In the competitive landscape of logistics and transportation, ensuring that your fleet’s tires are consistently inflated is crucial for operational efficiency and safety. Sourcing the best tire inflator for truck tires can present a significant challenge, particularly for international B2B buyers navigating varying product standards and supplier capabilities across regions. This guide aims to demystify the process by providing a comprehensive overview of the top tire inflators suitable for trucks, including their types, applications, and essential features to consider.

As you delve into this resource, you will find insights on the most reliable inflators tested for performance, speed, and accuracy, tailored specifically to meet the demands of heavy-duty vehicles. We will also explore supplier vetting processes, helping you identify reputable manufacturers and distributors that align with your business needs. Additionally, this guide will address cost considerations and value propositions, enabling you to make informed purchasing decisions.

Whether you are operating in Africa, South America, the Middle East, or Europe, our focus on regional requirements and market dynamics empowers you to select the right tire inflator that enhances your operational readiness. By equipping yourself with the knowledge from this guide, you can streamline your procurement process, ensuring that your fleet remains roadworthy and efficient, regardless of geographic challenges.

| Nome del tipo | Caratteristiche distintive principali | Applicazioni primarie B2B | Brevi pro e contro per gli acquirenti |

|---|---|---|---|

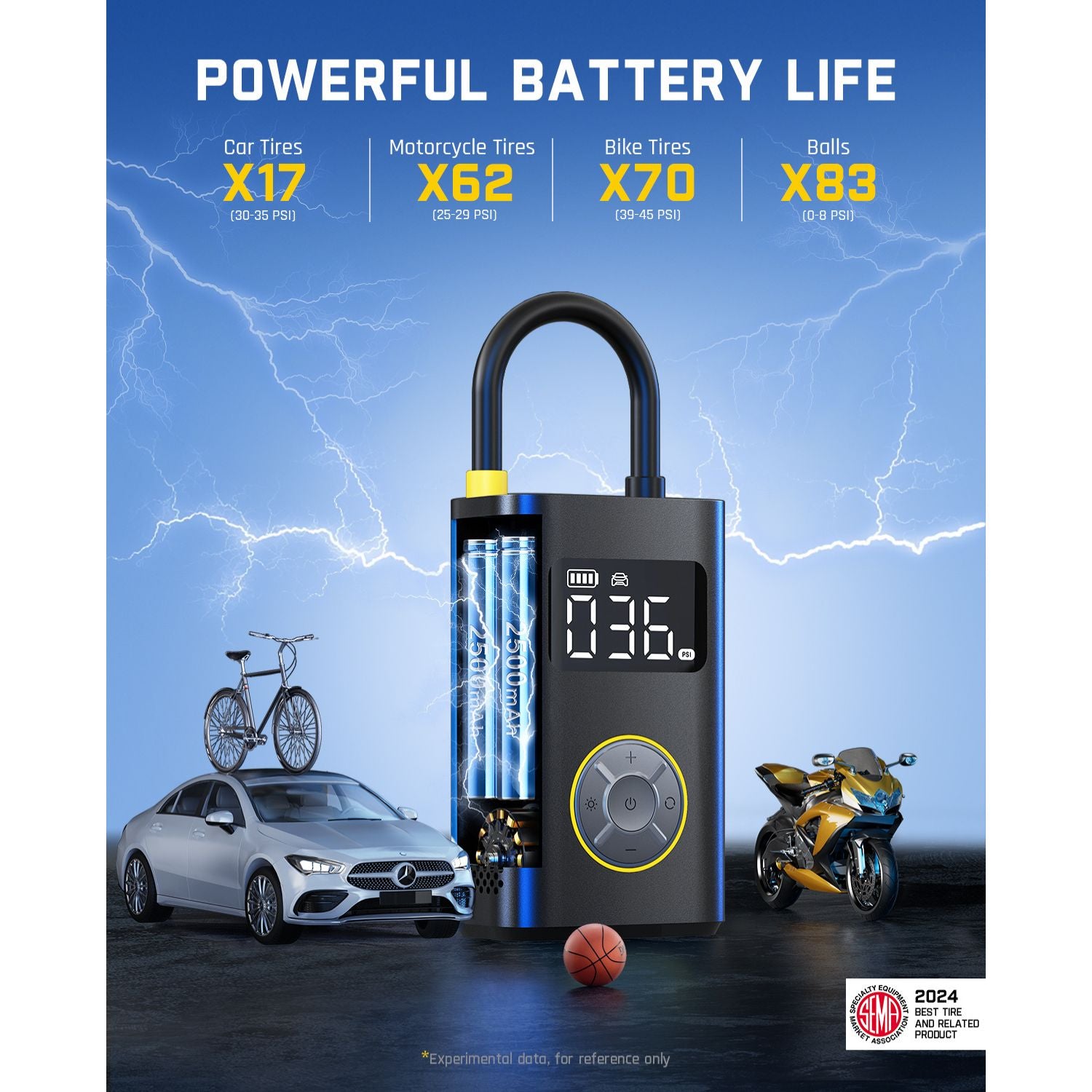

| Gonfiatori per pneumatici a batteria | Rechargeable battery, portable design | Fleet maintenance, roadside assistance | Pro: Highly portable, quick to use. Contro: Battery life may limit extensive use. |

| 12V Plug-In Tire Inflators | Powered via vehicle’s 12V outlet, often compact | Automotive service centers, rental companies | Pro: Convenient for vehicles, often compact. Contro: Limited reach without extension cables. |

| Heavy-Duty Battery Clamp Inflators | High PSI capability, rugged design, connects to battery | Construction sites, off-road vehicle support | Pro: Suitable for large tires, fast inflation. Contro: Requires battery access, less portable. |

| Gonfiatori digitali per pneumatici | Built-in digital pressure gauge, automatic shut-off features | Automotive repair shops, logistics companies | Pro: Accurate readings, easy to use. Contro: May be pricier than analog options. |

| Ultra Compact Tire Inflators | Small size, lightweight, often USB rechargeable | Personal vehicles, emergency kits | Pro: Extremely portable, ideal for emergencies. Contro: Limited power for larger tires. |

Cordless tire inflators are designed for maximum portability, featuring rechargeable batteries that allow for use without direct power sources. These inflators are ideal for fleet maintenance and roadside assistance, where quick and easy access to tire inflation is critical. When purchasing, consider battery life and charging options, as these factors can significantly affect usability in field conditions.

12V plug-in tire inflators connect directly to a vehicle’s power outlet, making them a convenient choice for automotive service centers and rental companies. Their compact design often allows for easy storage within vehicles. However, buyers should consider the need for extension cables to reach all tires efficiently, especially in larger vehicles or when inflating multiple tires.

Heavy-duty battery clamp inflators are tailored for high-pressure applications, making them perfect for larger tires found on trucks and construction vehicles. Their rugged construction ensures durability in demanding environments, such as construction sites or off-road scenarios. Buyers should evaluate their ease of use, as these models require connecting to the vehicle’s battery, which may pose challenges for some operators.

Digital tire inflators come equipped with built-in pressure gauges and automatic shut-off features, providing accuracy and ease of use for automotive repair shops and logistics companies. These inflators minimize the risk of over-inflation and ensure precise tire pressures, which is crucial for vehicle safety and performance. While they may come at a higher price point, the investment often pays off in reliability and efficiency.

Ultra compact tire inflators are designed for convenience, easily fitting into glove compartments or emergency kits. Their lightweight and often USB rechargeable nature make them perfect for personal vehicles or emergency situations. However, their limited power output may not be suitable for larger truck tires, so B2B buyers should assess their specific needs before opting for this type.

| Industria/Settore | Specific Application of best tire inflator for truck tires | Valore/Beneficio per l'azienda | Considerazioni chiave sull'approvvigionamento per questa applicazione |

|---|---|---|---|

| Logistics and Transportation | Maintaining fleet tire pressure for delivery trucks | Enhances fuel efficiency and extends tire lifespan | Durability, ease of use, and compatibility with various truck sizes |

| Costruzione | Inflating tires on heavy machinery and trucks | Reduces downtime and ensures operational readiness | High PSI capability, ruggedness, and portability |

| Agricoltura | Tire maintenance for farm vehicles | Increases productivity and reduces tire wear | Adaptability to different tire sizes and ease of transport |

| Mining | Tire inflation for mining trucks | Minimizes operational disruptions and ensures safety | Robust design, ability to handle extreme environments, and high efficiency |

| Servizi di emergenza | Quick tire inflation for rescue vehicles | Ensures rapid response times in critical situations | Compact design, fast inflation rates, and reliability |

In the logistics and transportation sector, tire inflators are essential for maintaining the correct tire pressure of delivery trucks. Properly inflated tires can significantly enhance fuel efficiency and prolong tire life, which is crucial for companies operating large fleets. Buyers in this sector should prioritize inflators that are durable, easy to use, and compatible with various truck sizes to ensure consistent performance across their fleet.

In the construction industry, tire inflators are used to maintain the pressure of heavy machinery and trucks. Keeping these vehicles operational is vital for avoiding costly downtime on job sites. Buyers require inflators that can achieve high PSI levels, are rugged enough to withstand harsh environments, and are portable for easy transportation around sites.

For the agriculture sector, tire maintenance for farm vehicles is critical. Inflators help ensure that tractors and other equipment are always ready for use, thus enhancing productivity. Buyers should look for inflators that can adapt to different tire sizes and are easy to transport across large farms, ensuring they can quickly address any tire issues.

In the mining industry, tire inflation for mining trucks is necessary to minimize operational disruptions and ensure safety in challenging environments. Mining companies need robust inflators that can handle extreme conditions and provide high-efficiency inflation. Buyers should consider the inflator’s design durability and ability to operate effectively in rugged terrains.

Lastly, emergency services rely on quick tire inflation for rescue vehicles to ensure rapid response times during critical situations. Time is of the essence in emergencies, so inflators must be compact, reliable, and capable of fast inflation. Buyers in this sector should prioritize inflators that can be easily stored in vehicles and provide consistent performance under pressure.

Il problema: Many B2B buyers face challenges when sourcing tire inflators that require a stable power supply, particularly in remote locations or regions with inconsistent electricity. For businesses operating in rugged environments, such as construction sites or agriculture, inflators that rely solely on AC power can become impractical. This can lead to downtime, as workers may struggle to inflate tires when they are flat, affecting productivity and operational efficiency.

La soluzione: Opt for tire inflators with multiple power options, including battery-operated and DC-powered models. For instance, the AstroAI Cordless Tire Inflator offers both a rechargeable lithium-ion battery and a 12-volt car adapter, allowing users to inflate tires without relying on an external power source. When sourcing, prioritize inflators that can recharge quickly and maintain charge for multiple uses. Additionally, consider investing in portable solar chargers or power banks that can recharge inflators in areas without reliable electricity. Training staff on the effective use of these tools will ensure they can manage tire maintenance efficiently, minimizing delays in operations.

Illustrative image related to best tire inflator for truck tires

Il problema: Many B2B buyers, particularly those new to the trucking industry, often struggle with understanding the correct tire pressure requirements for their heavy-duty vehicles. Incorrect tire pressure can lead to increased fuel consumption, tire wear, and even safety hazards. This lack of knowledge can be especially problematic for businesses in regions with varying climates, where tire pressure may need to be adjusted frequently.

La soluzione: It is essential to educate your team about the optimal tire pressure for different vehicles, which can typically be found in the owner’s manual or on a sticker inside the driver’s door. When selecting a tire inflator, ensure it features an accurate built-in pressure gauge to avoid under- or over-inflation. Models like the Viair 88P are designed for heavy-duty use, capable of inflating larger tires up to 120 psi. Implement a regular tire maintenance schedule, including pressure checks and adjustments before long trips or heavy loads. Additionally, consider providing training sessions on tire maintenance and inflation techniques to enhance your team’s confidence and competence in managing tire pressures effectively.

Il problema: In industries where time is of the essence, such as logistics or construction, the speed of tire inflation can significantly impact operations. Slow inflators can result in extended downtime, affecting delivery schedules and project timelines. Many B2B buyers find that standard inflators take too long to inflate tires, especially larger ones commonly found on trucks and heavy vehicles.

La soluzione: To address this pain point, it is crucial to select high-efficiency tire inflators that are specifically designed for rapid inflation. For example, the Viair 88P is known for its quick inflation capabilities, taking less than seven minutes to inflate a flat tire. When sourcing inflators, look for those that offer high maximum psi ratings and short inflation times, ensuring they meet the demands of your fleet. Additionally, consider investing in multiple units so that several tires can be serviced simultaneously, reducing overall downtime. Regularly maintain these inflators to ensure they operate at peak efficiency, and train your staff on best practices for quick tire servicing to further enhance operational efficiency.

When selecting the best tire inflator for truck tires, understanding the materials used in their construction is crucial for ensuring reliability, durability, and performance. Below is an analysis of four common materials used in tire inflators, focusing on their properties, advantages, disadvantages, and specific considerations for international B2B buyers.

Plastic is often used in the casing and components of tire inflators due to its lightweight and moldable nature. Key properties include resistance to corrosion and a moderate temperature rating, typically around -40°C to 80°C.

Pro: Plastic is lightweight, which enhances portability, and is generally less expensive than metals. It can be molded into complex shapes, allowing for ergonomic designs.

Contro: While durable, plastics can be less robust under extreme conditions, such as high temperatures or heavy impacts. They may also degrade over time with exposure to UV light.

Illustrative image related to best tire inflator for truck tires

Impatto sull'applicazione: Plastic is suitable for non-structural components and housing, but care should be taken regarding its heat resistance, especially in high-performance inflators.

Considerazioni per gli acquirenti internazionali: Compliance with international standards such as ASTM for material safety is essential. Buyers from regions like Africa and South America should also consider the availability of replacement parts, as plastic components may require specific sourcing.

Metals, particularly aluminum and steel, are commonly used in the construction of tire inflators, especially in high-stress areas like the pump mechanism. They offer superior strength and can withstand higher pressures, often rated above 100 psi.

Pro: Metals are durable, providing longevity and resistance to wear and tear. They can also handle higher temperatures, making them suitable for heavy-duty applications.

Illustrative image related to best tire inflator for truck tires

Contro: The primary downside is weight; metal inflators can be cumbersome. Additionally, they are typically more expensive than plastic counterparts.

Impatto sull'applicazione: Metal components are ideal for the pump and motor housing, ensuring that the inflator can handle the demands of inflating truck tires.

Considerazioni per gli acquirenti internazionali: Buyers should ensure that the metal used complies with international standards such as DIN or JIS for quality assurance. Corrosion resistance is particularly important in humid or coastal regions.

Rubber is often used in seals, hoses, and other flexible components of tire inflators. Its key properties include excellent elasticity and a good temperature range, typically from -30°C to 100°C.

Illustrative image related to best tire inflator for truck tires

Pro: Rubber provides a tight seal, preventing air leaks, and can absorb vibrations, enhancing user comfort. It is also resistant to wear from repeated use.

Contro: Rubber can degrade over time, particularly when exposed to ozone or UV light. It may also have limitations in extreme temperature environments.

Impatto sull'applicazione: Rubber is critical for ensuring airtight connections and preventing air loss during inflation, which is vital for maintaining tire pressure.

Considerazioni per gli acquirenti internazionali: Buyers should check for compliance with international rubber standards and consider the availability of replacement hoses and seals, especially in remote areas.

Composite materials, often a blend of plastics and metals, are increasingly used in tire inflators. They combine the lightweight nature of plastics with the strength of metals, providing a balanced solution.

Illustrative image related to best tire inflator for truck tires

Pro: Composites are lightweight and can be engineered for specific performance characteristics, such as enhanced durability and temperature resistance.

Contro: The manufacturing process can be complex, potentially leading to higher costs. Additionally, not all composites are recyclable, raising environmental concerns.

Impatto sull'applicazione: Composite materials can be used in both structural and non-structural components, offering versatility in design.

Considerazioni per gli acquirenti internazionali: Buyers should inquire about the environmental impact and recycling options for composite materials, as sustainability is becoming increasingly important in global markets.

Illustrative image related to best tire inflator for truck tires

| Materiale | Typical Use Case for best tire inflator for truck tires | Vantaggio chiave | Svantaggi/limitazioni principali | Costo relativo (Basso/Medio/Alto) |

|---|---|---|---|---|

| Plastica | Housing and non-structural components | Leggero e conveniente | Less durable under extreme conditions | Basso |

| Metallo | Pump and motor housing | Elevata resistenza e durata | Più pesante e più costoso | Alto |

| Gomma | Seals and hoses | Excellent elasticity and airtight sealing | Si degrada nel tempo | Medio |

| Composito | Structural and non-structural components | Balanced strength and weight | Complex manufacturing process | Medio |

This guide provides B2B buyers with essential insights into material selection for tire inflators, ensuring informed purchasing decisions that align with performance and regional requirements.

The manufacturing process of tire inflators, particularly those designed for trucks, involves several critical stages that ensure the end product is reliable and efficient.

The first stage of manufacturing begins with material preparation. High-quality materials are essential for the durability and performance of tire inflators. Common materials include:

Suppliers must ensure that the raw materials meet industry standards and specifications, as this directly impacts the quality of the final product.

The forming process involves shaping the prepared materials into the necessary components. This can include:

Each technique is chosen based on the material’s properties and the specific requirements of the tire inflator design.

Once the components are formed, the assembly process begins. This stage typically involves:

Effective assembly techniques are crucial for minimizing defects and ensuring that each inflator operates correctly.

After assembly, finishing processes enhance the product’s aesthetics and functionality. This includes:

These finishing touches not only improve the product’s usability but also its marketability.

Quality assurance (QA) is a crucial aspect of manufacturing tire inflators, particularly for B2B buyers who require reliable products.

Illustrative image related to best tire inflator for truck tires

Manufacturers often adhere to international standards such as ISO 9001, which focuses on quality management systems. Additionally, specific industry standards may apply, including:

Understanding these standards helps B2B buyers assess the credibility of manufacturers.

Quality control (QC) involves several checkpoints throughout the manufacturing process:

These checkpoints are critical for maintaining high-quality standards throughout the production cycle.

Manufacturers employ various testing methods to ensure tire inflators meet performance requirements:

Illustrative image related to best tire inflator for truck tires

Conducting these tests provides confidence in the reliability of the inflators.

For B2B buyers, verifying a supplier’s quality control processes is essential to ensure product reliability. Here are several strategies:

Buyers should conduct regular audits of potential suppliers. This can include:

These audits provide insights into the supplier’s commitment to quality.

Requesting quality control reports can help buyers understand the supplier’s performance history. Additionally, engaging third-party inspection services can provide an unbiased assessment of the manufacturer’s capabilities.

International buyers, especially from regions like Africa, South America, the Middle East, and Europe, may encounter unique QC challenges:

Being aware of these nuances helps buyers make informed decisions when sourcing tire inflators.

In summary, understanding the manufacturing processes and quality assurance protocols for tire inflators is crucial for B2B buyers. By considering material preparation, forming techniques, assembly methods, and finishing processes, buyers can better evaluate potential suppliers. Furthermore, being knowledgeable about international standards, quality control checkpoints, and verification strategies ensures that they procure reliable and high-quality products that meet their operational needs.

In the dynamic landscape of B2B procurement, selecting the right tire inflator for truck tires is essential for ensuring operational efficiency and vehicle maintenance. This guide provides a systematic approach to sourcing the best tire inflators, focusing on functionality, reliability, and value. By following this checklist, you can make informed decisions that align with your business needs.

Establishing clear technical requirements is the foundation of your procurement process. Consider the types of trucks you service and the average tire size, as this will influence the inflator’s capacity. Look for specifications such as maximum PSI, duty cycle, and power source options (battery, 12V outlet, or AC) to ensure compatibility with your fleet.

Conduct thorough research on the market to identify models that meet your specifications. Utilize trusted automotive review platforms and industry publications to compare features and performance. Pay attention to user reviews and ratings, as these can provide insights into real-world reliability and ease of use, particularly for inflators designed specifically for heavy-duty applications.

Before finalizing your choice, ensure that the suppliers you consider are certified and compliant with international standards. Certifications such as ISO 9001 for quality management systems can indicate a supplier’s commitment to quality. Additionally, check for any industry-specific certifications that might be relevant to your region, especially in markets like Africa and South America.

Obtaining product samples from potential suppliers is a critical step in the evaluation process. Testing inflators in real-world scenarios can help you assess their performance and durability. Look for ease of use, speed of inflation, and the accuracy of built-in pressure gauges during your assessments to ensure they meet your operational needs.

Illustrative image related to best tire inflator for truck tires

A robust warranty and customer support can significantly enhance your procurement decision. Evaluate the warranty terms offered by suppliers to understand coverage duration and conditions. Additionally, consider the availability of customer support services, such as technical assistance and replacement parts, which can be crucial for minimizing downtime in your operations.

While price is a significant factor, it’s essential to consider the total cost of ownership, which includes maintenance, operational efficiency, and longevity of the product. Compare quotes from multiple suppliers and analyze the potential return on investment (ROI). A slightly higher upfront cost may be justified if the inflator has a longer lifespan or lower maintenance needs.

Once you have gathered all necessary information, finalize your procurement strategy. Decide whether to purchase outright or consider leasing options based on your budget and operational needs. Ensure that your final choice aligns with your business goals and offers flexibility for future scaling or changes in your fleet requirements.

By following these steps, you can confidently select the best tire inflator for your truck tires, ensuring optimal performance and reliability in your fleet management operations.

When analyzing the cost structure of tire inflators, several components contribute to the overall pricing. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margin.

Illustrative image related to best tire inflator for truck tires

I materiali: The materials used in tire inflators, such as durable plastics, metal components for pumps, and electronic parts, significantly influence costs. High-quality materials may elevate the price but can enhance durability and performance, which is crucial for heavy-duty applications like truck tires.

Lavoro: Labor costs vary by region and production scale. In countries with lower labor costs, like some in Africa and South America, manufacturing can be cheaper, allowing suppliers to offer competitive pricing. Conversely, regions with higher labor standards may see increased production costs.

Spese generali di produzione: This includes expenses related to factory operations, utilities, and maintenance. Efficient production processes can help reduce overhead, impacting the final pricing of the product.

Utensili: Tooling costs pertain to the equipment and molds needed to manufacture the inflators. Custom designs or specialized features can lead to higher tooling costs, which must be amortized over production volume.

Controllo qualità (CQ): Rigorous QC processes ensure that inflators meet safety and performance standards. While QC adds to manufacturing costs, it ultimately protects brand reputation and customer satisfaction.

Logistica: Transportation and warehousing costs play a critical role in the overall cost structure. International shipping, especially to regions like Africa and South America, can be significant, influenced by factors such as fuel prices and shipping routes.

Margine: Finally, suppliers set profit margins based on market conditions, competition, and brand positioning. Understanding the balance between quality and price is essential for buyers seeking the best value.

Several factors can influence the pricing of tire inflators, impacting B2B sourcing decisions:

Volume/MOQ: Minimum order quantities (MOQs) can significantly affect pricing. Bulk purchases often lead to discounts, making it advantageous for businesses to order larger quantities to lower per-unit costs.

Specifiche e personalizzazione: Custom features can increase costs but may be necessary for specific applications. Buyers should weigh the benefits of customization against the potential price increase.

Materiali e certificazioni di qualità: Products made with certified materials (e.g., ISO certifications) may come at a premium. However, these certifications can assure buyers of product reliability, especially in demanding environments.

Fattori di fornitura: Relationships with suppliers can influence pricing. Long-term partnerships may yield better terms and conditions, including favorable payment options and discounts.

Incoterms: Understanding International Commercial Terms (Incoterms) is crucial. They define the responsibilities of buyers and sellers concerning shipping, insurance, and tariffs, impacting the overall cost of procurement.

For international B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, several strategies can enhance cost-efficiency:

Negoziazione: Always negotiate terms with suppliers. Leverage volume commitments or long-term purchasing agreements to secure better pricing or additional services.

Costo totale di proprietà (TCO): Consider not just the initial purchase price but the TCO, which includes maintenance, operational costs, and potential downtime. Investing in higher-quality inflators may reduce long-term costs due to lower failure rates.

Sfumature di prezzo: Be aware of regional pricing differences. Factors like local demand, currency fluctuations, and import duties can significantly affect the final cost. Conduct market research to understand competitive pricing within your region.

Diversificazione dei fornitori: Avoid reliance on a single supplier. By diversifying your supplier base, you can compare prices, quality, and lead times, leading to better overall sourcing decisions.

Prices for tire inflators can vary widely based on specifications, suppliers, and market conditions. The figures referenced in analyses may serve as a guideline but should not be considered fixed or definitive. Always consult with suppliers for the most accurate and current pricing information.

When considering the best tire inflator for truck tires, it’s essential to explore alternative solutions that can also fulfill the need for tire inflation. Understanding these alternatives will help B2B buyers make informed decisions based on their specific requirements and operational contexts. Below, we compare the best tire inflator for truck tires with other viable solutions, enabling a comprehensive analysis of performance, cost, ease of implementation, maintenance, and best use cases.

| Aspetto di confronto | Best Tire Inflator For Truck Tires | Compressore d'aria portatile | Manual Foot Pump |

|---|---|---|---|

| Prestazioni | High PSI capacity, quick inflation | Moderate PSI, slower | Low PSI, very slow |

| Costo | $65 – $90 | $50 – $150 | $15 – $30 |

| Facilità di implementazione | Plug-and-play, user-friendly | Requires power source | Requires physical effort |

| Manutenzione | Low, occasional checks needed | Moderate, requires cleaning | Very low, minimal upkeep |

| Il miglior caso d'uso | Heavy-duty trucks and SUVs | General household use | Emergency or light use |

Portable air compressors are versatile and can handle various inflation tasks beyond just tires, making them a popular choice for many users. They typically have a higher PSI capability than manual pumps, allowing for quicker inflation. However, they require access to a power source, which can be a limitation in remote locations. Additionally, while they are generally user-friendly, they may require some maintenance, such as cleaning filters and checking hoses. The cost can vary significantly based on the brand and features, ranging from $50 to $150.

Manual foot pumps are an economical option for tire inflation, particularly for light use and emergencies. They are extremely portable, require no power source, and have minimal maintenance needs. However, their performance is considerably lower, as they typically inflate tires at a much slower rate and to lower pressures than electric inflators. This makes them less suitable for heavy-duty applications, such as inflating truck tires, where efficiency and high PSI are crucial. The cost is significantly lower, usually between $15 and $30, which may appeal to budget-conscious buyers.

B2B buyers need to carefully assess their specific operational requirements when choosing a tire inflation solution. If quick and high-pressure inflation for heavy-duty vehicles is a priority, investing in a high-quality tire inflator is advisable. Conversely, for lighter applications or budget constraints, a portable air compressor or manual foot pump may suffice. Evaluating factors such as frequency of use, inflation speed, and available power sources will guide buyers in selecting the most effective solution for their fleet management or service needs. By understanding the pros and cons of each option, businesses can optimize their tire maintenance strategies, enhance vehicle safety, and ultimately reduce operational costs.

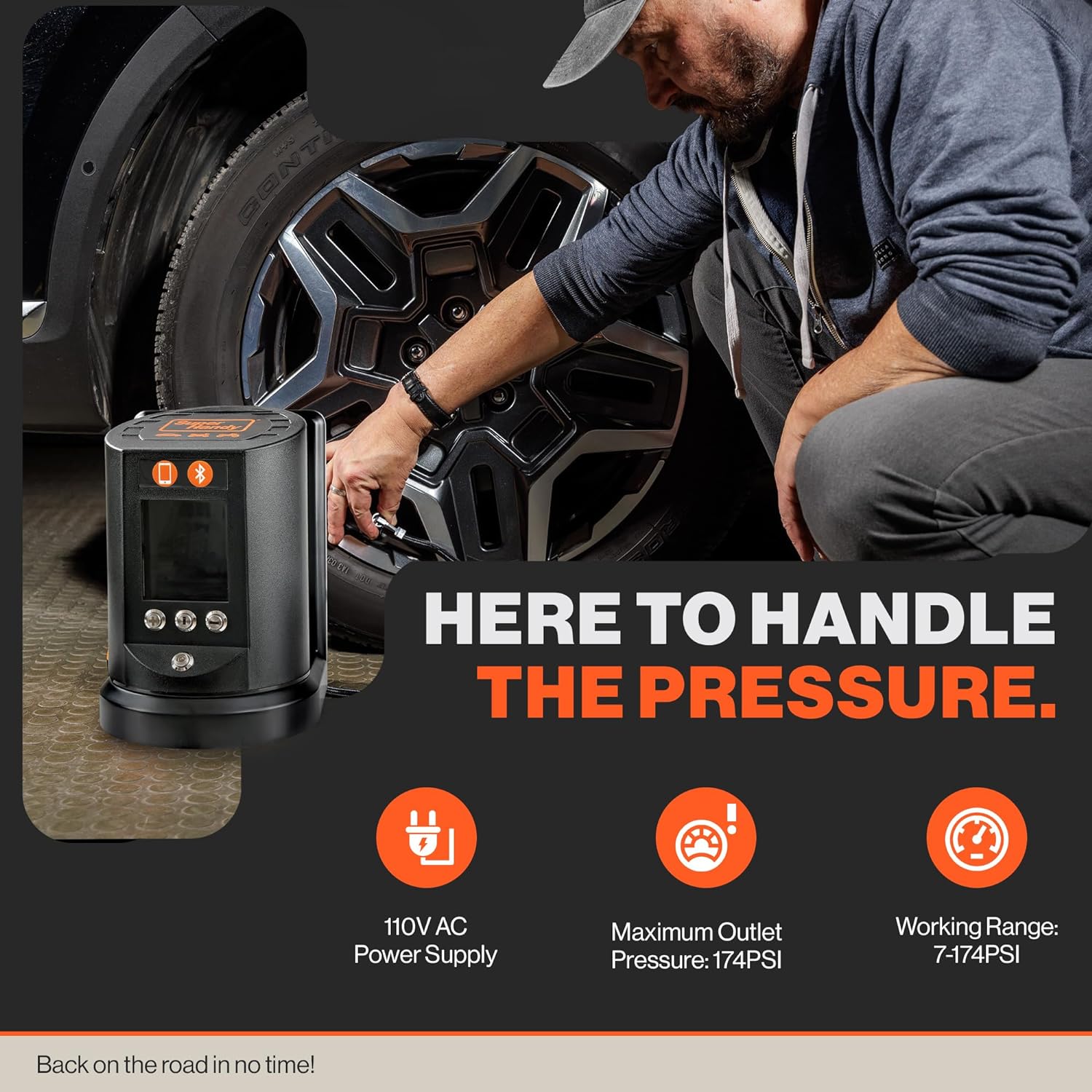

When selecting a tire inflator specifically designed for truck tires, several technical specifications must be considered to ensure optimal performance and suitability for heavy-duty use.

Pressione massima (PSI)

The maximum pressure a tire inflator can achieve, measured in pounds per square inch (PSI), is crucial for truck tires, which often require higher pressures than standard passenger vehicle tires. A tire inflator capable of reaching 80 PSI or more is essential for heavy-duty applications, ensuring that it can adequately service large tires used in trucks and SUVs.

Duty Cycle

The duty cycle refers to the amount of time the inflator can operate before needing to cool down. For commercial applications, a higher duty cycle (expressed as a percentage) indicates that the inflator can be used continuously for extended periods without overheating. This is particularly important in environments where multiple tires may need servicing in one session.

Fonte di alimentazione

Tire inflators can be powered by various sources, including 12-volt car outlets, rechargeable batteries, or AC power. For B2B buyers, understanding the power source is critical to ensure compatibility with the intended use environment, whether on a job site or in a workshop. Battery-operated models offer portability, while those that plug into vehicle outlets provide continuous power without the risk of battery depletion.

Hose Length

The length of the hose affects the convenience and reach of the inflator. A longer hose allows for easier access to tires, especially in larger vehicles or when multiple tires need servicing. For truck tires, a hose length of at least 16 feet is recommended to provide flexibility in positioning the inflator.

Pressure Gauge Type

The accuracy of the pressure gauge is paramount. Digital gauges tend to offer better precision than analog counterparts, which can be less accurate. For B2B buyers, choosing an inflator with a reliable pressure gauge minimizes the risk of under-inflation or over-inflation, which can lead to tire damage or increased fuel consumption.

Portability and Storage

Consideration of the inflator’s size and weight is vital for B2B applications. Models that are compact and lightweight can be easily transported in service vehicles, while those with durable carrying cases protect the equipment during transport and storage.

Understanding industry-specific jargon can significantly aid B2B buyers in making informed purchasing decisions.

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. For tire inflators, OEM products are typically seen as high-quality and reliable, making them a preferred choice for businesses seeking durable equipment.

MOQ (quantità minima d'ordine)

MOQ indicates the smallest number of units a supplier is willing to sell. Knowing the MOQ is essential for B2B buyers to plan their inventory and budget, especially if they require multiple units for fleet maintenance.

RFQ (Richiesta di offerta)

An RFQ is a document sent to suppliers to solicit price quotes for specific products or services. B2B buyers should utilize RFQs to compare costs and negotiate better deals, ensuring they receive the best value for their investment in tire inflators.

Incoterms (Termini commerciali internazionali)

These are predefined commercial terms published by the International Chamber of Commerce, which clarify the responsibilities of buyers and sellers in international trade. Familiarity with Incoterms helps B2B buyers understand shipping costs, delivery responsibilities, and risk management in purchasing tire inflators from international suppliers.

Periodo di garanzia

This term refers to the duration during which the manufacturer guarantees the product against defects. A longer warranty period can be indicative of product quality and reliability, which is essential for B2B buyers investing in equipment that will see regular use.

Assistenza post-vendita

This encompasses the services provided after a product has been purchased, including maintenance, repairs, and customer service. Strong after-sales support can be a deciding factor for B2B buyers, ensuring they have access to assistance if issues arise with their tire inflators.

By understanding these technical properties and trade terms, B2B buyers can make more informed decisions when selecting tire inflators that best meet their operational needs.

The tire inflator market, particularly for trucks, is experiencing notable growth driven by several global factors. Increased freight transport and the expansion of e-commerce have led to a surge in demand for heavy-duty vehicles, necessitating effective maintenance solutions like tire inflators. In regions such as Africa, South America, the Middle East, and Europe, where road conditions can be challenging, having reliable tire inflation tools is critical for operational efficiency and safety.

Emerging technologies are also reshaping the sourcing landscape. The rise of smart tire inflators equipped with digital pressure gauges and automatic shut-off features enhances user experience and reliability. Moreover, the integration of mobile applications for real-time monitoring of tire pressure is becoming popular, offering added convenience for B2B buyers looking to streamline maintenance processes.

Illustrative image related to best tire inflator for truck tires

International buyers should also be aware of the competitive pricing dynamics. Manufacturers are increasingly focusing on cost-effective solutions without compromising quality, allowing businesses in developing markets to access high-quality inflators at reasonable prices. Additionally, as the market becomes more saturated, suppliers are differentiating themselves through value-added services such as warranty extensions and robust after-sales support.

Sustainability is becoming a pivotal factor in the sourcing strategies of B2B buyers in the tire inflator sector. The environmental impact of manufacturing processes, particularly in developing regions, necessitates a shift toward sustainable practices. Buyers are now prioritizing suppliers who demonstrate commitment to reducing carbon footprints through eco-friendly production methods and materials.

Ethical sourcing is equally important, with a focus on transparent supply chains that ensure fair labor practices and responsible resource extraction. Certifications such as ISO 14001 for environmental management and fair trade certifications are increasingly sought after by conscientious buyers. This trend not only enhances brand reputation but also aligns with the growing consumer demand for sustainable products.

Moreover, the incorporation of recycled materials in tire inflators is becoming more prevalent. Suppliers that invest in ‘green’ innovations, such as using biodegradable plastics or energy-efficient manufacturing processes, are likely to attract a growing segment of eco-conscious buyers. This shift not only contributes to environmental conservation but also meets regulatory requirements that are becoming stricter across various regions.

The evolution of tire inflators has been marked by significant technological advancements and changing consumer preferences. Initially, tire inflators were simple manual pumps, often cumbersome and inefficient. However, the introduction of electric and portable inflators transformed the market, making it more accessible and user-friendly.

Illustrative image related to best tire inflator for truck tires

Over the past two decades, the focus has shifted towards enhanced performance and features such as digital pressure gauges, rapid inflation capabilities, and multifunctionality (e.g., inflating sports equipment). The advent of cordless models has further revolutionized the market, providing convenience for users who require portability.

As the demand for heavy-duty vehicle maintenance solutions has grown, manufacturers have adapted their products to meet the specific needs of truck owners, offering inflators that can handle higher pressures and larger volumes. This evolution reflects a broader trend in the automotive industry toward prioritizing efficiency, safety, and user experience, ultimately shaping the current landscape of tire inflators for trucks.

How do I choose the right tire inflator for truck tires?

Selecting the appropriate tire inflator involves assessing several critical factors. First, consider the inflator’s maximum PSI rating; for truck tires, look for models that can reach at least 80 PSI. Additionally, evaluate the inflator’s power source—battery-operated models offer portability, while those that plug into a vehicle’s outlet can provide continuous power. Assess the inflator’s speed and efficiency in inflating multiple tires, as well as its size and weight for storage. Lastly, check for features such as built-in pressure gauges and additional accessories that enhance usability.

What is the best tire inflator for heavy-duty truck tires?

The Viair 88P is widely regarded as one of the best tire inflators for heavy-duty truck tires. It has a maximum pressure of 120 PSI and is designed for quick inflation, making it ideal for larger tires. Its ability to connect directly to the vehicle’s battery ensures that it can handle the demands of off-road and heavy-duty applications. While it is bulkier than some competitors, its rugged construction and reliability make it a solid choice for professional users who require consistent performance.

What should I consider when sourcing tire inflators from international suppliers?

When sourcing tire inflators from international suppliers, prioritize quality assurance and supplier reliability. Verify the supplier’s certifications and compliance with international standards. Request samples to evaluate product quality firsthand. Additionally, consider the supplier’s manufacturing capabilities, lead times, and flexibility in fulfilling your specific order requirements. Communication is crucial, so ensure that the supplier can effectively address your inquiries and provide timely updates throughout the sourcing process.

What are the typical minimum order quantities (MOQ) for tire inflators?

Minimum order quantities (MOQ) for tire inflators can vary significantly based on the supplier and the specific product. Typically, MOQs range from 50 to 500 units, but some manufacturers may accommodate smaller orders, especially for established businesses or repeat customers. When negotiating with suppliers, be clear about your order needs and explore options for bulk pricing or discounts for larger orders. Understanding the MOQ can help you plan your inventory and cash flow more effectively.

How can I ensure quality control when importing tire inflators?

To ensure quality control when importing tire inflators, implement a comprehensive quality assurance (QA) strategy. Begin with thorough supplier vetting, checking references and certifications. Consider conducting pre-shipment inspections to verify that products meet your specifications and quality standards. Utilize third-party inspection services to assess the products before they leave the factory. Additionally, maintain clear communication with your supplier regarding quality expectations and potential penalties for non-compliance.

What payment terms are commonly used in international B2B transactions for tire inflators?

Payment terms in international B2B transactions can vary widely, but common options include letters of credit, wire transfers, and payment upon delivery. Many suppliers prefer a deposit upfront (typically 30% to 50%) with the balance due before shipping or upon receipt. It’s essential to discuss and agree upon payment terms early in negotiations to avoid misunderstandings. Also, consider using escrow services for larger transactions to ensure both parties fulfill their obligations before the funds are released.

What logistics considerations should I keep in mind when importing tire inflators?

When importing tire inflators, logistics considerations are crucial for ensuring timely and cost-effective delivery. Assess shipping methods, such as air freight for speed or sea freight for cost efficiency. Understand the customs regulations of your destination country, including tariffs and import duties that may apply. Work with reliable freight forwarders who can navigate the complexities of international shipping, and ensure that all documentation, such as bills of lading and commercial invoices, is correctly prepared to avoid delays.

Can tire inflators be customized for branding purposes?

Yes, many manufacturers offer customization options for tire inflators, allowing businesses to incorporate their branding. Customization may include adding logos, specific color schemes, or packaging designs. It’s important to discuss these options with suppliers early in the negotiation process, as minimum order quantities and additional costs may apply for customized products. Custom-branded tire inflators can enhance brand visibility and create a unique selling proposition in competitive markets.

Dominio: reddit.com

Registrato: 2005 (20 anni)

Introduzione: 1. ETENWOLF Tire Inflator: Runs off truck battery clamps, inflates to 95 psi, compact size fits behind the seat, good customer service experience reported.

2. Milwaukee Inflator: Recommended by users for air up after trips, operates well for heavy-duty use.

Dominio: facebook.com

Registrato: 1997 (28 anni)

Introduzione: This company, All Top Overland – Double Head Compressor, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Dominio: thetruckersreport.com

Registrato: 2003 (22 anni)

Introduzione: AstroAI Cordless Tire Inflator Air Compressor 20V Rechargeable Battery Powered 160PSI Portable Handheld Air Pump with 12V Car Power Adapter Digital Pressure Gauge for Cars Motorcycles ACJY21LIDCYE

Dominio: lasfit.com

Registrato: 2016 (9 anni)

Introduzione: Lasfit Tire Inflator | Portable Tire Pumps for Pickup Trucks & Large SUVs & Off-Road Vehicles. Features include fast inflation, accurate pressure readings, compact design, multi-purpose use for car tires, bikes, motorcycles, and more. Digital display with auto shut-off for precise inflation. Designed for 12V DC outlets, built with durable components for long-lasting performance. Available models: …

In the rapidly evolving landscape of tire maintenance, selecting the right tire inflator for trucks is crucial for operational efficiency and cost savings. The top products, such as the AstroAI Cordless Tire Inflator and the Viair 88P, demonstrate that performance, portability, and precision are key factors for B2B buyers. These inflators not only ensure that vehicles are road-ready but also contribute to prolonging tire life and optimizing fuel efficiency—critical considerations for businesses operating in diverse environments.

Strategic sourcing of tire inflators involves assessing factors such as ease of use, power options, and the ability to handle varying tire pressures. For international buyers, particularly in Africa, South America, the Middle East, and Europe, investing in high-quality inflators can enhance fleet management and reduce downtime, ultimately leading to greater profitability.

Illustrative image related to best tire inflator for truck tires

As you consider your procurement strategies, prioritize suppliers that offer reliable products and exceptional support. The future of tire maintenance lies in innovation and efficiency—seize the opportunity to equip your operations with the best tools available. Engage with trusted manufacturers today to secure tire inflators that meet your specific needs and drive your business forward.

Le informazioni fornite in questa guida, compresi i contenuti relativi ai produttori, alle specifiche tecniche e all'analisi di mercato, hanno uno scopo puramente informativo ed educativo. Non costituiscono una consulenza professionale in materia di acquisti, né una consulenza finanziaria o legale.

Pur avendo compiuto ogni sforzo per garantire l'accuratezza e la tempestività delle informazioni, non siamo responsabili di eventuali errori, omissioni o informazioni non aggiornate. Le condizioni di mercato, i dettagli aziendali e gli standard tecnici sono soggetti a modifiche.

Gli acquirenti B2B devono condurre una due diligence indipendente e approfondita. prima di prendere qualsiasi decisione di acquisto. È necessario contattare direttamente i fornitori, verificare le certificazioni, richiedere campioni e chiedere una consulenza professionale. Il rischio di affidarsi alle informazioni contenute in questa guida è esclusivamente a carico del lettore.

Illustrative image related to best tire inflator for truck tires