In today’s competitive automotive industry, sourcing reliable tools such as the AutoZone tire pressure gauge is essential for maintaining vehicle safety and performance. International B2B buyers face the challenge of selecting the right products that not only meet quality standards but also align with regional requirements and pricing structures. This comprehensive guide delves into the various types of tire pressure gauges available, their applications across different vehicle types, and critical factors to consider when vetting suppliers.

From understanding the nuances of analog versus digital gauges to assessing the importance of compatibility with local tire inflation systems, this guide aims to equip decision-makers with the knowledge needed to make informed purchasing choices. We will explore cost considerations, including potential bulk purchasing discounts, and highlight key features that enhance usability and accuracy, such as ease of reading and durability.

By addressing the unique needs of B2B buyers from Africa, South America, the Middle East, and Europe, including regions like Saudi Arabia and Brazil, this guide empowers businesses to optimize their procurement strategies. With actionable insights and expert recommendations, you will be better positioned to enhance your fleet maintenance practices, ensuring safety and efficiency on the road.

| Nome del tipo | Caratteristiche distintive principali | Applicazioni primarie B2B | Brevi pro e contro per gli acquirenti |

|---|---|---|---|

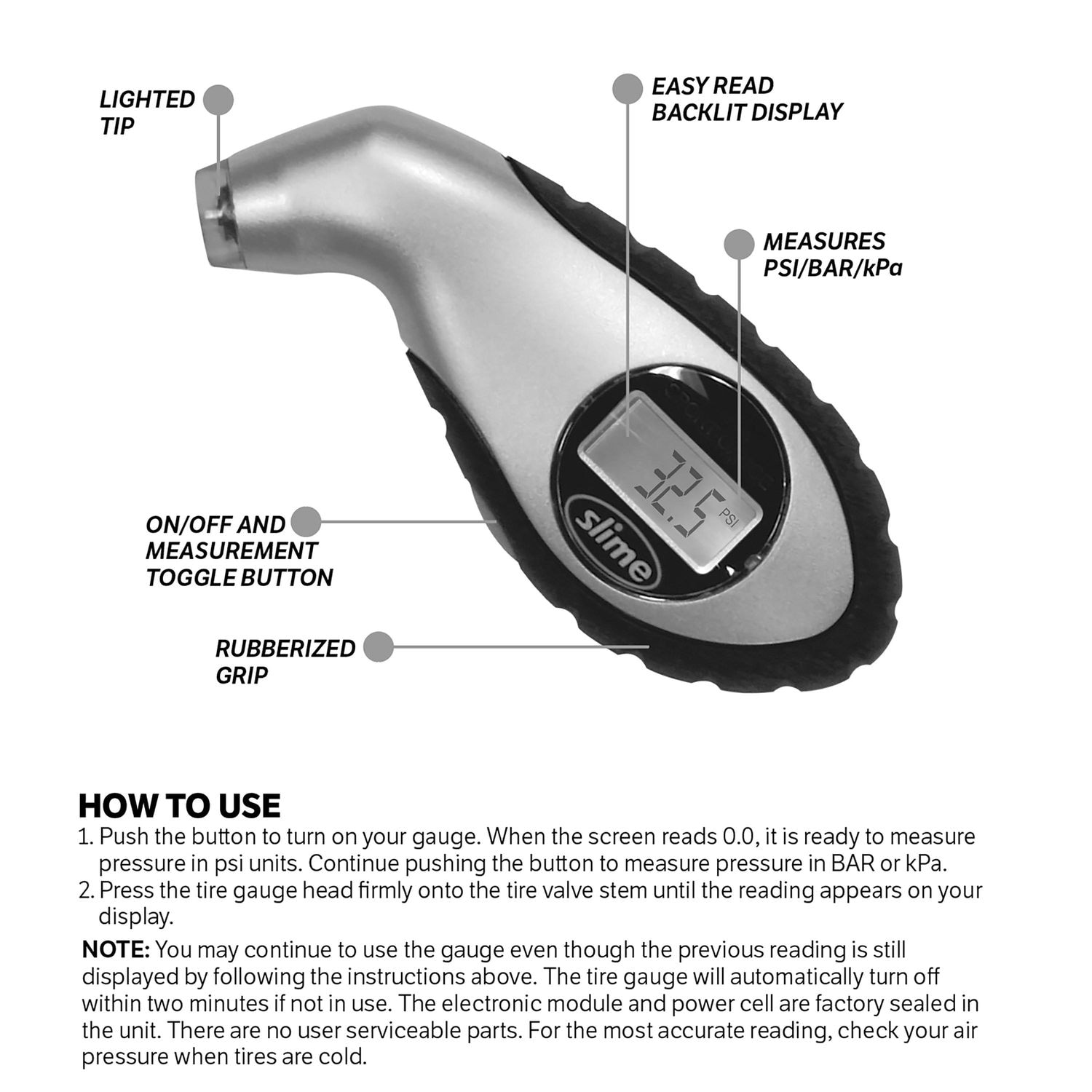

| Digital Tire Pressure Gauge | Backlit display, multiple pressure units, one-button operation | Automotive repair shops, fleet services | Pro: Easy to read, versatile; Contro: Requires batteries, may be more expensive. |

| Dial Tire Pressure Gauge | Analog readout, typically up to 150 PSI, robust construction | Tire shops, service stations | Pro: No batteries needed, durable; Contro: Less precise, can be harder to read in low light. |

| Stick Tire Pressure Gauge | Compact, lightweight, often pocket-sized, simple design | Mobile mechanics, personal use | Pro: Portable, easy to use; Contro: Limited features, may not be as durable. |

| Inflator with Gauge | Combines inflation and measurement, often digital | Roadside assistance, emergency kits | Pro: Multi-functional, saves space; Contro: Heavier, can be more expensive. |

| Professional Tire Pressure Gauge | High accuracy, often used in calibration settings | Racing teams, high-performance garages | Pro: Extremely precise, built for heavy use; Contro: Higher cost, may be overkill for general use. |

Digital tire pressure gauges are characterized by their backlit displays, allowing for easy reading in various lighting conditions. They typically offer multiple pressure unit options (PSI, bar, kPa), making them suitable for international markets. Their one-button operation simplifies usage, making them ideal for automotive repair shops and fleet services where efficiency is crucial. When purchasing, consider the need for battery replacements and the overall cost, as these gauges can be more expensive than analog options.

Dial tire pressure gauges feature an analog readout and are known for their robust construction, often able to measure pressures up to 150 PSI. They are frequently utilized in tire shops and service stations where reliability is essential. While they do not require batteries, which can be a cost-saving advantage, they may lack precision compared to digital gauges. Buyers should assess their specific needs for accuracy versus durability when considering this type.

Stick tire pressure gauges are compact and lightweight, making them ideal for mobile mechanics or personal use. Their simple design allows for quick readings, and they are typically very affordable. However, their limited features and durability may not meet the demands of a busy shop. B2B buyers should weigh the trade-off between portability and robustness when selecting this type for their operations.

Inflators with built-in gauges combine the functions of measuring and inflating tire pressure, providing a convenient solution for roadside assistance and emergency kits. These devices are often digital, enhancing usability with clear readings. However, they can be heavier and more expensive than standalone gauges. Buyers should consider the space-saving benefits against the increased weight and cost when deciding on this option.

Professional tire pressure gauges are designed for high accuracy, often used in calibration settings or by racing teams and high-performance garages. These gauges are built to withstand heavy use and provide extremely precise measurements. While they come at a higher cost, their durability and accuracy make them worthwhile for businesses requiring reliable performance. B2B buyers should evaluate whether the investment aligns with their operational needs and service quality expectations.

| Industria/Settore | Specific Application of autozone tire pressure gauge | Valore/Beneficio per l'azienda | Considerazioni chiave sull'approvvigionamento per questa applicazione |

|---|---|---|---|

| Negozi di riparazione di autoveicoli | Routine tire pressure checks for customer vehicles | Enhances safety and performance, reducing tire wear and improving fuel efficiency. | Ensure compatibility with various tire types and vehicles; consider digital vs. analog gauges. |

| Transportation and Logistics | Regular maintenance of fleet vehicles’ tire pressure | Reduces operational costs by improving fuel efficiency and extending tire life. | Look for high-capacity gauges suitable for heavy-duty vehicles; consider ease of use and durability. |

| Agricoltura | Monitoring tire pressure of agricultural machinery | Prevents equipment failure and ensures optimal performance in the field. | Gauge should handle high-pressure levels typical in agricultural tires; consider rugged design for outdoor use. |

| Costruzione | Checking tire pressure on construction vehicles | Ensures safety and efficiency of machinery, minimizing downtime due to tire issues. | Prioritize gauges that can withstand harsh environments; consider ease of calibration and accuracy. |

| Mining | Regular tire pressure assessments for mining trucks | Enhances safety and reduces the risk of tire blowouts in rugged terrains. | Select gauges that are durable and can operate in extreme conditions; ensure compatibility with large tire sizes. |

In the automotive repair sector, the AutoZone tire pressure gauge is essential for conducting routine checks on customer vehicles. By maintaining optimal tire pressure, repair shops can enhance vehicle safety and performance while reducing the likelihood of premature tire wear. International buyers should prioritize gauges that offer compatibility with various tire types and consider whether a digital or analog gauge best meets their needs.

For transportation and logistics, accurate tire pressure management is critical for fleet vehicles. Regular use of the AutoZone tire pressure gauge can significantly lower operational costs by improving fuel efficiency and extending tire lifespan. Buyers in this sector should focus on high-capacity gauges designed for heavy-duty vehicles, ensuring they are both durable and user-friendly.

In the agricultural industry, maintaining the tire pressure of machinery such as tractors and harvesters is vital. The AutoZone tire pressure gauge helps prevent equipment failures and ensures optimal performance in challenging field conditions. Buyers from regions with extensive agricultural activities should look for gauges that can handle the high-pressure levels typical of agricultural tires and are designed for rugged outdoor use.

For the construction sector, checking tire pressure on heavy machinery is crucial for safety and efficiency. The AutoZone tire pressure gauge allows construction companies to minimize downtime caused by tire issues, ensuring that equipment operates smoothly on job sites. When sourcing, buyers should prioritize gauges that can endure harsh environments and provide easy calibration for accurate readings.

In the mining industry, regular tire pressure assessments for mining trucks are vital to enhance safety and reduce the risk of blowouts in rugged terrains. The AutoZone tire pressure gauge is an indispensable tool in this context. Buyers should select gauges known for their durability and ability to operate under extreme conditions, while also ensuring compatibility with the large tire sizes commonly used in mining operations.

Il problema: For B2B buyers managing fleets, accurate tire pressure is crucial for safety, efficiency, and longevity of the vehicles. However, many tire pressure gauges can produce inconsistent readings, leading to inflated or deflated tires, which affect fuel consumption and tire wear. In regions with extreme weather variations, such as the Middle East or South America, tire pressure can fluctuate significantly, complicating the task of maintaining optimal performance across the fleet. Buyers may find themselves frustrated with frequent discrepancies in pressure readings, leading to operational inefficiencies and increased costs.

Illustrative image related to autozone tire pressure gauge

La soluzione: To mitigate these challenges, it’s essential to invest in high-quality tire pressure gauges like those from AutoZone, which offer reliable performance and accuracy. Buyers should prioritize gauges that feature digital displays and high maximum pressure limits, such as the Vaper 0-174 PSI Digital Tire Inflator. This tool not only measures tire pressure but also provides the ability to inflate or deflate tires as needed, ensuring that the correct pressure is maintained. For fleet operations, it is advisable to implement a standardized procedure for checking tire pressures regularly—ideally before each trip or at least once a week. Training staff on the correct use of the gauge will enhance their understanding of how to properly attach the gauge to the valve stem, minimizing the risk of air leaks and ensuring accurate readings. By maintaining consistent tire pressure, fleets can improve fuel efficiency and extend the lifespan of their tires.

Il problema: International B2B buyers, particularly those new to tire maintenance, often struggle with understanding the different tire pressure specifications for various vehicles. Misunderstandings can arise from confusing maximum pressure ratings with operating pressure, which can lead to over-inflation or under-inflation of tires. This issue is compounded by the varied standards and practices across different countries in Africa and Europe, where local regulations may affect tire performance standards.

La soluzione: To address this knowledge gap, buyers should familiarize themselves with the manufacturer’s recommended tire pressure for each vehicle in their fleet. The correct specifications can typically be found on a placard located inside the driver’s door or within the vehicle’s manual. AutoZone’s resources, including their online guides, can be invaluable in providing clarity on how to interpret these specifications. Additionally, purchasing a tire pressure gauge with a multi-pressure unit option (PSI, bar, kPa) can help accommodate different regional standards. Buyers should also consider establishing a comprehensive training program for their teams, emphasizing the importance of adhering to the manufacturer’s specifications and demonstrating how to accurately use the gauges. This proactive approach not only ensures compliance but also enhances overall vehicle safety and efficiency.

Il problema: As many modern vehicles come equipped with Tire Pressure Monitoring Systems (TPMS), some B2B buyers may assume these systems eliminate the need for manual checks. However, relying solely on TPMS can lead to complacency and oversight, especially if the system fails to provide accurate readings or if the sensors are not calibrated correctly. This is particularly concerning in regions where vehicles are exposed to harsh conditions that can affect sensor performance, such as high temperatures or rough terrains found in parts of Brazil or Saudi Arabia.

La soluzione: To ensure a comprehensive approach to tire maintenance, buyers should integrate the use of an AutoZone tire pressure gauge alongside TPMS. Regular manual checks can serve as a vital backup to electronic systems, catching discrepancies before they lead to serious issues. Buyers should develop a routine that incorporates manual pressure checks at least once a month or before long trips, regardless of TPMS alerts. When using the gauge, it’s crucial to follow the manufacturer’s instructions to ensure accurate readings. Additionally, incorporating a preventative maintenance schedule that includes checking and recalibrating TPMS sensors can significantly enhance their reliability. By combining technology with traditional methods, businesses can ensure safer and more efficient fleet operations, ultimately reducing costs associated with tire wear and fuel consumption.

When selecting materials for the AutoZone tire pressure gauge, it is essential to consider the properties, advantages, and limitations of various materials. This analysis will focus on four common materials used in tire pressure gauges: plastic, aluminum, brass, and stainless steel. Each material presents unique characteristics that can impact performance, durability, and overall suitability for international markets.

Plastic is often used in the housing and components of tire pressure gauges due to its lightweight nature and resistance to corrosion. Key properties include good insulation against temperature fluctuations and adequate pressure resistance for standard applications. However, the temperature rating can be limited, typically around 70°C (158°F), which may not be suitable for extreme conditions.

Illustrative image related to autozone tire pressure gauge

Pro: Plastic is cost-effective and lightweight, making it easy to manufacture and transport. It can also be molded into complex shapes, allowing for innovative designs.

Contro: While it is generally durable, plastic can become brittle over time, especially when exposed to UV light or extreme temperatures. This may lead to cracks or failures in the gauge.

Impatto sull'applicazione: Plastic gauges are best suited for general consumer use but may not withstand harsh industrial environments or high-temperature applications.

Considerazioni per gli acquirenti internazionali: Compliance with local regulations regarding material safety and environmental impact is crucial. For example, buyers in Europe may need to consider REACH regulations, while those in South America might focus on local material standards.

Illustrative image related to autozone tire pressure gauge

Aluminum is a popular choice for tire pressure gauges due to its excellent strength-to-weight ratio and corrosion resistance. It can withstand higher pressures and temperatures than plastic, making it suitable for more demanding applications. Aluminum typically has a temperature rating of up to 200°C (392°F).

Pro: Its lightweight nature combined with high durability makes aluminum gauges easy to handle and long-lasting. Additionally, aluminum can be anodized for enhanced corrosion resistance.

Contro: Aluminum can be more expensive than plastic, and its manufacturing process may be more complex, requiring specialized equipment.

Impatto sull'applicazione: Aluminum gauges are ideal for both consumer and commercial applications, especially in environments where durability is paramount.

Considerazioni per gli acquirenti internazionali: Buyers should ensure compliance with local standards for aluminum products, such as ASTM or DIN specifications, and consider the availability of aluminum in their regions.

Brass is commonly used in the fittings and valves of tire pressure gauges due to its excellent corrosion resistance and machinability. It can handle high pressures and has a temperature tolerance that can exceed 200°C (392°F).

Pro: Brass is durable and resistant to corrosion, making it suitable for long-term use. Its machinability allows for precise fittings, which can enhance the accuracy of pressure readings.

Contro: Brass can be more expensive than both plastic and aluminum, and its weight may be a drawback for portable gauges.

Impatto sull'applicazione: Brass components are essential in applications requiring precise pressure measurements, such as in automotive or industrial settings.

Considerazioni per gli acquirenti internazionali: Buyers should verify that brass components meet international standards for safety and performance, as well as consider the potential for lead content regulations in various regions.

Stainless steel is often used in high-end tire pressure gauges due to its exceptional strength, durability, and corrosion resistance. It can withstand extreme temperatures and pressures, making it suitable for industrial applications.

Pro: Stainless steel is highly durable and resistant to rust and corrosion, ensuring a long lifespan. It also maintains its integrity under high-pressure conditions.

Contro: The cost of stainless steel is generally higher than other materials, and its weight can make it less suitable for portable applications.

Illustrative image related to autozone tire pressure gauge

Impatto sull'applicazione: Stainless steel gauges are ideal for heavy-duty applications, particularly in industrial settings where reliability is critical.

Considerazioni per gli acquirenti internazionali: Buyers should ensure that stainless steel products comply with relevant international standards, such as JIS or ASTM, and consider the sourcing of materials to avoid supply chain issues.

| Materiale | Typical Use Case for autozone tire pressure gauge | Vantaggio chiave | Svantaggi/limitazioni principali | Costo relativo (Basso/Medio/Alto) |

|---|---|---|---|---|

| Plastica | General consumer use | Leggero e conveniente | Limited durability in extreme conditions | Basso |

| Alluminio | Consumer and commercial applications | Elevata durata e resistenza alla corrosione | Più costoso e complesso da produrre | Medio |

| Brass | Precision fittings and valves | Excellent machinability and corrosion resistance | Higher cost and weight | Medio |

| Acciaio inox | Heavy-duty industrial applications | Exceptional strength and durability | Costo più elevato e peso maggiore | Alto |

This strategic material selection guide provides valuable insights for international B2B buyers, helping them make informed decisions based on the unique requirements of their markets and applications.

The manufacturing process of AutoZone tire pressure gauges involves several critical stages that ensure the final product meets both performance and durability standards.

The first step in the manufacturing process is material preparation, where high-quality materials such as aluminum and brass are sourced. These materials are selected for their strength, corrosion resistance, and ability to withstand pressure changes. Suppliers typically need to provide certification that their materials comply with international standards such as ISO 9001, which ensures consistency in quality.

Once the materials are prepared, they undergo forming processes. This includes casting, machining, and stamping to create the necessary components such as the gauge body, valve stem, and connectors. Advanced techniques like CNC machining may be employed for precision and efficiency, ensuring that each component is manufactured to exact specifications.

The assembly process involves integrating the various components into a functional tire pressure gauge. This step requires skilled labor and automated machinery to ensure that each part fits together correctly. The assembly line is typically designed to minimize errors, with workers trained in best practices for handling delicate instruments.

After assembly, the gauges undergo finishing processes, including anodizing or powder coating, which provide a protective layer and enhance aesthetic appeal. This stage also includes calibration to ensure accuracy in pressure readings. Calibration is crucial, as even minor discrepancies can lead to incorrect tire pressure readings, affecting vehicle performance and safety.

Quality assurance (QA) is a pivotal aspect of the manufacturing process, ensuring that every tire pressure gauge meets the required standards for functionality and safety.

Manufacturers of tire pressure gauges must adhere to several international standards. ISO 9001 is a fundamental quality management standard that emphasizes customer satisfaction and continuous improvement. Additionally, compliance with CE marking regulations indicates that the product meets European safety, health, and environmental protection standards. For markets in the Middle East, obtaining Gulf Conformity Mark (G Mark) can also be important.

Quality control (QC) is typically divided into several checkpoints throughout the production process:

Controllo qualità in entrata (CQI): This involves inspecting raw materials upon arrival to ensure they meet the specified standards. Suppliers are often required to provide certificates of compliance.

Controllo di qualità in corso d'opera (IPQC): During manufacturing, regular inspections are conducted at various stages to identify defects early. This can include visual inspections and functional tests of components.

Controllo finale della qualità (CQC): After assembly, the final product undergoes comprehensive testing, including pressure testing and accuracy verification. This ensures that the gauges perform reliably under different conditions.

Testing is integral to the QA process, with various methods employed to evaluate performance and reliability.

Pressure Testing: Gauges are subjected to pressure tests to ensure they can handle the specified maximum pressure without failure. This is critical for safety and reliability.

Calibration Testing: Each gauge is calibrated against known pressure standards to ensure accuracy. This process typically involves using specialized equipment to compare the gauge’s readings with reference standards.

Test di durata: Gauges may be subjected to environmental tests, including temperature fluctuations and humidity exposure, to verify that they maintain performance under various conditions.

For international B2B buyers, particularly those in regions like Africa, South America, the Middle East, and Europe, verifying the quality control processes of suppliers is crucial.

Conducting supplier audits is a fundamental practice to ensure compliance with quality standards. Buyers should request access to the supplier’s quality management system documentation, including their ISO certifications and internal QA procedures.

Buyers should also request regular quality control reports, which should detail results from IQC, IPQC, and FQC processes. This transparency allows buyers to assess the consistency and reliability of the supplier’s products.

Engaging third-party inspection services can add an additional layer of assurance. These independent organizations can conduct audits and testing, providing unbiased assessments of the supplier’s quality control processes and the products themselves.

When sourcing from international suppliers, buyers must be aware of the specific quality control nuances that may affect product reliability.

Differenze culturali: Different regions may have varying standards for quality, which can impact manufacturing practices. Understanding these cultural differences can help in negotiating and setting expectations.

Compliance with Local Regulations: It is essential for buyers to ensure that the products comply with local regulations in their markets. This may involve additional certifications or testing requirements that differ from those in the supplier’s country.

Logistics and Transportation Considerations: The shipping process can also affect the quality of products. Buyers should ensure that suppliers use appropriate packaging and handling procedures to prevent damage during transport.

By understanding the manufacturing processes and quality assurance measures in place for AutoZone tire pressure gauges, B2B buyers can make informed decisions that ensure they source reliable and high-quality products for their markets.

When sourcing tire pressure gauges, particularly from reputable suppliers like AutoZone, it’s essential to follow a structured approach to ensure that you secure high-quality products that meet your operational needs. This guide provides a step-by-step checklist tailored for international B2B buyers, focusing on essential actions to take during the procurement process.

Begin by defining the specifications you need in a tire pressure gauge. Consider factors such as measurement range (e.g., PSI, bar, kPa), gauge type (digital vs. analog), and additional features like inflation capabilities. Having clear requirements helps streamline your search and ensures compatibility with your existing tools and systems.

Conduct thorough research on potential suppliers, specifically focusing on those that offer AutoZone products. Look for suppliers with a strong reputation and positive reviews in your region. Check their websites, industry presence, and feedback from previous customers to gauge reliability and service quality.

Before making a purchase, assess the quality of the tire pressure gauges offered. Examine product specifications and certifications, such as ISO or CE marks, which indicate compliance with international standards. High-quality gauges ensure accurate readings and durability, which are crucial for maintaining vehicle safety.

Illustrative image related to autozone tire pressure gauge

Whenever possible, request samples of the tire pressure gauges to evaluate their performance firsthand. This step allows you to verify accuracy, ease of use, and overall build quality. Testing samples can prevent costly mistakes and ensure that the products meet your expectations.

Once you have identified a suitable supplier and evaluated their products, initiate negotiations on pricing and purchase terms. Discuss bulk order discounts, payment terms, and delivery options. Ensure that the agreed terms align with your budget and operational timelines.

Before finalizing your order, clarify the warranty terms and after-sales support provided by the supplier. A reliable warranty can protect your investment against defects or performance issues. Additionally, check if the supplier offers ongoing technical support or training for your team.

After confirming all terms and conditions, place your order. Keep track of the delivery schedule and maintain communication with the supplier to address any potential delays or issues. Proper monitoring ensures that you receive your gauges in a timely manner, allowing for uninterrupted operations.

By following this checklist, B2B buyers can effectively navigate the sourcing process for tire pressure gauges from AutoZone or similar suppliers, ensuring they procure the right products for their needs while fostering strong supplier relationships.

Illustrative image related to autozone tire pressure gauge

Understanding the cost structure and pricing dynamics for sourcing AutoZone tire pressure gauges is essential for international B2B buyers looking to optimize their procurement processes. This analysis provides insights into the various components that influence costs and pricing, along with practical tips for buyers in diverse markets such as Africa, South America, the Middle East, and Europe.

I materiali: The primary cost driver for tire pressure gauges includes the raw materials used in their production. Common materials include durable plastics and metals, which impact the gauge’s longevity and reliability. High-quality materials may increase the initial cost but can lead to lower replacement rates and reduced maintenance expenses.

Lavoro: Labor costs are determined by the manufacturing location. Regions with lower labor costs may offer attractive pricing, but it’s crucial to consider the trade-off with quality and adherence to safety standards. In contrast, manufacturing in regions with higher labor costs often correlates with better craftsmanship and quality assurance.

Illustrative image related to autozone tire pressure gauge

Spese generali di produzione: This encompasses expenses related to facilities, utilities, and indirect labor. Efficient production processes can help mitigate overhead costs, thereby impacting the final price of the product.

Utensili: Initial investments in tooling for specialized gauges can be significant, especially if customization is required. Buyers should assess whether the tooling costs can be amortized over a high volume of units to justify the investment.

Controllo qualità (CQ): Implementing strict QC measures ensures that each tire pressure gauge meets specified standards. While this adds to the cost, it is essential for maintaining brand reputation and minimizing returns.

Logistica: Shipping costs are a critical component, especially for international buyers. Factors such as distance, shipping method, and Incoterms can significantly influence the overall cost of goods.

Margine: Supplier margins vary based on market competition and the perceived value of the product. Buyers should be aware that premium brands may command higher margins due to established reputations.

Volume e quantità minima d'ordine (MOQ): Pricing often scales with order volume. Larger orders typically lead to lower per-unit costs, making it essential for buyers to negotiate MOQs that align with their demand forecasts.

Specifiche e personalizzazione: Custom features or specifications can drive up costs. Buyers should clearly define their requirements to avoid unexpected price increases.

Illustrative image related to autozone tire pressure gauge

Materiali e certificazioni di qualità: Products that meet international quality standards or certifications may incur higher costs but can provide assurance of reliability and performance, which is particularly important in regulated markets.

Fattori di fornitura: The supplier’s reputation, reliability, and financial stability can influence pricing. Building long-term relationships with reputable suppliers can lead to better pricing and favorable terms.

Incoterms: Understanding the implications of various Incoterms is crucial for international transactions. Terms like FOB (Free on Board) and CIF (Cost, Insurance, and Freight) can significantly affect the total cost of ownership.

Negoziazione: Buyers should prepare to negotiate prices and terms. Understanding market rates and having alternative suppliers can strengthen your bargaining position.

Costo totale di proprietà (TCO): Beyond the purchase price, consider factors such as logistics, maintenance, and potential warranty claims. A lower upfront cost may not always equate to better value if the product requires frequent replacements or incurs high shipping fees.

Le sfumature dei prezzi per gli acquirenti internazionali: Buyers in regions like Africa and South America should be aware of currency fluctuations and import tariffs that can affect pricing. It’s advisable to work with local distributors who understand the market dynamics and can provide insights into the total cost implications.

Disclaimer sui prezzi indicativi: Pricing can fluctuate based on market conditions, currency exchange rates, and supplier negotiations. Buyers should always seek updated quotes to ensure they are making informed purchasing decisions.

In summary, a thorough understanding of the cost structure and pricing influencers for AutoZone tire pressure gauges is vital for B2B buyers. By considering these factors, buyers can strategically navigate their sourcing processes and enhance overall procurement efficiency.

In the automotive industry, ensuring optimal tire pressure is crucial for safety, performance, and longevity of tires. While the AutoZone tire pressure gauge is a popular choice among vehicle maintenance tools, there are several viable alternatives that cater to different needs and preferences. This section provides a comprehensive comparison to assist B2B buyers in making informed decisions.

| Aspetto di confronto | AutoZone Tire Pressure Gauge | Vaper Digital Tire Inflator | Tire Pressure Monitoring System (TPMS) |

|---|---|---|---|

| Prestazioni | Reliable manual readings | Digital display with multi-functionality | Real-time monitoring with alerts |

| Costo | $15 – $30 | $81.49 | $50 – $300 depending on vehicle type |

| Facilità di implementazione | Simple to use, requires manual checks | Easy to use with one-button operation | Installed in vehicle, requires initial setup |

| Manutenzione | Low, requires occasional calibration | Moderate, battery replacement needed | Low, but may require occasional sensor checks |

| Il miglior caso d'uso | Personal vehicle maintenance | Professional workshops and frequent users | Fleet management and vehicles with TPMS |

The Vaper Digital Tire Inflator offers a professional-grade solution with a backlit display for clear readings. Its versatility allows for inflating, deflating, and measuring tire pressure, making it an excellent choice for workshops and heavy users. The main advantage is its ease of use, featuring a one-button operation that simplifies the process. However, it is priced higher than manual gauges, which may be a consideration for budget-conscious buyers. Additionally, the need for battery replacements can lead to moderate maintenance costs.

TPMS is a sophisticated system that continuously monitors tire pressure and alerts drivers of any deviations from the optimal range. This technology is particularly beneficial for fleet management, as it reduces the need for manual checks and enhances safety by providing real-time data. The initial investment can be significant, especially for vehicles that require specialized systems, but the long-term benefits in safety and efficiency may outweigh these costs. Maintenance is generally low, but buyers should be aware that sensor checks may be necessary to ensure accurate readings over time.

When selecting a tire pressure measurement solution, B2B buyers should consider their specific operational requirements. For businesses that prioritize cost-effectiveness and simplicity, the AutoZone tire pressure gauge remains a reliable choice. However, for those seeking advanced functionality and real-time monitoring, investing in a Vaper Digital Tire Inflator or a TPMS may provide better long-term value. Assessing factors such as the scale of operations, frequency of use, and budget will guide buyers to the most suitable option for maintaining tire safety and performance.

When sourcing tire pressure gauges for automotive applications, it’s essential to understand their technical specifications. Here are some critical properties that can influence purchasing decisions:

Illustrative image related to autozone tire pressure gauge

Pressure Range

The pressure range indicates the minimum and maximum tire pressure that the gauge can accurately measure, typically expressed in PSI (pounds per square inch). For example, a gauge with a range of 0-150 PSI is suitable for most passenger vehicles, while a digital inflator may extend up to 174 PSI. Understanding this range is crucial for ensuring the gauge meets the specifications of various vehicles, especially in diverse markets.

Accuracy

Accuracy is usually expressed as a percentage of the full scale (e.g., ±1%). This specification is vital for providing reliable readings, which can affect tire performance and safety. Inaccurate measurements can lead to improper tire inflation, affecting vehicle handling and fuel efficiency. B2B buyers should prioritize gauges with high accuracy ratings to minimize liability and enhance customer satisfaction.

Material Construction

The materials used in the gauge’s construction—such as aluminum, brass, or durable plastic—impact durability and longevity. A gauge with a robust aluminum die-cast body is likely to withstand rough handling in workshop environments. Buyers should consider the material properties to ensure that the product can endure the specific conditions of their operational context.

Display Type

The display type can be analog (dial) or digital. Digital displays often provide backlighting for visibility in low-light conditions, while analog gauges may be simpler and more cost-effective. The choice between these two types can affect usability, especially in environments with varying lighting. Understanding the display type helps B2B buyers cater to their customers’ preferences and needs.

Unit Options

Many tire pressure gauges offer multiple unit options, including PSI, bar, kPa, and kgf/cm². This versatility allows for use in international markets where different measurement systems are standard. B2B buyers should ensure that the gauges they procure can accommodate the diverse needs of their clientele.

Ease of Use

Features such as a swivel air chuck, flexible hose, and simple one-button operation enhance usability. These characteristics can significantly impact customer experience, especially for non-professional users. Investing in gauges that prioritize ease of use can lead to higher customer retention and satisfaction.

Understanding industry terminology is vital for effective communication and negotiation in B2B transactions. Here are some commonly used terms in the automotive parts sector:

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of tire pressure gauges, OEM products are typically viewed as higher quality because they meet the original specifications set by vehicle manufacturers.

MOQ (quantità minima d'ordine)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is critical for B2B buyers to understand as it affects inventory costs and supply chain management. Negotiating a favorable MOQ can lead to better pricing and reduced overhead.

RFQ (Richiesta di offerta)

An RFQ is a document that buyers send to suppliers to request pricing and terms for a specific product. B2B buyers should utilize RFQs to compare suppliers effectively and obtain the best possible deal on tire pressure gauges.

Incoterms (Termini commerciali internazionali)

Incoterms define the responsibilities of buyers and sellers in international transactions. They specify who is responsible for shipping, insurance, and tariffs. Understanding these terms is essential for B2B buyers to manage logistics and mitigate risks in global trade.

Tempi di consegna

Lead time is the period between placing an order and receiving the product. This term is crucial for inventory planning and can impact a company’s ability to meet customer demand promptly. B2B buyers should inquire about lead times when sourcing tire pressure gauges to ensure timely delivery.

Garanzia

A warranty provides assurance regarding the quality and longevity of a product. Understanding warranty terms can protect buyers from defective products and ensure customer satisfaction. B2B buyers should look for products with favorable warranty conditions to reduce long-term risk.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions when sourcing tire pressure gauges, ultimately leading to better product offerings and enhanced customer satisfaction.

The global tire pressure gauge market is experiencing significant growth, driven by rising awareness of vehicle safety and maintenance among consumers and businesses alike. In regions like Africa, South America, the Middle East, and Europe, there is an increasing emphasis on vehicle upkeep, particularly in urban areas where transportation efficiency is critical. This has led to a surge in demand for reliable tire pressure gauges as essential tools for maintaining optimal tire performance.

Emerging B2B technology trends are also reshaping the sourcing landscape. The integration of digital solutions, such as smart tire pressure monitoring systems (TPMS), is becoming more prevalent. These systems provide real-time data and alerts, reducing reliance on manual gauges. However, traditional tire pressure gauges remain essential for many businesses, especially in regions with varying climate conditions that can affect tire pressure. B2B buyers are increasingly looking for gauges that are not only accurate but also versatile, with features like digital displays and multiple pressure unit options.

Moreover, the global shift towards e-commerce is impacting sourcing strategies. B2B buyers are leveraging online platforms to access a wider range of products, compare prices, and read customer reviews, enhancing their purchasing decisions. Supply chain dynamics are also evolving, with manufacturers focusing on direct-to-consumer models, which can offer competitive pricing and faster delivery times.

Illustrative image related to autozone tire pressure gauge

The tire pressure gauge sector is increasingly under scrutiny regarding its environmental impact and the ethics of its supply chains. B2B buyers are more conscientious about the sustainability practices of their suppliers, seeking products that minimize environmental harm. This includes sourcing materials that are recyclable and manufactured through processes that reduce carbon emissions.

Ethical sourcing is becoming a critical factor in supplier selection. Companies are expected to comply with environmental regulations and demonstrate a commitment to sustainable practices. Certifications such as ISO 14001 (Environmental Management) or the use of eco-friendly materials can enhance a product’s appeal in the marketplace. For instance, tire pressure gauges made from recycled plastics or sustainable materials can attract environmentally conscious buyers.

Furthermore, companies that prioritize transparency in their supply chains and ensure fair labor practices can gain a competitive edge. This is particularly relevant in regions like Africa and South America, where ethical sourcing can significantly influence purchasing decisions. As sustainability becomes a central theme in global commerce, B2B buyers in the tire pressure gauge market must consider the long-term benefits of partnering with suppliers who share their values.

The evolution of tire pressure gauges can be traced back to the early 20th century when basic mechanical gauges were introduced. Initially, these tools were rudimentary, often leading to inaccurate readings and safety concerns. As vehicle technology advanced, so did the design and functionality of tire pressure gauges. The introduction of digital technology in the late 20th century marked a significant turning point, offering improved accuracy and user-friendliness.

In recent years, the rise of smart technologies and integrated vehicle systems has further transformed the landscape. Digital tire pressure gauges, equipped with features such as Bluetooth connectivity and smartphone integration, have emerged, catering to the needs of modern consumers and businesses. This historical context highlights the continuous innovation within the tire pressure gauge market and underscores the importance of staying updated with technological advancements for B2B buyers seeking reliable and efficient solutions.

How do I solve issues with fluctuating tire pressure readings?

To address fluctuating tire pressure readings, first ensure that you are using a high-quality tire pressure gauge. Verify that the gauge is calibrated correctly and that it fits snugly on the valve stem to prevent air leaks during measurement. If fluctuations persist, inspect the tires for punctures or leaks, particularly around the valve stem. Additionally, consider environmental factors such as temperature changes, which can significantly affect tire pressure. Regular maintenance and checks can help in maintaining consistent readings.

What is the best tire pressure gauge for commercial use?

For commercial applications, a digital tire pressure gauge with a high PSI range (up to 174 PSI) and backlit display is ideal. Look for gauges that offer multiple pressure unit options (PSI, bar, kPa) for versatility. A model with a built-in inflator and deflator feature can save time and streamline operations. Durability and ease of use are also crucial; select gauges with protective rubber sleeves and ergonomic designs for enhanced longevity and comfort during frequent use.

What are the minimum order quantities (MOQ) for tire pressure gauges?

Minimum order quantities (MOQ) for tire pressure gauges can vary significantly depending on the supplier and the gauge model. Typically, MOQs range from 50 to 200 units for bulk orders. It’s advisable to negotiate terms with suppliers, especially if you are considering larger orders or long-term partnerships. For customized gauges, MOQs may be higher due to the additional production processes involved. Always confirm these details before finalizing your order to ensure it aligns with your business needs.

What payment terms should I expect when sourcing from international suppliers?

Payment terms for international suppliers often include options like upfront payment, partial payment upon order confirmation, and balance upon shipment. Letters of credit are also commonly used to secure transactions. Always clarify payment methods accepted (e.g., bank transfer, PayPal) and ensure that terms are documented in the purchase agreement. Consider potential currency fluctuations and associated fees when dealing with international suppliers, as these can impact overall costs.

How can I vet suppliers for tire pressure gauges?

To effectively vet suppliers, start by researching their reputation in the industry through reviews and testimonials. Request references from previous clients to gain insights into their reliability and product quality. Evaluate their certifications, such as ISO or other relevant industry standards, which indicate adherence to quality management practices. Additionally, consider conducting factory visits or audits if feasible, and check their capacity to handle your order volume and customization requirements.

What quality assurance processes should be in place for tire pressure gauges?

Quality assurance processes for tire pressure gauges should include rigorous testing for accuracy and durability. Suppliers should conduct calibration checks to ensure gauges provide precise readings within specified tolerances. Look for manufacturers that have established quality control protocols, such as regular inspections during production and post-production testing. Certifications from recognized bodies can also indicate a commitment to maintaining high quality standards in manufacturing.

What logistics considerations should I keep in mind when importing tire pressure gauges?

When importing tire pressure gauges, consider shipping costs, customs duties, and import regulations specific to your country. Ensure that you have a reliable logistics partner to handle shipping and customs clearance efficiently. Packaging is also crucial; ensure that gauges are packaged securely to prevent damage during transit. Additionally, factor in lead times for production and shipping when planning your inventory to avoid stock shortages.

Are there customization options available for tire pressure gauges?

Yes, many suppliers offer customization options for tire pressure gauges, including branding with your company logo, color variations, and specific pressure ranges tailored to your needs. Customization may require higher MOQs and longer lead times, so it’s essential to discuss these details with your supplier early in the negotiation process. Ensure that you provide clear specifications to avoid misunderstandings and ensure the final product meets your expectations.

Dominio: reddit.com

Registrato: 2005 (20 anni)

Introduzione: 1. Tire inflators that plug into the cigarette lighter outlet are recommended as a cost-effective solution for airing up tires. 2. Locations mentioned for airing up tires include: – Shell in Irmo (paid service) – Kroger (free service) – Costco (free service) – Walmart tire centers (free service) – Love’s Station by Bluff Road exit ($1.50, card swipe available) 3. Some users have had issues with fa…

The strategic sourcing of tire pressure gauges, particularly from reputable suppliers like AutoZone, presents significant opportunities for international buyers. By prioritizing quality and reliability, businesses in Africa, South America, the Middle East, and Europe can ensure that their tire maintenance tools meet the demands of diverse vehicle types and conditions. The importance of accurate tire pressure cannot be overstated; it directly affects vehicle safety, fuel efficiency, and tire longevity.

Investing in high-quality tire pressure gauges not only enhances operational efficiency but also fosters customer satisfaction and loyalty. As global supply chains evolve, B2B buyers should leverage strategic partnerships to secure favorable pricing, consistent quality, and timely delivery.

Looking ahead, the market for tire maintenance products is poised for growth, driven by increasing vehicle ownership and heightened awareness of safety standards. Now is the time for international buyers to act—align with trusted suppliers, like AutoZone, and invest in tools that ensure optimal vehicle performance. By doing so, you position your business to thrive in an increasingly competitive landscape.

Le informazioni fornite in questa guida, compresi i contenuti relativi ai produttori, alle specifiche tecniche e all'analisi di mercato, hanno uno scopo puramente informativo ed educativo. Non costituiscono una consulenza professionale in materia di acquisti, né una consulenza finanziaria o legale.

Pur avendo compiuto ogni sforzo per garantire l'accuratezza e la tempestività delle informazioni, non siamo responsabili di eventuali errori, omissioni o informazioni non aggiornate. Le condizioni di mercato, i dettagli aziendali e gli standard tecnici sono soggetti a modifiche.

Gli acquirenti B2B devono condurre una due diligence indipendente e approfondita. prima di prendere qualsiasi decisione di acquisto. È necessario contattare direttamente i fornitori, verificare le certificazioni, richiedere campioni e chiedere una consulenza professionale. Il rischio di affidarsi alle informazioni contenute in questa guida è esclusivamente a carico del lettore.