

Domain: dewalt.com

Registered: 1997 (28 years)

Introduction: Product Name: 20V MAX* Corded/Cordless Air Inflator (Tool Only)\nPower Sources: 20V MAX* battery, 12V DC, or 110V AC\nMax Pressure: 160 PSI\nHorsepower: 0.16 hp\nNoise Level: 77.0 dB\nWeight: 5.5 lbs (88 oz)\nDimensions: 9.8 in (H) x 11.9 in (L) x 5.2 in (W)\nFeatures: High-pressure inflation mode with automatic shutoff, high-volume inflation and deflation modes, LED light for illumination, heavy-…

Domain: whitecap.com

Registered: 2004 (21 years)

Introduction: {“product_name”: “20V MAX Corded/Cordless Air Inflator”, “brand”: “DEWALT”, “model_number”: “324DCC020IB”, “power_source”: “Corded/Cordless”, “voltage”: “20V”, “features”: [“High-pressure inflation”, “Inflation and deflation capabilities”, “Built-in LED light”, “Digital gauge”, “Auto shut-off feature”], “applications”: [“Inflating tires”, “Inflating sports equipment”, “Inflating air mattresses”], …

In conclusion, the DEWALT 20V tire inflator stands out as a versatile and reliable tool for various applications, from automotive to recreational use. Its capability to operate on three power sources—20V MAX battery, 12V DC, or 110V AC—enhances its adaptability, making it an essential asset for professionals across diverse sectors. The inclusion of features like a digital gauge, auto-shutoff, and onboard LED light not only boosts user convenience but also ensures precision and safety during inflation tasks.

Illustrative image related to dewalt 20v tire inflator

For B2B buyers in Africa, South America, the Middle East, and Europe, strategic sourcing of this inflator can significantly enhance operational efficiency and customer satisfaction. By leveraging DEWALT’s reputation for quality and durability, businesses can secure a competitive edge in the marketplace.

As you consider procurement options, look beyond immediate costs and focus on the long-term value that high-quality tools like the DEWALT 20V tire inflator bring to your operations. Now is the time to invest in reliable tools that will support your business growth and customer needs. Explore your sourcing opportunities today and elevate your operations with DEWALT’s innovative solutions.

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.