In today’s competitive landscape, sourcing the right bomba de aire (air compressor) can pose a significant challenge for international B2B buyers, especially in diverse markets across Africa, South America, the Middle East, and Europe. With a plethora of options available, businesses must navigate varying specifications, applications, and supplier credibility to ensure they are making informed purchasing decisions. This guide is designed to serve as a comprehensive resource, equipping you with the insights needed to select the most suitable air compressor for your operations.

Throughout this guide, you will explore various types of air compressors, their specific applications in industries ranging from construction to manufacturing, and critical factors to consider when vetting suppliers. We will also delve into cost considerations, helping you understand the pricing structures prevalent in different regions, including Brazil and Saudi Arabia. By addressing these key aspects, this guide empowers B2B buyers to make knowledgeable choices that align with their operational needs and budget constraints.

Whether you are looking to invest in high-performance models for industrial applications or portable options for smaller projects, our insights aim to streamline your sourcing process. With the right information at your fingertips, you can confidently navigate the global market for air compressors, ensuring your business remains competitive and efficient.

| Nome del tipo | Caratteristiche distintive principali | Applicazioni primarie B2B | Brevi pro e contro per gli acquirenti |

|---|---|---|---|

| Reciprocating Air Compressors | Uses a piston mechanism to compress air, typically oil-lubricated | Manufacturing, automotive, construction | Pro: High pressure, robust design. Contro: Noisy, requires maintenance. |

| Rotary Screw Compressors | Employs two rotating screws to compress air, typically oil-injected | Large-scale industrial applications | Pro: Continuous operation, lower noise. Contro: Higher initial cost, complex installation. |

| Scroll Compressors | Utilizes spiral-shaped scrolls to compress air, usually oil-free | Healthcare, laboratories, food processing | Pro: Quiet, low maintenance. Contro: Limited to lower pressure applications. |

| Portable Air Compressors | Lightweight and compact, designed for mobility and ease of use | DIY projects, small workshops, automotive | Pro: Easy to transport, versatile. Contro: Limited capacity, may not suit heavy-duty tasks. |

| Centrifugal Compressors | Uses high-speed rotating impellers to compress air, ideal for high flow | Power generation, HVAC systems | Pro: Efficient for large volumes, low energy consumption. Contro: Requires precise engineering, expensive. |

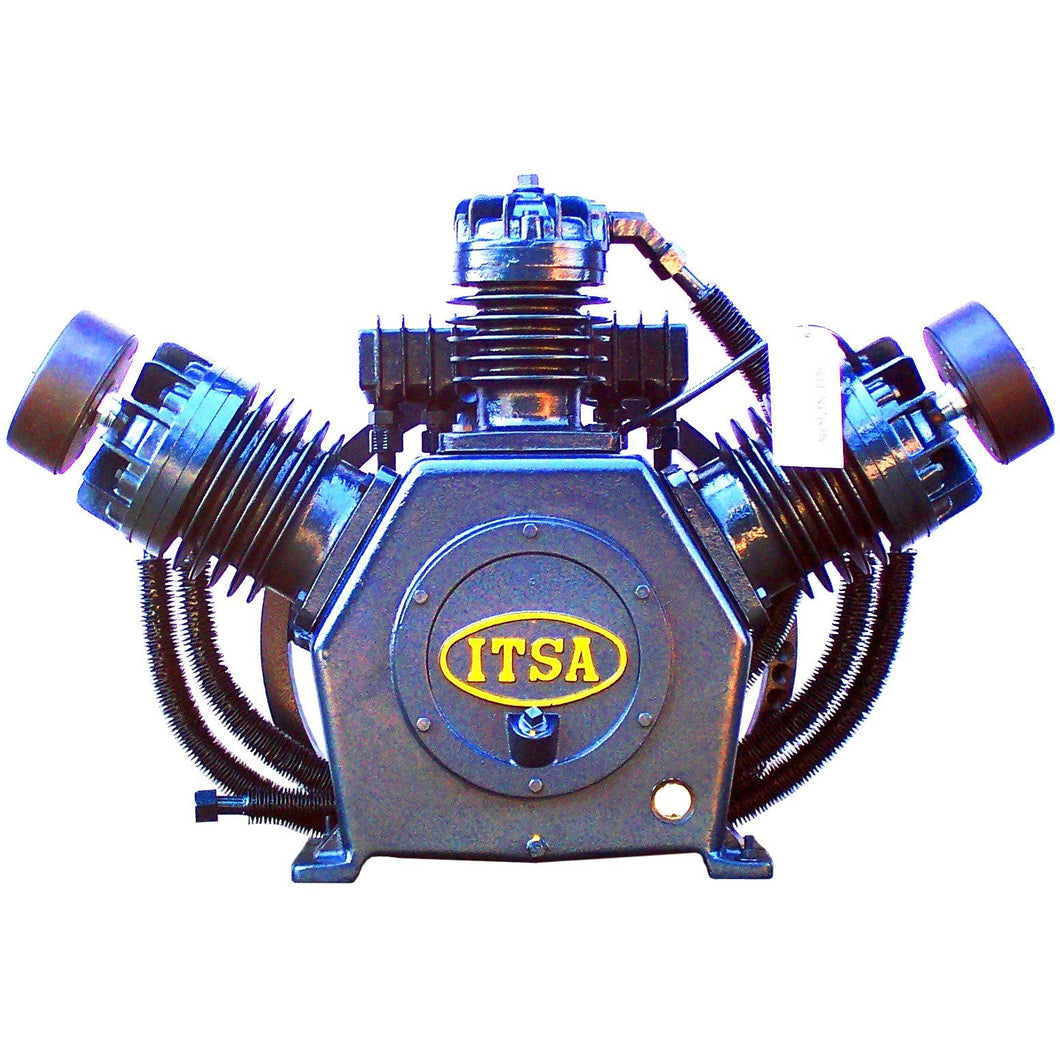

Reciprocating air compressors are commonly used in various industries due to their ability to generate high pressure. They work by using a piston mechanism, which can either be oil-lubricated or oil-free. These compressors are particularly suitable for manufacturing and automotive applications where high pressure is essential. When considering a purchase, buyers should weigh the benefits of their robust design against the noise levels and maintenance needs associated with these machines.

Illustrative image related to bomba de aire

Rotary screw compressors utilize two rotating screws to compress air, making them ideal for continuous operation in large-scale industrial settings. Their design allows for lower noise levels compared to reciprocating compressors, which can be a significant advantage in environments where sound levels are a concern. However, the initial investment is typically higher, and installation can be complex. Buyers should evaluate their operational needs and budget before choosing this type.

Scroll compressors are known for their compact design and quiet operation, making them ideal for sensitive environments such as healthcare facilities and laboratories. These compressors are typically oil-free, which is an essential feature for applications where air purity is crucial, such as food processing. While they are low maintenance and efficient for lower pressure applications, buyers should consider their limitations in terms of pressure capacity.

Portable air compressors are designed for mobility and ease of use, making them a favorite among DIY enthusiasts and small workshops. They are lightweight and versatile, suitable for a variety of tasks such as inflating tires or powering small pneumatic tools. However, their limited capacity may not meet the demands of heavy-duty tasks. Buyers should assess their specific requirements to determine if a portable option is sufficient for their needs.

Centrifugal compressors are engineered for high flow applications, making them essential in industries such as power generation and HVAC systems. They operate using high-speed rotating impellers, offering efficiency for large volumes of compressed air. While they consume less energy and provide significant operational benefits, the engineering precision required for installation and their higher cost can be drawbacks. Buyers should ensure that their operational scale justifies the investment in centrifugal technology.

| Industria/Settore | Specific Application of bomba de aire | Valore/Beneficio per l'azienda | Considerazioni chiave sull'approvvigionamento per questa applicazione |

|---|---|---|---|

| Produzione | Pneumatic tools and machinery operation | Increased efficiency and productivity | Reliability, energy consumption, and maintenance needs |

| Costruzione | Concrete and material compaction | Enhanced project timelines and quality of work | Durability, capacity, and compatibility with tools |

| Riparazione di autoveicoli | Tire inflation and air tool operation | Improved service quality and customer satisfaction | Portability, pressure regulation, and ease of use |

| Agricoltura | Crop spraying and irrigation systems | Optimized resource use and reduced labor costs | Weather resistance, energy efficiency, and capacity |

| Food and Beverage | Packaging and bottling processes | Enhanced production speed and quality control | Hygiene standards, energy efficiency, and reliability |

In the manufacturing sector, bombas de aire are integral to the operation of pneumatic tools and machinery. They provide a reliable source of compressed air necessary for tools such as drills, hammers, and conveyor systems. By ensuring a continuous air supply, these compressors enhance operational efficiency, reduce downtime, and improve overall productivity. For international buyers, it is crucial to consider the reliability and energy consumption of the compressor, as these factors significantly impact operational costs and performance.

Illustrative image related to bomba de aire

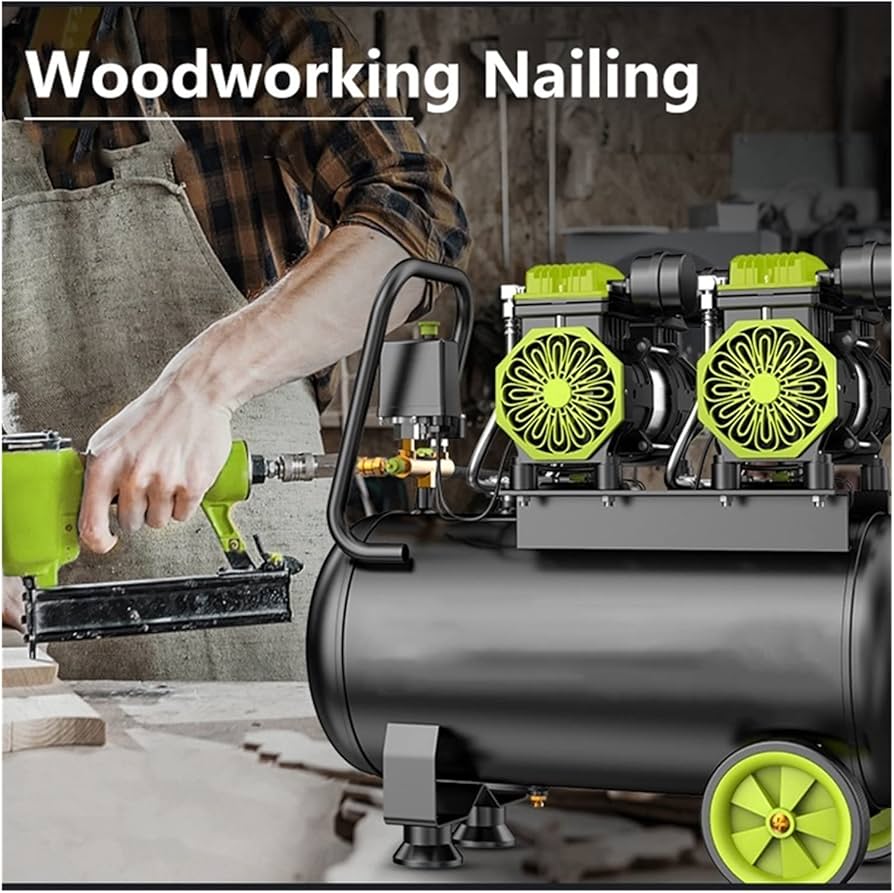

In construction, bombas de aire are widely used for concrete and material compaction, ensuring the integrity and durability of structures. They power pneumatic tools that are essential for tasks such as nail guns and jackhammers, which expedite project timelines. Additionally, the use of air compressors can lead to improved quality in construction work. Buyers in this sector should focus on the durability and capacity of the compressors, ensuring they can handle the demands of various construction environments.

In the automotive repair industry, bombas de aire are vital for tire inflation and the operation of air tools like impact wrenches and spray guns. Their ability to provide a consistent air supply enhances service quality and speeds up repair processes, ultimately leading to higher customer satisfaction. When sourcing compressors, automotive businesses should prioritize portability and pressure regulation features, enabling technicians to work efficiently in various settings.

In agriculture, bombas de aire are utilized in crop spraying and irrigation systems, optimizing the application of fertilizers and pesticides. This technology allows for precise resource use, reducing waste and labor costs while maximizing crop yields. Buyers from agricultural sectors should consider weather resistance and energy efficiency when sourcing compressors, as these factors can greatly influence operational effectiveness in outdoor environments.

In the food and beverage sector, bombas de aire facilitate packaging and bottling processes, enhancing production speed and maintaining quality control. Compressed air is essential for operating machinery that seals and fills containers, ensuring products are safely and efficiently packaged. For businesses in this industry, compliance with hygiene standards and energy efficiency are critical considerations when sourcing air compressors to ensure both product safety and cost-effectiveness.

Illustrative image related to bomba de aire

Il problema: Many B2B buyers, especially those in manufacturing and construction sectors, often struggle with selecting the right size and capacity of a ‘bomba de aire’. An undersized compressor can lead to insufficient air supply, causing inefficiencies and delays in operations, while an oversized unit can be unnecessarily expensive and consume more energy than needed. This challenge is compounded by the diverse range of tools and machines that require varying levels of air pressure and volume.

La soluzione: To effectively address this issue, buyers should conduct a thorough assessment of their air consumption needs. Start by compiling a list of all tools and equipment that will be powered by the compressor, noting their individual CFM (Cubic Feet per Minute) and PSI (Pounds per Square Inch) requirements. Once you have this data, calculate the total air demand and add a safety margin of about 20-30% to account for peak usage. Consulting with manufacturers or suppliers who can provide detailed product specifications and recommendations based on your specific operational needs can also be beneficial. Additionally, investing in variable speed compressors can help to optimize energy use by adjusting output according to demand, thus ensuring that you are neither under nor over-supplied.

Il problema: Another common pain point for B2B buyers is dealing with frequent maintenance issues and unexpected downtime of ‘bomba de aire’ units. This can arise from poor-quality equipment or a lack of proper maintenance protocols. For companies that rely heavily on compressed air for production, even a brief interruption can lead to significant financial losses and missed deadlines.

La soluzione: To mitigate these risks, buyers should prioritize investing in high-quality, durable compressors designed for their specific applications. Choosing models with robust warranties and proven reliability can save future costs. Implementing a regular maintenance schedule is crucial; this should include routine inspections, cleaning air filters, checking for leaks, and monitoring oil levels if applicable. Additionally, training staff on proper operational practices can prevent misuse and prolong the life of the equipment. Utilizing advanced monitoring technologies, such as IoT-enabled sensors, can provide real-time data on compressor performance and alert operators to potential issues before they escalate, thus reducing unexpected downtime.

Illustrative image related to bomba de aire

Il problema: B2B buyers often face the challenge of high energy costs linked to the operation of air compressors. Given that compressors can consume a significant amount of electricity, especially in continuous operation scenarios, this can lead to increased operational expenses. Companies may find it difficult to balance their need for reliable air supply with the desire to maintain cost efficiency.

La soluzione: To combat high energy costs, consider investing in energy-efficient models that are rated for lower consumption. Look for compressors that use advanced technologies, such as variable frequency drives (VFDs), which adjust the motor speed to match the required airflow, thereby reducing energy use. Additionally, implementing a system for air leakage detection and repair can dramatically improve efficiency; even small leaks can lead to substantial energy waste. Regular audits of the compressed air system to identify inefficiencies and re-evaluating air distribution piping can further enhance performance. Lastly, integrating alternative energy sources, such as solar or wind power, can offer significant savings in the long run, particularly in regions where energy costs are high.

When selecting materials for bomba de aire (air pumps), understanding the properties, advantages, and limitations of common materials is crucial for ensuring optimal performance and compliance with international standards. Below, we analyze four prevalent materials used in the manufacturing of air pumps, focusing on their key properties, pros and cons, and their implications for various applications.

Aluminum is a lightweight metal known for its excellent corrosion resistance and good thermal conductivity. It typically has a temperature rating of up to 150°C and can handle moderate pressure levels, making it suitable for various air pump applications.

Pro: Aluminum’s lightweight nature facilitates easier installation and portability, which is particularly advantageous for mobile or DIY air pump applications. It is also cost-effective compared to other metals, making it a popular choice for manufacturers.

Contro: While aluminum is resistant to corrosion, it can be susceptible to wear and fatigue over time, especially under high-pressure conditions. Additionally, its thermal conductivity may lead to heat dissipation issues in high-temperature environments.

Impatto sull'applicazione: Aluminum is compatible with a range of media, including air and some non-corrosive gases. However, it may not be suitable for applications involving aggressive chemicals or high humidity.

Considerazioni per gli acquirenti internazionali: Buyers from regions like Africa and the Middle East should ensure that aluminum components comply with local standards such as ASTM or DIN, particularly regarding heat treatment processes to enhance durability.

Steel, particularly carbon steel, is commonly used in bomba de aire due to its high strength and durability. It can withstand high pressures (up to 300 PSI) and has a temperature rating of around 200°C, making it suitable for heavy-duty applications.

Illustrative image related to bomba de aire

Pro: The primary advantage of steel is its strength, which allows for the construction of robust air pumps that can handle demanding tasks. Steel is also widely available and can be manufactured at a relatively low cost.

Contro: Steel is prone to corrosion if not properly treated, which can lead to premature failure in humid or corrosive environments. Additionally, its weight can be a disadvantage for portable applications.

Impatto sull'applicazione: Steel is compatible with a wide range of media, including air and various gases. However, its susceptibility to corrosion necessitates careful consideration of the operating environment.

Considerazioni per gli acquirenti internazionali: Buyers should look for corrosion-resistant coatings or treatments, especially in humid regions like Brazil or coastal areas in the Middle East, to ensure longevity.

Plastic materials, such as polycarbonate and nylon, are increasingly used in bomba de aire applications due to their lightweight and corrosion-resistant properties. These materials can handle moderate pressures (up to 150 PSI) and have a temperature rating of around 80°C.

Pro: The lightweight nature of plastics makes them ideal for portable air pumps. They also offer excellent resistance to corrosion and chemicals, making them suitable for a variety of environments.

Contro: Plastics may not offer the same level of strength as metals, which can limit their use in high-pressure applications. Additionally, they may degrade under prolonged exposure to UV light unless treated.

Impatto sull'applicazione: Plastics are suitable for air and non-corrosive gases but may not be ideal for high-temperature applications or those involving aggressive chemicals.

Considerazioni per gli acquirenti internazionali: Buyers should verify compliance with international standards for plastics used in industrial applications, particularly in regions with stringent regulations.

Rubber is often used in seals and gaskets within bomba de aire systems due to its excellent elasticity and ability to create airtight seals. It typically operates effectively at temperatures up to 100°C and can handle moderate pressures.

Pro: Rubber provides excellent sealing capabilities, which is essential for maintaining pressure and preventing leaks. It is also relatively inexpensive and easy to manufacture.

Contro: Rubber can degrade over time due to exposure to UV light and certain chemicals, which may limit its lifespan. Additionally, it may not perform well in extremely high-pressure applications.

Impatto sull'applicazione: Rubber is suitable for air and non-corrosive gases but may require regular replacement in harsh environments.

Considerazioni per gli acquirenti internazionali: Buyers should ensure that rubber components meet relevant standards for durability and chemical resistance, especially in regions with extreme weather conditions.

| Materiale | Typical Use Case for bomba de aire | Vantaggio chiave | Svantaggi/limitazioni principali | Costo relativo (Basso/Medio/Alto) |

|---|---|---|---|---|

| Alluminio | Portable air pumps | Leggero e resistente alla corrosione | Susceptible to wear under pressure | Basso |

| Acciaio | Heavy-duty air pumps | Elevata resistenza e durata | Prone to corrosion | Medio |

| Plastica | Lightweight, portable applications | Excellent corrosion resistance | Limited strength under pressure | Basso |

| Gomma | Guarnizioni | Excellent sealing capability | Degrades under UV exposure | Basso |

This strategic material selection guide provides essential insights for international B2B buyers in selecting the most suitable materials for their bomba de aire applications, ensuring compliance with local standards and optimizing performance.

Manufacturing a bomba de aire, or air pump, involves several critical stages that ensure both functionality and reliability. Understanding these stages can help B2B buyers make informed decisions when sourcing products.

The manufacturing process begins with material preparation, which involves selecting the right materials for durability and performance. Common materials include:

Illustrative image related to bomba de aire

These materials undergo rigorous inspection to ensure they meet industry standards before moving to the forming stage.

The next stage is forming, where raw materials are shaped into specific components. Key techniques include:

These techniques ensure that each part meets exact specifications and tolerances necessary for optimal performance.

Illustrative image related to bomba de aire

Once individual components are ready, assembly takes place. This process typically includes:

Attention to detail during assembly is crucial, as even minor errors can lead to significant performance issues.

Quality assurance is vital in the manufacturing of bomba de aire, as it directly affects the product’s reliability and longevity. B2B buyers should familiarize themselves with relevant international standards and industry-specific certifications.

The most recognized international quality management standard is ISO 9001, which focuses on meeting customer expectations and delivering consistent quality. Additionally, other certifications like CE (Conformité Européenne) indicate compliance with European safety and environmental standards. For industries involving hazardous materials or specific operational standards, certifications from organizations like API (American Petroleum Institute) can also be essential.

Quality control (QC) checkpoints play a crucial role throughout the manufacturing process. Key checkpoints include:

Illustrative image related to bomba de aire

Implementing these checkpoints minimizes the risk of defects and enhances overall product reliability.

Testing methods vary but are essential for verifying the performance and safety of bomba de aire. Common methods include:

These tests are typically documented, providing B2B buyers with transparent verification of quality standards.

For international B2B buyers, verifying a supplier’s quality control processes is crucial. Here are effective strategies:

International buyers, especially from diverse regions such as Africa, South America, the Middle East, and Europe, face unique challenges in quality control. Factors to consider include:

Illustrative image related to bomba de aire

By focusing on these elements, B2B buyers can navigate the complexities of sourcing bomba de aire effectively, ensuring they receive high-quality products that meet their specific needs.

This sourcing guide is designed to assist B2B buyers in procuring ‘bomba de aire’ (air compressors) effectively and efficiently. With a global market that includes diverse regions like Africa, South America, the Middle East, and Europe, understanding the key steps in sourcing these essential tools will help ensure that you make informed purchasing decisions that meet your operational needs.

Establishing clear technical specifications is the first step in the sourcing process. This includes determining the required horsepower, tank size, and pressure output needed for your specific applications. By clarifying these requirements upfront, you can narrow down your options and avoid unnecessary complications later in the procurement process.

Conduct thorough research to identify potential suppliers. Look for manufacturers and distributors with a strong reputation in the industry, especially those who specialize in ‘bomba de aire.’ Use platforms like industry trade shows, online directories, and business networks to gather a list of credible suppliers.

Before making a commitment, it’s crucial to verify that potential suppliers hold relevant industry certifications. Certifications such as ISO 9001 or CE mark indicate that the manufacturer adheres to international quality standards. This step is essential for ensuring product reliability and compliance with safety regulations.

Illustrative image related to bomba de aire

Requesting product samples allows you to assess the quality and performance of the air compressors firsthand. Evaluate the samples based on your defined specifications and ensure they meet your operational requirements. Pay attention to build quality, noise levels, and overall functionality during this evaluation.

Once you have shortlisted suppliers, analyze their pricing structures and payment terms. Compare the total cost of ownership, including maintenance and operational costs, not just the upfront price. Look for flexible payment options that align with your budget and cash flow needs, such as installment plans or discounts for bulk purchases.

Understanding the warranty and after-sales support offered by suppliers is critical. Ensure that there is a clear warranty policy covering repairs or replacements for faulty products. Additionally, inquire about the availability of spare parts and technical support, as this can significantly impact your operational efficiency.

After selecting a supplier, it’s time to finalize your contract. Ensure that all terms, including delivery timelines, pricing, and warranty agreements, are clearly outlined. Having a well-documented contract protects both parties and minimizes potential disputes in the future.

By following these steps, you can streamline your sourcing process for ‘bomba de aire’ and ensure that your procurement meets both your operational needs and budget considerations.

When sourcing bombas de aire, understanding the cost structure is crucial for B2B buyers. The main cost components include:

I materiali: The type of materials used in the manufacturing process significantly influences cost. Common materials include metals for the compressor housing and plastic for controls. Higher quality materials, such as aluminum or reinforced polymers, may increase initial costs but enhance durability and performance.

Lavoro: Labor costs can vary based on the region of manufacturing. Countries with lower labor costs may offer more competitive pricing, but it’s essential to consider the skill level and expertise of the workforce to ensure quality.

Spese generali di produzione: This encompasses all indirect costs related to production, such as utilities, rent, and administrative expenses. Efficient manufacturing processes can help keep these costs low.

Utensili: The initial investment in tooling and machinery can be substantial, particularly for custom or specialized models. Buyers should inquire about these costs, especially if they require unique specifications.

Controllo qualità (CQ): Implementing rigorous QC processes ensures that the bombas de aire meet industry standards. While this may add to the cost, it can prevent costly returns and dissatisfaction in the long run.

Logistica: Shipping and handling costs can vary widely based on the origin of the product and the destination. Understanding freight charges, customs duties, and insurance is vital, especially for international buyers.

Margine: Suppliers will typically add a margin to cover their costs and profit. This margin can vary depending on market demand, competition, and the supplier’s positioning.

Several factors can influence the pricing of bombas de aire, including:

Volume/MOQ (quantità minima d'ordine): Larger orders often lead to lower per-unit costs due to economies of scale. Buyers should negotiate for better pricing based on their order volume.

Specifiche e personalizzazione: Customized products may incur additional costs. Buyers should clearly define their specifications to avoid unexpected expenses.

Qualità dei materiali e certificazioni: Products that meet international standards or specific certifications may come at a premium. Buyers should assess the need for certifications based on their market requirements.

Fattori di fornitura: The supplier’s reputation, reliability, and geographic location can impact pricing. Established suppliers may charge more due to their quality assurance and service levels.

Incoterms: Understanding shipping terms can help buyers manage costs effectively. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) dictate who bears the cost of shipping and insurance, affecting the overall pricing.

When negotiating pricing for bombas de aire, consider the following tips:

Ricerca sui prezzi di mercato: Familiarize yourself with current market prices to understand what constitutes a fair offer. This knowledge will empower you during negotiations.

Leverage Volume Discounts: If you are planning to purchase in bulk, communicate this to the supplier upfront. Many suppliers offer discounts for larger orders, so don’t hesitate to negotiate on this front.

Assess Total Cost of Ownership (TCO): Evaluate not just the purchase price but also the long-term costs associated with the product, including maintenance, energy consumption, and potential downtime. A higher initial investment may lead to lower TCO.

Build Relationships with Suppliers: Establishing a rapport with suppliers can lead to better pricing and service. Long-term partnerships often yield benefits like priority service or better payment terms.

Be Cautious with Low Offers: While it may be tempting to go for the lowest price, ensure that quality isn’t compromised. A slightly higher cost for a reliable product can save money in the long run.

International buyers, especially from regions like Africa, South America, the Middle East, and Europe, should be aware of specific pricing nuances:

Currency Fluctuations: Keep an eye on exchange rates, as they can significantly affect the total cost of the purchase.

Import Regulations and Duties: Familiarize yourself with local regulations regarding imports, as tariffs and duties can add to the cost.

Shipping Times and Costs: Understand the implications of shipping times on your operations. Delays in shipment can lead to increased costs and project overruns.

Prices for bombas de aire can vary widely based on the factors mentioned above. It is advisable to obtain multiple quotes and conduct thorough due diligence before finalizing any purchase to ensure optimal pricing and product quality.

When considering the best solutions for air compression and inflation needs, it’s essential to evaluate various options available in the market. The ‘bomba de aire’ (air pump) is a popular choice due to its versatility and efficiency. However, alternatives such as air compressors and manual pumps also serve similar purposes, each with distinct advantages and limitations. This analysis will provide insights into these alternatives to help B2B buyers make informed decisions.

| Aspetto di confronto | Bomba De Aire | Compressore d'aria | Manual Pump |

|---|---|---|---|

| Prestazioni | Efficient for various inflation tasks | High-pressure output, suitable for heavy-duty applications | Limited to low-pressure tasks |

| Costo | Generally affordable, varies by type | Higher initial investment; long-term savings on maintenance | Very low cost, but manual effort required |

| Facilità di implementazione | Simple to use, portable | Requires installation and setup | Very easy to use, no setup needed |

| Manutenzione | Low maintenance, occasional cleaning | Regular maintenance needed, oil changes for some models | Minimal maintenance required |

| Il miglior caso d'uso | Inflating tires, sports equipment, and small inflatables | Industrial applications, powering air tools, and heavy machinery | Casual use, small inflatables, and low-pressure tasks |

Air compressors are robust tools designed for a variety of applications, including powering pneumatic tools and inflating larger items. The primary advantage of air compressors is their ability to produce high-pressure air, making them ideal for industrial and construction settings. However, they come with a higher initial cost and require regular maintenance, which can add to the overall expenditure. Additionally, installation may be necessary, making them less portable compared to bomba de aire.

Manual pumps, while often overlooked, provide a cost-effective alternative for low-pressure inflation tasks. They are incredibly easy to use and require no electricity or complicated setup. This makes them suitable for casual users or specific low-pressure applications. However, their performance is limited, as they are not designed for high-pressure outputs or large volumes of air. Thus, while they may be inexpensive, they are not a suitable replacement for more demanding tasks that a bomba de aire or an air compressor would handle.

Choosing the right solution depends heavily on the specific needs of your business. For occasional tasks or low-pressure applications, a bomba de aire or manual pump may suffice. However, for more demanding industrial applications that require consistent high-pressure output, investing in an air compressor would be more beneficial despite the higher upfront costs. Ultimately, consider factors such as the frequency of use, the scale of operations, and budget constraints when making your decision. By carefully assessing your requirements, you can select the most effective air solution that aligns with your business objectives.

When sourcing a bomba de aire (air pump), understanding its technical properties is crucial for ensuring the equipment meets your operational requirements. Here are several key specifications to consider:

Illustrative image related to bomba de aire

The material grade of a bomba de aire significantly impacts its durability and performance. Common materials include aluminum for lightweight applications and steel for heavy-duty use. Choosing the right material ensures resistance to corrosion and wear, ultimately extending the lifespan of the pump. For B2B buyers, selecting a bomba de aire made from high-grade materials can minimize maintenance costs and downtime.

This specification indicates the maximum pressure the bomba de aire can handle, typically measured in PSI (pounds per square inch). A higher pressure rating allows for more versatile applications, such as powering pneumatic tools or inflating larger items. Understanding pressure ratings is essential for buyers to match the pump’s capabilities with their specific operational needs.

Measured in cubic feet per minute (CFM), the flow rate determines how much air the pump can deliver in a given timeframe. A higher flow rate is crucial for applications requiring rapid air delivery, such as in construction or manufacturing settings. B2B buyers should assess their air consumption needs to select a bomba de aire that can maintain efficiency during peak demand.

Horsepower is a critical indicator of the motor’s power in the bomba de aire. Different applications require varying horsepower levels; for instance, light-duty tasks may only need 1 HP, while industrial applications might require 5 HP or more. Understanding the horsepower requirements can help buyers choose a pump that effectively meets their operational demands without overpaying for unnecessary power.

The size of the air tank is vital for determining how much compressed air can be stored. Smaller tanks are suitable for intermittent use, while larger tanks are necessary for continuous operations. B2B buyers must evaluate their operational workflow to select an appropriately sized tank that balances air storage with equipment portability.

Familiarity with industry jargon can streamline the purchasing process and enhance negotiations. Here are several common terms that every B2B buyer should know:

Illustrative image related to bomba de aire

This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of bomba de aire, knowing whether you are dealing with an OEM can ensure you receive products that meet original specifications and quality standards.

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is critical for B2B buyers to avoid over-committing to stock that may not align with their immediate needs, especially when budgeting for large-scale purchases.

An RFQ is a standard business process where a buyer requests price quotes from suppliers. When considering a bomba de aire, submitting an RFQ can help buyers obtain competitive pricing and better understand the market.

Short for International Commercial Terms, Incoterms define the responsibilities of buyers and sellers in international trade. Familiarity with these terms is essential for B2B buyers to understand shipping costs, risk management, and delivery responsibilities when importing bombas de aire.

Illustrative image related to bomba de aire

These terms outline the manufacturer’s commitment to product support and maintenance. Understanding warranty specifics is vital for B2B buyers to protect their investment and ensure long-term reliability of the bomba de aire.

By grasping these technical properties and trade terminologies, B2B buyers can make informed decisions, ensuring that their investment in bombas de aire aligns with their operational needs and strategic goals.

The global bomba de aire market is witnessing significant growth, driven by the increasing demand for air compressors across various industries such as construction, automotive, and manufacturing. As international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, navigate this landscape, understanding the key trends and market dynamics becomes imperative. One notable trend is the shift towards digitalization and smart technologies. B2B buyers are increasingly seeking air compressors equipped with IoT capabilities, enabling real-time monitoring and predictive maintenance, thereby enhancing operational efficiency.

Moreover, the rise of portable and compact air compressors is gaining traction due to their ease of use and versatility. These products cater to both professional and DIY markets, making them attractive to a broad range of buyers. Another emerging trend is the focus on energy efficiency. Manufacturers are innovating to create compressors that consume less energy while delivering higher performance, responding to the global push for sustainability. Buyers should also keep an eye on regional variations in demand. For instance, in markets like Brazil and Saudi Arabia, infrastructure projects are driving higher demand for robust, high-capacity compressors.

Illustrative image related to bomba de aire

Sustainability and ethical sourcing are becoming crucial considerations for B2B buyers in the bomba de aire sector. The environmental impact of manufacturing processes and product life cycles is under increasing scrutiny. Buyers are now prioritizing suppliers that demonstrate a commitment to reducing their carbon footprint and implementing sustainable practices. This includes utilizing eco-friendly materials and processes in the production of air compressors.

Furthermore, certifications such as ISO 14001 for environmental management systems and ENERGY STAR for energy efficiency are gaining importance among buyers. These certifications not only validate a company’s commitment to sustainability but also assure buyers of the quality and reliability of the products. By opting for suppliers with these credentials, businesses can enhance their own sustainability profiles, which is increasingly being demanded by consumers and regulatory bodies alike. As a result, integrating sustainability into sourcing strategies can lead to competitive advantages in the marketplace.

The bomba de aire sector has evolved significantly over the past century. Initially, air compressors were bulky, mechanical devices primarily used in industrial settings. However, advancements in technology have transformed them into versatile tools suitable for a variety of applications, including automotive repair, construction, and even home use. The introduction of electric-powered compressors in the late 20th century marked a pivotal shift, making air compressors more accessible and user-friendly.

In recent years, the focus has shifted from merely enhancing performance to improving energy efficiency and reducing environmental impact. This evolution reflects broader trends in manufacturing and consumer preferences, where sustainability and technological innovation play critical roles. As the market continues to evolve, B2B buyers must remain agile and informed, ensuring they are sourcing products that not only meet their operational needs but also align with their sustainability goals.

How do I choose the right bomba de aire for my business needs?

Selecting the appropriate bomba de aire involves assessing your specific applications, such as pressure requirements, volume of air needed, and portability. Evaluate the horsepower, tank size, and type of compressor (oil-lubricated vs. oil-free) based on your operational demands. Additionally, consider the noise level if your operations are in a sensitive environment. Consulting with suppliers about your needs can help you find a model that balances performance and cost-effectiveness.

What types of bombas de aire are available for industrial applications?

Industrial bombas de aire come in various forms, including reciprocating, rotary screw, and centrifugal compressors. Reciprocating compressors are suitable for smaller operations requiring high pressure, while rotary screw compressors are ideal for continuous, high-volume applications. Centrifugal compressors are used for large-scale operations needing significant air flow. Assess your operational scale and specific requirements to determine the best type for your business.

What factors should I consider when vetting suppliers for bombas de aire?

When evaluating suppliers, consider their industry experience, reputation, and certifications. Look for reviews and testimonials from previous clients to gauge reliability. Ensure they provide comprehensive product warranties and after-sales support, as well as a clear understanding of international trade regulations. It’s also essential to confirm their ability to meet your customization needs and delivery timelines.

What is the typical minimum order quantity (MOQ) for bombas de aire in international trade?

MOQs for bombas de aire can vary widely depending on the supplier and the specific product. Generally, for bulk purchases, MOQs range from 10 to 50 units. However, some suppliers may accommodate smaller orders, especially for samples or trial runs. Discuss your requirements with potential suppliers to negotiate favorable terms that align with your purchasing strategy.

What payment terms are commonly offered by suppliers of bombas de aire?

Payment terms can vary based on the supplier and your business relationship. Common options include full payment upfront, a deposit with the balance due upon delivery, or extended payment terms such as 30, 60, or 90 days after receipt of goods. It’s crucial to clarify these terms during negotiations to ensure they align with your cash flow management.

How can I ensure quality assurance when sourcing bombas de aire?

To ensure quality, request detailed product specifications and certifications from suppliers. Consider conducting factory audits or requesting samples before placing large orders. Establish clear quality control benchmarks, including performance testing and compliance with international standards. Additionally, maintain open communication with suppliers to address any quality concerns promptly.

What logistics considerations should I keep in mind when importing bombas de aire?

When importing bombas de aire, consider shipping methods, customs regulations, and potential tariffs. Choose a reliable freight forwarder familiar with your destination country’s import requirements. Factor in lead times for production and shipping to ensure timely delivery. It’s also advisable to have a contingency plan for delays or unforeseen issues during transit.

Can I customize bombas de aire to fit my specific operational needs?

Yes, many suppliers offer customization options for bombas de aire, allowing you to tailor features like size, power output, and additional functionalities to your business requirements. Discuss your specific needs with potential suppliers, including any unique operational conditions you may have. Customization may affect the MOQ and lead time, so be sure to factor this into your planning.

Dominio: ebay.com

Registrato: 1995 (30 anni)

Introduzione: Key product details for Bomba De Aire on eBay include: Voltage options (12 V, 120 V, 110 V), various brands (Unbranded, AstroAI, Digital, EPAuto), types (Pancake Air Compressor, Piston Compressor), colors (Black, Yellow, Red, Blue, etc.), tank materials (Aluminum, Steel, Cast Iron), horsepower ratings (0.8 hp, 2 hp, etc.), flow rates (Less than 100 L/min, 101-300 L/min), power sources (Corded Elec…

In conclusion, the strategic sourcing of bomba de aire is critical for international B2B buyers aiming to optimize their procurement processes and enhance operational efficiency. As the demand for reliable and versatile air compressors grows across diverse industries, understanding the unique requirements of different markets—such as those in Africa, South America, the Middle East, and Europe—becomes paramount. Key takeaways include the importance of evaluating supplier capabilities, prioritizing quality and durability, and considering total cost of ownership rather than just initial purchase price.

Moreover, strategic sourcing allows businesses to build long-term partnerships with manufacturers who align with their quality standards and logistical needs. By leveraging insights into market trends and technological advancements, companies can make informed purchasing decisions that drive competitive advantage.

Looking ahead, it is essential for international buyers to remain agile and proactive in their sourcing strategies. Engaging with reputable suppliers, exploring innovative solutions, and staying abreast of industry developments will position businesses for success in a rapidly evolving market. Embrace the opportunity to refine your sourcing approach and elevate your operations with high-quality bomba de aire that meets your unique demands.

Le informazioni fornite in questa guida, compresi i contenuti relativi ai produttori, alle specifiche tecniche e all'analisi di mercato, hanno uno scopo puramente informativo ed educativo. Non costituiscono una consulenza professionale in materia di acquisti, né una consulenza finanziaria o legale.

Pur avendo compiuto ogni sforzo per garantire l'accuratezza e la tempestività delle informazioni, non siamo responsabili di eventuali errori, omissioni o informazioni non aggiornate. Le condizioni di mercato, i dettagli aziendali e gli standard tecnici sono soggetti a modifiche.

Gli acquirenti B2B devono condurre una due diligence indipendente e approfondita. prima di prendere qualsiasi decisione di acquisto. È necessario contattare direttamente i fornitori, verificare le certificazioni, richiedere campioni e chiedere una consulenza professionale. Il rischio di affidarsi alle informazioni contenute in questa guida è esclusivamente a carico del lettore.

Illustrative image related to bomba de aire