In today’s competitive landscape, sourcing a Central Tire Inflation System (CTIS) can significantly enhance operational efficiency and vehicle performance for international B2B buyers. As businesses grapple with challenges such as rising fuel costs, tire maintenance issues, and the need for improved mobility across diverse terrains, the CTIS emerges as a vital solution. This guide delves into the myriad types and applications of CTIS technology, offering insights into how these systems can be leveraged across various industries, from agriculture to military operations.

The comprehensive scope of this guide includes critical elements such as supplier vetting processes, cost considerations, and the latest technological advancements in CTIS. By understanding the nuances of these systems, buyers from regions like Africa, South America, the Middle East, and Europe—including countries like Brazil and Vietnam—will be better equipped to make informed purchasing decisions. The guide aims to empower decision-makers with actionable insights, enabling them to select the right CTIS that not only meets their operational needs but also maximizes return on investment.

As you navigate the global market for CTIS, this resource will serve as your strategic companion, providing the knowledge necessary to optimize tire performance, reduce downtime, and ultimately enhance your fleet’s productivity.

| Nome del tipo | Caratteristiche distintive principali | Applicazioni primarie B2B | Brevi pro e contro per gli acquirenti |

|---|---|---|---|

| Military CTIS | High reliability, remote diagnostics, limp home mode | Defense vehicles, tactical transport | Pro: Enhanced mobility in harsh conditions; Contro: Investimento iniziale più elevato. |

| Agricultural CTIS | Adjustable pressure for various terrains, on-the-go control | Farming equipment, tractors | Pro: Increases productivity, reduces soil compaction; Contro: Requires maintenance for optimal function. |

| Commercial Vehicle CTIS | Automatic pressure adjustment, real-time diagnostics | Trucks, construction vehicles | Pro: Reduces tire wear, improves fuel efficiency; Contro: Complexity may require specialized training. |

| Off-Road CTIS | Optimized for low-pressure operation, rugged design | Mining, off-road vehicles | Pro: Increases traction on difficult terrains; Contro: Limited application in urban settings. |

| Heavy-Duty CTIS | Designed for high-load capacities, robust construction | Heavy machinery, freight transport | Pro: Enhances tire lifespan under heavy loads; Contro: Weight can affect vehicle performance. |

Military Central Tire Inflation Systems (CTIS) are engineered for reliability and performance under extreme conditions. These systems feature advanced diagnostics and a “limp home” mode, allowing vehicles to maintain mobility even with significant tire damage. Suitable for tactical transport and defense vehicles, military CTIS can be a vital asset in ensuring operational readiness. Buyers should consider the initial investment against the long-term benefits of enhanced mobility and safety in challenging environments.

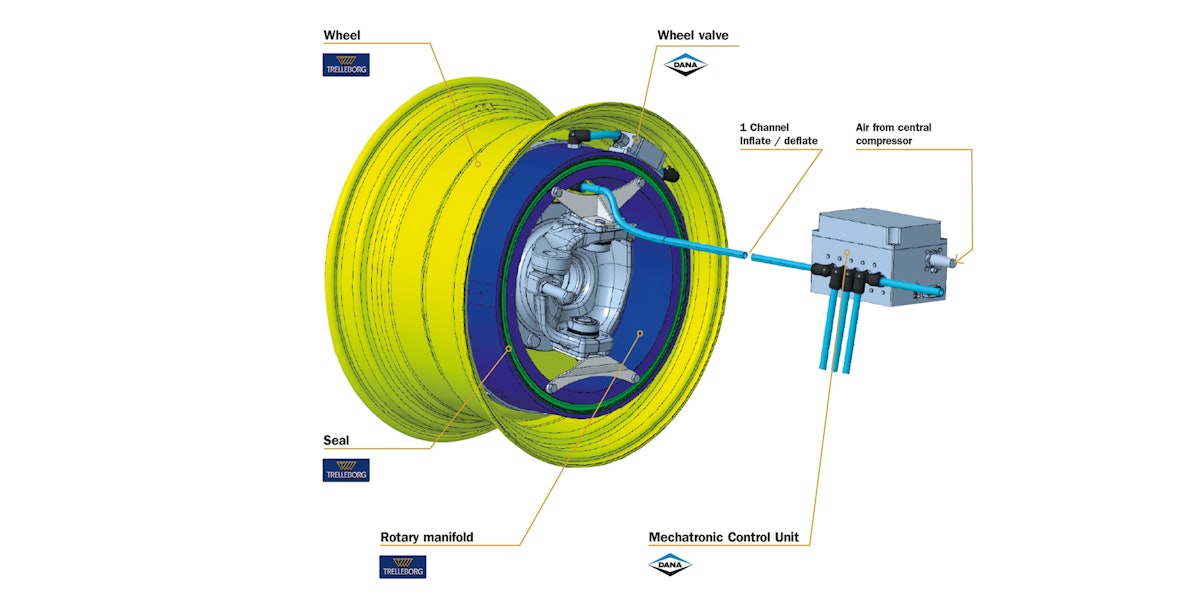

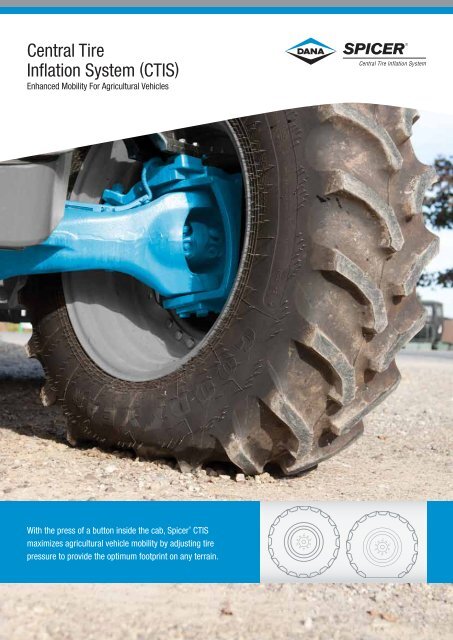

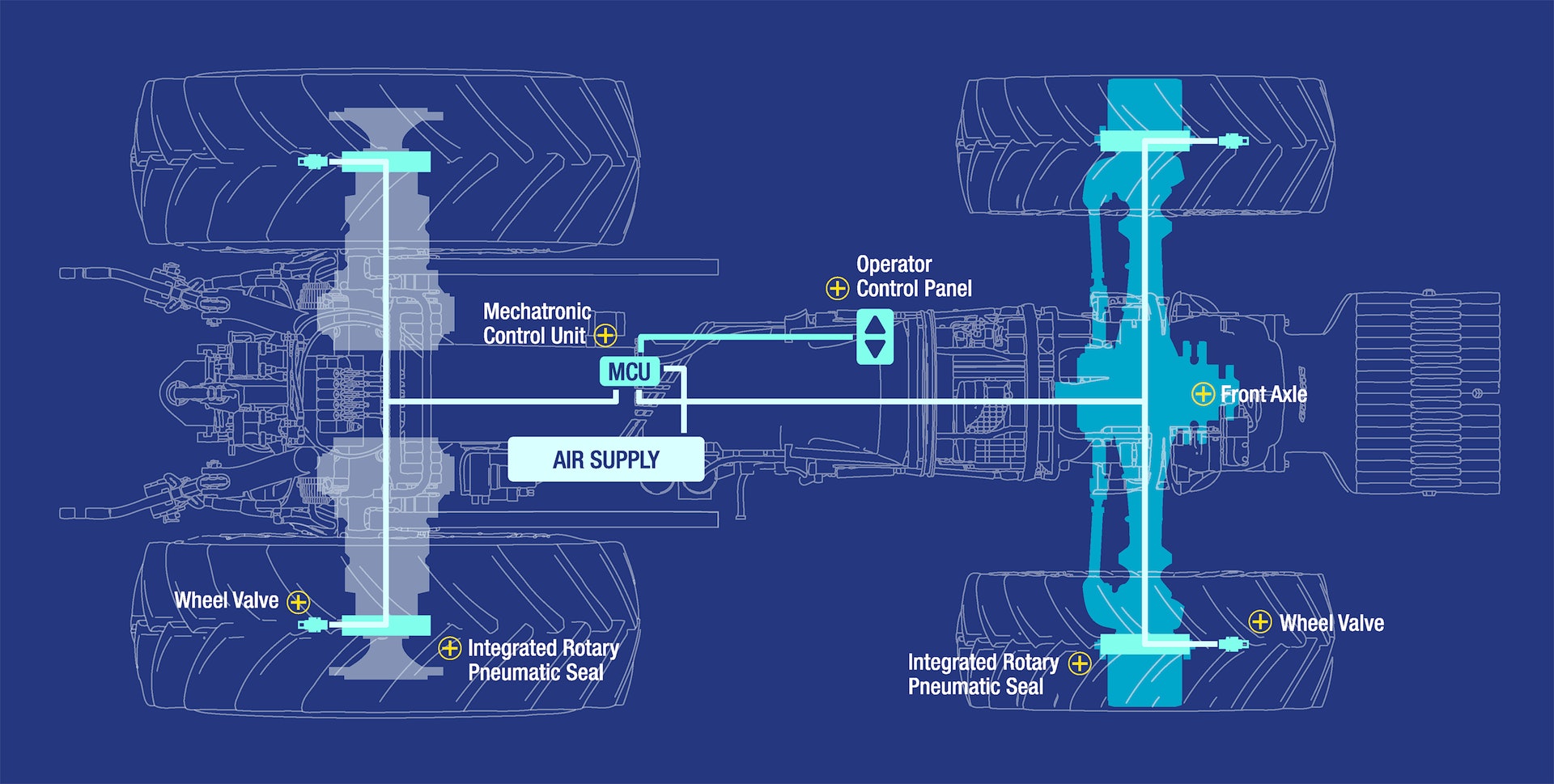

Agricultural CTIS allows farmers to adjust tire pressure from the cab, optimizing performance for various terrains and crop types. This capability is crucial for maintaining soil health and maximizing yield while minimizing wheel spin. The system is particularly beneficial for tractors and other farming equipment that require frequent pressure adjustments throughout the day. Buyers must evaluate the potential productivity gains against ongoing maintenance needs to ensure a worthwhile investment.

Commercial vehicle CTIS systems automatically adjust tire pressure based on load and terrain, significantly reducing tire wear and improving fuel efficiency. These systems are ideal for trucks and construction vehicles that operate in diverse conditions. While they offer substantial operational cost savings, buyers should be aware of the complexity of these systems, which may necessitate specialized training for drivers and maintenance staff.

Off-road CTIS are specifically designed to function effectively at low tire pressures, enhancing traction in rugged environments such as mining sites or off-road adventures. Their robust design ensures durability against harsh conditions. However, their specialized nature may limit their use in urban settings, making it essential for buyers to assess their operational needs carefully.

Heavy-duty CTIS are built for high-load capacities, making them ideal for heavy machinery and freight transport vehicles. These systems extend tire lifespan and improve overall vehicle performance under demanding conditions. Buyers should weigh the benefits of enhanced durability and efficiency against the potential impact of additional system weight on vehicle handling and performance.

| Industria/Settore | Specific Application of ctis tire inflation system | Valore/Beneficio per l'azienda | Considerazioni chiave sull'approvvigionamento per questa applicazione |

|---|---|---|---|

| Agricoltura | Optimizing tire pressure for tractors and harvesters on varied terrain | Improved crop yield, reduced soil compaction, enhanced traction | Compatibility with existing machinery and terrain adaptability |

| Costruzione | Enhancing mobility of heavy machinery on construction sites | Reduced downtime, improved tire life, better fuel efficiency | Durability under heavy loads and harsh conditions |

| Military | Providing operational flexibility for tactical vehicles | Increased safety, enhanced maneuverability in difficult terrain | Reliability, rapid response features, and maintenance support |

| Mining | Adjusting tire pressure for haul trucks in rugged environments | Lower operational costs, enhanced vehicle stability | Robust design for extreme conditions and ease of maintenance |

| Transportation | Maintaining optimal tire pressure for long-haul trucks | Improved fuel efficiency, reduced tire wear, enhanced safety | Integration with telematics systems and real-time monitoring |

In the agricultural sector, the Central Tire Inflation System (CTIS) is crucial for optimizing tire pressure on tractors and harvesters. Farmers often encounter diverse terrains that require frequent adjustments to tire pressure for peak performance. By allowing operators to manage tire pressure from the driver’s seat, CTIS minimizes soil compaction, enhances traction, and ultimately leads to improved crop yields. Buyers in this sector should consider the system’s compatibility with existing equipment and its adaptability to various soil types and crop conditions, particularly in regions like Brazil and Vietnam where agricultural practices vary significantly.

In construction, the CTIS enhances the mobility of heavy machinery, enabling vehicles to navigate both paved and unpaved surfaces efficiently. By automatically adjusting tire pressure based on load and terrain, it reduces downtime caused by tire malfunctions and improves fuel efficiency. This is particularly valuable in construction projects across Africa and South America, where sites may feature challenging conditions. Buyers should prioritize systems that offer durability under heavy loads and can withstand harsh environmental factors, ensuring operational efficiency on-site.

Military applications of the CTIS focus on providing operational flexibility for tactical vehicles. The system’s ability to adjust tire pressure on-the-fly enhances maneuverability in difficult terrains and ensures that vehicles can escape potentially dangerous situations. This feature is vital for military operations in the Middle East, where varied landscapes can pose significant challenges. Buyers in this sector should look for systems with reliability, rapid response features, and comprehensive maintenance support to guarantee mission readiness.

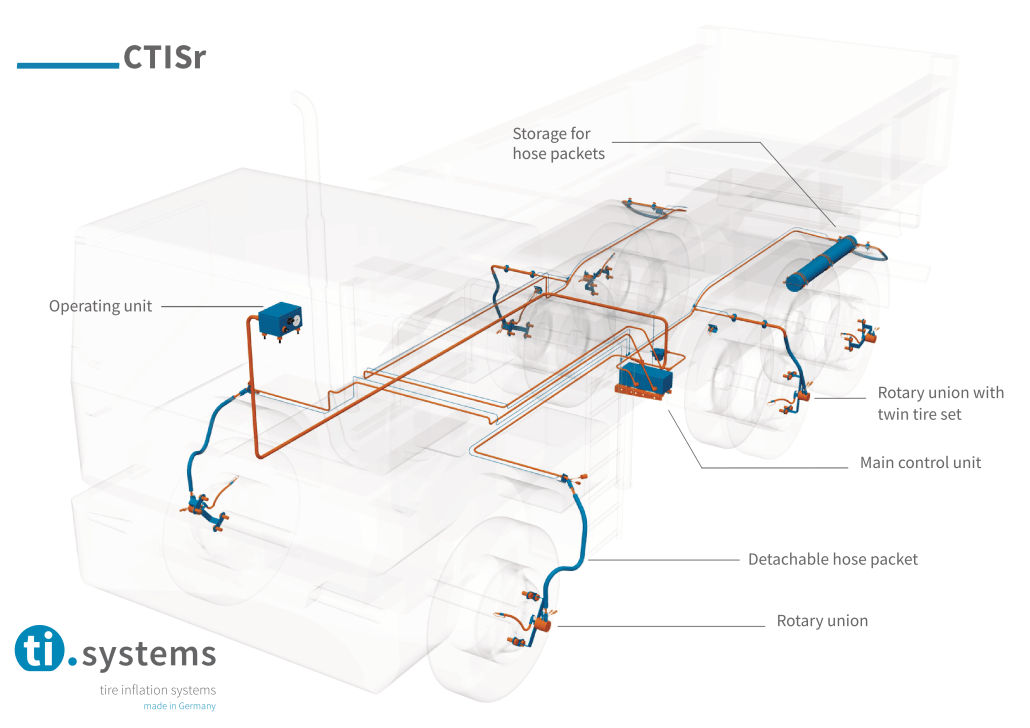

Illustrative image related to ctis tire inflation system

In the mining industry, the CTIS is essential for adjusting tire pressure on haul trucks operating in rugged environments. By optimizing tire pressure, the system enhances vehicle stability and reduces operational costs associated with tire wear and fuel consumption. This is particularly beneficial in mining operations across regions like South America and Africa, where terrain can be unpredictable. Buyers should seek robust designs that can withstand extreme conditions and offer ease of maintenance to ensure continuous operation.

For the transportation sector, maintaining optimal tire pressure is critical for long-haul trucks. The CTIS allows drivers to adjust tire pressure to improve fuel efficiency and reduce tire wear, leading to cost savings over time. This capability is especially important for logistics companies operating across Europe, where regulations on emissions and fuel efficiency are stringent. Buyers should consider systems that integrate with telematics for real-time monitoring, ensuring that adjustments can be made proactively based on route conditions.

Il problema: For B2B buyers managing fleets of heavy vehicles, such as those used in construction or agriculture, navigating harsh terrains can be a significant challenge. These vehicles often face varying ground conditions, including muddy fields or rocky paths. The inability to adjust tire pressure on-the-fly can lead to reduced traction, increased wear on tires, and even vehicle immobilization. Buyers are concerned about the operational downtime that results from tire issues, which can severely impact productivity and profitability.

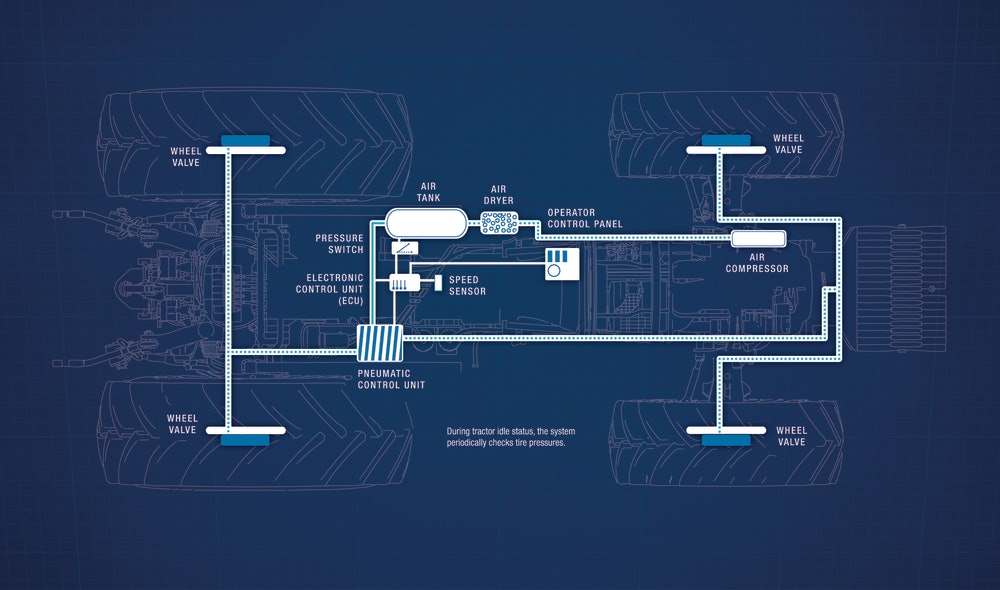

La soluzione: Implementing a Central Tire Inflation System (CTIS) can effectively address these concerns. This system allows for real-time adjustments of tire pressure based on the terrain and vehicle load directly from the driver’s seat. When sourcing a CTIS, it’s essential to partner with reputable manufacturers who provide systems with automatic pressure monitoring and adjustment capabilities. Ensure that the CTIS is integrated with vehicle diagnostics to alert drivers of any potential tire issues before they become critical. Training drivers to utilize the system effectively will further enhance vehicle performance and reduce the risk of getting stuck in challenging conditions, ultimately leading to increased operational efficiency and reduced costs associated with tire maintenance.

Illustrative image related to ctis tire inflation system

Il problema: B2B buyers in industries such as logistics or mining often face escalating tire maintenance costs due to frequent punctures and uneven wear. This not only strains budgets but also leads to unplanned downtime, where vehicles are out of commission for repairs. Buyers need a solution that not only minimizes tire-related issues but also enhances the overall lifecycle of the tires, thereby controlling costs.

La soluzione: The implementation of a CTIS can significantly reduce tire maintenance costs by allowing for optimal tire pressure adjustments based on load and road conditions. When selecting a CTIS, look for systems that feature integrated diagnostics to monitor tire health continuously. These systems can alert operators to potential issues such as leaks or low pressure, enabling timely interventions before problems escalate. Additionally, educate your maintenance team on interpreting these diagnostics to preemptively address tire wear and ensure tires are inflated to the correct pressure according to the manufacturer’s specifications. This proactive approach can prolong tire life and minimize operational interruptions, leading to substantial cost savings over time.

Il problema: Safety is paramount for B2B buyers operating fleets in remote or hazardous environments, such as military or emergency response sectors. Drivers often face unpredictable conditions that can lead to tire blowouts or loss of vehicle control if tire pressures are not adequately managed. The need for a system that enhances both mobility and safety in these situations is critical.

Illustrative image related to ctis tire inflation system

La soluzione: A reliable CTIS can improve driver safety by allowing for quick adjustments to tire pressure based on immediate environmental conditions. When considering a CTIS for your fleet, prioritize systems that offer a “limp home” feature, which enables vehicles to maintain mobility even with significant tire pressure loss. This feature can be particularly vital in emergency situations where every second counts. Ensure that the system you choose includes comprehensive training for your drivers on how to use the CTIS effectively, including how to respond to alerts and warnings. Additionally, routine maintenance checks should be scheduled to ensure the CTIS is functioning correctly. By investing in a quality CTIS and training, you not only enhance driver safety but also ensure that your fleet can operate effectively in diverse and challenging environments.

When selecting materials for a Central Tire Inflation System (CTIS), it is essential to consider properties that directly influence performance, durability, and cost-effectiveness. Here, we analyze four common materials used in CTIS components: rubber, aluminum, stainless steel, and composite materials.

Rubber is widely utilized in tire components, including valves and seals within the CTIS. Its key properties include excellent flexibility, good temperature resistance (typically up to 100°C), and inherent corrosion resistance.

Pro: Rubber offers high elasticity, making it suitable for dynamic applications where components must withstand repeated flexing. It is relatively inexpensive and easy to manufacture, which is advantageous for large-scale production.

Contro: However, rubber can degrade under extreme temperatures or exposure to certain chemicals, limiting its lifespan in harsh environments. Additionally, it may require frequent replacement, increasing long-term costs.

Impatto sull'applicazione: Rubber is compatible with air and various gases, making it suitable for standard tire inflation. However, international buyers should ensure compliance with local standards such as ASTM for rubber quality.

Aluminum is often used for structural components of CTIS due to its lightweight nature and high strength-to-weight ratio. It can withstand temperatures up to 150°C and offers good corrosion resistance, especially when anodized.

Pro: The lightweight property of aluminum enhances fuel efficiency in vehicles, making it a preferred choice for commercial applications. It is also recyclable, aligning with sustainability goals.

Contro: On the downside, aluminum can be more expensive than rubber and may require complex manufacturing processes, such as machining or extrusion, which can increase production costs.

Impatto sull'applicazione: Aluminum is suitable for components exposed to moisture and varying temperatures. International buyers should consider compliance with standards like DIN for aluminum alloys.

Stainless steel is favored for high-stress components within CTIS, such as valves and fittings, due to its exceptional strength and corrosion resistance. It can handle extreme temperatures and pressures, making it ideal for demanding applications.

Illustrative image related to ctis tire inflation system

Pro: The durability of stainless steel translates to a longer lifespan and reduced maintenance costs. Its resistance to rust and corrosion makes it suitable for diverse environments, including humid or saline conditions.

Contro: The primary drawback is its higher cost compared to rubber and aluminum. Additionally, stainless steel may be heavier, potentially affecting fuel efficiency.

Impatto sull'applicazione: Stainless steel’s compatibility with various media makes it a reliable choice for tire inflation systems. Buyers from regions with strict regulations should ensure compliance with JIS standards for stainless steel.

Composite materials, often a blend of polymers and fibers, are increasingly used in CTIS for their lightweight and high-strength characteristics. They can withstand a range of temperatures and pressures, depending on their specific formulation.

Pro: Composites offer excellent resistance to chemicals and environmental stress, which enhances longevity. They can be molded into complex shapes, allowing for innovative designs.

Contro: However, composites can be more expensive to produce and may require specialized manufacturing techniques. Their performance can also vary significantly based on the specific materials used.

Impatto sull'applicazione: Composites are suitable for components that face varying environmental conditions. International buyers should verify compliance with relevant standards and consider the specific environmental conditions of their operational regions.

| Materiale | Typical Use Case for ctis tire inflation system | Vantaggio chiave | Svantaggi/limitazioni principali | Costo relativo (Basso/Medio/Alto) |

|---|---|---|---|---|

| Gomma | Seals and valves | High elasticity and flexibility | Degrades under extreme conditions | Basso |

| Alluminio | Componenti strutturali | Lightweight and recyclable | Maggiore complessità di produzione | Med |

| Acciaio inox | High-stress valves and fittings | Exceptional strength and durability | Higher cost and weight | Alto |

| Composito | Innovative component designs | Excellent chemical resistance | Higher production costs | Med |

This strategic material selection guide provides valuable insights for B2B buyers looking to optimize their CTIS components, ensuring performance, compliance, and cost-effectiveness across various international markets.

The manufacturing process of a Central Tire Inflation System (CTIS) involves several critical stages, each designed to ensure the system’s reliability and performance. Understanding these stages can help international B2B buyers assess the quality and efficiency of potential suppliers.

Illustrative image related to ctis tire inflation system

The first stage in manufacturing a CTIS is material preparation. High-quality raw materials, such as durable plastics, metals, and rubber, are selected based on their performance characteristics. Suppliers often provide material certifications to ensure compliance with industry standards.

Materials undergo various treatments, such as heat treatment for metals and surface treatments for plastics, to enhance durability and resistance to environmental factors. Buyers should look for suppliers that maintain robust sourcing practices to ensure the consistency and quality of materials used.

In the forming stage, various techniques are used to create the components of the CTIS. Common methods include:

Illustrative image related to ctis tire inflation system

Each technique has specific advantages and is chosen based on the component’s functional requirements. B2B buyers should inquire about the forming techniques employed by suppliers to ensure they meet the necessary quality standards.

The assembly stage involves integrating all manufactured components into a fully functional CTIS. This process typically includes:

B2B buyers should assess suppliers’ assembly processes, including workforce training and the use of automated systems, to ensure high-quality assembly practices.

The finishing stage is essential for enhancing the overall quality and appearance of the CTIS. This stage includes:

Buyers should inquire about the finishing processes employed by suppliers to ensure that the products are not only functional but also resilient against environmental challenges.

Quality assurance (QA) is integral to the manufacturing of CTIS, ensuring that the systems meet international and industry-specific standards. For B2B buyers, understanding these QA measures is crucial for selecting reliable suppliers.

Suppliers of CTIS should comply with internationally recognized standards such as ISO 9001, which outlines requirements for quality management systems. Compliance with ISO standards indicates that a supplier has established processes for consistent quality assurance.

In addition to ISO certifications, industry-specific certifications such as CE (European Conformity) and API (American Petroleum Institute) may be relevant, depending on the application of the CTIS. Buyers should verify these certifications during supplier assessments.

Illustrative image related to ctis tire inflation system

Quality control (QC) checkpoints are established at various stages of the manufacturing process to ensure that each component meets quality standards. Common checkpoints include:

B2B buyers should request documentation of these QC processes to understand how suppliers maintain quality throughout production.

Various testing methods are employed to evaluate the performance and reliability of CTIS, including:

Buyers should inquire about the testing protocols used by suppliers, as robust testing is a key indicator of product reliability.

To ensure that a potential supplier adheres to high-quality standards, B2B buyers can undertake several verification steps:

For international B2B buyers, understanding the nuances of quality control is essential, particularly in regions like Africa, South America, the Middle East, and Europe. Differences in regulations, standards, and practices can impact procurement decisions.

Buyers should familiarize themselves with local regulations regarding CTIS and ensure that their suppliers comply with both international and regional standards. Additionally, language barriers and logistical challenges may necessitate clear communication and documentation to ensure that quality expectations are met.

By thoroughly evaluating the manufacturing processes and quality assurance measures of potential suppliers, international B2B buyers can make informed decisions that align with their operational needs and quality expectations.

Illustrative image related to ctis tire inflation system

To assist B2B buyers in procuring a Central Tire Inflation System (CTIS), this guide provides a clear, step-by-step checklist aimed at ensuring a successful and informed sourcing process. With the right system, organizations can enhance vehicle mobility, reduce operational costs, and improve tire longevity.

Understanding your specific requirements is critical for selecting the right CTIS. Determine factors such as vehicle type, load capacity, and the terrains your vehicles will navigate. Knowing these parameters will help you identify a system that meets your operational needs.

Explore the various CTIS products available on the market. Each system may offer different features such as automated pressure adjustments, diagnostic alerts, and emergency modes. Familiarize yourself with the brands and models that align with your specifications.

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. This will help you gauge their reliability and track record in delivering quality products.

Illustrative image related to ctis tire inflation system

Ensure that your potential suppliers comply with international standards and certifications relevant to CTIS products. This not only ensures quality but also mitigates risks associated with procurement.

Once you have narrowed down your options, request detailed quotations from the shortlisted suppliers. Analyze these quotes not just for price, but for the value offered, including warranty terms, support services, and delivery timelines.

Before making a full-scale purchase, consider implementing a trial or pilot program with the selected CTIS. This will allow you to assess the system’s performance in real-world conditions and ensure it meets your expectations.

Once satisfied with the trial, finalize your purchase with the chosen supplier. Ensure that all terms, including payment schedules, delivery dates, and installation support, are clearly defined in the contract.

By following this checklist, B2B buyers can ensure a systematic approach to sourcing a Central Tire Inflation System that meets their operational needs while maximizing efficiency and cost-effectiveness.

Illustrative image related to ctis tire inflation system

When sourcing Central Tire Inflation Systems (CTIS), understanding the cost structure is crucial for buyers, especially in diverse markets such as Africa, South America, the Middle East, and Europe. The primary cost components include:

I materiali: The quality of materials used in CTIS significantly impacts costs. Key materials include high-grade metals for valves and sensors, durable rubber for hoses, and specialized electronics for control units. Sourcing high-quality materials can increase the initial costs but often results in lower maintenance expenses and longer system lifespans.

Lavoro: Labor costs can vary depending on the region and the complexity of the assembly process. Skilled technicians are required to ensure that the CTIS is manufactured to the highest standards. Regions with lower labor costs may provide more competitive pricing, but it is essential to balance this with quality considerations.

Spese generali di produzione: This includes costs related to factory operations, utilities, and equipment depreciation. Efficient manufacturing processes can reduce overhead, allowing suppliers to offer more competitive pricing.

Utensili: Custom tooling for specific CTIS configurations can add to the cost. If a buyer requires unique specifications, they should anticipate higher tooling costs that may not be present in standard configurations.

Controllo qualità (CQ): Investing in robust QC processes ensures that CTIS units meet safety and performance standards. This is particularly important in sectors such as military and agriculture, where reliability is non-negotiable. High QC standards may increase upfront costs but can lead to lower total costs over time due to fewer failures and replacements.

Logistica: Shipping costs can vary widely based on the origin of the CTIS, destination, and chosen transportation methods. Buyers should consider the total logistics costs when evaluating supplier quotes, particularly for international shipments.

Margine: Suppliers typically mark up prices to cover their costs and ensure profitability. Understanding the margin structure can help buyers gauge fair pricing and identify areas for negotiation.

Several factors influence the pricing of CTIS systems beyond the basic cost components:

Volume and Minimum Order Quantities (MOQ): Larger orders often benefit from bulk pricing discounts. Buyers should assess their needs and consider collaborating with other companies to meet MOQs for better pricing.

Specifiche e personalizzazione: Custom features or specifications can significantly affect pricing. Buyers should clearly define their requirements to avoid unexpected costs.

Qualità dei materiali e certificazioni: The presence of industry certifications (e.g., ISO) can enhance the perceived value of the CTIS and justify higher prices. Buyers should verify the quality standards of suppliers to ensure they align with their operational needs.

Fattori di fornitura: The supplier’s reputation, experience, and reliability can also impact pricing. Established suppliers may charge a premium for their proven products and services.

Incoterms: The choice of Incoterms (International Commercial Terms) affects the overall price, including who bears shipping costs, insurance, and risk during transit. Understanding these terms is vital for international buyers to accurately assess total costs.

To achieve cost efficiency when sourcing CTIS, buyers can employ several strategies:

Engage Multiple Suppliers: Request quotes from various suppliers to create a competitive environment. This can lead to better pricing and terms.

Sfruttare il costo totale di proprietà (TCO): Focus on the long-term savings associated with lower maintenance costs, improved fuel efficiency, and reduced downtime when discussing pricing with suppliers. Emphasizing TCO can justify higher upfront costs.

Negotiate Payment Terms: Flexible payment terms can ease cash flow concerns. Buyers should negotiate terms that align with their financial capabilities.

Consider Total Contract Value: Rather than focusing solely on unit prices, evaluate the overall value of the contract, including warranties, service agreements, and support.

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should be aware of certain pricing nuances:

Currency Fluctuations: Exchange rates can significantly impact costs. Buyers should consider securing fixed pricing or engaging in currency hedging.

Import Duties and Taxes: Import tariffs can add to the overall cost of CTIS systems. Understanding local regulations and potential exemptions can lead to savings.

Considerazioni culturali: Negotiation styles can vary by region. Building relationships and understanding local business practices can enhance negotiation outcomes.

The pricing analysis provided is indicative and can vary based on market conditions, supplier negotiations, and specific buyer requirements. Always conduct thorough research and consult with industry experts to obtain the most accurate and relevant pricing information.

When evaluating tire inflation solutions, it is crucial for B2B buyers to consider various alternatives alongside the Central Tire Inflation System (CTIS). Each option presents unique advantages and limitations that can impact operational efficiency, cost-effectiveness, and suitability for specific applications. This analysis will compare the CTIS with two viable alternatives: Automatic Tire Inflation Systems (ATIS) and Manual Tire Inflation Methods.

| Aspetto di confronto | Ctis Tire Inflation System | Automatic Tire Inflation Systems (ATIS) | Manual Tire Inflation Methods |

|---|---|---|---|

| Prestazioni | Optimizes tire pressure on-the-go for various terrains and loads | Provides automatic pressure adjustments but may lack real-time adaptability | Dependent on operator skill and timing; less efficient |

| Costo | Higher initial investment; long-term savings through reduced tire wear and fuel consumption | Moderate to high investment; potential savings on tire life and downtime | Low initial cost; higher long-term costs due to inefficiencies |

| Facilità di implementazione | Requires professional installation; integration with vehicle systems needed | Generally easier to install than CTIS; can be fitted to various vehicles | Simple to implement; requires manual labor |

| Manutenzione | Requires regular checks of the system and components; robust diagnostics available | Moderate maintenance; reliant on electronic components | Minimal maintenance; dependent on manual checks |

| Il miglior caso d'uso | Ideal for heavy-duty, off-road, and military vehicles requiring flexibility and reliability | Suitable for commercial fleets and vehicles operating in predictable environments | Best for low-usage vehicles or fleets with limited budgets |

Automatic Tire Inflation Systems (ATIS)

ATIS offers automated tire pressure adjustments, similar to CTIS, but often lacks the real-time adaptability of the latter. These systems are designed for commercial fleets, providing a balance between convenience and efficiency. While they may require a moderate to high initial investment, ATIS can lead to savings in tire life and operational downtime. However, their reliance on electronic components can introduce additional maintenance challenges. ATIS is best suited for predictable environments where consistent tire pressure is essential.

Manual Tire Inflation Methods

Manual tire inflation is the most straightforward approach, requiring minimal investment and maintenance. Operators manually adjust tire pressures, which can be effective for low-usage vehicles. However, this method is highly dependent on the operator’s skill and timing, leading to potential inefficiencies. Manual systems can result in higher long-term costs due to increased tire wear and fuel consumption, making it less viable for fleets that operate under diverse conditions. This method is best for organizations with limited budgets or infrequent tire pressure adjustments.

When selecting a tire inflation solution, B2B buyers should assess their operational needs, vehicle types, and budget constraints. The CTIS stands out for heavy-duty applications requiring flexibility and reliability across various terrains, while ATIS provides a balance of automation and cost-effectiveness for commercial fleets. On the other hand, manual methods may appeal to businesses seeking lower initial costs but can lead to greater long-term inefficiencies. Ultimately, the right choice will depend on the specific operational requirements and financial considerations of the buyer’s organization.

Understanding the essential technical properties of a Central Tire Inflation System (CTIS) is crucial for B2B buyers who are looking to enhance vehicle performance, improve safety, and reduce operational costs. Here are several critical specifications to consider:

Illustrative image related to ctis tire inflation system

Grado del materiale

The materials used in CTIS components must withstand harsh environmental conditions and high wear rates. Common materials include high-strength steel and specialized polymers for valves and seals. This is important in ensuring the longevity and reliability of the system, which directly impacts maintenance costs and vehicle downtime.

Pressure Range

CTIS systems typically operate within a specific pressure range, often between 20 to 100 psi. This range allows for optimal tire pressure adjustments based on terrain and load. B2B buyers should assess how well a system can accommodate varying pressure levels for different applications, as this flexibility enhances traction and fuel efficiency.

Response Time

The response time of a CTIS in adjusting tire pressure is critical for maintaining vehicle stability and performance. A system that can adjust pressures within seconds is ideal for off-road and military applications where quick reactions to changing conditions are essential. Buyers should inquire about the average response time to ensure it meets operational needs.

Diagnostic Capabilities

Modern CTIS units are equipped with integrated diagnostics that monitor system performance and alert drivers to potential tire issues. This feature is crucial for proactive maintenance, helping to avoid costly repairs and downtime. Buyers should look for systems that provide comprehensive diagnostic feedback and ease of integration with existing vehicle monitoring systems.

Weight and Compactness

The weight of the CTIS system can impact vehicle load capacity and fuel efficiency. A lighter, more compact system is often preferred, especially for military and commercial vehicles that require maximum mobility. B2B buyers should evaluate the weight specifications against performance requirements to ensure optimal vehicle operation.

Sealing Mechanisms

Effective sealing mechanisms, such as sealed wheel valves, are essential for preventing air leaks and contamination. These mechanisms must be robust enough to operate under extreme conditions without compromising system integrity. Buyers should prioritize systems with advanced sealing technologies to enhance reliability and reduce maintenance needs.

Familiarity with industry terminology can facilitate smoother negotiations and transactions for B2B buyers. Here are several common terms related to CTIS systems:

OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts and equipment that may be marketed by another manufacturer. When considering CTIS systems, understanding whether a product is OEM can assure buyers of its quality and compatibility with existing vehicle systems.

MOQ (quantità minima d'ordine)

MOQ is the smallest quantity of a product that a supplier is willing to sell. For CTIS systems, knowing the MOQ can help buyers plan inventory and manage budgets effectively, especially when considering large-scale deployments.

RFQ (Richiesta di offerta)

An RFQ is a standard business process where a buyer requests price quotes from suppliers for specific products or services. In the context of CTIS systems, submitting an RFQ allows buyers to compare pricing, terms, and specifications, ensuring they make informed purchasing decisions.

Incoterms (Termini commerciali internazionali)

Incoterms are a series of predefined commercial terms published by the International Chamber of Commerce, which define the responsibilities of buyers and sellers in international transactions. Understanding these terms is essential for B2B buyers to clarify delivery obligations and risk management when sourcing CTIS systems globally.

Tempi di consegna

Lead time refers to the amount of time it takes from placing an order to receiving the product. In the context of CTIS systems, shorter lead times can be crucial for companies needing quick replacements or upgrades. Buyers should consider lead times when planning their procurement strategies.

Periodo di garanzia

The warranty period is the duration during which a product is guaranteed against defects and failures. A robust warranty can provide peace of mind and indicates the manufacturer’s confidence in their CTIS system’s reliability. Buyers should evaluate warranty offerings as part of their purchasing decision to ensure long-term support.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions that enhance operational efficiency and reduce costs in their tire management strategies.

The Central Tire Inflation System (CTIS) sector is witnessing robust growth, driven by increasing demand for enhanced vehicle performance and operational efficiency across various industries, including agriculture, construction, and military applications. Global drivers such as rising fuel costs, heightened awareness of tire maintenance, and the need for improved safety features are propelling this trend. In regions like Africa and South America, where off-road and agricultural vehicles dominate, CTIS technology is gaining traction for its ability to adapt tire pressure to varying terrain conditions, ultimately reducing downtime and enhancing productivity.

Emerging B2B technologies, such as IoT-enabled sensors and advanced diagnostic systems, are transforming the CTIS landscape. These technologies allow for real-time monitoring and adjustments, improving responsiveness to tire issues. Furthermore, the integration of automated systems that communicate with vehicle control units is streamlining operations for fleet managers, particularly in sectors where vehicle uptime is critical. International buyers are increasingly focused on sourcing CTIS solutions that offer these advanced features, making it essential for suppliers to stay ahead of technological advancements.

Market dynamics are also influenced by geopolitical factors, especially in the Middle East and Europe, where defense contracts drive the demand for military-grade CTIS solutions. As these regions emphasize reliability and performance in defense applications, manufacturers are adapting their offerings to meet these rigorous standards. This trend underscores the necessity for B2B buyers to evaluate suppliers not just on product features but also on their ability to comply with stringent quality and performance benchmarks.

In an era where sustainability is paramount, the CTIS sector is increasingly prioritizing environmentally friendly practices and ethical sourcing. The environmental impact of tire wear and maintenance is significant, contributing to pollution and resource depletion. As a result, companies are seeking CTIS solutions that not only enhance tire longevity and performance but also minimize ecological footprints.

Ethical supply chains are becoming essential for B2B buyers who wish to align with global sustainability goals. Suppliers are increasingly adopting ‘green’ certifications and utilizing recyclable materials in their CTIS products. For instance, using eco-friendly components in the manufacturing process and ensuring that suppliers adhere to ethical labor practices are becoming standard expectations.

Moreover, international buyers are encouraged to look for CTIS solutions that incorporate energy-efficient technologies, which not only reduce operational costs but also lower greenhouse gas emissions. Investing in sustainable CTIS systems can significantly enhance a company’s reputation and appeal to environmentally conscious consumers and partners. By prioritizing sustainability, B2B buyers can drive long-term benefits while contributing positively to the environment.

The Central Tire Inflation System has its roots in military applications dating back to the 1980s, where it was developed to enhance the mobility and operational effectiveness of military vehicles in challenging terrains. Over the years, the technology has evolved significantly, transitioning from purely military uses to various commercial applications, including agriculture and construction.

Today, the CTIS is recognized for its ability to optimize tire performance by allowing real-time adjustments based on terrain and load conditions. This evolution has been driven by advancements in technology, such as IoT integration, which enhances the system’s efficiency and reliability. As the sector continues to mature, the focus on performance, sustainability, and technological innovation remains pivotal for both manufacturers and buyers in the B2B landscape.

In conclusion, the CTIS market presents significant opportunities for international buyers. By understanding current trends, prioritizing sustainability, and recognizing the historical context of the technology, B2B buyers can make informed decisions that enhance their operational capabilities and align with global market demands.

Illustrative image related to ctis tire inflation system

How do I solve issues with tire pressure monitoring in my fleet?

To effectively address tire pressure monitoring issues, consider implementing a Central Tire Inflation System (CTIS). This system allows for real-time tire pressure adjustments based on vehicle load and terrain, enhancing safety and efficiency. Regular diagnostics can alert drivers to potential tire problems like leaks or punctures. Additionally, training your drivers on the system’s functionalities ensures they can respond promptly to alerts, significantly reducing downtime and maintenance costs associated with tire issues.

What is the best CTIS solution for off-road vehicles?

The best CTIS solution for off-road vehicles is one that offers robust performance in diverse terrains. Look for systems that feature automatic pressure adjustments, integrated diagnostics, and user-friendly interfaces for in-cab operation. The Spicer® CTIS™, for example, provides enhanced mobility and safety by allowing drivers to adjust tire pressure on the go, ensuring optimal traction and stability on rugged surfaces. It’s crucial to evaluate systems based on their reliability, ease of use, and support for your specific vehicle types.

What should I consider when sourcing CTIS suppliers internationally?

When sourcing CTIS suppliers internationally, evaluate their manufacturing capabilities, certifications, and experience in your industry. Check for compliance with international quality standards and inquire about their supply chain logistics. Additionally, assess their customer service and technical support, as these are vital for ongoing maintenance and troubleshooting. Reading reviews or case studies from other buyers in your region can provide insights into the supplier’s reliability and product performance.

What are the minimum order quantities (MOQ) for CTIS products?

Minimum order quantities for CTIS products can vary widely based on the supplier and the specific components required. Typically, suppliers may set MOQs to cover production costs and ensure efficiency. It’s advisable to discuss your purchasing needs directly with potential suppliers to negotiate MOQs that align with your operational requirements. Some manufacturers may offer flexibility for first-time buyers or bulk orders, so inquire about options that suit your fleet size and budget.

What payment terms should I expect when purchasing CTIS systems?

Payment terms for CTIS systems can differ based on the supplier’s policies and your negotiation. Common terms include upfront payments, deposits, or payment upon delivery. Some suppliers may offer financing options or credit terms for established business relationships. Ensure that you clarify payment methods accepted, such as wire transfers, letters of credit, or credit card payments, and confirm any additional fees associated with international transactions to avoid surprises.

How does quality assurance (QA) work for CTIS products?

Quality assurance for CTIS products typically involves rigorous testing and validation processes to ensure reliability and performance. Suppliers should provide documentation demonstrating compliance with international quality standards, such as ISO certifications. Additionally, inquire about their QA procedures, including material inspections, product testing, and post-production evaluations. A reputable supplier will be transparent about their QA processes, ensuring that the products meet your specifications and operational requirements.

What logistics considerations should I keep in mind when importing CTIS systems?

When importing CTIS systems, logistics considerations include shipping methods, customs clearance, and delivery timelines. Choose a reliable freight forwarder experienced in handling automotive parts to navigate international shipping regulations effectively. Be aware of potential tariffs and duties that may apply to your shipment, and ensure all documentation is accurate to prevent delays. Planning for logistics well in advance can help avoid disruptions in your supply chain and ensure timely delivery of the systems.

Can CTIS systems be customized for specific vehicle applications?

Yes, many suppliers offer customization options for CTIS systems to cater to specific vehicle applications and operational needs. Customization may include modifying the system’s pressure settings, integrating advanced monitoring features, or adapting components to fit unique vehicle specifications. When discussing customization with suppliers, clearly outline your requirements and seek examples of past projects to gauge their capability. Collaborating with a supplier experienced in custom solutions can lead to a system that maximizes performance and efficiency for your fleet.

Dominio: spicerparts.com

Registrato: 2004 (21 anni)

Introduzione: Central Tire Inflation System (CTIS™) – Axle

Part Numbers:

– 673215: Valve – Tank

– 676532: Wheel Valve

– 599827: Quick Release Valve

– 673217: Wheel Valve Assy

Caratteristiche principali:

– Automatic emergency mode to handle leaks

– Adjusts tire pressure based on vehicle load for increased traction, longer tire life, and reduced fuel consumption

– Push-button operation for optimum pressure selection

– Integr…

Dominio: dana.com

Registered: 1993 (32 years)

Introduzione: Central Tire Inflation System (CTIS) enhances mobility for government defense and vocational vehicles. Key features include: reliability and performance for military applications, improved all-wheel drive performance, maximum mobility, full diagnostics, a ‘limp home’ feature for disabled vehicles, complete mobility optimization, remote wheel-end venting, sealed wheel valves to prevent environmenta…

Dominio: ftl.technology

Introduzione: Central Tire Inflation System (CTIS) allows precise tire pressure adjustment on the move, enhancing vehicle mobility and performance in demanding conditions. Key features include:

– Adjusts tire pressure to improve traction, eliminate tire leaks, and reduce soil compaction.

– Provides remote operation from within the vehicle cab.

– Continuously checks and maintains optimum tire pressure.

– Red…

Dominio: business.michelinman.com

Registrato: 2001 (24 anni)

Introduzione: Central Tire Inflation System (CTIS) for agricultural equipment allows on-demand adjustment of tire pressure from the driver’s seat. Key features include:

– Utilizes sensors, valves, and a control unit to optimize tire pressure based on terrain.

– Increases productivity by up to 4% due to improved traction.

– Reduces fuel costs by up to 10% in field use.

– Decreases soil pressure by up to 33% …

Dominio: fst.com

Registrato: 1995 (30 anni)

Introduzione: Freudenberg Sealing Technologies has developed a new double-lipped sealing component for Central Tire Inflation Systems (CTIS) aimed at enhancing safety and efficiency in heavy-duty vehicles. This innovative seal reduces friction and power loss, improving the functionality and lifespan of CTIS. It allows for more sophisticated, automatic tire pressure systems that can be controlled with a single b…

Dominio: raytech-group.com

Registrato: 2010 (15 anni)

Introduzione: Raytech’s Central Tire Inflation System (CTIS) technology maximizes vehicle mobility by adjusting tire pressure to any terrain. Key features include:

– Adjustable tire pressure based on vehicle load, terrain type, and usage.

– Control of tire pressure regardless of vehicle load and terrain (mud, sand, snow, swamp, etc.).

– Increased maneuverability, tire preservation, and reduced fuel consumption….

Incorporating a Central Tire Inflation System (CTIS) into your fleet can lead to significant operational advantages. By enabling precise tire pressure adjustments on the go, CTIS enhances vehicle mobility, reduces fuel consumption, and extends tire life—all critical factors for businesses in diverse industries. This technology not only minimizes downtime associated with tire malfunctions but also helps maintain optimal traction on various terrains, making it ideal for operations in challenging environments typical in regions like Africa and South America.

Strategic sourcing of CTIS systems ensures that you partner with reliable suppliers who offer advanced technology and exceptional after-sales support. By evaluating multiple vendors, you can negotiate better terms, ensuring that your investment aligns with your operational needs and budget constraints. This proactive approach empowers organizations to achieve cost efficiencies while enhancing their fleet’s performance.

As the demand for efficient and reliable fleet management solutions grows, the CTIS market is poised for innovation. International buyers, particularly in emerging markets such as Brazil, Vietnam, and the Middle East, should consider integrating CTIS technology to future-proof their operations. Engage with industry experts and suppliers today to explore how CTIS can transform your fleet’s performance, ensuring you stay competitive in a rapidly evolving landscape.

Le informazioni fornite in questa guida, compresi i contenuti relativi ai produttori, alle specifiche tecniche e all'analisi di mercato, hanno uno scopo puramente informativo ed educativo. Non costituiscono una consulenza professionale in materia di acquisti, né una consulenza finanziaria o legale.

Pur avendo compiuto ogni sforzo per garantire l'accuratezza e la tempestività delle informazioni, non siamo responsabili di eventuali errori, omissioni o informazioni non aggiornate. Le condizioni di mercato, i dettagli aziendali e gli standard tecnici sono soggetti a modifiche.

Illustrative image related to ctis tire inflation system

Gli acquirenti B2B devono condurre una due diligence indipendente e approfondita. prima di prendere qualsiasi decisione di acquisto. È necessario contattare direttamente i fornitori, verificare le certificazioni, richiedere campioni e chiedere una consulenza professionale. Il rischio di affidarsi alle informazioni contenute in questa guida è esclusivamente a carico del lettore.