In an increasingly interconnected world, sourcing the right tire adapter for air compressors presents a significant challenge for international B2B buyers. Whether in Africa, South America, the Middle East, or Europe, businesses face the daunting task of ensuring compatibility, efficiency, and cost-effectiveness in their equipment. This guide serves as a comprehensive resource, addressing the various types of tire adapters available, their applications across different industries, and the critical factors to consider when vetting suppliers.

Understanding the nuances of tire adapter specifications, such as threading types and material durability, can dramatically influence operational efficiency and safety. This guide empowers buyers by providing actionable insights into market trends, pricing strategies, and supplier reliability, ensuring informed purchasing decisions. By equipping decision-makers with essential knowledge about the landscape of tire adapters for air compressors, we aim to facilitate smoother transactions and foster long-term partnerships.

Buyers will find a wealth of information tailored to their unique needs, whether they’re seeking high-performance adapters for automotive applications or robust solutions for industrial use. With a focus on quality and value, this guide is designed to support B2B buyers in navigating the complexities of the global market, ultimately enhancing their procurement strategies and operational success.

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| 1. Schrader Valve Adapter | Connects air compressor to standard Schrader valves; often 1/4 NPT male fitting. | Automotive service, tire shops | Pros: Universal compatibility; easy installation. Cons: Limited to Schrader valve systems. |

| 2. Lock-On Air Chuck Adapter | Provides a secure, lock-on connection to the tire valve; prevents air loss. | Fleet maintenance, construction sites | Pros: Reduces air leakage; faster inflation. Cons: May require specific inflator models. |

| 3. Twist-On Adapter | Features a twist-on design for secure attachment; suitable for various inflators. | Retail automotive, DIY workshops | Pros: Versatile; simple to use. Cons: Slower than lock-on options. |

| 4. Quick-Connect Adapter | Allows for rapid attachment and detachment from inflators; often used in high-volume settings. | Manufacturing, logistics | Pros: Saves time during inflation; easy to operate. Cons: May be incompatible with older models. |

| 5. Extension Hose Adapter | Extends reach for inflating hard-to-access tires; often includes multiple fittings. | Roadside assistance, emergency services | Pros: Enhances versatility; useful for various vehicles. Cons: Bulkier; may require additional storage space. |

The Schrader Valve Adapter is a fundamental component for connecting air compressors to vehicles equipped with Schrader valves, commonly found in most cars and bicycles. Typically featuring a 1/4 NPT male fitting, this adapter is straightforward to install and widely compatible. B2B buyers in automotive service and tire shops benefit from its universal nature, allowing for efficient tire inflation across different vehicle types. However, its limitation to Schrader systems may require additional adapters for other valve types, which could complicate operations.

The Lock-On Air Chuck Adapter is designed to create a secure connection to the tire valve, significantly reducing air loss during inflation. This feature is particularly advantageous for fleet maintenance and construction sites, where time efficiency is crucial. The secure fit ensures faster inflation and minimizes the risk of accidental disconnections. However, B2B buyers should consider compatibility with specific inflator models, as not all inflators may support this type of adapter.

Twist-On Adapters provide a simple and versatile solution for connecting inflators to tire valves. Their design allows for easy attachment to various inflators, making them a popular choice in retail automotive and DIY workshops. While they are user-friendly and adaptable, the twist-on mechanism may result in slower inflation compared to lock-on alternatives, which could be a consideration for high-volume operations.

Quick-Connect Adapters are engineered for rapid attachment and detachment, making them ideal for high-volume settings such as manufacturing and logistics. Their ease of use can significantly enhance workflow efficiency, as workers can quickly switch between tasks without losing time. However, B2B buyers should ensure compatibility with existing equipment, as older models may not support this modern connection type.

Extension Hose Adapters are invaluable for inflating tires in hard-to-reach areas, making them essential for roadside assistance and emergency services. These adapters often come with multiple fittings, allowing for greater versatility across various vehicles. While they enhance operational flexibility, their bulkier design may require additional storage space, which is a consideration for businesses with limited storage capacity.

| Industry/Sector | Specific Application of tire adapter for air compressor | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Repair | Tire inflation and maintenance for vehicles | Reduces downtime and increases efficiency in service | Quality of materials, compatibility with various inflators |

| Manufacturing | Inflation of pneumatic tools and machinery | Enhances operational efficiency and tool performance | Durability, pressure ratings, and international shipping options |

| Construction | Tire inflation for heavy machinery and vehicles | Ensures equipment reliability and safety on-site | Adaptability to different tire sizes and valve types |

| Transportation & Logistics | Tire maintenance for fleet vehicles | Minimizes vehicle downtime and maintenance costs | Bulk purchasing options and support for diverse valve types |

| Sports & Recreation | Inflation of sports equipment (e.g., balls, bikes) | Improves customer satisfaction through quick service | Versatility for various inflators and ease of use |

In the automotive repair industry, tire adapters for air compressors play a vital role in efficiently inflating and maintaining vehicle tires. These adapters enable seamless connections between air compressors and various tire valve types, allowing technicians to quickly inflate tires, check pressure, and perform maintenance tasks. The primary problems solved include preventing tire damage due to under-inflation and reducing the time spent on tire servicing. Buyers in this sector should prioritize compatibility with a wide range of inflators and vehicles, ensuring that the adapters can accommodate different valve types commonly found in the market.

Manufacturers utilize tire adapters to inflate pneumatic tools and machinery, ensuring that all equipment operates at optimal pressure levels. This is crucial for maintaining productivity and preventing equipment failure, which can lead to costly downtime. The adapters solve issues related to inconsistent pressure, which can impair tool performance. For B2B buyers in this sector, sourcing high-quality, durable adapters that can withstand industrial environments is essential. Additionally, buyers should consider suppliers that offer products meeting international standards to facilitate global operations.

In the construction industry, tire adapters are essential for inflating tires on heavy machinery and vehicles. Ensuring that construction equipment is properly inflated enhances reliability and safety on job sites, where equipment failure can lead to significant delays and increased costs. The adapters facilitate quick and easy inflation, addressing issues of equipment readiness. Buyers should seek adapters that are versatile enough to fit various tire sizes and valve types, as construction projects often involve a diverse range of machinery.

Transportation and logistics companies rely on tire adapters for efficient tire maintenance across their fleet vehicles. Properly inflated tires improve fuel efficiency and reduce wear, which minimizes overall maintenance costs. The adapters help streamline the process of checking and adjusting tire pressure, directly impacting vehicle availability and operational efficiency. For international B2B buyers, bulk purchasing options and the ability to source adapters compatible with different valve types are critical considerations to ensure smooth logistics operations.

In the sports and recreation sector, tire adapters are crucial for inflating various types of sports equipment, including balls and bicycles. Quick inflation capabilities enhance customer satisfaction and streamline service at sports facilities and retail locations. These adapters solve problems related to slow or inefficient inflation methods, allowing staff to provide timely support for athletes and customers. Buyers in this industry should focus on sourcing versatile adapters that can easily connect to different inflators, ensuring a seamless experience for both staff and users.

The Problem: B2B buyers frequently encounter issues with air compressor tire adapters that do not create a secure seal with the valve stems. This problem can lead to air leaks during inflation, wasting time and resources, and ultimately causing frustration among technicians. In environments where time is critical, such as automotive repair shops or tire service centers, a poorly fitted adapter can delay operations, impacting service efficiency and customer satisfaction.

The Solution: To mitigate this issue, buyers should prioritize sourcing high-quality tire adapters that are specifically designed to fit various valve types. Look for adapters made from durable materials such as aluminum or heavy-duty rubber that offer a tight fit and prevent leaks. When specifying products, ensure they have been tested for compatibility with the most common valve types in your region. Additionally, training staff on the proper technique for connecting and disconnecting adapters can significantly reduce the risk of leaks. Regularly inspect and maintain the adapters to ensure they remain in good working condition, which can help prolong their lifespan and reliability.

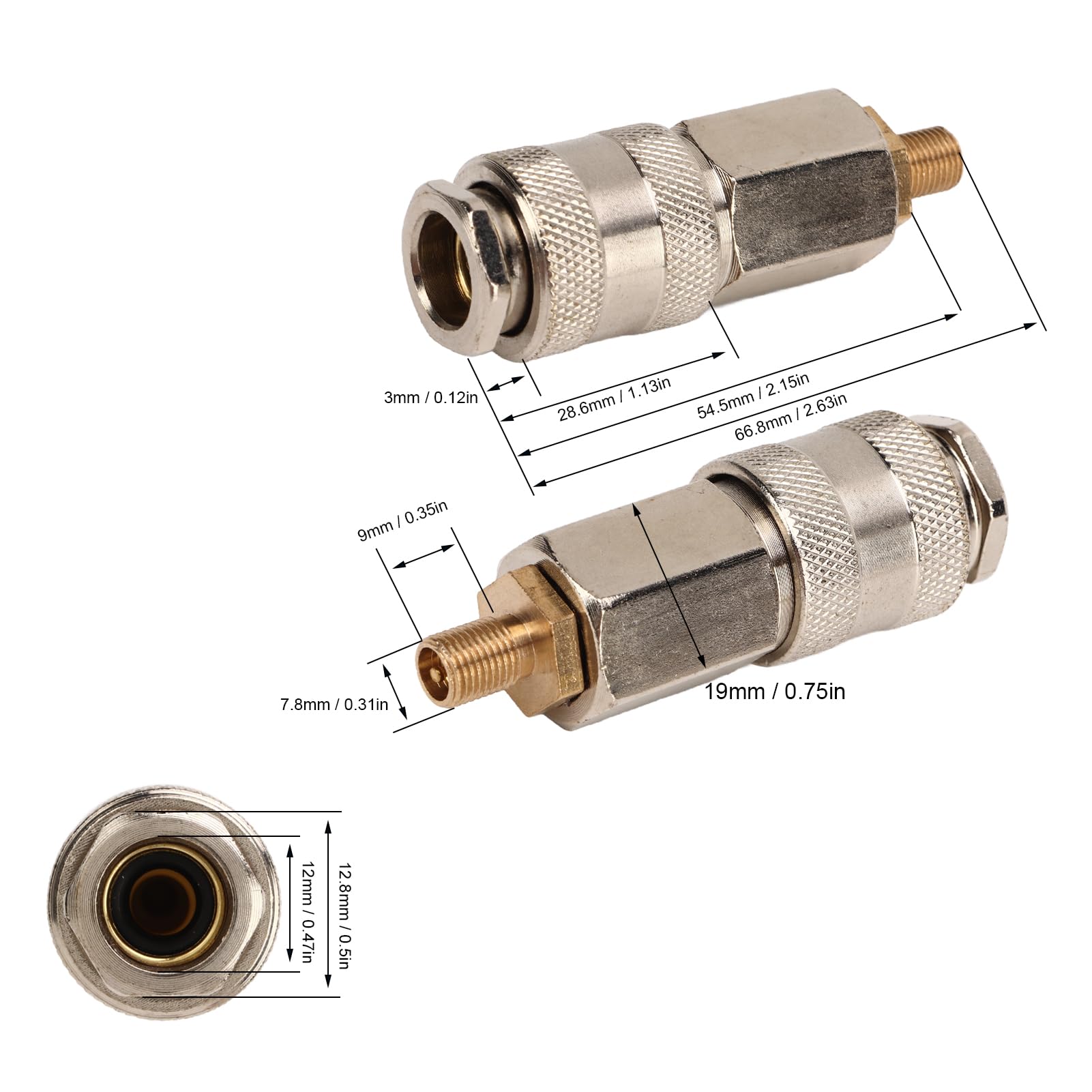

Illustrative image related to tire adapter for air compressor

The Problem: Many buyers face compatibility challenges when trying to use tire adapters with different brands of air compressors and inflators. This is particularly problematic in diverse operational settings where multiple types of equipment are used. An adapter that works seamlessly with one inflator may not fit another, leading to increased downtime as technicians search for compatible solutions or resort to purchasing additional adapters.

The Solution: To address compatibility concerns, businesses should conduct a thorough inventory assessment of their existing air compressor and inflator brands before making purchases. This will help identify the specific types of adapters required for each piece of equipment. When sourcing tire adapters, opt for universal models that are designed to work across multiple brands and types of inflators. Investing in a comprehensive set of adapters can also be beneficial, allowing for flexibility in operations. Additionally, consider partnering with suppliers that provide detailed specifications and compatibility charts to ensure informed purchasing decisions.

The Problem: A common pain point for B2B buyers is the inefficiency of the inflation process when using tire adapters. Many adapters require users to manually hold the connection in place while inflating, which can be cumbersome and lead to inconsistent results. This not only wastes time but can also result in inaccurate tire pressure readings, ultimately affecting vehicle performance and safety.

The Solution: To streamline the inflation process, buyers should look for tire adapters that feature a locking mechanism or a quick-connect design. These types of adapters allow for a secure attachment without the need to manually hold them in place, significantly reducing the time taken to inflate tires. When selecting these products, ensure they are compatible with your air compressor’s output and the specific tire valve type. Additionally, training technicians on the effective use of these locking adapters can enhance overall efficiency. Regular maintenance and cleanliness of the adapters will further ensure optimal performance, reducing the risk of air leaks and ensuring accurate tire inflation.

When selecting materials for tire adapters for air compressors, it’s crucial to consider various factors that affect performance, durability, and cost. The following analysis covers four common materials used in the manufacturing of these adapters: brass, aluminum, rubber, and stainless steel. Each material has distinct properties that influence its suitability for specific applications, especially for international B2B buyers.

Illustrative image related to tire adapter for air compressor

Brass is a popular choice due to its excellent corrosion resistance and good mechanical properties. It typically withstands temperatures up to 200°C and pressures around 2000 psi, making it suitable for a wide range of applications. Its natural resistance to rust and oxidation ensures longevity, especially in humid or corrosive environments.

Pros: Brass is durable and easy to machine, allowing for complex designs. It also provides a good seal, minimizing air leaks.

Cons: The primary drawback is its cost, as brass is generally more expensive than other materials. Additionally, it may not be suitable for high-pressure applications beyond its rating.

Impact on Application: Brass is compatible with air and some liquids, making it ideal for tire inflation and other pneumatic uses.

Considerations for International Buyers: Buyers in regions like Africa and South America should ensure compliance with local standards for brass components, such as ASTM or JIS, to avoid quality issues.

Aluminum is lightweight and has a high strength-to-weight ratio, making it an attractive option for tire adapters. It can handle temperatures up to 150°C and pressures similar to brass, but its corrosion resistance is less robust unless anodized.

Illustrative image related to tire adapter for air compressor

Pros: The lightweight nature of aluminum makes it easy to handle and transport. It is also more cost-effective compared to brass.

Cons: Aluminum can corrode in certain environments, especially when exposed to salt or moisture, unless treated. It may also not perform well under extreme temperatures.

Impact on Application: Aluminum is suitable for air applications but may not be ideal for corrosive environments without protective coatings.

Illustrative image related to tire adapter for air compressor

Considerations for International Buyers: Buyers should look for aluminum products that meet international standards for quality and corrosion resistance, especially in coastal regions.

Rubber is often used in seals and gaskets within tire adapters due to its excellent flexibility and sealing properties. It can typically withstand temperatures from -40°C to 100°C and pressures up to 150 psi.

Pros: Rubber provides a tight seal and is resistant to wear and tear, making it ideal for applications requiring frequent use.

Cons: Its lifespan can be limited by exposure to UV light and extreme temperatures, which can degrade the material over time.

Impact on Application: Rubber is primarily compatible with air and some non-corrosive fluids, making it suitable for tire inflation.

Considerations for International Buyers: Buyers should ensure that the rubber used in adapters complies with international standards for durability and safety, especially in regions with extreme weather conditions.

Stainless steel is known for its exceptional strength and corrosion resistance, making it a robust choice for tire adapters. It can withstand high temperatures (up to 400°C) and pressures, making it suitable for demanding applications.

Illustrative image related to tire adapter for air compressor

Pros: The durability of stainless steel ensures a long service life, and it is resistant to rust and corrosion, making it ideal for various environments.

Cons: The primary disadvantage is its higher cost compared to other materials. Additionally, stainless steel is heavier, which may not be ideal for all applications.

Impact on Application: Stainless steel is compatible with air and various fluids, making it versatile for tire inflation and other pneumatic applications.

Considerations for International Buyers: Buyers should verify compliance with international standards such as ASTM or DIN to ensure quality and performance in diverse environments.

| Material | Typical Use Case for tire adapter for air compressor | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Brass | Tire inflation, pneumatic tools | Excellent corrosion resistance | Higher cost | High |

| Aluminum | Tire inflation, lightweight applications | Lightweight and cost-effective | Corrosion potential without treatment | Medium |

| Rubber | Seals and gaskets in tire adapters | Provides a tight seal | Limited lifespan in extreme conditions | Low |

| Stainless Steel | Heavy-duty tire inflation, industrial applications | Exceptional strength and durability | Higher cost and weight | High |

This strategic material selection guide provides valuable insights for international B2B buyers, helping them make informed decisions based on performance, cost, and application suitability.

The manufacturing process of tire adapters for air compressors involves several key stages, each critical for ensuring the final product meets quality and performance standards.

The process begins with material selection, typically involving high-quality metals such as aluminum or brass due to their durability and resistance to corrosion. The selected materials undergo preparation, which includes cutting and shaping into manageable sizes for subsequent processing. This stage also involves sourcing materials from reliable suppliers who comply with international quality standards, ensuring that the raw materials meet the necessary specifications for strength and longevity.

Once materials are prepared, the forming stage commences. This can involve various techniques such as machining, forging, or casting, depending on the design requirements of the tire adapter. For instance, precision machining is often employed to achieve the necessary tolerances and surface finishes required for a snug fit with both the air compressor and tire valves. Techniques like CNC (Computer Numerical Control) machining allow for high precision and repeatability, ensuring that each adapter produced meets the same specifications as the first.

Illustrative image related to tire adapter for air compressor

Following the forming stage, the components are assembled. This may involve attaching the adapter to a hose or integrating it with other components like pressure gauges or locking mechanisms. The assembly process must be meticulously executed to ensure that all parts fit together seamlessly. Quality control checkpoints are typically integrated at this stage to verify the integrity of the assembly, including visual inspections and functional tests.

Finishing processes are the final step in manufacturing tire adapters. This may include surface treatments such as anodizing or plating to enhance corrosion resistance and aesthetic appeal. Additionally, any sharp edges are deburred, and the final product is cleaned to remove any contaminants from the manufacturing process. A thorough inspection is performed to ensure that the finish meets the desired quality standards before packaging.

Quality assurance is critical in the manufacturing of tire adapters, ensuring that each product meets both international and industry-specific standards.

For tire adapter manufacturers, adhering to international standards such as ISO 9001 is essential. This standard outlines the criteria for a quality management system, emphasizing continuous improvement and customer satisfaction. Compliance with ISO standards can reassure B2B buyers that the manufacturer has a structured approach to quality management.

In addition to ISO certifications, industry-specific standards such as CE marking for products sold in the European market and API standards for products intended for the oil and gas industry may also apply. These certifications provide a benchmark for safety and performance, which is particularly important for B2B buyers looking to ensure product reliability.

Quality control involves several checkpoints throughout the manufacturing process:

Incoming Quality Control (IQC): This initial checkpoint involves inspecting raw materials upon delivery. Manufacturers conduct tests to verify that materials meet specified standards before they are used in production.

In-Process Quality Control (IPQC): During manufacturing, ongoing inspections are essential. This may involve dimensional checks, performance tests, and visual inspections to ensure that components are being produced correctly.

Final Quality Control (FQC): After assembly, the completed tire adapters undergo final inspections. This includes functional testing to ensure the adapter performs correctly under pressure and visual inspections for any defects in finish or assembly.

Manufacturers employ various testing methods to validate the performance and durability of tire adapters:

Pressure Testing: This test evaluates the adapter’s ability to withstand pressure, simulating the conditions it will face in real-world applications.

Leak Testing: Ensuring that there are no leaks at the connection points is crucial for performance. This is often performed using helium leak detection or pressure decay methods.

Material Testing: Manufacturers may perform tensile strength tests and corrosion resistance tests to ensure that the materials used can withstand environmental stresses over time.

For international B2B buyers, especially those from regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control practices is vital for ensuring product reliability.

Buyers should request audits of the manufacturing facility, which should include a review of quality management systems and compliance with international standards. A reputable supplier will be willing to share audit reports and certifications, providing transparency into their quality practices.

Illustrative image related to tire adapter for air compressor

Engaging third-party inspection services can provide an additional layer of assurance. These services can perform independent assessments at various stages of the manufacturing process, ensuring that the products meet the agreed specifications before shipment.

When sourcing from international suppliers, B2B buyers must be aware of potential nuances in quality control practices. Variations in compliance with local regulations, cultural attitudes towards quality, and differences in manufacturing capabilities can all impact the final product.

It is advisable for buyers to establish clear quality expectations upfront and engage in regular communication throughout the manufacturing process. Additionally, understanding the supplier’s capabilities and limitations can help buyers make informed decisions and foster successful partnerships.

In conclusion, a thorough understanding of the manufacturing processes and quality assurance practices associated with tire adapters for air compressors is essential for B2B buyers. By focusing on the manufacturing stages, adhering to international quality standards, and implementing robust verification processes, buyers can ensure they source reliable and high-quality products for their needs.

Illustrative image related to tire adapter for air compressor

In the competitive landscape of B2B procurement, securing the right tire adapter for air compressors is crucial for operational efficiency and cost-effectiveness. This guide provides a structured approach to help international buyers, particularly from Africa, South America, the Middle East, and Europe, navigate the sourcing process effectively.

Begin by identifying the specific requirements for your tire adapter. Consider the type of air compressor you are using and the connection type needed, such as 1/4 NPT or Schrader valve compatibility. Clear specifications ensure that you acquire an adapter that fits seamlessly with your existing equipment, minimizing downtime and operational disruptions.

Conduct thorough research to identify reputable suppliers that specialize in tire adapters. Utilize online marketplaces, industry directories, and trade shows to gather a list of potential vendors. Look for suppliers with a strong presence in your target regions, as local knowledge can enhance service delivery and support.

Before making a decision, it is essential to verify the credentials of your shortlisted suppliers. Check for certifications that demonstrate compliance with international quality standards, such as ISO or ASTM. These certifications indicate that the supplier adheres to best practices in manufacturing, which can significantly impact the reliability of the product.

Illustrative image related to tire adapter for air compressor

Once you have narrowed down your options, request samples from potential suppliers. Testing samples allows you to evaluate the quality, durability, and compatibility of the tire adapter with your equipment. This step is vital to ensure that the product meets your operational needs and expectations before committing to larger orders.

Compare pricing structures from different suppliers, but avoid making decisions based solely on cost. Consider the total cost of ownership, including shipping, taxes, and potential import duties. Additionally, negotiate payment terms that align with your cash flow and procurement strategy, such as net payment terms or early payment discounts.

Understand the shipping and delivery capabilities of your chosen suppliers. Assess their lead times, shipping methods, and any associated costs. Efficient logistics are crucial for timely operations, especially in regions with varying infrastructure challenges.

Finally, aim to build long-term relationships with your suppliers. Regular communication and feedback can foster a partnership that enhances service levels and responsiveness. A reliable supplier can offer ongoing support, updates on new products, and insights into industry trends, which can be invaluable for your business.

Illustrative image related to tire adapter for air compressor

By following these steps, B2B buyers can streamline the sourcing process for tire adapters for air compressors, ensuring they make informed decisions that align with their operational requirements and business goals.

When sourcing tire adapters for air compressors, understanding the cost structure is crucial for effective budgeting and price negotiation. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and the desired profit margin.

Materials: The choice of materials significantly affects the cost. Common materials include rubber, aluminum, and various metals that ensure durability and compatibility with different tire valves. High-grade materials often come with a higher price tag but can lead to better performance and longevity.

Labor: Labor costs can vary based on the manufacturing location. Regions with lower labor costs may offer competitive pricing, but this should be weighed against quality and reliability.

Manufacturing Overhead: This includes costs associated with utilities, maintenance, and factory operations. Efficient production processes can help minimize overhead, contributing to lower overall costs.

Tooling: Initial investments in specialized tooling for manufacturing custom adapters can be substantial. However, these costs are often amortized over larger production runs, making it essential to consider minimum order quantities (MOQs).

Quality Control (QC): Implementing stringent QC processes ensures that products meet international standards, which can add to costs. However, this investment helps avoid costly recalls and customer dissatisfaction.

Logistics: Transportation costs can fluctuate based on distance, shipping methods, and fuel prices. International buyers should factor in customs duties and tariffs, which can significantly impact the total cost.

Margin: Suppliers typically include a profit margin in their pricing, influenced by market demand, competition, and perceived value.

Several factors influence the pricing of tire adapters, making it essential for buyers to be aware of these nuances.

Volume/MOQ: Bulk orders often lead to discounts. Buyers should negotiate terms that align with their projected needs to maximize cost efficiency.

Specifications and Customization: Customized adapters that meet specific requirements may incur additional costs. Buyers should clearly define their needs to avoid unexpected charges.

Materials and Quality Certifications: Higher-quality materials and certifications (e.g., ISO, CE) can enhance product value but also increase costs. Buyers should assess whether these certifications are necessary for their market.

Supplier Factors: The reputation and reliability of suppliers play a significant role in pricing. Established suppliers may charge more but can provide assurance of quality and service.

Incoterms: Understanding the chosen Incoterms is crucial for determining who bears the risk and cost during shipping. This knowledge can help buyers make informed decisions regarding logistics and pricing.

Effective negotiation strategies can lead to significant savings when sourcing tire adapters for air compressors.

Leverage Volume Discounts: Communicate projected purchase volumes clearly to negotiate better pricing. Suppliers are often willing to offer lower prices for guaranteed large orders.

Request Detailed Quotes: Ensure that quotes break down all cost components. This transparency allows for better comparisons and highlights areas for potential negotiation.

Explore Alternative Suppliers: Do not hesitate to seek multiple quotes from various suppliers. This competitive approach can reveal better pricing and terms.

Understand Total Cost of Ownership (TCO): Evaluate not just the purchase price but also long-term costs, including maintenance, replacement, and potential savings from efficiency improvements.

Be Aware of Pricing Nuances in International Markets: Buyers from regions such as Africa, South America, the Middle East, and Europe should consider currency fluctuations, import duties, and local market conditions when negotiating prices.

While indicative prices for tire adapters can vary widely based on the factors discussed, a thorough understanding of cost components and price influencers can empower buyers to make informed decisions. By applying strategic negotiation techniques, businesses can enhance their cost efficiency and ensure they receive the best value for their investments.

Illustrative image related to tire adapter for air compressor

In the realm of tire maintenance and inflation, selecting the right tools is crucial for efficiency and effectiveness. While tire adapters for air compressors are popular for their functionality, various alternatives exist that can also serve the purpose of inflating tires. This analysis aims to compare tire adapters with other viable solutions, enabling B2B buyers to make informed decisions based on their specific operational needs.

| Comparison Aspect | Tire Adapter For Air Compressor | LockNFlate Tire Inflator Adapter | Slime Tire Inflator Hose Adapter |

|---|---|---|---|

| Performance | High, reliable for various tires | Very high, precision-engineered for optimal fit | Moderate, quick connection but may require more effort |

| Cost | Moderate, typically around $10-20 | Affordable, approx. $10.99 | Low to moderate, usually around $10 |

| Ease of Implementation | Simple, connects easily to most compressors | User-friendly, designed for quick attachment | Moderate, requires some manual adjustments |

| Maintenance | Low, minimal wear and tear | Very low, built to last | Moderate, occasional checks needed |

| Best Use Case | General tire inflation needs | Best for professional settings requiring high reliability | Ideal for occasional users or emergency kits |

The LockNFlate Tire Inflator Adapter is designed specifically for seamless connections between air compressors and tire valves. Its precision engineering ensures a leak-free and quick inflation process, making it ideal for high-demand scenarios. While the cost is comparable to traditional adapters, its performance is superior, and it requires minimal maintenance. This adapter is best suited for businesses that prioritize efficiency and reliability in tire maintenance.

The Slime Tire Inflator Hose Adapter offers a quick-connect feature that simplifies the inflation process. It converts a twist-on inflator hose to a snap-on connection, enabling faster attachment to tire valve stems. Although its performance is generally good, some users may find it less efficient compared to more robust options like the LockNFlate. This adapter is particularly beneficial for businesses that need an affordable solution for less frequent use or for emergency roadside kits.

When selecting a tire inflation solution, B2B buyers must consider factors such as performance, cost, ease of use, and maintenance requirements. Tire adapters for air compressors provide a reliable option, especially for high-volume applications. In contrast, alternatives like the LockNFlate and Slime adapters cater to different needs, with the former excelling in professional settings and the latter serving well for occasional use. By aligning the choice of equipment with operational requirements, businesses can enhance their tire maintenance capabilities and ensure optimal performance in their fleet management.

When sourcing tire adapters for air compressors, understanding their technical properties is crucial for making informed purchasing decisions. Below are some key specifications that buyers should consider:

The material used in tire adapters typically includes brass, aluminum, or high-grade plastic. Brass is favored for its durability and resistance to corrosion, making it ideal for outdoor use. Aluminum offers a lightweight solution without compromising strength. Understanding the material grade helps buyers assess the product’s longevity and suitability for specific applications.

Most tire adapters are designed to connect with standard valve systems, such as Schrader or Presta valves. Common thread specifications include 1/4 NPT (National Pipe Thread) and 0.305’’ x 32 TPI (threads per inch) for Schrader valves. Knowing the thread specifications ensures compatibility with existing equipment, reducing the likelihood of leaks or malfunctions during operation.

Illustrative image related to tire adapter for air compressor

The pressure rating indicates the maximum pressure the adapter can safely handle, typically measured in PSI (pounds per square inch). Adapters intended for high-performance applications may have ratings exceeding 150 PSI. Buyers must ensure that the pressure rating aligns with their compressor’s capabilities to prevent failures and ensure safety.

Tolerance refers to the permissible limit of variation in a physical dimension. High-precision adapters may have tighter tolerances (e.g., ±0.001 inches) to ensure a secure fit and minimize air loss. For B2B buyers, selecting adapters with appropriate tolerance levels is essential for maintaining efficiency and performance in tire inflation tasks.

The length of the adapter can affect usability, especially in tight spaces. Longer adapters may provide better reach but could compromise flexibility. Buyers should assess their specific operational needs to determine the optimal length and flexibility for their tire inflating tasks.

Illustrative image related to tire adapter for air compressor

Familiarity with industry jargon can enhance communication and negotiations with suppliers. Here are several essential terms:

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the tire adapter industry, OEM products are often synonymous with quality and reliability, as they meet specific design and performance standards.

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is vital for B2B buyers to avoid overcommitting resources or facing increased costs. It also influences inventory management and budget planning.

An RFQ is a document sent to suppliers requesting pricing and terms for specific products. B2B buyers use RFQs to compare offers from multiple vendors, ensuring they receive competitive pricing and favorable terms for tire adapters.

Illustrative image related to tire adapter for air compressor

Incoterms are internationally recognized rules that define the responsibilities of buyers and sellers in international transactions. Terms such as FOB (Free on Board) or CIF (Cost, Insurance, and Freight) clarify shipping responsibilities and costs, which is crucial for B2B transactions involving tire adapters.

Lead time refers to the amount of time it takes from placing an order to receiving the product. For B2B buyers, understanding lead times is essential for planning inventory and ensuring timely operations, particularly in markets where demand can fluctuate rapidly.

By understanding these essential technical properties and trade terminologies, international B2B buyers can make more informed decisions when sourcing tire adapters for air compressors, ensuring compatibility, reliability, and efficiency in their operations.

The tire adapter for air compressor sector is experiencing dynamic shifts driven by several global factors. The increased demand for efficient, portable inflators, particularly in emerging markets such as Africa and South America, is a notable trend. The rise of electric vehicles and the growing awareness of vehicle maintenance are fueling the need for accessible tire inflation solutions. Moreover, the trend toward DIY maintenance among consumers has created a vibrant market for tire adapters, as these tools enable users to quickly and effectively inflate tires without professional assistance.

In terms of technology, the integration of smart features in inflators is becoming prevalent. Innovations like digital pressure gauges and automatic shut-off functions are appealing to both end-users and distributors. Additionally, e-commerce platforms are reshaping sourcing strategies, allowing international B2B buyers to access a broader range of products and suppliers, particularly from regions like Europe and the Middle East. This shift toward online purchasing is complemented by an increasing reliance on reviews and ratings, which help buyers make informed decisions.

Illustrative image related to tire adapter for air compressor

Sustainability has emerged as a critical factor influencing sourcing decisions within the tire adapter sector. As global awareness of environmental issues rises, B2B buyers are increasingly prioritizing suppliers who demonstrate commitment to ethical sourcing practices and sustainable manufacturing processes. This includes the use of recycled materials and eco-friendly packaging, which not only reduce the environmental footprint but also align with corporate responsibility goals.

Furthermore, certifications such as ISO 14001 for environmental management systems are becoming essential for suppliers to showcase their dedication to sustainability. Buyers are seeking partnerships with manufacturers that can provide transparency in their supply chains, ensuring that raw materials are sourced responsibly and production processes minimize waste. By prioritizing sustainable options, businesses can enhance their brand reputation while meeting the growing consumer demand for environmentally friendly products.

The evolution of tire adapters for air compressors dates back to the early 20th century when pneumatic tires became standard in automobiles. Initially, inflation was a labor-intensive process, often requiring manual pumps and considerable physical effort. As automotive technology advanced, so did inflation solutions, leading to the development of air compressors and specialized adapters designed to simplify the process.

In the late 20th century, the introduction of quick-connect fittings revolutionized the market, allowing for faster and more efficient tire inflation. The rise of portable and electric air compressors in the 21st century further transformed the landscape, making tire maintenance more accessible to consumers. Today, the focus is on enhancing user experience through innovations that improve efficiency, safety, and ease of use, solidifying the tire adapter’s role as a vital accessory in automotive maintenance.

Illustrative image related to tire adapter for air compressor

Overall, understanding these market dynamics and sourcing trends will empower international B2B buyers to make informed decisions, ensuring they remain competitive in an evolving landscape.

How do I solve compatibility issues when sourcing tire adapters for air compressors?

To avoid compatibility issues, ensure that you know the specifications of both your air compressor and the tire valves you intend to use. Check for standard threading sizes, such as 1/4 NPT or Schrader valve dimensions. Request detailed product specifications from suppliers, including technical drawings if necessary. It may also be beneficial to order samples before making a bulk purchase to confirm compatibility with your equipment.

What is the best tire adapter for high-pressure air compressors?

The best tire adapter for high-pressure air compressors typically features robust construction, such as precision-machined metal, to withstand increased pressure without leaking. Look for adapters that provide a secure fit, such as those with locking mechanisms or rubber linings to prevent air loss. Brands like LockNFlate and Fanttik offer models designed specifically for high-pressure applications, ensuring reliability and safety during use.

How can I verify the reliability of a tire adapter supplier?

To verify a supplier’s reliability, conduct thorough research including checking their business licenses, certifications, and customer reviews. Request references from previous clients and inquire about their quality assurance processes. It’s also advisable to assess their responsiveness and customer service during the initial contact. Consider visiting their facilities or utilizing third-party inspection services if feasible.

What are the common minimum order quantities (MOQ) for tire adapters?

Minimum order quantities (MOQ) for tire adapters can vary widely based on the supplier and the specific product. Typically, MOQs range from 100 to 1,000 units. When negotiating, clarify if there is flexibility in the MOQ for first-time orders or sample requests. Suppliers may be willing to lower the MOQ for established relationships or large contracts.

What payment terms should I expect when purchasing tire adapters internationally?

Payment terms for international purchases can vary significantly, but common practices include a 30% deposit upon order confirmation with the balance due before shipping. Some suppliers may offer letters of credit or payment through secure platforms like PayPal or Alibaba for added safety. Always clarify payment terms and potential additional fees for currency conversion or international transfers to avoid unexpected costs.

How can I ensure quality assurance for tire adapters sourced internationally?

To ensure quality assurance, establish clear quality standards and specifications before placing an order. Request samples for testing, and consider implementing a quality control checklist that includes dimensional checks and performance testing. Engaging a third-party inspection company to assess the products prior to shipment can further guarantee that the items meet your required standards.

What logistics considerations should I take into account when importing tire adapters?

When importing tire adapters, consider shipping methods, customs duties, and delivery timelines. Evaluate whether air freight or sea freight is more suitable based on urgency and cost. Understanding local customs regulations and potential tariffs can prevent delays and additional charges. Partnering with a logistics provider experienced in international trade can streamline the process.

Can I customize tire adapters to fit specific equipment?

Yes, many manufacturers offer customization options for tire adapters. This may include altering dimensions, threading types, or even branding the product with your company logo. Discuss your specific requirements with the supplier and ask for any design capabilities they have. Be prepared to provide detailed specifications and possibly pay a premium for custom tooling or production runs.

Domain: locknlube.com

Registered: 2013 (12 years)

Introduction: LockNFlate Tire Inflator Adapter 1/4 NPT (m) to Schrader Valve (m) SKU: LNL65196 Price: $10.99 Precision-machined tire inflator adapter that connects the LockNFlate Air Chuck to any inflator or pump with a screw-on or other female Schrader valve connection, such as the Milwaukee M18 Inflator. Specifications: 1/4 NPT (m) to standard Schrader valve (m) [VG8/8V1 valve threads]. Made in the USA by Loc…

In the evolving landscape of air compressor accessories, the tire adapter market presents significant opportunities for international B2B buyers. Understanding the variety of products available—ranging from precision-machined adapters to innovative locking mechanisms—allows businesses to streamline operations and enhance service efficiency. The strategic sourcing of these components not only reduces costs but also improves reliability and customer satisfaction.

Investing in high-quality tire adapters can lead to notable long-term benefits, including reduced downtime and increased productivity. Buyers from regions such as Africa, South America, the Middle East, and Europe should prioritize suppliers who offer robust warranties, competitive pricing, and responsive customer service to ensure a seamless procurement process.

As the demand for reliable tire inflation solutions continues to grow, now is the ideal time to strengthen your supply chain partnerships. By leveraging the insights gained from this guide, you can make informed purchasing decisions that align with your operational needs. Embrace the future of tire inflation technology and position your business for success in an increasingly competitive marketplace.

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.