In today’s fast-paced automotive market, sourcing reliable tire inflators for cars is a critical challenge for international B2B buyers. With increasing demands for efficiency and safety in vehicle maintenance, understanding the diverse range of tire inflators available is essential. This comprehensive guide delves into the various types of tire inflators, their applications across different vehicle categories, and crucial supplier vetting processes. By addressing cost considerations, performance metrics, and additional features, this guide equips businesses with the knowledge needed to make informed purchasing decisions.

For buyers from regions such as Africa, South America, the Middle East, and Europe—including key markets like Vietnam and Germany—navigating the global landscape can be daunting. This guide not only highlights the best products on the market but also offers insights into the latest technological advancements and industry trends. By providing actionable strategies for sourcing and evaluating tire inflators, we empower businesses to enhance their operational efficiency and customer satisfaction. As you read through this guide, you will gain a clear understanding of how to select the right tire inflator that meets your specific needs, ensuring that your fleet remains safe and road-ready at all times.

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Cordless Tire Inflators | Battery-powered, portable, often lightweight | Automotive service, roadside assistance | Pros: Highly portable, easy to use. Cons: Limited battery life, may not suit heavy-duty applications. |

| 12V Powered Tire Inflators | Connects to vehicle’s 12V outlet, often more powerful | Fleet maintenance, workshops | Pros: Consistent power supply, suitable for multiple tires. Cons: Requires vehicle access, less portable. |

| Heavy-Duty Tire Inflators | Designed for high PSI and larger tires, often bulky | Commercial vehicles, off-road fleets | Pros: Fast inflation, durable. Cons: Bulky, may require battery clamps for connection. |

| Compact Tire Inflators | Ultra-portable, small size, typically lower PSI capabilities | Personal vehicles, emergency kits | Pros: Fits in small spaces, lightweight. Cons: Limited functionality, slower inflation times. |

| Digital Tire Inflators | Features digital displays for precise pressure readings | Automotive diagnostics, garages | Pros: Accurate readings, easy to use. Cons: May be more expensive, requires power source. |

Cordless tire inflators are battery-operated devices designed for maximum portability. They are ideal for roadside emergencies and personal use, allowing users to inflate tires without the need for an external power source. These inflators typically feature built-in pressure gauges and automatic shut-off capabilities, making them user-friendly. B2B buyers should consider the battery life and PSI capabilities when selecting cordless inflators, as these factors impact efficiency in various applications.

12V powered tire inflators connect directly to a vehicle’s cigarette lighter or 12V outlet, providing a reliable power source for consistent performance. These inflators are suitable for workshops and fleet maintenance where multiple tires need to be inflated regularly. B2B purchasers should evaluate the hose length and compatibility with various tire sizes, ensuring that the inflator can efficiently service the intended fleet or vehicle type.

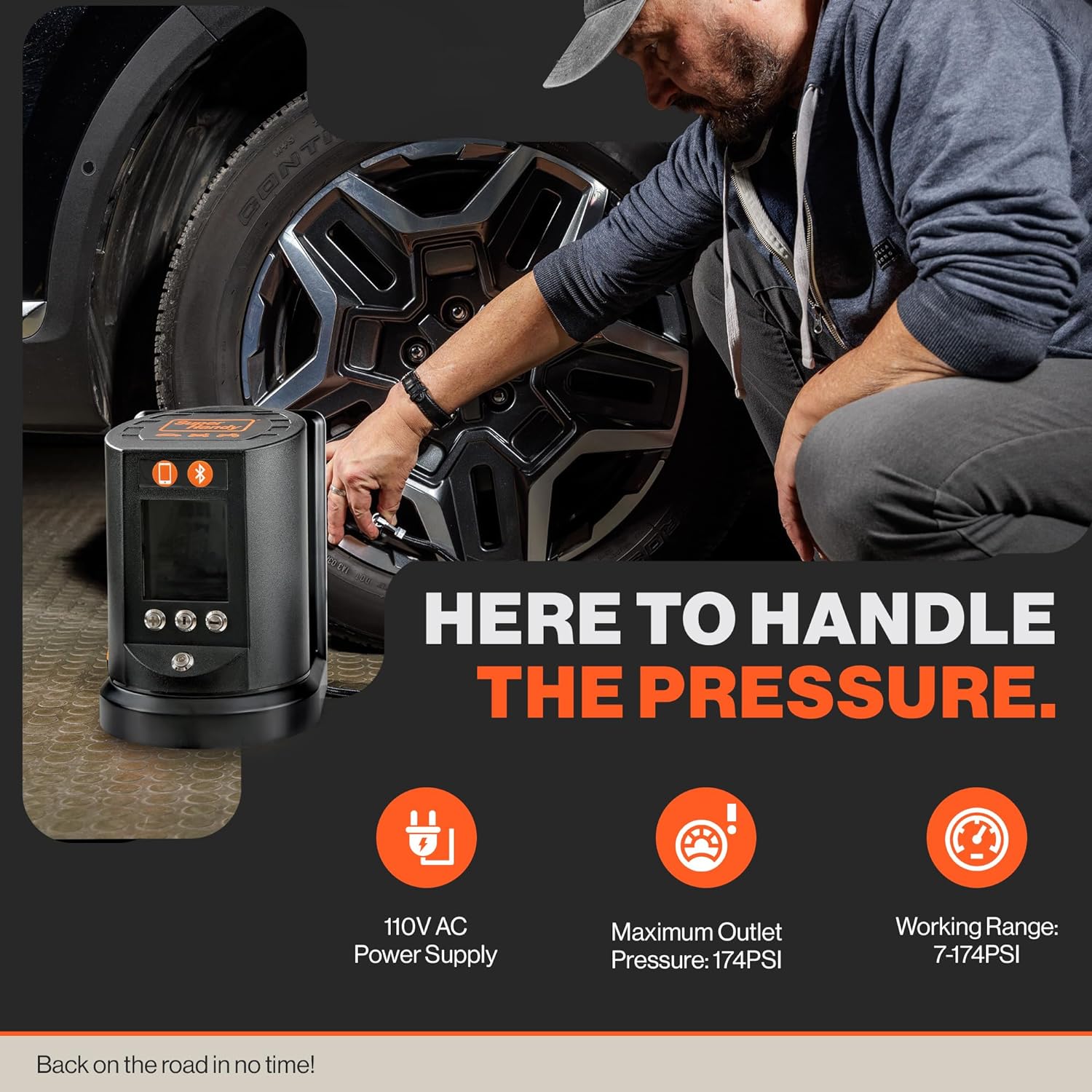

Illustrative image related to tire inflator car

Heavy-duty tire inflators are specifically engineered to handle high PSI levels and larger tires, making them essential for commercial vehicles and off-road fleets. These inflators often feature robust construction and fast inflation capabilities, catering to the demands of businesses that require quick turnaround times for vehicle maintenance. Buyers should assess the portability versus power trade-off, as these models tend to be bulkier and may require direct battery connections.

Compact tire inflators are designed for convenience, fitting easily into glove compartments or emergency kits. Although they have lower PSI capabilities and slower inflation times, their lightweight design makes them perfect for personal vehicles and on-the-go situations. B2B buyers looking for compact solutions should consider the specific inflation needs of their vehicles and whether the slower performance aligns with their operational requirements.

Digital tire inflators come equipped with digital displays that provide precise pressure readings, making them an excellent choice for automotive diagnostics and garage use. They often feature programmable settings for different tire types, enhancing user experience. When purchasing digital inflators, B2B buyers should weigh the importance of accuracy against potential higher costs, ensuring they choose models that meet their specific operational demands.

| Industry/Sector | Specific Application of tire inflator car | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Service Centers | Routine tire maintenance for customer vehicles | Enhances customer satisfaction and loyalty | Reliability, speed of inflation, and ease of use |

| Logistics and Fleet | Emergency tire inflation for delivery vehicles | Reduces downtime and improves operational efficiency | Portability, battery life, and compatibility with various tire sizes |

| Construction | Tire inflation for heavy machinery and equipment | Ensures safety and maximizes equipment uptime | High PSI capability, durability, and ruggedness |

| Agricultural Sector | Inflation for agricultural vehicles and machinery | Increases productivity and reduces operational delays | Robust construction, ease of transport, and power options |

| Recreational Vehicle Rentals | Quick tire inflation for RVs and trailers | Improves customer experience and reduces maintenance costs | Compact design, multiple inflation options, and accuracy |

In automotive service centers, tire inflator cars are essential tools for performing routine tire maintenance. They enable technicians to quickly check and inflate tires to the recommended pressure, enhancing vehicle performance and safety. This not only improves customer satisfaction but also builds loyalty, as clients appreciate efficient service. B2B buyers in this sector should prioritize inflators that are reliable, easy to use, and capable of rapid inflation to handle multiple vehicles efficiently.

Illustrative image related to tire inflator car

For logistics and fleet management companies, tire inflator cars are vital for minimizing downtime due to flat tires. These inflators allow drivers to quickly address tire issues on-site, ensuring vehicles are back on the road swiftly. This capability is crucial for maintaining operational efficiency and meeting delivery schedules. When sourcing tire inflators, businesses should consider factors such as portability, battery life, and compatibility with various tire sizes to accommodate their diverse fleet.

In the construction sector, tire inflator cars are used for maintaining the tires of heavy machinery and equipment. Properly inflated tires enhance safety and maximize equipment uptime, which is essential for maintaining project timelines. Buyers in this industry should look for inflators that can achieve high PSI levels and are built to withstand rugged environments. Durability and ease of transport are also critical factors to ensure that these tools are readily available on-site.

Agricultural businesses utilize tire inflator cars to maintain the tires on various vehicles and machinery, including tractors and harvesters. Keeping these tires properly inflated increases productivity and reduces operational delays caused by tire failures. When sourcing inflators, agricultural businesses should seek robust models that can handle the demands of outdoor use, offer multiple power options, and are easy to transport across vast fields.

In the recreational vehicle rental industry, tire inflator cars are essential for providing quick and efficient tire inflation for RVs and trailers. This capability not only improves the customer experience but also helps rental companies reduce maintenance costs associated with tire issues. Buyers in this sector should focus on compact designs that are easy to store and transport, as well as inflators with multiple inflation options to cater to various types of recreational vehicles.

The Problem: B2B buyers managing fleets often face the challenge of maintaining optimal tire pressure across multiple vehicles. Insufficient tire pressure can lead to increased fuel consumption, reduced tire lifespan, and compromised safety. With varying tire pressure requirements depending on load and terrain, fleet managers may struggle to keep track of tire conditions, leading to operational inefficiencies and unexpected breakdowns.

Illustrative image related to tire inflator car

The Solution: To address this issue, B2B buyers should invest in high-quality tire inflators that feature digital pressure gauges and programmable pressure settings. Models like the AstroAI Cordless Tire Inflator offer the ability to preset desired pressures, allowing for quick adjustments without constant manual checks. Additionally, implementing a regular maintenance schedule that includes tire pressure checks can help mitigate issues. Fleet managers can also consider tire pressure monitoring systems (TPMS) that provide real-time data, alerting them to low-pressure situations before they escalate into more significant problems. This proactive approach not only enhances safety but also reduces operational costs related to fuel inefficiency and tire replacements.

The Problem: Companies with a diverse fleet, including cars, trucks, and SUVs, often encounter compatibility issues with tire inflators. Many inflators are designed for standard passenger vehicles, which can leave fleet managers with inadequate solutions for larger vehicles that require higher pressures or unique valve types. This mismatch can lead to wasted time, frustration, and potentially unsafe driving conditions.

The Solution: To overcome compatibility issues, B2B buyers should prioritize tire inflators that are versatile and capable of handling a range of tire types and pressures. The Viair 88P, for example, is particularly suited for trucks and SUVs, handling larger tires effectively. Buyers should also ensure that their inflators come with various nozzle attachments to accommodate different valve types, which can be crucial for mixed fleets. Furthermore, conducting thorough research and testing before procurement can ensure that the selected inflator meets the specific demands of the fleet, ultimately enhancing operational efficiency and safety.

Illustrative image related to tire inflator car

The Problem: Accessibility and portability of tire inflators are critical pain points for businesses that operate in varied environments, such as construction sites or remote areas. Heavy, cumbersome inflators may not be practical for quick roadside repairs or in locations where electricity is not readily available, leading to delays and potential safety hazards.

The Solution: B2B buyers should consider sourcing compact and cordless tire inflators that are designed for mobility. The Craftsman 12V Max Portable Air Inflator, for example, is lightweight and easily rechargeable via USB, making it ideal for on-the-go applications. Buyers should also assess the inflator’s battery life and charging options to ensure they can perform multiple inflations on a single charge. Additionally, establishing a protocol for regular checks of inflator functionality and battery levels will ensure that these tools are always ready for use, minimizing downtime and enhancing operational reliability in the field.

When selecting materials for tire inflators, understanding the properties, advantages, and limitations of each material is crucial for B2B buyers. Here, we analyze four common materials: plastic, aluminum, steel, and rubber, focusing on their relevance to tire inflator performance and international market considerations.

Plastic is often used in the housing and components of tire inflators due to its lightweight and moldable nature. Key properties include good resistance to corrosion and a temperature rating that typically ranges from -40°C to 80°C, making it suitable for various environments.

Illustrative image related to tire inflator car

Pros: Plastic is cost-effective, lightweight, and allows for intricate designs, which can enhance the aesthetic appeal of the product.

Cons: However, it may not withstand high pressures as effectively as metals, and its durability can be compromised under extreme temperatures or UV exposure.

Impact on Application: Plastic components are generally compatible with air and non-corrosive gases, but care must be taken when using them with solvents or oils.

Considerations for International Buyers: Compliance with standards such as ASTM for plastics is crucial. In regions like Europe, buyers may prefer materials that meet REACH regulations for safety and environmental concerns.

Aluminum is frequently chosen for its strength-to-weight ratio and resistance to corrosion. With a temperature rating of -50°C to 150°C, aluminum is ideal for tire inflators that may experience varying environmental conditions.

Pros: Its lightweight nature contributes to the portability of inflators, and it can handle higher pressures, making it suitable for heavy-duty applications.

Cons: The primary drawback is the higher cost compared to plastic, and it may require additional treatment to prevent oxidation, which can add to manufacturing complexity.

Impact on Application: Aluminum is compatible with air and can handle various tire pressures effectively, making it a reliable choice for both passenger vehicles and trucks.

Considerations for International Buyers: Buyers should ensure that aluminum components meet relevant standards such as DIN for materials in Europe, and consider the environmental impact of aluminum sourcing.

Steel is often utilized in the construction of tire inflators, particularly in high-stress components like the pump assembly. It boasts a temperature rating of -40°C to 200°C and excellent pressure resistance.

Illustrative image related to tire inflator car

Pros: Steel is highly durable and can withstand significant wear and tear, providing longevity to the inflator.

Cons: However, it is heavier than other materials, which can affect portability. Additionally, steel is susceptible to rust if not properly coated or treated.

Impact on Application: Steel is suitable for high-pressure applications and is compatible with air, making it ideal for inflators designed for trucks and SUVs.

Considerations for International Buyers: Compliance with standards such as JIS in Japan or ASTM in the U.S. is essential. Buyers should also consider the implications of steel sourcing and its environmental impact.

Illustrative image related to tire inflator car

Rubber is primarily used for seals and hoses in tire inflators due to its elasticity and ability to create airtight seals. It typically operates effectively within a temperature range of -30°C to 100°C.

Pros: Rubber is excellent for preventing air leaks, ensuring that the inflator maintains pressure during operation.

Cons: The main limitation is its degradation over time when exposed to UV light and extreme temperatures, which can lead to cracks and loss of functionality.

Illustrative image related to tire inflator car

Impact on Application: Rubber is compatible with air and non-corrosive gases, making it ideal for sealing applications in inflators.

Considerations for International Buyers: Buyers should ensure that rubber materials meet relevant safety standards and are free from harmful chemicals, particularly in regions with strict regulations like the EU.

| Material | Typical Use Case for tire inflator car | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Plastic | Housing and lightweight components | Cost-effective and lightweight | Limited pressure resistance | Low |

| Aluminum | Pump assemblies and high-pressure components | Excellent strength-to-weight ratio | Higher cost and oxidation treatment needed | Medium |

| Steel | High-stress components like pumps | Highly durable and pressure-resistant | Heavier and rust-prone | High |

| Rubber | Seals and hoses | Creates airtight seals | Degrades under UV and extreme temperatures | Medium |

This analysis provides B2B buyers with a comprehensive understanding of material selection for tire inflators, helping them make informed decisions based on performance, cost, and compliance with international standards.

The manufacturing process of tire inflators involves several critical stages, each designed to ensure the final product meets the high standards expected by B2B buyers. The primary stages include material preparation, forming, assembly, and finishing.

Illustrative image related to tire inflator car

Material preparation is the foundational step in the manufacturing process. It involves sourcing high-quality raw materials such as plastic, metal, and rubber. Manufacturers often use materials that are durable and lightweight to enhance the portability of tire inflators. Key considerations during material selection include resistance to wear and tear, thermal stability, and cost-effectiveness.

Once the materials are procured, they undergo a series of inspections to ensure they meet specified quality standards. This might include checking for dimensional accuracy, tensile strength, and chemical composition. Suppliers often provide material certifications that can be verified by B2B buyers to ensure compliance with international standards.

Forming techniques are pivotal in shaping the components of tire inflators. Common methods include injection molding for plastic parts, metal stamping for structural components, and extrusion for hoses. Injection molding is particularly popular due to its ability to produce complex shapes with high precision.

Illustrative image related to tire inflator car

During the forming process, manufacturers often utilize advanced technologies like Computer Numerical Control (CNC) machining to achieve greater accuracy in dimensions. This ensures that parts fit together seamlessly during assembly, which is crucial for the inflator’s overall performance.

The assembly stage involves piecing together the various components of the tire inflator. This typically occurs on an assembly line where workers or automated machines follow a standardized procedure to ensure consistency. Each component—such as the motor, pressure gauge, and air hose—is integrated carefully to facilitate the inflator’s functionality.

During assembly, manufacturers often implement lean manufacturing principles to minimize waste and enhance efficiency. Each workstation may incorporate quality control measures to detect any defects early in the process. This proactive approach not only improves productivity but also reduces the risk of costly recalls later.

Finishing processes are essential for enhancing the aesthetic and functional qualities of tire inflators. This stage may involve surface treatments such as painting, powder coating, or applying decals. These finishes not only improve appearance but also provide additional protection against environmental factors like moisture and UV exposure.

Illustrative image related to tire inflator car

Final inspections are conducted during the finishing phase to ensure that the inflators meet visual and functional standards. This may include checking for scratches, dents, or any imperfections in the finish that could affect the product’s marketability.

Quality assurance is a critical aspect of tire inflator manufacturing, ensuring that products meet both international and industry-specific standards. Notably, ISO 9001 is a widely recognized standard that outlines the criteria for a quality management system. Compliance with ISO 9001 indicates that a manufacturer has established a systematic approach to managing quality across all processes.

In addition to ISO standards, certifications such as CE (Conformité Européenne) and API (American Petroleum Institute) are relevant for tire inflator manufacturers. CE marking is essential for products sold in the European Economic Area, indicating conformity with health, safety, and environmental protection standards. Meanwhile, API standards may apply to inflators designed for specific industrial applications.

Illustrative image related to tire inflator car

Quality control (QC) is integrated throughout the manufacturing process, with specific checkpoints established to maintain product integrity. These checkpoints typically include:

Incoming Quality Control (IQC): At this stage, raw materials and components are inspected upon arrival at the manufacturing facility. This includes verifying certifications and conducting random sampling tests to ensure materials meet specifications.

In-Process Quality Control (IPQC): During manufacturing, continuous monitoring occurs to check for compliance with design specifications. This may involve using statistical process control (SPC) methods to track production metrics and identify variations that could indicate defects.

Final Quality Control (FQC): Before products are packaged and shipped, a comprehensive final inspection is conducted. This includes functional testing of the inflators to ensure they perform as intended, along with visual inspections to check for aesthetic defects.

B2B buyers must be diligent in verifying the quality control practices of their suppliers. This can be achieved through several methods:

Supplier Audits: Conducting on-site audits allows buyers to assess the manufacturing processes, quality management systems, and compliance with international standards. Audits can reveal critical insights into the supplier’s operational practices and quality culture.

Reviewing Quality Reports: Requesting documentation such as quality control reports, test results, and certifications can provide evidence of a supplier’s commitment to quality. These documents should outline the QC processes employed and the outcomes of various inspections.

Third-Party Inspections: Engaging independent third-party inspection agencies can provide unbiased evaluations of a supplier’s quality control measures. These agencies often have the expertise to conduct thorough assessments and can help ensure that the products meet the required specifications.

International B2B buyers, particularly those from diverse regions such as Africa, South America, the Middle East, and Europe, must navigate various nuances in quality control and certification. Understanding regional regulations and standards is crucial, as they can vary significantly.

Regional Compliance: Buyers should familiarize themselves with local regulations that may affect product acceptance. For instance, specific markets may have unique safety standards or environmental regulations that must be adhered to.

Cultural Considerations: Different regions may have varying expectations regarding product quality and service. Buyers should consider these cultural factors when evaluating suppliers and their quality assurance practices.

Documentation and Certifications: Ensure that all required documentation, including import/export certifications and compliance certificates, is in order. This will facilitate smoother transactions and reduce the risk of delays at customs.

By being informed about the manufacturing processes and quality assurance practices for tire inflators, B2B buyers can make more educated purchasing decisions that align with their operational needs and regulatory requirements.

To effectively procure tire inflators for automotive applications, B2B buyers must navigate a series of important considerations to ensure they select the best products for their needs. This guide serves as a comprehensive checklist to facilitate informed decision-making in sourcing tire inflators.

Establishing clear technical specifications is crucial for ensuring the tire inflators meet the needs of your business. Consider factors such as maximum pressure (psi), power source (cordless vs. corded), and whether the inflators will be used for standard vehicles or larger trucks and SUVs. This clarity will guide your search and help in evaluating suppliers.

Understanding current market trends and desirable features in tire inflators can give you a competitive edge. Look for innovations such as built-in pressure gauges, fast inflation times, and additional functionalities like USB charging ports or integrated lights. Features that enhance usability can differentiate your offerings in a crowded market.

Before committing to a supplier, conduct a thorough evaluation to ensure reliability and quality. Request detailed company profiles, product samples, and case studies from existing customers in similar industries. Pay attention to their manufacturing capabilities and quality assurance processes, as these will impact the durability and performance of the tire inflators.

Certifications can be a reliable indicator of product quality and compliance with international standards. Check for certifications such as ISO 9001 or CE marking, which demonstrate adherence to quality management systems and safety regulations. This verification process helps mitigate risks associated with subpar products.

Illustrative image related to tire inflator car

A hands-on demonstration of the tire inflators can provide invaluable insights into their performance and usability. Schedule meetings with potential suppliers to test the inflators, focusing on their inflation speed, pressure accuracy, and ease of use. This practical evaluation can help you gauge whether the product meets your specifications.

Once you have shortlisted potential suppliers, compare their pricing structures and payment terms. Consider not only the initial cost but also long-term value, including warranties, customer support, and shipping options. Look for suppliers who offer competitive prices without compromising quality.

Maintaining clear communication with your chosen supplier is essential for a successful partnership. Discuss expectations regarding delivery timelines, after-sales support, and any customization needs upfront. Establishing a strong communication channel ensures that any issues can be promptly addressed, fostering a smoother procurement process.

Illustrative image related to tire inflator car

By following this structured checklist, B2B buyers can navigate the complexities of sourcing tire inflators effectively, ensuring they select products that meet their operational needs while establishing strong supplier relationships.

When sourcing tire inflators for vehicles, understanding the cost structure is crucial for B2B buyers. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margins.

Materials comprise a significant portion of the cost, which varies based on the type of inflator (cordless, compact, or heavy-duty). For instance, inflators with advanced features like digital gauges or built-in batteries often require higher-grade materials, increasing overall costs.

Labor costs are influenced by the region of production. Countries with higher labor costs, such as Germany, may yield a more expensive product compared to manufacturing in regions like Vietnam or South America, where labor is typically less expensive.

Illustrative image related to tire inflator car

Manufacturing overhead includes expenses related to the production facility, utilities, and administrative costs. Efficient manufacturing processes can minimize these overheads, impacting the final pricing.

Tooling costs are associated with the design and production of specialized components. Custom designs will increase tooling expenses, which should be factored into negotiations.

Quality control is paramount in ensuring that each unit meets safety and performance standards, especially for international markets. The costs associated with QC can vary significantly based on the certifications required in different regions.

Logistics costs encompass shipping, customs duties, and transportation. For international buyers, understanding these costs is vital, as they can vary based on Incoterms and shipping methods.

Illustrative image related to tire inflator car

Margins will depend on the supplier’s pricing strategy, competition in the market, and perceived value of the product.

Several factors influence the pricing of tire inflators, including order volume (MOQ), specifications, material quality, certifications, supplier characteristics, and Incoterms.

Volume/MOQ: Higher order volumes often lead to better pricing due to economies of scale. Buyers should negotiate minimum order quantities that align with their purchasing capacity to achieve cost efficiency.

Specifications and Customization: Custom features such as specific PSI ratings, additional accessories, or unique designs can significantly impact pricing. Buyers should clearly define their specifications to avoid unexpected costs.

Materials and Quality: The choice of materials directly affects both the durability and price of the inflators. Higher quality materials may lead to a higher initial cost but can result in lower Total Cost of Ownership (TCO) due to reduced failure rates and longer lifespan.

Illustrative image related to tire inflator car

Certifications: Compliance with international safety and performance standards can add to costs but is essential for market acceptance. Understanding the certification requirements for each target market can aid in cost forecasting.

Supplier Factors: The supplier’s reputation, reliability, and production capacity can influence pricing. Establishing a long-term relationship with a trusted supplier can lead to better pricing and service.

Incoterms: These terms define the responsibilities of buyers and sellers in terms of shipping costs and risks. Buyers should choose Incoterms that minimize their total expenses and risks during transportation.

Illustrative image related to tire inflator car

To optimize sourcing strategies for tire inflators, buyers should consider several best practices.

Negotiation: Engage in open discussions with suppliers to negotiate better terms, especially for larger orders. Suppliers may be willing to adjust pricing based on long-term commitments.

Cost-Efficiency: Evaluate not just the purchase price but also the TCO. Consider maintenance, warranty, and potential failure rates when assessing overall value.

Pricing Nuances for International Buyers: Understanding local market conditions, including tariffs, taxes, and currency fluctuations, is essential for buyers from regions like Africa, South America, the Middle East, and Europe. These factors can significantly impact the landed cost of inflators.

Be Informed: Stay updated on market trends, competitor pricing, and emerging technologies in tire inflators. This knowledge will empower buyers to make informed decisions and negotiate effectively.

Disclaimer on Indicative Prices: Prices for tire inflators can fluctuate based on market dynamics, material costs, and supplier pricing strategies. Buyers are advised to obtain current quotations and consider potential price variations in their budgeting.

By understanding these cost components and pricing influencers, B2B buyers can make strategic sourcing decisions that align with their operational needs and budgetary constraints.

In the automotive maintenance landscape, tire inflators serve a vital role in ensuring vehicle safety and performance. However, there are various alternatives that can also achieve the goal of maintaining optimal tire pressure. This section examines the ‘tire inflator car’ against other viable solutions, helping B2B buyers make informed decisions based on their specific needs.

| Comparison Aspect | Tire Inflator Car | Portable Air Compressor | Manual Pump |

|---|---|---|---|

| Performance | Quick inflation for multiple tires | High PSI capability, ideal for heavy-duty vehicles | Limited to lower pressures, manual effort required |

| Cost | Moderate ($50 – $100) | Higher ($100 – $300) | Low ($15 – $50) |

| Ease of Implementation | User-friendly, plug-and-play | Requires basic electrical knowledge | Simple, no power needed |

| Maintenance | Minimal maintenance required | Regular checks needed for electrical components | Very low maintenance |

| Best Use Case | Everyday vehicles; convenience | Commercial vehicles and heavy-duty applications | Emergency or occasional use |

Portable air compressors are a robust alternative to tire inflators, especially for B2B buyers operating in sectors that require heavy-duty vehicles. They can deliver high PSI levels, making them suitable for larger tires found on trucks and SUVs. However, they tend to be pricier and may require a basic understanding of electrical connections, which could complicate their use in remote areas. Maintenance is also a consideration, as these units need regular checks to ensure electrical components function optimally.

Manual pumps are the most basic form of tire inflation and offer a cost-effective solution for infrequent tire maintenance. Their simplicity means no reliance on power sources, making them ideal for emergency situations or locations where electricity is unavailable. However, they require significant physical effort and are limited in terms of pressure capacity, making them less suitable for routine maintenance of modern vehicles. While they have very low maintenance needs, their performance may not meet the expectations of businesses with a fleet of vehicles.

Selecting the appropriate tire inflation solution depends on various factors, including vehicle type, frequency of use, and budget constraints. For businesses that prioritize convenience and speed, a tire inflator car is an excellent choice. In contrast, those dealing with heavy-duty vehicles may find that a portable air compressor better meets their needs. Meanwhile, manual pumps serve as a reliable backup option for emergency situations. By evaluating these factors, B2B buyers can choose a tire inflation method that aligns with their operational requirements and enhances their vehicle maintenance strategy.

When considering tire inflators for automotive applications, several technical properties are critical for ensuring performance, reliability, and user satisfaction. Understanding these specifications can aid B2B buyers in making informed purchasing decisions.

The maximum pressure rating, measured in pounds per square inch (PSI), indicates the highest air pressure the inflator can achieve. For most passenger vehicles, a rating of 30-35 PSI is adequate; however, heavy-duty vehicles may require inflators capable of reaching 80 PSI or higher. This specification is crucial for ensuring that the inflator meets the demands of various vehicle types, particularly in markets with a mix of passenger cars and trucks.

Illustrative image related to tire inflator car

The duty cycle refers to the duration an inflator can operate continuously before it needs to cool down. For instance, a duty cycle of 20 minutes means the inflator can run for that period before requiring a rest. This property is particularly important for B2B buyers in regions where tire maintenance is frequent, as it directly affects efficiency and productivity.

Tire inflators can be powered by various sources, including 12-volt car outlets, rechargeable batteries, or standard AC power. Understanding the power source is essential for ensuring compatibility with the intended use environment. For instance, inflators powered by rechargeable batteries may be more suitable for remote locations or markets with limited access to electrical outlets.

The pressure gauge type, whether analog or digital, affects the accuracy and ease of use of the inflator. Digital gauges generally provide more precise readings and are easier to read under various lighting conditions. This specification is important for B2B buyers who prioritize reliability and user-friendliness in their equipment.

Inflation speed measures how quickly an inflator can raise a tire’s pressure to a specified level. This property is often evaluated in terms of time taken to inflate a tire from a low pressure to the desired PSI. Faster inflation speeds can enhance customer satisfaction, particularly in high-demand environments, making it an essential consideration for B2B buyers.

The physical dimensions and weight of a tire inflator can significantly impact its usability and convenience. Compact and lightweight designs are preferable for consumers who need to store the inflator in a vehicle. Buyers in emerging markets, where space may be limited, will find this property particularly relevant.

Illustrative image related to tire inflator car

Understanding industry-specific terminology can facilitate smoother transactions and clearer communication between suppliers and buyers.

This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of tire inflators, OEM products are those that meet original design specifications. B2B buyers often seek OEM components to ensure compatibility and quality.

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is crucial for B2B buyers as it impacts inventory levels and cost management. Understanding MOQs can help buyers negotiate better terms and optimize their purchasing strategies.

An RFQ is a document used to solicit price quotes from suppliers. It typically includes detailed specifications and quantities required. For B2B buyers, issuing an RFQ is an effective way to compare offers and ensure they receive competitive pricing.

Incoterms are a set of predefined international trade terms that clarify the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with these terms is essential for B2B transactions, particularly when dealing with international suppliers.

Lead time refers to the time it takes from placing an order to receiving the product. Understanding lead times is critical for inventory planning and ensuring timely availability of tire inflators, especially in markets with high demand.

The warranty period specifies the duration during which a product is guaranteed to perform as advertised. This term is vital for B2B buyers who wish to mitigate risks associated with product failures and ensure long-term reliability.

By understanding these technical properties and trade terms, B2B buyers can navigate the tire inflator market more effectively, ensuring they select products that meet their needs and those of their customers.

The tire inflator car market is experiencing significant growth driven by several global factors. First, the increasing awareness of vehicle maintenance and safety among consumers is prompting a rise in demand for portable tire inflators. Moreover, as vehicles become more technologically advanced, the need for efficient and user-friendly inflators has gained traction. Emerging markets in Africa and South America are witnessing an influx of automotive sales, further boosting demand for tire maintenance products.

In terms of sourcing trends, international B2B buyers are increasingly focusing on products that combine functionality with advanced technology. For instance, inflators that feature digital pressure gauges, automatic shut-off mechanisms, and compact designs are becoming preferred choices. Additionally, the rise of e-commerce platforms has made it easier for buyers in regions like Vietnam and Germany to access a wider variety of products, allowing for better price comparisons and enhanced purchasing decisions.

Another notable trend is the growing inclination towards multi-functional inflators that not only inflate tires but also provide additional features such as USB charging ports and built-in lights. This trend aligns with the consumer preference for versatile tools that offer value beyond their primary function. As a result, suppliers are urged to innovate continuously to meet these evolving expectations.

Sustainability is becoming a pivotal concern for B2B buyers in the tire inflator sector. As environmental regulations tighten globally, businesses are increasingly scrutinizing their supply chains for ethical sourcing and environmental impact. This scrutiny extends to the materials used in tire inflators, with buyers seeking products that incorporate recycled or eco-friendly components.

Furthermore, ‘green’ certifications are gaining importance in purchasing decisions. Certifications such as ISO 14001 (Environmental Management) and Energy Star help buyers identify products that adhere to sustainable practices. Companies that can demonstrate their commitment to sustainability not only enhance their brand reputation but also attract environmentally-conscious consumers and businesses.

In addition, the emphasis on product lifecycle management is reshaping sourcing strategies. Suppliers that prioritize durability and repairability in their tire inflators are likely to gain favor among B2B buyers who aim to reduce waste. By investing in sustainable and ethically sourced products, companies can significantly mitigate their environmental footprint while aligning with the values of their target market.

The tire inflator sector has undergone a remarkable evolution, transitioning from simple hand pumps to sophisticated, battery-operated devices. In the early days, inflators were primarily mechanical, requiring manual operation and physical effort. However, advancements in technology have led to the development of electric inflators that provide quicker and more efficient inflation.

The introduction of digital gauges and automatic shut-off features has further transformed the user experience, making inflators not only easier to use but also more reliable. Today’s inflators are compact, lightweight, and often equipped with multiple functionalities, catering to the needs of modern consumers and businesses alike. This evolution highlights the importance of innovation in maintaining competitiveness in the B2B marketplace, as suppliers strive to meet the growing expectations of their clientele.

In summary, understanding these dynamics, sustainability trends, and historical context is crucial for international B2B buyers looking to navigate the tire inflator car sector effectively. By staying informed and adaptable, businesses can make strategic sourcing decisions that align with market demands and ethical considerations.

1. How do I choose the right tire inflator for my business needs?

Choosing the right tire inflator involves assessing your specific requirements, such as the types of vehicles you service and the frequency of use. Consider factors like portability, maximum PSI, and whether you need a cordless option for convenience. Additionally, evaluate the inflator’s speed and accuracy based on your operational needs. For businesses dealing with heavy-duty vehicles, a model that can handle higher pressures and larger tire volumes is essential. Reviewing customer feedback and product tests can also provide insights into performance and reliability.

2. What are the key features to look for in a tire inflator?

When selecting a tire inflator, prioritize features such as a built-in pressure gauge for accuracy, multiple power options (cordless or 12-volt), and a quick inflation time. Compatibility with various tire types, including those for trucks and SUVs, is crucial. Additional features like a carrying case, USB charging ports, and adapters for inflating recreational items can enhance usability. Ensure the inflator’s dimensions allow for easy storage within your service vehicles or workshops.

3. What is the best tire inflator for commercial use?

The best tire inflator for commercial use typically balances power, speed, and portability. Models like the AstroAI Cordless Tire Inflator stand out for their ability to quickly fill multiple tires on a single charge. For heavy-duty applications, the Viair 88P offers rapid inflation for larger tires but requires a direct connection to the vehicle’s battery. Evaluate your specific operational requirements, including tire sizes and expected inflation frequency, to choose the most effective model for your business.

4. How do I vet suppliers for tire inflators in international markets?

Vetting suppliers requires thorough research and due diligence. Start by checking their certifications, production capacity, and quality control processes. Request product samples to evaluate performance and reliability firsthand. Additionally, seek references or reviews from other businesses that have sourced from them. Engaging in direct communication can also help assess their responsiveness and customer service capabilities, which are critical for maintaining a successful partnership in international trade.

5. What are typical minimum order quantities (MOQs) for tire inflators?

Minimum order quantities for tire inflators can vary significantly depending on the supplier and the product type. Generally, MOQs can range from 50 to 500 units for commercial-grade inflators. It’s advisable to discuss MOQs upfront during negotiations to ensure they align with your business needs. Some suppliers may offer flexibility for first-time orders or bulk purchases, so exploring these options can help you optimize your inventory management.

6. What payment terms should I expect when purchasing tire inflators internationally?

Payment terms for international purchases typically vary by supplier but often include options like advance payment, letter of credit, or open account terms. It is common to negotiate a percentage upfront, with the balance due upon shipment or delivery. Ensure that the agreed payment terms are clearly outlined in the contract to avoid misunderstandings. Familiarize yourself with any currency exchange implications and transaction fees that may arise from international payments.

7. How can I ensure quality assurance for tire inflators sourced from abroad?

To ensure quality assurance, request detailed quality control processes from your supplier, including inspection protocols and testing standards. It’s beneficial to establish a quality assurance agreement that outlines acceptable defect rates and the procedures for handling non-conforming products. Additionally, consider engaging third-party inspection services to verify product quality before shipment. Consistent communication with your supplier throughout the production process can help address any issues proactively.

8. What logistics considerations should I keep in mind when importing tire inflators?

When importing tire inflators, consider factors like shipping methods, lead times, and customs regulations in your destination country. Evaluate the total landed cost, including shipping fees, duties, and taxes, to avoid budget overruns. Partnering with a reliable logistics provider can streamline the import process and ensure timely delivery. Familiarize yourself with your country’s import regulations to ensure compliance and mitigate delays at customs.

Domain: target.com

Registered: 1997 (28 years)

Introduction: This company, Target – Top-Rated Tire Inflators, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Key features to look for in a tire inflator include: 1. Auto shut-off function to prevent over-inflation. 2. Dual power options (battery and car plug) for versatility. 3. Fast inflation speed suitable for various vehicle types (cars, SUVs, trucks). 4. Clear digital display for easy reading. 5. PSI range between 120-150 for adequate pressure handling. 6. Compatibility with different nozzles for inf…

As the tire inflator market evolves, strategic sourcing remains paramount for international B2B buyers. By carefully selecting suppliers based on performance, reliability, and cost-effectiveness, businesses can optimize their inventory and enhance customer satisfaction. The recent evaluations highlight that inflators like the AstroAI Cordless Tire Inflator and Craftsman 12V Max Portable Air Inflator stand out for their efficiency and user-friendly features, making them ideal choices for diverse vehicle types across varying markets.

Investing in high-quality tire inflators not only ensures vehicle safety and performance but also translates into long-term savings through improved fuel efficiency and tire longevity. As buyers from Africa, South America, the Middle East, and Europe consider their sourcing strategies, it is essential to prioritize products that meet rigorous quality standards while also addressing regional market demands.

Looking ahead, the tire inflator sector is poised for growth, driven by advancements in technology and increasing awareness of vehicle maintenance. B2B buyers are encouraged to stay ahead of the curve by exploring innovative products and establishing partnerships with reputable manufacturers. By doing so, they can secure a competitive edge in their respective markets.

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.