In the competitive landscape of automotive accessories, sourcing a reliable 12 volt air compressor for cars can pose significant challenges for international B2B buyers. With the diverse applications of these compressors—ranging from tire inflation to powering air suspension systems—understanding the specific needs of your market is crucial. This guide aims to equip decision-makers with the insights necessary to navigate the global market effectively.

Within these pages, we delve into the various types of 12 volt air compressors, their applications across different sectors, and key considerations for supplier vetting. Additionally, we will analyze cost factors and the implications of duty cycles and performance specifications, enabling buyers to make informed decisions that align with their operational requirements.

For B2B buyers from regions such as Africa, South America, the Middle East, and Europe, including markets like Vietnam and Germany, this guide serves as a comprehensive resource. By highlighting best practices in sourcing and providing actionable insights, we empower you to optimize your procurement strategies. Ultimately, the knowledge shared here will help you select the right air compressor solutions that enhance your product offerings and meet the demands of your clientele.

| Nome del tipo | Caratteristiche distintive principali | Applicazioni primarie B2B | Brevi pro e contro per gli acquirenti |

|---|---|---|---|

| Portable Air Compressors | Compact, lightweight, often battery-operated | Tire inflation, recreational vehicle support | Pro: Easy to transport, versatile; Contro: Limited power and duty cycle. |

| Heavy-Duty Onboard Compressors | High PSI and CFM ratings, designed for continuous use | Air suspension systems, powering air horns, off-road vehicles | Pro: Reliable performance, durable; Contro: Requires installation, higher cost. |

| Dual Air Compressors | Two compressors in one unit for increased output | Commercial vehicles, fleet operations | Pro: Faster inflation, versatile applications; Contro: Heavier, more complex installation. |

| Tankless Compressors | No storage tank, continuous air supply | Industrial applications, service vehicles | Pro: Space-saving, constant airflow; Contro: May not handle high-demand tasks as efficiently. |

| Miniature Air Compressors | Very compact, often designed for specific tasks | Inflating small tires, sports equipment | Pro: Highly portable, cost-effective; Contro: Limited functionality and power. |

Portable air compressors are designed for flexibility and ease of use, making them ideal for B2B applications that require mobility. They are typically lightweight and compact, allowing for easy transportation and storage. These compressors are often powered by the vehicle’s battery, providing convenience for quick tire inflation or recreational uses. However, their limited power output and duty cycle may restrict their effectiveness for larger tasks, making them best suited for small-scale applications.

Heavy-duty onboard compressors are built to withstand rigorous demands, featuring high PSI (pounds per square inch) and CFM (cubic feet per minute) ratings. These compressors are ideal for continuous use in demanding environments, such as air suspension systems and powering air horns in commercial vehicles. Their robust design ensures durability and consistent performance, making them a staple in fleet operations. However, their installation can be complex and may require a higher upfront investment, which is a critical consideration for B2B buyers.

Dual air compressors combine two compressors into one unit, significantly increasing air output for faster inflation and enhanced versatility. They are particularly beneficial for commercial vehicles and fleet operations where quick turnaround times are essential. While they provide superior performance, their weight and complexity can pose challenges during installation. B2B buyers should weigh the benefits of increased efficiency against the potential installation hurdles and costs.

Tankless compressors offer the advantage of continuous air supply without the need for a storage tank. This feature is particularly useful in industrial applications where space is limited and a constant airflow is required. They are commonly found in service vehicles that demand consistent performance. However, while they save space and reduce weight, tankless compressors may struggle with high-demand tasks, making it essential for buyers to assess their specific needs before purchasing.

Miniature air compressors are designed for specific, smaller tasks, such as inflating sports equipment or small tires. Their compact size makes them highly portable and cost-effective, appealing to businesses that prioritize convenience. However, their limited functionality and power mean they are not suitable for more demanding applications. B2B buyers should consider the specific tasks they need to accomplish and ensure that a miniature compressor aligns with their operational requirements.

| Industria/Settore | Specific Application of 12 Volt Air Compressor for Car | Valore/Beneficio per l'azienda | Considerazioni chiave sull'approvvigionamento per questa applicazione |

|---|---|---|---|

| Riparazione di autoveicoli | Tire Inflation and Maintenance | Increases customer satisfaction by ensuring vehicle safety and performance. | Look for compressors with high PSI and CFM ratings for fast inflation. |

| Trasporto e logistica | Fleet Maintenance and Tire Management | Reduces downtime and maintenance costs for vehicle fleets. | Consider durability and ease of use for various types of vehicles. |

| Ricreazione all'aperto | Inflating Recreational Equipment (e.g., boats, air mattresses) | Enhances customer experience and satisfaction during outdoor activities. | Prioritize portability and lightweight models for easy transport. |

| Costruzione e attrezzature pesanti | Powering Air Tools for On-Site Repairs | Improves efficiency in on-site repairs and maintenance tasks. | Ensure compatibility with specific air tools and check the duty cycle. |

| Servizi di emergenza | Emergency Tire Inflation for First Responders | Provides critical support in emergency situations, enhancing response times. | Look for robust models with reliable performance under pressure. |

In the automotive repair industry, a 12 volt air compressor is essential for tire inflation and maintenance. These compressors provide a quick and efficient means to inflate tires to the correct pressure, which is crucial for vehicle safety and performance. By ensuring that tires are properly inflated, repair shops can enhance customer satisfaction and reduce the likelihood of accidents caused by tire failure. B2B buyers in this sector should prioritize compressors with high PSI and CFM ratings to facilitate rapid inflation, thereby minimizing wait times for customers.

Transportation and logistics companies utilize 12 volt air compressors for fleet maintenance, particularly for tire management. Regular tire inflation is vital to avoid breakdowns and costly repairs, thereby reducing downtime across the fleet. A reliable air compressor allows fleet managers to maintain optimal tire pressure, improving fuel efficiency and extending tire life. Buyers in this sector should consider the durability of compressors and their ease of use across various vehicle types to ensure seamless integration into their maintenance routines.

In the outdoor recreation sector, 12 volt air compressors are invaluable for inflating recreational equipment such as boats, air mattresses, and inflatable kayaks. These compressors enhance the customer experience by allowing for quick setup and use of outdoor gear. B2B buyers should focus on models that are portable and lightweight, making them easy to transport to various locations. Additionally, compressors with versatile nozzles can accommodate different types of inflatables, providing added value for businesses catering to outdoor enthusiasts.

Construction companies often rely on 12 volt air compressors to power air tools for on-site repairs and maintenance. These compressors facilitate tasks like powering nail guns and other pneumatic tools, thereby improving overall efficiency on job sites. B2B buyers should ensure that the compressors they select are compatible with the specific air tools used in their operations and have a suitable duty cycle for prolonged use. This capability allows for uninterrupted work, minimizing delays and enhancing productivity.

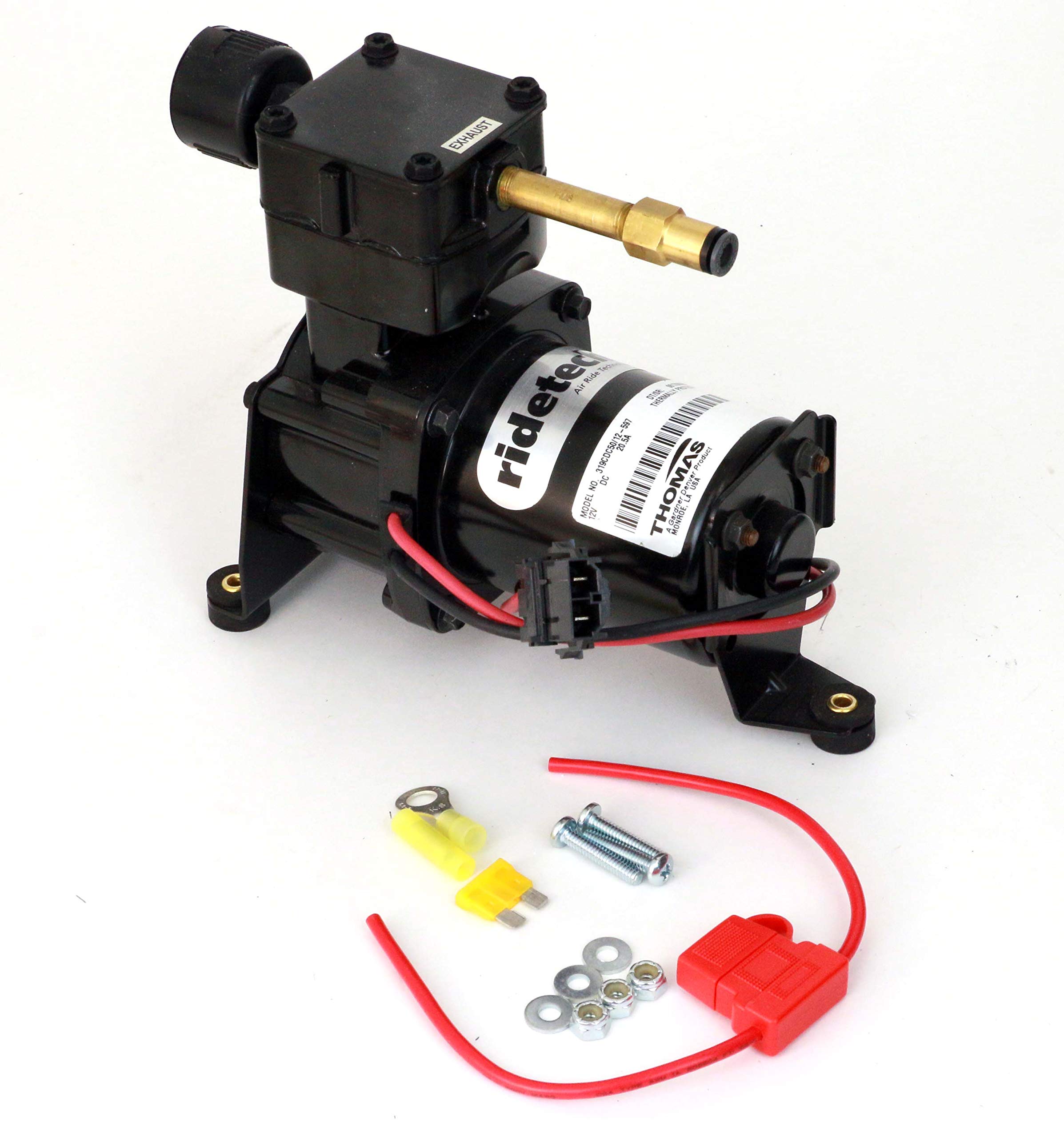

Illustrative image related to 12 volt air compressor for car

In emergency services, 12 volt air compressors are critical for emergency tire inflation, particularly for first responders who need to act quickly in urgent situations. These compressors provide immediate support to ensure vehicles are operational and can respond effectively to emergencies. Buyers in this field should look for robust models that can deliver reliable performance under pressure, as well as features like portability and rapid inflation capabilities to meet the demands of emergency scenarios.

Il problema: Many B2B buyers in industries such as construction or emergency services face challenges when using 12 volt air compressors that lack sufficient power output. For instance, a construction company may rely on a portable compressor to inflate heavy-duty tires or power pneumatic tools. When the compressor doesn’t deliver adequate PSI (pounds per square inch) or CFM (cubic feet per minute), it leads to downtime, inefficiencies, and potentially costly delays in projects.

La soluzione: To address this issue, it is crucial for buyers to thoroughly assess the specifications of 12 volt air compressors before making a purchase. Look for models that offer higher PSI and CFM ratings, especially those designed for heavy-duty applications. Buyers should prioritize compressors labeled as “constant duty,” which can sustain prolonged use without overheating. Additionally, ensure the compressor is compatible with the vehicle’s power system, typically connecting directly to the battery. When sourcing these units, consider reputable suppliers who offer robust after-sales support, ensuring that you can troubleshoot and maintain performance over time.

Il problema: For businesses operating in sectors like logistics or outdoor adventure services, the portability of a 12 volt air compressor can be a significant concern. A company may find that the compressor they purchased is too bulky or heavy, making it difficult to transport between job sites or events. This can result in inefficiencies, as employees struggle to load and unload equipment, potentially leading to damage or wear.

Illustrative image related to 12 volt air compressor for car

La soluzione: To overcome portability issues, buyers should look for compact and lightweight models specifically designed for ease of transport. Prioritize air compressors that come with carrying cases or are designed to fit easily in a vehicle’s trunk or storage compartments. It’s beneficial to choose models with integrated wheels or handles for easier mobility. When purchasing, consider the compressor’s dimensions and weight, and compare several models to ensure you find one that balances performance with portability. Engaging with manufacturers who specialize in portable solutions can also provide insights into the latest designs that prioritize both functionality and transportability.

Il problema: B2B buyers often face challenges when a 12 volt air compressor lacks versatility. For example, a rental company that provides equipment for various outdoor activities may require a compressor that can handle different tasks—from inflating tires to powering air tools. If the compressor is not versatile enough, it may limit the range of services the company can offer, reducing potential revenue streams.

La soluzione: To ensure maximum versatility, buyers should consider compressors that come with multiple attachments and functionalities. Look for models that can handle a range of applications, such as tire inflation, air suspension adjustments, and even powering smaller air tools. It’s also advisable to select compressors with adjustable pressure settings and quick-connect fittings for different attachments, making it easy to switch between tasks. When sourcing these compressors, consult with suppliers who can provide tailored solutions and expert recommendations based on the specific needs of your business. Engaging in product demonstrations or trials can also help in assessing the compressor’s performance across various applications before making a significant investment.

When selecting materials for 12 volt air compressors, several options stand out due to their properties and suitability for various applications. The choice of material significantly impacts the performance, durability, and overall cost of the compressor, making it crucial for international B2B buyers to understand these factors.

Aluminum is a popular choice for the housing and components of 12 volt air compressors due to its lightweight nature and excellent corrosion resistance. Key properties include a temperature rating that can withstand moderate heat and pressure levels typical in automotive applications.

Pro: Aluminum is durable and offers good thermal conductivity, which helps in dissipating heat during operation. It is also relatively cost-effective and easy to machine, making it suitable for mass production.

Illustrative image related to 12 volt air compressor for car

Contro: While aluminum is resistant to corrosion, it can be less durable compared to steel under extreme conditions. Additionally, its lower tensile strength means it may not be suitable for high-stress applications.

Impatto sull'applicazione: Aluminum is compatible with air and non-corrosive gases, making it ideal for tire inflation and air suspension systems.

Considerazioni per gli acquirenti internazionali: Buyers from regions like Europe and South America should ensure compliance with standards such as ASTM and DIN, particularly regarding manufacturing processes and safety certifications.

Steel, particularly stainless steel, is often used for components that require high strength and durability. It has a high temperature and pressure rating, making it suitable for heavy-duty applications.

Pro: Steel’s robustness ensures longevity and reliability, especially in demanding environments. It is also cost-effective for large-scale production.

Illustrative image related to 12 volt air compressor for car

Contro: Steel is heavier than aluminum, which can affect the portability of the compressor. It is also prone to corrosion if not properly treated or coated.

Impatto sull'applicazione: Steel is suitable for applications requiring high pressure and can handle a variety of media, including air and some corrosive gases, depending on the treatment.

Considerazioni per gli acquirenti internazionali: Buyers should be aware of the different grades of steel and their compliance with international standards. For instance, buyers in Africa may need to consider local corrosion resistance requirements.

Illustrative image related to 12 volt air compressor for car

Plastic materials, such as high-density polyethylene (HDPE) or polypropylene, are increasingly used for certain components of 12 volt air compressors, particularly in non-structural parts.

Pro: Plastics are lightweight and resistant to corrosion, which enhances the overall portability of the compressor. They are also less expensive and can be molded into complex shapes, allowing for design flexibility.

Contro: Plastics generally have lower temperature and pressure ratings compared to metals, which may limit their use in high-performance applications. Additionally, they can be less durable under mechanical stress.

Impatto sull'applicazione: Plastics are suitable for housing, connectors, and other non-critical components, but they may not be appropriate for high-pressure applications.

Considerazioni per gli acquirenti internazionali: Buyers should ensure that the plastics used comply with relevant safety and environmental regulations, especially in regions with strict compliance standards like Germany.

Rubber is primarily used for seals and hoses in 12 volt air compressors. Its flexibility and resilience make it an ideal choice for components that experience pressure fluctuations.

Pro: Rubber offers excellent sealing capabilities and is resistant to wear and tear, enhancing the longevity of the compressor. It is also relatively inexpensive.

Contro: Rubber can degrade over time, especially under exposure to heat and certain chemicals, which may necessitate more frequent replacements.

Impatto sull'applicazione: Rubber components are critical for maintaining airtight seals, ensuring efficient operation in tire inflation and air suspension systems.

Considerazioni per gli acquirenti internazionali: Buyers should look for rubber materials that meet international standards for automotive applications, particularly in regions with varying climatic conditions like the Middle East.

| Materiale | Typical Use Case for 12 volt air compressor for car | Vantaggio chiave | Svantaggi/limitazioni principali | Costo relativo (Basso/Medio/Alto) |

|---|---|---|---|---|

| Alluminio | Housing and components for tire inflation | Leggero e resistente alla corrosione | Lower tensile strength under stress | Medio |

| Acciaio | Heavy-duty components for high-pressure applications | Elevata resistenza e durata | Heavier and prone to corrosion | Medio |

| Plastica | Non-structural parts like housings and connectors | Lightweight and design flexibility | Lower temperature and pressure ratings | Basso |

| Gomma | Seals and hoses for pressure management | Excellent sealing capabilities | Può degradarsi nel tempo | Basso |

This analysis provides a comprehensive overview of the materials commonly used in 12 volt air compressors for cars. By understanding the properties, advantages, and limitations of each material, B2B buyers can make informed decisions that align with their operational needs and compliance requirements.

The manufacturing process of a 12 volt air compressor involves several critical stages that ensure the final product meets the performance and durability standards expected in the automotive sector. Here’s a breakdown of the main stages involved:

The first step is the selection and preparation of raw materials. High-quality metals such as aluminum or steel are commonly used for the compressor body due to their strength and lightweight properties. Components like pistons, cylinders, and electric motors are sourced from certified suppliers to ensure reliability. Materials undergo rigorous testing to assess their mechanical properties, corrosion resistance, and thermal stability.

Once the materials are prepared, they undergo various forming techniques. These include:

These techniques ensure that components fit together seamlessly, which is vital for the compressor’s efficiency and durability.

The assembly stage involves integrating all components into a functioning unit. This process typically follows a systematic approach:

After assembly, the compressor undergoes finishing processes, including painting, anodizing, or coating, to enhance durability and appearance. These processes also provide corrosion resistance, which is crucial for products expected to operate in various environmental conditions.

Quality assurance (QA) is critical in ensuring that each compressor meets international standards and customer expectations. Here are key aspects of QA in this manufacturing context:

Illustrative image related to 12 volt air compressor for car

Manufacturers of 12 volt air compressors often adhere to several international quality standards, including:

These certifications not only ensure product quality but also enhance marketability across different regions.

Quality control is typically segmented into several checkpoints throughout the manufacturing process:

Each checkpoint serves as a critical control mechanism to catch potential issues before they escalate into larger problems.

Testing is a vital part of the quality assurance process. Common methods include:

These tests help verify that the compressors are reliable and safe for consumer use.

For international B2B buyers, especially those from regions like Africa, South America, the Middle East, and Europe, verifying the quality control processes of suppliers is crucial. Here are strategies for effective verification:

Conducting on-site audits allows buyers to evaluate the manufacturing environment, processes, and compliance with quality standards. This hands-on approach helps identify potential risks and ensures that suppliers maintain high standards.

Requesting detailed quality reports from suppliers can provide insights into their quality management practices. These reports should include data on defect rates, testing results, and corrective actions taken for any identified issues.

Engaging third-party inspection agencies can offer an unbiased assessment of the supplier’s manufacturing and quality control processes. These agencies can perform random inspections and testing, providing an additional layer of assurance for buyers.

Illustrative image related to 12 volt air compressor for car

Understanding the nuances of quality control and certification is essential for international B2B transactions. Here are some considerations:

By focusing on these aspects, B2B buyers can ensure they are partnering with reliable suppliers that prioritize quality and compliance, ultimately leading to successful transactions and satisfied customers.

When sourcing a 12-volt air compressor for vehicles, it’s essential for B2B buyers to follow a structured approach. This guide serves as a practical checklist to help you navigate the complexities of procurement, ensuring you select a reliable product that meets your operational needs.

Before initiating the sourcing process, clearly outline the technical requirements of the air compressor. Consider factors such as maximum pressure (PSI), airflow (CFM), and power compatibility with your vehicles.

– Pressure and Airflow: Ensure the compressor can meet the demands of your applications, whether for tire inflation, air suspension, or powering air tools.

– Power Source Compatibility: Confirm that the compressor is compatible with your vehicle’s electrical system, typically requiring direct connection to the battery.

Conduct thorough research to identify potential suppliers. Utilize online marketplaces, industry directories, and trade shows to compile a list of manufacturers and distributors.

– Reputazione dei fornitori: Look for suppliers with a strong market presence and positive reviews from other businesses.

– Product Range: Ensure they offer a variety of models that fit your specifications and needs.

Verify that your shortlisted suppliers possess necessary industry certifications and comply with international standards. This step is crucial for ensuring product quality and reliability.

– Garanzia di qualità: Certifications such as ISO 9001 can indicate a commitment to quality management practices.

– Safety Standards: Check for compliance with safety regulations relevant to your region, particularly in the automotive sector.

Before making a bulk purchase, request product samples or demonstrations. This allows you to assess the compressor’s performance and suitability for your needs.

– Test delle prestazioni: Evaluate the compressor’s operation under real-world conditions to ensure it meets your performance expectations.

– Esperienza utente: Assess ease of use, portability, and any additional features that enhance functionality.

Gather detailed pricing information from each supplier, including shipping costs and potential bulk discounts. Additionally, review warranty terms to understand the level of post-purchase support offered.

– Costo totale di gestione: Consider not just the initial price, but also long-term costs associated with maintenance and potential repairs.

– Warranty Coverage: A comprehensive warranty can protect your investment and ensure you receive support if issues arise.

Illustrative image related to 12 volt air compressor for car

Effective communication with your chosen supplier is vital throughout the procurement process. Ensure that you have established clear points of contact for inquiries and updates.

– Responsiveness: Evaluate how quickly the supplier responds to your queries during the sourcing phase, as this can indicate their level of customer service.

– Ongoing Support: Clarify what post-purchase support will be available, including technical assistance and spare parts availability.

Once you have selected a supplier, finalize the terms of your purchase agreement. Ensure that all aspects, including pricing, delivery schedules, and payment terms, are clearly outlined.

– Contract Review: Have legal counsel review the agreement to protect your interests.

– Delivery Expectations: Confirm timelines for delivery and any penalties for delays to avoid disruptions in your operations.

By following this checklist, B2B buyers can make informed decisions, ensuring they procure high-quality 12-volt air compressors that meet their specific needs.

When sourcing 12 volt air compressors for cars, understanding the cost structure is crucial for effective budgeting and negotiation. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margins.

I materiali: The cost of raw materials can vary significantly based on quality and sourcing location. Components such as motors, pistons, and electrical wiring contribute to the overall material costs. Higher quality materials may raise initial costs but can enhance durability and performance.

Lavoro: Labor costs encompass wages for production workers and engineers. In regions with higher labor costs, such as Europe, manufacturers may face increased expenses compared to sourcing from countries with lower labor costs, like Vietnam.

Spese generali di produzione: This includes costs associated with running production facilities, such as utilities, rent, and maintenance. Efficient manufacturing processes can help mitigate overhead costs.

Utensili: The initial investment in tooling can be significant, especially for custom designs. Manufacturers may require specialized tools for production, which can affect pricing, particularly for low-volume orders.

Controllo qualità (CQ): Implementing rigorous QC processes ensures product reliability and compliance with international standards, which can add to overall costs. Products with certifications, such as ISO or CE, often command higher prices.

Logistica: Shipping and handling costs are critical, especially for international buyers. Factors such as shipping distance, mode of transport, and freight terms (Incoterms) can significantly impact logistics expenses.

Margine: Finally, suppliers will add their profit margin, which can vary based on market conditions, competition, and perceived value of the product.

Several factors influence the pricing of 12 volt air compressors, which are essential for buyers to consider when evaluating suppliers.

Volume/MOQ: Minimum order quantities (MOQs) can lead to price breaks for larger purchases. Buyers should assess their needs against supplier MOQs to optimize costs.

Specifiche e personalizzazione: Custom specifications or unique features can increase the price. Buyers should clearly define their requirements to avoid unexpected costs.

Materiali e certificazioni di qualità: Higher quality materials and certified products typically command higher prices. Buyers must balance the need for quality with budget constraints.

Fattori di fornitura: Supplier reputation, reliability, and location can influence pricing. Established suppliers with a track record of quality may charge a premium.

Incoterms: Understanding the Incoterms used in shipping agreements is vital. Terms like FOB (Free On Board) or CIF (Cost, Insurance, and Freight) can affect total landed costs and should be negotiated upfront.

To achieve cost efficiency when sourcing 12 volt air compressors, buyers can employ several strategies.

Negoziazione: Always negotiate pricing and terms. Suppliers may be willing to offer discounts for larger orders or long-term contracts.

Cost-Efficiency Analysis: Consider the Total Cost of Ownership (TCO), which includes not only the purchase price but also maintenance, warranty, and operational costs. A lower upfront cost may lead to higher long-term expenses.

Ricerca e confronto: Conduct thorough market research to compare different suppliers. Understanding market rates can empower buyers in negotiations.

Local Regulations and Tariffs: Be aware of any import tariffs or local regulations that may affect pricing. Understanding these factors can help avoid unexpected costs.

Supplier Relationships: Building strong relationships with suppliers can lead to better pricing, preferential treatment, and improved service.

Pricing for 12 volt air compressors can fluctuate based on market conditions, supplier pricing strategies, and fluctuations in raw material costs. The prices mentioned in various sources are indicative and may not reflect the final purchase price. Buyers are encouraged to obtain quotes from multiple suppliers to ensure competitive pricing and value for their specific needs.

When considering air compression solutions for automotive applications, the 12-volt air compressor for cars is a popular choice due to its convenience and versatility. However, there are alternative technologies that can also fulfill similar requirements. Understanding these alternatives helps businesses make informed decisions based on their specific needs, operational conditions, and budget constraints.

| Aspetto di confronto | 12 Volt Air Compressor For Car | Portable Battery-Powered Air Compressor | AC-Powered Air Compressor |

|---|---|---|---|

| Prestazioni | Moderate PSI (up to 200 PSI) with varying CFM ratings | Lower PSI (up to 150 PSI) but portable; limited CFM | High PSI (up to 150 PSI) with high CFM output |

| Costo | Ranges from $80 to $500 | Typically $50 to $300 | $100 to $700 |

| Facilità di implementazione | Directly connects to vehicle battery; easy setup | Simple setup; requires charging | Requires AC power source; may need outlet access |

| Manutenzione | Low; occasional filter cleaning | Moderate; battery replacement needed | Low; regular maintenance checks |

| Il miglior caso d'uso | Tire inflation, air suspension adjustments, and powering air horns | Small tire inflation, sports equipment, and camping gear | Industrial applications, larger tools, and continuous use |

Portable battery-powered air compressors are compact and designed for convenience, allowing users to inflate tires and equipment without needing a power outlet. They are ideal for emergencies, especially in remote areas. However, their performance is generally limited; they may not reach the same PSI levels as a 12-volt compressor and often have a reduced CFM output, making them less suitable for high-demand applications. Their reliance on battery life means that they require periodic recharging, which can be a limitation during extended use.

AC-powered air compressors are known for their robust performance and are often used in industrial or workshop settings. They can deliver higher PSI and CFM outputs, making them suitable for powering air tools and performing continuous tasks. However, they require a reliable AC power source, which can limit their portability. Additionally, these compressors typically come at a higher price point, and they may involve more complex installation and maintenance needs compared to their 12-volt counterparts. They are best suited for businesses needing high-capacity and continuous air supply.

Illustrative image related to 12 volt air compressor for car

Selecting the appropriate air compression solution depends on the specific requirements of your operations. For businesses requiring a portable, vehicle-compatible solution, a 12-volt air compressor is ideal due to its versatility and ease of use. Conversely, if your needs include inflating smaller items or occasional use, a portable battery-powered air compressor may suffice. For heavy-duty applications where continuous air supply is essential, an AC-powered air compressor is the best choice despite its limitations in mobility. By carefully evaluating performance, cost, and operational needs, B2B buyers can identify the most effective air compression solution for their specific contexts.

When evaluating a 12 volt air compressor for cars, understanding its technical specifications is crucial for ensuring it meets specific operational needs. Here are several critical properties to consider:

The maximum pressure, measured in pounds per square inch (PSI), indicates the compressor’s capability to inflate tires and power pneumatic tools. A higher PSI rating is essential for applications requiring significant air pressure, such as inflating larger tires or operating air suspension systems. For B2B buyers, selecting a compressor with adequate PSI is vital to avoid underperformance in demanding situations.

Cubic feet per minute (CFM) measures the volume of air the compressor can deliver. This specification is particularly important for tasks that require quick inflation or continuous air supply, such as powering air horns or air suspension adjustments. A higher CFM rating means faster inflation times, which can enhance customer satisfaction and operational efficiency.

The duty cycle indicates the percentage of time the compressor can operate continuously before requiring a cooldown period. For instance, a duty cycle of 50% means the compressor can run for 5 minutes and must then cool for 5 minutes. Understanding the duty cycle is critical for B2B buyers, especially those in industries where compressors are used for prolonged periods, as it impacts overall productivity and equipment lifespan.

Power consumption, measured in watts, defines how much electrical energy the compressor requires to function. For 12 volt systems, ensuring compatibility with the vehicle’s electrical system is essential to prevent damage or inefficiencies. Buyers should consider power consumption not only for operational feasibility but also for energy cost management.

The size and weight of a 12 volt air compressor affect its ease of use and transportability. Lightweight and compact models are ideal for mobile applications, while heavier, more powerful units may be suited for fixed installations. Buyers must assess how the compressor will be used to determine the best balance between power and portability.

Understanding industry terminology is essential for effective communication and negotiation. Here are several common terms that B2B buyers should be familiar with:

OEM refers to companies that produce parts and equipment that may be marketed by another manufacturer. In the context of air compressors, understanding OEM relationships can help buyers source high-quality, compatible components and accessories for their systems.

Illustrative image related to 12 volt air compressor for car

MOQ denotes the smallest quantity of product that a supplier is willing to sell. For B2B buyers, knowing the MOQ is crucial for budgeting and inventory management, especially when evaluating suppliers for large-scale purchases.

An RFQ is a document sent to suppliers to solicit price quotes for specific products or services. This process helps buyers compare pricing, specifications, and terms from multiple vendors, enabling informed purchasing decisions.

Incoterms are standardized terms used in international trade that define the responsibilities of buyers and sellers regarding shipping, risk, and insurance. Familiarity with Incoterms is vital for B2B buyers engaged in cross-border transactions, as they clarify obligations and help mitigate risks.

These terms refer to the guarantees provided by manufacturers regarding the performance and lifespan of the air compressor. Understanding warranty conditions is crucial for B2B buyers to ensure long-term support and maintenance, which can significantly affect total cost of ownership.

By grasping these technical specifications and trade terms, B2B buyers can make more informed decisions when procuring 12 volt air compressors for automotive applications, ultimately enhancing operational efficiency and customer satisfaction.

Illustrative image related to 12 volt air compressor for car

The global market for 12 volt air compressors is experiencing dynamic shifts driven by several factors. Growing vehicle ownership in emerging markets such as Africa and South America is fueling demand for portable and reliable inflation solutions. Additionally, the rising popularity of off-road vehicles and recreational activities has amplified the need for high-performance air compressors that can handle diverse applications, from tire inflation to powering air horns and suspension systems.

Technological advancements are also playing a crucial role in market dynamics. Innovations such as lightweight materials, energy-efficient designs, and smart features (like automatic shut-off mechanisms) are becoming standard in new models. Buyers are increasingly seeking products that combine performance with portability, leading to the emergence of compact, battery-operated variants that cater to the demands of modern consumers. Furthermore, e-commerce platforms are simplifying the sourcing process, allowing international buyers from regions like the Middle East and Europe to access a wider variety of products and manufacturers.

Lastly, regulatory frameworks focusing on safety and emissions are influencing sourcing decisions. Buyers are now more inclined to choose suppliers that meet stringent quality standards and provide reliable warranties. This trend emphasizes the importance of due diligence in supplier selection to ensure compliance and product reliability.

Illustrative image related to 12 volt air compressor for car

In today’s business landscape, sustainability and ethical sourcing are critical considerations for B2B buyers. The environmental impact of manufacturing processes and the materials used in 12 volt air compressors are under increasing scrutiny. As global awareness of climate change grows, businesses must consider the carbon footprint associated with their sourcing practices. This includes evaluating the lifecycle of products, from raw material extraction to end-of-life disposal.

Ethical supply chains are becoming non-negotiable for many companies. Buyers are encouraged to seek manufacturers that adhere to green certifications, such as ISO 14001 for environmental management and certifications indicating responsible sourcing of raw materials. Utilizing recycled materials in compressor production can significantly reduce environmental impact and appeal to eco-conscious consumers.

Moreover, incorporating sustainability into procurement strategies can enhance brand reputation and customer loyalty. Businesses that prioritize ethical sourcing are not only contributing to environmental preservation but also positioning themselves as leaders in corporate responsibility, which is increasingly valued in the global marketplace.

The 12 volt air compressor industry has seen significant evolution since its inception. Initially designed for basic tire inflation, these compressors have transformed into multifunctional tools essential for a variety of automotive applications. In the early days, compressors were primarily bulky and limited in functionality, often requiring manual operation.

As technology advanced, manufacturers began to focus on portability and efficiency, leading to the development of compact, high-performance models. The introduction of continuous duty compressors allowed for extended use in demanding situations, such as powering air suspension systems and air horns.

Today, the market is characterized by diverse offerings that cater to both consumer and industrial needs. With the rise of e-commerce and global supply chains, international buyers can now access a wider range of products, enhancing competition and driving innovation in the sector. As the industry continues to evolve, staying informed about trends and best practices will be essential for B2B buyers looking to make informed purchasing decisions.

How do I choose the right 12 volt air compressor for my business needs?

When selecting a 12 volt air compressor, prioritize performance specifications such as maximum pressure (PSI) and airflow (CFM) to match your specific applications. Consider the intended use—whether for tire inflation, powering air tools, or other purposes. Evaluate the compressor’s duty cycle, ensuring it can handle your operational demands without overheating. Additionally, assess portability and compatibility with your vehicle’s power system. Research various brands and models to find the best balance of price, performance, and durability suitable for your business.

What are the typical applications for a 12 volt air compressor?

12 volt air compressors serve multiple applications, including tire inflation for cars, trucks, and recreational vehicles. They can also power air horns and adjust air pressure in vehicle suspension systems, enhancing ride quality. Additionally, these compressors are useful for inflating sports equipment, small boats, and camping gear, making them ideal for both commercial and recreational purposes. Their versatility makes them a valuable asset for businesses involved in automotive services, outdoor recreation, and emergency roadside assistance.

Can I use a 12 volt air compressor for industrial air tools?

While 12 volt air compressors can power some smaller air tools, their suitability largely depends on the tool’s air requirements. They are typically best for light-duty tools such as staple guns, brad nailers, and small impact wrenches. For more demanding tools that require higher volumes of air, such as larger impact wrenches or sanders, a more powerful compressor with higher CFM output is recommended. Always verify the air consumption specifications of your tools before purchasing a compressor.

What minimum order quantities (MOQs) should I expect when sourcing 12 volt air compressors?

MOQs for 12 volt air compressors can vary significantly based on the supplier, brand, and region. Typically, manufacturers may set MOQs ranging from 50 to 500 units for bulk orders, especially for customized products. It’s essential to communicate your needs clearly with suppliers to negotiate favorable terms, especially if your business is just starting. Consider exploring different suppliers to find one that aligns with your purchasing capacity and offers flexible MOQ terms.

What payment terms are common when purchasing 12 volt air compressors internationally?

Payment terms for international purchases of 12 volt air compressors often vary by supplier but commonly include options like advance payment, letter of credit, or partial payment with the balance due upon delivery. It’s crucial to establish clear payment terms upfront to avoid potential disputes. Additionally, consider using secure payment methods that offer buyer protection, especially when dealing with new suppliers. Always ensure that payment terms are documented in your contract to protect your investment.

How can I verify the quality of 12 volt air compressors from potential suppliers?

To ensure product quality, request certifications such as ISO, CE, or other relevant industry standards from your suppliers. Conduct factory audits or request samples for testing before placing bulk orders. Additionally, check for customer reviews and testimonials to gauge the supplier’s reputation. Engaging with third-party quality assurance services can also help verify product specifications and ensure that the compressors meet your quality expectations.

What logistics considerations should I keep in mind when importing 12 volt air compressors?

When importing 12 volt air compressors, consider shipping methods, freight costs, and customs regulations in your country. Determine whether air or sea freight is more cost-effective based on your timeline and budget. Ensure that your supplier provides proper documentation, including invoices and packing lists, to facilitate smooth customs clearance. Additionally, factor in potential tariffs and taxes that may apply to your imports, as these can significantly impact your overall costs.

Are there customization options available for 12 volt air compressors?

Many manufacturers offer customization options for 12 volt air compressors, including branding, color, and specific technical specifications tailored to your business needs. If you require unique features or configurations, discuss your requirements with potential suppliers during the initial negotiation phase. Customization may come with additional costs and longer lead times, so it’s important to clarify these details upfront to align expectations and ensure the final product meets your operational requirements.

Dominio: thorslightningairsystems.com

Registrazione: 2022 (3 anni)

Introduzione: 12v Portable Air Compressors from Thor’s Lightning include various models with key features and pricing:

– Thor’s Lightning Strike Compressor: FROM $449.99 (originally $499.00)

– Jeep® Thor’s Lightning Strike Compressor: FROM $449.99 (originally $599.99)

– Customize Your Compressor: FROM $0.00

– Thor’s Lightning Bolt TrueDual Air Compressor TotalControl: FROM $255.99 (originally $319.99)

– Th…

Dominio: hornblasters.com

Registrato: 2003 (22 anni)

Introduzione: This company, HornBlasters – 12V Air Compressors, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Dominio: reddit.com

Registrato: 2005 (20 anni)

Introduzione: Onboard 12v air compressors discussed include: 1. Belt drive compressor (8 CFM) – previously used in a TJ. 2. Electric compressor (10.6 CFM) from MorrFlate – recommended for performance. 3. Chinese single cylinder (160LPM) and twin cylinder (300LPM) compressors – budget-friendly options available under various brands (e.g., Iron Man, Smittybilt, Kings). 4. Features include pressure control, pressu…

Dominio: griotsgarage.com

Registrato: 1996 (29 anni)

Introduzione: 12V Car Tire Air Compressor – Portable & Efficient

Item# 10285

UPC: Not specified

MSRP: $74.99

Fills typical car tire in 2 minutes

Power cord and hose will reach all four tires

Outstanding build quality, compact size, quiet operation

Free shipping on orders over $49

100% Satisfaction Guarantee

Current Stock: 78

Dominio: garagejournal.com

Registrato: 2006 (19 anni)

Introduzione: 1. Viair: Popular among off-road enthusiasts, reliable performance. 2. ARB: Offers both portable and onboard versions, single and double cylinder options. Known for quality but can be expensive. 3. Sherpa: Noted for a specific model that looks appealing. 4. HF (Harbor Freight): Generally considered low quality, but some users report satisfactory performance for smaller tires. 5. Puma: Well-regarde…

Dominio: store.arbusa.com

Registrato: 1998 (27 anni)

Introduzione: Portable & Vehicle Mounted Air Compressor Systems | ARB 4×4 USA. ARB Air Compressors are designed for reliable, on-the-go air to power tires, tools, and Air Lockers. Key products include: 1. Twin Motor Onboard 12V Air Compressor CKMTA12 – $593.95 2. Single Motor Onboard 12V Air Compressor CKMA12 – $323.95 3. Single Motor Portable 12V Air Compressor CKMP12V2 – $449.95 4. Twin Motor Portable 12V Air…

In conclusion, the strategic sourcing of 12 volt air compressors for cars presents a significant opportunity for international B2B buyers. Key takeaways emphasize the importance of performance specifications, portability, and duty cycles in selecting the right compressor for varied applications, from tire inflation to powering air tools. By focusing on reliable suppliers that offer robust, high-performance models, businesses can enhance their operational capabilities while ensuring customer satisfaction.

Moreover, as markets across Africa, South America, the Middle East, and Europe continue to expand, the demand for versatile and durable air compressors is set to rise. Establishing strong supplier relationships and negotiating favorable terms will be essential in this competitive landscape.

Looking ahead, it is crucial for buyers to stay informed about industry trends and innovations in air compressor technology. This proactive approach will not only secure better pricing but also align with evolving customer needs. We encourage international buyers to engage with reputable manufacturers and distributors to explore tailored solutions that can drive efficiency and profitability in their operations.

Le informazioni fornite in questa guida, compresi i contenuti relativi ai produttori, alle specifiche tecniche e all'analisi di mercato, hanno uno scopo puramente informativo ed educativo. Non costituiscono una consulenza professionale in materia di acquisti, né una consulenza finanziaria o legale.

Pur avendo compiuto ogni sforzo per garantire l'accuratezza e la tempestività delle informazioni, non siamo responsabili di eventuali errori, omissioni o informazioni non aggiornate. Le condizioni di mercato, i dettagli aziendali e gli standard tecnici sono soggetti a modifiche.

Gli acquirenti B2B devono condurre una due diligence indipendente e approfondita. prima di prendere qualsiasi decisione di acquisto. È necessario contattare direttamente i fornitori, verificare le certificazioni, richiedere campioni e chiedere una consulenza professionale. Il rischio di affidarsi alle informazioni contenute in questa guida è esclusivamente a carico del lettore.