In the fast-paced world of cycling, punctures are an inevitable challenge that can disrupt a rider’s experience. For B2B buyers seeking reliable solutions, sourcing effective bike tire CO2 inflators becomes crucial in ensuring cyclists can resume their journeys quickly. This comprehensive guide delves into the multifaceted aspects of bike tire CO2 inflators, covering various types, applications, supplier vetting processes, and cost considerations.

As the global market continues to evolve, particularly in regions such as Africa, South America, the Middle East, and Europe, understanding the nuances of CO2 inflators is essential for making informed purchasing decisions. This guide empowers international B2B buyers by providing insights into the best products available, highlighting features that enhance usability and efficiency, and offering practical advice on supplier selection.

By addressing key challenges, such as ensuring product reliability and compatibility with different bike valve types, this resource serves as a valuable tool for businesses aiming to meet the demands of their customers. Whether you are a distributor looking to expand your product line or a retailer seeking to enhance your offerings, this guide will equip you with the knowledge necessary to navigate the complexities of the CO2 inflator market confidently.

| Nome del tipo | Caratteristiche distintive principali | Applicazioni primarie B2B | Brevi pro e contro per gli acquirenti |

|---|---|---|---|

| CO2 Chucks | Simple design, often lightweight, easy to use | Retail bike shops, cycling events | Pro: Compact, affordable. Contro: Limited control over inflation speed. |

| Integrated Inflators | Combines pump and CO2 inflator functionality | Bicycle repair shops, rental services | Pro: Versatile, multi-functional. Contro: Heavier, may require more maintenance. |

| Inline Inflators | Streamlined design for direct attachment to valves | Competitive cycling, emergency kits | Pro: Compact, precise control. Contro: Can be tricky to use for novices. |

| Dual-Head Inflators | Compatible with both Presta and Schrader valves | International markets, diverse cycling communities | Pro: Versatile compatibility. Contro: Slightly bulkier design. |

| Electric CO2 Pumps | Battery-operated, automated inflation process | High-end bike retailers, premium service providers | Pro: Effortless operation, consistent inflation. Contro: Higher cost, reliance on battery life. |

CO2 chucks are the most basic type of inflator, designed for quick and efficient inflation. Their simplicity makes them a popular choice for retailers and cyclists who prioritize portability. B2B buyers should consider the weight and size of these inflators, as they are often used in competitive environments where space is limited. While they are generally affordable, the lack of inflation control may be a drawback for some users.

Integrated inflators combine the functionality of a pump with a CO2 inflator, providing versatility for various cycling needs. This type is particularly beneficial for businesses that offer repair services or rental bikes, as it caters to a wide range of inflation scenarios. B2B buyers should assess the durability and ease of use, as these inflators may require more maintenance due to their complexity. While they are heavier than standalone options, their multi-functionality can justify the investment.

Inline inflators are designed for direct attachment to tire valves, offering a sleek and efficient inflation solution. Their compact size makes them suitable for competitive cyclists who need quick inflation without extra bulk. B2B buyers in the competitive cycling sector should focus on the precision of these devices, as they allow for controlled inflation rates. However, their ease of use may pose a challenge for novice cyclists, which is an important consideration for retailers.

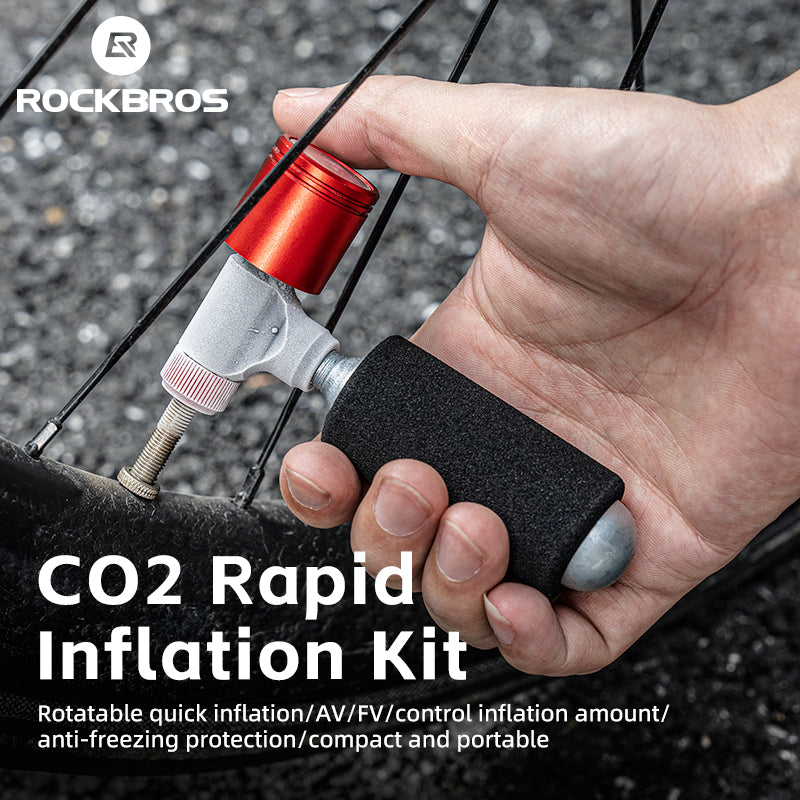

Illustrative image related to bike tire co2 inflator

Dual-head inflators accommodate both Presta and Schrader valves, making them a versatile choice for international markets. This feature is particularly valuable for businesses operating in regions with varied cycling preferences. B2B buyers should consider the balance between versatility and size, as dual-head designs can be bulkier than single-valve options. Despite this, their compatibility can enhance customer satisfaction and reduce inventory complexity.

Electric CO2 pumps automate the inflation process, providing a user-friendly experience that appeals to high-end markets. They are particularly advantageous for premium bike retailers and service providers aiming to offer top-tier products. When purchasing, B2B buyers should evaluate battery life and maintenance requirements, as these factors can impact long-term usability. While the initial investment is higher, the effortless operation can attract customers looking for convenience.

| Industria/Settore | Specific Application of bike tire co2 inflator | Valore/Beneficio per l'azienda | Considerazioni chiave sull'approvvigionamento per questa applicazione |

|---|---|---|---|

| Cycling Retail | Quick inflation solutions for customer service | Enhances customer satisfaction and loyalty | Availability of diverse models, pricing, and bulk discounts |

| Bike Tours and Rentals | Emergency tire inflation for tour guides | Minimizes downtime, ensuring smooth operations | Durability, ease of use, and compatibility with various tire types |

| Logistica e consegna | Maintenance of delivery bikes | Reduces operational delays due to flat tires | Compact size, weight, and ease of storage for delivery vehicles |

| Sports Events Management | On-site tire inflation for participants | Ensures readiness and safety for competitors | Reliability, speed of inflation, and ease of transportation |

| Manufacturing & Assembly | Quality control in bike assembly lines | Streamlines production and ensures product quality | Consistency in performance and availability of CO2 cartridges |

In cycling retail, bike tire CO2 inflators serve as a quick inflation solution for customers experiencing flat tires. Retailers can enhance customer satisfaction by providing instant service, allowing cyclists to resume their rides without prolonged interruptions. For B2B buyers in this sector, sourcing high-quality, reliable inflators that are easy to operate is crucial. Retailers should consider bulk purchasing options to reduce costs and ensure a steady supply of diverse models that cater to different customer needs.

Bike tours and rental services utilize CO2 inflators as essential tools for tour guides and support staff. These inflators enable quick tire inflation in emergency situations, which minimizes downtime and ensures that tours can proceed smoothly. For international buyers in regions such as Africa and South America, it is vital to select inflators that are durable and user-friendly, as staff may need to assist cyclists with varying levels of mechanical knowledge. Additionally, compatibility with both Presta and Schrader valves is a significant consideration to accommodate diverse bike types.

In the logistics and delivery sector, bike tire CO2 inflators are critical for maintaining the operational efficiency of delivery bikes. These inflators allow couriers to quickly address flat tires, reducing delays in service and enhancing customer satisfaction. For B2B buyers in this industry, sourcing compact and lightweight inflators is essential, as they need to fit within limited storage spaces on delivery vehicles. Reliability and ease of use are also paramount, ensuring that couriers can quickly resolve tire issues without extensive downtime.

Illustrative image related to bike tire co2 inflator

During sports events, bike tire CO2 inflators provide on-site tire inflation for participants, ensuring they remain ready and safe to compete. Event organizers can facilitate quick repairs, which is crucial for maintaining the flow of the event and ensuring participant satisfaction. B2B buyers in this sector should prioritize sourcing reliable and fast-acting inflators that can withstand the rigors of event logistics. Additionally, ease of transportation and setup are vital factors to consider, as they will be used across multiple locations.

In manufacturing and assembly contexts, bike tire CO2 inflators are used for quality control processes during bike assembly lines. They ensure that tires are inflated to the correct pressure, which is essential for product quality and safety. B2B buyers in this sector should focus on sourcing consistent and high-performance inflators that can handle high volumes of use. Availability of CO2 cartridges and the ability to integrate inflators into existing assembly processes are also key considerations for maintaining efficiency and productivity.

Il problema: B2B buyers often face the challenge of sourcing CO2 inflators that are compatible with available cartridges in their region. In many cases, suppliers may offer a variety of inflators, but without a clear indication of which cartridges are compatible, buyers can end up with stock that does not fit their existing inflators. This can lead to operational delays and increased costs due to the need for additional procurement efforts. Additionally, the inconsistency in cartridge sizes and threading standards across different brands further complicates matters, making it difficult for buyers to maintain a reliable inventory.

La soluzione: To alleviate this issue, B2B buyers should prioritize sourcing inflators that are versatile and compatible with multiple cartridge sizes, such as 16g, 20g, and 25g. When evaluating inflators, look for those that explicitly mention compatibility with both Presta and Schrader valves, ensuring they can cater to a wider range of bikes. Establishing strong relationships with reliable suppliers who can provide a consistent inventory of both inflators and cartridges will also help maintain operational efficiency. Additionally, consider bundling CO2 inflators with the appropriate cartridges to streamline the purchasing process and minimize compatibility issues.

Il problema: Many users report difficulty in achieving the desired tire pressure when using CO2 inflators, leading to frustration and potential safety risks. The lack of flow control on some models can result in over-inflation or under-inflation, which compromises the performance of the bike and the safety of the rider. This inconsistency can be particularly problematic for businesses that rely on bikes for deliveries or tours, as they need to ensure all equipment is in optimal condition at all times.

La soluzione: To address inflation control challenges, B2B buyers should opt for CO2 inflators that feature adjustable flow controls. These inflators allow users to regulate the release of CO2, enabling precise inflation to the required pressure. When selecting inflators, request samples or demonstrations to evaluate their ease of use and flow control capabilities. Additionally, providing training for staff on proper inflation techniques can further enhance reliability. It’s also beneficial to keep a digital or printed pressure guide accessible to users, helping them quickly reference the recommended pressures for various tire types.

Il problema: As businesses increasingly prioritize sustainability, the environmental impact of CO2 cartridges has come under scrutiny. Many B2B buyers are concerned about the waste generated by disposable cartridges and the carbon footprint associated with their production and disposal. This concern is particularly pronounced in regions where recycling facilities for such items are limited, making it difficult to adhere to eco-friendly practices.

La soluzione: B2B buyers should explore partnerships with manufacturers that offer refillable CO2 inflators or sustainable cartridge options. Investing in reusable systems allows companies to significantly reduce waste and demonstrate their commitment to environmental responsibility. Additionally, consider implementing a cartridge recycling program within your business, encouraging users to return empty cartridges for recycling or proper disposal. Educating staff and customers about the environmental benefits of using refillable options will also enhance your brand image and align with sustainable practices. By prioritizing eco-friendly solutions, companies can not only mitigate environmental impact but also meet the growing consumer demand for sustainability in their operations.

When selecting materials for bike tire CO2 inflators, manufacturers must consider various factors that affect performance, durability, and cost. The following analysis explores four common materials used in the construction of these inflators, focusing on their properties, advantages, disadvantages, and implications for international B2B buyers.

Illustrative image related to bike tire co2 inflator

Aluminum is a popular choice for CO2 inflators due to its lightweight nature and excellent strength-to-weight ratio. It typically has a high temperature and pressure rating, making it suitable for handling the rapid expansion of CO2 gas. Aluminum also exhibits good corrosion resistance, particularly when anodized, which is essential for maintaining performance in diverse environments.

Pro: Aluminum is durable and can withstand repeated use without significant wear. It is also relatively cost-effective compared to other metals, making it an attractive option for manufacturers looking to balance quality and price.

Contro: While aluminum is resistant to corrosion, it can still be susceptible to scratches and dents, which may affect the aesthetics and functionality of the inflator. Additionally, the manufacturing process can be complex, requiring precision machining.

Illustrative image related to bike tire co2 inflator

Impatto sull'applicazione: Aluminum inflators are compatible with both Presta and Schrader valves, making them versatile for various bike types. However, buyers should ensure that the aluminum used meets international standards such as ASTM or JIS to guarantee safety and reliability.

Plastic materials, particularly high-density polyethylene (HDPE) and polycarbonate, are often used in CO2 inflators for components like handles and protective casings. These plastics are lightweight and can be molded into complex shapes, allowing for innovative designs that enhance user experience.

Pro: Plastic components can be produced at a lower cost than metal parts, making them an economical choice for manufacturers. They are also resistant to corrosion and can be designed to be shock-absorbent, providing additional protection during use.

Contro: The primary drawback of plastic is its lower temperature and pressure tolerance compared to metals, which may limit its use in high-stress areas of the inflator. Additionally, plastics may degrade over time when exposed to UV light or extreme temperatures.

Impatto sull'applicazione: While plastic can be used effectively in non-structural components, it is crucial for buyers to assess the specific grades of plastic used to ensure they meet performance standards for CO2 applications.

Stainless steel is often utilized for valves and other critical components in CO2 inflators due to its excellent strength and corrosion resistance. It can withstand high pressures and temperatures, making it a reliable choice for safety-critical applications.

Pro: Stainless steel is highly durable and resistant to rust and corrosion, ensuring a long lifespan for inflators. Its robustness also allows for a more compact design without sacrificing performance.

Contro: The primary disadvantage of stainless steel is its higher cost compared to aluminum and plastic. Additionally, the weight of stainless steel can be a consideration for manufacturers focused on creating lightweight inflators.

Impatto sull'applicazione: Stainless steel components are essential for maintaining the integrity of the inflator under pressure. B2B buyers should verify that the stainless steel used complies with relevant international standards to ensure safety and reliability.

Composite materials, such as carbon fiber reinforced polymers, are emerging in the production of high-end CO2 inflators. These materials combine the benefits of lightweight and high strength, making them ideal for performance-oriented products.

Illustrative image related to bike tire co2 inflator

Pro: Composites are incredibly strong yet lightweight, allowing for innovative designs that can enhance user experience. They also offer excellent resistance to environmental factors, such as moisture and UV exposure.

Contro: The manufacturing process for composites can be more complex and costly, which may increase the final price of the product. Additionally, not all composites are created equal; quality can vary significantly based on the manufacturing process.

Impatto sull'applicazione: Composites can be tailored for specific applications, but international buyers should ensure that the materials meet necessary compliance standards to avoid issues related to performance and safety.

| Materiale | Typical Use Case for bike tire co2 inflator | Vantaggio chiave | Svantaggi/limitazioni principali | Costo relativo (Basso/Medio/Alto) |

|---|---|---|---|---|

| Alluminio | Body and structural components | Leggero e resistente | Susceptible to scratches | Medio |

| Plastica | Handles and protective casings | Cost-effective and moldable | Lower temperature tolerance | Basso |

| Acciaio inox | Valves and critical components | Excellent corrosion resistance | Higher cost | Alto |

| Composito | High-performance inflators | Strong and lightweight | Complex manufacturing process | Alto |

This material selection guide provides valuable insights for B2B buyers in regions like Africa, South America, the Middle East, and Europe, ensuring that they make informed decisions that align with their operational needs and market standards.

Illustrative image related to bike tire co2 inflator

The manufacturing process of bike tire CO2 inflators typically involves several key stages, including material preparation, forming, assembly, and finishing. Each stage plays a critical role in ensuring the final product meets the high standards expected in the cycling industry.

The first step in manufacturing CO2 inflators is material preparation, where manufacturers select high-quality materials such as aluminum, plastic, and rubber. Aluminum is often used for the body of the inflator due to its lightweight and durable properties. High-grade plastics may be employed for components that require flexibility and resilience, while rubber seals are essential for preventing leaks during operation. Suppliers must ensure that all materials comply with relevant international standards to guarantee safety and performance.

After materials are selected, the next stage is forming the components. This often involves techniques such as CNC machining for aluminum parts, which allows for precise shaping and sizing. Injection molding is frequently used for plastic components, enabling mass production while maintaining high accuracy. For rubber parts, processes like extrusion and molding are employed to create seals that fit perfectly within the inflator design.

Illustrative image related to bike tire co2 inflator

Once the components are formed, they move to the assembly stage. In this phase, individual parts are meticulously put together, often utilizing automated assembly lines for efficiency. Skilled labor may also be involved in tasks that require a high level of precision, such as fitting the rubber seals or attaching the gas cartridges. Quality checks during assembly are crucial; each inflator must be tested to ensure that all parts fit correctly and function as intended.

The final stage of manufacturing is finishing, which may include surface treatments such as anodizing for aluminum parts, painting, or applying protective coatings. These processes not only enhance the aesthetic appeal of the inflator but also improve its resistance to corrosion and wear. Proper finishing techniques are vital for ensuring the longevity and reliability of the product, especially in various environmental conditions.

Quality assurance is critical in the manufacturing of bike tire CO2 inflators, ensuring that each product meets international safety and performance standards. B2B buyers should be familiar with various quality certifications and checkpoints throughout the manufacturing process.

International standards like ISO 9001 are essential for ensuring effective quality management systems within manufacturing facilities. Compliance with ISO standards indicates that a manufacturer consistently meets customer requirements and enhances satisfaction. Other relevant certifications may include CE marking, which signifies compliance with European health, safety, and environmental protection standards.

Illustrative image related to bike tire co2 inflator

In addition to general international standards, industry-specific certifications such as the American Petroleum Institute (API) standards may apply, especially if the inflators are designed for high-pressure applications. B2B buyers should inquire about these certifications to ensure that products are manufactured with the highest safety standards in mind.

Quality control (QC) is integrated at various checkpoints throughout the manufacturing process, ensuring that defects are identified and corrected promptly.

Controllo qualità in entrata (CQI): This initial checkpoint focuses on raw materials, where suppliers are evaluated based on the quality of the materials they deliver. Inspections ensure that materials meet specified standards before production begins.

Controllo qualità in corso d'opera (IPQC): During manufacturing, IPQC checkpoints monitor the production process. This includes examining the forming techniques, assembly procedures, and ensuring that machinery operates correctly. Regular checks help identify any deviations from production standards.

Controllo qualità finale (CQC): After assembly, the finished inflators undergo FQC to ensure they meet all design specifications and performance criteria. This may involve functional tests, such as checking for gas leakage and confirming that inflators can achieve the required pressure levels.

B2B buyers need to ensure that their suppliers adhere to strict quality control measures. Here are several methods to verify supplier QC effectively.

Conducting supplier audits is a crucial step for B2B buyers. These audits can be performed either by the buyer’s quality assurance team or through third-party inspection services. Audits should assess the supplier’s adherence to quality standards, production processes, and QC measures.

Buyers should request detailed quality control reports from suppliers. These reports should include data on material inspections, manufacturing processes, and results from FQC tests. Transparency in reporting allows buyers to assess the reliability and quality of their suppliers.

International B2B buyers, particularly those from diverse regions such as Africa, South America, the Middle East, and Europe, should be aware of specific nuances related to quality control and certifications.

Different regions may have unique regulatory requirements that affect product certifications. Buyers should familiarize themselves with local standards and ensure that their suppliers can meet these requirements. For instance, products sold in the European market must comply with CE marking, while others may require different certifications depending on local laws.

Buyers should inquire about the testing methods used by suppliers to verify product quality. Common testing methods for CO2 inflators include pressure testing, leak testing, and performance testing under various conditions. Understanding these methods can provide insights into the reliability of the products being sourced.

By gaining a comprehensive understanding of the manufacturing processes and quality assurance measures in place for bike tire CO2 inflators, B2B buyers can make informed decisions that ensure they source reliable and high-quality products for their markets.

In this guide, we provide a practical checklist for B2B buyers seeking to procure bike tire CO2 inflators. This essential tool for cyclists requires careful consideration of various factors to ensure that you select a product that meets your quality, performance, and market needs.

Establishing clear technical specifications is the first step in your procurement process. Consider the types of valves your target market uses (Presta and Schrader compatibility), the size and weight of the inflator, and the capacity of CO2 cartridges. These specifications will help you identify products that best meet the needs of your customers.

Understanding the current market demand and trends in bike accessories is crucial. Analyze sales data, customer preferences, and emerging trends such as eco-friendly products or integrated inflator systems. This information can guide your purchasing decisions and help you stock items that will sell well.

Illustrative image related to bike tire co2 inflator

Before committing to a supplier, conduct a thorough evaluation. Request company profiles, product catalogs, and references from other businesses in your region or industry. Look for suppliers who have experience in the cycling market and can demonstrate reliability and quality in their products.

Quality assurance is paramount when sourcing inflators. Verify that the products comply with international safety and quality standards. Request certifications such as ISO or CE markings and inquire about the testing processes the supplier employs to ensure the inflators are durable and reliable.

Before making a bulk purchase, always request samples to test the product’s performance. Ensure the inflators meet your specifications, check for ease of use, and evaluate their inflation speed. Testing samples will help you ascertain product quality and customer satisfaction potential.

Once you’ve identified a suitable supplier, negotiate pricing and terms. Discuss bulk purchase discounts, payment terms, and shipping options. Understanding the total cost of procurement, including shipping and customs duties, will help you maintain your budget and ensure profitability.

Effective communication with your supplier is essential for a successful partnership. Set up regular check-ins to discuss order status, product updates, and market feedback. This proactive approach will help you address any issues quickly and build a strong business relationship.

By following these steps, B2B buyers can ensure they source high-quality bike tire CO2 inflators that meet the needs of their customers while maintaining competitive pricing and reliable supply chains.

When sourcing bike tire CO2 inflators, a thorough understanding of the cost structure is essential. The primary cost components include:

I materiali: The raw materials, such as aluminum, plastic, and rubber for seals, significantly influence the cost. High-quality materials can enhance durability and performance but may raise the initial price.

Lavoro: Labor costs vary by region. Countries with lower labor costs, such as Vietnam or Brazil, may offer more competitive pricing. However, the skill level of the workforce can affect the overall quality of the product.

Spese generali di produzione: This includes costs related to factory operations, utilities, and equipment maintenance. Efficient manufacturing processes can help keep these costs down, impacting the final pricing structure.

Utensili: Initial tooling costs for molds and machinery can be significant. These costs are often amortized over production runs, making them critical for understanding unit costs.

Controllo qualità (CQ): Implementing robust QC measures is essential for maintaining product standards. While it may increase costs upfront, it reduces returns and warranty claims, ultimately benefiting the buyer.

Logistica: Shipping costs, tariffs, and insurance can significantly influence total expenses, especially for international buyers. Understanding the logistical landscape is crucial for accurate budgeting.

Margine: Suppliers typically include a profit margin in their pricing. This margin can vary based on competition, demand, and the supplier’s business model.

Several factors can influence the pricing of bike tire CO2 inflators, including:

Volume/MOQ (quantità minima d'ordine): Larger orders often result in lower per-unit costs due to economies of scale. Buyers should negotiate MOQs to achieve better pricing.

Specifiche e personalizzazione: Custom features or specifications can raise costs. Buyers should balance the need for customization against budget constraints.

Qualità dei materiali e certificazioni: Premium materials and certifications (e.g., ISO standards) can justify higher prices. Buyers should assess whether the added cost aligns with their target market’s expectations.

Fattori di fornitura: The reputation and reliability of the supplier can impact pricing. Established suppliers may charge more due to perceived quality and service, while newer companies might offer competitive rates to build their market presence.

Incoterms: The choice of Incoterms affects logistics costs and responsibilities. Buyers should be aware of how terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) influence total expenses.

When negotiating prices for bike tire CO2 inflators, consider the following strategies to enhance cost efficiency:

Comprendere il costo totale di proprietà (TCO): Beyond the initial purchase price, evaluate the long-term costs associated with the inflators, including maintenance, repairs, and potential warranty claims.

Leverage Volume Discounts: If planning to order in bulk, use this leverage during negotiations to secure better pricing.

Esplora i fornitori alternativi: Don’t hesitate to explore multiple suppliers to compare pricing and quality. A competitive landscape can often lead to better deals.

Assess Payment Terms: Flexible payment terms can ease cash flow concerns. Negotiate favorable terms that allow for better financial management.

Be Aware of Regional Pricing Nuances: International buyers should understand regional market conditions, currency fluctuations, and import duties that can affect pricing.

Understanding the comprehensive cost structure and pricing influencers for bike tire CO2 inflators is vital for B2B buyers. By focusing on cost components, recognizing price influencers, and employing effective negotiation strategies, buyers can optimize their sourcing decisions and achieve better value. As always, indicative prices should be taken with caution as they can fluctuate based on market conditions and supplier negotiations.

Illustrative image related to bike tire co2 inflator

In the realm of cycling, maintaining optimal tire pressure is crucial for performance and safety. While bike tire CO2 inflators are a popular choice for quick inflation, several alternative solutions can also meet the needs of cyclists. Understanding these alternatives can help B2B buyers make informed decisions based on performance, cost, and usability.

| Aspetto di confronto | Bike Tire CO2 Inflator | Manual Hand Pump | Electric Tire Pump |

|---|---|---|---|

| Prestazioni | Fast, high-pressure fill | Slower, variable pressure | Quick, consistent pressure |

| Costo | Moderate ($15 – $55) | Low ($10 – $30) | Higher ($50 – $150) |

| Facilità di implementazione | Simple, portable | Requires physical effort | User-friendly, plug-in |

| Manutenzione | Low (replace cartridges) | Moderate (cleaning needed) | Low (occasional checks) |

| Il miglior caso d'uso | Emergency repairs | General maintenance | Home use, larger tires |

Manual hand pumps are a time-tested solution for inflating bike tires. They are cost-effective and often lightweight, making them an excellent choice for regular maintenance. Users must exert physical effort to inflate the tire, which can be a drawback during emergencies when speed is critical. However, manual pumps can achieve high pressure and are generally more reliable in the long run, as they do not rely on consumable cartridges.

Electric tire pumps offer a modern solution for inflation, providing quick and consistent tire pressure without manual effort. They are user-friendly, often featuring automatic shut-off functions when the desired pressure is reached. However, electric pumps tend to be more expensive and less portable than CO2 inflators and manual pumps. They are best suited for home use or in situations where power sources are readily available, making them less ideal for on-the-go cyclists.

When selecting the best tire inflation solution, B2B buyers should consider the specific needs of their target market. For businesses focused on emergency repair kits for cyclists, CO2 inflators offer unmatched speed and convenience. Conversely, manual pumps may appeal to eco-conscious consumers or those seeking a cost-effective solution for regular maintenance. Electric pumps are ideal for consumers who prioritize ease of use and are willing to invest in a higher upfront cost. By understanding the strengths and weaknesses of each option, businesses can effectively align their product offerings with the preferences of their customers, ultimately enhancing customer satisfaction and loyalty.

When evaluating bike tire CO2 inflators, several technical properties are crucial for ensuring performance, reliability, and compatibility. Understanding these specifications can aid B2B buyers in making informed purchasing decisions.

CO2 inflators are typically constructed from high-grade materials like aluminum or composite plastics. Aluminum offers durability and resistance to corrosion, which is essential for outdoor use. Composite materials can reduce weight while still providing adequate strength. For B2B buyers, selecting inflators made from higher-grade materials can mean longer product lifespans and better performance under diverse conditions.

The weight of a CO2 inflator is a critical consideration for cyclists, especially those who prioritize portability. Inflators generally weigh between 16g to 30g, impacting how easily they can be carried during rides. Lighter inflators are often preferred, but they must also balance strength and functionality. B2B buyers should assess the weight in relation to the target market’s needs, especially for competitive cyclists or long-distance riders.

Most CO2 inflators are designed to work with both Presta and Schrader valves. This dual compatibility is vital for retailers targeting a broad customer base, as it minimizes the need for multiple inflator models. Understanding valve compatibility helps B2B buyers ensure they stock products that meet various customer requirements.

Flow control is a feature that allows users to regulate the release of CO2 into the tire. Inflators with adjustable flow control offer better user experience, enabling cyclists to achieve the desired tire pressure without over-inflation. B2B buyers should prioritize inflators with precise flow control to enhance customer satisfaction and reduce the likelihood of product returns.

Illustrative image related to bike tire co2 inflator

CO2 inflators typically use cartridges of different sizes, commonly ranging from 16g to 25g. The size of the cartridge directly affects the volume of air dispensed and, consequently, the speed of inflation. Buyers should consider the target market’s preferences and typical use cases when selecting inflators with specific cartridge compatibility.

The operating temperature range indicates the conditions under which the inflator can function optimally. Extreme temperatures can affect the performance and safety of CO2 inflators. For B2B buyers, understanding the temperature specifications can help in selecting products that cater to diverse geographic markets, ensuring reliability in various climates.

Familiarity with industry terminology is essential for B2B transactions, as it facilitates clearer communication and understanding between manufacturers, suppliers, and buyers.

OEM refers to companies that produce products or components that are sold under another company’s brand name. In the context of CO2 inflators, buyers may seek OEM partnerships to offer branded inflators, ensuring quality and consistency in manufacturing.

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is crucial for B2B buyers to manage inventory effectively and negotiate better pricing with manufacturers. Lower MOQs may be beneficial for new businesses or those testing market demand.

Illustrative image related to bike tire co2 inflator

An RFQ is a document issued by buyers to solicit pricing and terms from suppliers. It is a critical step in the procurement process, allowing buyers to compare offers from different manufacturers for CO2 inflators, ensuring they get the best value.

Incoterms define the responsibilities of buyers and sellers in international transactions, including shipping, insurance, and tariffs. For B2B buyers, understanding Incoterms is vital for managing logistics and ensuring compliance with international trade regulations.

SKU is a unique identifier for each product variant, allowing retailers to manage inventory efficiently. For CO2 inflators, distinct SKUs can help track sales performance and stock levels, aiding in inventory management.

Lead time is the period between placing an order and receiving the goods. For B2B buyers, understanding lead times for CO2 inflators is essential for planning inventory and meeting customer demand, especially in seasonal markets.

By grasping these technical properties and trade terminologies, B2B buyers can make informed decisions that enhance their product offerings and meet market demands effectively.

The bike tire CO2 inflator market is experiencing notable growth driven by the increasing popularity of cycling as a sustainable mode of transport and recreational activity. Globally, urbanization and a shift towards eco-friendly transportation options are fueling demand. Emerging markets in Africa, South America, the Middle East, and Europe are particularly significant as cycling infrastructure improves and more consumers seek efficient solutions for tire maintenance. The rise of e-commerce is also transforming the way B2B buyers source these products, making it easier for international buyers to access a wide range of CO2 inflators and associated products.

B2B technology trends are influencing sourcing practices within this sector. For instance, the integration of smart technology into inflators is becoming prevalent, with features like digital pressure gauges and Bluetooth connectivity for app integration. These innovations cater to the tech-savvy cyclist and provide a competitive edge for manufacturers. Additionally, the trend towards multifunctional products—such as inflators that double as compact pumps—reflects a growing preference for space-saving and versatile solutions among consumers.

International buyers should also be aware of fluctuating material costs, particularly for aluminum and plastic components, which can impact pricing strategies. Collaborating with manufacturers who offer transparency in their supply chains can mitigate risks associated with price volatility and ensure steady supply.

Sustainability is a critical concern in the bike tire CO2 inflator sector, as manufacturers face increasing pressure to minimize their environmental footprint. The production of CO2 cartridges, which are often made from aluminum, involves energy-intensive processes that contribute to greenhouse gas emissions. Consequently, many B2B buyers are prioritizing suppliers who commit to sustainable practices, such as using recycled materials and employing energy-efficient manufacturing techniques.

Ethical sourcing is also gaining traction, with buyers increasingly demanding transparency in the supply chain. This includes verification of labor practices, environmental compliance, and adherence to international standards. Certifications like ISO 14001 for environmental management and fair trade certifications can serve as indicators of a supplier’s commitment to sustainability and ethical practices.

Moreover, the development of biodegradable or eco-friendly CO2 cartridges is emerging as a significant trend. These innovations appeal to environmentally conscious consumers and can enhance brand reputation in competitive markets. B2B buyers are advised to seek partnerships with manufacturers who are not only compliant with sustainability standards but also actively innovate to reduce the environmental impact of their products.

The bike tire CO2 inflator has evolved significantly since its inception, transitioning from simple manual pumps to sophisticated devices that prioritize speed and convenience. Initially, inflators were bulky and primarily mechanical, requiring manual effort for tire inflation. However, the introduction of CO2 cartridges revolutionized the market by offering a quick and efficient solution for cyclists facing flat tires.

As cycling gained traction as a popular sport and mode of transportation, manufacturers began incorporating advanced features such as flow control mechanisms and compatibility with various valve types. The rise of electric bikes and the demand for portable solutions have further spurred innovation, resulting in compact, multifunctional inflators that cater to a diverse range of consumer needs. This evolution reflects a broader trend towards convenience and efficiency in cycling accessories, aligning with the lifestyle of modern cyclists who prioritize readiness and reliability in their gear.

In summary, the bike tire CO2 inflator market is positioned for continued growth, driven by technological advancements and a strong focus on sustainability. B2B buyers should remain vigilant about sourcing trends and prioritize partnerships that align with their values and market demands.

How do I choose the right CO2 inflator for my business needs?

Selecting the ideal CO2 inflator involves assessing your target market’s preferences and your product range. Consider factors such as valve compatibility (Presta and Schrader), inflation speed, and ease of use. Additionally, evaluate the size and weight of the inflator for portability, especially for outdoor cycling markets. Research customer reviews and expert opinions to gauge the reliability of different brands. Finally, ensure that the inflators meet any relevant safety and environmental standards, especially when distributing in diverse regions.

What features should I look for in a CO2 inflator for resale?

Key features to consider include flow control mechanisms for precise inflation, compatibility with various valve types, and a compact design for portability. Durability is crucial, so choose inflators made from high-quality materials. Look for options that come with safety features, such as protective sleeves to prevent cold burns during use. Additionally, consider whether the inflator can accommodate different CO2 cartridge sizes, as this can add versatility for end-users.

What are the typical payment terms when sourcing CO2 inflators internationally?

Payment terms can vary significantly by supplier and region. Common practices include advance payment, letters of credit, or payment upon delivery. Establishing a relationship with your supplier can lead to more favorable terms, such as partial payments or credit. Be sure to clarify payment methods (e.g., bank transfer, PayPal, etc.) and currency options. Always review the terms in the context of your business cash flow and risk tolerance.

How can I verify the reliability of CO2 inflator suppliers?

To ensure supplier reliability, conduct thorough due diligence. Check for industry certifications, customer reviews, and their track record in international trade. Request samples to evaluate product quality firsthand. Additionally, consider visiting the supplier’s manufacturing facility or utilizing third-party inspection services. Engaging with other businesses in your network that have previously worked with the supplier can also provide valuable insights.

What is the minimum order quantity (MOQ) for CO2 inflators?

MOQs for CO2 inflators can vary widely based on the supplier and product type. Typically, they range from 100 to 1,000 units. Discussing your specific needs with potential suppliers can lead to negotiated terms that suit your business model. Keep in mind that larger orders may yield better pricing and lower per-unit costs, but ensure that your business can handle the inventory effectively.

Are there customization options available for CO2 inflators?

Many suppliers offer customization options, such as branding, color variations, or packaging. Customization can enhance brand recognition and appeal to specific markets. When negotiating with suppliers, inquire about their capabilities and any associated costs. Be clear about your design specifications and expected lead times, as customized orders may require additional production time.

What quality assurance measures should I expect from CO2 inflator suppliers?

Reputable suppliers should have established quality assurance protocols, including material inspections, functional testing, and compliance with safety standards. Request documentation of these processes, such as ISO certifications or test reports. It’s also beneficial to establish a return policy for defective products and to discuss warranty terms, ensuring you are protected against quality issues after purchase.

What are the logistics considerations when importing CO2 inflators?

Logistics for importing CO2 inflators involve understanding shipping methods, customs regulations, and tariffs in your target market. Choose a reliable freight forwarder familiar with handling sporting goods. Be aware of the regulations regarding the import of compressed gases, as these can vary by country. Prepare all necessary documentation, including invoices, packing lists, and customs declarations, to facilitate smooth clearance at customs.

Dominio: ride.lezyne.com

Registered: 2007 (18 years)

Introduzione: Lezyne CO2 inflators provide instant, reliable tire inflation in seconds, ideal for road bikes and mountain bikes. Key products include: PRESSURE DRIVE CFH ($43.99), CLIK™ DRIVE CO2 WITH 20G CARTRIDGE ($37.99), CADDY KIT ($26.39), CONTROL DRIVE CO2 (from $23.99), TWIN KIT (from $23.99), 25G CO2 – 5 PACK ($22.39), REPAIR KIT ($19.99), 20G CO2 – 5 PACK ($15.99), TRIGGER SPEED DRIVE CO2 (from $15.99)…

Dominio: planetbike.com

Registrato: 1997 (28 anni)

Introduzione: {“products”:[{“name”:”ALX 2.0 bike floor pump”,”price”:”$60.00″},{“name”:”20g CO2 replacement cartridges – threaded”,”price”:”$15.00 – $55.00″},{“name”:”Red Zeppelin CO2 bike tire inflator”,”price”:”$20.00″},{“name”:”Comp 2.0 bike floor pump”,”price”:”$30.00″},{“name”:”STX bike floor pump”,”price”:”$55.00″,”availability”:”Out of stock”},{“name”:”Fresh Air mini pump”,”price”:”$20.00″},{“name”:”Shoc…

Dominio: ridepdw.com

Registrato: 2008 (17 anni)

Introduzione: Timber to Town: Cloud Cap CO2 Inflator – $39.00

Shiny Object – from $19.00

Tiny Object – $22.00

Fatty Object – from $19.00

Timber to Town: Cloud Cap Gravel Pump + CO2 Inflator – $89.00

Ninja Pump – $35.00

38g CO2 Cartridge – $15.00

16g CO2 Cartridge Packs – from $10.00

Leather CO2 Cartridge Sleeve – $5.00

Pump Mount – $5.00

Shiny Object Rebuild Kit – $4.00

Tiny Object Rebuild Kit – $4.00

FEATURED …

Dominio: reddit.com

Registrato: 2005 (20 anni)

Introduzione: 1. Portland Design Works Shiny Object CO2 Inflator: Easy and simple to use, easy to take apart, no need for servicing, parts/o-rings available from the manufacturer website. 2. Pro Bike Tool Inflator: Works well, used sparingly over the years. 3. Dynaplug: Two-in-one plug-it and air-it CO2 device. 4. Specialized Inflator: Threads onto the valve to prevent air loss, available with or without a gaug…

Dominio: northtownebikes.com

Registrato: 1999 (26 anni)

Introduzione: [{‘name’: ‘Serfas 12-Gram CO2 Non-Threaded Cartridges’, ‘price’: ‘$12.99’, ‘details’: ‘Compact, non-threaded 12-gram cartridges compatible with CO2 inflators, easy to pack.’}, {‘name’: ‘Planet Bike 25g CO2 Replacement Cartridges – Threaded’, ‘price’: ‘$8.99 – $99.99’, ‘details’: ‘Quick and easy tire repairs, compatible with most inflators, made of pure CO2, 100% recyclable steel.’}, {‘name’: ‘Genu…

Dominio: blackburndesign.com

Registrato: 1996 (29 anni)

Introduzione: {“name”: “Pro Plugger CO2 Inflator Kit”, “price”: “$79.95”, “color”: “Black”, “size”: “One Size”, “availability”: “In Stock”, “weight”: “75 grams”, “features”: [“Pre-loaded with 10 tire plugs”, “Integrated Presta valve core tool”, “Includes 1 x 25g CO2 cartridge”, “Universal frame mounting kit”, “CO2 inflator for quick inflation or topping off tires”], “tools_included”: [“Presta valve core tool”],…

Dominio: biciclette.stackexchange.com

Registrato: 2009 (16 anni)

Introduzione: Advantages of CO₂ inflators: 1. Fast tire inflation compared to hand pumps. 2. Requires less physical effort (hook up and push button). 3. Potentially lighter than some frame pumps. 4. Lower initial investment (valve and cartridges are generally cheaper than a good small pump). Disadvantages: 1. Consumable cartridges can become costly if used frequently. 2. No backup if a flat is patched incorrect…

In summary, the strategic sourcing of bike tire CO2 inflators presents a unique opportunity for international B2B buyers to enhance their product offerings while addressing the growing demand for efficient, portable inflation solutions. The diverse range of inflators available—from compact models ideal for road cyclists to more robust options for mountain biking—highlights the importance of understanding customer needs and market trends.

Investing in high-quality inflators not only improves customer satisfaction but also positions businesses as leaders in the competitive cycling accessories market. As CO2 inflators continue to evolve, incorporating features such as flow control and compatibility with both Presta and Schrader valves, sourcing partners should prioritize innovation and sustainability in their procurement strategies.

Looking ahead, B2B buyers across Africa, South America, the Middle East, and Europe should seize the moment to align their sourcing strategies with the latest industry trends. By partnering with reliable suppliers and focusing on quality, companies can ensure they meet the expectations of discerning cyclists while driving profitability. Embrace this opportunity to elevate your product line and meet the demands of a growing market—now is the time to act.

Le informazioni fornite in questa guida, compresi i contenuti relativi ai produttori, alle specifiche tecniche e all'analisi di mercato, hanno uno scopo puramente informativo ed educativo. Non costituiscono una consulenza professionale in materia di acquisti, né una consulenza finanziaria o legale.

Pur avendo compiuto ogni sforzo per garantire l'accuratezza e la tempestività delle informazioni, non siamo responsabili di eventuali errori, omissioni o informazioni non aggiornate. Le condizioni di mercato, i dettagli aziendali e gli standard tecnici sono soggetti a modifiche.

Illustrative image related to bike tire co2 inflator

Gli acquirenti B2B devono condurre una due diligence indipendente e approfondita. prima di prendere qualsiasi decisione di acquisto. È necessario contattare direttamente i fornitori, verificare le certificazioni, richiedere campioni e chiedere una consulenza professionale. Il rischio di affidarsi alle informazioni contenute in questa guida è esclusivamente a carico del lettore.