The global market for street glide crash bar saddle bags presents a unique challenge for B2B buyers seeking reliable and stylish protective solutions for Harley Davidson motorcycles. Sourcing high-quality crash bar saddle bags that meet diverse regional preferences and regulatory standards can be daunting. This guide aims to demystify the complexities of navigating this niche market by providing a comprehensive overview of available products, their applications, and critical factors to consider when selecting suppliers.

Throughout this guide, we will explore various types of street glide crash bar saddle bags, including options for different Harley models, materials, and designs. Additionally, we will delve into essential aspects of supplier vetting, ensuring that international buyers from regions such as Africa, South America, the Middle East, and Europe—particularly in markets like Saudi Arabia and Brazil—can make informed purchasing decisions. Understanding pricing structures, shipping logistics, and compliance with local regulations will empower B2B buyers to select products that not only enhance the aesthetics of their motorcycles but also provide the necessary protection.

By arming yourself with the insights found in this guide, you can confidently navigate the global landscape of street glide crash bar saddle bags, ensuring that your business meets customer demands while maintaining quality and compliance standards.

| Nome del tipo | Caratteristiche distintive principali | Applicazioni primarie B2B | Brevi pro e contro per gli acquirenti |

|---|---|---|---|

| Pork Chop Saddlebag Guards | 1.25″ diameter, available in chrome and black finishes | Retailers catering to Harley enthusiasts | Pros: Stylish design, quick installation. Cons: Limited fitment options. |

| Anarchy Bag Guards | High-quality steel, unique aggressive design | Custom bike shops, aftermarket retailers | Pros: Durable construction, aesthetic appeal. Cons: Higher price point. |

| ProTek Rear Performance Guards | Two-step design, fully TIG welded, includes sliders | Performance-focused dealerships | Pros: Enhanced protection, easy installation. Cons: Compatibility issues with some models. |

| Stretched Saddlebag Guards | Designed for extended bags, available with color options | Specialty retailers for custom builds | Pros: Tailored fit for stretched bags, stylish customization. Cons: May require modifications. |

| Saddlebag Guard Eliminator Kits | Simplifies installation by removing existing guards | Cost-effective solutions for budget buyers | Pros: Affordable, easy to install. Cons: Less protection than full guards. |

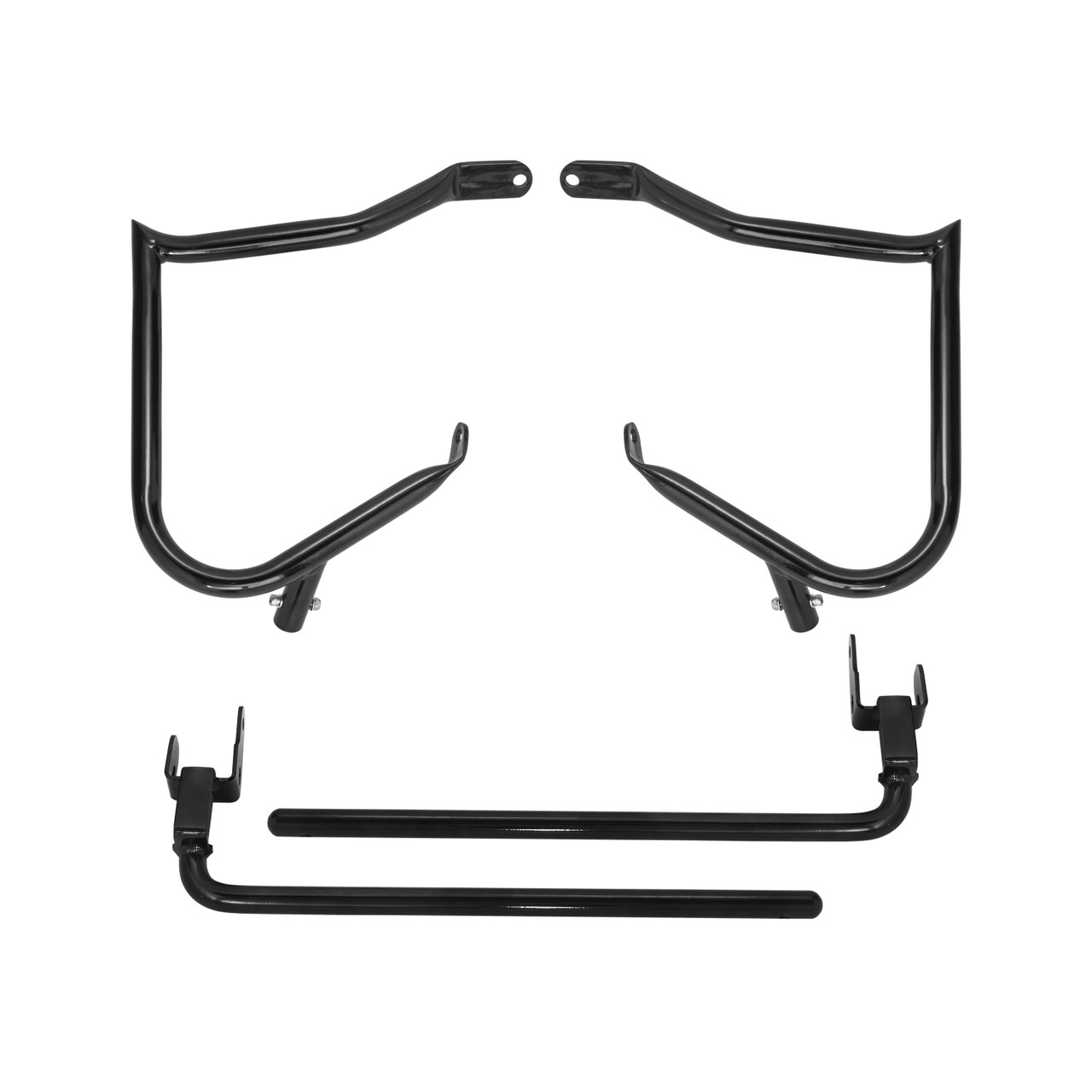

Pork Chop Saddlebag Guards are designed specifically for Harley Touring models from 2014 to 2025. These guards feature a robust 1.25-inch diameter tubing and are available in both chrome and black finishes, catering to diverse aesthetic preferences. For B2B buyers, these guards offer a quick installation process, making them an attractive option for retailers. However, limited fitment options may restrict their appeal to a broader audience.

Illustrative image related to street glide crash bar saddle bag

Anarchy Bag Guards are crafted from high-quality steel and boast a distinctive aggressive design that enhances the overall aesthetic of Harley Davidson motorcycles. These guards fit a range of bagger models from 1997 to 2023, making them versatile for various retail applications. The combination of durability and style makes them a popular choice, although their premium pricing may deter budget-conscious buyers.

The ProTek Rear Performance Guards feature a two-step design that provides dual-level protection for both the engine area and saddlebags. Made from mild steel and fully TIG welded, they are designed for strength and durability. These guards come with sliders for additional customization and easy installation, appealing to performance-focused dealerships. However, compatibility issues with certain models may limit their market reach.

Stretched Saddlebag Guards are specifically designed for motorcycles with extended saddlebags, offering a tailored fit that enhances both protection and aesthetics. These guards often come with various color options, appealing to specialty retailers focused on custom builds. While they provide a unique look and fit, buyers should be aware that installation may require additional modifications, which could increase labor costs.

Illustrative image related to street glide crash bar saddle bag

Saddlebag Guard Eliminator Kits offer a cost-effective solution for buyers looking to simplify their motorcycle’s design by removing existing guards. These kits are easy to install and provide an affordable option for budget-conscious consumers. However, potential buyers should consider that these kits offer less protection compared to full guards, which may be a critical factor for some motorcycle enthusiasts.

| Industria/Settore | Specific Application of street glide crash bar saddle bag | Valore/Beneficio per l'azienda | Considerazioni chiave sull'approvvigionamento per questa applicazione |

|---|---|---|---|

| Produzione di motocicli | Integration into new touring bike models | Enhances product appeal and safety for end-users | Quality of materials, compatibility with existing models |

| Accessori per moto al dettaglio | Retail of aftermarket saddlebag guards | Increases inventory diversity and customer satisfaction | Shipping logistics, supplier reliability, pricing strategies |

| Motorcycle Rental Services | Protection for rental fleet motorcycles | Reduces maintenance costs and damage claims | Cost-effectiveness, ease of installation, durability |

| Negozi di moto personalizzate | Customization options for clients | Attracts a niche market and enhances service offerings | Design options, customization capabilities, lead time |

| International Logistics | Shipping and handling of motorcycle accessories | Streamlines supply chain and reduces transit damage | Packaging quality, compliance with international regulations |

In the motorcycle manufacturing sector, street glide crash bar saddle bags are integrated into new touring bike models to enhance safety and aesthetics. These components provide essential protection for saddlebags, which are often vulnerable to damage during operation. For manufacturers targeting international markets, ensuring compatibility with diverse bike models and compliance with regional safety standards is crucial. Buyers from regions such as Africa and the Middle East may prioritize robust materials that withstand varying climates.

For motorcycle accessories retailers, offering aftermarket street glide crash bar saddle bags can significantly enhance product offerings. These guards not only improve the aesthetic appeal of motorcycles but also provide essential protection, increasing customer satisfaction and repeat business. Retailers should consider sourcing high-quality products that offer competitive pricing and reliable shipping options to meet the demands of international buyers, especially in South America and Europe, where customization is popular.

Illustrative image related to street glide crash bar saddle bag

Motorcycle rental services utilize street glide crash bar saddle bags to protect their fleet of touring motorcycles. These guards minimize damage during rentals, thereby reducing maintenance costs and liability claims. Rental companies in regions with high tourist traffic, such as Brazil and Saudi Arabia, benefit from investing in durable and easy-to-install solutions. Buyers should focus on the cost-effectiveness and ease of maintenance of these accessories to ensure a solid return on investment.

Custom motorcycle shops often seek street glide crash bar saddle bags to offer personalized solutions to their clients. These guards can be tailored to fit specific models, allowing shops to differentiate themselves in a competitive market. By sourcing customizable options, shops can attract a niche clientele interested in unique designs and enhanced functionality. International buyers may prioritize suppliers that can deliver bespoke products with reasonable lead times.

International logistics plays a vital role in the sourcing of street glide crash bar saddle bags, especially for businesses involved in shipping motorcycle accessories. Ensuring that products are packaged securely to prevent damage during transit is essential for maintaining quality. Compliance with international shipping regulations is also critical for avoiding delays and additional costs. Buyers from diverse markets, including Europe and the Middle East, should prioritize suppliers with proven logistics capabilities to streamline their supply chain.

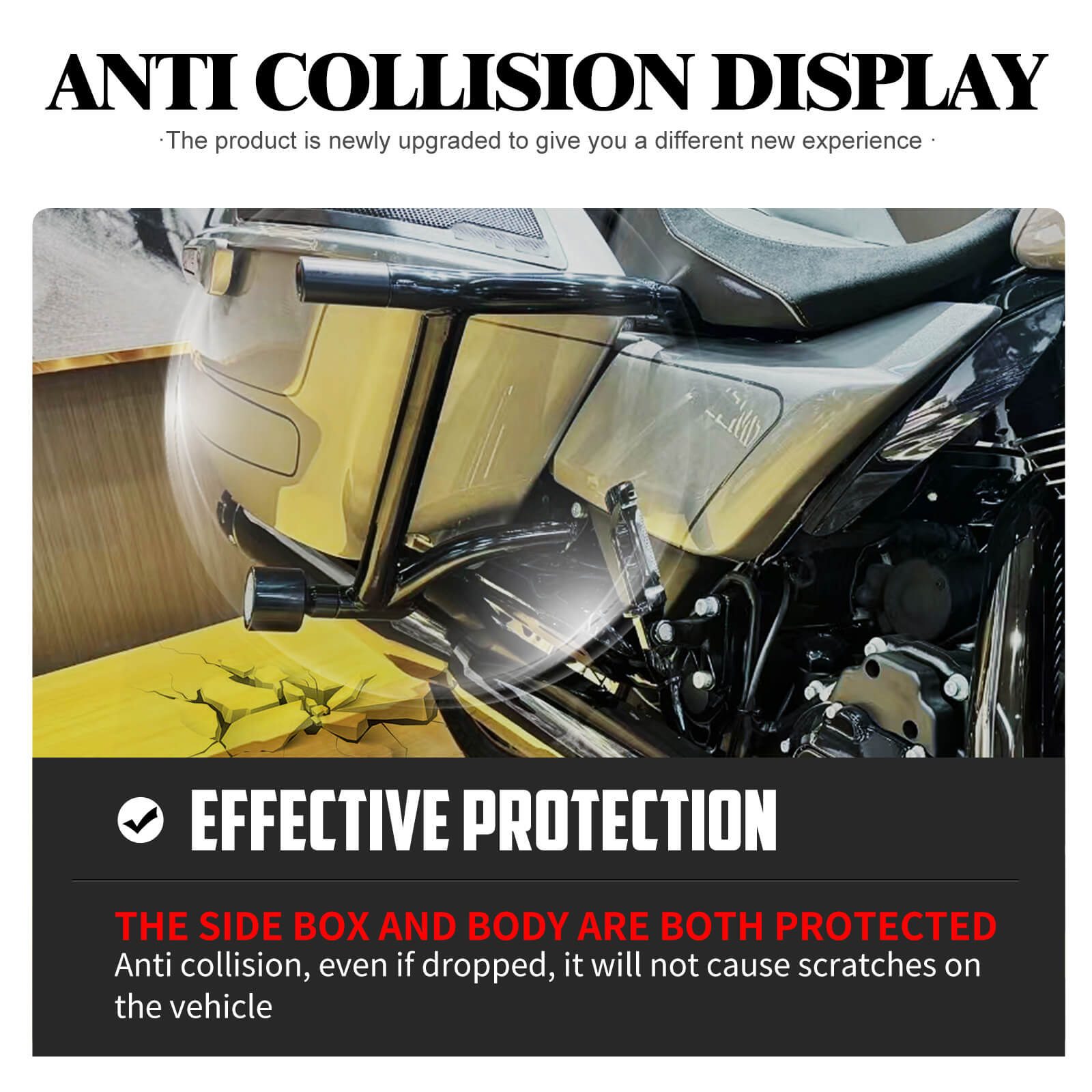

Il problema: B2B buyers often face challenges in sourcing high-quality materials for crash bar saddlebag guards. This is particularly true for companies looking to maintain a reputation for durability and reliability in their products. Many suppliers offer low-quality materials that compromise the structural integrity of the guards, leading to increased returns and dissatisfied customers. Additionally, international buyers may encounter issues with inconsistent quality standards across different regions, making it hard to ensure uniformity in their product offerings.

La soluzione: To overcome this challenge, B2B buyers should prioritize suppliers known for their commitment to quality. When sourcing crash bar saddlebag guards, look for manufacturers that utilize high-grade materials, such as mild steel with a powder-coated finish for enhanced durability. It’s beneficial to request samples or detailed specifications before placing large orders to ensure that the materials meet your quality standards. Additionally, establishing a relationship with suppliers who have robust quality control processes can help guarantee consistent product quality across shipments. Collaborating with manufacturers who offer customization options can also enable you to cater to specific market demands, enhancing your competitive edge.

Il problema: Many businesses struggle with the installation process of crash bar saddlebag guards, particularly when compatibility issues arise with different Harley models. Buyers may find that the guards do not fit perfectly, requiring additional modifications or leading to installation delays. This not only affects customer satisfaction but also increases labor costs and time spent on installations.

La soluzione: To address these installation challenges, it is essential to source crash bar saddlebag guards that come with clear installation instructions and all necessary hardware. Look for suppliers who provide detailed installation videos or guides, as these can significantly reduce the time and frustration involved in the setup process. Additionally, consider purchasing products that offer a universal fit or come with adjustable features to accommodate various models. Engaging with manufacturers that provide technical support or consultations can also help your team troubleshoot any installation issues that may arise, ensuring a smoother experience for your customers.

Il problema: B2B buyers often face difficulties in managing inventory levels and supply chain disruptions, particularly in the motorcycle accessory market, where demand can fluctuate unpredictably. Unexpected shortages or delays in receiving crash bar saddlebag guards can lead to lost sales opportunities and customer dissatisfaction. This is especially pertinent for businesses operating in international markets, where logistics can be further complicated by customs regulations and shipping times.

La soluzione: To mitigate these inventory management challenges, businesses should adopt a proactive approach by forecasting demand based on historical sales data and market trends. Establishing agreements with multiple suppliers can create a safety net against potential disruptions, allowing for alternative sourcing options when needed. Implementing inventory management software can also streamline the process, providing real-time visibility into stock levels and helping to predict when reorders are necessary. Additionally, fostering strong relationships with logistics partners can facilitate smoother international shipping processes, reducing lead times and enhancing overall supply chain resilience.

When selecting materials for street glide crash bar saddle bags, it is essential to consider their properties, advantages, and limitations. The choice of material directly influences the performance, durability, and cost-effectiveness of the product, making it a critical decision for B2B buyers.

Mild steel is a popular choice for crash bar saddle bags due to its excellent strength-to-weight ratio. It can withstand significant impacts, making it suitable for protective applications. Mild steel typically has a temperature rating of around 300°C and offers moderate corrosion resistance when properly coated.

Pro: The material is relatively inexpensive and easy to manufacture, allowing for cost-effective production. Its strength ensures durability, making it ideal for crash protection.

Contro: Mild steel is prone to rust if not adequately coated, which can be a concern in humid or coastal environments. Additionally, it may require regular maintenance to preserve its appearance and functionality.

International Considerations: Buyers in regions with high humidity, such as parts of Africa and South America, should ensure that the mild steel used meets corrosion resistance standards. Compliance with ASTM standards can enhance marketability in Europe and the Middle East.

Stainless steel, particularly grades like 304 and 316, is renowned for its corrosion resistance and aesthetic appeal. With a temperature rating exceeding 800°C, it is suitable for high-temperature applications.

Pro: The primary advantage of stainless steel is its resistance to rust and staining, making it ideal for long-term outdoor use. It also has a polished finish that enhances the visual appeal of motorcycles.

Illustrative image related to street glide crash bar saddle bag

Contro: The main drawback is the higher cost compared to mild steel. Manufacturing processes for stainless steel can be more complex, requiring specialized equipment and techniques.

International Considerations: For buyers in the Middle East and Europe, stainless steel products must adhere to specific standards such as DIN and JIS for quality assurance. The investment in stainless steel may be justified by the long-term savings on maintenance and replacement.

Aluminum is lightweight and offers good corrosion resistance, making it a suitable option for crash bar saddle bags. Its temperature rating is around 200°C, which is adequate for most motorcycle applications.

Pro: The lightweight nature of aluminum improves the overall handling of the motorcycle. It is also resistant to corrosion, reducing maintenance needs.

Contro: Aluminum can be less durable than steel, especially under high-stress conditions, which may lead to deformation or failure. Additionally, it is often more expensive than mild steel.

Illustrative image related to street glide crash bar saddle bag

International Considerations: Buyers in regions like Brazil and Africa should consider local availability and the cost implications of sourcing aluminum. Compliance with local manufacturing standards is crucial for market acceptance.

Composite materials, often a blend of fiberglass and resin, are becoming increasingly popular in motorcycle accessories. They offer unique properties that can enhance performance.

Pro: Composites are lightweight and can be molded into complex shapes, allowing for innovative designs. They also provide excellent corrosion resistance and do not rust.

Illustrative image related to street glide crash bar saddle bag

Contro: The primary limitation is their relatively high cost and the complexity of manufacturing processes. Additionally, composites may not withstand high-impact forces as well as metals.

International Considerations: For international buyers, especially in Europe, compliance with environmental regulations regarding composite materials is essential. Understanding local market trends can help in positioning composite products effectively.

| Materiale | Typical Use Case for street glide crash bar saddle bag | Vantaggio chiave | Svantaggi/limitazioni principali | Costo relativo (Basso/Medio/Alto) |

|---|---|---|---|---|

| Mild Steel | Crash bar guards for durability | Cost-effective and strong | Prone to rust without proper coating | Basso |

| Acciaio inox | Premium crash bar guards for aesthetic and durability | Excellent corrosion resistance | Costi più elevati e produzione complessa | Alto |

| Alluminio | Lightweight crash bar guards for improved handling | Leggero e resistente alla corrosione | Less durable under high stress | Medio |

| Composito | Innovative designs for crash bar guards | Lightweight and moldable | High cost and potential impact limitations | Alto |

This material selection guide provides a comprehensive overview of the key materials for street glide crash bar saddle bags, enabling B2B buyers to make informed decisions based on their specific needs and regional considerations.

The manufacturing process for street glide crash bar saddle bags involves several crucial stages that ensure both quality and functionality. Understanding these stages can help B2B buyers evaluate suppliers and make informed decisions.

Illustrative image related to street glide crash bar saddle bag

The primary materials used in the manufacturing of crash bar saddle bags are typically high-grade mild steel or stainless steel, chosen for their strength and resistance to corrosion. The first step in the manufacturing process is material preparation, which includes cutting raw materials to specified dimensions and ensuring that they meet industry standards.

Quality suppliers often utilize advanced cutting technologies such as laser cutting or water jet cutting, which provide precision and reduce material waste. Once the materials are cut, they undergo a cleaning process to remove any contaminants, such as oil, rust, or dirt, which could affect the welding and finishing stages.

After preparation, the next stage is forming. This involves bending, stamping, or shaping the steel into the desired configurations. For crash bar saddle bags, this may include creating curves or angles that fit the specific design requirements of Harley Davidson models.

Manufacturers may employ techniques like CNC (Computer Numerical Control) machining, which allows for high precision in shaping the metal components. The use of CNC technology not only increases production efficiency but also ensures that each part is consistent in dimensions, which is critical for assembly.

Once the components are shaped, they move to the assembly stage. This process involves welding, bolting, or riveting the various parts together. Quality control during assembly is vital to ensure that all components fit correctly and function as intended.

For crash bar saddle bags, a common technique used is fully TIG (Tungsten Inert Gas) welding, which provides strong, clean welds. The assembly is often performed in a controlled environment to minimize the risk of contamination and defects.

The final stage of manufacturing is finishing, which enhances both aesthetics and durability. This typically involves applying a protective coating such as powder coating or plating. Powder coating is particularly popular due to its resistance to scratches, chips, and rust, making it ideal for motorcycle accessories that are exposed to the elements.

Some manufacturers also employ additional finishing techniques, such as polishing or applying a clear coat, to enhance the visual appeal of the product. Quality suppliers will often conduct adhesion tests to ensure that the finish adheres properly to the metal substrate.

Illustrative image related to street glide crash bar saddle bag

Quality assurance (QA) is a critical aspect of the manufacturing process, especially for B2B buyers looking to source crash bar saddle bags. Understanding international and industry-specific standards can help buyers assess the reliability of suppliers.

One of the most recognized international quality management standards is ISO 9001. This standard outlines criteria for a quality management system and emphasizes customer satisfaction through effective processes. Suppliers certified under ISO 9001 demonstrate a commitment to quality and continuous improvement.

In addition to ISO standards, industry-specific certifications such as CE (Conformité Européenne) for products sold in Europe and API (American Petroleum Institute) certifications for oil and gas applications may also be relevant. These certifications ensure that products meet specific safety and performance standards.

Quality control typically consists of several checkpoints throughout the manufacturing process.

Controllo qualità in entrata (CQI): This step involves inspecting raw materials upon receipt to ensure they meet specified standards before processing begins.

Controllo di qualità in corso d'opera (IPQC): During manufacturing, various checkpoints are established to monitor processes and identify defects early. This may include inspections during material cutting, forming, and assembly.

Controllo finale della qualità (CQC): Once the product is fully assembled, a comprehensive inspection is performed to ensure it meets all quality standards and specifications before shipping.

Common testing methods for crash bar saddle bags include:

Visual Inspection: Checking for surface defects, inconsistencies, and overall craftsmanship.

Dimensional Inspection: Measuring components to ensure they conform to specified dimensions.

Strength Testing: Conducting stress tests to evaluate the durability and performance of the assembled product.

Corrosion Resistance Testing: Exposing samples to harsh environments to test the effectiveness of protective coatings.

For international B2B buyers, verifying a supplier’s quality control processes is crucial. Here are some strategies to ensure compliance and reliability:

Illustrative image related to street glide crash bar saddle bag

Conducting regular audits of suppliers can provide insights into their quality control processes. Buyers should look for suppliers who welcome audits and can provide documentation of their quality management systems, including certifications and inspection reports.

Engaging third-party inspection services can further validate the quality of products before they are shipped. Independent inspectors can assess compliance with industry standards and provide unbiased reports on product quality.

Buyers should request detailed quality control reports from suppliers, which should include information on inspection results, testing methods used, and any corrective actions taken for defects. This transparency can help build trust and ensure that the products meet necessary standards.

When sourcing from international suppliers, particularly in regions like Africa, South America, the Middle East, and Europe, buyers must consider various factors:

Illustrative image related to street glide crash bar saddle bag

Differenze culturali: Understanding local manufacturing practices and business customs can facilitate smoother communication and collaboration.

Logistics and Shipping: Ensuring that quality is maintained during shipping is critical. Buyers should discuss packaging and handling procedures with suppliers to minimize damage during transit.

Conformità normativa: Different regions have varying regulations regarding product safety and performance. B2B buyers must ensure that their suppliers comply with local laws and international standards.

By thoroughly understanding the manufacturing processes and quality assurance practices for street glide crash bar saddle bags, B2B buyers can make informed decisions, ensuring they source high-quality products that meet their needs.

This guide serves as a comprehensive checklist for international B2B buyers aiming to procure ‘street glide crash bar saddle bags.’ By following these steps, you can ensure a smooth purchasing process, minimize risks, and secure high-quality products that meet your business needs.

Before initiating the sourcing process, clearly outline the technical specifications required for the crash bar saddle bags. Consider factors such as material (e.g., mild steel, aluminum), dimensions, weight capacity, and compatibility with specific Harley Davidson models. This ensures that you only engage with suppliers who can meet your precise requirements.

Illustrative image related to street glide crash bar saddle bag

Conduct thorough research to identify suppliers with a proven track record in manufacturing motorcycle accessories. Look for companies that specialize in Harley Davidson products and have positive reviews from previous clients. Checking their market presence in regions like Africa, South America, the Middle East, and Europe can also provide insight into their reliability and customer service.

Quality is paramount when sourcing crash bar saddle bags. Inquire about the materials used and the manufacturing processes employed by potential suppliers. Verify if they adhere to industry standards and possess relevant certifications (e.g., ISO certifications). This step helps ensure that the products are durable and safe for use.

Before placing a bulk order, request samples of the crash bar saddle bags. Testing these samples allows you to assess their quality, fit, and functionality firsthand. Pay attention to features such as the ease of installation and the finish quality, as these factors can significantly impact customer satisfaction.

Illustrative image related to street glide crash bar saddle bag

Clarify the pricing structure with potential suppliers, including unit prices, bulk discounts, and shipping costs. Be aware of additional fees that may arise, such as customs duties or taxes, especially when importing products across international borders. Understanding the total cost will help you evaluate the financial feasibility of your purchase.

Once you have identified a supplier that meets your criteria, engage in negotiations regarding payment terms, delivery timelines, and warranty conditions. Establish clear communication about these aspects to avoid misunderstandings later. Favorable terms can also lead to a long-term partnership, benefiting both parties.

Consider the logistics involved in receiving the crash bar saddle bags. Identify potential challenges related to shipping, customs clearance, and distribution within your target markets. Collaborating with a logistics partner familiar with international shipping can streamline this process and ensure timely delivery.

By following this checklist, B2B buyers can navigate the complexities of sourcing street glide crash bar saddle bags effectively. Each step is designed to mitigate risks and enhance the likelihood of a successful procurement outcome, ultimately leading to satisfied customers and repeat business.

Illustrative image related to street glide crash bar saddle bag

When analyzing the cost structure for sourcing street glide crash bar saddle bags, several components play a crucial role. I materiali are the primary cost driver, typically involving high-quality mild steel or aluminum for durability. Prices can vary based on market fluctuations and sourcing regions. Labor costs encompass the wages for skilled workers involved in fabrication and assembly, which can differ significantly based on the country of production.

Additionally, manufacturing overhead includes expenses related to factory maintenance, utilities, and administrative costs. Tooling costs are relevant for custom designs or modifications, impacting the initial investment required for production. Controllo qualità (CQ) procedures are essential for ensuring product reliability and safety, which can add to the overall cost but are necessary for maintaining brand reputation.

Infine, logistics costs must be considered, including shipping and handling fees, especially for international buyers. These costs can vary widely based on the distance, mode of transportation, and any tariffs or duties applicable.

Illustrative image related to street glide crash bar saddle bag

Several price influencers can affect the final pricing of street glide crash bar saddle bags. Volume e quantità minima d'ordine (MOQ) play a significant role; larger orders typically yield lower per-unit costs due to economies of scale. Customization options, such as unique designs or specific finishes, can increase costs but also cater to niche markets.

The choice of materials is another critical factor. Premium materials or certifications for quality assurance can elevate costs. Fattori di fornitura, including reliability and reputation, can also impact pricing; established suppliers may charge more due to their proven track record.

Understanding Incoterms is essential for international buyers, as they dictate the responsibilities of sellers and buyers in the shipping process, which can influence total costs. For instance, terms like FOB (Free on Board) can transfer responsibility to the buyer earlier in the shipping process, affecting logistics costs.

For B2B buyers, especially those operating in regions like Africa, South America, the Middle East, and Europe, effective negotiation strategies can lead to significant cost savings. Begin by conducting thorough market research to understand prevailing prices and supplier capabilities. This knowledge empowers buyers to negotiate better terms and prices.

Consider leveraging Costo totale di proprietà (TCO) analysis when negotiating. This approach accounts for all costs associated with a product over its lifecycle, including maintenance, potential repairs, and resale value. By presenting a TCO perspective, buyers can justify their pricing expectations and negotiate more effectively.

Additionally, fostering long-term relationships with suppliers can yield benefits such as discounts on repeat orders or flexibility in payment terms. Establishing clear communication about expectations and quality standards can also enhance collaboration, leading to mutually beneficial arrangements.

International buyers should be mindful of specific sfumature di prezzo that can impact their purchasing decisions. Currency fluctuations can significantly affect costs, especially if transactions occur in foreign currencies. Buyers should consider locking in exchange rates or negotiating prices in their local currency to mitigate this risk.

Illustrative image related to street glide crash bar saddle bag

Tariffs and import duties can also add unexpected costs to international shipments. It’s essential to factor these into the overall pricing strategy. Furthermore, understanding local regulations regarding product compliance and safety certifications can prevent costly delays or penalties.

Lastly, shipping times and costs can vary significantly based on the chosen logistics provider and route. Buyers should evaluate these factors to optimize their supply chain and ensure timely deliveries.

Sourcing street glide crash bar saddle bags involves a comprehensive understanding of cost components, pricing influencers, and effective negotiation strategies. By being aware of these elements, international B2B buyers can make informed decisions that enhance their purchasing power and overall profitability.

In the pursuit of protecting saddlebags while enhancing the aesthetic appeal of Harley-Davidson motorcycles, several solutions exist beyond the traditional street glide crash bar saddle bag. This analysis compares the street glide crash bar saddle bag to two viable alternatives: saddlebag guards and performance crash bar saddlebags. Each option has its unique characteristics that cater to different needs and preferences, particularly for international B2B buyers in regions like Africa, South America, the Middle East, and Europe.

| Aspetto di confronto | Street Glide Crash Bar Saddle Bag | Saddlebag Guards | Performance Crash Bar Saddlebags |

|---|---|---|---|

| Prestazioni | Provides moderate protection against drops and impacts. | Offers enhanced protection for saddlebags and aesthetic integration. | Dual-layer protection that shields engine and saddlebags, minimizing damage from tip-overs. |

| Costo | Typically priced between $200-$450 depending on materials and design. | Generally ranges from $130-$370, based on design and material. | Priced around $450, reflecting higher durability and performance features. |

| Facilità di implementazione | Requires moderate mechanical skills for installation; might need custom fittings. | Generally straightforward installation using existing mounts, minimal modifications needed. | Bolt-on design for quick installation, though some cutting of brackets may be necessary. |

| Manutenzione | Low maintenance; occasional checks for wear recommended. | Minimal maintenance; regular cleaning to prevent rust is advisable. | Requires some upkeep on the powder-coated finish to prevent chipping or rust. |

| Il miglior caso d'uso | Ideal for riders looking for a balance of style and basic protection. | Best for riders focused on aesthetic appeal and moderate protection. | Suited for frequent riders who need robust protection for long-distance travel and touring. |

Saddlebag guards provide a cost-effective and visually appealing solution for motorcycle owners. They are designed to protect saddlebags from minor impacts while enhancing the overall look of the bike. However, their protective capabilities are generally limited compared to more robust options. While they are easy to install and maintain, they may not offer the same level of security against severe drops or accidents.

Performance crash bar saddlebags are engineered for optimal protection, featuring a dual-layer design that safeguards both the engine and saddlebags. Constructed from durable materials, they are particularly suited for long-distance riders who require enhanced security during their journeys. Despite their higher price point, the benefits of increased durability and protective features often justify the investment. However, some installation complexity, such as cutting brackets, may deter less experienced users.

Selecting the right solution for saddlebag protection involves evaluating the specific needs and usage patterns of the motorcycle owner. For riders seeking a balance between aesthetics and basic protection, the street glide crash bar saddle bag may suffice. In contrast, those prioritizing durability and extensive protection for long rides should consider performance crash bar saddlebags. Meanwhile, saddlebag guards serve as an appealing compromise for those desiring stylish protection without extensive modifications. Ultimately, understanding the unique advantages and limitations of each option will empower B2B buyers to make informed purchasing decisions that align with their clientele’s preferences and riding habits.

When considering the procurement of street glide crash bar saddle bags, understanding the technical specifications is crucial for ensuring compatibility and performance. Here are some essential properties that B2B buyers should prioritize:

Grado del materiale: Most crash bar saddle bags are constructed from high-quality steel or aluminum alloys. Steel, particularly mild steel, is favored for its strength and durability, making it resistant to impacts during falls. Aluminum offers a lightweight alternative, which can improve overall vehicle performance. Buyers should assess the material grade for its ability to withstand environmental factors, as well as its weight-bearing capacity.

Diameter of Tubing: The diameter of the tubing used in crash bars typically ranges from 1 to 1.25 inches. A larger diameter often indicates a sturdier construction, providing better protection for the saddlebags and the bike itself. This specification is vital for ensuring that the crash bar can absorb impacts effectively, thus minimizing damage during low-speed falls.

Finish: The protective finish—such as powder coating—plays a significant role in longevity. A gloss black or chrome finish not only enhances aesthetics but also protects against rust and corrosion. In regions with high humidity or exposure to salt (like coastal areas), selecting a finish that resists corrosion is particularly important.

Capacità di peso: Understanding the weight capacity of crash bar saddle bags is essential, especially for businesses that cater to riders who carry heavy loads. Manufacturers often specify the maximum load the bars can handle without compromising structural integrity. This detail is crucial for ensuring safety and performance under load.

Installation Ease: The design should allow for straightforward installation, often with a bolt-on feature that utilizes existing mounting points. Clear installation instructions and compatibility with stock components can significantly reduce labor costs and installation time for B2B buyers.

Garanzia e assistenza: A robust warranty indicates the manufacturer’s confidence in their product quality. B2B buyers should consider the length and terms of the warranty, as well as the availability of customer support, which can be crucial in resolving potential issues post-purchase.

Familiarity with industry-specific terminology will enhance communication and negotiation processes. Here are some essential trade terms relevant to street glide crash bar saddle bags:

OEM (Original Equipment Manufacturer): This term refers to companies that produce parts and equipment that may be marketed by another manufacturer. Understanding OEM specifications helps ensure that products meet the necessary quality and compatibility standards.

MOQ (quantità minima d'ordine): This is the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is essential for budgeting and inventory management, particularly for businesses that want to minimize excess stock.

RFQ (Richiesta di offerta): An RFQ is a document sent to suppliers to solicit pricing and terms for specific products. B2B buyers should prepare detailed RFQs to ensure they receive accurate quotes and understand the terms of sale.

Incoterms: These are international commercial terms that outline the responsibilities of buyers and sellers in global trade. Familiarity with Incoterms is crucial for understanding shipping responsibilities, insurance, and risk management, especially for international transactions.

Tempi di consegna: This refers to the amount of time it takes from placing an order to receiving the product. Understanding lead times helps businesses plan their inventory and manage customer expectations effectively.

Aftermarket: This term refers to parts or accessories that are not sourced from the original manufacturer. Knowing the aftermarket landscape can offer buyers additional options for customization and potentially lower costs.

By mastering these technical properties and trade terms, B2B buyers can make informed decisions that enhance their purchasing strategies for street glide crash bar saddle bags, ensuring optimal performance and satisfaction.

The street glide crash bar saddle bag market is experiencing significant growth, driven by the increasing popularity of motorcycle tourism and the rising number of motorcycle enthusiasts globally. In regions like Africa, South America, the Middle East, and Europe, this trend is particularly pronounced, as consumers seek both functional and aesthetic enhancements for their motorcycles. The demand for saddle bag guards is not only about protection but also about personalization, as riders look to express their individuality through unique designs and high-quality materials.

Emerging B2B tech trends are reshaping how suppliers operate within this sector. E-commerce platforms are becoming essential for international buyers, enabling them to source products directly from manufacturers with greater efficiency. Additionally, advancements in supply chain management technologies, such as real-time inventory tracking and automated order processing, are streamlining procurement processes. International buyers are increasingly valuing quick shipping times and reliable customer service, making it crucial for suppliers to maintain robust logistics frameworks.

Moreover, sustainability is becoming a key consideration in purchasing decisions. Buyers are actively seeking products that not only meet performance standards but also align with environmentally responsible practices. This shift is prompting suppliers to innovate and adapt their offerings, incorporating sustainable materials and practices into their manufacturing processes.

The environmental impact of motorcycle accessories, including street glide crash bar saddle bags, is under scrutiny as businesses and consumers alike prioritize sustainability. The production of motorcycle parts traditionally involves materials and processes that can be harmful to the environment. As a response, companies are increasingly focusing on ethical sourcing and sustainable manufacturing practices.

For international buyers, understanding the importance of ethical supply chains is essential. Suppliers are being held accountable for their sourcing decisions, and buyers are encouraged to inquire about the materials used in products. The trend toward ‘green’ certifications is gaining traction, with manufacturers exploring biodegradable materials and recyclable components to meet consumer demand for eco-friendly options.

Additionally, certifications such as ISO 14001 (Environmental Management) and LEED (Leadership in Energy and Environmental Design) are becoming important indicators of a supplier’s commitment to sustainability. Buyers from regions like Europe, where sustainability regulations are stricter, are particularly focused on sourcing products that meet these criteria. This trend not only enhances brand reputation but also appeals to a growing consumer base that values environmental stewardship.

The street glide crash bar saddle bag segment has evolved significantly since its inception. Initially designed primarily for protection, the functionality of saddle bags has expanded alongside advancements in motorcycle technology and design. The introduction of more robust materials and innovative engineering solutions has allowed manufacturers to create products that not only protect but also enhance the aesthetic appeal of motorcycles.

Illustrative image related to street glide crash bar saddle bag

In recent years, the market has witnessed a shift from purely functional designs to more stylish and customizable options. The rise of custom motorcycle culture has fueled demand for unique and personalized accessories, leading to a diversification of product offerings. This evolution reflects broader trends in consumer preferences, where riders are not just looking for practicality but also a means to express their personality through their motorcycles.

As the market continues to grow, it is essential for international B2B buyers to stay informed about these trends, ensuring they can source products that meet both performance and aesthetic demands while adhering to sustainability practices.

How do I solve quality concerns when sourcing street glide crash bar saddle bags?

To address quality concerns, it is essential to vet suppliers thoroughly. Request product samples to assess material quality, craftsmanship, and durability. Additionally, review certifications or compliance with industry standards. Establish quality assurance processes, including third-party inspections before shipment. Regular communication with suppliers regarding quality expectations can also mitigate potential issues. Lastly, consider suppliers with positive reviews and a proven track record in delivering high-quality motorcycle accessories.

What is the best material for street glide crash bar saddle bags?

The best materials for street glide crash bar saddle bags typically include high-grade mild steel or stainless steel for the frame, ensuring durability and resistance to corrosion. Powder-coated finishes are recommended for added protection against scratches and environmental elements. Additionally, consider saddle bags made from weather-resistant materials to protect against moisture and dirt, which is crucial for maintaining the appearance and functionality of the bags over time.

What customization options are available for street glide crash bar saddle bags?

Many suppliers offer customization options for street glide crash bar saddle bags, including color finishes, sizes, and additional features like integrated lighting or branding options. When sourcing, inquire about the possibility of custom designs that align with your brand identity. Ensure to communicate your specifications clearly and confirm lead times for customized products, as these may vary based on complexity and supplier capabilities.

What are the minimum order quantities (MOQs) for street glide crash bar saddle bags?

Minimum order quantities can vary significantly among suppliers, typically ranging from 50 to 500 units depending on the product and manufacturer. When negotiating terms, it’s essential to discuss MOQs upfront to ensure they align with your purchasing capacity. Some suppliers may offer flexibility on MOQs for first-time buyers or larger orders. Always clarify whether MOQs include different models or customizations.

What payment terms should I expect when sourcing street glide crash bar saddle bags internationally?

Payment terms can differ widely depending on the supplier and the country of origin. Common arrangements include a deposit upon order confirmation (usually 30-50%) with the balance due before shipment. Some suppliers may offer favorable terms like letter of credit or net payment terms after delivery. It’s crucial to clarify payment methods accepted (e.g., bank transfer, PayPal) and any potential currency exchange implications.

How can I ensure timely delivery of street glide crash bar saddle bags?

To ensure timely delivery, establish clear timelines with your supplier, including production and shipping schedules. Utilize reliable logistics partners experienced in international shipping to minimize delays. Discuss potential customs clearance issues, especially when importing to regions like Africa or South America, as these can impact delivery times. Regularly track your shipment and maintain communication with your supplier throughout the process.

What quality assurance measures should I implement for street glide crash bar saddle bags?

Implementing quality assurance measures involves setting clear specifications and expectations with suppliers. Conduct pre-shipment inspections to verify that the products meet your standards. Consider third-party inspections for larger orders, and maintain a quality checklist that includes material checks, finish quality, and packaging integrity. Establish a return policy for defective items, and document any discrepancies for future reference.

How do I choose the right supplier for street glide crash bar saddle bags?

Selecting the right supplier involves evaluating their experience, reputation, and product quality. Conduct thorough research, including checking reviews and testimonials from other B2B buyers. Request references and assess their production capabilities and lead times. Additionally, consider their responsiveness to inquiries and willingness to collaborate on custom projects. A reliable supplier should also be transparent about their sourcing practices and compliance with international trade regulations.

Dominio: hogworkz.com

Registrato: 2014 (11 anni)

Introduzione: HOGWORKZ® Saddlebag Guards and Skid Plates for Harley-Davidson® Motorcycles

Dominio: advanblack.com

Registrato: 2016 (9 anni)

Introduzione: ProTek Rear Performance Crash Bar Saddlebags Guards for ’14-’25 Harley Touring. Two-Steps design, made from mild steel, fully TIG welded for enhanced strength. Gloss black powder coat finish. 37″ overall width, 1.25″ diameter tube. Comes with 4 sliders. Options available for black Delrin, anodized CNC, or anodized CNC with carbon inlay sliders in different colors. All sliders come with 3/8-16 scre…

Dominio: harley-davidson.com

Registrato: 1994 (31 anni)

Introduzione: {“product_name”: “Saddlebag Tip-Over Bar Set”, “price”: “$399.95”, “part_number”: “90202657”, “description”: “Get tip-over protection with sleek low-profile West Coast performance style, without ‘old school’ hoops. Provides limited cosmetic vehicle protection to the saddlebags in a low-speed tip-over event.”, “finish”: “Gloss Black”, “features”: [“End caps with Harley-Davidson logo”, “Easy to repl…

Dominio: facebook.com

Registrato: 1997 (28 anni)

Introduzione: This company, Facebook – Crash Bars and Bag Guards, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Dominio: worldwide.wingscustom.com

Registrato: 2015 (10 anni)

Introduzione: {“product_name”: “Saddlebag Guard Diablo Harley-Davidson Street Glide 2015 to 2025 – Black”, “compatible_models”: [“FLHX ANV STREET GLIDE ANNI EDITION”, “FLHXS STREET GLIDE SPECIAL ANNI EDITION”, “FLHXST STREET GLIDE ST”, “FLHXSE CVO STREET GLIDE”, “FLHXS STREET GLIDE SPECIAL”, “FLHX STREET GLIDE”], “years_compatible”: [2015, 2016, 2017, 2018, 2019, 2020, 2021, 2022, 2023, 2024, 2025], “finish”: “…

In the competitive landscape of motorcycle accessories, particularly for Harley Davidson models, strategic sourcing of street glide crash bar saddle bags is crucial for B2B buyers aiming to enhance their product offerings. Key insights from market leaders indicate a strong demand for high-quality, durable materials that provide both protection and aesthetic appeal. By focusing on established suppliers who offer reliable shipping and comprehensive installation support, businesses can ensure they meet the expectations of discerning customers across diverse markets.

Investing in premium saddlebag guards, such as those crafted with high-grade steel and sophisticated design features, not only elevates the customer experience but also enhances brand loyalty. As the motorcycle accessory market continues to expand, particularly in regions such as Africa, South America, the Middle East, and Europe, there is an opportunity for international buyers to capitalize on this growth.

Looking forward, it is essential to forge partnerships with innovative manufacturers who prioritize quality and customer satisfaction. By embracing strategic sourcing practices, businesses can position themselves for success, offering products that resonate with riders seeking both protection and style. Explore your sourcing options today to stay ahead in this dynamic market.

Le informazioni fornite in questa guida, compresi i contenuti relativi ai produttori, alle specifiche tecniche e all'analisi di mercato, hanno uno scopo puramente informativo ed educativo. Non costituiscono una consulenza professionale in materia di acquisti, né una consulenza finanziaria o legale.

Pur avendo compiuto ogni sforzo per garantire l'accuratezza e la tempestività delle informazioni, non siamo responsabili di eventuali errori, omissioni o informazioni non aggiornate. Le condizioni di mercato, i dettagli aziendali e gli standard tecnici sono soggetti a modifiche.

Gli acquirenti B2B devono condurre una due diligence indipendente e approfondita. prima di prendere qualsiasi decisione di acquisto. È necessario contattare direttamente i fornitori, verificare le certificazioni, richiedere campioni e chiedere una consulenza professionale. Il rischio di affidarsi alle informazioni contenute in questa guida è esclusivamente a carico del lettore.