In the ever-evolving landscape of industrial machinery, sourcing portable compressor air solutions presents a formidable challenge for B2B buyers. With various options available, companies must navigate through a myriad of features, functionalities, and specifications to find the ideal compressor that meets their operational needs. This guide is designed to serve as a comprehensive resource, illuminating the diverse types of portable air compressors, their applications across various industries, and the critical factors to consider when vetting suppliers.

Understanding the nuances of cost, performance, and reliability is essential for making informed purchasing decisions. Our focus is particularly aimed at international B2B buyers from regions such as Africa, South America, the Middle East, and Europe, including countries like Nigeria and Vietnam. By providing actionable insights and expert recommendations, this guide empowers businesses to confidently select the right portable air compressor that aligns with their specific requirements.

Whether you are looking to enhance productivity in construction, manufacturing, or any other sector, this resource will equip you with the knowledge needed to navigate the global market effectively. Join us as we delve into the essential considerations that will help streamline your purchasing process and ensure optimal operational efficiency.

| Nome del tipo | Caratteristiche distintive principali | Applicazioni primarie B2B | Brevi pro e contro per gli acquirenti |

|---|---|---|---|

| Oil-Free Compressors | Require no oil for lubrication; quieter operation | Automotive repair, woodworking | Pro: Low maintenance, less contamination risk. Contro: May have lower durability compared to oil-lubed models. |

| Oil-Lubricated Compressors | Use oil for lubrication; typically more robust | Construction, heavy machinery | Pro: Higher durability, better performance under heavy loads. Contro: Requires regular maintenance and oil changes. |

| Electric Compressors | Powered by electricity; portable and easy to use | HVAC services, small workshops | Pro: Quiet operation, no emissions. Contro: Limited by power availability and cord length. |

| Gas-Powered Compressors | Run on gasoline; ideal for remote locations | Outdoor construction, farming | Pro: High mobility, can operate in remote areas. Contro: Noise and emissions, requires fuel management. |

| Battery-Powered Compressors | Operate on rechargeable batteries; highly portable | Fieldwork, maintenance tasks | Pro: Excellent portability, no cords or fuel needed. Contro: Limited run time and power output. |

Oil-free compressors are designed to operate without lubrication, making them ideal for applications where air quality is crucial, such as in food processing or pharmaceuticals. Their quieter operation is a significant advantage for indoor use. When purchasing, consider factors like tank size and pressure output to ensure they meet specific application needs. While they require less maintenance, the trade-off may be a shorter lifespan compared to oil-lubricated variants.

Oil-lubricated compressors are known for their robustness and ability to handle high-demand environments, making them suitable for construction and heavy machinery applications. These compressors are designed to operate under significant load and provide consistent pressure. Buyers should evaluate the maintenance requirements, as these units need regular oil changes and checks. Their durability often justifies the additional upkeep, especially in demanding industrial settings.

Electric compressors are favored for their ease of use and low noise levels, making them perfect for HVAC services and small workshops. They are typically lightweight and easy to transport, allowing for flexible operation. When considering an electric compressor, buyers should assess the power supply availability and the necessary voltage requirements. While they produce no emissions, their reliance on electricity can limit their use in remote areas without access to power.

Gas-powered compressors excel in mobility and can function in remote or outdoor settings where electricity is unavailable. They are particularly advantageous for construction sites and agricultural applications. However, buyers should be aware of the noise and emissions associated with gas engines. Fuel management is also a consideration, as it requires planning for refueling during extended use. Their ruggedness often compensates for these drawbacks in demanding environments.

Battery-powered compressors offer unparalleled portability, making them ideal for fieldwork and maintenance tasks where mobility is critical. These units eliminate the need for cords and fuel, enhancing convenience. However, buyers must consider run time and power output limitations, as these compressors may not be suitable for high-demand applications. Understanding the specific needs of the task at hand will help in selecting the right model for efficient operation.

| Industria/Settore | Specific Application of Portable Compressor Air | Valore/Beneficio per l'azienda | Considerazioni chiave sull'approvvigionamento per questa applicazione |

|---|---|---|---|

| Costruzione | Powering pneumatic tools and equipment | Aumenta l'efficienza e riduce il lavoro manuale | Durability, portability, and compliance with local regulations |

| Riparazione di autoveicoli | Tire inflation and paint spraying | Enhances service speed and quality of finishes | Oil-free options, pressure range, and maintenance support |

| Produzione | Operating assembly line tools | Streamlines production and improves product quality | Energy efficiency, noise levels, and capacity requirements |

| Agricoltura | Crop spraying and irrigation systems | Boosts productivity and reduces labor costs | Mobility, fuel type, and compatibility with existing equipment |

| Mining | Dust suppression and equipment operation | Improves safety and operational efficiency | Robustness, power output, and adaptability to harsh environments |

In the construction industry, portable air compressors are essential for powering pneumatic tools such as nail guns, jackhammers, and impact wrenches. These tools significantly enhance productivity by allowing for faster assembly and disassembly processes. For international buyers, especially in regions like Africa and South America, sourcing compressors that can withstand tough environmental conditions and provide consistent pressure is crucial. Additionally, understanding local regulations regarding noise and emissions can help ensure compliance and avoid potential fines.

Automotive repair shops utilize portable air compressors for tire inflation and spray painting. The quick inflation of tires ensures that vehicles are service-ready, while air compressors provide the necessary pressure for an even and professional paint finish. Buyers in this sector should consider oil-free compressors to avoid contamination in paint jobs. Furthermore, understanding the specific pressure requirements for different applications can lead to better equipment selection and improved service delivery.

In manufacturing, portable air compressors are vital for operating various assembly line tools, including drills and riveters. They help streamline production processes, leading to higher output and improved product quality. For B2B buyers in Europe and the Middle East, sourcing energy-efficient models can reduce operational costs and align with sustainability goals. Additionally, considering the noise levels of compressors is important for maintaining a safe and compliant working environment.

Agricultural operations frequently employ portable air compressors for crop spraying and irrigation systems. These compressors enable farmers to cover large areas quickly and efficiently, thus enhancing productivity while minimizing labor costs. Buyers in regions like Nigeria and Vietnam should prioritize compressors that offer mobility and versatility, ensuring compatibility with various agricultural equipment. Fuel type and ease of maintenance are also critical factors to consider in the selection process.

In the mining sector, portable air compressors are crucial for dust suppression and powering equipment such as drills and hoppers. They contribute to safer working conditions by minimizing airborne particles and enhancing operational efficiency. International buyers must focus on sourcing robust compressors that can operate under extreme conditions and provide adequate power output. Additionally, understanding the adaptability of compressors to various mining environments can significantly impact operational success.

Il problema: Many B2B buyers face significant challenges when their portable air compressors lack mobility. This can be especially problematic for companies that rely on portable compressors for on-site jobs, such as construction, landscaping, or maintenance services. If the compressor is too heavy, cumbersome, or lacks adequate transport features, it can lead to delays in project timelines, increased labor costs, and ultimately a loss of client trust.

La soluzione: To mitigate mobility issues, buyers should prioritize compressors designed with lightweight materials and integrated transport features, such as wheels and ergonomic handles. For instance, selecting models specifically labeled as “portable” that weigh under 50 lbs and have robust wheel systems can enhance mobility. Additionally, evaluate the design of the compressor to ensure that it can easily fit into various transport vehicles. Investing in compressors with a compact footprint or foldable designs can further simplify transport and setup. It’s also beneficial to train staff on the best practices for loading and unloading these units to ensure efficiency and minimize potential damage during transport.

Il problema: In regions where electricity supply is inconsistent or unavailable, B2B buyers often struggle with the limitations of air compressors that require a continuous power source. This is particularly common in remote areas of Africa, South America, and the Middle East, where project sites may lack reliable electrical infrastructure. This situation can lead to stalled operations, increased project costs, and frustration among workers who are unable to perform their tasks effectively.

La soluzione: Buyers should consider investing in dual-power or multi-power portable air compressors that can operate on alternative power sources, such as gasoline or diesel, in addition to electricity. This flexibility allows for operation in diverse environments without being tethered to a power grid. Furthermore, it’s essential to assess the fuel availability in the region where the compressor will be used. Establishing relationships with local fuel suppliers can ensure easy access to necessary resources. Additionally, exploring solar-powered options can be beneficial, especially in sun-rich areas, providing an eco-friendly alternative that reduces dependency on fossil fuels.

Il problema: B2B buyers often encounter high maintenance costs and unexpected downtimes with portable air compressors, which can significantly affect productivity. Frequent breakdowns not only disrupt workflow but also incur additional costs for repairs and replacements. This is particularly concerning for industries that rely heavily on compressed air, such as automotive repair and construction, where time is money.

La soluzione: To combat maintenance issues, buyers should focus on selecting high-quality, durable compressors known for their reliability and low maintenance requirements. Researching brands with strong reputations for longevity can pay off in the long run. Furthermore, establishing a regular maintenance schedule can help in identifying potential issues before they escalate into costly repairs. Implementing a preventive maintenance program, including routine inspections and timely servicing, can significantly extend the lifespan of the compressor. Finally, providing training for operators on proper usage and care of the equipment can minimize wear and tear, ensuring that the compressors run efficiently and reducing overall maintenance costs.

By proactively addressing these pain points with well-thought-out strategies, B2B buyers can improve their operational efficiency and enhance their bottom line when using portable compressor air solutions.

When selecting materials for portable air compressors, it’s essential to consider their performance characteristics, durability, and suitability for specific applications. Here, we analyze four common materials: Aluminum, Steel, Plastic, and Cast Iron, focusing on their properties, advantages, disadvantages, and implications for international B2B buyers.

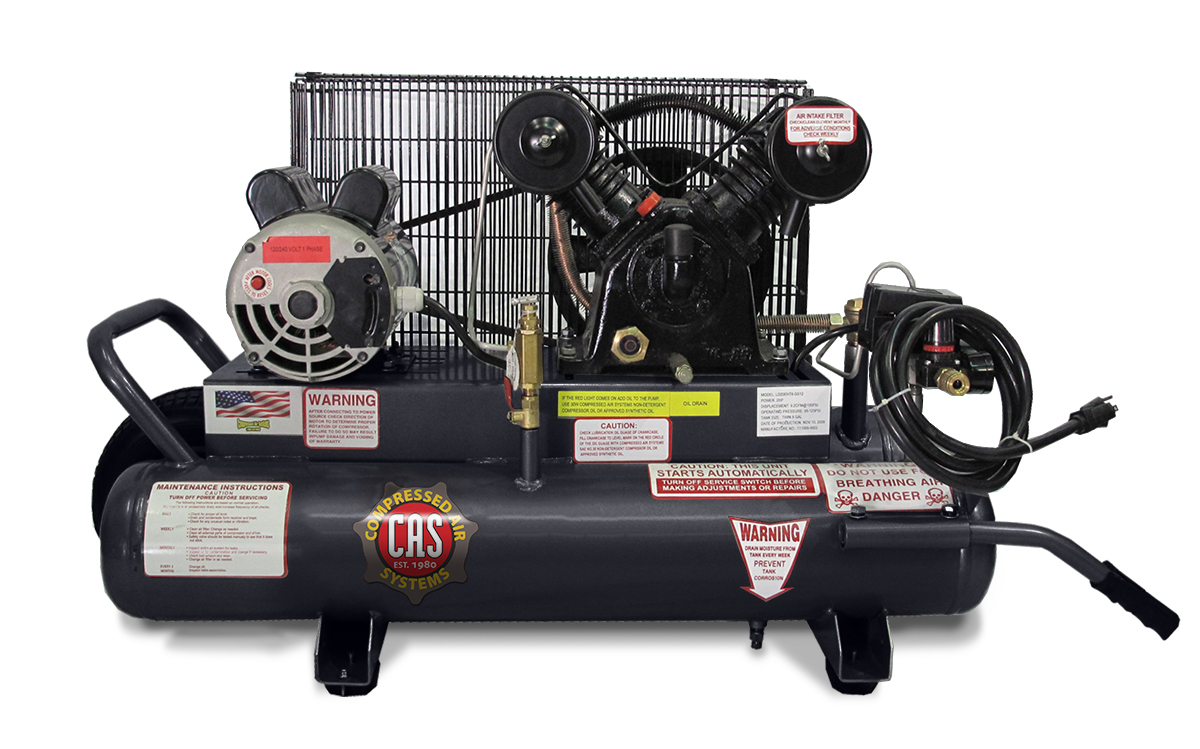

Illustrative image related to portable compressor air

Aluminum is a lightweight and corrosion-resistant material often used in the construction of portable air compressors. Its temperature and pressure ratings are generally suitable for most applications, making it a popular choice for components like tanks and casings.

Pro: Aluminum’s lightweight nature enhances portability, making it easier to transport and handle. It also offers good thermal conductivity and resistance to corrosion, which is beneficial in humid environments.

Contro: While aluminum is durable, it can be more expensive than some alternatives and may not withstand extreme pressures as well as steel. Manufacturing processes can be complex, especially for intricate designs.

Impatto sull'applicazione: Aluminum is compatible with various media, including air and certain gases, but care must be taken with aggressive chemicals.

Considerazioni per gli acquirenti internazionali: Buyers in regions like Africa and South America should verify compliance with local standards such as ASTM and ISO. The availability of aluminum may vary, impacting lead times and costs.

Illustrative image related to portable compressor air

Steel is frequently used in portable compressors due to its strength and durability. It can handle higher pressures than aluminum, making it ideal for high-performance applications.

Pro: Steel’s robustness translates to longevity, making it suitable for heavy-duty use. It is also generally more cost-effective than aluminum.

Contro: Steel is heavier, which can affect the portability of the compressor. Additionally, it is prone to rust if not properly coated or maintained.

Impatto sull'applicazione: Steel is highly compatible with various media and can withstand high pressures, making it ideal for industrial applications.

Considerazioni per gli acquirenti internazionali: Compliance with standards such as DIN and JIS is crucial for buyers in Europe and the Middle East. Additionally, the availability of treated steel to prevent corrosion may vary by region.

Illustrative image related to portable compressor air

Plastic is increasingly used in portable air compressors, particularly for smaller components and housings. It is lightweight and can be molded into complex shapes.

Pro: The primary advantage of plastic is its low cost and ease of manufacturing. It is also resistant to corrosion and can be designed for specific applications.

Contro: Plastic generally has lower strength and pressure ratings compared to metals, making it unsuitable for high-pressure applications. Its durability may also be lower, leading to potential long-term reliability issues.

Impatto sull'applicazione: Plastic is suitable for applications involving air and non-corrosive gases, but it may not be compatible with certain chemicals.

Considerazioni per gli acquirenti internazionali: Buyers should ensure that the plastics used comply with relevant safety and environmental standards, particularly in regions with stringent regulations.

Illustrative image related to portable compressor air

Cast iron is often used in the construction of compressor cylinders and other high-stress components due to its excellent wear resistance and ability to handle high pressures.

Pro: Cast iron is incredibly durable and can withstand high temperatures and pressures, making it ideal for heavy-duty applications. It also has good vibration-damping properties.

Contro: The weight of cast iron can make compressors less portable. Additionally, it is more expensive to manufacture and can be prone to rust if not properly treated.

Impatto sull'applicazione: Cast iron is suitable for high-pressure applications and can handle a variety of media, including air and gases.

Illustrative image related to portable compressor air

Considerazioni per gli acquirenti internazionali: Buyers should be aware of the need for protective coatings to prevent rust, especially in humid environments. Compliance with local standards is also essential.

| Materiale | Typical Use Case for portable compressor air | Vantaggio chiave | Svantaggi/limitazioni principali | Costo relativo (Basso/Medio/Alto) |

|---|---|---|---|---|

| Alluminio | Lightweight tanks and casings | Corrosion resistance and portability | Higher cost and pressure limitations | Medio |

| Acciaio | Heavy-duty compressors | Elevata resistenza e durata | Più pesante e soggetto a ruggine | Basso |

| Plastica | Small components and housings | Basso costo e facilità di produzione | Lower strength and pressure ratings | Basso |

| Cast Iron | Cylinders and high-stress components | Excellent durability and wear resistance | Heavy and expensive to manufacture | Alto |

This guide provides a comprehensive overview of material selection for portable air compressors, helping international B2B buyers make informed decisions based on application needs and regional considerations.

The manufacturing process of portable compressors involves several critical stages designed to ensure high performance and durability. Each stage requires meticulous attention to detail and adherence to industry standards.

Preparazione del materiale:

The process begins with sourcing high-quality materials such as aluminum, steel, and various plastics. These materials are selected based on their durability, weight, and corrosion resistance. Suppliers often undergo a stringent vetting process to ensure they meet international standards.

Formazione:

In this stage, raw materials are shaped into the required components using techniques like casting, forging, and machining. CNC (Computer Numerical Control) machines are commonly used for precision machining, ensuring that components meet tight tolerances. Additionally, advanced forming techniques, such as hydroforming and stamping, may be utilized to create complex shapes with minimal waste.

Montaggio:

Once components are formed, they move to the assembly line. Here, skilled technicians assemble the compressor parts, including the motor, tank, and control systems. This stage often employs automated systems for efficiency while still requiring manual oversight to ensure quality. Each compressor is built according to specific models and configurations, which may vary based on customer requirements.

Finitura:

The final stage involves surface treatments such as painting, powder coating, or galvanizing to protect against environmental factors. This not only enhances aesthetics but also prolongs the lifespan of the compressor. Quality checks are performed at every stage to ensure that the finishing meets specifications.

Quality assurance (QA) is crucial in the manufacturing of portable compressors to ensure that the end product is reliable and meets customer expectations. Various international and industry-specific standards govern this process.

Standard internazionali:

Many manufacturers adhere to ISO 9001, which emphasizes a quality management system focused on continuous improvement. Compliance with ISO standards ensures that the manufacturing process is efficient and consistent. Additionally, CE marking is essential for products sold in the European market, indicating compliance with health, safety, and environmental protection standards.

Standard specifici del settore:

For compressors, adherence to standards set by organizations like the American Petroleum Institute (API) is critical, especially for products intended for oil and gas applications. These standards ensure that compressors can withstand the demanding conditions of such industries.

Punti di controllo della qualità:

– Controllo qualità in entrata (CQI): This initial checkpoint involves inspecting raw materials and components as they arrive at the manufacturing facility. Suppliers must provide certificates of compliance, and samples are often tested against specifications.

– Controllo qualità in corso d'opera (IPQC): Throughout the manufacturing process, quality checks are performed at various stages to identify defects early. This includes monitoring dimensions, tolerances, and assembly integrity.

– Controllo qualità finale (CQC): Once assembly is complete, each unit undergoes rigorous testing, including performance tests and safety checks, before it is packaged for shipment.

Testing is a critical aspect of quality assurance in the manufacturing of portable compressors. Various methods are utilized to ensure that each unit meets performance and safety standards.

Test funzionali:

Each compressor is subjected to a series of operational tests to verify its performance under various conditions. This may include running the compressor at different pressures and load conditions to ensure it operates efficiently.

Pressure Testing:

To ensure safety and reliability, compressors undergo pressure testing to identify any leaks or weaknesses in the tank and other critical components. This is particularly important for air tanks, which must withstand high pressures.

Noise and Vibration Testing:

Since many portable compressors are used in residential or commercial settings, noise levels are tested to ensure compliance with regulations. Vibration testing is also conducted to assess the durability of components under operational conditions.

International B2B buyers must take proactive steps to ensure their suppliers maintain rigorous quality control processes. Here are several strategies to effectively verify supplier quality:

Audit dei fornitori:

Conducting regular audits of the manufacturing facility can provide insights into the supplier’s quality management practices. Audits should evaluate compliance with international standards and assess the effectiveness of quality control measures.

Requesting Quality Assurance Reports:

Suppliers should provide detailed quality assurance reports, including results from IQC, IPQC, and FQC stages. These reports should outline testing methods used and any corrective actions taken for defective products.

Engaging Third-Party Inspectors:

Utilizing third-party inspection services can offer an unbiased assessment of the supplier’s quality control processes. Inspectors can verify compliance with international standards and conduct independent testing of products before shipment.

B2B buyers from diverse regions face unique challenges regarding quality assurance in the procurement of portable compressors.

Conformità normativa:

Understanding local regulations and standards is crucial. For instance, buyers in Europe must ensure that products meet CE marking requirements, while those in Africa may need to consider additional certifications relevant to their specific markets.

Logistics and Shipping Considerations:

The transportation of compressors can pose risks, including damage during transit. Buyers should verify that suppliers use appropriate packaging and handling methods to minimize such risks.

Cultural and Communication Factors:

Effective communication with suppliers is vital to ensure that quality expectations are clearly understood. Language barriers and cultural differences may affect negotiations and quality perceptions, making it essential to establish clear guidelines and expectations.

The manufacturing processes and quality assurance measures in the portable compressor industry are designed to ensure that products meet stringent performance and safety standards. By understanding these processes and employing effective verification strategies, international B2B buyers can make informed decisions when sourcing portable compressors from various regions, ultimately leading to successful partnerships and high-quality products.

This guide serves as a practical checklist for B2B buyers looking to procure portable air compressors. With a variety of options available in the market, it is essential to follow a structured approach to ensure you select a unit that meets your operational needs and budget constraints. This checklist outlines critical steps to help streamline your sourcing process.

Before initiating your search, clarify the technical requirements of the portable air compressor. Consider factors such as air pressure (PSI), tank capacity, and power source (electric or gas).

– Air Pressure Needs: Identify the maximum pressure your applications require, as this will dictate the type of compressor you need.

– Capacity Considerations: Evaluate how much air volume you need at peak operation to avoid performance issues.

Establish a realistic budget for your purchase, factoring in both the initial cost and ongoing operational expenses.

– Cost of Ownership: Consider not only the purchase price but also maintenance, energy consumption, and potential repair costs.

– Financing Options: Explore financing or leasing options that may be available from suppliers, especially for higher-end models.

Conduct thorough research to identify reliable suppliers who specialize in portable air compressors. Look for suppliers with a proven track record in your region.

– Reputazione dei fornitori: Check online reviews, testimonials, and ratings from previous clients to gauge reliability.

– Industry Experience: Prioritize suppliers who have experience serving businesses in your specific industry or geographic area.

Ensure that your selected suppliers hold necessary certifications and comply with industry standards.

– Quality Assurance: Look for certifications such as ISO 9001 or CE marking, which indicate adherence to quality and safety standards.

– Local Regulations: Be aware of local compliance requirements that may affect the operational legality of the equipment in your region.

Whenever possible, request live demonstrations or trial periods for the portable air compressors you are considering. This will allow you to evaluate performance firsthand.

– Hands-On Experience: Assess ease of use, noise levels, and overall performance in real-world scenarios.

– Training Opportunities: Inquire whether the supplier provides training on operation and maintenance as part of the purchase agreement.

Review the warranty offered by the supplier, as well as the level of after-sales support available.

– Warranty Terms: A comprehensive warranty can protect your investment and reduce long-term costs associated with repairs.

– Support Availability: Ensure that the supplier provides accessible customer service and technical support for troubleshooting and maintenance.

Before finalizing your purchase, negotiate terms such as pricing, delivery schedules, and payment terms to ensure favorable conditions.

– Sconti per acquisti in blocco: If you are buying multiple units, inquire about bulk pricing options.

– Delivery Logistics: Clarify delivery timelines and any associated costs to avoid surprises later in the process.

By following these steps, you can make a well-informed decision when sourcing portable air compressors, ensuring that the equipment you choose meets your operational needs while providing value for your investment.

When sourcing portable air compressors, understanding the cost structure is crucial for B2B buyers. The primary cost components include:

I materiali: The quality of raw materials significantly affects the overall cost. High-grade metals and components designed for durability will increase the initial price but may lead to lower maintenance costs over time.

Lavoro: The cost of labor varies by region. In countries with higher labor costs, the manufacturing price will be higher. However, sourcing from regions with lower labor costs can reduce expenses, but this may impact quality and consistency.

Spese generali di produzione: This includes expenses related to factory operations, such as utilities and equipment maintenance. Efficient manufacturing processes can minimize overhead costs, contributing to lower prices.

Utensili: Specialized tooling for production can be a significant upfront cost. Buyers should inquire about tooling costs, especially if they require customized products.

Controllo qualità (CQ): Implementing rigorous QC processes ensures product reliability, which is vital for portable compressors used in demanding environments. This can increase costs but is essential for maintaining brand reputation.

Logistica: Transportation costs can vary widely based on the supplier’s location and the shipping method. Buyers should factor in logistics as a crucial part of the total cost, especially for international shipments.

Margine: Suppliers will typically apply a margin to cover their costs and profit. Understanding the average market margins can aid in negotiations.

Several factors influence the pricing of portable air compressors:

Volume e quantità minima d'ordine (MOQ): Larger orders often result in reduced per-unit costs due to economies of scale. Buyers should consider negotiating MOQs to secure better pricing.

Specifiche e personalizzazione: Custom features or specifications can increase costs. Buyers need to clearly define their requirements to avoid unexpected expenses during production.

Materiali e certificazioni di qualità: Higher quality materials and certifications (e.g., ISO standards) will raise costs but can enhance product reliability and performance, making them worth the investment.

Fattori di fornitura: The reputation and reliability of the supplier can impact pricing. Established suppliers may offer higher prices but also provide better quality assurance and customer service.

Incoterms: Understanding the terms of trade (Incoterms) is vital, as they dictate who is responsible for shipping costs, insurance, and tariffs. This can significantly affect the final price.

For B2B buyers, especially in international markets such as Africa, South America, the Middle East, and Europe, here are actionable tips:

Negotiate Wisely: Leverage your purchasing power by negotiating terms and pricing. Always ask for discounts on bulk orders and clarify payment terms to avoid cash flow issues.

Attenzione al costo totale di proprietà (TCO): Evaluate not just the purchase price but also maintenance, energy consumption, and potential downtime. A cheaper compressor may cost more in the long run due to higher operational costs.

Comprendere le sfumature dei prezzi: Prices can vary greatly based on region, demand, and economic factors. Stay informed about market trends and regional pricing to make educated decisions.

Research Suppliers: Investigate multiple suppliers to compare prices, quality, and reliability. Consider visiting manufacturing sites or requesting samples before committing to large orders.

Attenzione alle fluttuazioni valutarie: For international buyers, currency exchange rates can impact overall costs. Locking in prices early can mitigate risks associated with fluctuating exchange rates.

Prices for portable air compressors can fluctuate based on market conditions, supplier pricing strategies, and global economic factors. It is advisable for buyers to conduct thorough market research and obtain multiple quotes to ensure competitive pricing and make informed purchasing decisions.

In the competitive landscape of industrial tools and equipment, understanding the various options available is crucial for B2B buyers. Portable air compressors are widely recognized for their versatility and efficiency; however, alternative solutions exist that may better suit specific operational needs. This section will compare portable compressor air with two viable alternatives: stationary air compressors and gas-powered air compressors.

| Aspetto di confronto | Portable Compressor Air | Stationary Air Compressor | Gas-Powered Air Compressor |

|---|---|---|---|

| Prestazioni | High portability; ideal for small to medium tasks | Higher power output for continuous use | Excellent mobility; suitable for remote locations |

| Costo | Moderate initial investment; lower operating costs | Higher upfront cost; economical for long-term use | Variable cost; fuel and maintenance can add up |

| Facilità di implementazione | Easy setup; minimal installation required | Requires professional installation | Simple setup; requires fuel management |

| Manutenzione | Low maintenance; regular checks needed | Higher maintenance frequency; parts replacement may be necessary | Moderate maintenance; fuel and oil checks required |

| Il miglior caso d'uso | Ideal for construction sites and DIY projects | Best for manufacturing plants with high demand | Suitable for outdoor jobs without electricity access |

Stationary air compressors are designed for high-demand applications. They offer a consistent power supply and can handle heavy-duty tasks, making them suitable for manufacturing and industrial environments. The initial cost is higher compared to portable compressors, but they tend to be more economical in the long run for businesses with continuous air supply needs. However, they require professional installation and are less flexible in terms of mobility, which can be a limitation for businesses that operate in multiple locations or require on-site solutions.

Gas-powered air compressors provide an excellent solution for operations in remote locations where electricity is unavailable. Their mobility allows for easy transportation to job sites, making them a favorite among contractors working outdoors. While the initial investment might be comparable to portable electric compressors, the ongoing costs can fluctuate significantly due to fuel prices and maintenance. Additionally, gas-powered compressors tend to produce more noise and emissions, which may not align with environmental regulations or workplace safety standards.

When selecting the right air compressor solution, B2B buyers should assess their specific operational needs, budget constraints, and the nature of their projects. For businesses requiring mobility and flexibility, portable air compressors may be the best fit. Conversely, companies with a steady demand for compressed air may find that investing in a stationary compressor is more cost-effective. Meanwhile, those operating in remote areas without reliable power sources should consider gas-powered compressors despite their higher ongoing costs. By carefully evaluating these factors, buyers can make informed decisions that align with their operational goals and financial parameters.

Understanding the technical specifications of portable air compressors is crucial for B2B buyers, as these specifications directly affect performance, efficiency, and suitability for specific applications. Here are some essential properties to consider:

Illustrative image related to portable compressor air

Horsepower (HP): This measures the power output of the compressor’s motor. Higher horsepower typically translates to greater air delivery capacity, making it essential for heavy-duty applications. Buyers should align horsepower with their operational needs to ensure efficiency without overpaying for unnecessary power.

Tank Size: Measured in gallons, tank size dictates how much compressed air the unit can store. Larger tanks allow for longer run times between refills, which is advantageous for extended operations. Buyers should consider the balance between tank size and portability, especially in mobile applications.

Cubic Feet per Minute (CFM): CFM measures the volume of air the compressor can deliver at a specific pressure. This specification is critical for determining whether a compressor can power tools effectively. Buyers should assess the CFM requirements of their pneumatic tools to avoid performance issues.

Pressione massima (PSI): This indicates the highest pressure the compressor can achieve. Different applications require varying pressure levels; for instance, nail guns may need less PSI compared to sanders. Understanding the PSI requirement for specific tasks helps buyers choose the right model.

Noise Level (Decibels): Noise levels can significantly impact work environments, especially in residential or noise-sensitive areas. Buyers should consider oil-free models for quieter operation, which can be crucial for compliance with local regulations or for worker comfort.

Familiarity with industry jargon can empower B2B buyers to make informed decisions. Here are some key terms:

OEM (Original Equipment Manufacturer): This term refers to a company that produces parts or equipment that may be marketed by another manufacturer. Understanding OEM relationships can help buyers assess the reliability and quality of the components used in compressors.

MOQ (quantità minima d'ordine): This is the smallest quantity a supplier is willing to sell. Knowing the MOQ is essential for buyers to manage inventory and negotiate better terms with suppliers, especially when sourcing products from international markets.

RFQ (Richiesta di offerta): An RFQ is a document sent to suppliers to request pricing for specified products or services. Utilizing RFQs can streamline the procurement process, enabling buyers to compare prices and terms effectively.

Incoterms (Termini commerciali internazionali): These are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Understanding Incoterms helps buyers manage shipping costs and risks associated with transportation and delivery.

PSI (Pounds per Square Inch): A unit of measurement for pressure. This term is frequently used in specifications to describe the operational capabilities of compressors. Buyers should ensure that the PSI ratings meet the requirements of their applications.

Duty Cycle: This refers to the ratio of time a compressor can run versus the time it needs to rest. A higher duty cycle indicates that a compressor can operate longer without overheating. Buyers should consider duty cycles for applications requiring continuous operation.

By understanding these technical specifications and trade terms, B2B buyers can navigate the portable air compressor market more effectively, ensuring that their purchases align with operational needs and budget constraints.

The portable compressor air sector is experiencing significant growth driven by the increasing demand for compact, efficient, and versatile equipment across various industries. In regions such as Africa, South America, the Middle East, and Europe, key drivers include rapid urbanization, infrastructure development, and the rise of construction and manufacturing activities. For B2B buyers, understanding these dynamics is essential for strategic sourcing.

Emerging technologies, such as IoT integration, are revolutionizing how portable compressors are monitored and maintained. Smart compressors equipped with sensors can provide real-time data on performance and usage, enhancing operational efficiency and reducing downtime. Furthermore, the shift towards oil-free compressors is gaining traction due to their lower environmental impact and reduced maintenance costs. In addition, there is a growing preference for electric-powered models, which align with sustainability goals and energy efficiency standards.

B2B buyers should also be aware of regional sourcing trends. For instance, local manufacturers in Africa and South America are beginning to offer competitive pricing and tailored solutions, which can be advantageous for buyers looking to optimize their supply chains. However, international buyers must also consider the complexities of logistics, regulatory compliance, and quality assurance when sourcing equipment from these regions.

Sustainability is becoming a non-negotiable aspect of procurement in the portable compressor air sector. The environmental impact of manufacturing processes, energy consumption, and product lifecycle management are critical factors that international B2B buyers need to consider. Companies are increasingly held accountable for their carbon footprints and resource usage, making it essential to partner with suppliers who prioritize sustainable practices.

Ethical sourcing is equally important. Buyers should look for suppliers who maintain transparent supply chains and adhere to fair labor practices. This not only mitigates risks associated with unethical labor practices but also enhances brand reputation and customer loyalty. Certifications such as ISO 14001 for environmental management and Fair Trade certifications can serve as indicators of a supplier’s commitment to sustainability.

Illustrative image related to portable compressor air

In the context of portable compressors, using ‘green’ materials and technologies can significantly reduce environmental impact. For instance, selecting compressors that utilize eco-friendly refrigerants and are designed for energy efficiency can contribute to a greener operational footprint. B2B buyers should actively seek out suppliers who align with these sustainability goals, as this can lead to long-term cost savings and compliance with increasingly stringent environmental regulations.

The portable compressor air sector has evolved significantly since its inception in the late 19th century. Initially designed for simple pneumatic applications, advancements in technology have transformed these machines into sophisticated tools capable of powering a wide range of equipment across various industries.

The introduction of electric and battery-powered compressors marked a pivotal shift, allowing for greater mobility and convenience. As industries began to prioritize efficiency and environmental responsibility, the development of oil-free and low-noise models gained popularity. Today, the sector continues to innovate with smart technology integration, enabling remote monitoring and predictive maintenance.

For B2B buyers, understanding this evolution provides valuable context for making informed decisions about sourcing portable compressors that meet current operational needs while anticipating future trends.

How do I choose the right portable air compressor for my business needs?

Choosing the right portable air compressor involves assessing your specific requirements such as airflow (CFM), pressure (PSI), and the types of tools you plan to use. Consider the power source—electric or gas—based on your operational environment. It’s also crucial to evaluate the tank size for the intended duration of use, especially for heavy-duty applications. Finally, compare brands and models for reliability and after-sales support, particularly for international sourcing.

What are the key features to look for in a portable air compressor?

When sourcing a portable air compressor, prioritize features such as noise level, weight, and portability. Look for oil-free models for minimal maintenance and quieter operation. A robust build and durable materials are essential for longevity, especially in rugged environments. Also, consider additional features like built-in regulators, gauges, and multiple outlets for increased versatility in usage.

What are the common payment terms for international B2B transactions?

Payment terms can vary widely among suppliers. Common options include advance payment, letters of credit, and payment upon delivery. It’s advisable to negotiate terms that align with your cash flow and risk management strategies. Ensure clarity on currency, payment methods (e.g., wire transfer, PayPal), and any potential fees. Always confirm the supplier’s reputation to mitigate risks associated with non-payment.

How can I vet suppliers for portable air compressors?

Vetting suppliers is critical in ensuring product quality and reliability. Start by checking their business credentials, such as registration and certifications. Request references and case studies from previous clients, particularly those in your industry. Assess their manufacturing capabilities and quality assurance processes. Visiting their facility, if feasible, can provide further insights into their operations and reliability.

What is the Minimum Order Quantity (MOQ) for portable air compressors?

The MOQ for portable air compressors can vary significantly based on the supplier and the specific product. Many manufacturers have flexible MOQs, especially for established relationships. It’s essential to communicate your requirements upfront to negotiate an acceptable MOQ that suits your purchasing needs. Be aware that lower MOQs might come at a higher unit price, affecting your overall budget.

Are there customization options available for portable air compressors?

Yes, many manufacturers offer customization options for portable air compressors, including modifications to size, color, and additional features like pressure gauges or noise reduction technology. Customization can also extend to branding, allowing you to incorporate your logo. Discuss your specific requirements with potential suppliers early in the negotiation process to understand the feasibility and cost implications.

Quali sono le considerazioni logistiche da tenere a mente quando si importano compressori d'aria portatili?

When importing portable air compressors, consider shipping methods, import duties, and local regulations. Ensure you understand the logistics chain from the supplier to your location, including freight forwarding and customs clearance. Assess the total landed cost, which includes shipping, duties, and taxes. Partnering with a reliable logistics provider can streamline the process and mitigate delays.

How do I ensure quality assurance for portable air compressors?

To ensure quality assurance, establish clear specifications with your supplier before production begins. Request samples for testing and evaluation. Implement regular inspections during the manufacturing process, either through third-party services or by visiting the facility. Additionally, consider requesting a warranty or guarantee that covers defects and provides options for recourse should issues arise post-purchase.

Dominio: airliftcompany.com

Registrato: 1996 (29 anni)

Introduzione: {“product_name”: “Digital Portable Compressor”, “part_number”: “16188”, “price”: “$195.95”, “features”: [{“feature”: “12 Volt, 120 PSI Portable Compressor”}, {“feature”: “Backlit digital pressure gauge”}, {“feature”: “Pressure presets with automatic shutoff at the desired pressure”}, {“feature”: “Quickly and accurately read air spring pressures, tire pressures, or anything with a standard Schrader…

Dominio: store.arbusa.com

Registrato: 1998 (27 anni)

Introduzione: Portable & Vehicle Mounted Air Compressor Systems by ARB 4×4 USA. Key features include: durable, high-performance compressors for tires, tools, and Air Lockers; available types: Brushless, Onboard, and Portable; various models with prices ranging from $224.95 to $1,379.95; Black Friday deals offering 10% off and free ground shipping over $75; models include Twin Motor Onboard 12V Air Compressor CK…

Dominio: jacosuperiorproducts.com

Registrato: 2014 (11 anni)

Introduzione: SmartPro™ Digital Tire Inflator – 100 PSI (12V DC) – $49.95 (was $79.99) – Ultra compact, powerful, and highly efficient. SmartPro 2.0™ AC/DC Digital Tire Inflator – 100 PSI (12V DC, 120V AC) – $69.95 (was $99.99) – Fast, powerful, quiet, and efficient with automatic shut-off and inflation progress bar. TrailPro™ Heavy Duty Portable Air Compressor – 3.5 CFM (12V/33A) – $169.95 (was $199.99) – Comp…

In conclusion, strategic sourcing of portable air compressors is crucial for international B2B buyers, particularly those operating in emerging markets such as Africa, South America, the Middle East, and Europe. Buyers should prioritize understanding the specific needs of their operations, whether that involves selecting oil-free models for quieter environments or gas-powered units for remote locations. Establishing relationships with reliable suppliers and manufacturers can enhance procurement efficiency and ensure access to the latest technology and innovations in air compressor systems.

Investing in portable compressors not only boosts operational efficiency but also provides versatility across various applications—from construction to automotive industries. By leveraging strategic sourcing, companies can negotiate better pricing, improve supply chain reliability, and secure after-sales support, which is vital for maintenance and longevity of equipment.

Illustrative image related to portable compressor air

Looking ahead, the demand for portable air compressors is expected to grow, driven by advancements in technology and increased construction activities globally. As buyers, it is essential to stay informed about industry trends and innovations. Engage with suppliers who offer not just products, but comprehensive solutions tailored to your business’s unique challenges. Embrace this opportunity to enhance your operations and drive growth in your markets.

Le informazioni fornite in questa guida, compresi i contenuti relativi ai produttori, alle specifiche tecniche e all'analisi di mercato, hanno uno scopo puramente informativo ed educativo. Non costituiscono una consulenza professionale in materia di acquisti, né una consulenza finanziaria o legale.

Pur avendo compiuto ogni sforzo per garantire l'accuratezza e la tempestività delle informazioni, non siamo responsabili di eventuali errori, omissioni o informazioni non aggiornate. Le condizioni di mercato, i dettagli aziendali e gli standard tecnici sono soggetti a modifiche.

Illustrative image related to portable compressor air

Gli acquirenti B2B devono condurre una due diligence indipendente e approfondita. prima di prendere qualsiasi decisione di acquisto. È necessario contattare direttamente i fornitori, verificare le certificazioni, richiedere campioni e chiedere una consulenza professionale. Il rischio di affidarsi alle informazioni contenute in questa guida è esclusivamente a carico del lettore.