In an increasingly competitive global market, sourcing an Amazon portable air compressor can present unique challenges for B2B buyers, especially in regions like Africa, South America, the Middle East, and Europe. The need for reliable, efficient, and cost-effective air compressors is paramount for businesses across various sectors, including automotive, construction, and manufacturing. However, navigating the complexities of international procurement, supplier reliability, and product specifications can often overwhelm even the most seasoned professionals.

This comprehensive guide aims to simplify your sourcing journey by providing in-depth insights into the different types of portable air compressors available on Amazon, their diverse applications, and the critical factors to consider when vetting suppliers. From understanding the technical specifications that best suit your operational needs to evaluating costs and ensuring compliance with regional standards, this resource is designed to empower international B2B buyers.

With actionable strategies and expert recommendations, you will be equipped to make informed purchasing decisions that align with your business objectives. Whether you are looking to enhance your product offerings or streamline your operational efficiency, this guide will serve as a valuable tool in your quest for the ideal portable air compressor. By addressing common pain points and providing practical solutions, we aim to facilitate your success in the dynamic landscape of global commerce.

| Nome del tipo | Caratteristiche distintive principali | Applicazioni primarie B2B | Brevi pro e contro per gli acquirenti |

|---|---|---|---|

| Piston Air Compressors | High pressure, durable design, suitable for heavy-duty tasks | Construction, automotive, manufacturing | Pro: High efficiency, robust performance. Contro: Bulkier, noisier than other types. |

| Diaphragm Air Compressors | Compact, lightweight, low maintenance, quiet operation | Medical equipment, food processing | Pro: Low noise, clean air output. Contro: Lower pressure capacity, less suitable for heavy-duty tasks. |

| Rotary Screw Compressors | Continuous operation, high air delivery, energy-efficient | Industrial applications, large workshops | Pro: Reliable, efficient for long-term use. Contro: Higher initial investment, complex maintenance. |

| Portable Electric Compressors | Lightweight, easy to transport, powered by electricity | DIY projects, small workshops, inflating tires | Pro: User-friendly, versatile. Contro: Limited pressure output, dependent on power source. |

| Gas-Powered Compressors | Mobility, suitable for outdoor use, high pressure | Construction sites, remote locations | Pro: No power source required, high performance. Contro: Emissions, higher operational costs. |

Piston air compressors are characterized by their ability to generate high pressure through a reciprocating motion. They are typically used in construction, automotive, and manufacturing sectors where heavy-duty tasks are common. When considering a piston compressor, B2B buyers should evaluate the compressor’s efficiency, noise levels, and maintenance needs. While these compressors are robust and efficient, they are often bulkier and noisier, which may not be suitable for all environments.

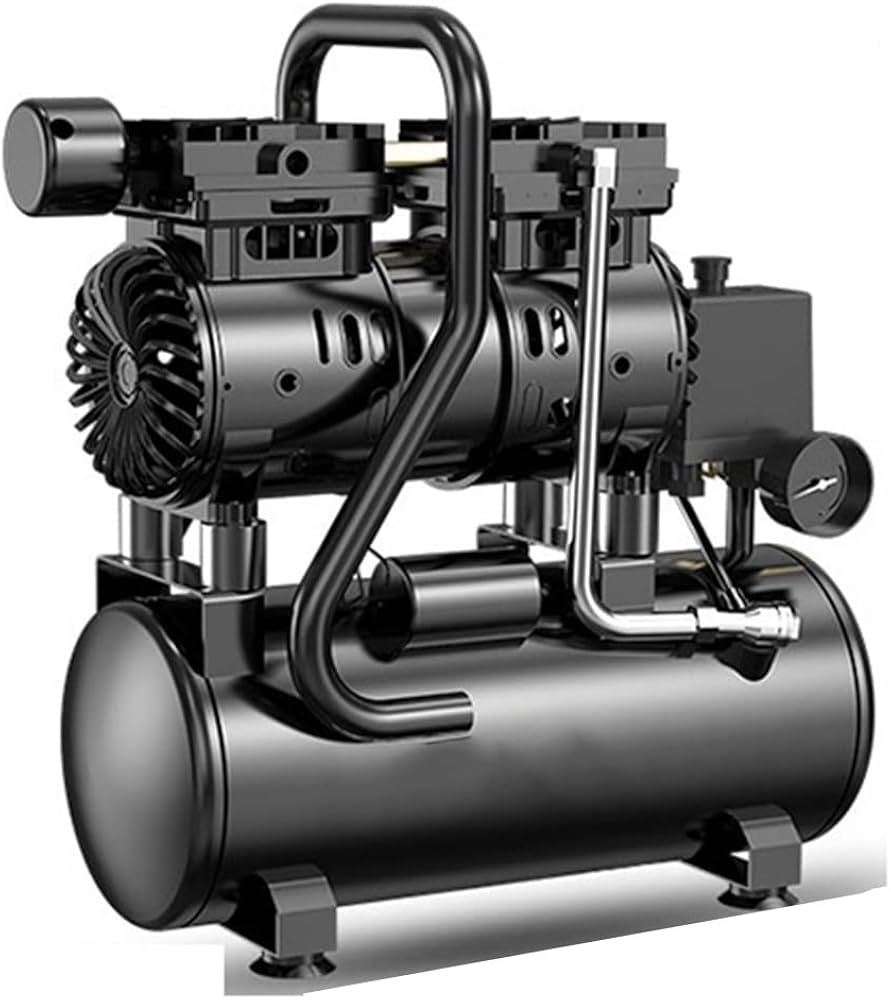

Illustrative image related to amazon portable air compressor

Diaphragm air compressors are known for their compact design and quiet operation, making them ideal for applications in medical equipment and food processing where clean air is crucial. These compressors require minimal maintenance and are less prone to contamination. B2B buyers should consider their lower pressure capacity, which may limit their use in more demanding applications. However, their low noise levels and cleanliness make them a valuable choice for sensitive environments.

Rotary screw compressors are designed for continuous operation and are recognized for their high air delivery rates, making them suitable for large workshops and industrial applications. B2B buyers should assess their energy efficiency and reliability, as these compressors are built for long-term use. Despite their higher initial investment and more complex maintenance requirements, the long-term savings and performance can justify the cost for businesses with substantial air demand.

Portable electric compressors are lightweight and user-friendly, making them ideal for DIY projects, small workshops, and tasks like inflating tires. They are easy to transport and operate but have limitations in pressure output and are dependent on an electrical power source. B2B buyers should consider the specific applications they require and whether the convenience of portability outweighs the limitations in performance.

Gas-powered compressors offer significant mobility and are designed for outdoor use, making them perfect for construction sites and remote locations where electricity is unavailable. They provide high pressure and performance but come with higher operational costs and emissions concerns. B2B buyers should weigh the benefits of mobility and power against environmental regulations and the potential for increased fuel expenses when considering gas-powered options.

| Industria/Settore | Specific Application of amazon portable air compressor | Valore/Beneficio per l'azienda | Considerazioni chiave sull'approvvigionamento per questa applicazione |

|---|---|---|---|

| Costruzione | Pneumatic tool operation | Enhances efficiency and productivity on job sites | Ensure compatibility with tools and power requirements |

| Automotive | Tire inflation and maintenance | Quick turnaround for vehicle servicing, reducing downtime | Check for pressure range and portability features |

| Agricoltura | Crop spraying and irrigation systems | Increases yield through efficient application of fertilizers | Consider tank capacity and durability for outdoor use |

| Produzione | Cleaning and maintenance of machinery | Reduces operational costs by maintaining equipment efficiency | Assess noise levels and energy consumption |

| HVAC Systems | Air duct cleaning and pressure testing | Improves air quality and system performance | Verify pressure output and hose compatibility |

In the construction industry, the Amazon portable air compressor is primarily utilized for powering pneumatic tools such as nail guns, drills, and impact wrenches. This application is crucial for enhancing efficiency and productivity on job sites, allowing for quicker assembly and disassembly of structures. For international buyers, particularly from regions like Africa and the Middle East, it is essential to ensure that the compressor is compatible with the specific pneumatic tools used locally and meets the required power specifications to avoid operational delays.

Illustrative image related to amazon portable air compressor

In automotive applications, this portable air compressor is invaluable for tire inflation and maintenance tasks. Quick inflation capabilities enable service stations to improve their turnaround time, thereby reducing vehicle downtime for customers. B2B buyers in South America and Europe should focus on the compressor’s pressure range and ease of transport to ensure it meets the demands of busy service environments where efficiency is paramount.

For agricultural businesses, the Amazon portable air compressor is effectively used in crop spraying and irrigation systems. By providing a reliable source of compressed air, it enables farmers to efficiently apply fertilizers and pesticides, which can lead to increased crop yields. Buyers from regions like Nigeria and Saudi Arabia should prioritize tank capacity and durability, as these factors are critical for outdoor operations in varying climates.

In the manufacturing sector, the Amazon portable air compressor serves as a vital tool for cleaning and maintaining machinery. Regular maintenance using compressed air helps to reduce operational costs by ensuring that equipment runs efficiently and has a longer lifespan. B2B buyers in Europe should assess the noise levels and energy consumption of the compressor, as these factors can significantly impact workplace conditions and operational costs.

The Amazon portable air compressor is also utilized in HVAC systems for air duct cleaning and pressure testing. This application is essential for improving indoor air quality and ensuring that HVAC systems operate at peak efficiency. International buyers should verify the pressure output and hose compatibility to ensure the compressor can effectively service the specific HVAC systems prevalent in their regions.

Il problema: B2B buyers, particularly those in developing regions like Africa and South America, often struggle to find reliable suppliers for portable air compressors on platforms like Amazon. Many listings may lack detailed specifications or customer reviews, leading to uncertainty about product quality and performance. This can result in wasted time and resources, as businesses may end up with subpar equipment that doesn’t meet their operational needs.

Illustrative image related to amazon portable air compressor

La soluzione: To address this challenge, B2B buyers should prioritize sourcing from reputable sellers with verified customer feedback. When browsing Amazon, utilize filtering options to focus on products with high ratings and substantial reviews. Additionally, consider engaging directly with suppliers for clarification on specifications and warranties. Building relationships with manufacturers who can offer bulk purchasing options may also provide more assurance of quality, and negotiating for better terms or trial periods can further mitigate risks.

Il problema: Many businesses operating in regions like the Middle East and parts of Europe may encounter issues with power supply compatibility when using portable air compressors. Different voltage and frequency requirements can lead to equipment malfunction or failure, creating operational disruptions and potential safety hazards. This issue is particularly prevalent in industries like construction or automotive, where reliable air compressors are crucial for daily tasks.

La soluzione: To ensure compatibility, buyers should thoroughly assess the power requirements of the portable air compressors they are considering. Look for models that are designed to operate within the local voltage range or those that come with dual voltage capabilities. Before purchasing, consult product manuals and specifications, and verify if the compressor requires any additional transformers or converters. It may also be beneficial to invest in a power management system that can regulate voltage fluctuations, ensuring consistent performance of the air compressors.

Il problema: In many B2B scenarios, particularly in construction or agricultural sectors, users need portable air compressors that can adapt to various environments. However, some models available on Amazon may be too bulky or lack features that enhance usability in rugged conditions. This limitation can hinder productivity, as teams may struggle to transport and operate the equipment efficiently on job sites.

Illustrative image related to amazon portable air compressor

La soluzione: When evaluating portable air compressors, prioritize models specifically designed for enhanced mobility and versatility. Features such as lightweight construction, built-in wheels, and robust handles can significantly improve transportation ease. Additionally, look for compressors that come with multiple power options (e.g., battery-operated or dual power sources) to ensure usability across different environments. It may also be wise to invest in protective accessories, such as weather-resistant covers or carrying cases, which can prolong the life of the compressor and maintain its functionality in challenging conditions.

By addressing these common pain points with targeted solutions, B2B buyers can make more informed purchasing decisions, ensuring that their investment in portable air compressors meets operational demands efficiently and effectively.

When selecting materials for Amazon portable air compressors, it is crucial to consider their properties, advantages, and limitations, particularly from a B2B perspective. This guide analyzes four common materials used in the manufacturing of these compressors, focusing on their performance characteristics and implications for international buyers from regions such as Africa, South America, the Middle East, and Europe.

Illustrative image related to amazon portable air compressor

Aluminum is a widely used material in portable air compressors due to its favorable properties. It boasts a high strength-to-weight ratio, excellent corrosion resistance, and good thermal conductivity. Aluminum can typically withstand temperatures up to 150°C and pressures around 200 psi, making it suitable for various applications.

Pro e contro: The primary advantage of aluminum is its lightweight nature, which enhances portability. Additionally, it is relatively easy to manufacture, allowing for complex designs. However, aluminum can be more expensive than steel and may not be as durable under high-stress conditions, leading to a shorter lifespan in demanding environments.

Impatto sull'applicazione: Aluminum is compatible with air and non-corrosive gases, making it ideal for general-purpose compressors. However, it may not be suitable for applications involving aggressive chemicals or high humidity, which are common in certain regions.

Considerazioni per gli acquirenti internazionali: Buyers should ensure that aluminum components meet international standards such as ASTM or DIN for quality assurance. In regions like Saudi Arabia or Nigeria, where high temperatures and humidity are prevalent, it is essential to verify the alloy specifications to ensure performance longevity.

Illustrative image related to amazon portable air compressor

Steel is another common material in the construction of portable air compressors, particularly for components that require high strength and durability. It has excellent tensile strength and can withstand high pressures, typically rated up to 300 psi in some designs.

Pro e contro: The key advantage of steel is its robustness, making it suitable for heavy-duty applications. It is also generally less expensive than aluminum. However, steel is heavier, which can affect portability, and it is prone to corrosion if not properly treated.

Impatto sull'applicazione: Steel is highly compatible with various gases and fluids, including those that may be slightly corrosive. This makes it versatile for different industrial applications, especially in regions with diverse operational conditions.

Considerazioni per gli acquirenti internazionali: Buyers should consider the corrosion resistance of steel, especially in humid climates like those in Nigeria or Brazil. Compliance with local standards for steel quality and treatment (such as JIS or ASTM) is crucial to ensure product reliability.

Plastic materials, particularly high-density polyethylene (HDPE) and polycarbonate, are increasingly being used in portable air compressors for non-structural components. These materials offer good chemical resistance and are lightweight.

Pro e contro: The primary advantage of plastic is its low weight and resistance to corrosion, making it ideal for components exposed to moisture. However, plastics generally have lower temperature and pressure ratings compared to metals, limiting their use in high-performance applications.

Impatto sull'applicazione: Plastics are suitable for housing and protective covers, especially in applications where weight is a critical factor. However, they may not withstand high temperatures or pressures, which could lead to failure in demanding environments.

Considerazioni per gli acquirenti internazionali: Buyers should ensure that the plastics used comply with relevant safety and environmental standards, especially in regions with strict regulations on materials. Understanding the thermal and pressure limitations is essential to avoid operational failures.

Copper is often used in air compressor components such as tubing and fittings due to its excellent thermal and electrical conductivity. It can handle high-pressure applications, typically rated up to 250 psi.

Illustrative image related to amazon portable air compressor

Pro e contro: The main advantage of copper is its ability to efficiently transfer heat, which can improve compressor performance. However, it is more expensive than aluminum and steel, and its susceptibility to corrosion in certain environments can be a drawback.

Impatto sull'applicazione: Copper is ideal for applications where heat dissipation is critical, such as in refrigeration or air conditioning systems. However, its compatibility with certain fluids should be assessed to prevent corrosion.

Considerazioni per gli acquirenti internazionali: Buyers should look for copper components that meet international standards to ensure quality. In regions with high humidity or corrosive environments, additional protective coatings may be necessary to enhance durability.

| Materiale | Typical Use Case for amazon portable air compressor | Vantaggio chiave | Svantaggi/limitazioni principali | Costo relativo (Basso/Medio/Alto) |

|---|---|---|---|---|

| Alluminio | Housing and structural components | Leggero e resistente alla corrosione | Higher cost and less durable under stress | Medio |

| Acciaio | Heavy-duty structural components | Elevata resistenza e durata | Heavier and prone to corrosion | Basso |

| Plastica | Non-structural components like covers | Low weight and good chemical resistance | Valori di temperatura/pressione inferiori | Basso |

| Copper | Tubing and fittings for heat transfer | Excellent thermal conductivity | Expensive and can corrode in certain environments | Alto |

This strategic material selection guide provides B2B buyers with essential insights into the materials used in Amazon portable air compressors, facilitating informed purchasing decisions tailored to specific operational needs and regional conditions.

The manufacturing process of portable air compressors typically involves several key stages, each crucial for ensuring the final product meets the desired performance and quality standards. These stages include material preparation, forming, assembly, and finishing.

Illustrative image related to amazon portable air compressor

Preparazione del materiale: The first step is sourcing high-quality materials, such as aluminum, steel, and plastics. Suppliers often conduct rigorous assessments to ensure the materials meet specifications. Quality assurance begins here, as the integrity of the materials affects the overall durability and performance of the air compressor.

Formazione: This stage involves shaping the raw materials into usable components. Techniques such as casting, forging, and machining are commonly employed. Advanced manufacturing technologies, including CNC machining, allow for precision and consistency in producing parts like the compressor housing and cylinder. This step is critical, as any defects at this stage can lead to functional failures later.

Montaggio: Once the components are prepared, they are assembled into the final product. This process often involves both manual and automated techniques. Skilled technicians oversee the assembly line, ensuring that parts fit together correctly and that each unit is assembled according to specifications. Integration of automated systems can enhance efficiency and reduce human error.

Finitura: The final stage includes surface treatments, painting, and packaging. Finishing processes not only enhance the aesthetic appeal of the air compressors but also contribute to their durability and resistance to environmental factors. Quality checks are essential during this stage to ensure that the finished product meets international and industry-specific standards.

Quality assurance (QA) is a fundamental aspect of the manufacturing process for portable air compressors. It ensures that products are reliable, efficient, and safe for end-users. Various international standards and industry-specific certifications play a critical role in shaping QA practices.

Standard internazionali: Compliance with ISO 9001 is vital for manufacturers aiming to demonstrate their commitment to quality management systems. This standard provides a framework for continuous improvement and customer satisfaction. Additionally, certifications like CE (Conformité Européenne) are essential for products sold in European markets, as they indicate compliance with health, safety, and environmental protection standards.

Standard specifici del settore: Depending on the application, additional certifications may be relevant. For example, the American Petroleum Institute (API) standards are crucial for compressors used in oil and gas applications. Understanding these requirements can help B2B buyers ensure that they are sourcing products suitable for their specific industry needs.

Punti di controllo della qualità: Effective quality control involves multiple checkpoints throughout the manufacturing process:

– Controllo qualità in entrata (CQI): This initial inspection assesses the quality of raw materials before they enter the production line. It ensures that only materials meeting stringent specifications are used.

– Controllo qualità in corso d'opera (IPQC): During the manufacturing process, IPQC monitors the production to catch defects early. This involves regular inspections and testing of components and assemblies.

– Controllo qualità finale (CQC): Before products are packaged and shipped, FQC involves comprehensive testing and evaluation of the final product. This step ensures that the portable air compressors meet all quality standards and function as intended.

Common Testing Methods: Various testing methods are employed to assess the performance and safety of air compressors. These may include:

– Pressure Testing: Ensures that the compressor can withstand operational pressures without leakage.

– Noise Level Testing: Assesses the sound output to ensure it complies with regulatory standards.

– Test di durata: Simulates long-term usage to evaluate the compressor’s longevity and reliability.

For B2B buyers, especially those in international markets such as Africa, South America, the Middle East, and Europe, verifying supplier quality control is essential for ensuring product reliability and compliance. Here are several strategies buyers can employ:

Audit dei fornitori: Conducting on-site audits of potential suppliers can provide valuable insights into their manufacturing processes and quality control practices. During these audits, buyers can evaluate the facilities, equipment, and workforce involved in production.

Richiesta di rapporti sulla qualità: Buyers should request documentation related to quality assurance, such as ISO certifications, test reports, and compliance certificates. These documents can provide evidence of the supplier’s commitment to quality standards.

Ispezioni di terzi: Engaging third-party inspection services can offer an impartial assessment of the manufacturing process and product quality. These services can conduct inspections at various stages, from material sourcing to final product evaluation.

Understanding QC Nuances for International Markets: Different regions may have specific regulatory requirements or quality expectations. Buyers should familiarize themselves with the standards relevant to their market, such as CE for Europe or specific certifications for Middle Eastern and African markets, to ensure that their suppliers meet these requirements.

International B2B buyers face unique challenges when it comes to quality assurance in sourcing portable air compressors. Understanding these challenges can help buyers navigate the complexities of international procurement.

Conformità normativa: Each region may have its own set of regulations and standards that must be met. Buyers must be diligent in understanding these requirements to avoid legal complications and ensure product acceptance in their markets.

Cultural and Language Barriers: Communication issues can arise due to cultural differences and language barriers. Clear communication about quality expectations and specifications is crucial to avoid misunderstandings that could lead to subpar products.

Logistical Considerations: Shipping and transportation can introduce risks to product quality. Buyers should ensure that suppliers have robust logistics and handling processes to protect the integrity of the compressors during transit.

Supplier Reliability: Establishing trust with suppliers is essential for long-term partnerships. Buyers should consider the supplier’s track record, financial stability, and reputation in the industry to mitigate risks associated with quality assurance.

By understanding the manufacturing processes and quality assurance practices for portable air compressors, B2B buyers can make informed decisions, ensuring they source reliable and compliant products that meet their operational needs.

In the competitive landscape of B2B procurement, sourcing a reliable and efficient Amazon portable air compressor requires a structured approach. This checklist serves as a practical guide to help international buyers navigate the complexities of sourcing, ensuring that they make informed decisions that align with their operational needs.

Before initiating the procurement process, clearly outline the technical specifications required for the portable air compressor. Consider factors such as pressure capacity, tank size, and power source. These specifications will guide your search and help in evaluating potential suppliers more effectively.

Understanding current market trends and pricing is essential for making informed purchasing decisions. Conduct thorough market research to identify average pricing, popular brands, and features that are in demand. This information will empower you to negotiate better terms and avoid overpaying for your compressors.

Before committing to a supplier, it’s crucial to conduct a comprehensive evaluation. Request detailed company profiles, including their manufacturing capabilities, product range, and financial stability. Look for client references and case studies from similar industries or regions to gauge their reliability and service quality.

Illustrative image related to amazon portable air compressor

Ensure that the suppliers you are considering possess the necessary certifications and comply with international standards. Look for ISO certifications, CE markings, and any relevant safety certifications that apply to portable air compressors. This step is vital for ensuring product quality and compliance with local regulations.

Once you have shortlisted potential suppliers, request samples of the portable air compressors. Testing samples allows you to assess the build quality, performance, and suitability of the product for your specific applications. Pay attention to the compressor’s ease of use, noise levels, and maintenance requirements.

Before finalizing your order, carefully review the warranty and after-sales support offered by the supplier. A solid warranty can protect your investment, while robust customer support ensures that you can resolve any issues that may arise post-purchase. Look for suppliers that offer comprehensive service agreements.

Once you have assessed all aspects, negotiate the terms of your purchase, including price, payment conditions, and delivery timelines. Clear communication is key to establishing a good working relationship. Ensure that all agreed terms are documented in a formal purchase agreement to avoid misunderstandings.

By following this structured checklist, B2B buyers can effectively navigate the sourcing process for Amazon portable air compressors, ensuring that they select the right products and suppliers that meet their operational needs and standards.

When analyzing the cost structure for sourcing portable air compressors, several key components must be considered. These include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margins.

Illustrative image related to amazon portable air compressor

I materiali: The primary materials used in portable air compressors, such as metal casings, motors, and hoses, can significantly impact costs. Suppliers often provide varying quality levels, affecting both price and durability.

Lavoro: Labor costs vary by region, impacting the final price of the product. Countries with lower labor costs can produce cheaper units, but this may come at the expense of quality.

Spese generali di produzione: This includes costs associated with facilities, equipment maintenance, and utilities. Efficient manufacturing processes can minimize overhead, leading to better pricing for buyers.

Utensili: Initial tooling costs can be significant, especially for custom designs. Buyers should consider whether they are ordering standard models or require specialized tooling for unique specifications.

Controllo qualità (CQ): Investing in thorough QC processes can raise initial costs but ultimately ensures product reliability and customer satisfaction. This is particularly crucial for international buyers who may face stringent import regulations.

Logistica: Shipping and handling costs are critical, especially for international orders. Factors such as distance, shipping method, and customs duties can add significant expenses to the overall cost.

Margine: Suppliers typically add a profit margin to cover their costs and ensure sustainability. Understanding this margin can help buyers negotiate better pricing.

Several factors can influence the pricing of portable air compressors, particularly for B2B buyers:

Volume/MOQ: Minimum order quantities (MOQs) can affect pricing. Larger orders often secure better pricing, making it essential for buyers to assess their needs versus budget constraints.

Specifiche e personalizzazione: Custom features or specifications can lead to higher prices. Buyers should clearly define their requirements to avoid unnecessary costs.

Materiali e certificazioni di qualità: Higher-quality materials and certifications (like ISO) can increase costs but may be essential for compliance with local regulations or customer expectations.

Fattori di fornitura: The reputation and reliability of suppliers can affect pricing. Established suppliers may charge more but offer better service and product consistency.

Incoterms: Understanding Incoterms is vital for international transactions. They define responsibilities for shipping, insurance, and tariffs, impacting the total landed cost of the product.

For international B2B buyers, especially from regions such as Africa, South America, the Middle East, and Europe, navigating the cost landscape effectively is crucial:

Negoziazione: Engage in open discussions with suppliers regarding pricing. Many suppliers may offer discounts for bulk purchases or long-term contracts.

Costo totale di proprietà (TCO): Look beyond the initial purchase price. Consider maintenance, energy consumption, and expected lifespan to evaluate the overall investment.

Sfumature di prezzo: Be aware of currency fluctuations and local economic conditions that can influence pricing. Establishing contracts in stable currencies can mitigate risks.

Ricerca e confronto: Conduct thorough market research to compare prices across different suppliers. This can provide leverage during negotiations and help identify the best value options.

Quality Assurance: Prioritize suppliers with strong QC processes. While it may seem more expensive upfront, it can save costs associated with returns and repairs in the long run.

Prices for portable air compressors can vary widely based on the factors discussed above. It is essential to obtain quotes from multiple suppliers and consider the total cost of ownership when making purchasing decisions. Prices listed in this guide are indicative and subject to change based on market conditions and specific sourcing needs.

When considering the purchase of an air compressor, particularly the Amazon portable air compressor, it’s essential to evaluate alternative solutions that might better suit specific operational needs. Various models and technologies exist that can provide similar functionalities, and understanding their advantages and disadvantages can lead to more informed purchasing decisions. Below is a comparative analysis of the Amazon portable air compressor against two viable alternatives: the industrial air compressor and the battery-powered air compressor.

Illustrative image related to amazon portable air compressor

| Aspetto di confronto | Amazon Portable Air Compressor | Industrial Air Compressor | Battery-Powered Air Compressor |

|---|---|---|---|

| Prestazioni | Good for light to medium tasks | High performance for heavy-duty applications | Moderate performance for light tasks |

| Costo | Affordable (around $50-$150) | Higher investment ($500+) | Moderate cost ($200-$400) |

| Facilità di implementazione | Plug-and-play, user-friendly | Requires professional installation | Simple setup, no outlet needed |

| Manutenzione | Bassa manutenzione, facile da pulire | Regular maintenance needed | Minimal maintenance required |

| Il miglior caso d'uso | Home use, small workshops | Industrial settings, construction sites | Remote locations, DIY projects |

Industrial air compressors are designed for high-volume applications and are typically used in manufacturing and construction settings. Their primary advantage is their robust performance, capable of powering multiple pneumatic tools simultaneously. However, they come with a significant cost and require more extensive installation and maintenance efforts. For businesses with high air demand, this option can be worthwhile, but smaller operations may find it excessive.

Battery-powered air compressors offer convenience and portability, making them suitable for light tasks and projects in remote areas without electrical access. They are generally more affordable than industrial models and allow for easy transport, which is advantageous for contractors and DIY enthusiasts. However, their performance may be limited compared to the Amazon portable air compressor and industrial options, making them less suitable for heavy-duty tasks.

When selecting the right air compressor, B2B buyers should carefully assess their specific requirements, including the nature of tasks, budget constraints, and operational environments. The Amazon portable air compressor serves well for light to medium applications, while industrial models cater to high-demand scenarios. Battery-powered compressors excel in portability and convenience but may not meet the performance needs of all users. By evaluating the performance, cost, ease of implementation, maintenance, and best use cases of each option, businesses can make a decision that aligns with their operational goals and budgetary considerations.

Illustrative image related to amazon portable air compressor

When selecting an Amazon portable air compressor, understanding its technical properties is essential for making informed purchasing decisions. Here are several critical specifications to consider:

Pressione nominale (PSI)

The pressure rating, measured in pounds per square inch (PSI), indicates the maximum pressure the compressor can generate. For B2B buyers, this property is crucial as it determines the compressor’s suitability for various applications, from inflating tires to powering pneumatic tools. Higher PSI ratings often mean the ability to handle more demanding tasks, which can enhance operational efficiency.

Airflow (CFM)

Cubic feet per minute (CFM) measures the volume of air the compressor can deliver. A higher CFM rating means the compressor can supply more air, making it ideal for tools that require a continuous air supply. For businesses, ensuring that the CFM meets the requirements of your tools can prevent downtime and improve productivity.

Capacità del serbatoio (galloni)

The tank capacity, expressed in gallons, reflects how much air the compressor can store. A larger tank allows for longer run times between refills, which is particularly beneficial for projects requiring extended use. B2B buyers should consider their operational needs to determine the optimal tank size, balancing portability with performance.

Power Source (Electric vs. Gas)

Portable air compressors can be powered by electricity or gas. Electric models are typically quieter and more suitable for indoor use, while gas-powered models offer greater mobility and are ideal for outdoor or remote locations. Understanding the power source can help businesses align their equipment with their operational environments and specific use cases.

Weight and Portability

The weight of the compressor impacts its portability. Lighter models are easier to transport but may compromise on power and tank size. For businesses that require frequent movement of equipment, choosing a model that strikes the right balance between weight and functionality is essential.

Noise Level (Decibels)

The noise level, measured in decibels (dB), is an important consideration for workplaces where noise control is a priority. Many portable compressors are designed to operate quietly, making them suitable for residential or noise-sensitive environments. Selecting a model with a low noise level can enhance employee comfort and compliance with local regulations.

Familiarity with trade terminology is vital for B2B transactions. Here are some common terms that buyers should know:

OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of portable air compressors, understanding whether a product is OEM can indicate its quality and compatibility with existing systems.

MOQ (quantità minima d'ordine)

MOQ is the minimum number of units that a supplier is willing to sell. For B2B buyers, knowing the MOQ helps in budgeting and inventory planning. It also impacts negotiations and can influence purchasing decisions, especially for smaller businesses.

RFQ (Richiesta di offerta)

An RFQ is a document sent to suppliers requesting a quote for specific products or services. For B2B buyers, submitting an RFQ can help in comparing prices and terms across different suppliers, ensuring that they secure the best deal for their needs.

Incoterms (Termini commerciali internazionali)

Incoterms are internationally recognized rules that define the responsibilities of buyers and sellers in international transactions. Familiarity with these terms helps B2B buyers understand shipping costs, risks, and delivery obligations, facilitating smoother cross-border transactions.

Tempi di consegna

Lead time refers to the amount of time it takes from placing an order to receiving it. Understanding lead times is crucial for businesses that rely on timely deliveries to maintain operations and meet project deadlines.

Garanzia

A warranty is a guarantee provided by the manufacturer or seller regarding the condition of the product. For B2B buyers, evaluating warranty terms is essential for assessing long-term value and protection against potential defects or failures.

By understanding these technical properties and trade terms, B2B buyers can make more informed decisions regarding portable air compressors, ultimately enhancing their operational efficiency and project outcomes.

The global market for portable air compressors is experiencing significant growth, driven by a surge in demand across various sectors, including automotive, construction, and DIY projects. One of the key trends influencing this market is the increasing adoption of electric and battery-powered compressors, which are favored for their portability, reduced noise levels, and lower environmental impact. International B2B buyers, particularly in regions such as Africa, South America, the Middle East, and Europe, are also noting a shift towards multifunctional compressors that combine air inflation with other utilities, enhancing their value proposition.

Illustrative image related to amazon portable air compressor

As competition intensifies, suppliers are leveraging advanced technologies like IoT (Internet of Things) for smart monitoring and maintenance solutions, appealing to businesses focused on efficiency and productivity. Additionally, the rise of e-commerce platforms, including Amazon, has transformed sourcing strategies, enabling buyers to access a broader range of products and suppliers with ease. This shift is particularly advantageous for buyers in emerging markets who seek competitive pricing and diverse options.

Another notable trend is the increasing emphasis on customization and branding, as B2B buyers look for products that can be tailored to their specific needs and reflect their corporate identity. This trend is particularly relevant for companies in regions like Saudi Arabia and Nigeria, where localized branding can significantly enhance market acceptance.

In an era of heightened environmental consciousness, sustainability has become a pivotal concern for B2B buyers in the portable air compressor sector. The environmental impact of manufacturing processes, material sourcing, and product lifecycle management is under scrutiny, compelling companies to adopt greener practices. Buyers are increasingly prioritizing suppliers that demonstrate a commitment to sustainable manufacturing, which includes using recyclable materials and reducing energy consumption during production.

Ethical supply chains are also gaining traction, as businesses recognize the importance of transparency and accountability in their sourcing strategies. Companies are now more inclined to partner with suppliers who uphold fair labor practices and contribute positively to their communities. This shift towards ethical sourcing not only aligns with corporate social responsibility goals but also enhances brand reputation in the eyes of consumers and stakeholders.

Moreover, certifications such as ISO 14001 (Environmental Management) and LEED (Leadership in Energy and Environmental Design) are becoming crucial indicators of a supplier’s commitment to sustainability. B2B buyers should actively seek out portable air compressor manufacturers that hold these certifications, as they often reflect a higher standard of environmental stewardship and quality assurance.

The portable air compressor market has evolved significantly over the past few decades, transitioning from traditional gas-powered models to modern, electric-driven solutions. Initially, these compressors were primarily utilized in industrial settings, but advancements in technology and a growing focus on personal and commercial applications have broadened their appeal.

In the early 2000s, the introduction of lightweight and compact models made portable air compressors more accessible to DIY enthusiasts and small businesses. This evolution was further accelerated by the rise of e-commerce platforms, which facilitated easier sourcing and distribution of these products on a global scale.

Today, the market is characterized by rapid innovation, with manufacturers continuously enhancing product features and functionalities to meet the diverse needs of B2B buyers. As businesses increasingly recognize the value of portable air compressors for enhancing operational efficiency and versatility, the sector is poised for continued growth and transformation in the coming years.

How do I choose the right portable air compressor for my business needs?

Choosing the right portable air compressor depends on your specific applications. Consider factors such as the required PSI (pounds per square inch) and CFM (cubic feet per minute) to ensure it meets your operational needs. Evaluate the compressor’s tank size for air storage capacity, especially if you’ll be using multiple tools simultaneously. Additionally, assess portability features, such as weight and design, to ensure ease of transport across job sites. Reading product reviews and consulting with suppliers can further guide your decision.

What features should I look for in a portable air compressor?

When sourcing a portable air compressor, key features to consider include power source (electric or gas), noise level, and duty cycle. Look for models with built-in safety features such as thermal overload protection and automatic shut-off. Durability is crucial, so select compressors with robust construction materials. Moreover, consider additional functionalities like multiple output ports, pressure regulators, and built-in gauges for enhanced usability. It’s also wise to check for warranty options that protect your investment.

Quali sono le quantità minime d'ordine (MOQ) per i compressori d'aria portatili?

Minimum order quantities for portable air compressors can vary significantly based on the supplier and model. Typically, MOQs may range from a single unit for smaller suppliers to several dozen for larger manufacturers. When negotiating with suppliers, inquire about flexibility in MOQs, especially if you are testing the market. Additionally, consider the potential for bulk discounts, which can be advantageous for businesses planning to scale their operations.

How can I vet suppliers of portable air compressors for quality assurance?

Vetting suppliers is crucial for ensuring quality and reliability. Start by checking their certifications, such as ISO standards, which indicate adherence to quality management systems. Request samples to evaluate product performance firsthand. Additionally, review customer feedback and case studies to gauge the supplier’s reputation. Establishing clear communication regarding your expectations can also help ensure that the supplier meets your quality standards.

What payment terms should I expect when purchasing portable air compressors?

Payment terms can vary widely among suppliers. Common practices include upfront payments, partial payments before shipment, or net terms post-delivery. It’s essential to negotiate terms that align with your cash flow management strategy. Be aware of any additional costs, such as shipping fees or customs duties, and factor these into your budgeting. Establishing a solid relationship with your supplier can also lead to more favorable payment conditions over time.

What logistical considerations should I keep in mind when importing air compressors?

Logistics play a vital role in the successful importation of portable air compressors. Consider shipping methods (air vs. sea) based on cost, urgency, and destination. Ensure compliance with import regulations in your country, including obtaining necessary permits. Engage a reliable freight forwarder to facilitate the shipping process and manage customs clearance. Additionally, plan for potential delays and ensure you have adequate storage solutions upon arrival.

Can I customize portable air compressors to meet specific requirements?

Many manufacturers offer customization options for portable air compressors. Custom features can include specific tank sizes, pressure settings, and additional attachments tailored to your business needs. When discussing customization with suppliers, clearly outline your requirements and verify their capability to meet those specifications. Be aware that customization may affect lead times and pricing, so factor these into your project timeline and budget.

What warranty options are available for portable air compressors?

Warranty options for portable air compressors can vary significantly depending on the manufacturer. Typically, warranties cover defects in materials and workmanship for a period ranging from one to three years. Some suppliers may offer extended warranties or service plans for an additional fee. When evaluating warranty options, consider the availability of parts and service support in your region, as this can impact long-term operational efficiency. Always read the warranty terms carefully to understand coverage limitations.

Could not verify enough suppliers for amazon portable air compressor to create a list at this time.

In the competitive landscape of portable air compressors, strategic sourcing emerges as a pivotal component for international B2B buyers. By understanding market dynamics and supplier capabilities, businesses can effectively reduce costs while enhancing product quality. The diverse offerings available on platforms like Amazon present an opportunity for buyers in regions such as Africa, South America, the Middle East, and Europe to access innovative solutions tailored to their specific needs.

Key takeaways include the importance of evaluating suppliers based on reliability, product specifications, and after-sales support. Additionally, fostering relationships with manufacturers can lead to better pricing and exclusive deals, ultimately driving profitability.

Illustrative image related to amazon portable air compressor

Looking ahead, the demand for portable air compressors is expected to grow as industries prioritize mobility and efficiency. As international buyers, your proactive engagement in strategic sourcing will position you favorably in this expanding market. Embrace the opportunity to leverage e-commerce platforms and establish partnerships that align with your operational goals. Start your sourcing journey today, and unlock the potential of portable air compressors to enhance your business capabilities.

Le informazioni fornite in questa guida, compresi i contenuti relativi ai produttori, alle specifiche tecniche e all'analisi di mercato, hanno uno scopo puramente informativo ed educativo. Non costituiscono una consulenza professionale in materia di acquisti, né una consulenza finanziaria o legale.

Pur avendo compiuto ogni sforzo per garantire l'accuratezza e la tempestività delle informazioni, non siamo responsabili di eventuali errori, omissioni o informazioni non aggiornate. Le condizioni di mercato, i dettagli aziendali e gli standard tecnici sono soggetti a modifiche.

Gli acquirenti B2B devono condurre una due diligence indipendente e approfondita. prima di prendere qualsiasi decisione di acquisto. È necessario contattare direttamente i fornitori, verificare le certificazioni, richiedere campioni e chiedere una consulenza professionale. Il rischio di affidarsi alle informazioni contenute in questa guida è esclusivamente a carico del lettore.