In today’s fast-paced global market, sourcing the best air tire inflator poses a significant challenge for B2B buyers. As businesses strive to maintain fleet efficiency and ensure vehicle safety, selecting the right tire inflator becomes crucial. This comprehensive guide delves into the diverse types of tire inflators available, their various applications, and essential factors to consider when making a purchase. From compact, portable models ideal for light vehicles to robust inflators suited for heavy-duty trucks, understanding the specifications and capabilities of each option is key to informed decision-making.

Moreover, this guide will provide insights into supplier vetting processes, ensuring that buyers can identify reputable manufacturers that meet international quality standards. Cost considerations will also be explored, helping businesses to balance budget constraints with the need for reliability and performance. By equipping international B2B buyers—particularly those in Africa, South America, the Middle East, and Europe (including markets like Germany and Brazil)—with the knowledge needed to evaluate and compare products, this guide empowers organizations to make strategic purchasing decisions. Ultimately, investing in the right air tire inflator not only enhances operational efficiency but also contributes to overall road safety and cost savings.

| Nome del tipo | Caratteristiche distintive principali | Applicazioni primarie B2B | Brevi pro e contro per gli acquirenti |

|---|---|---|---|

| Gonfiatori per pneumatici a batteria | Battery-operated, portable, and often compact | Autofficine, assistenza stradale | Pro: Easy to use, no cords, highly portable. Contro: Limited battery life, may require frequent charging. |

| 12V Plug-In Tire Inflators | Connects to vehicle’s 12V outlet, suitable for cars | Fleet maintenance, automotive workshops | Pro: Continuous power supply, fast inflation. Contro: Limited reach if vehicle is stationary, requires vehicle access. |

| Heavy-Duty Tire Inflators | High PSI capabilities, often designed for trucks/SUVs | Construction sites, off-road vehicle service | Pro: Suitable for larger tires, robust construction. Contro: Bulkier, may be more expensive. |

| Compact Portable Tire Inflators | Ultra-lightweight, small size, often USB rechargeable | Personal use, small vehicle maintenance | Pro: Extremely portable, easy to store. Contro: Limited inflation capacity, slower performance. |

| Multi-Function Tire Inflators | Includes additional features like lights and adapters | Emergency services, outdoor recreation | Pro: Versatile, can inflate various items. Contro: May lack power for heavy-duty tasks, potentially higher cost. |

Cordless tire inflators are powered by rechargeable batteries, making them highly portable and ideal for emergency situations. Their compact design allows them to fit in a glove compartment or small storage space, making them suitable for automotive repair shops and roadside assistance services. When considering a purchase, B2B buyers should evaluate battery life, maximum PSI capabilities, and the speed of inflation to ensure they meet their operational needs.

12V plug-in tire inflators connect directly to a vehicle’s power outlet, providing a reliable source of continuous power. These inflators are commonly used in fleet maintenance and automotive workshops, where quick and efficient tire inflation is crucial. Buyers should assess the inflator’s hose length and pressure gauge accuracy, as these factors can significantly impact usability and efficiency in a busy work environment.

Heavy-duty tire inflators are specifically designed to handle the high PSI requirements of larger tires found on trucks and SUVs. They are essential for applications in construction sites and off-road vehicle servicing, where durability and performance are paramount. B2B buyers should consider the inflator’s build quality, inflation speed, and ease of use, especially in rugged conditions.

Compact portable tire inflators are lightweight and can be easily stored or carried, making them ideal for personal use or small vehicle maintenance. Their USB rechargeable feature adds convenience for users on the go. However, these inflators may have limitations in terms of inflation capacity and speed, so businesses should weigh these factors against their specific use cases.

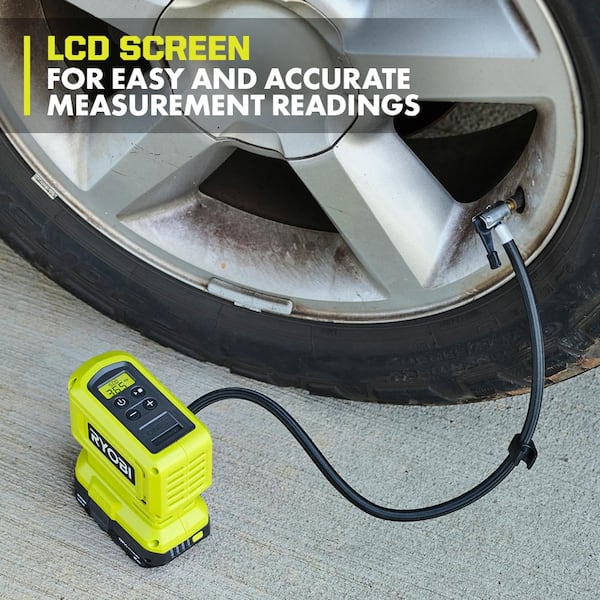

Illustrative image related to best air tire inflator

Multi-function tire inflators not only inflate tires but also come equipped with additional features like built-in lights and various adapters for different inflation needs. They are particularly useful for emergency services and outdoor recreation companies that require versatility in their tools. When purchasing, B2B buyers should evaluate the range of functions offered and the inflator’s performance in tire inflation tasks to ensure it meets their operational requirements.

| Industria/Settore | Specific Application of best air tire inflator | Valore/Beneficio per l'azienda | Considerazioni chiave sull'approvvigionamento per questa applicazione |

|---|---|---|---|

| Negozi di riparazione di autoveicoli | Manutenzione ordinaria degli pneumatici e riparazioni di emergenza | Enhances service efficiency and customer satisfaction | Reliability, ease of use, and power source options |

| Logistics and Transportation | Fleet vehicle tire maintenance | Reduces downtime and operational costs | Durability, maximum PSI capacity, and portability |

| Construction and Heavy Equipment | Tire inflation for machinery and vehicles | Ensures safety and operational efficiency | Heavy-duty capabilities and compatibility with various tire sizes |

| Agricoltura | Inflation of agricultural vehicle tires | Optimizes productivity and reduces tire wear | Adaptability to various tire pressures and power options |

| Retail (Consumer Products) | Tire inflation for retail service stations | Attracts customers and increases ancillary service revenue | Compact design, ease of use, and quick inflation time |

Automotive repair shops utilize the best air tire inflators for routine tire maintenance and emergency repairs. These inflators allow technicians to quickly and accurately inflate tires to the recommended pressure, thereby enhancing service efficiency and improving customer satisfaction. For international buyers, particularly in regions with varying climate conditions, sourcing inflators with reliable performance and ease of use is crucial. Additionally, a variety of power source options (cordless, 12V) can be beneficial in diverse working environments.

In the logistics and transportation sector, maintaining fleet vehicle tires is vital for reducing downtime and operational costs. Tire inflators are essential for quick inflation, enabling drivers to manage tire pressure effectively while on the road. For B2B buyers, durability and maximum PSI capacity are key considerations, as inflators must withstand frequent use in various conditions. Portability is also important, allowing drivers to carry inflators in their vehicles for immediate access.

Construction and heavy equipment industries rely on tire inflators to ensure the safety and operational efficiency of machinery and vehicles. Properly inflated tires enhance traction and reduce the risk of tire blowouts, which can lead to costly delays. Buyers in these sectors should focus on inflators with heavy-duty capabilities that can accommodate various tire sizes and pressure requirements. Additionally, compatibility with both standard and specialized equipment is crucial for seamless operations.

Agricultural businesses utilize tire inflators for the inflation of agricultural vehicle tires, which is essential for optimizing productivity and minimizing tire wear. In a sector where time is critical, having reliable inflators can prevent delays during planting and harvesting seasons. Buyers should consider inflators that adapt to various tire pressures and offer multiple power options to ensure they can operate effectively in remote locations without access to standard power supplies.

Retail service stations can attract customers and increase ancillary service revenue by providing tire inflation services using high-quality inflators. These inflators must be compact, easy to use, and capable of quick inflation to enhance customer experience. For B2B buyers, sourcing inflators that meet these criteria while also ensuring they are durable enough for continuous use is vital. The ability to handle multiple tire types and pressures will further enhance service offerings in diverse markets.

Il problema: Many B2B buyers, particularly those managing fleets of vehicles, face the challenge of inflating high-pressure tires, such as those on trucks and SUVs. These tires often require specific PSI levels that standard inflators may not adequately support. The result can be time-consuming delays, increased operational costs, and potential safety hazards due to improperly inflated tires.

La soluzione: When sourcing an air tire inflator, it is crucial to specify models designed for high PSI capabilities. Look for inflators that can handle pressures up to 80 PSI or higher, such as the Viair 88P, which is tailored for larger vehicles. Ensure that the inflator features a robust construction and an accurate pressure gauge, as this will enhance reliability during use. Additionally, consider inflators with a rapid inflation speed to minimize downtime. Implement regular training for staff on the correct usage of these devices to promote safety and efficiency in tire maintenance.

Il problema: In many industries, such as logistics and construction, tire maintenance often occurs in remote locations. B2B buyers struggle with the bulkiness of traditional tire inflators, which can be cumbersome to transport and store. This can lead to inefficiencies, as teams may find themselves without adequate tools to address tire issues promptly.

Illustrative image related to best air tire inflator

La soluzione: To overcome portability challenges, opt for compact and lightweight models like the AstroAI Cordless Tire Inflator. When purchasing, prioritize inflators that are battery-operated and can inflate multiple tires on a single charge. This ensures that your team can quickly respond to tire issues without the need for cumbersome cords or access to a power source. Additionally, investing in carrying cases or bags can facilitate easier transport and organization of tire inflators, ensuring they are always ready for use at job sites.

Il problema: Another significant pain point for B2B buyers is the reliance on tire inflators with inaccurate pressure gauges. This can lead to overinflated or underinflated tires, which pose safety risks and can lead to costly tire damage or accidents. For businesses, these issues can result in vehicle downtime and increased maintenance expenses.

La soluzione: When selecting a tire inflator, prioritize models with digital pressure gauges known for their accuracy, like those found in the Craftsman 12V Max Portable Air Inflator. Conduct thorough research or request user reviews focusing on the gauge’s precision. Additionally, consider implementing a dual-system approach where employees use a calibrated external gauge to verify tire pressure after inflation. Regularly testing and calibrating your inflators will ensure they maintain accuracy over time, thereby enhancing safety and operational efficiency.

Illustrative image related to best air tire inflator

When selecting the best air tire inflator, the choice of materials significantly influences performance, durability, and overall user satisfaction. This section analyzes four common materials used in tire inflators, focusing on their properties, advantages, disadvantages, and implications for international B2B buyers.

Plastic is often used for the housing and components of air tire inflators due to its lightweight nature and resistance to corrosion. Key properties include a temperature rating typically between -20°C to 60°C and moderate pressure resistance.

Pro: Plastic is generally cost-effective, easy to mold, and lightweight, making it suitable for portable inflators. It also provides good insulation against electrical components.

Contro: However, plastics can degrade under extreme temperatures and UV exposure, leading to brittleness over time. They may not withstand high-pressure applications as effectively as metals.

Impatto sull'applicazione: Plastic components are compatible with low to moderate pressure applications, which is suitable for standard vehicle tires but may not be ideal for heavy-duty inflators.

Considerazioni per gli acquirenti internazionali: Buyers should ensure compliance with local regulations regarding plastic materials, such as RoHS in Europe or similar standards in other regions.

Aluminum is frequently used for structural components in tire inflators due to its excellent strength-to-weight ratio and corrosion resistance. It can handle higher temperatures and pressures, typically rated up to 200°C and 150 psi.

Pro: Aluminum is durable, lightweight, and resistant to corrosion, making it ideal for both portable and stationary inflators. Its recyclability also appeals to environmentally conscious buyers.

Contro: The primary drawback is the higher manufacturing cost compared to plastics, which may affect the retail price of the inflator.

Illustrative image related to best air tire inflator

Impatto sull'applicazione: Aluminum is suitable for high-performance inflators that require durability and reliability, especially in harsh environments.

Considerazioni per gli acquirenti internazionali: Compliance with international standards such as ASTM for material properties is crucial. Buyers in regions like Germany and Brazil may also look for certifications that indicate quality and safety.

Steel is commonly used in the construction of high-pressure components, such as valves and fittings, due to its superior strength and durability. It can typically withstand temperatures up to 300°C and pressures exceeding 200 psi.

Illustrative image related to best air tire inflator

Pro: Steel’s high tensile strength makes it ideal for heavy-duty applications. It is also resistant to deformation under pressure, ensuring long-term reliability.

Contro: The main downside is its weight, which can reduce portability. Additionally, steel is prone to corrosion if not properly treated or coated.

Impatto sull'applicazione: Steel components are essential for inflators designed for heavy-duty vehicles and industrial applications, where high pressure and durability are paramount.

Considerazioni per gli acquirenti internazionali: Buyers should ensure that steel components meet local corrosion resistance standards, especially in humid or coastal regions.

Rubber is primarily used for seals and hoses in tire inflators due to its flexibility and excellent sealing properties. It can typically handle temperatures from -30°C to 100°C and moderate pressure levels.

Pro: Rubber provides excellent sealing capabilities and flexibility, allowing for easy connection to various tire valves. It is also relatively inexpensive.

Contro: However, rubber can degrade over time due to exposure to ozone and UV light, leading to potential leaks.

Impatto sull'applicazione: Rubber is suitable for standard tire inflators where flexibility and sealing are required, but may not be ideal for extreme conditions.

Considerazioni per gli acquirenti internazionali: Buyers should consider the specific rubber compounds used, as different grades may be required for varying climates and applications.

| Materiale | Typical Use Case for best air tire inflator | Vantaggio chiave | Svantaggi/limitazioni principali | Costo relativo (Basso/Medio/Alto) |

|---|---|---|---|---|

| Plastica | Housing and lightweight components | Economico e leggero | Degrades under extreme conditions | Basso |

| Alluminio | Structural components for durability | Elevato rapporto resistenza/peso | Higher manufacturing cost | Med |

| Acciaio | High-pressure valves and fittings | Resistenza e durata superiori | Prone to corrosion if untreated | Alto |

| Gomma | Seals and hoses | Excellent flexibility and sealing | Degrades over time due to environmental exposure | Basso |

This analysis highlights the importance of material selection in air tire inflators, providing B2B buyers with actionable insights for making informed purchasing decisions.

Illustrative image related to best air tire inflator

The manufacturing process of tire inflators involves several key stages that ensure the final product meets performance and safety standards. Each stage is critical in producing a reliable and efficient inflator that can cater to diverse markets, including those in Africa, South America, the Middle East, and Europe.

Preparazione del materiale: The first stage involves sourcing high-quality materials, including plastics, metals, and electronic components. Manufacturers often rely on suppliers who adhere to international quality standards. Material testing is performed to ensure durability, resistance to heat, and overall performance under various conditions.

Formazione: In this stage, materials are shaped into parts using techniques such as injection molding for plastic components and stamping or machining for metal parts. Precision is vital here; therefore, automated machinery is frequently employed to achieve consistent dimensions and tolerances.

Montaggio: Once individual components are formed, they are assembled into the final product. This process may involve manual labor, especially for intricate parts, or automated assembly lines. Key focus areas include ensuring proper electrical connections and integrating features like digital displays, pressure gauges, and power sources.

Finitura: The final stage includes surface treatments, painting, and quality checks. Finishing not only enhances the aesthetic appeal but also adds protective layers to resist environmental factors. The inflators are often packaged with user manuals and accessories, ready for distribution.

Quality assurance (QA) is crucial in ensuring that tire inflators are safe, reliable, and perform as expected. Various international standards and industry-specific regulations guide these practices.

Standard internazionali: Compliance with ISO 9001 is fundamental, as it sets out the criteria for a quality management system. Manufacturers are expected to demonstrate their ability to consistently provide products that meet customer and regulatory requirements. Additionally, CE marking may be required for products sold within the European Union, indicating conformity with health, safety, and environmental protection standards.

Standard specifici del settore: For certain markets, compliance with industry-specific standards such as API (American Petroleum Institute) may be necessary. These standards ensure that products meet the technical specifications required for specific applications, such as inflators used in commercial or industrial settings.

Punti di controllo della qualità:

– Controllo qualità in entrata (CQI): This involves inspecting raw materials and components upon arrival to ensure they meet specified standards.

– Controllo qualità in corso d'opera (IPQC): During manufacturing, regular checks are conducted to monitor processes and detect any deviations from quality standards.

– Controllo qualità finale (CQC): After assembly, finished products undergo rigorous testing to verify functionality, safety, and performance metrics.

Manufacturers utilize various testing methods to ensure the reliability and safety of tire inflators. These tests often include:

Performance Testing: This includes evaluating the inflator’s speed and efficiency in inflating tires to specified pressures. Manufacturers simulate real-world conditions to assess performance under different scenarios.

Test di durata: Products are subjected to stress tests that mimic extreme conditions. This may involve repeated inflation cycles, exposure to temperature variations, and humidity to ensure long-term reliability.

Test di sicurezza: Manufacturers check for electrical safety, including insulation resistance and overcurrent protection. This ensures that the inflator does not pose a risk to users during operation.

For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control is paramount. Here are actionable steps:

Conduzione di audit: Schedule regular audits of potential suppliers to assess their manufacturing processes and QA practices. This can reveal insights into their compliance with international standards and operational efficiency.

Richiesta di rapporti sulla qualità: Suppliers should provide detailed reports on their quality control measures, including results from IQC, IPQC, and FQC. These documents offer transparency regarding their manufacturing capabilities and adherence to standards.

Coinvolgere ispettori di terze parti: Utilizing third-party inspection services can provide an unbiased evaluation of the supplier’s products. These inspectors can conduct on-site evaluations and product testing to verify compliance with quality standards.

When sourcing tire inflators from international suppliers, B2B buyers must navigate several nuances related to quality control and certification:

Conformità regionale: Different regions have varying compliance requirements. For instance, products sold in the EU must meet CE marking standards, while those in the U.S. may require compliance with ANSI (American National Standards Institute) regulations.

Documentazione: Buyers should ensure that suppliers provide all necessary documentation, including certificates of compliance, test reports, and quality management system certifications. This documentation is critical for customs clearance and regulatory compliance.

Considerazioni culturali: Understanding cultural differences in business practices can help in establishing effective communication with suppliers. Buyers should be aware of the local regulatory landscape, which may affect quality assurance practices and certification requirements.

Pratiche di sostenibilità: Increasingly, buyers are looking for suppliers who incorporate sustainable practices in their manufacturing processes. Verifying adherence to environmental standards (such as ISO 14001) can be an essential part of the procurement decision-making process.

In conclusion, the manufacturing processes and quality assurance practices for tire inflators are critical for ensuring that these products meet the diverse needs of B2B buyers across the globe. By understanding these processes and implementing rigorous quality control measures, manufacturers can deliver reliable, efficient, and safe products, while buyers can make informed decisions that align with their operational needs and compliance requirements.

Illustrative image related to best air tire inflator

This practical sourcing guide serves as a comprehensive checklist for B2B buyers looking to procure the best air tire inflators suitable for various applications, including automotive, commercial, and industrial uses. Selecting the right tire inflator is critical for ensuring operational efficiency, safety, and cost-effectiveness. This guide will help you navigate the essential steps to make an informed purchasing decision.

Establishing clear technical specifications is the foundation of your procurement process. Identify the types of vehicles or equipment the inflator will be used for, and determine the required PSI levels for effective tire inflation. Consider factors such as:

– Power Source: Decide between battery-operated, plug-in, or hybrid options based on your operational needs.

– Inflation Speed: Assess how quickly you need the inflator to work, especially for businesses with high turnover.

Conduct thorough market research to identify available models and brands that meet your specifications. Utilize online resources, industry publications, and customer reviews to compare performance metrics and features. Focus on:

– Brand Reputation: Look for manufacturers known for reliability and customer service.

– Product Range: Evaluate whether suppliers offer a variety of models to suit different needs.

Before committing to a purchase, it’s essential to vet potential suppliers. Request company profiles, product catalogs, and case studies from other businesses within your industry. Key considerations include:

– Certificazioni: Ensure the supplier has the necessary certifications for quality and safety standards.

– References: Ask for testimonials or references from clients in similar sectors to gauge supplier reliability.

Analyze the specific features of each tire inflator model to ensure they align with your operational requirements. Important features to consider include:

– Built-in Pressure Gauges: Accurate gauges prevent over-inflation and enhance safety.

– Portability: Compact designs with carrying cases can facilitate easier transport for mobile applications.

Investigate the after-sales support offered by suppliers, including warranty terms and maintenance services. Strong after-sales support can be crucial in minimizing downtime. Look for:

– Warranty Length: A longer warranty often indicates confidence in the product’s durability.

– Service Availability: Confirm that the supplier provides accessible customer service and technical support.

While upfront costs are important, consider the total cost of ownership over the product’s lifespan. Analyze factors such as:

– Initial Purchase Price: Ensure it fits within your budget without compromising quality.

– Operating Costs: Factor in maintenance, parts replacement, and energy consumption to gauge long-term value.

Once you’ve completed your evaluation and selected a supplier, finalize your purchase. Pay attention to logistics to ensure timely delivery. Key aspects include:

– Delivery Terms: Confirm shipping times and costs.

– Order Tracking: Ensure that the supplier provides order tracking capabilities for transparency.

Illustrative image related to best air tire inflator

By following this checklist, you can confidently procure the best air tire inflator tailored to your business needs, ensuring operational efficiency and safety across your vehicle fleet.

Understanding the cost structure of air tire inflators is crucial for international B2B buyers looking to make informed purchasing decisions. The primary cost components include:

I materiali: The cost of raw materials such as plastics, metals, and electronic components significantly influences the overall pricing. Higher-quality materials enhance durability and performance but may increase costs.

Lavoro: Labor costs vary by region, impacting the final product price. Skilled labor in manufacturing hubs can lead to higher wages, especially when quality control and precision engineering are essential.

Spese generali di produzione: This encompasses indirect costs associated with production, including utilities, rent, and equipment maintenance. Efficient manufacturing processes can help lower these costs.

Utensili: Initial setup costs for molds and production tools can be substantial. Buyers should consider how these costs will be amortized over production runs, influencing unit costs.

Controllo qualità (CQ): Rigorous QC processes are vital for ensuring the reliability of tire inflators. However, they add to the overall cost structure, especially if certifications (like ISO) are required.

Logistica: Shipping, warehousing, and distribution costs can fluctuate based on the destination and chosen Incoterms. Buyers must account for these when calculating total costs.

Margine: Suppliers will typically include a profit margin in their pricing. Understanding the industry standard for margins can aid in negotiations.

Several factors influence the pricing of air tire inflators that buyers should consider:

Volume/MOQ: Minimum order quantities (MOQs) can significantly affect pricing. Higher volume orders often lead to lower per-unit costs due to economies of scale.

Specifiche e personalizzazione: Customized features, such as advanced digital displays or additional accessories (like USB ports), can increase costs. Buyers should weigh the necessity of these features against their budget.

Materiali e qualità: Premium materials and certifications (like CE or UL) can justify higher prices. Buyers must assess whether these enhancements align with their market demands.

Fattori di fornitura: The reputation and reliability of suppliers can impact pricing. Established manufacturers with a track record may command higher prices due to perceived quality and service.

Incoterms: The choice of Incoterms (e.g., FOB, CIF) affects shipping costs and responsibilities, influencing the final landed cost of the product.

Navigating the procurement process for air tire inflators requires strategic approaches:

Negoziazione: Engage suppliers in discussions regarding bulk pricing, payment terms, and potential discounts for long-term contracts. Establishing a good relationship can lead to more favorable terms.

Efficienza dei costi: Evaluate total cost of ownership (TCO), including maintenance, warranty services, and replacement parts, rather than focusing solely on the initial purchase price. This holistic view can lead to better long-term investments.

Le sfumature dei prezzi per gli acquirenti internazionali: Be aware of currency fluctuations, tariffs, and import duties, particularly when sourcing from different regions. These factors can significantly alter the total cost.

Ricerca di mercato: Conduct thorough market research to compare prices and features across different suppliers. Understanding regional pricing trends can also help in negotiations and decision-making.

When sourcing air tire inflators, understanding the detailed cost structure and pricing influencers is essential for making informed purchasing decisions. By considering the various cost components, leveraging effective negotiation strategies, and being mindful of international pricing nuances, B2B buyers can optimize their procurement processes and achieve better value in their investments. Always remember that prices are indicative and can vary based on multiple factors, including market conditions and supplier capabilities.

Illustrative image related to best air tire inflator

In the realm of tire maintenance, air tire inflators have established themselves as essential tools for both individual and commercial vehicle upkeep. However, various alternatives exist that can meet similar needs, often providing unique advantages depending on the context of use. This analysis explores how the best air tire inflator compares to other viable solutions, offering insights for B2B buyers seeking the most effective method for tire inflation.

| Aspetto di confronto | Best Air Tire Inflator | Manual Pump | Compressor Air Pump |

|---|---|---|---|

| Prestazioni | Quick inflation; suitable for multiple tires; digital accuracy | Slower, labor-intensive; manual effort needed | Fast inflation; can inflate multiple tires; high pressure capability |

| Costo | $40 – $90 | $15 – $50 | $100 – $300 |

| Facilità di implementazione | User-friendly; portable; battery or vehicle-powered | Requires physical effort; limited portability | Requires electrical outlet; bulky |

| Manutenzione | Minimal; battery checks needed | Low; clean and store properly | Regular oil changes and filter replacements needed |

| Il miglior caso d'uso | Ideal for regular vehicle maintenance and emergencies | Suitable for low-volume needs (e.g., bicycles) | Best for heavy-duty applications (e.g., trucks, commercial vehicles) |

Manual pumps, often characterized by their simplicity and low cost, serve as a practical alternative to electric inflators. They are particularly beneficial for smaller inflation tasks, such as inflating bicycle tires or sports equipment. However, the disadvantages include the time-consuming nature of manual inflation and the physical effort required, which may not be feasible for all users. Additionally, the accuracy of pressure readings can vary, making it challenging to achieve the desired inflation level.

Compressor air pumps offer a robust solution for tire inflation, especially in heavy-duty applications. They can inflate tires quickly and handle high-pressure requirements, making them ideal for commercial vehicles and fleet management. However, they typically come at a higher price point and require a constant power source, limiting their portability. Moreover, compressors may necessitate regular maintenance, such as oil changes, which can add to their overall cost of ownership.

When selecting a tire inflation solution, B2B buyers must consider factors such as performance needs, budget constraints, and the specific use cases relevant to their operations. The best air tire inflator stands out for its combination of portability, ease of use, and quick inflation capabilities, making it suitable for both personal and fleet use. In contrast, manual pumps may suffice for low-volume applications, while compressor air pumps are better suited for larger-scale operations. Ultimately, understanding the unique requirements of your fleet or business will guide you in choosing the most effective tire inflation method.

When selecting air tire inflators for B2B applications, several technical specifications are critical for ensuring optimal performance and reliability. Understanding these properties helps buyers make informed purchasing decisions that align with their operational needs.

Maximum pressure, measured in pounds per square inch (PSI), indicates the highest air pressure the inflator can achieve. This is crucial for ensuring compatibility with various tire types, especially for heavy-duty vehicles like trucks and SUVs that may require higher PSI levels. A higher maximum pressure allows for versatility in inflation tasks, making it essential for businesses managing a diverse fleet.

The duty cycle refers to the duration an inflator can operate continuously before requiring a cooldown period. This specification is vital for commercial users who need to inflate multiple tires in succession. A higher duty cycle means less downtime and greater efficiency, allowing businesses to maintain productivity during peak operational periods.

Illustrative image related to best air tire inflator

The length and type of hose can significantly impact usability and efficiency. Longer hoses provide greater reach and flexibility, particularly in commercial settings where tires may not be easily accessible. Additionally, a durable hose material ensures resistance to wear and tear, extending the inflator’s lifespan.

Air tire inflators can be powered by batteries, 12-volt outlets, or standard electrical outlets. Each power source has its advantages; for instance, battery-operated models offer portability, while models powered by 12-volt sources are suitable for vehicles. Understanding the power requirements can help businesses select inflators that fit their operational setup and mobility needs.

The accuracy of the built-in pressure gauge is critical for ensuring correct tire inflation. An inaccurate gauge can lead to under-inflation or over-inflation, both of which can adversely affect tire performance and safety. Businesses should prioritize inflators with digital gauges for better precision and ease of use.

Illustrative image related to best air tire inflator

Weight is an important consideration for businesses that require mobility in their inflators. Lighter models are easier to transport and store, which is beneficial for service vehicles or mobile maintenance teams. However, the balance between weight and durability should also be evaluated to ensure long-term usability.

Familiarity with industry jargon is essential for effective communication and negotiation in B2B transactions. Here are some key terms relevant to air tire inflators.

OEM refers to companies that produce parts or products that are used in another company’s end product. In the context of air tire inflators, understanding OEM specifications can help buyers identify quality and compatibility with existing equipment.

Illustrative image related to best air tire inflator

MOQ is the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is crucial for businesses as it affects inventory management and purchasing strategies. Buyers should negotiate MOQs that align with their demand to avoid excess stock or shortages.

An RFQ is a standard business process used to invite suppliers to bid on specific products or services. This process helps businesses obtain competitive pricing for air tire inflators while ensuring they meet required specifications.

Incoterms define the responsibilities of buyers and sellers in international transactions, specifying who is responsible for shipping, insurance, and tariffs. Understanding these terms is essential for B2B buyers involved in cross-border procurement of air tire inflators to avoid unexpected costs.

Lead time refers to the amount of time it takes from placing an order until it is received. For businesses relying on air tire inflators for operations, understanding lead times is critical for planning and ensuring that they have the necessary tools on hand when needed.

A warranty is a guarantee provided by the manufacturer regarding the quality and longevity of the inflator. Knowing warranty terms can help businesses assess the risk of their investment and the level of support available should issues arise.

Illustrative image related to best air tire inflator

By grasping these technical specifications and industry terms, B2B buyers can make more informed decisions when selecting air tire inflators, ultimately improving operational efficiency and cost-effectiveness.

The global air tire inflator market is experiencing robust growth, driven by increasing vehicle ownership and rising awareness of vehicle maintenance. In regions like Africa, South America, the Middle East, and Europe, factors such as urbanization and economic development are propelling demand for reliable tire inflators. The growing focus on safety and efficiency in vehicle operation is also influencing purchasing decisions, as businesses seek to mitigate risks associated with under-inflated tires, which can lead to higher fuel consumption and increased wear.

Emerging technologies in the sector, such as smart tire inflators equipped with digital pressure gauges and automatic shut-off features, are gaining traction. These innovations enhance user experience and improve accuracy, making them attractive to B2B buyers looking for high-quality, efficient solutions. Furthermore, the rise of e-commerce platforms has made it easier for international buyers to source products directly, facilitating competitive pricing and broader access to diverse brands.

Illustrative image related to best air tire inflator

Notably, the trend towards cordless and portable inflators is on the rise, driven by consumer preference for convenience and ease of use. For B2B buyers, understanding these dynamics is crucial for making informed sourcing decisions that align with market demand and technological advancements.

Sustainability is becoming a central theme in the air tire inflator sector, with an increasing emphasis on reducing environmental impact. As global awareness of climate change grows, B2B buyers are prioritizing products that minimize ecological footprints. This includes sourcing inflators made from recycled materials and those that adhere to stringent environmental regulations.

Ethical sourcing practices are equally important, as companies strive to ensure that their supply chains are free from exploitative labor practices. Certifications such as ISO 14001 (Environmental Management) and the Global Organic Textile Standard (GOTS) can enhance credibility and appeal to environmentally conscious buyers. Manufacturers that commit to sustainable practices not only mitigate risks associated with compliance but also attract a growing segment of consumers who value ethical consumption.

Moreover, the integration of energy-efficient technologies in tire inflators not only reduces operational costs for businesses but also contributes to lower greenhouse gas emissions. For B2B buyers, selecting products that align with these sustainability goals is not just a matter of corporate responsibility; it is increasingly becoming a competitive differentiator in the marketplace.

The evolution of air tire inflators has been closely tied to advancements in automotive technology and consumer needs. Initially, tire inflators were simple, manual pumps that required significant physical effort. As the automotive industry evolved, so did the need for more efficient and user-friendly inflators.

Illustrative image related to best air tire inflator

The introduction of electric inflators in the late 20th century marked a significant turning point, making it easier for consumers and businesses to maintain proper tire pressure without the labor-intensive effort of manual pumps. Over the years, technological advancements have led to the development of portable, battery-operated models that cater to the growing demand for convenience and efficiency.

Today, the air tire inflator market is characterized by a diverse range of products, from compact, cordless models to heavy-duty inflators designed for larger vehicles. This evolution reflects broader trends in consumer behavior and the increasing importance of maintenance and safety in vehicle operation, positioning air tire inflators as essential tools for both individual consumers and businesses alike.

How do I choose the right air tire inflator for my business needs?

Selecting the appropriate air tire inflator involves assessing your specific requirements, including the types of vehicles you service and the average tire sizes. Consider factors such as maximum PSI, power source (cordless vs. corded), and portability. Evaluate the inflator’s speed, efficiency, and additional features like built-in pressure gauges and carrying cases. For businesses in regions with varying climates, durability and performance under different conditions are crucial. Lastly, ensure the supplier can provide reliable after-sales support and maintenance options.

What is the best tire inflator for commercial use?

For commercial applications, the AstroAI Cordless Tire Inflator stands out due to its high performance and portability. It can inflate multiple tires on a single charge, making it suitable for businesses with a fleet of vehicles. Additionally, its digital pressure gauge ensures accurate readings, while features like a built-in flashlight enhance usability in low-light conditions. If servicing larger vehicles like trucks and SUVs, consider the Viair 88P, which offers rapid inflation but requires a direct connection to the vehicle’s battery.

What are the key features to look for in a tire inflator?

When sourcing a tire inflator, prioritize features such as maximum pressure capability, power options (battery, 12V adapter), and inflation speed. A reliable built-in pressure gauge is essential for accuracy. Look for models that include additional accessories like adapters for inflating sports equipment or pool toys. Portability is also important, especially for businesses that require on-the-go solutions. Finally, consider the warranty and customer service offered by the manufacturer to ensure long-term support.

How can I verify the quality of tire inflators from suppliers?

To ensure quality, conduct thorough research on potential suppliers. Request product samples for testing and evaluate their performance against your specifications. Review certifications and compliance with international quality standards, such as ISO 9001. Additionally, seek references from other businesses that have purchased from the supplier. Consider visiting the supplier’s facility if possible, or use third-party inspection services to assess their manufacturing processes and quality control measures.

What are the typical minimum order quantities (MOQs) for tire inflators?

MOQs for tire inflators can vary significantly based on the supplier and the type of inflator. Generally, you can expect MOQs to range from 50 to 500 units for bulk orders. Some suppliers may offer flexibility for first-time buyers or smaller businesses. It’s essential to discuss your specific needs with potential suppliers to negotiate favorable terms, especially if you are looking for customization or branding options on the inflators.

What payment terms should I expect when purchasing tire inflators internationally?

Payment terms for international purchases can vary, but common options include advance payment, letter of credit, or payment upon delivery. It’s advisable to negotiate terms that provide a balance of security and flexibility. Many suppliers may require a deposit upfront, typically 30-50%, with the balance due before shipment. Ensure that the payment method is secure and offers protection against fraud. Additionally, confirm any currency exchange considerations and potential bank fees that may apply.

How do I handle logistics and shipping for tire inflators?

Logistics for importing tire inflators involves coordinating with freight forwarders and understanding shipping options, such as air freight for faster delivery or sea freight for cost efficiency. Ensure that the supplier can provide the necessary documentation for customs clearance. Familiarize yourself with import duties and taxes applicable in your country. Consider working with logistics experts who can guide you through the process and handle potential challenges, such as delays or damages during transit.

What are the common issues encountered with tire inflators, and how can they be resolved?

Common issues with tire inflators include inaccurate pressure readings, insufficient power, and overheating during prolonged use. To resolve these problems, ensure regular maintenance and proper usage as per manufacturer guidelines. Invest in models with built-in safety features, such as automatic shut-off to prevent overheating. If issues persist, consult the supplier for troubleshooting advice or warranty claims. Keeping an open line of communication with the supplier can also aid in quickly resolving any concerns.

Dominio: reddit.com

Registrato: 2005 (20 anni)

Introduzione: 1. Royobi air pump with a 4ah 18v battery – noted for reliability. 2. EPAUTO air pump – plugs into cigarette lighter, available on Amazon. 3. VIAIR 12v cigarette lighter air pump – recommended for its performance. 4. Dewalt air compressor – rechargeable battery or car plug option. 5. Milwaukee air pump – features smart air function, automatically stops at desired tire pressure. 6. Kobalt 24v porta…

Dominio: macheforum.com

Registrato: 2018 (7 anni)

Introduzione: Portable tire inflators recommended include the Fanttik X8 Apex and a model from AstroAI that also includes a jump starter. Users have mentioned using inflators from Ryobi and noted the importance of checking the mode on inflators that can inject sealant. One user shared a link to a specific product on Amazon. The discussion highlights the need for a reliable inflator, especially after receiving l…

In the competitive landscape of tire inflators, strategic sourcing is essential for international buyers looking to enhance their product offerings. The tested models, including the AstroAI Cordless Tire Inflator and the Viair 88P, exemplify the diverse needs of various vehicle types, from compact cars to larger trucks and SUVs. Key takeaways emphasize the importance of evaluating inflators based on efficiency, portability, and functionality—ensuring they meet specific regional demands.

Illustrative image related to best air tire inflator

For B2B buyers in Africa, South America, the Middle East, and Europe, identifying reliable suppliers that provide quality products at competitive prices will be vital. As market trends lean towards cordless and compact solutions, sourcing partners that offer innovative features—such as built-in pressure gauges and multiple power options—will set your business apart.

Looking ahead, the tire inflator market is poised for growth, driven by increasing vehicle ownership and the need for maintenance solutions. Now is the time to engage with trusted suppliers and invest in high-quality inflators that align with your business strategy. Ensure your procurement decisions are informed and forward-thinking to capitalize on future opportunities in this evolving market.

Le informazioni fornite in questa guida, compresi i contenuti relativi ai produttori, alle specifiche tecniche e all'analisi di mercato, hanno uno scopo puramente informativo ed educativo. Non costituiscono una consulenza professionale in materia di acquisti, né una consulenza finanziaria o legale.

Illustrative image related to best air tire inflator

Pur avendo compiuto ogni sforzo per garantire l'accuratezza e la tempestività delle informazioni, non siamo responsabili di eventuali errori, omissioni o informazioni non aggiornate. Le condizioni di mercato, i dettagli aziendali e gli standard tecnici sono soggetti a modifiche.

Gli acquirenti B2B devono condurre una due diligence indipendente e approfondita. prima di prendere qualsiasi decisione di acquisto. È necessario contattare direttamente i fornitori, verificare le certificazioni, richiedere campioni e chiedere una consulenza professionale. Il rischio di affidarsi alle informazioni contenute in questa guida è esclusivamente a carico del lettore.