In today’s fast-paced global marketplace, sourcing reliable compressors for tires is a critical challenge for B2B buyers. With a variety of types, applications, and specifications available, understanding the nuances of tire inflators can significantly impact operational efficiency and customer satisfaction. This guide serves as a comprehensive resource, providing insights into the different types of tire compressors, their applications across various industries, and practical strategies for vetting suppliers.

International buyers, particularly those from regions such as Africa, South America, the Middle East, and Europe—including countries like Nigeria and Germany—face unique challenges in navigating diverse market conditions and supplier landscapes. By exploring key factors such as cost considerations, product performance, and quality certifications, this guide empowers you to make informed purchasing decisions.

Whether you’re looking to supply your fleet, enhance your automotive service offerings, or provide essential tools for retail environments, understanding the full spectrum of tire compressor options will enable you to select the best solutions tailored to your specific needs. This guide equips you with actionable insights that foster strategic sourcing, ensuring that you secure high-quality products that deliver reliability and value in your operations.

| Nome del tipo | Caratteristiche distintive principali | Applicazioni primarie B2B | Brevi pro e contro per gli acquirenti |

|---|---|---|---|

| Portable Electric Inflators | Compact, battery-operated, easy to transport | Small vehicle fleets, roadside assistance | Pro: Lightweight, user-friendly; Contro: Limited power for larger tires. |

| Heavy-Duty Air Compressors | High PSI output, durable construction, often stationary | Workshops, garages, large vehicle fleets | Pro: Fast inflation, handles larger tires; Contro: Bulky, requires dedicated space. |

| Gonfiatori per pneumatici a batteria | Rechargeable, often features built-in pressure gauges | Emergency kits, personal vehicles | Pro: Convenient for on-the-go use; Contro: Battery life may limit usage. |

| Dual-Power Tire Inflators | Operate on both AC and DC power, versatile | Mixed-use environments, garages, home use | Pro: Flexible power options; Contro: May be heavier due to dual functionality. |

| Industrial Air Compressors | Large capacity, designed for continuous use | Manufacturing, construction sites | Pro: High efficiency, can power multiple tools; Contro: High initial investment, requires maintenance. |

Portable electric inflators are designed for ease of use and transportability. They are typically battery-operated, making them ideal for small vehicle fleets and roadside assistance applications. These devices are lightweight and user-friendly, allowing for quick tire inflation without the need for a power source. However, they may struggle with larger tires due to limited power output, making them less suitable for heavy-duty applications.

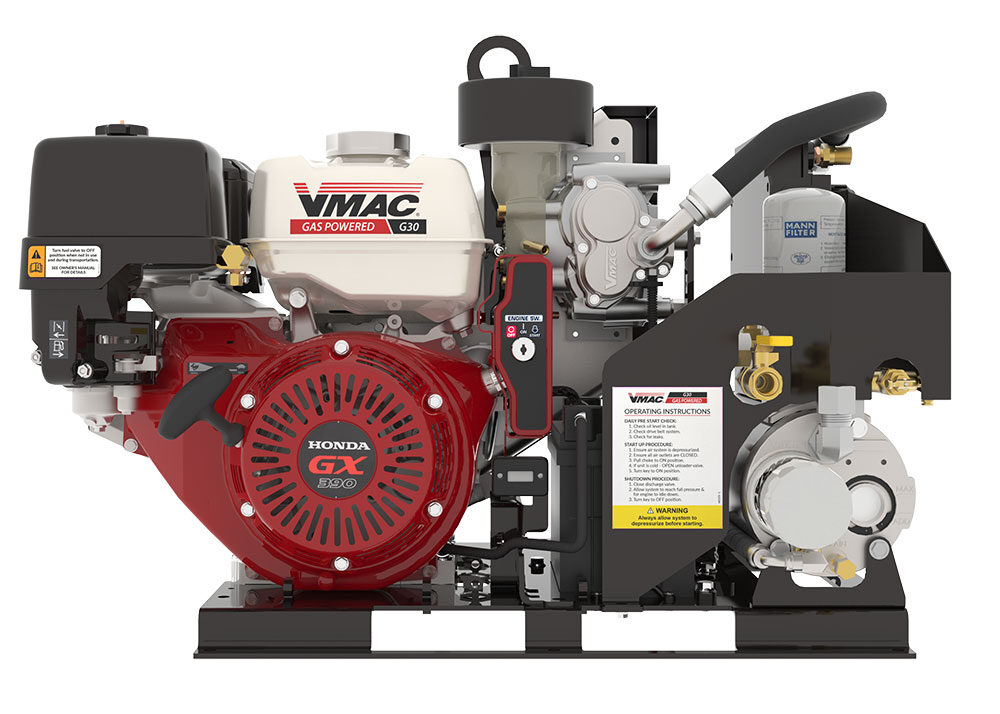

Illustrative image related to compressor for tires

Heavy-duty air compressors are characterized by their high PSI output and robust construction, often designed for stationary use in workshops or garages. These compressors are capable of inflating large tires quickly and efficiently, making them ideal for large vehicle fleets and commercial garages. While they offer significant performance advantages, their bulkiness requires dedicated space, which can be a consideration for B2B buyers with limited room.

Cordless tire inflators provide the convenience of rechargeable batteries and often come equipped with built-in pressure gauges. These features make them suitable for emergency kits and personal vehicles, allowing users to inflate tires quickly and easily on the go. While they offer portability, buyers should consider battery life, as it may limit the number of tires that can be inflated in one session, especially in high-demand scenarios.

Dual-power tire inflators are versatile machines that can operate on both AC and DC power, making them suitable for a variety of environments, including garages and mixed-use facilities. Their flexibility allows users to switch between power sources as needed, which can be a significant advantage in fluctuating work conditions. However, these inflators may be heavier than single-source models, which could impact portability.

Industrial air compressors are designed for high-capacity, continuous use, making them ideal for manufacturing and construction sites. They can efficiently power multiple tools and handle significant workloads, providing a strong return on investment for businesses that require constant air supply. However, the initial investment can be substantial, and ongoing maintenance is necessary to ensure optimal performance, making them a serious consideration for B2B buyers.

Illustrative image related to compressor for tires

| Industria/Settore | Specific Application of compressor for tires | Valore/Beneficio per l'azienda | Considerazioni chiave sull'approvvigionamento per questa applicazione |

|---|---|---|---|

| Automotive Manufacturing | Tire assembly and testing | Ensures quality control and safety standards | Reliability, compliance with industry standards, service support |

| Trasporto e logistica | Fleet maintenance and tire inflation | Reduces downtime and extends tire life | Portability, efficiency, power source options |

| Costruzione e attrezzature pesanti | Tire inflation for heavy machinery | Enhances operational efficiency and safety | Durability, high PSI capabilities, ease of use |

| Negozi di riparazione di autoveicoli | Tire servicing and repair | Improves customer satisfaction and service speed | Versatility, ease of use, accuracy of pressure gauges |

| Retail & E-commerce | Tire sales and customer service | Increases sales through quick service | Compact size, power options, multi-functionality |

In the automotive manufacturing sector, compressors are vital for tire assembly and testing. They are used to inflate tires to precise specifications before they are fitted onto vehicles, ensuring adherence to safety and quality standards. This application not only enhances the reliability of the tires but also minimizes the risk of defects, which is critical for manufacturers aiming to maintain brand reputation. International buyers, especially from regions like Germany and Nigeria, should prioritize compressors that meet stringent industry standards and offer robust after-sales support.

In the transportation and logistics industry, compressors are essential for maintaining the tire health of fleets. Regular tire inflation prevents breakdowns and minimizes downtime, directly impacting operational efficiency. By ensuring that tires are inflated to optimal levels, companies can extend tire life and improve fuel efficiency. For international buyers, especially in Africa and South America, sourcing compressors that are portable and efficient is crucial, as they often operate in diverse environments.

Construction and heavy equipment sectors rely on tire compressors to inflate the tires of large machinery, which is critical for safety and operational efficiency. These compressors must handle high PSI levels to accommodate heavy-duty tires, ensuring that machinery operates safely on various terrains. Buyers in these sectors should focus on the durability and ruggedness of compressors, particularly in regions where equipment is exposed to harsh conditions, such as the Middle East.

Automotive repair shops utilize compressors for tire servicing and repair, making them essential tools for enhancing customer satisfaction. Quick and efficient tire inflation can significantly reduce service times, allowing shops to serve more customers and increase revenue. Repair shops should look for compressors that are versatile and easy to use, as well as those with accurate pressure gauges to ensure tire safety. This is particularly important for international buyers who may face varying customer expectations and regulatory standards.

In the retail and e-commerce sectors, tire compressors are used to provide quick service to customers purchasing tires. By offering tire inflation services, retailers can enhance customer experience and drive additional sales. Compressors that are compact and multi-functional are particularly advantageous in retail settings, allowing for easy storage and versatility in use. Buyers from regions like Europe should consider sourcing compressors that can efficiently cater to a wide range of tire types and sizes, facilitating a seamless customer service experience.

Il problema: B2B buyers often face challenges in sourcing tire compressors that meet the varying requirements of different markets. For instance, compressors that work efficiently in the humid climates of West Africa might not perform well in the dry, arid conditions of the Middle East. Additionally, buyers may struggle to find suppliers who can guarantee quality, consistency, and compliance with local regulations, which can lead to issues with reliability and customer satisfaction. This inconsistency can impact operations, especially for businesses that rely on tire compressors for logistics or automotive services.

La soluzione: To overcome sourcing challenges, B2B buyers should conduct thorough market research to identify suppliers with a proven track record in specific regions. Utilizing platforms like Alibaba or regional trade shows can help buyers connect with manufacturers who understand the local climate and regulatory landscape. Buyers should specify their requirements clearly, including performance metrics like PSI levels, power sources, and durability standards. Establishing long-term relationships with trusted suppliers who offer warranties and after-sales support can mitigate risks associated with inconsistent product quality. Engaging in pilot testing with selected compressors before making bulk purchases can also ensure compatibility with local conditions.

Il problema: Another common issue for B2B buyers is the unexpected downtime caused by compressor malfunctions. Frequent breakdowns not only lead to operational delays but can also result in financial losses, especially for companies that depend on tire inflation for their service offerings. Buyers may find it challenging to keep track of maintenance schedules or to source spare parts quickly, which exacerbates the problem.

Illustrative image related to compressor for tires

La soluzione: Implementing a proactive maintenance schedule is crucial for minimizing downtime. Buyers should work with suppliers to understand the maintenance needs of their compressors, including recommended service intervals and common wear-and-tear issues. Creating a digital log for maintenance records can help businesses keep track of service dates and performance metrics. Additionally, establishing a partnership with local service providers or creating an in-house maintenance team can expedite repairs. Stocking essential spare parts based on usage patterns can also reduce downtime. Training staff on basic troubleshooting and maintenance techniques can empower teams to handle minor issues promptly, maintaining operational efficiency.

Il problema: In many B2B environments, the workforce can vary in technical expertise. This diversity can lead to challenges when operating complex tire compressors, as less experienced employees may struggle to use the equipment safely and effectively. Misunderstandings about pressure settings or operation protocols can result in inefficiencies, potential accidents, or damage to the tires or compressors themselves.

La soluzione: To ensure safe and effective operation, businesses should prioritize user-friendly designs in their compressor selection. When sourcing compressors, buyers should look for models that feature intuitive interfaces, clear instructional labels, and automatic shut-off mechanisms to prevent over-inflation. Providing comprehensive training sessions for employees on the correct usage of the compressors is vital. This can include hands-on demonstrations and easy-to-follow manuals. Additionally, creating a quick-reference guide that includes troubleshooting tips and maintenance procedures can be beneficial for employees at all skill levels. Encouraging a culture of safety and communication can also help in addressing any operational concerns quickly, enhancing overall productivity.

When selecting materials for compressors used in tire inflation, it is essential to consider their properties and performance characteristics. Below, we analyze four common materials: aluminum, steel, plastic, and brass, focusing on their suitability for tire compressors from a B2B perspective.

Proprietà chiave: Aluminum is lightweight and has excellent thermal conductivity, making it ideal for dissipating heat generated during operation. It typically has a temperature rating up to 150°C and can handle moderate pressures effectively.

Illustrative image related to compressor for tires

Pro e contro: The primary advantage of aluminum is its lightweight nature, which enhances portability. It is also resistant to corrosion, making it suitable for various environments. However, aluminum can be less durable under high-stress conditions compared to steel and may have a higher manufacturing cost due to the need for specialized machining.

Impatto sull'applicazione: Aluminum is compatible with various media, including air and nitrogen, but it may not be suitable for corrosive gases or liquids.

Considerazioni per gli acquirenti internazionali: Buyers from regions like Europe and the Middle East must ensure compliance with EU regulations and standards such as EN 15085 for welding aluminum components. In contrast, buyers in Africa and South America should consider local availability and cost implications.

Proprietà chiave: Steel is known for its high strength and durability, with a temperature rating that can exceed 200°C. It is also capable of handling high pressures, making it a robust choice for tire compressors.

Illustrative image related to compressor for tires

Pro e contro: The main advantage of steel is its exceptional durability and resistance to deformation. However, it is heavier than aluminum, which may affect portability. Steel can also be prone to corrosion if not properly treated or coated, leading to potential maintenance issues.

Impatto sull'applicazione: Steel is suitable for high-pressure applications and can handle various gases. It is particularly effective for compressors designed for heavy-duty use.

Considerazioni per gli acquirenti internazionali: Buyers should be aware of compliance with international standards such as ASTM A36 for structural steel. In regions like Germany, adherence to DIN standards is crucial, while buyers in Nigeria may need to consider local regulations regarding material sourcing.

Proprietà chiave: Plastics, particularly high-density polyethylene (HDPE) and polycarbonate, offer good chemical resistance and can withstand temperatures up to 80°C. They are lightweight and can be molded into complex shapes.

Pro e contro: The primary advantage of plastics is their lightweight nature and resistance to corrosion. They are generally more cost-effective than metals. However, plastics may not withstand high pressures as effectively as metals, limiting their use in high-performance applications.

Impatto sull'applicazione: Plastics are well-suited for components that do not require high pressure, such as housing or non-structural parts. They are compatible with air and non-corrosive gases.

Considerazioni per gli acquirenti internazionali: Compliance with safety standards such as ISO 9001 is essential. Buyers in South America should consider the availability of high-quality plastics that meet international standards.

Proprietà chiave: Brass offers excellent corrosion resistance and a moderate temperature rating of up to 120°C. It is also known for its good machinability and strength.

Pro e contro: The key advantage of brass is its resistance to corrosion, making it suitable for components exposed to moisture. However, brass can be more expensive than steel and may not be suitable for high-pressure applications.

Impatto sull'applicazione: Brass is often used for fittings and connectors in tire compressors due to its resistance to rust and wear.

Considerazioni per gli acquirenti internazionali: Buyers should ensure compliance with standards such as JIS H 3250 for brass materials. In regions like the Middle East, local sourcing may affect availability and pricing.

| Materiale | Typical Use Case for compressor for tires | Vantaggio chiave | Svantaggi/limitazioni principali | Costo relativo (Basso/Medio/Alto) |

|---|---|---|---|---|

| Alluminio | Lightweight compressor bodies | Leggero e resistente alla corrosione | Less durable under high stress | Medio |

| Acciaio | Heavy-duty compressor structures | Elevata resistenza e durata | Heavier and prone to corrosion | Alto |

| Plastica | Non-structural components | Leggero e conveniente | Limited pressure tolerance | Basso |

| Brass | Fittings and connectors | Excellent corrosion resistance | More expensive than steel | Medio |

This analysis highlights the importance of selecting the appropriate materials for tire compressors based on performance, application, and regional compliance. Understanding these factors can help B2B buyers make informed decisions that align with their operational needs and market standards.

The manufacturing process for tire compressors involves several critical stages, each designed to ensure the final product meets quality and performance standards. Understanding these stages helps B2B buyers appreciate the complexity involved in producing reliable tire inflators.

The first stage involves selecting high-quality materials, typically metals such as aluminum or steel for the housing, and durable plastics for the casing and components. The choice of materials impacts the compressor’s weight, durability, and performance. Advanced techniques like computer-aided design (CAD) are often employed to optimize the material layout, reducing waste and ensuring structural integrity.

Once materials are prepared, the forming process begins. This includes cutting, stamping, and machining to create the various components of the compressor. Techniques like die casting are commonly used for metal parts, ensuring precise shapes and dimensions. Additionally, injection molding may be utilized for plastic components, allowing for complex geometries that enhance functionality.

After forming, the components move to the assembly stage. This is a critical phase where skilled technicians or automated systems fit together the various parts, including motors, pressure gauges, and hoses. Assembly lines often employ lean manufacturing principles to minimize waste and improve efficiency. Each assembly line may include specific stations where components are installed, tested, and prepared for the next phase.

The finishing stage involves applying surface treatments to enhance durability and aesthetic appeal. This may include powder coating, painting, or anodizing, which not only protect against corrosion but also improve the product’s visual quality. Quality control checks are integrated at this stage to ensure that the finishing meets the required standards before the compressor is packaged for distribution.

Illustrative image related to compressor for tires

Quality assurance (QA) is integral to the manufacturing process, ensuring that the final product meets international standards and customer expectations. B2B buyers should be aware of the QA processes in place to assess product reliability.

Manufacturers often adhere to international standards such as ISO 9001, which focuses on quality management systems. Compliance with these standards indicates that the manufacturer has established processes to ensure consistent quality. In addition to ISO, industry-specific certifications such as CE (Conformité Européenne) for European markets or API (American Petroleum Institute) standards for certain applications are critical indicators of quality.

Il controllo di qualità prevede diversi punti di controllo durante il processo di produzione:

Controllo qualità in entrata (CQI): At this stage, raw materials and components are inspected for defects before they enter the production line. This is crucial for preventing issues later in the manufacturing process.

Controllo di qualità in corso d'opera (IPQC): During assembly, ongoing inspections are conducted to ensure that each component is correctly installed and that the assembly meets design specifications. This stage often includes functional testing of individual components.

Controllo finale della qualità (CQC): Once the compressors are fully assembled, they undergo rigorous testing to verify that they function correctly and meet performance specifications. This may include pressure tests, noise level assessments, and durability evaluations.

Testing methods are vital to validate the performance and reliability of tire compressors. Common testing approaches include:

Test funzionali: Ensures that the compressor operates as intended under various conditions. This includes inflating tires to specified pressures and measuring the time taken to complete the task.

Test di durata: Simulates long-term use to assess the compressor’s lifespan. This may involve repetitive inflation cycles to identify potential failures.

Test di sicurezza: Evaluates the compressor’s safety features, including pressure relief valves and electrical components, ensuring compliance with safety standards.

For international buyers, particularly from regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is essential. Here are effective strategies:

Illustrative image related to compressor for tires

Conducting audits is a powerful way to assess a supplier’s manufacturing processes and quality assurance practices. Buyers should request detailed reports on quality control procedures, certifications, and test results. On-site audits can provide firsthand insight into the supplier’s operations, allowing buyers to evaluate compliance with international standards.

Engaging third-party inspection agencies can add an extra layer of assurance. These agencies can perform independent quality assessments, ensuring that products meet specified standards before shipment. This is particularly crucial for buyers importing goods across borders, where discrepancies can lead to costly delays and compliance issues.

International buyers must be aware of the nuances associated with different markets. Certifications may vary by region, and understanding these differences is critical for compliance. For instance, products sold in Europe may require CE marking, whereas products entering the U.S. may need to meet different safety standards. Buyers should ensure that suppliers can provide documentation for the necessary certifications.

For B2B buyers in the tire compressor market, comprehending the manufacturing processes and quality assurance mechanisms is vital. By familiarizing themselves with these elements, buyers can make informed decisions, ensuring that they partner with reliable suppliers who deliver high-quality products that meet international standards. This knowledge not only enhances purchasing strategies but also builds long-term relationships based on trust and quality assurance.

Illustrative image related to compressor for tires

When sourcing a compressor for tires, it’s essential to follow a structured approach to ensure you select the right equipment that meets your operational needs. This guide serves as a practical checklist to assist B2B buyers in making informed decisions, particularly in diverse markets such as Africa, South America, the Middle East, and Europe.

Establish clear technical requirements based on the intended use of the tire compressors. Consider factors such as the maximum PSI needed, portability, power source (electric vs. battery-operated), and any specific features required (like built-in gauges or additional adapters). This step is crucial as it lays the foundation for your procurement process and helps in comparing different products effectively.

Stay informed about the latest trends in tire compressor technology. Innovations can significantly impact efficiency and user experience. For instance, advanced features like automatic shut-off and digital pressure displays enhance usability and safety. Understanding market trends will help you identify which features are essential for your target audience and improve your competitive edge.

Before committing to any supplier, conduct thorough evaluations. Request company profiles, product catalogs, and references from other clients, particularly those in your industry or region. Look for suppliers with a proven track record of reliability and quality, as this can affect the performance and longevity of the compressors you intend to purchase.

Illustrative image related to compressor for tires

Once you have shortlisted potential suppliers, request samples of the compressors for hands-on evaluation. Testing the compressors in real-world conditions will help you assess their performance, ease of use, and durability. Pay attention to how quickly they inflate tires and their noise levels during operation.

Carefully analyze the pricing structures of the shortlisted suppliers. Compare not only the unit prices but also consider bulk order discounts, shipping costs, and payment terms. This step is crucial for budgeting and ensuring that you’re getting a competitive deal without sacrificing quality.

Understanding the warranty and return policies is essential to safeguard your investment. A robust warranty indicates the manufacturer’s confidence in their product. Ensure that you have clear terms regarding repairs, replacements, and the process for returning faulty units.

Once you’ve selected a supplier, finalize your order by confirming specifications, quantities, and delivery timelines. Establish logistics for shipping and handling, particularly if you are dealing with international suppliers. Clear communication regarding delivery schedules and customs clearance processes will ensure a smooth procurement experience.

Illustrative image related to compressor for tires

By following this checklist, B2B buyers can effectively navigate the sourcing process for tire compressors, ensuring they select the best products that meet their operational needs while maintaining cost efficiency.

When sourcing compressors for tires, understanding the cost structure and pricing dynamics is crucial for international B2B buyers. The costs associated with these products typically encompass several components, including materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and supplier margins.

I materiali: The choice of materials significantly impacts the cost. Common materials include high-grade plastics for housing, metal alloys for internal components, and rubber for seals. Quality materials enhance durability and performance, leading to higher initial costs but potentially lower long-term maintenance.

Lavoro: Labor costs vary depending on the manufacturing location. Regions with lower labor costs, such as parts of Asia or Africa, can offer competitive pricing. However, skilled labor is essential for quality assurance, especially in regions with stringent manufacturing standards.

Spese generali di produzione: This includes costs related to utilities, equipment maintenance, and factory operations. Efficient manufacturing processes can reduce these overhead costs, positively affecting pricing.

Utensili: Initial tooling costs can be substantial, particularly for customized or high-specification products. Buyers should inquire about the amortization of these costs over production volume to assess their impact on unit pricing.

Controllo qualità: Implementing robust QC processes ensures product reliability but can increase costs. Certifications, such as ISO or CE, are essential for compliance in various markets and may add to the manufacturing expense.

Logistica: Shipping and handling costs vary significantly based on distance, shipping method, and the Incoterms agreed upon. International buyers must consider these logistics costs when evaluating total pricing.

Margine: Supplier margins can fluctuate based on market conditions, demand, and competition. Understanding the typical markup in different regions can help buyers negotiate better pricing.

Several factors influence pricing beyond the basic cost components.

Volume e quantità minima d'ordine (MOQ): Larger orders often qualify for volume discounts. Buyers should negotiate MOQs that align with their inventory management strategies to maximize cost-efficiency.

Specifiche e personalizzazione: Custom features, such as specific PSI ratings or additional functionalities (like built-in pressure gauges or battery options), can increase costs. Buyers should evaluate whether these features are essential for their target market.

Qualità dei materiali e certificazioni: Higher-quality materials and certifications often command a premium. However, they can lead to lower failure rates and reduced warranty claims, impacting the Total Cost of Ownership (TCO).

Fattori di fornitura: The reputation and reliability of suppliers can affect pricing. Established manufacturers with proven track records may offer higher prices but provide peace of mind regarding product quality and support.

Incoterms: Understanding Incoterms is critical for international buyers. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) affect the total landed cost of products and should be clearly defined in contracts.

Condurre ricerche di mercato: Understand current market trends and pricing benchmarks to negotiate effectively. Having comparative pricing information can empower buyers during discussions.

Valutare il costo totale di proprietà: Consider not just the purchase price but also operational costs, maintenance, and potential downtime when assessing overall value.

Sfruttare le relazioni: Building strong relationships with suppliers can lead to better pricing, improved service, and priority during high-demand periods.

Be Prepared to Walk Away: If a supplier cannot meet your pricing or quality standards, be ready to explore alternative options. This mindset can strengthen your negotiation position.

Understand Regional Pricing Nuances: Be aware of regional differences in pricing strategies. For instance, buyers in Nigeria may face different logistics costs compared to those in Germany, influencing overall pricing strategies.

In conclusion, while indicative prices for tire compressors can vary widely based on the factors outlined, being informed about cost components, price influencers, and negotiation strategies can equip international B2B buyers with the knowledge needed to make advantageous purchasing decisions.

In the realm of tire maintenance, selecting the right inflation solution is crucial for operational efficiency and safety. While tire compressors are a popular choice, several alternative solutions exist that may better suit specific business needs. This section examines the performance, cost, ease of implementation, maintenance requirements, and best use cases for both tire compressors and viable alternatives.

| Aspetto di confronto | Compressor For Tires | Gonfiatore portatile per pneumatici | Manual Hand Pump |

|---|---|---|---|

| Prestazioni | High PSI, suitable for all vehicle types | Moderate PSI, ideal for cars and small vehicles | Low PSI, limited to smaller tires |

| Costo | Moderate to High | Low to Moderate | Very Low |

| Facilità di implementazione | Requires power source, easy to use | Battery-operated or plug-in, user-friendly | Manual operation, requires physical effort |

| Manutenzione | Regular checks needed, durable | Minimal maintenance, portable | Low maintenance, durable |

| Il miglior caso d'uso | Commercial fleets, heavy-duty vehicles | Personal vehicles, emergencies | Bicycles, small vehicles, outdoor activities |

Portable tire inflators are compact and designed for ease of use, making them a popular choice for individual vehicle owners. They typically operate on battery power or can be plugged into a vehicle’s 12V outlet. The performance can vary, with some models capable of inflating tires to moderate pressures (up to 150 PSI), making them suitable for most passenger vehicles. Their low cost and convenience make them an attractive option for emergency situations. However, they might not perform as efficiently for larger vehicles or in commercial applications where high volume and rapid inflation are necessary.

Illustrative image related to compressor for tires

Manual hand pumps offer a very economical solution for tire inflation, especially for smaller tires like those on bicycles or recreational vehicles. They are lightweight and require no power source, making them ideal for remote areas or outdoor activities. However, their performance is limited, as they typically do not provide the high PSI needed for standard car tires. The physical effort required can be a downside, especially for those who need to inflate multiple tires frequently. While they require minimal maintenance, their practicality is constrained to specific use cases and they may not be suitable for commercial operations.

When selecting a tire inflation solution, B2B buyers should consider several factors: the types of vehicles in use, the frequency of tire inflation, and the operational environment. For businesses managing a fleet of heavy-duty vehicles, a compressor for tires may be the best option due to its high performance and durability. Conversely, for personal use or in emergency situations, a portable tire inflator might provide the necessary convenience at a lower cost. Manual hand pumps, while limited, can serve niche markets effectively, particularly for outdoor enthusiasts or small-scale operations. Ultimately, understanding the specific needs of your operations will guide you to the most effective tire inflation solution.

When evaluating compressors for tires, understanding key specifications is crucial for making informed purchasing decisions. Here are critical technical properties that B2B buyers should consider:

The maximum pressure indicates the highest air pressure the compressor can produce, typically measured in pounds per square inch (PSI). For tire inflators, a range of 80-160 PSI is common. This specification is vital for compatibility with various tire types, especially for heavy-duty vehicles, ensuring optimal performance and safety.

The duty cycle represents the percentage of time a compressor can operate before it requires a rest period. For example, a 50% duty cycle means the compressor can run for 5 minutes and must rest for 5 minutes. This property is essential for understanding how long a compressor can function without overheating, particularly in commercial applications where efficiency is paramount.

Compressors can be powered by electricity (AC), vehicle batteries (DC), or rechargeable batteries. Understanding the power source is crucial for operational flexibility and convenience. For example, battery-operated models are portable and suitable for remote locations, while AC models may be more efficient for garage use.

Measured in cubic feet per minute (CFM), the airflow rate indicates how quickly air is delivered to the tire. A higher CFM is beneficial for rapid inflation, which is particularly important in commercial settings where time is money. This specification helps buyers assess the efficiency of the compressor in real-world scenarios.

Illustrative image related to compressor for tires

The weight of the compressor affects its portability. Lightweight models are easier to transport and store, making them suitable for emergency kits or on-the-go applications. For B2B buyers, balancing weight with performance capabilities is crucial to meet specific operational needs.

The material used in the construction of the compressor affects its durability and lifespan. Common materials include plastic and metal, with metal typically offering greater durability. Understanding the build quality is essential for ensuring that the compressor can withstand the rigors of frequent use in various environments.

Familiarity with industry jargon can enhance communication and negotiation with suppliers. Here are essential terms to know:

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of tire compressors, understanding whether a product is OEM can indicate quality and compatibility with existing equipment.

MOQ is the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ helps buyers plan inventory and budget effectively, ensuring they meet supplier requirements while avoiding excess stock.

An RFQ is a document used to solicit price quotes from suppliers for specific products or services. This process is crucial in B2B transactions, as it allows buyers to compare offers and negotiate better terms.

Incoterms are a set of rules that define the responsibilities of sellers and buyers in international transactions. Understanding these terms is essential for managing shipping costs and liabilities, ensuring smooth logistics operations.

Warranties outline the terms under which a manufacturer will repair or replace defective products. Service agreements specify maintenance and support services provided. Knowledge of these terms is vital for assessing the long-term value and reliability of a compressor investment.

By grasping these technical properties and trade terminologies, B2B buyers can make informed decisions, ensuring they select the right compressors for their operational needs.

The global compressor for tires market is experiencing a significant transformation driven by several key factors. First, the increasing demand for efficient tire maintenance solutions is reshaping the landscape. As vehicle ownership rises in regions like Africa and South America, the need for reliable and portable tire inflators is becoming crucial. Additionally, advancements in technology are leading to the development of more compact and energy-efficient models, appealing to both individual consumers and businesses. International B2B buyers are particularly interested in products that offer multi-functionality, such as inflators that can also serve as power banks or include built-in pressure gauges.

Illustrative image related to compressor for tires

Moreover, the ongoing trend towards e-commerce is influencing sourcing strategies. Buyers can now access a wider range of products and suppliers globally, allowing for competitive pricing and enhanced product variety. In markets like Germany and Nigeria, where logistics can be challenging, suppliers offering efficient shipping and after-sales support are gaining a competitive edge. Furthermore, the rise of electric vehicles is prompting innovations in tire compressor technology, with manufacturers exploring eco-friendly solutions that align with the growing emphasis on sustainability.

Sustainability is becoming a cornerstone of the compressor for tires market, as both consumers and businesses increasingly prioritize environmental impact. The production of tire inflators typically involves materials that can harm the environment if not sourced responsibly. As a result, ethical sourcing practices are gaining traction, with an emphasis on transparency in the supply chain. International B2B buyers are encouraged to seek suppliers who can demonstrate their commitment to sustainability through certifications such as ISO 14001 or other green accreditations.

Manufacturers are also exploring the use of recycled materials and eco-friendly manufacturing processes. For instance, some companies are beginning to produce compressors with parts made from sustainable plastics or metals, which not only minimize environmental impact but also appeal to the eco-conscious consumer. By prioritizing suppliers who focus on ethical sourcing and sustainability, B2B buyers can enhance their brand reputation and meet the growing demand for environmentally responsible products.

The compressor for tires market has evolved significantly over the past few decades, transitioning from bulky, manual pumps to sophisticated, portable electric inflators. Initially, tire inflation was a labor-intensive process requiring manual effort, which limited accessibility for many vehicle owners. The introduction of electric compressors revolutionized the market, providing a faster and more efficient solution for tire maintenance.

As technology progressed, manufacturers began incorporating features such as digital pressure gauges, automatic shut-off functions, and compact designs, making tire inflators more user-friendly. This evolution has been particularly impactful in developing regions, where access to reliable tire maintenance solutions has historically been limited. Today, the market continues to innovate, with a focus on enhancing usability and sustainability, catering to the needs of a diverse global customer base. International B2B buyers are now more equipped than ever to choose from a variety of advanced products that meet their specific requirements.

1. How do I choose the right compressor for tires for my business needs?

Choosing the right compressor for tires involves assessing your specific requirements, such as the volume of tires you need to inflate and the types of vehicles you service. Consider the compressor’s PSI (pounds per square inch) rating to ensure it meets the demands of heavy-duty vehicles if necessary. Evaluate features like portability, power source (electric vs. battery-operated), and additional functionalities such as built-in pressure gauges or adapters. Additionally, analyze the compressor’s duty cycle to ensure it can handle your workload without overheating.

2. What is the best type of tire compressor for commercial use?

For commercial use, the best type of tire compressor is typically a heavy-duty model that can handle high PSI levels and frequent use. Look for compressors with a minimum output of 150 PSI, especially if you work with larger vehicles like trucks and SUVs. Models with a quick inflation rate and durable construction are ideal, as they reduce downtime and enhance efficiency. Brands like Viair and AstroAI offer robust options that cater to commercial needs, ensuring reliability and performance under demanding conditions.

3. What should I consider when vetting suppliers for tire compressors?

When vetting suppliers for tire compressors, prioritize their reputation, experience in the industry, and customer reviews. Request product certifications and compliance with international quality standards to ensure reliability and safety. Evaluate their production capabilities, lead times, and flexibility in meeting your specific requirements, such as customization options. Additionally, assess their after-sales support and warranty policies to ensure a comprehensive partnership that safeguards your investment.

4. Are there minimum order quantities (MOQs) for tire compressors?

Yes, most manufacturers and suppliers set minimum order quantities (MOQs) for tire compressors, which can vary significantly based on the model and supplier. Generally, MOQs can range from a few units to several dozen, depending on production capabilities and inventory levels. It’s essential to communicate your needs with potential suppliers to negotiate favorable terms that align with your business scale. Some suppliers may be open to lower MOQs for first-time orders to build a long-term relationship.

5. What payment terms should I expect when purchasing tire compressors internationally?

Payment terms for international purchases of tire compressors often vary by supplier but typically include options like upfront payment, deposits, or payment upon delivery. Common methods include wire transfers, letters of credit, and PayPal. It’s crucial to clarify payment timelines and any potential additional costs, such as tariffs or shipping fees. Establishing clear terms upfront can help avoid misunderstandings and foster a trustworthy relationship between you and your supplier.

6. How can I ensure quality assurance (QA) for tire compressors sourced internationally?

To ensure quality assurance for internationally sourced tire compressors, request certifications that validate compliance with international standards, such as ISO or CE marking. Implement a quality inspection process, either through third-party services or in-house checks, to verify product specifications upon arrival. Additionally, maintain open communication with your supplier about quality expectations and establish a return policy for defective products. Consistent QA practices can help mitigate risks and ensure your compressors meet operational requirements.

7. What logistics considerations are important when importing tire compressors?

When importing tire compressors, key logistics considerations include understanding shipping methods (air vs. sea), costs, and delivery timelines. Ensure that your chosen logistics provider is experienced in handling heavy machinery and can navigate customs regulations effectively. It’s also vital to account for potential delays in transit and plan for storage upon arrival. Establishing a solid logistics plan helps streamline the import process and ensures timely availability of your compressors for business operations.

8. Can I customize tire compressors for my specific business needs?

Yes, many manufacturers offer customization options for tire compressors, allowing you to tailor features such as size, power source, and additional functionalities to meet your specific business needs. Customization can also include branding options, such as logos or color schemes, to enhance your company’s visibility. When discussing customization with suppliers, provide clear specifications and expectations to ensure that the final product aligns with your operational requirements.

Dominio: automoblog.com

Registrato: 2004 (21 anni)

Introduzione: Best Portable Tire Inflators for 2025: 1. Slime Cordless Tire Inflator – Easy to use and stow. 2. 20V Avid Power – Drill-style design and carrying case. 3. Fanttik X8 Apex – Overall good quality and functionality. 4. DeWalt 20V MAX – Built for lifetime usage and ownership. 5. Milwaukee M18 – Robust and powerful with four different memory settings. Price range: $80 to $180. Battery life and chargin…

In summary, strategic sourcing of tire compressors is essential for businesses aiming to enhance operational efficiency and customer satisfaction. By focusing on quality, compatibility, and cost-effectiveness, international buyers can secure reliable inflators that meet diverse market needs. Key considerations include evaluating specifications like pressure capacity, portability, and ease of use, which can directly impact service delivery and customer retention.

Additionally, establishing robust supplier relationships will facilitate access to cutting-edge technology and better pricing, ultimately driving profitability. As markets across Africa, South America, the Middle East, and Europe continue to evolve, the demand for reliable tire compressors is set to rise, providing a lucrative opportunity for savvy buyers.

Looking ahead, businesses should prioritize innovation and sustainability in their sourcing strategies. Embracing the latest advancements in tire inflation technology can lead to significant operational improvements and a competitive edge. International buyers are encouraged to engage with reputable suppliers to navigate this dynamic landscape effectively and ensure long-term success in their tire compressor investments.

Le informazioni fornite in questa guida, compresi i contenuti relativi ai produttori, alle specifiche tecniche e all'analisi di mercato, hanno uno scopo puramente informativo ed educativo. Non costituiscono una consulenza professionale in materia di acquisti, né una consulenza finanziaria o legale.

Illustrative image related to compressor for tires

Pur avendo compiuto ogni sforzo per garantire l'accuratezza e la tempestività delle informazioni, non siamo responsabili di eventuali errori, omissioni o informazioni non aggiornate. Le condizioni di mercato, i dettagli aziendali e gli standard tecnici sono soggetti a modifiche.

Gli acquirenti B2B devono condurre una due diligence indipendente e approfondita. prima di prendere qualsiasi decisione di acquisto. È necessario contattare direttamente i fornitori, verificare le certificazioni, richiedere campioni e chiedere una consulenza professionale. Il rischio di affidarsi alle informazioni contenute in questa guida è esclusivamente a carico del lettore.