In today’s fast-paced global market, sourcing reliable air pumps like Auto Air and Airmoto can present significant challenges for B2B buyers. With the diverse applications ranging from automotive maintenance to recreational use, choosing the right air pump is essential for ensuring efficiency and effectiveness in your operations. This comprehensive guide delves into the key differences between Auto Air and Airmoto, providing a detailed analysis of their specifications, performance capabilities, and user experiences.

We will explore various aspects, including inflation power, battery life, ease of use, and durability, enabling you to assess which product best fits your specific needs. Additionally, this guide offers insights into supplier vetting processes, cost considerations, and market trends relevant to international buyers, particularly those operating in Africa, South America, the Middle East, and Europe, including regions like Vietnam and Brazil.

Empowering informed purchasing decisions, this resource aims to equip you with the knowledge necessary to navigate the complexities of the air pump market. Whether you are looking for high-performance solutions for heavy-duty tasks or compact options for lighter applications, understanding the strengths and limitations of Auto Air and Airmoto will help you optimize your investments and streamline your operations.

| Nome del tipo | Caratteristiche distintive principali | Applicazioni primarie B2B | Brevi pro e contro per gli acquirenti |

|---|---|---|---|

| Auto Air | High PSI (up to 150), smart presets, cordless design | Automotive, sports equipment, camping | Pro: Fast inflation, versatile, long battery life. Contro: Higher price, may be overkill for small tasks. |

| Airmoto | Compact, lightweight, 120 PSI capacity | Light-duty tasks, occasional use | Pro: Portable, budget-friendly, user-friendly. Contro: Limited pressure, shorter battery life, slower inflation. |

| Heavy-Duty Auto Air | Enhanced durability, rugged design, high performance | Construction, agriculture, industrial | Pro: Built for tough environments, high efficiency. Contro: Bulkier, higher investment. |

| Mini Auto Air | Compact size, lower PSI (up to 100), affordable | Personal use, small vehicles, sports gear | Pro: Cost-effective, easy to store. Contro: Limited to light tasks, less powerful. |

| Solar-Powered Airmoto | Eco-friendly, solar charging capability | Remote areas, outdoor activities | Pro: Sustainable, no electricity needed. Contro: Slower charging, dependent on sunlight. |

Auto Air pumps are characterized by their high-pressure capabilities, often reaching up to 150 PSI, making them suitable for a range of applications from automotive to sports equipment. They typically feature smart presets that allow users to set desired pressure levels, enhancing user experience. For B2B buyers, the efficiency and speed of inflation are critical, especially in industries where time is money. The cordless design adds to their convenience, allowing for mobility across various job sites.

Airmoto pumps stand out for their compact and lightweight design, making them ideal for light-duty tasks such as inflating sports balls or bike tires. With a maximum pressure of 120 PSI, they cater to occasional use, appealing to businesses that require a portable solution without the need for heavy-duty performance. While they are budget-friendly, B2B buyers should consider the limitations in battery life and inflation speed, which may affect productivity during peak demands.

Heavy-Duty Auto Air pumps are designed for rugged environments and high-performance needs, making them essential in sectors such as construction and agriculture. Their enhanced durability ensures they can withstand harsh conditions while delivering efficient inflation. B2B buyers should weigh the initial investment against long-term durability and performance benefits, as these pumps can significantly reduce downtime and improve operational efficiency.

Mini Auto Air pumps provide a cost-effective solution for personal use or small vehicles. With a lower PSI capacity, they are ideal for light tasks but may not suffice for heavy-duty applications. Their compact size allows for easy storage, making them a practical choice for businesses that require an inflation solution without the bulk. B2B buyers should assess their specific needs to ensure that the pump’s capabilities align with their operational demands.

Solar-Powered Airmoto pumps are an innovative option for businesses operating in remote areas or those looking to reduce their carbon footprint. These pumps harness solar energy, making them ideal for outdoor activities where electricity is unavailable. However, B2B buyers must consider the slower charging times and dependence on sunlight, which may limit their usability in certain conditions. This option is best suited for eco-conscious companies looking to enhance sustainability in their operations.

| Industria/Settore | Specific Application of auto air vs airmoto | Valore/Beneficio per l'azienda | Considerazioni chiave sull'approvvigionamento per questa applicazione |

|---|---|---|---|

| Automotive | Tire inflation for vehicles | Ensures safety and reliability of vehicles | Consider PSI requirements, battery life, and portability |

| Sports and Recreation | Inflation of sports equipment | Enhances performance and user experience | Evaluate speed of inflation and battery capacity |

| Hospitality and Tourism | Inflating air mattresses and recreational gear | Improves guest satisfaction and comfort | Focus on ease of use and recharge time |

| Manufacturing and Logistics | Maintenance of equipment and machinery | Reduces downtime and increases operational efficiency | Assess durability, serviceability, and multi-functionality |

| Servizi di emergenza | Rapid inflation for emergency response equipment | Enhances response times in critical situations | Look for reliability, ease of transport, and battery longevity |

In the automotive industry, auto air plays a critical role in ensuring tire inflation for vehicles. Properly inflated tires enhance fuel efficiency and safety, reducing the risk of accidents. Auto air’s high PSI capabilities and fast inflation speed make it ideal for quickly addressing tire issues in both personal and commercial vehicles. International B2B buyers should consider the pump’s portability and battery life, especially in regions where access to power sources may be limited.

Airmoto is widely used in the sports and recreation sector for inflating various types of equipment such as basketballs, footballs, and inflatable toys. Its compact design allows for easy transport, making it a favorite among coaches and athletes who need quick inflation solutions. The lightweight nature and straightforward operation are particularly beneficial for international buyers in regions like Africa and South America, where convenience and efficiency are paramount for outdoor activities.

In the hospitality and tourism sector, both auto air and airmoto are utilized for inflating air mattresses and recreational gear for guests. Auto air’s robust features and high PSI capabilities ensure quick inflation, enhancing guest satisfaction and comfort. Meanwhile, airmoto serves well for lighter, portable tasks. Buyers in this sector should prioritize ease of use and recharge time, as these factors significantly impact guest experience, especially in high-demand tourist destinations.

In manufacturing and logistics, auto air is essential for maintaining equipment and machinery. Regular inflation of pneumatic tools and machinery components helps reduce downtime and increases operational efficiency. Auto air’s durability and multi-functionality make it a valuable asset in this sector. B2B buyers should assess the pump’s durability and serviceability, ensuring it meets the rigorous demands of industrial environments.

Emergency services rely on auto air for rapid inflation of emergency response equipment, such as inflatable shelters and rescue boats. The ability to quickly inflate these items can significantly enhance response times in critical situations. For international buyers, especially in regions prone to natural disasters, sourcing a reliable and portable air pump with long battery life is crucial for ensuring preparedness and effective emergency response.

Il problema: In fast-paced industries like logistics or event management, time is of the essence. B2B buyers often face the challenge of needing to inflate multiple items quickly, such as vehicle tires or inflatable event structures. If an air pump takes too long to inflate these items, it can delay operations, lead to increased labor costs, and negatively impact customer satisfaction. For instance, a logistics company may find itself in a bind if its air pump is slow, causing delays in vehicle readiness for transport.

La soluzione: To mitigate this issue, buyers should prioritize an air pump with faster inflation capabilities. The Auto Air model stands out with its ability to reach up to 150 PSI and complete inflations in significantly less time than the Airmoto. To optimize their purchasing decision, buyers should consider sourcing the Auto Air for environments where speed is critical. When specifying the pump, it’s advisable to evaluate its features such as smart presets for various tasks, as these can further streamline the inflation process. Training staff on the efficient use of Auto Air will ensure that they can quickly switch between tasks, maximizing productivity and minimizing downtime.

Il problema: For businesses that rely on air pumps for prolonged periods—such as outdoor sports equipment rental companies—battery life can become a critical issue. B2B buyers may find that the Airmoto, with its shorter battery runtime, necessitates frequent recharges, leading to interruptions in service and potential revenue loss. This is particularly problematic in regions where access to power sources is limited, such as remote areas in Africa or South America.

La soluzione: To address this challenge, companies should consider the Auto Air’s superior battery life, which allows for extended use on a single charge. For B2B buyers, it’s crucial to assess the typical usage scenarios and select the model that aligns with their operational needs. When purchasing, they should also inquire about the battery’s recharge time and ensure they have a reliable charging solution on hand. Implementing a battery management system, such as scheduling recharges during downtime or using multiple units in rotation, can further ensure that operations remain seamless, even in the field.

Il problema: Many businesses operate in diverse environments where they need to inflate a wide range of items—from car tires to inflatable promotional displays. B2B buyers may struggle with selecting an air pump that offers the versatility required for these various applications. Choosing a model that is too specialized can lead to inefficiencies and increased costs, as staff may need to switch between multiple devices.

La soluzione: Buyers should look for an air pump that can handle multiple inflation tasks efficiently, such as the Auto Air, which features multiple adapter tips and smart presets. This versatility makes it suitable for everything from high-pressure car tires to low-pressure inflatable toys. When considering their purchase, businesses should conduct a thorough assessment of their inflation needs and ensure that the chosen model can accommodate them. Additionally, investing in training for employees on how to switch between tasks using the Auto Air can enhance operational efficiency and reduce the need for multiple air pump models, ultimately saving costs and improving workflow.

When evaluating the strategic material selection for air pumps like Auto Air and Airmoto, several common materials come into play. Each material has specific properties, advantages, and disadvantages that can significantly influence product performance, durability, and cost. Below, we analyze four materials frequently used in the construction of these air pumps.

Proprietà chiave: Plastic, particularly high-density polyethylene (HDPE) or polycarbonate, is often used for the housing of air pumps. These plastics offer good temperature resistance and can withstand pressures up to 150 PSI, making them suitable for both Auto Air and Airmoto.

Pro e contro: The durability of plastic is generally good, but it can be susceptible to UV degradation over time. The manufacturing process is relatively simple and cost-effective, which keeps production costs low. However, while plastic is lightweight, it may not provide the same level of impact resistance as metals.

Impatto sull'applicazione: Plastic is compatible with a wide range of media, including air and other gases. However, it may not be suitable for applications involving high-temperature or corrosive environments.

Considerazioni per gli acquirenti internazionali: Buyers from regions like Africa and South America should ensure that the plastics used comply with local environmental regulations. Standards like ASTM D638 for tensile properties may also be relevant.

Proprietà chiave: Metals such as aluminum and stainless steel are commonly used in components that require higher strength and durability. Aluminum can withstand high pressures and offers excellent corrosion resistance, making it suitable for both Auto Air and Airmoto.

Pro e contro: While metal components are more durable and can handle heavy-duty tasks, they also increase the weight of the product. The manufacturing complexity is higher, which can lead to increased costs. However, the longevity of metal components often justifies the initial investment.

Impatto sull'applicazione: Metal is ideal for high-pressure applications, especially in environments where durability is critical. However, it may not be necessary for lighter tasks that Airmoto typically handles.

Considerazioni per gli acquirenti internazionali: Compliance with international standards such as ASTM A240 for stainless steel is crucial. Buyers should also consider the availability of metal components in their region to avoid supply chain issues.

Proprietà chiave: Rubber is primarily used for seals and gaskets in air pumps. It offers excellent flexibility and can handle varying temperatures and pressures, making it essential for maintaining airtight seals.

Pro e contro: Rubber is cost-effective and provides good durability, but it can degrade over time, especially when exposed to UV light or extreme temperatures. Its manufacturing process is straightforward, but the lifespan of rubber components can be limited compared to metals.

Impatto sull'applicazione: Rubber is critical for ensuring the efficiency of air pumps by preventing leaks. However, it may not be suitable for high-temperature applications.

Considerazioni per gli acquirenti internazionali: Buyers should verify that the rubber materials comply with local safety and environmental standards. For instance, compliance with ASTM D2000 for rubber materials is often necessary.

Proprietà chiave: Composite materials, such as fiberglass-reinforced plastics, are increasingly used for their lightweight and high-strength properties. They can withstand high pressures and offer better thermal stability compared to standard plastics.

Pro e contro: Composites are durable and lightweight, making them ideal for portable air pumps. However, they can be more expensive to manufacture, which may affect the overall cost of the product.

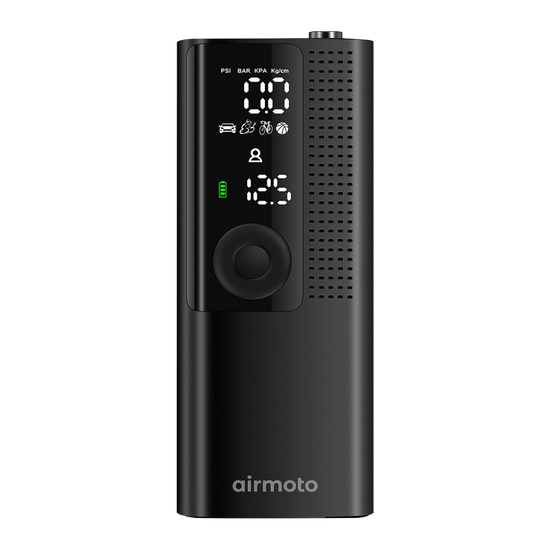

Illustrative image related to auto air vs airmoto

Impatto sull'applicazione: Composites are suitable for various applications, including those requiring high strength-to-weight ratios. They can be used in both Auto Air and Airmoto, particularly for housing and internal components.

Considerazioni per gli acquirenti internazionali: Buyers should check for compliance with international standards like ISO 9001 for quality management systems, especially when sourcing composite materials.

| Materiale | Typical Use Case for auto air vs airmoto | Vantaggio chiave | Svantaggi/limitazioni principali | Costo relativo (Basso/Medio/Alto) |

|---|---|---|---|---|

| Plastica | Alloggiamento e involucro | Leggero e conveniente | Degradazione UV nel tempo | Basso |

| Metallo | Componenti strutturali | Elevata durata e resistenza | Increased weight and cost | Alto |

| Gomma | Guarnizioni | Excellent flexibility and sealing | Limited lifespan under stress | Basso |

| Composito | Housing and internal components | Lightweight with high strength | Higher manufacturing costs | Med |

This analysis provides B2B buyers with a comprehensive understanding of the materials used in Auto Air and Airmoto, enabling informed purchasing decisions based on performance, cost, and compliance with regional standards.

The manufacturing process for air pumps like Auto Air and Airmoto involves several critical stages that ensure quality and performance. Understanding these stages is essential for B2B buyers looking to make informed purchasing decisions.

The first stage of manufacturing begins with material preparation. Both Auto Air and Airmoto typically utilize high-quality plastics and metals for durability. Common materials include:

Illustrative image related to auto air vs airmoto

These materials are sourced from certified suppliers who comply with international standards, ensuring that they meet specific quality criteria before being used in production.

Once the materials are prepared, they undergo forming processes that shape them into usable components. Key techniques in this phase include:

These processes ensure that each part is manufactured to exact specifications, which is crucial for the overall performance of the air pumps.

The assembly stage is where individual components come together to form the final product. This stage typically involves:

Efficient assembly processes reduce the risk of errors and enhance the speed of production, allowing suppliers to meet demand swiftly.

Illustrative image related to auto air vs airmoto

The finishing stage includes several important steps to ensure that the air pumps are ready for market:

Quality assurance (QA) is a critical aspect of the manufacturing process for both Auto Air and Airmoto. B2B buyers should be aware of the standards and practices that ensure product reliability.

Both Auto Air and Airmoto manufacturers typically adhere to international quality standards, such as:

These certifications not only enhance product credibility but also provide assurance of compliance with industry standards.

Illustrative image related to auto air vs airmoto

Quality control (QC) involves systematic checks at various stages of the manufacturing process. Key checkpoints include:

These QC checkpoints help identify defects early, reducing the risk of faulty products reaching the market.

Manufacturers employ various testing methods to ensure that both Auto Air and Airmoto meet performance standards:

Illustrative image related to auto air vs airmoto

Such testing not only verifies product quality but also builds trust with B2B buyers who require reliable products for their operations.

For international B2B buyers, verifying the quality control practices of suppliers is essential for ensuring product reliability. Here are actionable steps buyers can take:

These actions help mitigate risks associated with procurement, ensuring that buyers receive high-quality products that meet their requirements.

When sourcing air pumps from international suppliers, particularly in regions such as Africa, South America, the Middle East, and Europe, buyers should consider:

By being aware of these factors, B2B buyers can make more informed decisions and build stronger partnerships with their suppliers.

To assist B2B buyers in making informed procurement decisions between Auto Air and Airmoto air pumps, this practical sourcing guide outlines essential steps for a successful evaluation and selection process.

Understanding your unique requirements is the foundation of a successful procurement strategy. Consider the types of items you will be inflating—car tires, sports equipment, or air mattresses—and the frequency of use. This will help you determine if you need a high-pressure pump like Auto Air or a more portable option like Airmoto.

Dive into the technical details of both products. Look for specifications such as maximum pressure, battery life, and inflation speed.

– Auto Air offers up to 150 PSI, making it suitable for heavier tasks, while Airmoto provides 120 PSI, ideal for lighter jobs.

– Assess battery capacity; Auto Air’s 25,000mAh battery supports longer usage on a single charge compared to Airmoto’s shorter runtime.

Before committing to a purchase, verify the credentials of your potential suppliers.

– Request documentation such as certifications, quality control processes, and product warranties.

– Look for feedback from previous clients in your region, particularly in Africa, South America, the Middle East, and Europe, to ensure reliability and quality assurance.

Always ask for samples before finalizing your order. Testing the products in real-world scenarios can provide invaluable insights into their performance.

– Check how well each pump handles various inflation tasks and assess ease of use.

– Pay attention to noise levels and battery efficiency during prolonged use, especially in environments where quiet operation is necessary.

While price is a significant factor, it’s essential to evaluate the overall value each product offers.

– Consider not just the initial cost but also long-term savings related to durability and efficiency.

– For instance, although Auto Air may have a higher price point, its advanced features and longer lifespan could lead to lower costs over time.

Review the after-sales support and warranty options provided by the suppliers.

– A reliable warranty can protect your investment against defects or malfunctions. Inquire about the duration and coverage of warranties.

– Consider the availability of customer support for troubleshooting and maintenance issues, especially if you plan to use the air pumps extensively.

After evaluating all aspects, develop a procurement strategy that aligns with your operational needs and budget.

– Decide whether to purchase directly or through a distributor, considering factors like shipping costs and delivery times.

– Ensure that your final choice meets your company’s standards for quality, efficiency, and reliability.

By following these steps, B2B buyers can confidently navigate the procurement process and select the air pump that best suits their specific needs, whether that be the power of Auto Air or the portability of Airmoto.

In the competitive landscape of air pump sourcing, understanding the cost structure and pricing nuances between Auto Air and Airmoto is essential for international B2B buyers, especially those from regions like Africa, South America, the Middle East, and Europe.

When evaluating the total cost of ownership for Auto Air and Airmoto, several cost components come into play:

I materiali: The choice of materials significantly impacts the overall cost. Auto Air typically uses higher-grade materials to support its advanced features, such as a 150 PSI capacity and a robust battery life. Airmoto, while still reliable, employs more cost-effective materials, reflecting its lower price point and suitability for lighter tasks.

Lavoro: Labor costs can vary based on the manufacturing location. For instance, if manufacturing occurs in regions with lower labor costs, such as Southeast Asia, overall costs may decrease. Both brands may leverage different labor-intensive processes, affecting their final pricing.

Spese generali di produzione: This includes costs associated with factory operation, utilities, and administrative expenses. Auto Air, with its more complex production processes due to advanced technology, may experience higher overhead costs compared to Airmoto.

Tooling and Quality Control (QC): The investment in tooling can also differ. Auto Air’s sophisticated design requires precise tooling, which can increase initial costs. Moreover, the QC process for Auto Air may be more rigorous, leading to higher costs but potentially lower returns on defective products.

Logistica: Shipping costs can be influenced by the weight and volume of the products. Auto Air, being slightly bulkier due to its features, might incur higher logistics costs compared to the more compact Airmoto.

Margine: Manufacturers will often build their profit margins into the pricing. Given its advanced features and technology, Auto Air may have a higher margin compared to Airmoto, which targets a more budget-conscious segment.

Several factors can influence the pricing of both air pumps:

Volume e quantità minima d'ordine (MOQ): Purchasing in larger quantities can lead to significant cost savings. Buyers should negotiate MOQs with suppliers to secure better pricing tiers, particularly when sourcing from manufacturers in Asia or Europe.

Specifiche e personalizzazione: Customization options can significantly affect pricing. Auto Air’s advanced features may lead to higher customization costs, while Airmoto may offer simpler configurations at lower prices.

Qualità e certificazioni: Products with certifications for safety and performance (such as CE or ISO) may carry a premium price tag. Buyers should consider the value of these certifications against their specific market requirements.

Fattori di fornitura: The reputation and reliability of the supplier can impact pricing. Established suppliers may charge a premium due to their proven track record, while emerging suppliers might offer competitive pricing to gain market entry.

Incoterms: Understanding shipping terms (like FOB, CIF) is crucial for cost management. Buyers should clarify terms with suppliers to avoid unexpected costs.

When negotiating prices for Auto Air and Airmoto, consider the following strategies:

Condurre ricerche di mercato: Understanding the market landscape and competitor pricing can empower buyers to negotiate effectively.

Leverage Volume Discounts: Buyers should aim to consolidate orders to meet higher MOQ thresholds, which can lead to reduced unit costs.

Valutare il costo totale di proprietà (TCO): Beyond the initial purchase price, consider maintenance, warranty, and operational costs. A higher upfront investment in Auto Air might result in lower TCO due to its durability and efficiency.

Be Aware of Pricing Nuances in Different Markets: Prices may vary based on regional demand and economic conditions. Buyers in Africa or South America should consider import tariffs and local taxes when calculating the total price.

Build Relationships with Suppliers: Establishing long-term relationships can lead to better pricing, exclusive offers, or early access to new products.

In conclusion, understanding the cost structures and pricing influences for Auto Air and Airmoto can empower B2B buyers to make informed purchasing decisions, ensuring they choose the right air pump for their operational needs while optimizing their budget.

Illustrative image related to auto air vs airmoto

When evaluating air pump solutions for B2B applications, it’s crucial to consider various options that cater to diverse operational needs. While Auto Air and Airmoto are popular choices in the market, several alternative solutions exist that may provide distinct advantages depending on your specific requirements. This analysis will compare Auto Air and Airmoto against two viable alternatives, helping you make an informed decision.

| Aspetto di confronto | Auto Air Vs Airmoto | Portable Electric Air Pump | Manual Air Pump |

|---|---|---|---|

| Prestazioni | Up to 150 PSI; fast inflation | Up to 130 PSI; moderate speed | Variable PSI; labor-intensive |

| Costo | Higher initial investment | Mid-range pricing | Low initial cost |

| Facilità di implementazione | User-friendly with smart presets | Easy to operate; limited features | Requires physical effort |

| Manutenzione | Minimal; rechargeable battery | Moderate; occasional battery replacement | Low; no electrical components |

| Il miglior caso d'uso | Heavy-duty tasks; versatile | Light to moderate tasks; portability | Occasional use; simple inflations |

Portable electric air pumps offer a competitive option for users requiring a balance between performance and cost. These pumps typically provide up to 130 PSI, making them suitable for a range of inflatables, from sports equipment to car tires. They are user-friendly, often featuring straightforward controls and a compact design for easy storage. However, while they are generally more affordable than Auto Air, they might not match its speed or power for heavy-duty tasks. Maintenance is moderate, primarily involving battery checks and occasional replacements.

Manual air pumps are a cost-effective alternative for businesses that prioritize simplicity and low initial investment. These pumps do not rely on electricity, making them suitable for use in remote areas or situations where power access is limited. While they can handle various inflation tasks, their performance can be inconsistent, as inflation pressure depends on the user’s effort. They are ideal for occasional use, such as inflating sports balls or small inflatables. However, the labor-intensive nature of manual pumps may not meet the demands of businesses needing quick and efficient solutions.

When selecting an air pump solution, it is essential for B2B buyers to consider their specific operational needs, budget constraints, and the volume of inflation tasks. Auto Air stands out for its versatility and power, making it ideal for heavy-duty applications, while Airmoto offers portability for light, occasional use. Alternatives like portable electric pumps and manual pumps provide additional options that may suit businesses with varying requirements and budgets. Assessing the pros and cons of each solution will enable you to choose the air pump that best aligns with your operational goals and enhances efficiency.

When evaluating air pumps like Auto Air and Airmoto, understanding their technical specifications is crucial for making informed purchasing decisions. Here are some essential properties to consider:

Illustrative image related to auto air vs airmoto

The inflation pressure, measured in pounds per square inch (PSI), indicates the maximum air pressure the pump can deliver. Auto Air boasts a capacity of 150 PSI, making it suitable for heavy-duty tasks such as inflating car tires and larger inflatables. In contrast, Airmoto has a maximum pressure of 120 PSI, which limits its effectiveness for demanding applications. For B2B buyers, selecting a pump with appropriate PSI is vital to ensure it meets the specific needs of their operations.

Battery capacity, expressed in milliamp hours (mAh), reflects how long a pump can operate before needing a recharge. Auto Air features a robust 25,000mAh battery, allowing for extended use without frequent interruptions. Airmoto, however, offers a smaller battery that provides approximately 45 minutes of runtime. This difference is significant for businesses that require reliable performance for multiple inflations, particularly in remote locations without immediate access to power.

Weight plays a crucial role in the portability of air pumps. Auto Air is designed to be lightweight and easy to carry, making it suitable for on-the-go applications. Airmoto, while also portable, is particularly compact, allowing it to fit easily in glove compartments or backpacks. For B2B buyers, evaluating the weight and design of the pump ensures it aligns with their operational needs, especially in industries requiring frequent transport of equipment.

The durability of an air pump is directly linked to its material construction and overall design. Auto Air is built for heavy-duty use, featuring a robust casing that withstands wear and tear. Airmoto, while reliable for light tasks, may not hold up as well under rigorous conditions. For businesses, investing in durable equipment reduces the frequency of replacements and maintenance costs, ultimately impacting the bottom line.

Inflation speed indicates how quickly a pump can fill an object with air. Auto Air is recognized for its fast inflation capabilities, nearly doubling the efficiency of traditional models. Airmoto, while effective for smaller tasks, does not match the speed of Auto Air. B2B buyers should consider inflation speed, especially in scenarios where time efficiency translates into operational effectiveness.

Illustrative image related to auto air vs airmoto

Understanding industry jargon is crucial for effective communication and negotiation in the B2B landscape. Here are some key terms relevant to air pumps:

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of air pumps, it can denote the manufacturer of the pump itself or its components. Understanding OEM relationships can help businesses ensure they are sourcing quality products that meet industry standards.

MOQ represents the smallest number of units a supplier is willing to sell. This term is critical for B2B buyers who need to understand the quantity they must purchase to engage in a transaction, impacting inventory management and cash flow.

An RFQ is a document that an organization sends to potential suppliers to solicit price quotes for specific products or services. For buyers considering Auto Air or Airmoto, issuing an RFQ can help obtain competitive pricing and terms from multiple suppliers.

Incoterms are internationally recognized rules that define the responsibilities of buyers and sellers in international transactions. Understanding Incoterms is vital for B2B buyers involved in cross-border purchases of air pumps, as they clarify shipping costs, risk, and delivery obligations.

Lead time refers to the time it takes from placing an order until the product is received. For businesses relying on timely delivery of air pumps for operations, understanding lead times can help in planning and inventory management.

By familiarizing themselves with these technical properties and industry terms, B2B buyers can make more informed decisions regarding air pump procurement, ensuring they select products that align with their operational needs and strategic goals.

The global air pump market is experiencing a notable shift, driven by advancements in technology and changing consumer preferences. B2B buyers from regions such as Africa, South America, the Middle East, and Europe are increasingly seeking versatile and efficient solutions for inflation needs. The rise of e-commerce and digital platforms has made it easier for international buyers to access a variety of products, including auto air and airmoto pumps. As these markets continue to expand, the demand for high-performance air pumps that offer superior power, speed, and user-friendliness is rising.

Emerging trends include the integration of smart technologies, such as automated pressure settings and Bluetooth connectivity, enhancing user convenience. Additionally, the focus on portability and lightweight designs is essential for buyers in regions with varying terrain and transportation methods. The preference for cordless, rechargeable models is growing as businesses look for solutions that provide flexibility and ease of use. Furthermore, environmental sustainability is becoming a significant factor influencing purchasing decisions, with buyers increasingly prioritizing products that minimize ecological impact.

Sustainability and ethical sourcing are paramount in today’s B2B landscape, particularly in the auto air versus airmoto market. Environmental concerns are prompting businesses to reevaluate their supply chains and product offerings. For B2B buyers, understanding the environmental impact of their purchases is crucial. This includes assessing the materials used in air pumps, manufacturing processes, and the overall lifecycle of products.

A growing number of manufacturers are adopting sustainable practices, such as using recycled materials and reducing waste during production. Certifications like ISO 14001 (Environmental Management) and compliance with RoHS (Restriction of Hazardous Substances) are increasingly sought after by buyers looking for assurances of environmental responsibility. Furthermore, companies are focusing on lifecycle assessments to understand the carbon footprint associated with their products. By prioritizing suppliers that demonstrate a commitment to sustainability, B2B buyers can enhance their brand reputation while contributing to global efforts toward environmental stewardship.

The evolution of the air pump market can be traced back to the simple mechanical designs of the early 20th century. Initially, pumps were manually operated and primarily used for bicycles and basic inflatables. As consumer needs grew, so did the technology behind air pumps. The introduction of electric models in the late 20th century marked a significant advancement, allowing for faster and more efficient inflation.

Illustrative image related to auto air vs airmoto

Over the past decade, the market has seen a surge in demand for portable, battery-operated air pumps. This shift is largely driven by the increasing popularity of recreational activities that require reliable inflation solutions, such as camping and sports. The competition between auto air and airmoto pumps has intensified, with manufacturers continuously innovating to offer more powerful, user-friendly, and sustainable options. Today, both types of pumps cater to a wide range of applications, from automotive needs to leisure activities, reflecting the diverse requirements of modern consumers and businesses alike.

In summary, understanding the market dynamics, sustainability considerations, and the historical evolution of the auto air versus airmoto sector can empower B2B buyers to make informed sourcing decisions that align with their operational goals and values.

1. How do I solve the issue of inflating various items efficiently?

To address the challenge of efficiently inflating multiple items such as car tires, sports equipment, and air mattresses, consider investing in Auto Air. This air pump boasts a high maximum pressure of 150 PSI and features smart presets, making it suitable for diverse tasks. Its cordless design and long battery life allow for uninterrupted use, even for larger inflatables. In contrast, Airmoto is better for lighter tasks, but if you require versatility and speed, Auto Air is the optimal choice.

2. What is the best air pump for heavy-duty tasks?

For heavy-duty inflation tasks, Auto Air is the superior choice. With its ability to deliver up to 150 PSI, it efficiently handles larger items like car tires and inflatable camping gear. Its extended battery life and quiet operation further enhance its suitability for demanding applications. Airmoto, while portable and user-friendly, is limited to lighter tasks with a maximum pressure of 120 PSI and shorter battery life, making it less ideal for heavy-duty use.

3. How can I ensure the quality of air pumps when sourcing internationally?

To ensure quality when sourcing air pumps like Auto Air and Airmoto internationally, it is vital to conduct thorough supplier vetting. Request samples to assess product performance, durability, and features. Additionally, review the manufacturer’s certifications, such as ISO standards, and check customer reviews for feedback on reliability. Engaging in direct communication with suppliers can also clarify quality control processes and lead to better sourcing decisions.

4. What are the typical minimum order quantities (MOQs) for air pumps?

Minimum order quantities (MOQs) for air pumps vary by supplier and can range from a few dozen to several hundred units. For B2B buyers, negotiating MOQs is often possible, especially when establishing long-term partnerships. It’s advisable to inquire about bulk pricing and potential discounts for larger orders, as this can significantly affect overall procurement costs and inventory management.

5. What payment terms should I expect when sourcing air pumps?

Payment terms can differ significantly depending on the supplier and the region. Commonly, suppliers may offer options such as a 30% upfront deposit with the balance due before shipping, or payment through letters of credit. It’s essential to negotiate terms that align with your cash flow needs and risk tolerance. Additionally, ensure that the payment method is secure and provides a level of buyer protection, particularly for international transactions.

6. How do I evaluate potential suppliers for air pumps?

Evaluating potential suppliers for air pumps involves several key steps: reviewing their experience and reputation in the industry, checking references from other customers, and assessing their production capabilities. Requesting product samples and inspecting quality control measures will provide insights into their reliability. Additionally, engaging in discussions about their logistics and delivery capabilities can help gauge their overall suitability for your supply chain needs.

7. What logistics considerations should I keep in mind when importing air pumps?

When importing air pumps, consider logistics factors such as shipping methods, customs regulations, and delivery timelines. Choose a reliable freight forwarder familiar with the specific requirements of your destination country. Additionally, factor in potential tariffs and duties, which can impact overall costs. Planning for these logistics ahead of time can help ensure smooth operations and timely delivery of your air pump orders.

8. Can I customize air pumps to suit my brand requirements?

Yes, many manufacturers offer customization options for air pumps, including branding, color choices, and even specific features tailored to your market needs. When negotiating with suppliers, discuss your requirements and inquire about their capabilities for customization. Keep in mind that custom orders may have different MOQs and lead times, so it’s important to factor these into your planning process to meet your branding goals effectively.

Dominio: bestairpumps.com

Registered: 2024 (1 years)

Introduzione: {“Auto Air”: {“Overall Rating”: “5/5”, “Description”: “Designed for fast, reliable inflation with a focus on power and convenience.”, “Key Features”: {“Cordless Design”: “Clean, tangle-free operation without needing an outlet.”, “Rechargeable Battery”: “Powerful 25,000mAh battery supports extended use on a single charge.”, “High Inflation Pressure”: “Delivers up to 150 PSI, perfect for heavy-duty …

Dominio: reddit.com

Registrato: 2005 (20 anni)

Introduzione: Airmoto: Portable air pump, 120 PSI air compressor, fits car, truck & motorcycle tires, digital pressure gauge, cordless, compact bike pump. Rating: 4.3 (Fakespot Grade: C, Adjusted Rating: 2.6). Fanttik X8: Mentioned as another option but no specific details provided.

Dominio: ranger5g.com

Registrato: 2017 (8 anni)

Introduzione: Tested Products: AUXITO A502 Air Compressor, FANTTIK, AIRMOTO

Test Scenario: Inflating 195/60R15 tires from 0PSI to 36PSI

Key Features: Fast inflation, long range, ability to inflate multiple tires, continuous inflation using in-vehicle DC connector

Promotional Offer: 20% OFF with Code: A502

Dominio: getairmoto.com

Registrazione: 2021 (4 anni)

Introduzione: Airmoto – Portable Air Pump and Smart Tire Inflator

– Free Shipping for Orders $100+

– Compact and portable design, fits easily in glove box

– Effortlessly inflates vehicle tires, motorcycles, bicycles, and more

– Instant air anytime, anywhere with a push of a button

– Precision micro compressor technology for quick inflation

– Smart pressure control for optimal tire health and performance

– Infla…

In evaluating the strategic sourcing of air pumps, particularly Auto Air and Airmoto, it is clear that choosing the right equipment can significantly impact operational efficiency and customer satisfaction. Auto Air stands out with its superior inflation power, extended battery life, and versatility, making it an optimal choice for businesses that require reliability for both everyday and heavy-duty tasks. Meanwhile, Airmoto, while offering portability and ease of use, may fall short for more demanding applications, limiting its appeal for larger-scale operations.

For international B2B buyers, especially in regions like Africa, South America, the Middle East, and Europe, strategic sourcing should focus on total cost of ownership, performance reliability, and adaptability to local market needs. By investing in tools like Auto Air, companies can enhance their service offerings and streamline operations, ultimately driving profitability.

Illustrative image related to auto air vs airmoto

As you consider your sourcing strategies, prioritize products that align with your operational demands and market expectations. Engage with suppliers who understand your unique challenges and can provide tailored solutions. The right air pump can be a game-changer—position your business for success by choosing wisely today.

Le informazioni fornite in questa guida, compresi i contenuti relativi ai produttori, alle specifiche tecniche e all'analisi di mercato, hanno uno scopo puramente informativo ed educativo. Non costituiscono una consulenza professionale in materia di acquisti, né una consulenza finanziaria o legale.

Pur avendo compiuto ogni sforzo per garantire l'accuratezza e la tempestività delle informazioni, non siamo responsabili di eventuali errori, omissioni o informazioni non aggiornate. Le condizioni di mercato, i dettagli aziendali e gli standard tecnici sono soggetti a modifiche.

Gli acquirenti B2B devono condurre una due diligence indipendente e approfondita. prima di prendere qualsiasi decisione di acquisto. È necessario contattare direttamente i fornitori, verificare le certificazioni, richiedere campioni e chiedere una consulenza professionale. Il rischio di affidarsi alle informazioni contenute in questa guida è esclusivamente a carico del lettore.