In the competitive landscape of global commerce, sourcing high-quality tire inflator nozzles can pose significant challenges for B2B buyers. As businesses in Africa, South America, the Middle East, and Europe (notably Germany and Brazil) seek reliable solutions to meet their automotive needs, understanding the nuances of tire inflator nozzle selection becomes paramount. This guide aims to equip you with the insights necessary to navigate this market effectively, covering a comprehensive range of topics, from various nozzle types and their applications to supplier vetting processes and cost considerations.

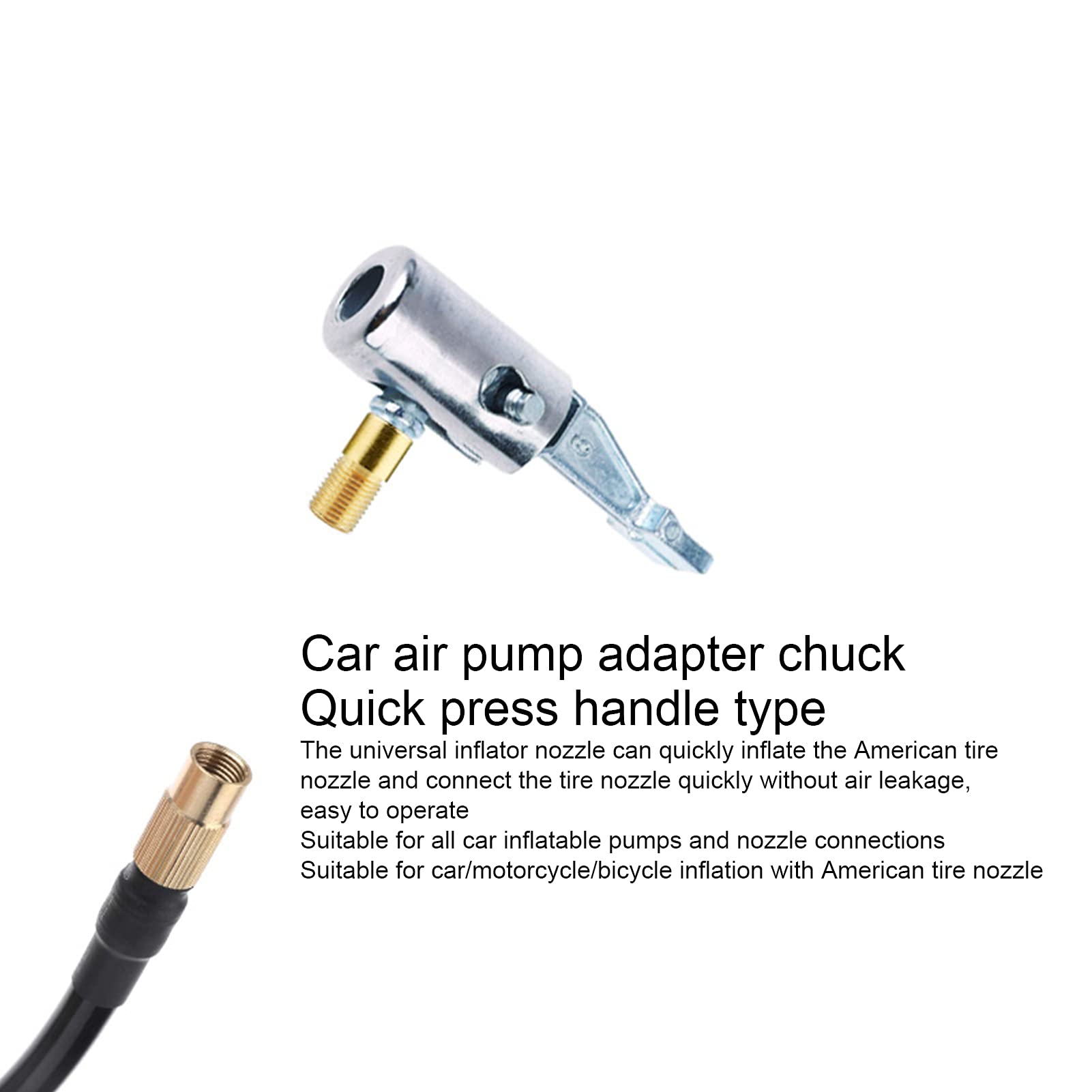

Tire inflator nozzles are not just simple attachments; they play a crucial role in ensuring efficient inflation processes and maintaining vehicle safety. With a myriad of options available, including self-locking and quick-release designs, choosing the right product can significantly impact operational efficiency. This guide is designed to empower you with the knowledge to make informed purchasing decisions, reducing the risk of costly errors and ensuring that your supply chain remains robust and responsive.

By delving into the intricacies of tire inflator nozzles, including market trends and supplier capabilities, this resource will help you streamline your procurement strategies. Whether you are looking to enhance your product offerings or secure reliable partnerships, our insights will serve as a valuable asset in your global sourcing endeavors.

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Screw-on Nozzle | Threaded connection for secure attachment | Automotive repair shops | Pros: Secure fit; Cons: Slower to attach/detach |

| Clip-on Nozzle | Spring-loaded mechanism for easy attachment | Tire service stations | Pros: Quick connection; Cons: Less secure than screw-on |

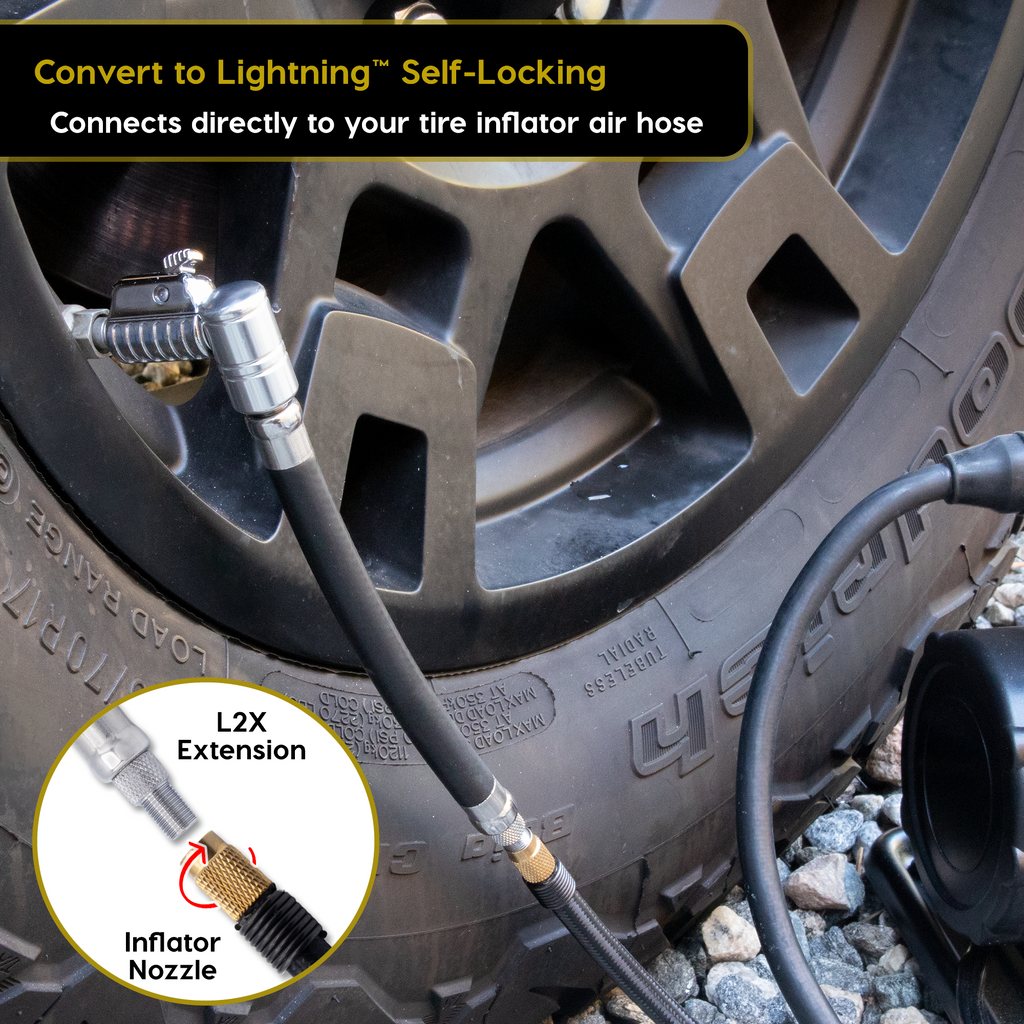

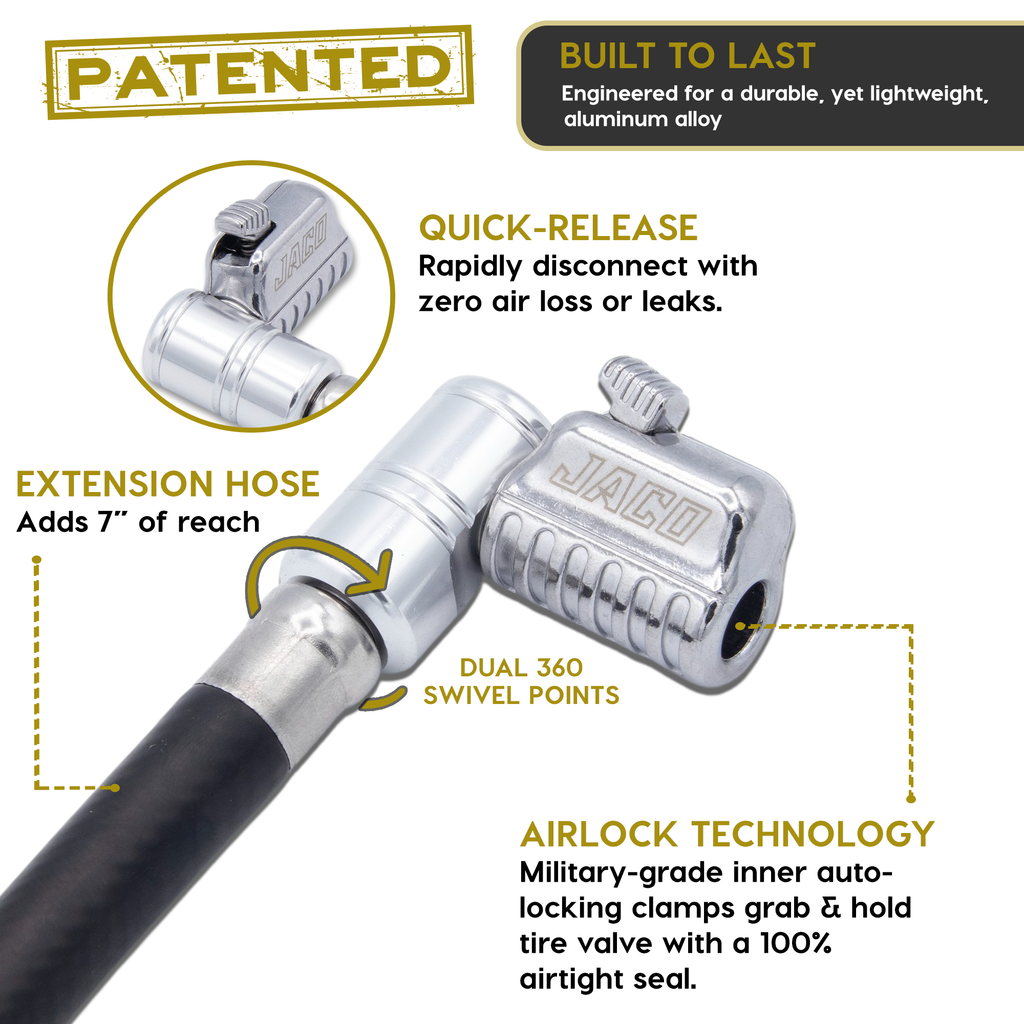

| Self-locking Nozzle | Patented design for automatic locking during inflation | Mobile tire service providers | Pros: Hands-free operation; Cons: Higher initial cost |

| Thumb-lock Nozzle | Manual locking mechanism for versatility | General consumer use | Pros: Affordable; Cons: Requires manual operation |

| Dual-purpose Nozzle | Compatible with both Schrader and Presta valves | Bicycle shops, automotive workshops | Pros: Versatile; Cons: May compromise performance on one type |

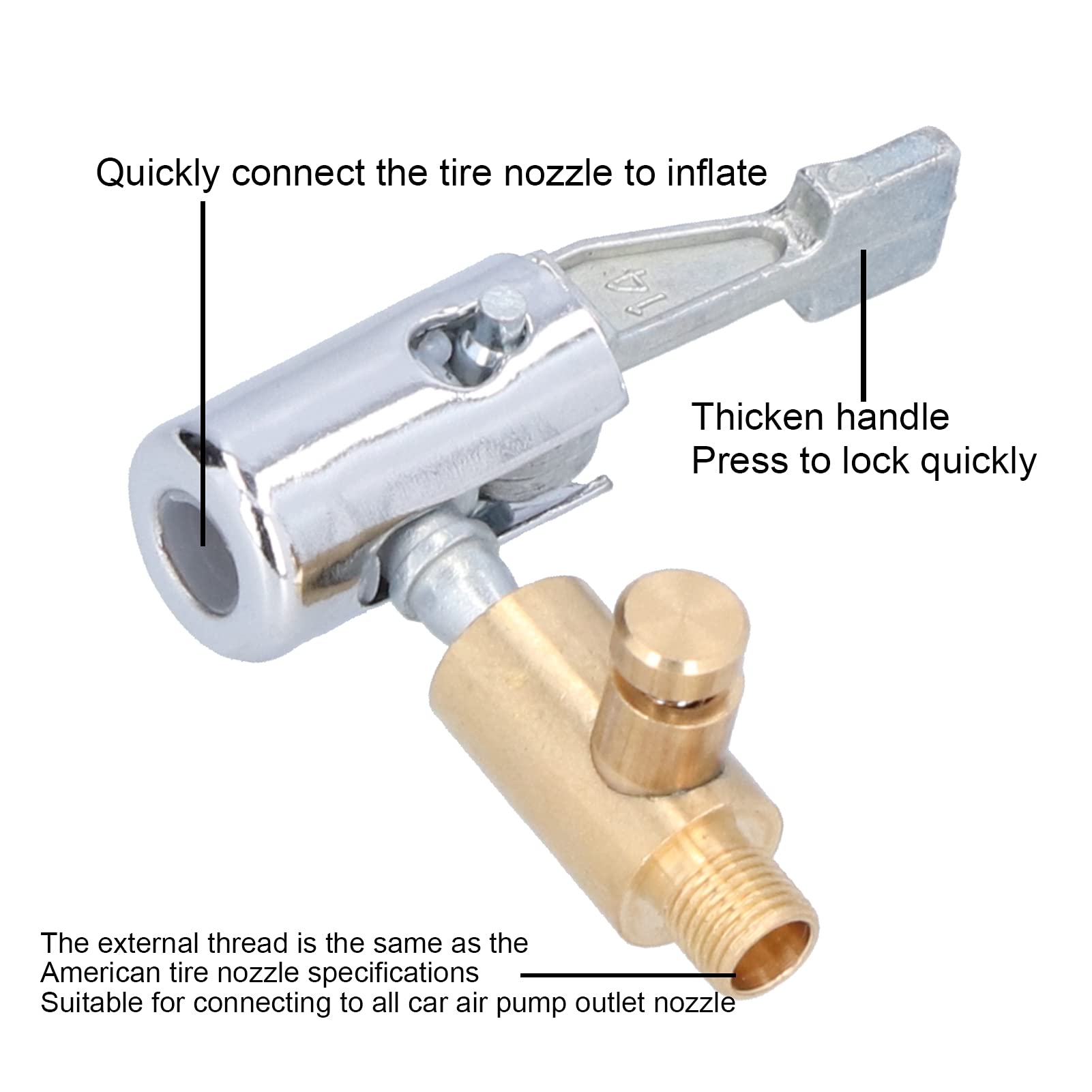

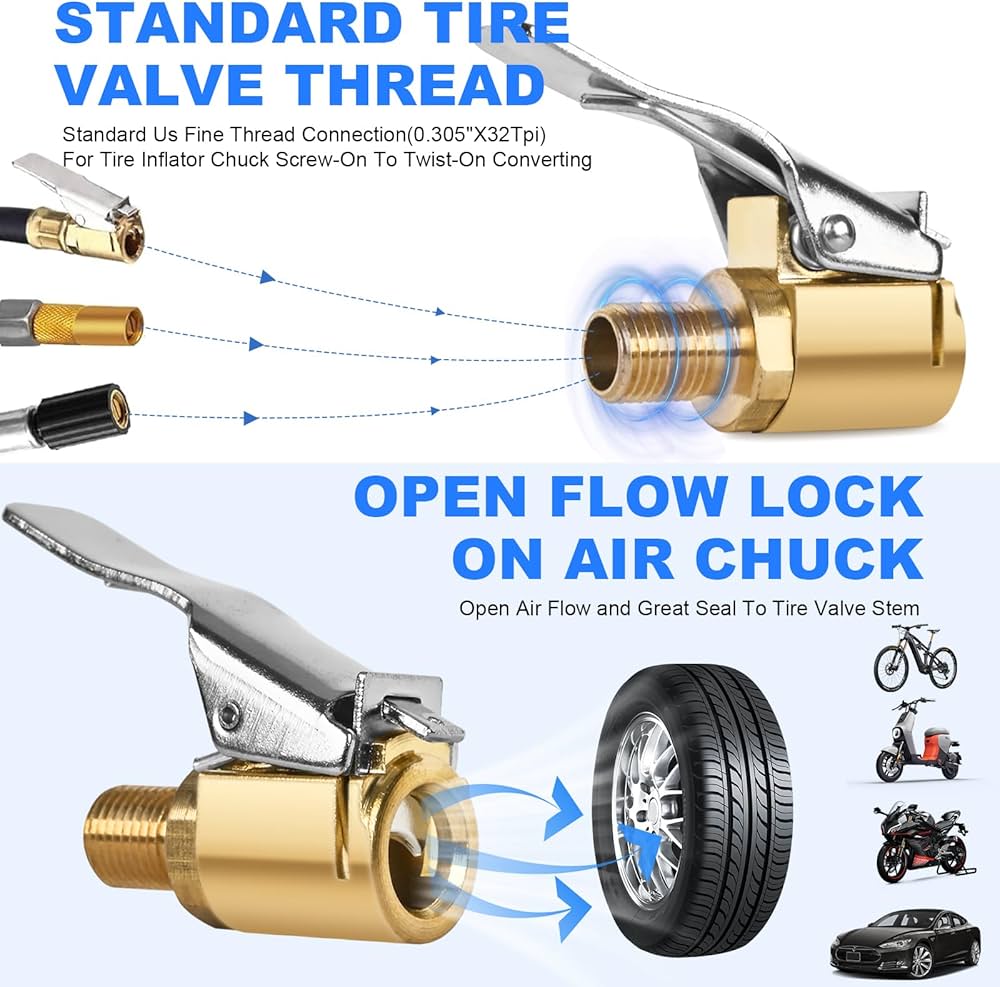

Screw-on nozzles feature a threaded design that ensures a tight seal during inflation, making them particularly suitable for automotive repair shops where reliability is paramount. Their secure fit minimizes air loss, which is critical for maintaining tire pressure. However, the time required to attach and detach these nozzles can be a drawback for businesses that prioritize speed in service delivery.

Clip-on nozzles utilize a spring-loaded mechanism that allows for quick attachment to the tire valve. This feature is especially beneficial in tire service stations, where rapid turnaround times are essential. While they provide a faster connection compared to screw-on variants, they may not offer the same level of security, leading to potential air loss during inflation.

Self-locking nozzles are designed to automatically lock onto the tire valve during inflation, allowing for hands-free operation. This innovation is particularly advantageous for mobile tire service providers who require efficiency and ease of use. Despite their higher initial cost, the labor savings and enhanced user experience can justify the investment, making them a valuable addition to a mobile tire service toolkit.

Thumb-lock nozzles are a cost-effective option commonly used in consumer applications. Their manual locking mechanism allows users to easily attach and detach the nozzle, making them suitable for personal use. While they are affordable and widely available, the need for manual operation may deter businesses that require faster inflation processes.

Dual-purpose nozzles are designed to work with both Schrader and Presta valves, making them ideal for bicycle shops and automotive workshops that service a variety of vehicles. This versatility allows businesses to streamline their operations by reducing the number of tools required. However, buyers should consider that performance may vary between valve types, potentially affecting inflation efficiency.

| Industry/Sector | Specific Application of tire inflator nozzle | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Services | Tire maintenance and repair in workshops | Enhances efficiency and reduces downtime | Durability, compatibility with various tire types, ease of use |

| Transportation & Logistics | Fleet vehicle tire inflation and maintenance | Ensures safety and reduces operational costs | Bulk purchasing options, reliability, quick-connect features |

| Manufacturing | Inflation of pneumatic tools and machinery | Improves productivity and equipment reliability | Industrial-grade materials, pressure ratings, and safety certifications |

| Agriculture | Tire inflation for agricultural machinery and vehicles | Increases operational efficiency and reduces tire wear | Versatility for different tire sizes, rugged design for harsh environments |

| Construction | Tire inflation for heavy construction equipment | Minimizes equipment failure and maintenance costs | Robust construction, compatibility with various air compressors |

In automotive workshops, tire inflator nozzles are essential for ensuring that tires are properly inflated for safety and performance. Technicians utilize these nozzles to quickly attach to tire valves, allowing for efficient air inflation. This process not only enhances vehicle safety but also minimizes downtime during repairs. International buyers in this sector should prioritize nozzles that offer durability and compatibility with a variety of tire types, ensuring they can meet diverse customer needs.

Illustrative image related to tire inflator nozzle

In the transportation and logistics sector, tire inflator nozzles are crucial for maintaining fleet vehicles. Regular tire inflation helps ensure optimal fuel efficiency and safety. Businesses can significantly reduce operational costs by preventing tire blowouts and extending tire life. Buyers should consider sourcing nozzles that offer quick-connect features for ease of use and reliability, especially when managing large fleets in diverse geographical regions.

In manufacturing, tire inflator nozzles are used to inflate pneumatic tools and machinery, which are vital for production processes. Properly inflated tires on equipment ensure improved productivity and minimize the risk of equipment failure. B2B buyers in this industry should seek nozzles made from industrial-grade materials that can withstand high pressures, as well as safety certifications to ensure compliance with industry standards.

Agricultural machinery relies heavily on tire inflator nozzles for maintaining optimal tire pressure. Proper inflation is critical for maximizing efficiency and reducing wear on tires, which can be costly for farmers. Buyers in the agriculture sector should look for nozzles that are versatile enough to accommodate different tire sizes and rugged enough to handle harsh outdoor conditions, ensuring reliability in the field.

Illustrative image related to tire inflator nozzle

In the construction industry, tire inflator nozzles are used to maintain the tires of heavy equipment, such as bulldozers and excavators. Proper tire inflation is essential for minimizing equipment failure and maintenance costs. Construction companies should focus on sourcing robust nozzles that are compatible with various air compressors, ensuring they can quickly and efficiently inflate tires on-site to keep projects on schedule.

The Problem: One of the primary challenges B2B buyers face when sourcing tire inflator nozzles is ensuring compatibility with various tire types and inflator models. Many businesses operate a fleet of vehicles or offer tire services for diverse makes and models. A nozzle that fits one type of tire valve may not fit another, leading to inefficiencies, wasted time, and potential customer dissatisfaction. This issue can be particularly pronounced in regions with a wide variety of vehicles, such as Africa and South America, where local automotive preferences can vary significantly.

The Solution: To address compatibility concerns, B2B buyers should prioritize sourcing nozzles that feature universal designs or adjustable fittings. When evaluating products, look for nozzles that come with specifications clearly indicating compatibility with multiple valve types, such as Schrader and Presta. Moreover, consider establishing relationships with suppliers who can provide comprehensive catalogs that include visual guides or charts comparing different nozzle types. Additionally, investing in a range of nozzles as part of your inventory can ensure that you are equipped to handle diverse customer needs without delay.

The Problem: Another significant pain point is the durability and reliability of tire inflator nozzles. Businesses often experience frequent breakdowns or failures of nozzles, especially in high-demand environments like automotive repair shops or logistics companies. Poor-quality nozzles can lead to air leaks, inefficient inflation, and increased operational costs, not to mention the inconvenience of having to replace them regularly. This is particularly concerning in regions with extreme weather conditions, which can exacerbate wear and tear.

Illustrative image related to tire inflator nozzle

The Solution: To combat durability issues, B2B buyers should invest in high-quality tire inflator nozzles made from robust materials such as brass or high-grade plastics that can withstand harsh conditions. When sourcing, look for products that offer warranties or guarantees, as these often indicate a manufacturer’s confidence in their product’s longevity. Additionally, implementing a regular maintenance schedule for inflators and their nozzles can significantly extend their lifespan. This includes checking for wear and tear, cleaning nozzles to prevent blockages, and replacing any worn components before they fail.

The Problem: Many B2B buyers encounter inefficiencies during the tire inflation process due to the design of the inflator nozzles. For instance, traditional screw-on or clip-on nozzles can be cumbersome and time-consuming, especially in a busy workshop environment where quick service is essential. Delays in inflation can lead to longer wait times for customers and reduced overall productivity, impacting a business’s bottom line.

The Solution: To enhance efficiency, buyers should consider sourcing tire inflator nozzles with innovative designs, such as self-locking or quick-release mechanisms. These types of nozzles allow for faster attachment and detachment, significantly reducing the time spent on each inflation. When selecting a supplier, look for those who offer advanced nozzle technologies that prioritize ease of use. Additionally, training staff on the optimal use of these nozzles can further streamline the inflation process, ensuring that all team members are adept at maximizing the equipment’s capabilities. Investing in user-friendly nozzles will not only improve operational efficiency but also enhance customer satisfaction through quicker service.

Illustrative image related to tire inflator nozzle

When selecting materials for tire inflator nozzles, it is crucial for B2B buyers to understand the properties, advantages, and limitations of various materials. This knowledge can significantly impact product performance, durability, and compliance with international standards. Below, we analyze four common materials used in the manufacturing of tire inflator nozzles.

Brass is a popular choice for tire inflator nozzles due to its excellent corrosion resistance and strength. It typically has a temperature rating of up to 200°C and can withstand moderate pressure levels, making it suitable for various tire inflation applications. Brass is also relatively easy to machine, allowing for precise manufacturing.

Pros and Cons of Brass:

The primary advantage of brass is its durability and resistance to rust, which is essential for products exposed to moisture. However, it can be more expensive than other materials like plastic or aluminum. Additionally, brass may not be suitable for high-pressure applications, which can limit its use in certain markets.

Impact on Application:

Brass nozzles are compatible with air and other non-corrosive gases, making them versatile. However, they may not be ideal for applications involving aggressive chemicals or extreme temperatures.

Illustrative image related to tire inflator nozzle

Considerations for International Buyers:

Buyers in regions like Europe and the Middle East should ensure that brass components meet relevant standards such as ASTM B16 or EN 12164. Compliance with local regulations regarding lead content is also essential, especially in the EU.

Aluminum is lightweight and offers excellent strength-to-weight ratios, making it an attractive option for portable tire inflators. It has a temperature rating of approximately 150°C and can handle moderate pressure, similar to brass.

Pros and Cons of Aluminum:

The key advantage of aluminum is its lightweight nature, which enhances the portability of tire inflators. However, aluminum is more prone to corrosion compared to brass unless it is anodized or treated. This treatment can increase manufacturing complexity and cost.

Impact on Application:

Aluminum nozzles are suitable for air and non-corrosive gases, but their susceptibility to corrosion may limit their use in humid environments or applications involving moisture.

Illustrative image related to tire inflator nozzle

Considerations for International Buyers:

Buyers should look for aluminum nozzles that comply with standards such as ASTM B221 or EN 573. In regions like Brazil, where humidity can be high, anodized aluminum may be preferred to enhance durability.

Plastic nozzles, often made from materials like polypropylene or nylon, are lightweight and resistant to corrosion. They can typically withstand temperatures up to 80°C and moderate pressures, making them suitable for less demanding applications.

Pros and Cons of Plastic:

The main advantage of plastic is its low cost and ease of manufacturing, allowing for high-volume production. However, plastic nozzles may not be as durable as metal options and can be less effective in high-pressure situations.

Impact on Application:

Plastic nozzles are ideal for consumer-grade tire inflators used in light-duty applications. They are compatible with air but may not be suitable for high-temperature or high-pressure uses.

Considerations for International Buyers:

Buyers should ensure that plastic nozzles meet relevant safety standards such as ISO 9001. In regions like Africa, where the market may demand cost-effective solutions, plastic options can be appealing.

Rubber is often used in conjunction with metal or plastic nozzles to create seals that enhance performance. Rubber seals can withstand temperatures up to 100°C and provide excellent sealing capabilities against air leaks.

Pros and Cons of Rubber:

The primary advantage of rubber seals is their ability to create airtight connections, which is crucial for effective tire inflation. However, rubber can degrade over time, especially when exposed to UV light or extreme temperatures.

Impact on Application:

Rubber seals are essential for ensuring that no air escapes during inflation, making them critical for all types of tire inflators.

Considerations for International Buyers:

Buyers should ensure that rubber components comply with standards like ASTM D2000 to guarantee quality and performance.

| Material | Typical Use Case for tire inflator nozzle | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Brass | High-durability inflators | Excellent corrosion resistance | Higher cost, limited pressure use | Medium |

| Aluminum | Portable tire inflators | Lightweight and strong | Prone to corrosion without treatment | Medium |

| Plastic | Consumer-grade inflators | Low cost and easy to manufacture | Less durable, limited pressure use | Low |

| Rubber | Sealing components in nozzles | Creates airtight connections | Degrades over time | Low |

This strategic material selection guide provides B2B buyers with essential insights into the properties and applications of various materials used in tire inflator nozzles, aiding in informed purchasing decisions tailored to specific market needs.

The manufacturing process for tire inflator nozzles typically comprises several key stages: material preparation, forming, assembly, and finishing.

Material Preparation: The process begins with the selection of appropriate materials, often high-grade plastics and metals that can withstand high pressure and corrosion. Suppliers must ensure that materials meet international quality standards to ensure durability and performance. This stage often involves sourcing raw materials from certified suppliers to guarantee quality.

Forming: Once materials are prepared, they undergo forming techniques such as injection molding or machining. Injection molding is widely used for plastic components, allowing for precision and scalability in production. Metal parts may be produced using CNC machining or die casting to achieve the required specifications and tolerances.

Assembly: After forming, components are assembled. This stage can include the integration of valves, seals, and locking mechanisms. Automated assembly lines are commonly employed to enhance efficiency and accuracy, reducing the likelihood of human error.

Finishing: The final stage involves surface treatment processes, such as anodizing for metal components or applying protective coatings for plastics. This not only enhances aesthetic appeal but also improves resistance to wear and environmental factors.

Quality assurance (QA) is critical in the production of tire inflator nozzles to ensure that products meet safety and performance standards.

International Standards Compliance: Manufacturers typically adhere to international standards such as ISO 9001, which outlines requirements for a quality management system. Compliance with additional certifications like CE for European markets and API for certain industrial applications further establishes product reliability.

Quality Control Checkpoints: QA involves several checkpoints throughout the manufacturing process:

– Incoming Quality Control (IQC): At this stage, raw materials are inspected to ensure they meet specified standards before they are used in production.

– In-Process Quality Control (IPQC): During manufacturing, random samples are taken to monitor ongoing production quality. This includes checking dimensions, weight, and other critical parameters.

– Final Quality Control (FQC): Before products are packaged and shipped, a thorough inspection is performed. This includes functionality tests, pressure tests, and visual inspections to identify any defects.

Various testing methods are employed to validate the quality and functionality of tire inflator nozzles.

Pressure Testing: This method assesses the ability of the nozzle to maintain pressure without leaking. It simulates real-world conditions and is crucial for safety.

Functional Testing: Each nozzle is tested to ensure it properly connects and seals with standard tire valves, allowing for efficient air transfer.

Durability Testing: Nozzles are subjected to repeated use scenarios to evaluate their performance over time. This includes resistance to wear, corrosion, and extreme temperatures.

Visual Inspections: A thorough visual check is conducted to identify any cosmetic defects, such as scratches or improper finishes, that could affect customer satisfaction.

For international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, verifying supplier quality control is essential for ensuring reliable partnerships.

Supplier Audits: Conducting regular audits of suppliers can provide insights into their manufacturing processes, quality management systems, and adherence to international standards. Buyers can assess the production environment, equipment, and employee training.

Quality Reports: Requesting detailed quality reports that document compliance with international standards and internal QC processes can help buyers gauge supplier reliability. This includes documentation of test results and corrective actions taken for any deviations.

Third-party Inspections: Engaging third-party quality assurance services can provide an unbiased evaluation of the supplier’s quality control processes. These inspections can be particularly useful for buyers unfamiliar with the local manufacturing landscape.

Understanding the nuances of quality control and certification is crucial for international buyers to navigate varying standards across regions.

Regional Certification Requirements: Different regions have specific certification requirements. For example, CE marking is essential for products sold in the European market, while other regions may have their own certifications that must be met.

Local Regulations: Buyers must be aware of local regulations governing product safety and quality. This can include environmental regulations that impact material selection and manufacturing processes.

Cultural Considerations: Building strong relationships with suppliers in different regions may require understanding cultural business practices. This can affect communication, negotiation, and the overall quality assurance process.

By closely examining the manufacturing processes and quality assurance measures for tire inflator nozzles, B2B buyers can make informed decisions that align with their operational standards and customer expectations. Ensuring compliance with international standards and conducting thorough supplier evaluations are critical steps in establishing successful partnerships in the global marketplace.

Illustrative image related to tire inflator nozzle

To successfully procure tire inflator nozzles for your business, it is essential to follow a structured approach. This guide provides a practical checklist to help international B2B buyers navigate the sourcing process effectively, ensuring you make informed decisions that align with your operational needs.

Establish clear technical specifications for the tire inflator nozzles you need. Consider factors such as compatibility with existing equipment, material quality, pressure ratings, and any specific features like self-locking mechanisms. Defining these criteria upfront will streamline your search and facilitate discussions with potential suppliers.

Conduct thorough market research to identify current trends in tire inflator nozzle technology and design. This includes understanding what features are popular among your competitors and any innovations that could enhance your product offering. Utilize industry reports, trade publications, and online resources to compile a list of potential suppliers who meet your criteria.

Illustrative image related to tire inflator nozzle

Before committing to any supplier, it’s crucial to conduct a comprehensive evaluation. Request detailed company profiles, product catalogs, and case studies that demonstrate their expertise in manufacturing tire inflator nozzles. Additionally, seek out references or testimonials from clients in your industry to gauge supplier reliability and performance.

Ensure that your chosen suppliers comply with relevant industry standards and regulations. Certifications such as ISO 9001 or specific safety standards can indicate a supplier’s commitment to quality and safety. Furthermore, check if they adhere to environmental regulations, especially if your business operates in regions with stringent environmental laws.

Before placing a bulk order, request samples of the tire inflator nozzles for testing. This step is critical to evaluate the product’s performance, durability, and compatibility with your systems. Testing samples will also help you identify any potential issues before committing to a larger purchase.

Illustrative image related to tire inflator nozzle

Once you have selected a supplier and tested their products, enter into negotiations regarding pricing and terms. Be clear about your budget constraints and the volume of nozzles you plan to order. Discuss payment terms, shipping options, and lead times to ensure that both parties have aligned expectations.

After successfully sourcing your tire inflator nozzles, focus on building a long-term relationship with your supplier. Regular communication, feedback, and collaboration on future projects can lead to better pricing, priority service, and access to new products. A strong partnership can significantly enhance your supply chain resilience and efficiency.

Following this checklist will help you navigate the complexities of sourcing tire inflator nozzles, ensuring that you make informed decisions that benefit your business in the long run.

When evaluating the cost structure for tire inflator nozzles, several components come into play. The primary cost elements include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margins.

Illustrative image related to tire inflator nozzle

Materials: The choice of materials directly impacts costs. Common materials include plastics and metals like aluminum or brass, each with varying price points depending on quality and source. For instance, high-grade aluminum nozzles may offer durability and performance but come at a higher cost compared to standard plastic options.

Labor: Labor costs can vary significantly based on the production location. For example, sourcing from regions with lower labor costs may provide short-term savings, but potential trade-offs in quality and reliability should be considered.

Manufacturing Overhead: This includes utilities, rent, and equipment maintenance associated with the production facility. Overhead costs can be minimized through efficient manufacturing processes, which is essential for competitive pricing.

Tooling: Initial tooling costs can be substantial, especially for custom designs. However, these costs are often amortized over large production runs, making them less significant per unit when ordering in bulk.

Quality Control: Investing in robust QC processes ensures that products meet required standards, thereby reducing returns and enhancing customer satisfaction. This can add to the initial cost but may reduce long-term expenses related to defects.

Logistics: Transportation and storage costs are critical, particularly for international buyers. Understanding Incoterms can help clarify who bears these costs and responsibilities throughout the shipping process.

Margin: Suppliers typically mark up prices to cover their costs and ensure profitability. This margin can vary based on competition, demand, and the perceived value of the nozzle.

Several factors influence the pricing of tire inflator nozzles, which B2B buyers must consider to optimize their sourcing strategy.

Volume/MOQ: Suppliers often offer better pricing for larger orders due to economies of scale. Minimum Order Quantities (MOQ) can affect the total cost, making it essential for buyers to align their purchasing strategies with supplier requirements.

Specifications and Customization: Custom designs or specific features can significantly increase costs. Buyers should weigh the benefits of customization against the potential for higher prices.

Materials and Quality Certifications: Premium materials and certifications (e.g., ISO, CE) can justify higher prices due to their assurance of quality and safety. Buyers targeting markets with stringent regulations must factor these costs into their budgeting.

Supplier Factors: The supplier’s reputation, reliability, and production capacity can affect pricing. Established suppliers may charge more, but their proven track record can mitigate risks associated with quality and delivery.

Incoterms: Understanding the agreed terms of shipment can impact overall costs. Different Incoterms (e.g., FOB, CIF) dictate who is responsible for shipping costs and insurance, which can influence the final price.

For international B2B buyers, especially in regions such as Africa, South America, the Middle East, and Europe, effective negotiation can lead to significant savings.

Research and Benchmarking: Conduct thorough market research to understand prevailing prices and quality standards. This knowledge empowers buyers during negotiations.

Total Cost of Ownership (TCO): Consider not just the purchase price but the entire lifecycle cost of the nozzles, including maintenance, durability, and potential replacement costs. A higher upfront cost may be justified by lower long-term expenses.

Leverage Relationships: Building strong relationships with suppliers can lead to better pricing and terms. Regular communication and a clear understanding of mutual goals enhance collaboration.

Flexibility in Orders: If possible, be flexible with order sizes and delivery timelines. This flexibility can encourage suppliers to offer better pricing or terms, particularly in volatile markets.

Consider Local Suppliers: For buyers in regions like Africa and South America, sourcing from local manufacturers may reduce logistics costs and import tariffs, enhancing overall cost efficiency.

In conclusion, a comprehensive understanding of the cost structure and price influencers in tire inflator nozzle sourcing can empower B2B buyers to make informed decisions. By applying strategic negotiation tactics and considering the total cost of ownership, buyers can optimize their procurement processes and enhance their competitive edge in the marketplace.

In the realm of tire maintenance, tire inflator nozzles serve a crucial role in ensuring optimal tire pressure. However, various alternatives exist that can also achieve similar results. Understanding these alternatives can help businesses make informed decisions that best suit their operational needs, especially in regions with unique market dynamics like Africa, South America, the Middle East, and Europe.

| Comparison Aspect | Tire Inflator Nozzle | Portable Air Compressor | Electric Tire Pump |

|---|---|---|---|

| Performance | Effective for quick inflation | High air volume for multiple uses | Convenient for small tasks |

| Cost | Low to moderate ($20-$40) | Moderate to high ($50-$200) | Moderate ($30-$80) |

| Ease of Implementation | Simple attachment to tire valve | Requires setup and power source | Plug-and-play operation |

| Maintenance | Minimal maintenance required | Regular maintenance needed | Low maintenance |

| Best Use Case | Individual tire inflation | Workshops, fleet maintenance | Personal vehicles, emergencies |

Portable air compressors are versatile tools that can inflate tires and power pneumatic tools. They are particularly advantageous for larger operations, such as workshops or fleet services, where consistent air supply is essential. While they offer a higher volume of air and can handle multiple tasks, they come with a higher price point and require regular maintenance. Their bulkiness may limit portability, making them less ideal for individual users who need quick, on-the-go solutions.

Illustrative image related to tire inflator nozzle

Electric tire pumps are compact devices that can inflate tires efficiently without needing a manual air source. They are user-friendly, with many models featuring automatic shut-off functions that prevent over-inflation. The convenience of having a plug-and-play design makes them suitable for personal vehicle maintenance and emergency situations. However, they generally have a lower air output compared to compressors and may take longer to inflate larger tires. Their pricing is moderate, appealing to individual buyers but potentially limiting for commercial use.

When selecting between tire inflator nozzles and their alternatives, B2B buyers should consider their specific needs, budget constraints, and the volume of tire maintenance required. For businesses focused on individual tire inflation, a tire inflator nozzle may be the most cost-effective and efficient solution. Conversely, companies needing to service multiple vehicles or equipment may find greater value in investing in portable air compressors or electric tire pumps. Ultimately, aligning the choice of equipment with operational demands will ensure optimal performance and cost-effectiveness.

When selecting tire inflator nozzles for B2B applications, several technical properties are crucial to ensure reliability, efficiency, and compatibility. Here are the key specifications to consider:

The material used in tire inflator nozzles typically includes high-strength plastics, aluminum, or brass. The choice of material affects durability, weight, and corrosion resistance. For example, brass nozzles are favored for their durability and resistance to wear, making them ideal for high-frequency use in commercial settings. Understanding material grade helps buyers assess the product’s lifespan and performance under various environmental conditions.

The pressure rating indicates the maximum pressure the nozzle can handle safely, usually expressed in PSI (pounds per square inch). A higher pressure rating allows for compatibility with various inflator models and ensures that the nozzle can withstand demanding tasks without failure. This specification is vital for B2B buyers, as it directly impacts operational efficiency and safety.

Illustrative image related to tire inflator nozzle

Different nozzles come with various connection types, such as clip-on, screw-on, or self-locking designs. The connection type determines how easily the nozzle can be attached to the tire valve and impacts the speed of inflation. For businesses, selecting the appropriate connection type is essential for minimizing downtime and ensuring smooth operations in high-volume environments.

The flow rate, often measured in cubic feet per minute (CFM), indicates how quickly air can be transmitted through the nozzle. A higher flow rate translates to faster inflation times, which is particularly beneficial for businesses that require quick turnaround times. Evaluating flow rates helps buyers match nozzles with their inflators and operational needs.

Temperature tolerance refers to the range of temperatures the nozzle can withstand without compromising its integrity. This is particularly important in regions with extreme weather conditions. Knowing the temperature tolerance helps businesses ensure that their inflator nozzles will perform reliably regardless of environmental factors.

Understanding industry terminology can streamline the procurement process and enhance communication between buyers and suppliers. Here are some common terms used in the tire inflator nozzle trade:

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of tire inflator nozzles, purchasing OEM parts ensures compatibility and quality, as they are designed specifically for certain tire inflator models. B2B buyers often prefer OEM parts to maintain warranty protections and reliability.

Illustrative image related to tire inflator nozzle

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ helps buyers plan their purchases effectively, ensuring they meet the supplier’s requirements while avoiding excess inventory. This is crucial for cost management in B2B transactions.

An RFQ is a formal request from a buyer to suppliers to provide pricing for specific products or services. In the context of tire inflator nozzles, submitting an RFQ allows businesses to compare prices, evaluate different suppliers, and make informed purchasing decisions based on cost-effectiveness.

Incoterms are a set of rules that define the responsibilities of buyers and sellers in international transactions. These terms clarify who is responsible for shipping, insurance, and tariffs, which can significantly impact the total cost of procurement. Understanding Incoterms is essential for B2B buyers engaged in global sourcing of tire inflator nozzles.

Lead time refers to the period between placing an order and receiving the product. In the tire inflator nozzle industry, shorter lead times can enhance a company’s ability to respond to market demands. B2B buyers should inquire about lead times to plan inventory levels and ensure timely service delivery to their customers.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions that enhance operational efficiency and drive profitability in their tire inflator nozzle procurement processes.

The tire inflator nozzle market is currently experiencing significant growth, driven by increasing vehicle ownership, the rise of e-commerce, and a growing awareness of vehicle maintenance among consumers. In regions such as Africa and South America, where automotive markets are expanding rapidly, the demand for reliable and efficient tire inflators is surging. This demand is further propelled by the need for quick solutions to roadside emergencies, making portable inflators with advanced nozzle designs particularly appealing.

Illustrative image related to tire inflator nozzle

Emerging technologies are transforming the way tire inflator nozzles are designed and produced. Innovations such as self-locking mechanisms and quick-release features are becoming standard, enhancing user experience and efficiency. Additionally, advancements in materials science are leading to the development of more durable and lightweight nozzles, appealing to both manufacturers and end-users. B2B buyers should be aware of these trends, as they can influence purchasing decisions and supplier selection.

Internationally, buyers are increasingly focusing on sourcing strategies that emphasize quality and reliability. As competition intensifies, suppliers who can offer superior product features, such as patented designs or enhanced compatibility with various tire valves, will have a competitive edge. Furthermore, a shift towards online procurement platforms is facilitating easier access to a wider range of products, allowing buyers from diverse regions to compare options and make informed decisions.

Sustainability and ethical sourcing are becoming paramount in the tire inflator nozzle sector. As global awareness of environmental issues grows, B2B buyers are increasingly prioritizing suppliers who adopt sustainable practices. This includes sourcing materials that are recyclable or made from renewable resources. For instance, nozzles made from high-quality, eco-friendly plastics not only reduce environmental impact but also appeal to a conscientious consumer base.

Moreover, transparency in supply chains is crucial. B2B buyers are now more inclined to partner with manufacturers who can demonstrate ethical practices, such as fair labor conditions and responsible sourcing of raw materials. Certifications like ISO 14001 for environmental management or Fair Trade can serve as critical indicators of a supplier’s commitment to sustainability.

As sustainability becomes a key differentiator, companies that invest in green technologies and practices will likely find themselves at an advantage. This trend not only aligns with global sustainability goals but also helps businesses mitigate risks associated with regulatory changes and shifting consumer preferences.

The evolution of tire inflator nozzles can be traced back to the early 20th century when the automobile industry began to flourish. Initially, tire inflation was a manual process, relying on cumbersome tools that required significant effort and skill. Over the decades, innovations in design and materials led to the development of more user-friendly nozzles, including the introduction of clip-on and thumb-lock designs.

By the late 20th century, the tire inflator nozzle market began to see the emergence of automated solutions, driven by advancements in pneumatic technology. Today, modern nozzles are characterized by features that enhance user convenience and efficiency, such as self-locking mechanisms and compatibility with multiple tire types. This historical context is essential for B2B buyers to understand the trajectory of product development and the factors influencing current market dynamics.

Illustrative image related to tire inflator nozzle

In conclusion, navigating the tire inflator nozzle sector requires a keen understanding of emerging trends, sustainability priorities, and historical developments. B2B buyers who stay informed and adapt to these dynamics will be better positioned to make strategic sourcing decisions that align with their business goals and market demands.

How do I choose the right tire inflator nozzle for my business needs?

Selecting the right tire inflator nozzle involves understanding your specific requirements, such as the type of vehicles you service, the inflation speed needed, and compatibility with existing inflators. Look for nozzles that offer features like self-locking mechanisms for ease of use, and ensure they fit the tire valve types common in your target market. Additionally, consider the materials used for durability and corrosion resistance, especially if operating in diverse climates.

What are the advantages of using self-locking tire inflator nozzles?

Self-locking tire inflator nozzles provide a secure connection to the tire valve, reducing the risk of air leaks during inflation. This feature enhances efficiency by allowing for hands-free operation, making the inflation process quicker and easier. Moreover, these nozzles often come with a quick-release mechanism, facilitating seamless transitions between different tires or vehicles, which is beneficial for businesses with high turnover.

What is the typical minimum order quantity (MOQ) for tire inflator nozzles?

The MOQ for tire inflator nozzles can vary significantly depending on the supplier and the specific product. Generally, you can expect MOQs to range from 100 to 500 units for bulk orders. It’s advisable to negotiate with suppliers, particularly if you’re looking for customizations or if you’re a new business. Some suppliers may offer flexible terms for first-time buyers or larger contracts.

How can I verify the quality of tire inflator nozzles before purchasing?

To ensure the quality of tire inflator nozzles, request samples from suppliers before placing a bulk order. This allows you to assess the product’s durability, compatibility, and performance. Additionally, look for certifications or compliance with international standards, such as ISO. Checking customer reviews and testimonials can also provide insights into the supplier’s reliability and product quality.

What payment terms should I expect when sourcing tire inflator nozzles internationally?

Payment terms can vary by supplier, but common practices include 30% upfront and 70% upon shipment, or net 30 days after delivery. It’s important to clarify these terms early in negotiations to avoid misunderstandings. Consider using secure payment methods like letters of credit or escrow services for larger transactions to protect your investment.

How do I manage logistics and shipping for international orders of tire inflator nozzles?

Managing logistics for international orders involves understanding customs regulations, shipping costs, and delivery times. Work with suppliers who have experience in international shipping and can provide DDP (Delivered Duty Paid) options to simplify the process. Establish a reliable freight forwarder to handle documentation and customs clearance, ensuring a smooth delivery to your location.

What customization options are available for tire inflator nozzles?

Many suppliers offer customization options for tire inflator nozzles, including branding, color, and specific design features tailored to your market needs. When discussing customization, clarify your requirements and any additional costs associated with these changes. It’s beneficial to engage with suppliers early in the design process to ensure feasibility and timely delivery.

How can I ensure timely delivery of tire inflator nozzles?

To ensure timely delivery, establish clear timelines with your supplier and account for any potential delays in production or shipping. Request regular updates during the manufacturing process and confirm shipping dates well in advance. Additionally, consider using suppliers with a proven track record of on-time delivery and those who offer tracking services for shipments.

Domain: jacosuperiorproducts.com

Registered: 2014 (11 years)

Introduction: Product Name: Lightning S2X Tire Inflator Hose Extension Self-Locking Nozzle

Price: $27.99 (originally $39.99)

Description: Patented air hose adapter for tire pumps (open flow) designed to replace standard screw-on, clip-on, or thumb-lock tire valve connectors. Features a self-locking and quick-release mechanism to prevent air loss during removal.

Product Name: Lightning L2X Tire Inflator Hose Ex…

In the competitive landscape of tire inflator nozzles, strategic sourcing emerges as a pivotal approach for international B2B buyers. Key takeaways emphasize the importance of selecting high-quality, reliable products that enhance operational efficiency and customer satisfaction. Innovative solutions, such as self-locking and quick-release nozzles, exemplify the advancements that can significantly improve user experience and reduce downtime.

Investing in strategic sourcing not only ensures access to superior products but also fosters strong supplier relationships, enabling businesses to adapt to market fluctuations and demand changes. For buyers in Africa, South America, the Middle East, and Europe, prioritizing suppliers who demonstrate a commitment to quality and innovation is essential for maintaining a competitive edge.

Looking ahead, the tire inflator nozzle market is poised for growth, driven by increasing demand for portable and efficient inflating solutions. We encourage buyers to leverage this moment to evaluate their sourcing strategies, engage with reputable suppliers, and explore new product offerings. By making informed sourcing decisions today, businesses can position themselves for success in the evolving landscape of tire maintenance solutions.

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Illustrative image related to tire inflator nozzle