In an increasingly competitive landscape, sourcing high-pressure tire inflators that meet specific operational needs can be a daunting task for international B2B buyers. The challenge lies not only in identifying reliable suppliers but also in understanding the various types of inflators available, their applications, and the associated costs. This guide is designed to empower businesses, particularly those in regions such as Africa, South America, the Middle East, and Europe—including key markets like Nigeria and Germany—by providing a comprehensive overview of the high-pressure tire inflator market.

Throughout this guide, we will explore the different types of high-pressure tire inflators, detailing their unique features and applications across various industries. Additionally, we will cover essential aspects of supplier vetting, ensuring that buyers can make informed decisions based on quality, service, and reliability. Cost considerations will also be addressed, offering insights into budgeting and potential return on investment.

By equipping buyers with the knowledge needed to navigate the complexities of sourcing high-pressure tire inflators, this guide aims to streamline the purchasing process and enhance operational efficiency. Whether you are a fleet manager, automotive service provider, or equipment distributor, understanding the nuances of this market will help you secure the best solutions tailored to your business needs.

| Nome del tipo | Caratteristiche distintive principali | Applicazioni primarie B2B | Brevi pro e contro per gli acquirenti |

|---|---|---|---|

| Automatic Tire Inflators | Hands-free operation, preset pressure settings, nitrogen compatibility | Fleet maintenance, tire shops | Pro: Efficient, accurate, saves time. Contro: Investimento iniziale più elevato. |

| Portable Tire Inflators | Compact design, battery or car-powered, versatile use | Roadside assistance, personal use | Pro: Easy to transport, affordable. Contro: Limited pressure capacity. |

| Wall-Mounted Tire Inflators | Fixed installation, long air hose, high PSI capability | Workshops, garages, commercial fleets | Pro: Saves space, consistent performance. Contro: Requires permanent installation. |

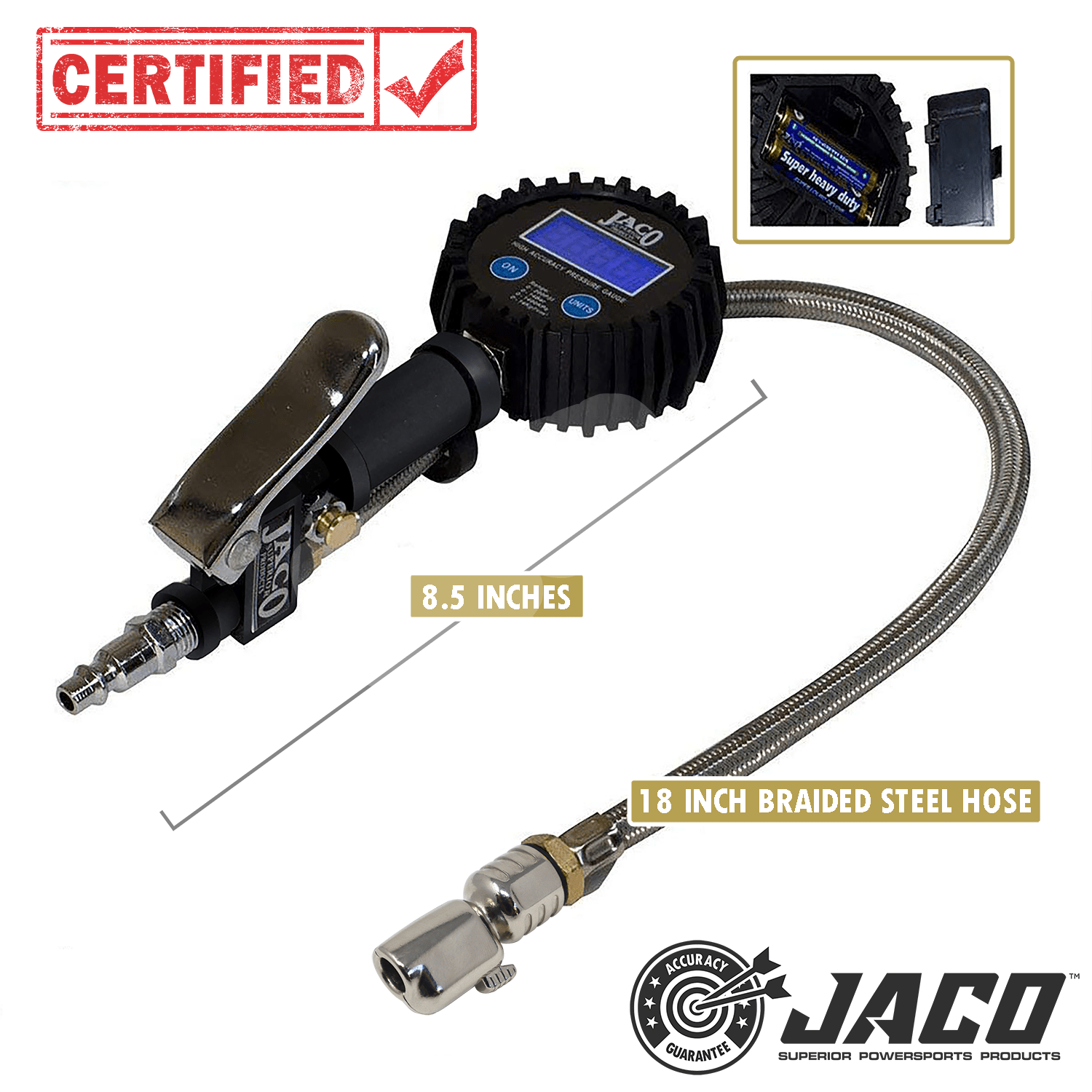

| Gonfiatori digitali per pneumatici | Digital readouts, programmable settings, precision inflation | Automotive service centers | Pro: High accuracy, user-friendly. Contro: May require calibration. |

| Heavy-Duty Tire Inflators | Robust construction, high pressure output, industrial-grade | Mining, construction, heavy machinery | Pro: Built to last, handles extreme conditions. Contro: Expensive, bulky. |

Automatic tire inflators are designed for efficiency and ease of use, allowing users to inflate tires without manual intervention. They typically feature preset pressure settings and can accommodate various tire types, including those requiring high pressures. This type is particularly suitable for businesses managing a fleet of vehicles or tire service centers, where quick turnaround times are crucial. When considering an automatic inflator, businesses should evaluate the unit’s PSI capabilities, compatibility with nitrogen inflation, and the necessary air compressor requirements.

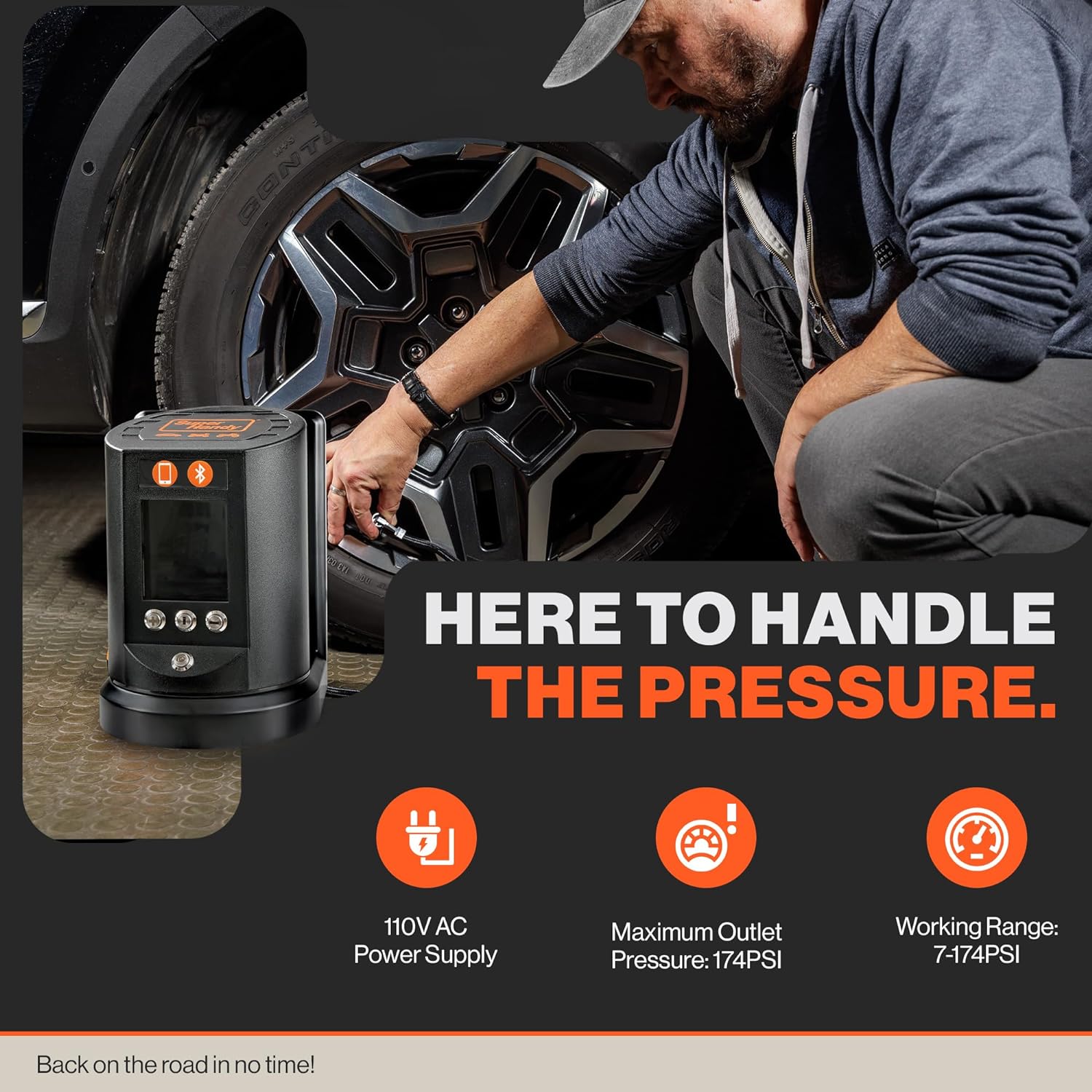

Portable tire inflators offer flexibility and convenience for on-the-go applications. These compact devices can be powered by either a vehicle’s battery or an AC outlet, making them ideal for roadside assistance or personal use. While they are generally more affordable, their pressure capacity may be limited compared to larger units. B2B buyers should consider the inflator’s portability, ease of use, and compatibility with various tire types to ensure it meets their operational needs.

Illustrative image related to high pressure tire inflator

Wall-mounted tire inflators are fixed installations that provide a reliable solution for workshops, garages, and commercial fleets. They usually come with long air hoses, allowing easy access to multiple vehicles without needing to move the unit. Their ability to deliver high pressure makes them suitable for larger tires found in trucks and buses. When purchasing, businesses should assess the inflator’s maximum PSI, durability, and maintenance requirements to ensure it aligns with their operational demands.

Digital tire inflators stand out due to their precision and user-friendly interfaces, often featuring digital readouts and programmable settings. This technology ensures accurate inflation, which is critical for maintaining tire health and safety. They are well-suited for automotive service centers that require consistent performance and accuracy. Buyers should consider the calibration needs, ease of use, and the accuracy of pressure readings when evaluating digital inflators.

Heavy-duty tire inflators are engineered to withstand rigorous conditions and are commonly used in industries such as mining and construction. These inflators can handle high-pressure outputs and are built with robust materials to ensure longevity. While they tend to be more expensive and bulkier than other types, their durability makes them a worthy investment for businesses that rely on heavy machinery. Key purchasing considerations include the unit’s pressure capacity, construction quality, and overall maintenance requirements to ensure reliability in demanding environments.

| Industria/Settore | Specific Application of High Pressure Tire Inflator | Valore/Beneficio per l'azienda | Considerazioni chiave sull'approvvigionamento per questa applicazione |

|---|---|---|---|

| Transportation | Fleet Maintenance for Commercial Vehicles | Reduces downtime by ensuring optimal tire pressure quickly | Ensure compatibility with existing air compressor systems. |

| Aviation | Ground Support Equipment Tire Inflation | Enhances safety and efficiency in aircraft operations | Look for inflators with high PSI capabilities and nitrogen options. |

| Mining | Heavy Equipment Tire Inflation | Improves productivity by minimizing equipment failure | Consider durability and performance in harsh environments. |

| Agricoltura | Agricultural Machinery Tire Inflation | Increases operational efficiency and reduces tire wear | Evaluate for compatibility with various tire sizes and types. |

| Produzione | Industrial Vehicle Tire Maintenance | Ensures safety and reduces maintenance costs over time | Focus on units with automatic calibration and easy installation. |

In the transportation sector, high pressure tire inflators are vital for maintaining the fleet of commercial vehicles. These inflators can quickly inflate tires to optimal pressure, thereby reducing downtime and enhancing fuel efficiency. The ability to maintain the correct tire pressure ensures better handling and safety on the road. For international buyers, especially from regions like Africa and South America, it is crucial to source inflators that are compatible with their existing air compressor systems and can function reliably in varying climatic conditions.

In aviation, high pressure tire inflators are essential for ground support equipment, including tugs and baggage carts. Proper tire inflation is critical for the safety and efficiency of aircraft operations. These inflators often come with features like nitrogen compatibility, which helps maintain tire integrity and performance. Buyers in Europe and the Middle East should prioritize inflators that offer high PSI capabilities and have robust safety certifications to meet stringent aviation standards.

Illustrative image related to high pressure tire inflator

The mining industry relies heavily on heavy equipment that requires regular tire maintenance. High pressure tire inflators enable quick and efficient inflation of large tires, minimizing the risk of equipment failure due to under-inflated tires. This not only boosts productivity but also enhances safety on-site. Buyers in harsh environments must consider inflators designed for durability and performance, ensuring they can withstand the rigors of mining operations.

In agriculture, maintaining the tire pressure of tractors and other machinery is essential for operational efficiency. High pressure tire inflators help farmers quickly adjust tire pressure, which can lead to reduced tire wear and improved fuel efficiency. Buyers should evaluate inflators for their compatibility with various tire sizes and types, particularly in regions like Africa where diverse agricultural machinery is used.

In manufacturing, high pressure tire inflators are crucial for the maintenance of industrial vehicles, such as forklifts and delivery trucks. Keeping tires at the correct pressure not only ensures safety but also reduces maintenance costs over time. For B2B buyers, it is important to focus on units that offer automatic calibration and easy installation, ensuring minimal disruption to operations while maximizing efficiency.

Illustrative image related to high pressure tire inflator

Il problema: Many B2B buyers, particularly in industries such as transportation and logistics, face the challenge of maintaining consistent tire pressure across their fleet. High-pressure tire inflators often struggle to deliver precise inflation, leading to issues such as uneven tire wear, reduced fuel efficiency, and increased operational costs. This inconsistency can be especially problematic in regions where environmental factors, like temperature fluctuations, impact tire performance. Buyers might find that some inflators do not adequately measure or maintain the desired pressure, resulting in tires that are either over-inflated or under-inflated.

La soluzione: To combat this issue, it is essential for buyers to select high-pressure tire inflators equipped with automatic calibration features and precise pressure gauges. When sourcing these inflators, look for models that offer real-time pressure readings and the ability to set specific targets. Ensure the chosen model, such as the Flatematic High Pressure, provides multiple measurement units and an audible alert when the desired pressure is reached. Additionally, integrating a maintenance schedule to regularly check the calibration of the inflator will ensure ongoing accuracy and reliability, ultimately leading to better tire performance and cost savings.

Il problema: Another common pain point for B2B buyers is the compatibility of high-pressure tire inflators with existing air compressor systems. Many inflators require specific air supply conditions, such as a stable pressure range and the absence of moisture and oil, which can lead to operational inefficiencies and equipment damage. Buyers may experience frustration when their inflators do not function optimally due to inadequate air supply or incorrect pressure settings, causing delays in service and increased downtime.

La soluzione: Buyers should prioritize the procurement of high-pressure tire inflators that specify their air supply requirements clearly. When selecting an inflator, confirm that it can be paired with air compressors capable of maintaining the required inlet pressure while also being equipped with proper filtration systems. Incorporating an air filter to remove moisture and oil from compressed air will not only prolong the life of the inflator but also enhance its performance. Conducting a comprehensive review of existing air compressor systems to ensure compatibility before purchasing an inflator can prevent future complications and facilitate smoother operations.

Illustrative image related to high pressure tire inflator

Il problema: In many businesses, especially those in sectors like mining or construction, accessibility to tires for inflation can be challenging. Manual inflation methods can be time-consuming and labor-intensive, leading to increased labor costs and operational inefficiencies. B2B buyers often find themselves in situations where tires are located in hard-to-reach areas, making it difficult to provide timely and effective maintenance.

La soluzione: To address this accessibility issue, B2B buyers should consider high-pressure tire inflators that come with extended hoses and wall-mounted designs, such as the Flatematic High Pressure. Opting for units with a 25-foot air hose allows for greater reach, ensuring that all tires can be easily accessed without the need for extensive movement or repositioning of equipment. Furthermore, investing in automatic inflators that start inflation upon connection frees up personnel to attend to other tasks while the inflation process occurs, thus enhancing overall productivity. Establishing a designated area with clear access to inflators can also streamline tire maintenance operations.

When selecting materials for high pressure tire inflators, it is essential to consider their properties, advantages, disadvantages, and how they align with the specific needs of international B2B buyers. Here, we analyze four common materials used in the construction of these devices: aluminum, stainless steel, reinforced plastics, and rubber.

Aluminum is widely used in high pressure tire inflators due to its lightweight and excellent strength-to-weight ratio. It typically has a pressure rating that can exceed 300 psi, making it suitable for high-pressure applications. Additionally, aluminum exhibits good corrosion resistance, particularly when anodized, which is crucial for durability in various environments.

Pro: Aluminum is durable, lightweight, and cost-effective, making it an ideal choice for portable inflators. Its ease of manufacturing allows for complex designs and shapes.

Contro: While aluminum is resistant to corrosion, it can be susceptible to scratches and dents. Furthermore, it may not perform well in extremely high temperatures compared to other metals.

Impatto sull'applicazione: Aluminum is compatible with air and nitrogen, which are commonly used in tire inflation. However, care must be taken to ensure that the inflator is protected from prolonged exposure to harsh environments.

Considerazioni per gli acquirenti internazionali: Compliance with international standards such as ASTM or DIN is essential. Buyers from regions like Germany may prefer aluminum products that meet stringent European safety standards.

Stainless steel is another popular material for high pressure tire inflators, particularly for components that require high durability and corrosion resistance. With a pressure rating often exceeding 500 psi, stainless steel is ideal for heavy-duty applications.

Pro: The primary advantage of stainless steel is its exceptional resistance to corrosion and wear, making it suitable for harsh environments. It also has a longer lifespan than aluminum, reducing the need for frequent replacements.

Contro: The primary disadvantage is its higher cost compared to aluminum. Additionally, stainless steel is heavier, which may not be ideal for portable inflators.

Impatto sull'applicazione: Stainless steel is compatible with a wide range of gases, including air and nitrogen. Its robustness makes it ideal for industrial applications where reliability is critical.

Illustrative image related to high pressure tire inflator

Considerazioni per gli acquirenti internazionali: Buyers in the Middle East and Africa should ensure that the stainless steel used complies with local corrosion resistance standards, particularly in humid or saline environments.

Reinforced plastics, such as fiberglass-reinforced nylon, are increasingly being used in high pressure tire inflators for non-structural components. These materials can withstand moderate pressure and provide excellent resistance to corrosion and chemicals.

Pro: Reinforced plastics are lightweight and can be molded into complex shapes, offering design flexibility. They are also generally more cost-effective than metals.

Contro: The primary limitation is their lower pressure rating compared to metals, which may restrict their use in high-pressure applications. They may also be less durable under extreme temperatures.

Impatto sull'applicazione: Reinforced plastics can be used for housings and non-critical components, but they may not be suitable for high-pressure connections or fittings.

Considerazioni per gli acquirenti internazionali: Buyers should verify the chemical compatibility of reinforced plastics with the media being used. Compliance with safety standards is also critical, especially in regions with strict regulations.

Rubber is commonly used in seals and hoses within high pressure tire inflators. It is essential for ensuring airtight connections and preventing leaks.

Illustrative image related to high pressure tire inflator

Pro: Rubber is flexible, durable, and provides excellent sealing capabilities. It can also withstand a range of temperatures, making it versatile for various applications.

Contro: Rubber can degrade over time, especially when exposed to UV light and ozone, which may necessitate more frequent replacements.

Impatto sull'applicazione: The effectiveness of rubber seals is crucial for maintaining pressure and ensuring the safety of the inflator.

Considerazioni per gli acquirenti internazionali: Buyers should ensure that rubber components meet international standards for durability and safety, especially in regions with extreme weather conditions.

Illustrative image related to high pressure tire inflator

| Materiale | Typical Use Case for high pressure tire inflator | Vantaggio chiave | Svantaggi/limitazioni principali | Costo relativo (Basso/Medio/Alto) |

|---|---|---|---|---|

| Alluminio | Body and structural components | Leggero e conveniente | Susceptible to scratches and dents | Medio |

| Acciaio inox | Heavy-duty components and fittings | Exceptional corrosion resistance | Higher cost and weight | Alto |

| Reinforced Plastics | Housings and non-critical components | Lightweight and design flexibility | Lower pressure rating | Basso |

| Gomma | Seals and hoses | Excellent sealing capabilities | Si degrada nel tempo | Basso |

This guide provides actionable insights into material selection for high pressure tire inflators, helping international B2B buyers make informed decisions based on performance, cost, and compliance considerations.

The manufacturing process for a high pressure tire inflator involves several critical stages, each designed to ensure that the final product meets performance and safety standards.

The first step in manufacturing is material preparation. Manufacturers typically source high-quality materials such as aluminum for the casing, rubber for hoses, and electronic components for the control system. These materials are selected based on their durability, resistance to pressure, and performance under varying environmental conditions. Suppliers often provide material certifications that verify compliance with international standards, ensuring that the materials can withstand the demands of high-pressure operation.

Illustrative image related to high pressure tire inflator

Once materials are prepared, the forming stage begins. This involves shaping the aluminum casing and other components using techniques such as extrusion and machining. Advanced CNC (Computer Numerical Control) machines are often employed to achieve precise dimensions and tolerances. This accuracy is crucial for the proper functioning of the inflator, especially given the high pressures involved.

The assembly process is critical for ensuring that all components fit together correctly and function as intended. Skilled technicians or automated systems carefully assemble the inflator, integrating the air hoses, electronic controls, and safety mechanisms. During this stage, manufacturers may utilize automated assembly lines to enhance efficiency and reduce human error.

Finishing touches include surface treatments like anodizing or powder coating, which enhance durability and corrosion resistance. Additionally, manufacturers may apply labels and markings that comply with international standards, making it easier for users to understand operational guidelines. This stage is essential for both aesthetic appeal and functional longevity.

Quality assurance (QA) is a fundamental aspect of the manufacturing process, ensuring that high pressure tire inflators meet stringent performance and safety standards.

Most manufacturers adhere to international quality standards such as ISO 9001, which establishes a framework for effective quality management systems. Compliance with ISO standards is crucial for B2B buyers, as it indicates that the manufacturer has established processes for continuous improvement and customer satisfaction. Additionally, industry-specific certifications, such as CE marking in Europe and API standards in the oil and gas sectors, provide further assurance of product quality.

Quality control (QC) checkpoints are integrated throughout the manufacturing process to identify and address issues early on. Common checkpoints include:

Various testing methods are employed to validate the performance and safety of high pressure tire inflators. Some common methods include:

For B2B buyers, especially those from regions like Africa, South America, the Middle East, and Europe, verifying the quality control practices of suppliers is paramount. Here are actionable steps buyers can take:

Illustrative image related to high pressure tire inflator

International buyers should be aware of specific nuances in quality control that may vary by region. For instance, regulatory compliance can differ significantly between Europe and Africa, necessitating a thorough understanding of local standards.

Additionally, language barriers and cultural differences may impact communication regarding quality expectations. Buyers should ensure that all specifications and quality requirements are clearly documented and understood by all parties involved.

In conclusion, the manufacturing and quality assurance processes for high pressure tire inflators are complex and multifaceted. By understanding these processes and implementing thorough verification methods, B2B buyers can make informed decisions and ensure they are sourcing high-quality, reliable products.

Sourcing a high-pressure tire inflator requires careful consideration to ensure you select the right equipment for your business needs. This guide provides a step-by-step checklist to assist international B2B buyers—particularly from Africa, South America, the Middle East, and Europe—in making informed procurement decisions. By following these steps, you can ensure you acquire a reliable and efficient tire inflator that meets your operational requirements.

Illustrative image related to high pressure tire inflator

Establishing clear technical specifications is essential for identifying the right high-pressure tire inflator. Consider factors such as maximum pressure, compatibility with existing equipment, and specific features like automatic inflation or nitrogen purging capabilities.

– Key Specifications to Identify:

– Maximum pressure rating (e.g., 232 psi).

– Required hose length and type of chuck.

Before engaging with suppliers, conduct thorough research to assess their credibility. Look for established companies with a solid reputation in the industry.

– Consider Checking:

– Company history and experience in the market.

– Customer reviews and testimonials from businesses similar to yours.

It’s crucial to vet potential suppliers thoroughly. Request detailed company profiles, case studies, and references from clients in similar industries or regions. This helps to gauge their reliability and the quality of their products.

– What to Look For:

– Product certifications (e.g., CE certification).

– After-sales support and maintenance services offered.

Once you’ve narrowed down potential suppliers, compare pricing structures and payment terms. While the lowest price may be tempting, consider the overall value, including warranty and service options.

– Considerazioni chiave:

– Total cost including shipping and handling.

– Availability of financing or installment payment options.

Illustrative image related to high pressure tire inflator

Understanding the supplier’s delivery times and logistics is crucial, especially for businesses that rely on timely operations. Confirm lead times and shipping methods to ensure they align with your operational needs.

– Logistics Factors to Verify:

– Shipping options available for your region.

– Estimated delivery timelines based on your location.

Different regions may have specific regulations regarding equipment safety and environmental standards. Verify that the inflator complies with local laws to avoid potential legal issues.

– Regulatory Aspects to Check:

– Safety certifications required in your country.

– Environmental impact regulations that may apply.

After selecting a supplier, finalize your order and ensure all details are documented clearly. This includes specifications, pricing, warranties, and delivery terms to prevent misunderstandings.

– Documentation Essentials:

– Written contract outlining terms and conditions.

– Confirmation of warranty and maintenance service agreements.

By following this checklist, you can navigate the procurement process for a high-pressure tire inflator effectively, ensuring you select the best option for your business.

Illustrative image related to high pressure tire inflator

The cost structure of high pressure tire inflators encompasses several critical components that directly impact the final pricing.

I materiali: The primary materials used in manufacturing tire inflators include aluminum for the casing, rubber for hoses, and various metals for internal components. The quality and sourcing of these materials can vary significantly, affecting the overall cost. Premium materials can lead to higher durability and performance but may increase the base price.

Lavoro: Labor costs are another significant factor, particularly in regions where skilled manufacturing personnel are in demand. Countries with higher labor costs may see inflated prices for inflators compared to those produced in areas with lower wages. Additionally, the complexity of the assembly process can affect labor expenses.

Spese generali di produzione: This includes costs related to facility maintenance, utilities, and administrative expenses. Efficient manufacturing processes can help minimize these overheads, thus lowering the price of the end product.

Utensili: The costs associated with the tools and machinery used in production can be substantial. Custom tooling for specialized designs can significantly increase initial costs but may provide long-term benefits through improved efficiency and product quality.

Controllo qualità (CQ): Implementing rigorous quality control measures is essential for maintaining product standards. This includes testing for pressure accuracy and ensuring compliance with safety certifications, which can add to the production costs.

Logistica: Shipping costs vary based on the destination, volume of goods, and chosen transportation methods. For international buyers, understanding logistics is crucial, as these costs can substantially affect the total price.

Margine: Finally, the profit margin set by manufacturers will influence the final price. This margin can fluctuate based on market competition, demand, and production costs.

Several factors influence the pricing of high pressure tire inflators that international buyers should consider:

Volume e quantità minima d'ordine (MOQ): Larger orders typically benefit from economies of scale, leading to lower per-unit costs. Negotiating MOQs can be beneficial for businesses looking to optimize pricing.

Specifiche e personalizzazione: Custom features, such as specific pressure ranges or additional functionalities (e.g., nitrogen compatibility), can increase costs. Understanding your needs upfront can help in negotiating the best price for tailored products.

Qualità dei materiali e certificazioni: Products with high-quality materials and certifications (e.g., CE marking) may command higher prices. Buyers should assess the necessity of such certifications based on their market requirements.

Fattori di fornitura: The reputation and reliability of the supplier can significantly influence pricing. Established suppliers may offer premium products at higher prices due to perceived value, while emerging manufacturers might offer competitive rates to gain market entry.

Incoterms: The choice of Incoterms (International Commercial Terms) affects shipping costs and responsibilities. Buyers should clarify these terms to avoid unexpected expenses during transportation.

Negotiation Strategies: Engage in discussions with suppliers about pricing flexibility, especially for larger orders. Understanding the cost structure can empower buyers to negotiate better terms.

Focus sull'efficienza dei costi: Consider the Total Cost of Ownership (TCO), which includes initial purchase price, maintenance, and operational costs over the product’s lifespan. This perspective can lead to more informed purchasing decisions.

Understanding Pricing Nuances: International buyers should be aware of fluctuations in currency exchange rates and their impact on pricing. Additionally, local market dynamics may affect supplier pricing strategies.

Conduct Thorough Market Research: Researching various suppliers and comparing their offerings can provide insights into competitive pricing and product quality. Utilizing trade shows and online platforms can facilitate this process.

By considering these cost components, pricing influencers, and strategic tips, B2B buyers can make more informed decisions when sourcing high pressure tire inflators, ensuring they achieve the best value for their investments.

In the realm of tire maintenance, high-pressure tire inflators provide a specialized solution for ensuring optimal tire pressure, especially in commercial settings. However, various alternatives can meet similar needs, each with distinct advantages and disadvantages. This section compares the high-pressure tire inflator against two notable alternatives: manual tire pumps and portable electric tire inflators.

Illustrative image related to high pressure tire inflator

| Aspetto di confronto | High Pressure Tire Inflator | Manual Tire Pump | Portable Electric Tire Inflator |

|---|---|---|---|

| Prestazioni | Up to 232 psi; fast inflation (2 min 20 sec for a standard tire) | Moderate pressure; slower inflation | Varies (typically 30-100 psi); moderate speed |

| Costo | Approximately $610 | Low cost (around $30) | Mid-range ($50 – $150) |

| Facilità di implementazione | Requires air compressor; wall-mounted | Simple, no power needed | Requires charging or power source; portable |

| Manutenzione | Regular calibration and air filter maintenance required | Minimal maintenance | Low maintenance; check battery and connections |

| Il miglior caso d'uso | Fleet maintenance, commercial vehicles | Personal vehicles, emergency use | Roadside assistance, small vehicle fleets |

Manual tire pumps are a traditional solution that offers simplicity and low cost. They are highly portable and do not require any power source, making them ideal for emergency situations or personal use. However, they require physical effort and can be time-consuming, especially when inflating larger tires. The maximum pressure achieved is often limited compared to high-pressure inflators, making them less suitable for commercial applications.

Portable electric tire inflators represent a modern approach, providing convenience and a range of inflation pressures suitable for various vehicles. They are easy to use, often equipped with digital displays and automatic shut-off features. While they are more expensive than manual pumps, they are generally cheaper than high-pressure inflators. However, their performance may not match that of high-pressure inflators, especially for larger tires or commercial fleets that require rapid inflation.

When selecting a tire inflation solution, B2B buyers should consider their specific needs, including the types of vehicles in use, inflation speed requirements, and available budget. High-pressure tire inflators are optimal for businesses with a fleet of vehicles requiring quick, precise tire inflation, particularly in high-pressure contexts. In contrast, manual pumps may suffice for smaller operations or personal use, while portable electric inflators offer a balance of convenience and cost-effectiveness for light commercial applications. Evaluating these factors will help ensure that you choose the most efficient solution for your tire maintenance needs.

Illustrative image related to high pressure tire inflator

When selecting a high-pressure tire inflator for your business, understanding its technical properties is crucial. Here are some critical specifications that can influence purchasing decisions:

Maximum Outlet Pressure (psi): This indicates the highest pressure the inflator can achieve when filling tires. A unit like the Flatematic High Pressure can inflate to 232 psi, making it suitable for high-performance vehicles. For businesses servicing commercial fleets, this capability ensures that all tire types can be adequately inflated.

Airflow Rate (CFM or L/min): The airflow rate measures the volume of air delivered by the inflator per minute. For instance, an inflator with a maximum airflow of 92 CFM can significantly reduce tire inflation time, enhancing operational efficiency. Businesses can benefit from quicker service times, which is especially important in high-demand environments.

Grado del materiale: The materials used in the construction of the inflator, such as aluminum for the body, impact durability and weight. High-grade materials ensure longevity and resistance to wear and tear, which is vital for businesses that require reliable equipment in demanding conditions.

Ingress Protection (IP) Rating: The IP rating indicates the device’s resistance to dust and water. An inflator with an IP66 rating is dust-tight and can withstand powerful water jets, making it suitable for various environments, including outdoor workshops. Understanding the IP rating helps businesses assess where and how the equipment can be used safely.

Temperature Range: The operational temperature range (e.g., -10°C to 50°C) defines the conditions under which the inflator can function effectively. This specification is crucial for businesses in regions with extreme weather conditions, ensuring that the equipment remains reliable regardless of temperature fluctuations.

Familiarity with industry jargon can streamline communication and enhance business transactions. Here are some essential trade terms:

OEM (Original Equipment Manufacturer): Refers to companies that produce components that are sold under another company’s brand. Understanding OEM relationships is essential for businesses looking to procure high-quality tire inflators that meet specific standards.

MOQ (quantità minima d'ordine): This term defines the smallest number of units that a supplier is willing to sell in a single order. Knowing the MOQ is vital for businesses to plan their inventory and manage cash flow effectively.

RFQ (Richiesta di offerta): An RFQ is a document sent to suppliers to request pricing for specific products or services. This process is crucial for businesses to obtain competitive pricing and negotiate terms with potential suppliers.

Incoterms (Termini commerciali internazionali): These are standardized trade terms used in international contracts to clarify the responsibilities of buyers and sellers. Familiarity with Incoterms helps businesses navigate shipping and delivery logistics, minimizing misunderstandings and disputes.

Calibration Certification: This term refers to documentation that verifies that the inflator has been tested and meets specified accuracy standards. For B2B buyers, ensuring that the equipment is calibrated is essential for maintaining quality control in tire maintenance.

Nitrogen Purge Cycle: This refers to the process of inflating tires with nitrogen, which can enhance tire performance and longevity. Understanding this feature allows businesses to offer advanced tire maintenance services, appealing to customers looking for quality and reliability.

Understanding these technical specifications and trade terms will empower B2B buyers to make informed decisions when procuring high-pressure tire inflators, ensuring they select equipment that meets operational needs while navigating the complexities of international trade.

Illustrative image related to high pressure tire inflator

The global market for high pressure tire inflators is experiencing significant growth, driven by increasing demand for efficient tire maintenance solutions across various sectors, including automotive, industrial, and aviation. As businesses prioritize operational efficiency, automatic tire inflators that can inflate tires quickly and accurately are becoming essential tools. Notably, the rise in e-commerce and the expansion of logistics networks in regions like Africa and South America are amplifying the need for reliable tire maintenance equipment.

Additionally, advancements in technology are shaping the sourcing landscape. Emerging trends include the integration of IoT (Internet of Things) capabilities, allowing for remote monitoring and management of tire pressure. This trend is particularly appealing to fleet operators who seek to optimize fuel efficiency and reduce downtime caused by tire-related issues. Furthermore, the demand for nitrogen-compatible inflators is increasing, as businesses recognize the benefits of nitrogen inflation, such as improved tire longevity and performance.

International B2B buyers from diverse regions, including Nigeria, Germany, and the Middle East, must navigate a competitive landscape characterized by fluctuating supply chains and varying regulatory standards. Establishing strong relationships with reliable suppliers who can provide timely quotes and flexible shipping options is crucial. As logistics costs rise, understanding the total cost of ownership—including maintenance and warranty provisions—will also play a significant role in sourcing decisions.

In today’s business environment, sustainability and ethical sourcing have become paramount for B2B buyers. The production and disposal of tire inflators can have significant environmental impacts, including the use of non-recyclable materials and energy-intensive manufacturing processes. Companies are increasingly held accountable for their supply chain practices, making it essential to consider suppliers who prioritize sustainability.

Buyers should look for high pressure tire inflators that are made from eco-friendly materials and offer certifications such as ISO 14001 for environmental management systems. Additionally, manufacturers that utilize renewable energy in their production processes or incorporate recycled materials into their products can significantly reduce their carbon footprint.

Moreover, ethical sourcing extends to the entire supply chain, encompassing fair labor practices and transparency. Buyers in regions like Africa and South America can benefit from engaging suppliers that demonstrate commitment to social responsibility, which can enhance brand reputation and customer loyalty. By prioritizing suppliers with sustainable practices, B2B buyers not only contribute to environmental preservation but also position themselves as leaders in their respective markets.

The evolution of high pressure tire inflators can be traced back to the early 20th century when manual pumps dominated the market. As automotive technology advanced, the need for more efficient tire inflation methods became apparent, leading to the development of electric and automatic inflators. The introduction of automatic tire inflators in the late 20th century marked a significant turning point, allowing for hands-free operation and precise inflation.

In recent years, the integration of digital technologies has further transformed the sector. Modern inflators now feature LCD displays, multiple measurement units, and compatibility with nitrogen inflation systems, catering to the evolving needs of international B2B buyers. This historical progression highlights the ongoing innovation within the industry, reflecting the demand for enhanced efficiency and user-friendliness in tire maintenance solutions.

Illustrative image related to high pressure tire inflator

As the market continues to grow, understanding this evolution can provide valuable insights for businesses looking to invest in high pressure tire inflators, ensuring they select products that meet contemporary operational demands while also aligning with sustainability goals.

How do I solve issues with tire inflator compatibility?

To address compatibility issues with tire inflators, ensure that your air compressor meets the required specifications for pressure and airflow. Check that your inflator is designed to work with the type of tires you are inflating, particularly high-pressure tires that may require specialized equipment. Additionally, confirm that you are using the correct chuck type and that your air supply is clean and free from moisture and oil, as these can adversely affect performance and lead to operational failures.

What is the best air compressor for high-pressure tire inflators?

The best air compressor for high-pressure tire inflators should provide a stable air supply with a minimum inlet pressure that matches the inflator’s specifications, typically around 261 psi. It should also have an effective air filter to remove moisture and oil to prevent damage to the inflator. Look for compressors that are calibrated and certified, ensuring they can maintain consistent pressure and airflow, which is crucial for efficient tire inflation.

What are common payment terms for international B2B transactions involving tire inflators?

Payment terms can vary based on the supplier and region but often include options such as 30% upfront payment with the balance due upon shipment, or net 30-60 days after delivery. It’s important to discuss and agree on payment methods that suit both parties, including wire transfers, letters of credit, or escrow services for added security. Always ensure that payment terms are documented in the purchase agreement to avoid misunderstandings.

What should I consider when vetting suppliers for high-pressure tire inflators?

When vetting suppliers, consider their experience and reputation in the industry, including customer reviews and testimonials. Assess their manufacturing capabilities, quality control processes, and adherence to international standards and certifications. Additionally, inquire about their after-sales support, warranty terms, and their ability to provide spare parts or maintenance services, which are essential for long-term operational efficiency.

How can I customize a high-pressure tire inflator for my specific needs?

Many manufacturers offer customization options for high-pressure tire inflators, which may include adjustments in design, color, or features like additional hoses or different chuck types. To initiate customization, communicate your specific requirements to the supplier, including any unique specifications related to the tires you will be inflating. Be prepared to discuss minimum order quantities and any potential cost implications for bespoke modifications.

What are typical lead times for high-pressure tire inflator orders?

Lead times for high-pressure tire inflators can vary based on factors such as the supplier’s inventory, production schedules, and shipping logistics. Generally, expect lead times of 2-10 business days for stock items, while made-to-order products may take 10-12 weeks. Always confirm lead times with your supplier prior to placing an order, especially if you have tight deadlines or specific project timelines.

How do logistics and shipping work for international orders of tire inflators?

Logistics for international orders typically involve coordinating with freight forwarders to manage shipping from the supplier’s location to your destination. It’s important to discuss shipping options, including air freight for faster delivery or sea freight for cost-effectiveness. Be aware of customs regulations and import duties in your country, and ensure that your supplier provides all necessary documentation, such as invoices and packing lists, to facilitate smooth customs clearance.

What quality assurance measures should I look for when purchasing tire inflators?

When purchasing tire inflators, seek suppliers that implement rigorous quality assurance measures. This includes ISO certification, regular product testing, and adherence to international safety standards. Inquire about the supplier’s warranty policy and whether they offer maintenance and calibration services. Additionally, request samples or product demonstrations to assess the inflator’s performance and reliability before committing to a larger order.

Dominio: reddit.com

Registrato: 2005 (20 anni)

Introduzione: 1. CFM Ratings: Look for pumps with high CFM (Cubic Feet/Minute) ratings, especially at higher psi levels. 2. Duty Cycle: Prefer pumps with a 100% Duty Cycle to avoid overheating issues; many cheaper models have only a 30% Duty Cycle. 3. Recommended Brands: ARB (4.68 CFM @ 29 psi), Rough Country (suitcase twin, $200 less than ARB), MorrFlate/Napa 300L/EZ-Flate MOAB (12 CFM @ 0 psi, around $120), a…

Dominio: facebook.com

Registrato: 1997 (28 anni)

Introduzione: This company, Sharper Image – 12 Volt Tire Inflator, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Dominio: craftsman.com

Registrato: 1998 (27 anni)

Introduzione: CRAFTSMAN® V20* Cordless High Pressure Inflator (Tool Only) – Model: CMCE521B. Maximum PSI: 150. Accuracy: + or – 2%. Features a digital gauge for easy pressure reading. Includes onboard storage for high pressure tapered nozzle, inflator needle, and Presta valve adaptor. Cordless design for convenience. Bare tool; battery and charger sold separately. Part of the V20* cordless power tool and outdoo…

Dominio: haltec.com

Registrato: 1998 (27 anni)

Introduzione: High Pressure Inflator SKU: 89XHB; Specifically designed for 19.5″ rims and larger or multiple truck tires; Equipped with higher rated pressure sensor; 1/2″ inlet/outlet; Adjustable from 5-188 PSI in 1 PSI increments; Custom faceplates with corporate logo and color available; Can be hardwired and mounted to mobile service trucks; Calibration confirmation every six minutes during use and every time…

In the evolving landscape of high-pressure tire inflators, strategic sourcing has emerged as a pivotal factor for B2B buyers aiming to optimize their operations. By prioritizing quality, reliability, and efficiency, businesses can ensure they select inflators that meet the rigorous demands of their fleets. The Flatematic High Pressure tire inflator exemplifies the technological advancements that streamline tire maintenance while reducing downtime, offering features such as automatic inflation, nitrogen compatibility, and precision calibration.

For international buyers, particularly in regions like Africa, South America, the Middle East, and Europe, the choice of a high-pressure tire inflator is not merely a procurement decision but a strategic investment in operational excellence. Understanding the nuances of sourcing, including supplier reliability, product specifications, and after-sales support, can significantly enhance the value derived from these tools.

As we look to the future, the demand for efficient and effective tire maintenance solutions will only grow. Therefore, we encourage B2B buyers to engage with trusted suppliers and leverage innovative products to elevate their service capabilities. Investing in quality inflators today will position your business for success in an increasingly competitive marketplace.

Le informazioni fornite in questa guida, compresi i contenuti relativi ai produttori, alle specifiche tecniche e all'analisi di mercato, hanno uno scopo puramente informativo ed educativo. Non costituiscono una consulenza professionale in materia di acquisti, né una consulenza finanziaria o legale.

Pur avendo compiuto ogni sforzo per garantire l'accuratezza e la tempestività delle informazioni, non siamo responsabili di eventuali errori, omissioni o informazioni non aggiornate. Le condizioni di mercato, i dettagli aziendali e gli standard tecnici sono soggetti a modifiche.

Gli acquirenti B2B devono condurre una due diligence indipendente e approfondita. prima di prendere qualsiasi decisione di acquisto. È necessario contattare direttamente i fornitori, verificare le certificazioni, richiedere campioni e chiedere una consulenza professionale. Il rischio di affidarsi alle informazioni contenute in questa guida è esclusivamente a carico del lettore.