In today’s dynamic global market, sourcing reliable and efficient DeWalt tire inflators presents a unique challenge for B2B buyers, particularly those operating in diverse regions such as Africa, South America, the Middle East, and Europe. The need for versatile, high-performance inflators that can cater to a variety of applications—from automotive maintenance to recreational activities—has never been more critical. This guide aims to equip international buyers with the insights necessary to navigate the complexities of the inflator market, detailing various types of DeWalt tire inflators, their specific applications, and essential criteria for supplier vetting.

Understanding the intricacies of product specifications, such as pressure capabilities and power sources, is paramount for making informed purchasing decisions. Additionally, this guide delves into cost considerations, warranty options, and after-sales support, ensuring buyers can evaluate potential suppliers comprehensively. By providing actionable insights and expert recommendations, this resource empowers businesses to select the right DeWalt tire inflators that meet their operational needs while also optimizing their procurement processes. Whether you are in Brazil looking for portable solutions or in Germany assessing supplier reliability, this guide serves as your roadmap to successful sourcing in the competitive inflator market.

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Corded/Cordless Air Inflator | Operates on 20V MAX battery, 12V DC, or 110V AC; digital gauge; auto shutoff | Tire inflation for vehicles, sports equipment, camping gear | Pros: Versatile power options; precise inflation. Cons: Battery and charger sold separately. |

| High-Volume Inflator | High-volume hose for rapid inflation; lightweight design | Inflating air mattresses, pool floats, and large equipment | Pros: Fast inflation; portable. Cons: Limited to high-volume applications. |

| Portable Tire Inflator | Compact design; high-pressure rubber hose; onboard storage | Automotive repair shops, roadside assistance, fleet management | Pros: Easy to transport; durable materials. Cons: Lower PSI limit compared to larger units. |

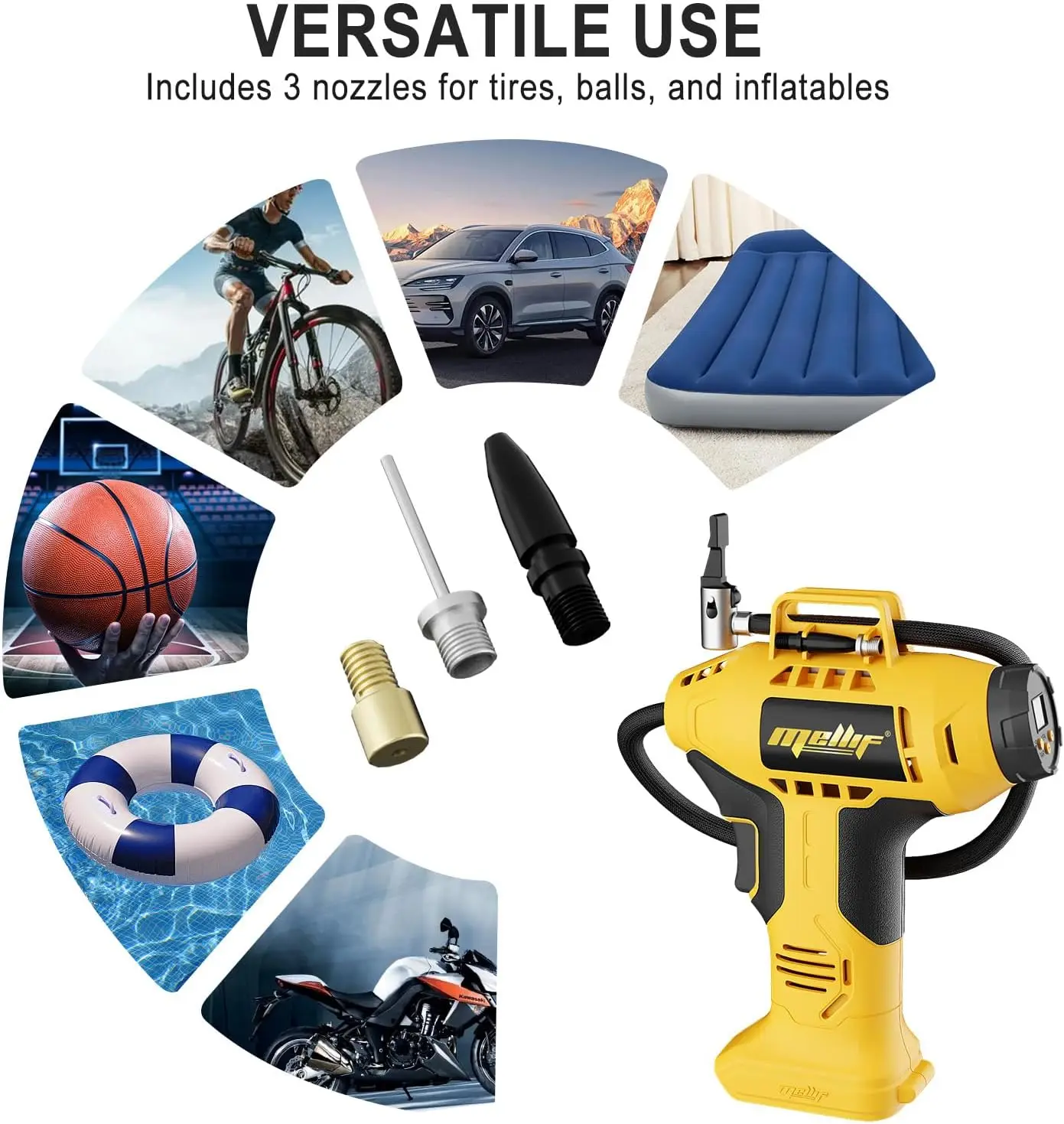

| Multi-Purpose Inflator | Includes various nozzle attachments; capable of deflation | Recreational activities, sports, and emergency situations | Pros: Versatile use; compact. Cons: May lack the power for heavy-duty tasks. |

| Heavy-Duty Inflator | Robust construction; higher PSI capacity; noise reduction features | Industrial applications, construction sites, off-road vehicles | Pros: Designed for frequent use; high performance. Cons: Heavier and less portable. |

The Corded/Cordless Air Inflator is designed for flexibility, allowing users to operate it via a 20V MAX battery, 12V DC, or 110V AC. It features a digital gauge for precise pressure settings and an automatic shutoff feature, enhancing user safety and convenience. This model is particularly suitable for businesses that require reliable inflation across various settings, from automotive shops to outdoor events. When purchasing, consider the need for additional batteries or chargers, which are sold separately, affecting total operational costs.

The High-Volume Inflator excels in rapid inflation tasks, making it ideal for inflating air mattresses, pool floats, and large inflatables quickly. Its lightweight design enhances portability, allowing it to be easily transported to job sites or events. B2B buyers should evaluate the inflator’s speed and ease of use against their specific needs, particularly in scenarios requiring quick setup and takedown of inflatable items.

Portable Tire Inflators are compact, durable tools designed for easy transport, making them perfect for automotive repair shops and roadside assistance services. Their high-pressure rubber hose ensures reliable inflation for vehicle tires and other applications. When considering this type, businesses should weigh the benefits of portability against the inflator’s lower PSI limits compared to larger models, which may affect performance in heavy-duty situations.

Multi-Purpose Inflators are equipped with various nozzle attachments, allowing them to inflate a wide range of items, from sports equipment to emergency inflatables. Their compact design makes them suitable for both recreational and professional use. B2B buyers should assess the inflator’s versatility against their specific requirements, particularly if they need a tool that can handle diverse applications without sacrificing performance.

Heavy-Duty Inflators are built for robust performance, featuring higher PSI capacities and noise reduction technology suitable for industrial environments and construction sites. This type is ideal for businesses that require frequent use and dependability in demanding conditions. Buyers should consider the trade-off between durability and portability, as these inflators tend to be heavier and less mobile, which may influence their operational efficiency in various settings.

| Industry/Sector | Specific Application of Dewalt Tire Inflators | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Services | Tire maintenance for vehicles | Enhanced efficiency and reduced downtime | Reliability, ease of use, and power source versatility |

| Construction | Inflating equipment and tools | Improved productivity on job sites | Portability, ruggedness, and compatibility with tools |

| Recreational Sports | Inflation of sports equipment (e.g., balls) | Quick setup and maintenance for sporting events | Lightweight design and onboard accessory storage |

| Outdoor and Camping Gear | Inflation of camping mattresses and inflatables | Increased customer satisfaction and convenience | Battery life, power options, and ease of transport |

| Logistics and Transport | Fleet tire management | Cost savings through effective tire maintenance | Max pressure capabilities and durability in diverse conditions |

In the automotive sector, Dewalt tire inflators are essential for tire maintenance. They facilitate quick inflation and deflation processes, allowing service providers to enhance efficiency and minimize vehicle downtime. With features like automatic shutoff and digital gauges, these inflators ensure accurate pressure levels, which is critical for vehicle safety. International buyers should prioritize reliability and ease of use, especially in regions with varying power supply conditions.

In construction, Dewalt tire inflators are used to maintain pneumatic tools and equipment, ensuring they operate optimally. Their portability allows workers to easily transport them across job sites, while their robust design withstands harsh environments. The versatility of being powered by battery, DC, or AC makes them suitable for diverse construction scenarios. Buyers in this sector must consider the inflator’s ruggedness and compatibility with existing tools.

Recreational sports organizations utilize Dewalt tire inflators to quickly inflate various sports equipment, such as soccer balls and basketballs. This efficiency not only saves time during events but also ensures that equipment is always ready for use. The lightweight design and onboard accessory storage enhance convenience for teams and event organizers. Buyers should focus on the inflator’s portability and ease of operation, especially for mobile sports setups.

For outdoor and camping gear, Dewalt tire inflators are invaluable for inflating mattresses and other inflatables. Their high-volume inflation capability allows users to set up camp quickly, improving overall customer satisfaction. The convenience of being able to power the inflator from various sources, including batteries, is particularly beneficial for outdoor enthusiasts. Sourcing considerations should include battery life and the inflator’s transportability for ease of use in remote locations.

In the logistics and transport industry, Dewalt tire inflators are crucial for fleet tire management. Regular tire maintenance helps in reducing fuel consumption and extending tire life, leading to significant cost savings. The high-pressure capabilities ensure that tires are maintained at optimal levels, which is essential for safety and efficiency. Buyers in this sector should prioritize durability and performance, particularly in regions with challenging road conditions.

The Problem: Many B2B buyers in industries reliant on vehicles or inflatable equipment face the challenge of inconsistent tire pressure when using inflators. This can lead to operational inefficiencies, increased downtime, and safety hazards. For instance, a logistics company in Brazil may find that their fleet’s tire pressures fluctuate, affecting fuel efficiency and increasing wear on tires. The frustration mounts when workers must frequently stop to manually check and adjust tire pressure, impacting delivery schedules.

The Solution: To overcome this issue, B2B buyers should consider Dewalt tire inflators equipped with an automatic shutoff feature and a digital pressure gauge. These inflators allow users to set the desired PSI, ensuring that tires are inflated to the correct pressure without the need for constant monitoring. When sourcing these inflators, buyers should prioritize models like the Dewalt 20V MAX Corded/Cordless Air Inflator, which offers high-pressure modes and accurate readings. Additionally, training staff on how to utilize the digital gauge effectively can further enhance operational efficiency. By implementing these practices, companies can significantly reduce downtime and maintain optimal vehicle performance.

The Problem: In the construction and outdoor recreation sectors, businesses often need to inflate a variety of items, such as vehicle tires, air mattresses, and sports equipment. B2B buyers may struggle to find an inflator that can handle these diverse requirements efficiently. For example, a construction firm in Germany might find that their existing inflator is too cumbersome for quick tire inflation yet lacks the power to inflate larger items like air mattresses rapidly.

The Solution: A versatile solution lies in selecting a Dewalt tire inflator that features multiple power sources and a range of attachments. The Dewalt 20V MAX inflator is designed to operate with a 20V MAX battery, 12V DC, or 110V AC, making it suitable for various environments, from job sites to outdoor events. Buyers should ensure that the inflator comes with essential accessories like a Presta valve adapter and different nozzle types to accommodate various inflatables. By investing in a multi-functional inflator, businesses can streamline their processes, saving time and resources while ensuring they are prepared for any inflation task.

The Problem: For B2B companies that operate in remote locations or on job sites, the portability of tools is crucial. However, many inflators are bulky or require cumbersome power sources, making them impractical for quick use. A South American construction company may find itself struggling to transport and deploy its inflator, leading to delays in project timelines and increased labor costs.

The Solution: Choosing a lightweight and portable inflator like the Dewalt 20V MAX is essential for these scenarios. Weighing just 5.5 lbs and featuring a compact design, this inflator is easy to transport and set up. Moreover, its ability to run on battery power means that it can be used in locations without direct access to electricity. B2B buyers should also consider investing in additional batteries to ensure continuous operation during lengthy projects. By focusing on portability and ease of use, companies can enhance their on-site performance and maintain productivity without unnecessary delays.

When selecting materials for Dewalt tire inflators, it is essential to consider their properties, advantages, and limitations. This analysis focuses on four common materials: high-pressure rubber, plastic composites, aluminum, and stainless steel. Each material plays a crucial role in the performance, durability, and overall suitability of the inflators for various applications.

High-pressure rubber is commonly used for hoses and seals in tire inflators. It boasts excellent flexibility and can withstand high-pressure conditions, making it ideal for applications requiring reliable air delivery. The temperature rating typically ranges from -40°F to 200°F, ensuring performance in diverse climates.

Pros: High-pressure rubber is durable and resistant to wear and tear, providing a long lifespan. It is also relatively low-cost, making it an economical choice for manufacturers.

Cons: While it offers good resistance to ozone and UV exposure, prolonged exposure to certain chemicals can degrade rubber. Additionally, it may require more complex manufacturing processes compared to simpler materials.

Illustrative image related to dewalt tire inflators

Impact on Application: High-pressure rubber is compatible with air and various gases, making it suitable for inflating tires, sports equipment, and recreational items.

Considerations for International Buyers: Buyers in regions like Africa and the Middle East should ensure compliance with local standards for rubber products, such as ASTM D2000, to guarantee quality and safety.

Plastic composites are increasingly used in the construction of inflator bodies and components. These materials are lightweight and resistant to corrosion, which is beneficial for portability and longevity.

Illustrative image related to dewalt tire inflators

Pros: The lightweight nature of plastic composites enhances the overall portability of inflators. They are also resistant to various chemicals, which is essential for maintaining performance over time.

Cons: While they are cost-effective, plastic composites may not provide the same level of durability as metals, particularly in high-stress applications. They can also be sensitive to extreme temperatures.

Impact on Application: Plastic composites can effectively house electronic components and digital displays, making them suitable for modern inflators with advanced features.

Considerations for International Buyers: Buyers should verify that plastic composites meet relevant standards such as ISO 9001 for quality management systems, ensuring product reliability.

Aluminum is often used in the construction of inflator frames and structural components due to its strength-to-weight ratio and resistance to corrosion.

Pros: Aluminum is lightweight yet robust, providing excellent durability without adding significant weight. It also has good thermal conductivity, which can be advantageous in dissipating heat generated during operation.

Cons: While aluminum is generally cost-effective, it can be more expensive than plastic options. Additionally, it may require surface treatments to enhance corrosion resistance, adding to manufacturing complexity.

Impact on Application: Aluminum is suitable for high-performance applications, including heavy-duty tire inflators used in commercial settings.

Considerations for International Buyers: Compliance with standards such as DIN EN 573 for aluminum alloys is critical for ensuring material quality and performance in diverse markets.

Illustrative image related to dewalt tire inflators

Stainless steel is primarily used in components that require exceptional strength and corrosion resistance, such as fittings and valves.

Pros: Stainless steel is highly durable and resistant to rust and corrosion, making it ideal for use in various environments, including humid or coastal areas. Its strength ensures long-term reliability.

Cons: The primary drawback is the higher cost compared to other materials. Additionally, stainless steel can be heavier, which may affect the portability of inflators.

Impact on Application: Stainless steel is suitable for high-pressure applications where reliability is paramount, ensuring safe and efficient inflation.

Considerations for International Buyers: Buyers should ensure compliance with standards such as ASTM A240 for stainless steel products to guarantee quality and performance.

Illustrative image related to dewalt tire inflators

| Material | Typical Use Case for dewalt tire inflators | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| High-Pressure Rubber | Hoses and seals | Durable and flexible | Chemical sensitivity | Low |

| Plastic Composites | Body and components | Lightweight and corrosion-resistant | Less durable under stress | Med |

| Aluminum | Structural components | Strong and lightweight | Higher cost and requires surface treatment | Med |

| Stainless Steel | Fittings and valves | Exceptional strength and corrosion resistance | Higher cost and heavier | High |

This analysis provides B2B buyers with actionable insights into material selection for Dewalt tire inflators, ensuring informed purchasing decisions that align with performance requirements and regional standards.

The manufacturing process of Dewalt tire inflators involves several key stages that ensure product quality and performance. Understanding these stages helps B2B buyers appreciate the complexities involved in producing reliable inflators suitable for various applications.

Material Preparation

The first stage of manufacturing involves sourcing high-quality materials. Dewalt prioritizes durable components such as high-pressure rubber hoses, robust plastic casings, and high-performance motors. Materials are subjected to rigorous quality checks to ensure they meet the necessary specifications before being moved to the next stage.

Forming

In this phase, the materials are shaped into components. Techniques such as injection molding are commonly used for plastic parts, while metal components may be produced through stamping or machining. The forming process is critical as it defines the physical attributes of each part, ensuring they fit together accurately in the assembly stage.

Assembly

During assembly, the various components are brought together. This process often employs automated machinery alongside skilled labor to ensure precision. Key features, such as the threaded chuck and digital gauge, are integrated, and multiple quality checkpoints are established throughout the assembly line to catch any defects early.

Finishing

The final manufacturing stage involves quality finishing touches, such as painting, labeling, and packaging. This stage not only enhances the aesthetics of the product but also ensures that all safety and compliance information is clearly displayed. A thorough inspection occurs before the inflators are packaged for distribution.

Quality assurance (QA) is a critical aspect of the manufacturing process for Dewalt tire inflators. The company adheres to international quality standards to guarantee that each inflator meets customer expectations.

Compliance with International Standards

Dewalt’s manufacturing processes align with ISO 9001, an internationally recognized standard for quality management systems. This certification demonstrates that Dewalt maintains consistent quality in its products and processes. Furthermore, industry-specific certifications such as CE (European Conformity) and API (American Petroleum Institute) ensure that the inflators meet regional safety and performance requirements.

Quality Control Checkpoints

The QA process includes several checkpoints throughout the manufacturing stages:

– Incoming Quality Control (IQC): Inspecting raw materials and components upon arrival to ensure they meet specified standards.

– In-Process Quality Control (IPQC): Ongoing inspections during the manufacturing process to catch defects before they escalate.

– Final Quality Control (FQC): A comprehensive examination of the finished product to verify its functionality and safety before it is shipped.

Common Testing Methods

Dewalt employs various testing methods to validate the performance and safety of tire inflators. These include:

– Pressure Testing: Ensuring that the inflator can handle its maximum pressure rating without failure.

– Durability Testing: Subjecting the inflators to conditions that simulate real-world use, including temperature extremes and physical stress.

– Electrical Safety Testing: Verifying that electrical components meet safety standards to prevent hazards.

B2B buyers, particularly in diverse markets like Africa, South America, the Middle East, and Europe, should implement strategies to verify the quality control measures of suppliers.

Supplier Audits

Conducting regular audits of suppliers is essential. These can include on-site inspections of manufacturing facilities to assess adherence to quality standards and practices. Buyers should look for evidence of ISO certifications and other relevant compliance documentation.

Requesting Quality Reports

Suppliers should provide detailed quality assurance reports, including results from IQC, IPQC, and FQC stages. These documents should outline any issues encountered during production and how they were resolved.

Third-Party Inspections

Engaging third-party inspection services can add an extra layer of assurance. These independent entities can evaluate the manufacturing processes and products to ensure they meet specified quality and safety standards.

Understanding Regional Compliance Nuances

B2B buyers must be aware of the specific regulatory requirements in their regions. For instance, while CE certification is crucial for European markets, other regions may have different compliance standards. This understanding helps buyers ensure that products are not only safe but also legally marketable in their respective countries.

When sourcing Dewalt tire inflators, international buyers should keep several considerations in mind:

Logistics and Supply Chain Management

Understanding the logistics involved in transporting inflators from the manufacturing site to the end market is crucial. Buyers should consider shipping times, customs regulations, and potential tariffs that could impact overall costs.

After-Sales Support and Warranty

Dewalt offers a three-year limited warranty on its inflators, along with one year of free service and a 90-day satisfaction guarantee. Buyers should evaluate the availability of after-sales support in their regions, as this can significantly affect customer satisfaction.

Cultural and Market Differences

Different regions may have varying preferences for product features, packaging, and marketing strategies. B2B buyers must adapt their approaches based on local consumer behavior and market conditions to optimize sales.

By understanding the manufacturing processes and quality assurance protocols behind Dewalt tire inflators, B2B buyers can make informed purchasing decisions that align with their operational requirements and customer expectations.

To assist international B2B buyers in sourcing DEWALT tire inflators effectively, this guide provides a practical checklist. By following these steps, you can ensure a thorough evaluation of your options, leading to informed purchasing decisions.

Identifying your specific requirements is crucial before approaching suppliers. Consider factors such as the inflator’s maximum pressure (e.g., 160 PSI), power sources (battery, DC, or AC), and intended applications (tires, sporting equipment, etc.). This clarity will help you communicate your needs effectively to suppliers and avoid unnecessary purchases.

Illustrative image related to dewalt tire inflators

Conduct comprehensive research to identify reputable suppliers of DEWALT tire inflators. Look for companies with a strong market presence, positive customer reviews, and a track record of reliability. Utilize trade directories, industry associations, and online platforms to compile a list of potential suppliers.

Before committing to a supplier, verify that they hold relevant certifications and comply with industry standards. This includes safety certifications and quality assurance programs that demonstrate the supplier’s commitment to producing reliable products. Certifications can vary by region, so ensure they meet the regulations applicable to your market.

Requesting product samples allows you to assess the quality and functionality of the inflators firsthand. This step is essential, as it provides an opportunity to evaluate features such as the digital gauge, auto-shutoff capabilities, and overall build quality. Testing the inflator in real-world scenarios can help confirm its suitability for your needs.

Understanding the warranty and service terms is vital for long-term satisfaction. Review the warranty period (DEWALT typically offers a 3-year limited warranty) and what it covers. Inquire about after-sales support and service options to ensure you have assistance if issues arise after purchase.

Illustrative image related to dewalt tire inflators

Once you have narrowed down your choices, compare pricing among the shortlisted suppliers. Look beyond the sticker price; consider payment terms, bulk discounts, and shipping costs. Negotiating favorable terms can significantly impact your overall budget and cash flow.

After selecting a supplier, finalize your order with clear communication regarding specifications, quantities, and delivery timelines. Discuss logistics to ensure timely delivery and confirm that all products meet your quality standards upon arrival. Establishing a reliable logistics plan can mitigate potential delays and ensure a smooth procurement process.

By following this checklist, B2B buyers can navigate the sourcing of DEWALT tire inflators with confidence, ensuring they make informed decisions that align with their operational needs and budget constraints.

When sourcing DeWalt tire inflators, understanding the cost structure is crucial for B2B buyers. The main cost components include:

Illustrative image related to dewalt tire inflators

Materials: The quality of materials used significantly affects the cost. DeWalt employs durable rubber hoses and high-quality electronic components, contributing to higher initial costs but ensuring longevity and reliability.

Labor: Labor costs vary by region. In countries with higher wage standards, such as Germany, labor can be a significant portion of manufacturing costs. Conversely, regions with lower labor costs may provide more competitive pricing.

Manufacturing Overhead: This includes expenses related to utilities, facilities, and equipment maintenance. Overhead costs can fluctuate based on geographic location and factory efficiency.

Tooling: The investment in specialized tools for manufacturing specific inflator models can increase costs, especially if the production volume is low.

Quality Control (QC): Ensuring that each inflator meets DeWalt’s stringent quality standards incurs additional costs. This is particularly important for B2B buyers who require reliable performance and safety certifications.

Logistics: Shipping costs, which can vary based on destination and shipping method, are a vital component. International buyers should consider additional fees such as customs duties and import taxes.

Margin: Suppliers typically add a margin to cover their costs and profit, which can vary based on market demand and competition.

Several factors can influence the pricing of DeWalt tire inflators:

Volume and Minimum Order Quantity (MOQ): Larger orders often yield better pricing. Suppliers may offer discounts for bulk purchases, which is beneficial for businesses looking to stock inventory.

Specifications and Customization: Customized inflators or specific configurations can lead to higher prices. Buyers should evaluate whether standard models meet their needs to avoid unnecessary costs.

Materials and Quality Certifications: Higher-quality materials and certifications can raise costs but are essential for ensuring product reliability. Buyers should weigh the benefits of investing in premium products against their budget constraints.

Supplier Factors: The reputation and reliability of the supplier can impact pricing. Established suppliers may charge more due to their quality assurance processes and customer support.

Incoterms: Understanding Incoterms (International Commercial Terms) is crucial for international transactions. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can significantly affect overall costs.

To maximize value when sourcing DeWalt tire inflators, consider the following tips:

Negotiation Tactics: Approach negotiations with a clear understanding of your budget and desired specifications. Leverage multiple quotes to foster competitive pricing among suppliers.

Cost-Efficiency Strategies: Evaluate the Total Cost of Ownership (TCO), which includes purchase price, maintenance, and operational costs. Investing in higher-quality inflators may reduce long-term expenses due to lower failure rates.

Understanding Pricing Nuances for International Buyers: Buyers from Africa, South America, the Middle East, and Europe should be aware of currency fluctuations and local economic conditions that can impact pricing. Establishing clear payment terms can help mitigate risks associated with exchange rates.

Long-term Relationships: Building a relationship with suppliers can lead to better pricing and terms over time. Regular communication can also facilitate smoother transactions and support.

While pricing can vary significantly based on the factors mentioned above, it is essential to conduct thorough market research to obtain accurate quotes tailored to specific needs and circumstances. Always consult with multiple suppliers to ensure competitive pricing and quality assurance.

When considering tire inflation solutions, it’s essential for B2B buyers to evaluate various alternatives to Dewalt tire inflators. Understanding the strengths and weaknesses of each option can assist in making an informed purchasing decision that aligns with operational needs and budget constraints.

| Comparison Aspect | Dewalt Tire Inflators | Portable Air Compressors | Manual Foot Pumps |

|---|---|---|---|

| Performance | High-pressure (up to 160 PSI), versatile for various applications | Moderate pressure, suitable for tires and inflatables | Limited pressure, best for small tasks |

| Cost | Moderate price point, typically $100-$150 | Ranges from $50 to $300 depending on capacity | Low-cost, usually under $50 |

| Ease of Implementation | Simple operation with digital gauge and auto shutoff | Requires basic setup and power source | Requires physical effort and skill |

| Maintenance | Minimal; regular checks for wear | Moderate; oil changes and cleaning needed | Low; mainly mechanical upkeep |

| Best Use Case | Ideal for professional settings and frequent use | Good for home use or light commercial tasks | Best for occasional use or emergencies |

Portable air compressors serve as a viable alternative to Dewalt tire inflators. These devices can inflate tires and other objects, but they generally operate at lower pressure levels compared to Dewalt models. While they are more affordable and versatile for various applications, they require a power source, which may limit their usability in remote locations. Maintenance can also be more intensive due to the need for regular oil changes and cleaning. However, for businesses that require a multi-purpose air supply, portable compressors can be a cost-effective solution.

Manual foot pumps represent a low-cost alternative for tire inflation. They are lightweight, portable, and require no power, making them suitable for emergencies or occasional use. However, their performance is significantly limited, producing less pressure and requiring physical effort, which may not be feasible for larger tasks. While they incur minimal maintenance costs, their practicality diminishes for frequent or professional applications where efficiency and speed are paramount.

Illustrative image related to dewalt tire inflators

In conclusion, selecting the right tire inflation solution depends on various factors, including performance needs, budget constraints, and ease of use. Dewalt tire inflators excel in high-pressure applications and are ideal for professional settings where efficiency is critical. In contrast, portable air compressors offer flexibility for various uses, albeit with more maintenance requirements. Manual foot pumps, while economical, are best reserved for occasional use. B2B buyers should assess their specific operational requirements and consider the long-term implications of their investment to ensure they choose a solution that best fits their needs.

When evaluating DeWalt tire inflators, it’s crucial for B2B buyers to understand several key technical properties that influence performance and usability in various applications. Below are some essential specifications:

Maximum Pressure (PSI)

The maximum pressure rating, typically measured in pounds per square inch (PSI), indicates the highest level of air pressure the inflator can deliver. DeWalt inflators, such as the DCC020IB, can achieve up to 160 PSI. This is vital for inflating high-pressure tires efficiently, ensuring that equipment can handle diverse inflation tasks without overloading.

Power Sources

DeWalt inflators are designed to operate on multiple power sources: a 20V MAX battery, a 12V DC outlet, or a standard 110V AC power supply. This versatility allows for use in various settings, from job sites to remote locations, making it a valuable tool for international buyers who may face varying power availability.

Noise Level (dB)

The noise level, measured in decibels (dB), is an important consideration, especially in urban environments or residential areas. The DCC020IB has a noise level of 77 dB, which is relatively moderate for power tools. Understanding noise levels can help businesses comply with local regulations and ensure worker comfort.

Weight and Portability

Weighing approximately 5.5 lbs, the DeWalt inflator is designed for portability. Lightweight tools are easier to transport and maneuver, making them ideal for both professional and recreational use. This feature is particularly important for B2B buyers in industries that require mobility, such as automotive services or outdoor event management.

Durability and Material Grade

The construction materials, including a high-pressure rubber hose and heavy-duty rubber feet, ensure durability and stability during operation. For B2B buyers, investing in tools with high material grades translates to lower maintenance costs and longer product lifespan, enhancing overall return on investment.

Digital Gauge and Auto-Shutoff Feature

A digital gauge simplifies the process of setting and monitoring desired air pressure, while the auto-shutoff function prevents over-inflation. These features enhance accuracy and ease of use, making the inflator suitable for both inexperienced users and professionals.

Familiarity with industry-specific jargon is essential for effective communication and negotiation in the B2B landscape. Here are some common trade terms relevant to DeWalt tire inflators:

OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts and equipment that may be marketed by another manufacturer. Understanding OEM relationships can help buyers identify potential suppliers and ensure they are sourcing high-quality components that meet industry standards.

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. B2B buyers should be aware of MOQs to assess whether a supplier’s offerings align with their purchasing needs and budget constraints.

RFQ (Request for Quotation)

An RFQ is a document that a buyer sends to suppliers to request price quotes for specific products or services. This process is crucial for B2B transactions, allowing buyers to compare costs and make informed purchasing decisions.

Incoterms (International Commercial Terms)

Incoterms are a set of international trade terms that define the responsibilities of buyers and sellers in a transaction. Familiarity with these terms can help buyers understand shipping costs, risks, and responsibilities, which is essential for international procurement.

Lead Time

Lead time refers to the amount of time it takes from placing an order to receiving the product. Understanding lead times can help businesses plan inventory and manage supply chain logistics effectively, ensuring that they meet customer demand without overstocking.

Warranty

A warranty is a guarantee provided by the manufacturer regarding the quality and performance of a product. DeWalt offers a 3-year limited warranty on their inflators, which provides peace of mind for B2B buyers regarding product reliability and service options.

Understanding these specifications and terms can empower B2B buyers to make informed decisions, ensuring they select the right DeWalt tire inflators for their operational needs.

The global market for Dewalt tire inflators is witnessing significant growth, driven by the increasing demand for portable and efficient inflation solutions across various sectors. Key drivers include a rise in vehicle ownership in emerging markets like Africa and South America, and a growing preference for DIY projects among consumers. Furthermore, the shift towards electric vehicles (EVs) is creating a new customer base for tire inflators, as EVs require specialized inflation tools that can handle specific tire pressures and types. The integration of smart technology into inflators, such as digital pressure gauges and automatic shutoff features, is another trend enhancing user convenience and safety.

In terms of sourcing trends, international B2B buyers are increasingly looking for versatile inflators that can operate on multiple power sources—such as Dewalt’s 20V MAX battery, 12V DC, and 110V AC. This adaptability is particularly appealing in regions with varied power availability. Moreover, the trend towards online procurement is reshaping how buyers source equipment, with many opting for e-commerce platforms that provide comprehensive product comparisons and customer reviews. This shift necessitates that suppliers enhance their digital presence and logistics capabilities to meet the demands of international buyers.

Illustrative image related to dewalt tire inflators

As sustainability becomes a focal point for businesses worldwide, B2B buyers are increasingly prioritizing products that are both environmentally friendly and ethically sourced. In the tire inflators sector, this means looking for manufacturers who utilize recyclable materials and sustainable manufacturing processes. Dewalt has made strides in this area by incorporating eco-friendly practices into their supply chain and product design, which can significantly influence purchasing decisions.

The importance of ethical sourcing cannot be overstated. Buyers from regions such as Europe, which have stringent regulations on environmental impact, are particularly vigilant about sourcing products from companies that demonstrate a commitment to ethical labor practices and environmental stewardship. Certifications such as ISO 14001 (Environmental Management) and adherence to global ethical standards can serve as valuable indicators for buyers assessing potential suppliers. Ensuring that products, including tire inflators, are made with minimal environmental impact not only enhances brand reputation but also aligns with the growing consumer preference for sustainable products.

The evolution of Dewalt tire inflators can be traced back to the brand’s commitment to innovation and quality. Originally focused on traditional air compressors, Dewalt expanded its product line to include portable tire inflators that meet the diverse needs of both professional and DIY users. The introduction of the 20V MAX Corded/Cordless Air Inflator exemplifies this evolution, offering versatility with multiple power sources and advanced features such as auto shutoff and digital pressure gauges.

Illustrative image related to dewalt tire inflators

This transition reflects broader market trends, where convenience and efficiency are increasingly prioritized. The integration of smart technology not only improves user experience but also positions Dewalt as a leader in the tire inflator sector. As global demand for efficient and portable inflation solutions continues to rise, Dewalt’s ongoing innovations will likely play a critical role in shaping the future of this market, catering to an expanding international B2B audience.

How do I choose the right DeWalt tire inflator for my business needs?

When selecting a DeWalt tire inflator, consider the specific applications you need it for, such as tire inflation, sports equipment, or inflatables. Evaluate the inflator’s power sources—whether it operates on a 20V MAX battery, 12V DC, or 110V AC—to ensure versatility for different environments. Look for features like a digital gauge for precise pressure settings, auto-shutoff for accuracy, and portability, which can enhance user experience on job sites or in remote locations.

What are the benefits of using DeWalt tire inflators in a commercial setting?

DeWalt tire inflators are designed for durability and efficiency, making them ideal for commercial use. They offer high-pressure inflation up to 160 PSI and have modes for both high-volume inflation and deflation. The built-in LED light provides visibility in low-light conditions, and the heavy-duty rubber feet prevent movement during operation. These features combined lead to faster, more reliable performance, reducing downtime and enhancing productivity.

What should I consider when importing DeWalt tire inflators internationally?

When importing DeWalt tire inflators, consider the regulatory requirements and import tariffs specific to your country. Ensure compliance with local safety standards and certifications to avoid issues upon arrival. Additionally, evaluate logistics options, including shipping times and costs, to determine the most efficient supply chain strategy. Establish a reliable customs broker to facilitate the process and minimize delays.

How can I verify the credibility of a DeWalt inflator supplier?

To vet a DeWalt inflator supplier, start by reviewing their business history, customer testimonials, and industry reputation. Request references from previous clients and check for certifications that validate their quality standards. Engage in direct communication to assess their responsiveness and willingness to address your concerns. Additionally, consider visiting their facility if possible, or arranging a virtual tour to gauge operational capabilities.

What are the typical minimum order quantities (MOQs) for DeWalt tire inflators?

Minimum order quantities (MOQs) for DeWalt tire inflators can vary based on the supplier and region. Generally, MOQs may range from 10 to 50 units, depending on the distributor’s policies. It’s important to discuss MOQs with your supplier to negotiate terms that align with your purchasing strategy, especially if you’re looking to test the market or introduce the product in smaller quantities initially.

What payment terms can I expect when purchasing DeWalt tire inflators?

Payment terms for purchasing DeWalt tire inflators typically range from upfront payments to net 30 or net 60 terms, depending on the supplier’s policies and your negotiation leverage. Some suppliers may offer discounts for early payments or bulk orders. Always clarify payment methods accepted, such as wire transfers, credit cards, or letters of credit, to ensure a smooth transaction process.

How do I ensure quality assurance for imported DeWalt inflators?

To ensure quality assurance for imported DeWalt inflators, establish clear quality control protocols with your supplier before shipment. This may include pre-shipment inspections and adherence to specific quality standards or certifications. Request samples for testing prior to larger orders and maintain open communication with your supplier regarding any quality issues or concerns that arise during the import process.

What logistics considerations should I keep in mind when sourcing DeWalt tire inflators?

When sourcing DeWalt tire inflators, consider logistics factors such as shipping methods, lead times, and potential customs delays. Evaluate freight options, including air and sea transport, to find the most cost-effective solution. Additionally, factor in warehousing needs and distribution channels in your region to ensure timely delivery to your customers. Collaborating with a logistics partner can help streamline the process and mitigate risks associated with international shipping.

In conclusion, the strategic sourcing of DeWalt tire inflators presents a compelling opportunity for B2B buyers across diverse regions, including Africa, South America, the Middle East, and Europe. The versatility of the 20V MAX* Corded/Cordless Air Inflator, with its capability to operate on multiple power sources, positions it as an essential tool for various applications—from automotive needs to recreational activities. Emphasizing quality, reliability, and ease of use, DeWalt inflators not only enhance operational efficiency but also ensure customer satisfaction through features like automatic shutoff and digital pressure gauges.

For international buyers, sourcing these inflators strategically means aligning with a brand renowned for its durability and performance, which can significantly contribute to operational effectiveness in your markets. As global demand for reliable inflators continues to rise, investing in DeWalt products can provide a competitive edge.

As you consider your sourcing decisions, engage with local distributors or explore direct purchasing options to leverage bulk pricing and favorable terms. Take proactive steps today to enhance your product offerings with DeWalt’s superior inflators, ensuring your business is well-equipped to meet the evolving needs of your customers.

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.