In the dynamic landscape of global trade, sourcing efficient and reliable tools such as the Ryobi tire inflator can pose significant challenges for B2B buyers. The need for high-quality inflators that meet varying regional demands—whether for automotive service centers in Brazil or logistics firms in Germany—underscores the importance of informed purchasing decisions. This comprehensive guide delves into the nuances of the Ryobi tire inflator, exploring various types, applications, and the critical aspects of supplier vetting.

From understanding the technical specifications to assessing performance metrics, this guide equips international buyers with the insights necessary to navigate the complexities of the market. Key considerations such as cost analysis, potential suppliers, and the unique needs of different regions—including Africa, South America, the Middle East, and Europe—are thoroughly examined. By providing a detailed overview of the Ryobi tire inflator’s capabilities and market positioning, we empower businesses to make strategic choices that enhance operational efficiency and customer satisfaction.

This resource aims to demystify the procurement process, enabling buyers to confidently evaluate their options and select the best inflator for their specific requirements. Whether you are a fleet manager looking to optimize maintenance costs or a retailer seeking to expand your product offerings, this guide serves as your essential companion in the pursuit of quality and value in the global market.

| Nome del tipo | Caratteristiche distintive principali | Applicazioni primarie B2B | Brevi pro e contro per gli acquirenti |

|---|---|---|---|

| Cordless High Pressure Inflator | Battery-powered, portable, high PSI capabilities | Automotive repair, construction, outdoor use | Pro: Portability, ease of use; Contro: Battery life may limit usage time. |

| Compact Tire Inflator | Small size, lightweight, often includes LED light | Emergency roadside assistance, personal use | Pro: Easy to store, quick inflation; Contro: Limited power and features compared to larger models. |

| Digital Tire Inflator | Digital pressure gauge, preset pressure settings | Fleet management, commercial vehicle maintenance | Pro: Accurate readings, customizable settings; Contro: Higher price point, potential for electronic failure. |

| Heavy-Duty Inflator | Rugged design, higher durability, often higher flow rate | Industrial use, heavy machinery maintenance | Pro: Built to last, efficient for large tires; Contro: Bulkier, often more expensive. |

| Multi-Purpose Inflator | Versatile, can inflate various items (e.g., sports equipment) | Sports facilities, event management | Pro: Multi-functional, great for diverse applications; Contro: May lack specialized features for tire inflation. |

Cordless high-pressure inflators are designed for mobility and convenience, making them ideal for various B2B applications such as automotive repairs and construction sites. These inflators typically feature a rechargeable battery, enabling users to operate them without being tethered to a power outlet. Their high PSI capabilities make them suitable for inflating larger tires, ensuring efficient performance in demanding environments. When purchasing, businesses should consider battery life and charging time, as these factors can impact operational efficiency.

Compact tire inflators are characterized by their lightweight and space-saving design, making them easy to transport and store. They are particularly useful for emergency roadside assistance and personal use, providing quick inflation for tires in distress. While they offer convenience, buyers should be aware of their limitations in power and features compared to larger inflators. Businesses that prioritize portability and ease of use will find these inflators advantageous, especially in scenarios where speed is crucial.

Digital tire inflators stand out due to their advanced features, including digital pressure gauges and preset pressure settings. These characteristics are particularly beneficial for fleet management and commercial vehicle maintenance, where accuracy and consistency are paramount. Digital models often provide precise readings, reducing the risk of over- or under-inflation. However, their higher price point and reliance on electronic components can be a consideration for budget-conscious buyers. Ensuring reliability in various operating conditions is key for businesses investing in this type of inflator.

Heavy-duty inflators are built for rigorous use, featuring rugged designs that withstand harsh environments. They are often employed in industrial settings, such as heavy machinery maintenance, where higher flow rates and durability are essential. While these inflators can efficiently handle large tires and demanding applications, their bulkier design and higher price point may deter some buyers. Businesses should assess their specific needs for durability and efficiency when considering these robust inflators.

Multi-purpose inflators are versatile tools capable of inflating a variety of items, including sports equipment and inflatable decorations. This flexibility makes them particularly valuable for sports facilities and event management companies. While they excel in diverse applications, they may lack the specialized features found in dedicated tire inflators. Buyers should evaluate their needs for versatility versus the need for precision in tire inflation, making informed decisions based on the primary applications they require.

| Industria/Settore | Specific Application of ryobi tire inflator review | Valore/Beneficio per l'azienda | Considerazioni chiave sull'approvvigionamento per questa applicazione |

|---|---|---|---|

| Riparazione di autoveicoli | Tire inflation for vehicle servicing | Enhances efficiency and reduces downtime in workshops | Reliability, portability, battery compatibility, and service support |

| Transportation Logistics | Maintaining tire pressure for fleet vehicles | Improves fuel efficiency and extends tire lifespan | Capacity to handle multiple vehicles, ease of use, and power source options |

| Costruzione | Inflating tires for heavy machinery and equipment | Ensures operational readiness and safety on-site | Durability, pressure range, and compatibility with various equipment |

| Agricoltura | Inflating tires on farm machinery | Reduces maintenance costs and enhances productivity | Weather resistance, battery life, and ease of transport |

| Recreational Vehicles | Tire maintenance for ATVs, motorcycles, and trailers | Promotes safety and performance during recreational use | Compact design, pressure accuracy, and charging options |

In automotive repair shops, the Ryobi tire inflator serves as an essential tool for quickly inflating tires during servicing. Its cordless feature allows technicians to move freely around the workshop without being tethered to a power source. This inflator addresses common issues such as tire under-inflation, which can lead to increased wear and reduced fuel efficiency. For B2B buyers in regions like Europe and South America, sourcing a reliable inflator that offers consistent performance and durability is crucial, especially in high-demand environments.

In the transportation logistics sector, maintaining optimal tire pressure is vital for fleet vehicles. The Ryobi tire inflator helps logistics companies ensure that their tires are properly inflated, which can significantly improve fuel efficiency and extend the lifespan of tires. B2B buyers in Africa and the Middle East should consider inflators that can handle high volume and frequent use, as well as those that offer quick inflation times to minimize vehicle downtime.

The construction industry relies heavily on heavy machinery and equipment, which often requires tire inflation for optimal performance. The Ryobi tire inflator provides a portable solution to inflate tires on-site, ensuring that equipment is operational and safe to use. Buyers from regions with rugged terrains, such as Brazil and parts of Africa, should prioritize inflators that are durable and can withstand harsh working conditions while offering a suitable pressure range for various machinery.

In agriculture, maintaining tire pressure on machinery is essential for operational efficiency. The Ryobi tire inflator can be used to inflate tires on tractors and other farm equipment, reducing maintenance costs associated with tire wear and tear. B2B buyers in agricultural sectors should focus on inflators that are not only effective but also weather-resistant and easy to transport, ensuring they can be used in diverse field conditions.

For recreational vehicle owners, ensuring proper tire inflation is critical for safety and performance. The Ryobi tire inflator is compact and easy to use, making it perfect for inflating tires on ATVs, motorcycles, and trailers. Buyers in Europe and South America should look for inflators that provide accurate pressure readings and have multiple charging options, allowing for convenient use during travels and adventures.

Il problema: B2B buyers, particularly those in regions with extreme weather conditions, often face challenges with inflators that do not perform consistently. For instance, a tire inflator may work well in temperate climates but struggle in very hot or cold temperatures. This inconsistency can lead to downtime in operations, especially for companies relying on vehicle fleets or machinery that require regular tire maintenance. The inability to inflate tires properly can result in safety issues, increased wear on tires, and ultimately, higher operational costs.

La soluzione: To address performance issues, it’s crucial for buyers to thoroughly review the specifications and user feedback on the Ryobi tire inflator. Look for models that feature robust temperature tolerance ratings and have been tested in various climates. Additionally, consider purchasing a unit that offers adjustable pressure settings, enabling users to adapt to different types of tires and conditions. Establish a maintenance schedule to ensure the inflator is regularly checked and calibrated, which can help mitigate performance inconsistencies. Investing in a quality inflator that guarantees reliable performance in the specific conditions of your operational environment is essential.

Il problema: Many B2B buyers may encounter difficulties in understanding how to operate the Ryobi tire inflator, especially if it features advanced technology or multiple functions. This can lead to operational delays and frustration among staff who may not be adequately trained. For instance, inflators that require specific battery types or have intricate settings may cause confusion, leading to improper usage or even damage to the unit.

La soluzione: To overcome this pain point, B2B buyers should prioritize user-friendly models with clear instructions and support materials. When considering a Ryobi tire inflator, look for products that offer comprehensive user guides and video tutorials. Additionally, consider arranging training sessions for employees who will be using the inflator. This can include hands-on demonstrations to familiarize staff with its functions. Implementing a simple, step-by-step setup process will also enhance usability and reduce the risk of errors, ensuring that the inflator can be used efficiently right from the start.

Il problema: For businesses that require tire inflation in various locations—such as construction sites or remote service areas—portability can be a significant concern. A tire inflator that is too heavy or lacks a reliable power source can restrict its usability, leading to inefficiencies and increased labor costs. Buyers may find that some models are not designed for easy transport, making it challenging to meet the demands of on-the-go operations.

La soluzione: To ensure maximum portability, buyers should look for lightweight, cordless models of the Ryobi tire inflator that use interchangeable batteries compatible with other Ryobi tools. This feature allows for a seamless transition between tools without the need for multiple chargers or power sources. Additionally, consider investing in carrying cases or bags designed for the inflator to protect it during transport and facilitate easy movement. Evaluate the weight and dimensions of the inflator against your specific operational needs to ensure it can be easily handled in various job sites. By prioritizing portability, businesses can enhance their efficiency and responsiveness in providing tire maintenance.

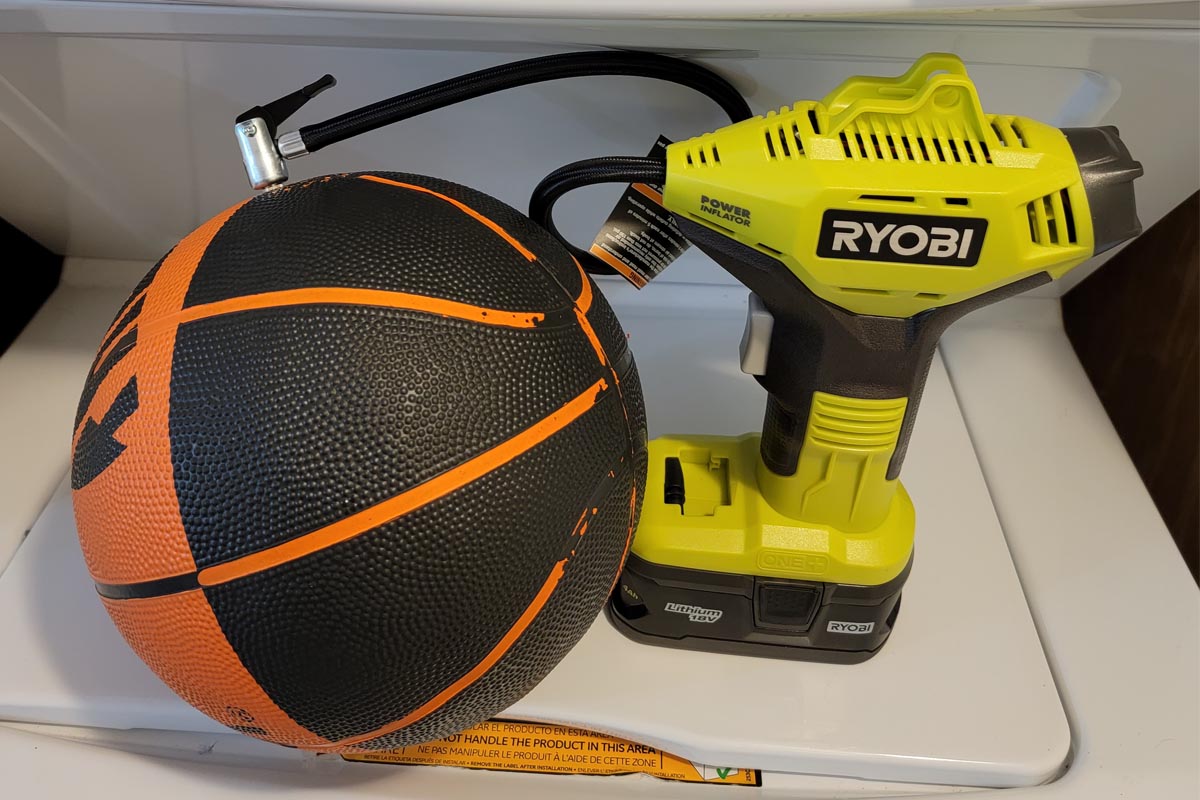

Illustrative image related to ryobi tire inflator review

When selecting materials for the Ryobi tire inflator, several key materials are commonly used, each with distinct properties and implications for performance. Understanding these materials can help international B2B buyers make informed purchasing decisions that align with their operational needs and regional standards.

Plastic is often used in the casing and some internal components of Ryobi tire inflators. Key properties include lightweight characteristics, resistance to corrosion, and the ability to be molded into complex shapes.

Pro: Plastics are generally less expensive than metals, making them cost-effective for manufacturers. They provide good insulation against heat and electricity, enhancing user safety.

Contro: However, plastics can have lower durability compared to metals, especially in high-temperature or high-pressure applications. They may also be more susceptible to wear and tear over time.

Illustrative image related to ryobi tire inflator review

Impatto sull'applicazione: Plastic components are suitable for applications where weight reduction is critical, but they may not be ideal for high-stress environments.

Considerations for B2B Buyers: In regions like Africa and South America, where environmental conditions can be harsh, buyers should ensure that the plastic used meets local standards for heat and UV resistance. Compliance with ASTM or ISO standards may be necessary for certain applications.

Aluminum is frequently utilized for structural components, such as the housing and internal frames. Its key properties include a high strength-to-weight ratio, excellent corrosion resistance, and good thermal conductivity.

Pro: Aluminum is lightweight yet strong, making it ideal for portable inflators. Its corrosion resistance extends the product’s lifespan, particularly in humid or saline environments.

Contro: The primary disadvantage is its higher cost compared to plastic. Additionally, while aluminum is durable, it can be prone to denting under heavy impact.

Impatto sull'applicazione: Aluminum is suitable for applications requiring durability and portability, making it a preferred choice for tire inflators used in various environments.

Considerations for B2B Buyers: Buyers in Europe, particularly in Germany, may prefer aluminum due to its compliance with stringent environmental regulations. Ensuring that the aluminum used is sourced responsibly can also be a selling point.

Steel is often used in critical structural components due to its exceptional strength and durability. Key properties include high tensile strength and resistance to deformation under stress.

Pro: Steel’s durability makes it ideal for components that experience high pressure or mechanical stress. It also has excellent wear resistance, which can be beneficial in demanding applications.

Contro: The main drawback is its weight, which can make the inflator less portable. Additionally, steel is susceptible to rust if not properly coated or treated.

Illustrative image related to ryobi tire inflator review

Impatto sull'applicazione: Steel is suitable for heavy-duty applications where performance and reliability are paramount, such as in industrial settings.

Considerations for B2B Buyers: Buyers in the Middle East and Africa should consider the local climate when selecting steel components, as corrosion resistance is crucial in humid or coastal areas. Compliance with local standards for material safety and performance is also essential.

Rubber is commonly used for seals and hoses in tire inflators due to its flexibility and resilience. Key properties include excellent elasticity and resistance to various chemicals.

Pro: Rubber components provide effective sealing, preventing air leaks and ensuring efficient operation. They are also generally inexpensive and easy to manufacture.

Contro: The downside is that rubber can degrade over time, especially when exposed to UV light or extreme temperatures. This can lead to premature failure of seals and hoses.

Impatto sull'applicazione: Rubber is suitable for applications requiring flexibility and sealing capability, particularly in tire inflators where maintaining pressure is critical.

Considerations for B2B Buyers: Buyers should ensure that the rubber used meets specific standards for chemical resistance and durability, particularly in regions with extreme weather conditions.

| Materiale | Typical Use Case for ryobi tire inflator review | Vantaggio chiave | Svantaggi/limitazioni principali | Costo relativo (Basso/Medio/Alto) |

|---|---|---|---|---|

| Plastica | Casing and lightweight components | Economico e leggero | Lower durability under stress | Basso |

| Alluminio | Housing and structural frames | High strength-to-weight ratio and corrosion resistance | Higher cost and dent-prone | Medio |

| Acciaio | Critical structural components | Exceptional strength and durability | Heavy and rust-prone | Alto |

| Gomma | Seals and hoses | Effective sealing and flexibility | Si degrada nel tempo | Basso |

This strategic material selection guide provides valuable insights for B2B buyers, helping them navigate the complexities of material choices in Ryobi tire inflators. By understanding the properties and implications of each material, buyers can align their purchasing decisions with their operational needs and regional standards.

The manufacturing process for Ryobi tire inflators involves several critical stages that ensure the product meets high-quality standards.

Illustrative image related to ryobi tire inflator review

Preparazione del materiale: The process begins with the selection of high-grade materials, including durable plastics and metals. These materials are inspected and prepped to meet specific technical specifications. This stage often involves cutting and shaping raw materials into parts that will be used in the inflator.

Formazione: This stage involves the actual shaping of components. Techniques such as injection molding for plastic parts and metal stamping for structural components are commonly utilized. Advanced machinery is employed to ensure precision in forming, which is crucial for the inflator’s performance and reliability.

Montaggio: Once the parts are formed, they move to the assembly line. Here, skilled workers or automated systems integrate various components, including motors, hoses, and controls. The assembly process is designed for efficiency while maintaining high standards for quality. Each unit is typically assembled under stringent protocols to ensure compatibility and functionality.

Finitura: The final stage includes surface finishing processes such as painting, coating, and polishing. This not only enhances the aesthetic appeal but also provides protection against environmental factors. Quality checks are performed at this stage to ensure that the product meets the required specifications and standards.

Quality assurance (QA) is a fundamental aspect of the manufacturing process for Ryobi tire inflators, ensuring that each product meets the necessary safety and performance standards.

International Standards Compliance: Manufacturers often adhere to international quality management standards such as ISO 9001. This certification indicates that the manufacturing processes are systematically controlled and continuously improved. Additionally, compliance with industry-specific standards such as CE (for European markets) and API (for certain industrial applications) is critical for market acceptance.

Quality Checkpoints: The quality assurance process includes several checkpoints:

– Controllo qualità in entrata (CQI): This involves inspecting raw materials and components upon arrival to ensure they meet specified standards.

– Controllo qualità in corso d'opera (IPQC): During manufacturing, regular inspections and tests are conducted to identify defects early. This may include measuring dimensions, checking assembly accuracy, and testing functionality.

– Controllo qualità finale (CQC): After assembly, each inflator undergoes a comprehensive inspection and testing phase, where performance tests are conducted to ensure that the product operates as intended.

Common Testing Methods: Testing methods may include pressure testing, performance testing under various conditions, and durability tests to simulate long-term use. These tests help verify that the inflators can withstand the demands of end-users.

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, verifying the quality control processes of suppliers is essential. Here are several actionable steps:

Audit dei fornitori: Conducting on-site audits of manufacturing facilities can provide insights into the quality control practices in place. Audits should focus on assessing compliance with international standards, the effectiveness of quality management systems, and the overall manufacturing environment.

Review of Quality Reports: Requesting quality assurance documentation, including certificates of compliance, testing reports, and previous audit results, can help buyers gauge the reliability of the supplier’s quality control measures.

Third-party Inspections: Engaging third-party inspection services can add an additional layer of assurance. These independent organizations can perform inspections at various stages of production, ensuring adherence to quality standards before products are shipped.

Understanding Certification Nuances: Buyers should be aware that different markets may have varying certification requirements. For instance, while CE certification is critical for European markets, other regions may require different certifications. Understanding these nuances can help in making informed purchasing decisions.

Quality assurance practices can vary significantly based on regional regulations and market expectations. For buyers from different regions, it is essential to understand these differences:

European Standards: In Europe, strict regulations regarding product safety and environmental impact necessitate comprehensive quality assurance practices. Manufacturers must often undergo rigorous testing and certification processes to comply with CE marking requirements.

Middle Eastern Markets: In the Middle East, quality assurance may focus more on performance and reliability, reflecting the harsh environmental conditions. Suppliers might need to demonstrate that their products can operate effectively in high temperatures and dusty environments.

African and South American Markets: In these regions, affordability and reliability are often prioritized. Suppliers may need to balance cost with quality assurance measures to meet the expectations of local buyers while remaining competitive.

Documentation and Transparency: Regardless of the region, the importance of clear documentation and transparency in quality assurance practices cannot be overstated. Buyers should seek suppliers who provide detailed quality assurance documentation and are willing to engage in open communication regarding their processes.

In conclusion, understanding the manufacturing processes and quality assurance practices for Ryobi tire inflators is essential for international B2B buyers. By focusing on supplier verification, compliance with international standards, and regional differences in quality expectations, buyers can make informed decisions that align with their business needs.

This practical sourcing guide is designed for B2B buyers looking to procure the Ryobi tire inflator. As a vital tool for maintenance and operations, understanding the key factors in selecting the right inflator can save businesses time and resources. This checklist will help you navigate the procurement process effectively, ensuring you choose a supplier that meets your technical, logistical, and budgetary needs.

Before initiating the procurement process, clearly outline the technical specifications you require from the Ryobi tire inflator. Consider factors such as pressure capacity, power source (cordless vs. corded), and compatibility with various tire types. By having a detailed specification, you can ensure that suppliers understand your needs and can provide suitable options.

Identifying reputable suppliers is crucial to ensure the quality of the product and reliability in service. Utilize online marketplaces, industry directories, and trade shows to compile a list of potential suppliers. Look for suppliers that specialize in automotive tools and have a proven track record in your region.

Verifying supplier certifications is essential to ensure compliance with international standards. Check for certifications such as ISO 9001 for quality management systems and any regional compliance certifications relevant to your target market. This step helps mitigate risks associated with product quality and safety.

Before finalizing your order, request samples of the Ryobi tire inflator from your shortlisted suppliers. Testing the inflator in real-world conditions allows you to assess its performance and durability firsthand. Ensure that the sample meets your specifications and expectations before proceeding with a bulk order.

Once you have evaluated the suppliers and their products, engage in negotiations to establish pricing and terms of sale. Consider factors such as bulk discounts, payment terms, and shipping costs. Clear agreements on these aspects can lead to significant savings and smoother transactions.

A strong customer support system and favorable warranty policies can significantly impact your long-term satisfaction with the purchase. Inquire about the supplier’s customer service availability and warranty coverage for the Ryobi tire inflator. A solid warranty can protect your investment and provide peace of mind in case of defects or performance issues.

After completing the previous steps, it is time to finalize the purchase agreement. Ensure that all terms discussed are documented clearly, including pricing, delivery timelines, and after-sales support. A well-structured agreement will help avoid misunderstandings and provide a clear framework for the transaction.

By following this checklist, B2B buyers can make informed decisions when procuring the Ryobi tire inflator, ensuring that they acquire a product that meets their operational requirements and contributes to their overall efficiency.

Illustrative image related to ryobi tire inflator review

When sourcing the Ryobi Tire Inflator, understanding the cost structure is essential for effective budgeting and pricing strategies. The primary components include:

I materiali: The quality and type of materials used significantly influence costs. The Ryobi Tire Inflator typically incorporates durable plastics and metal components, which can vary in price based on supplier relationships and market fluctuations. Bulk purchasing can reduce material costs.

Lavoro: Labor costs can vary by region, with countries in Africa and South America generally having lower labor costs compared to Europe. However, the skill level required for assembly or customization can affect these costs. Ensuring a skilled workforce can lead to higher initial costs but may enhance product quality and reliability.

Spese generali di produzione: This includes expenses related to factory operations, maintenance, and utilities. Efficient manufacturing processes can reduce overhead, impacting the overall cost structure favorably.

Utensili: Initial tooling costs for production can be substantial, especially if custom molds or machinery are required. This expense is often amortized over the production run, making it crucial to estimate order volumes accurately.

Controllo qualità (CQ): Implementing rigorous QC processes ensures the inflator meets industry standards and customer expectations. While this may increase costs upfront, it can prevent expensive recalls and enhance brand reputation.

Logistica: Transportation and warehousing costs can be significant, especially for international shipments. Factors like shipping distance, mode of transport, and customs duties all play a role in the final cost to the buyer.

Margine: Suppliers typically build a profit margin into their pricing. Understanding the competitive landscape can help buyers negotiate better terms.

Several factors influence the pricing of the Ryobi Tire Inflator, which are critical for international buyers to consider:

Volume/MOQ: Minimum order quantities (MOQ) can significantly impact pricing. Larger orders usually attract discounts, making it essential for buyers to forecast demand accurately.

Specifiche e personalizzazione: Custom features or specifications can increase costs. Buyers should weigh the benefits of customization against the potential price hike.

Materiali e certificazioni di qualità: The choice of materials directly impacts pricing. Additionally, certifications (e.g., ISO, CE) may be required in certain markets, adding to costs but enhancing product credibility.

Fattori di fornitura: The reputation and reliability of suppliers can affect pricing. Established suppliers may charge a premium for their products due to their proven track record, while newer entrants might offer lower prices but pose a risk to quality and service.

Incoterms: Understanding shipping terms (e.g., FOB, CIF) is crucial for cost management. Buyers should clarify responsibilities for shipping costs and liabilities to avoid unexpected expenses.

To maximize cost-efficiency, B2B buyers should consider the following strategies:

Negoziazione: Strong negotiation skills can lead to better pricing and terms. Building a relationship with suppliers may also result in favorable conditions over time.

Attenzione al costo totale di proprietà (TCO): Evaluate not just the purchase price but the total cost of ownership, including maintenance, warranty, and operational efficiency. This holistic view can guide purchasing decisions that save money long-term.

Comprendere le sfumature dei prezzi per i mercati internazionali: Buyers from Africa, South America, the Middle East, and Europe must consider currency fluctuations, import duties, and local regulations that can affect overall costs. Staying informed about these factors can prevent surprises.

Leverage Group Purchasing: Joining a consortium of buyers can increase purchasing power, leading to volume discounts and more favorable terms.

Please note that the prices discussed are indicative and can vary based on market conditions, supplier negotiations, and specific order requirements. It is advisable for buyers to conduct thorough market research and consult multiple suppliers to obtain accurate pricing tailored to their needs.

When evaluating the best tire inflators for B2B applications, it’s crucial to consider alternatives that meet the diverse needs of businesses across different regions. The Ryobi Tire Inflator stands out for its performance and reliability, but several alternatives may also cater to specific requirements in various industries. This analysis compares the Ryobi Tire Inflator with two notable alternatives: the DEWALT 20V Max Cordless Inflator and the BLACK+DECKER 20V MAX Cordless Inflator.

| Aspetto di confronto | Ryobi Tire Inflator Review | DEWALT 20V Max Cordless Inflator | BLACK+DECKER 20V MAX Cordless Inflator |

|---|---|---|---|

| Prestazioni | 0-150 PSI, fast inflation for tires and sports equipment | 0-160 PSI, high-efficiency with auto shutoff | 0-160 PSI, versatile for various inflatables |

| Costo | Moderate price point, generally around $70 | Higher price point, approximately $100 | Budget-friendly, around $60 |

| Facilità di implementazione | User-friendly with a straightforward interface | Intuitive controls but heavier than competitors | Lightweight, easy to carry and use |

| Manutenzione | Minimal upkeep, battery maintenance required | Low maintenance, battery replacement needed | Minimal maintenance, easy to store |

| Il miglior caso d'uso | Ideal for automotive and recreational use | Best for construction sites and heavy-duty tasks | Perfect for home use and light-duty tasks |

DEWALT 20V Max Cordless Inflator

The DEWALT inflator is known for its robust construction and superior performance. It features a high maximum pressure of 160 PSI, making it suitable for heavy-duty applications. The auto shutoff feature ensures that users do not over-inflate tires, which can be a significant advantage in commercial settings. However, its higher price point may deter budget-conscious buyers, and its weight could pose challenges for portability on job sites.

Illustrative image related to ryobi tire inflator review

BLACK+DECKER 20V MAX Cordless Inflator

The BLACK+DECKER inflator is an excellent choice for B2B buyers seeking a cost-effective solution. With a maximum pressure of 160 PSI, it is versatile enough for various inflatables, from tires to sports equipment. Its lightweight design makes it easy to transport, making it ideal for home users and light commercial applications. However, it may lack some advanced features and durability compared to the Ryobi and DEWALT models, which might limit its use in more demanding environments.

When choosing the right tire inflator for business needs, B2B buyers should assess several factors. First, consider the specific applications—whether the inflator will be used for automotive, construction, or recreational purposes. Performance is critical; therefore, selecting a model with the right PSI capabilities is essential. Cost is also a significant consideration, especially for businesses operating on tight budgets. Finally, ease of use and maintenance requirements can greatly influence the operational efficiency of the equipment. By carefully evaluating these aspects, buyers can select an inflator that aligns with their operational demands and budget constraints.

When evaluating the Ryobi Tire Inflator for B2B procurement, understanding its technical specifications is crucial. Here are several key properties that define its performance and usability:

Illustrative image related to ryobi tire inflator review

Pressione nominale (PSI)

The maximum pressure rating, often measured in pounds per square inch (PSI), indicates the inflator’s capability to inflate tires and other objects. A higher PSI is essential for heavy-duty applications, ensuring that the inflator can handle various tire types, including those on commercial vehicles. For B2B buyers, assessing the PSI helps determine whether the inflator meets the demands of their fleet or service requirements.

Flow Rate (CFM)

The flow rate, measured in cubic feet per minute (CFM), reflects how quickly the inflator can deliver air. A higher CFM means faster inflation times, which is critical for businesses that require efficiency, such as automotive services or fleet maintenance. Understanding flow rates helps buyers align the product with their operational timelines and customer service expectations.

Battery Compatibility

The Ryobi Tire Inflator is designed to work with Ryobi’s ONE+ battery system, which allows for versatility and ease of use across different tools. B2B buyers should consider battery life and interchangeability, as a compatible battery system can reduce overall costs and improve workflow efficiency, especially in environments where multiple tools are utilized.

Weight and Portability

The weight of the inflator affects its portability, which is crucial for fieldwork or mobile service applications. A lightweight design enhances ease of transport, making it suitable for businesses that operate in various locations. Buyers should assess whether the inflator’s weight aligns with their operational needs, particularly if it will be frequently moved.

Durability and Material Grade

The materials used in construction, including plastic and metal grades, can impact the inflator’s longevity and resistance to wear and tear. For B2B buyers, investing in durable equipment minimizes replacement costs and downtime. Understanding the material grade helps in evaluating the inflator’s suitability for different environments, especially in industrial or construction settings.

Noise Level (dB)

The operational noise level, measured in decibels (dB), is an important consideration for workplaces where noise regulation is critical. A quieter inflator can enhance the working environment, particularly in urban or noise-sensitive areas. Buyers should consider their operational context and any applicable regulations when evaluating noise levels.

Familiarity with industry terminology can significantly streamline the procurement process. Here are some essential terms to know:

OEM (Original Equipment Manufacturer)

This term refers to the company that produces the original product, such as the Ryobi brand itself. Understanding OEM relationships is vital for buyers seeking authentic parts and support, ensuring compatibility and quality in their equipment.

MOQ (quantità minima d'ordine)

MOQ denotes the smallest quantity a supplier is willing to sell. For B2B buyers, knowing the MOQ is critical for budgeting and inventory management, as it can affect the overall cost and availability of the inflators.

RFQ (Richiesta di offerta)

An RFQ is a document sent to suppliers to solicit price quotes for specific products or services. For buyers, issuing an RFQ can help compare pricing and terms from multiple suppliers, ensuring they receive the best value for their procurement needs.

Incoterms (Termini commerciali internazionali)

These are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Understanding Incoterms helps B2B buyers manage shipping costs and logistics, ensuring clarity on who is responsible for freight, insurance, and delivery.

Tempi di consegna

This term refers to the time it takes for an order to be fulfilled from the moment it is placed until it is delivered. B2B buyers should consider lead times to ensure that products are received in a timely manner to avoid disruptions in their operations.

Garanzia e assistenza

Warranty terms detail the manufacturer’s commitment to repair or replace defective products. Understanding warranty provisions is essential for B2B buyers to assess long-term reliability and support, which can impact overall satisfaction with the product.

By comprehensively understanding both the technical properties and trade terminology associated with the Ryobi Tire Inflator, B2B buyers can make informed decisions that align with their operational needs and market demands.

The Ryobi tire inflator market is currently experiencing a surge in demand, driven by several global factors. Increased vehicle ownership across regions such as Africa, South America, and the Middle East is propelling the need for reliable tire maintenance tools. Additionally, the rise in e-commerce has enabled easier access to these products, allowing B2B buyers to source inflators from diverse suppliers. Key trends include the integration of smart technology, where inflators feature digital pressure gauges and automatic shut-off mechanisms, enhancing user convenience and safety. Moreover, the push for portable and battery-operated models aligns with the growing consumer preference for mobility and ease of use, particularly in urban environments.

International B2B buyers are also observing a shift towards multi-functional devices that cater to various inflation needs, from tires to sports equipment. This versatility not only maximizes the utility of the product but also presents an attractive proposition for buyers looking to streamline their inventory. In Europe, particularly in Germany, there is an increasing emphasis on product reviews and consumer feedback as critical decision-making factors, highlighting the importance of quality assurance in purchasing processes.

Sustainability has become a crucial concern in the B2B landscape, influencing procurement strategies and supplier selection. The environmental impact of manufacturing processes for tire inflators, including carbon emissions and resource depletion, has prompted buyers to seek suppliers committed to sustainable practices. Ethical sourcing is not merely a trend; it is now a standard expectation among conscientious buyers. This includes ensuring that materials used in production are responsibly sourced and that labor practices adhere to fair treatment guidelines.

In the context of Ryobi tire inflators, B2B buyers are increasingly favoring suppliers that offer ‘green’ certifications or utilize recycled materials in their products. This shift not only helps in reducing the environmental footprint but also enhances brand reputation and customer loyalty. Furthermore, companies that prioritize sustainability often benefit from cost savings through improved operational efficiencies and waste reduction, making them more competitive in the marketplace.

The evolution of the Ryobi tire inflator can be traced back to the brand’s commitment to innovation and quality in power tools. Initially focused on the DIY market, Ryobi expanded its product line to include tire inflators, recognizing the growing need for portable and user-friendly solutions. Over the years, advancements in battery technology and materials science have enabled the development of more efficient and reliable inflators. Today, Ryobi’s offerings are characterized by their versatility, ease of use, and integration of smart features, positioning them as a preferred choice among B2B buyers seeking high-quality tire maintenance tools. This historical evolution reflects not only technological advancements but also a response to changing consumer demands in the automotive maintenance sector.

1. How do I select the right Ryobi tire inflator for my business needs?

Choosing the right Ryobi tire inflator involves assessing your specific requirements, such as the types of vehicles you service and the frequency of use. Consider factors like portability, battery life, and pressure capabilities. For businesses in remote areas, a cordless option like the ONE+ 18V model may be ideal. Additionally, check if the inflator includes features like automatic shut-off and digital pressure gauges, which enhance usability. Reading reviews and comparing specifications will help you make an informed decision.

2. What are the key features of the Ryobi tire inflator that appeal to B2B buyers?

B2B buyers often prioritize efficiency and reliability. Key features of the Ryobi tire inflator include its cordless operation, which offers mobility and convenience on job sites. The digital display provides accurate pressure readings, and the auto shut-off feature prevents over-inflation. Additionally, the compatibility with Ryobi’s ONE+ battery system allows for versatile use across various tools, maximizing investment value. These attributes make it a practical choice for workshops and service centers.

3. How do I ensure the quality of Ryobi tire inflators when sourcing from suppliers?

To ensure quality, vet suppliers by requesting certifications and product samples. Look for ISO certifications or other quality management standards that indicate adherence to international quality benchmarks. Ask for references from other clients and check their reputation in the market. Additionally, consider suppliers who provide warranties and after-sales support, as these can be indicators of a reliable partnership.

4. What is the typical minimum order quantity (MOQ) for Ryobi tire inflators?

The MOQ for Ryobi tire inflators can vary significantly based on the supplier and region. Typically, distributors may set MOQs ranging from 10 to 50 units. For larger orders, negotiating a lower MOQ may be possible, especially if you establish a long-term partnership. Always discuss your specific needs with suppliers to determine the most feasible order size that aligns with your budget and inventory strategy.

5. What payment terms should I expect when sourcing Ryobi tire inflators internationally?

Payment terms can vary based on the supplier’s policies and the nature of your business relationship. Common terms include payment in advance, letters of credit, or net 30/60 days after delivery. For international transactions, it’s essential to clarify currency, payment methods (like wire transfer or PayPal), and any additional fees. Establishing clear terms upfront helps avoid misunderstandings and ensures smoother transactions.

6. How can I customize Ryobi tire inflators for my brand?

Customization options may include branding the inflators with your company logo or specific color schemes. Contact suppliers to discuss available customization services, as not all manufacturers offer this. Minimum order quantities might apply for custom orders, and additional costs should be considered. Customization can enhance brand visibility, especially for businesses engaging in promotional activities or offering branded tools to clients.

7. What are the logistics considerations when importing Ryobi tire inflators?

Logistics considerations include shipping methods, import duties, and delivery timelines. Assess the most cost-effective shipping options, such as sea freight for larger orders or air freight for quicker delivery. Understand the customs regulations in your country, as these can affect lead times and costs. Partnering with a logistics provider experienced in international trade can simplify the process and ensure compliance with all necessary regulations.

8. How can I effectively manage quality assurance (QA) for imported Ryobi tire inflators?

Implementing a robust QA process involves setting clear standards for product inspections upon arrival. Consider conducting pre-shipment inspections at the supplier’s facility to catch potential issues early. Additionally, maintain open communication with suppliers regarding quality expectations and any issues that arise. Regular feedback loops will enhance product quality over time and foster a reliable relationship with your suppliers.

Dominio: reddit.com

Registrato: 2005 (20 anni)

Introduzione: The Ryobi inflator is a portable tool that operates on an 18V battery. Users have noted that while it is convenient for everyday tasks like inflating bike tires, basketballs, and car tires, it may be too slow for heavy-duty applications such as off-roading. The P737D model is a generic design with a digital display but lacks a pressure setting function and requires continuous trigger holding. The …

Dominio: thecardata.com

Registrazione: 2022 (3 anni)

Introduzione: {“Product Name”: “Ryobi Tire Inflator”, “Model”: “P737D”, “Voltage”: “18 Volts”, “Max PSI”: “150 PSI”, “Weight”: “2.5 Lbs”, “Dimensions”: “9\” x 2.86\” x 6.4\””, “Sound Level”: “78 dB”, “Price”: “Under $120”, “Rating”: “4.6/5.0 stars on Amazon”, “Pros”: [“Cordless portability”, “Very intuitive to use”, “Powerful”, “Affordable”, “Versatile”], “Cons”: [“Slightly larger than expected”, “Box may not i…

Dominio: garagejournal.com

Registrato: 2006 (19 anni)

Introduzione: Milwaukee M12™ Compact Inflator: Fast, accurate inflation for car, LT truck, and compact equipment tyres. Portable and efficient. Ryobi 18V ONE+ High Pressure Inflator: Digital display for pressure settings in kPa, Bar, or PSI. Hands-free operation with automatic shut-off. Ryobi 18V ONE+ Inflator/Deflator: Suitable for car, 4WD, bicycle, trailer tyres, air beds, pool toys, and sports balls. Compat…

Dominio: ryobitools.com

Registrato: 1999 (26 anni)

Introduzione: {“Product Name”: “18V ONE+ HIGH PRESSURE DIGITAL INFLATOR KIT”, “Model”: “PCL001K1”, “Price”: “$64.97 (originally $89.97)”, “Features”: [{“Feature”: “Precise Filling Up To 160 PSI With Auto Shut-off”}, {“Feature”: “Digital Pressure Gauge & On-board Accessory Storage”}, {“Feature”: “Ideal for Filling Car, Bike, and Other Small Tires and Sports Balls”}], “Specifications”: [{“Max Pressure”: “160 PSI”…

In summary, the Ryobi tire inflator stands out as a versatile, efficient, and user-friendly tool that meets the demands of various industries, from automotive to logistics. Its cordless design powered by the ONE+ battery system offers significant mobility, making it an ideal solution for businesses operating in diverse environments, especially in regions like Africa and South America where accessibility can be a challenge. The inflator’s robust performance and ease of use are critical factors that should resonate with B2B buyers looking to enhance operational efficiency.

Illustrative image related to ryobi tire inflator review

Strategic sourcing is essential for ensuring that your procurement decisions are not only cost-effective but also aligned with your operational needs. By focusing on quality and reliability, businesses can minimize downtime and improve overall service delivery. The Ryobi tire inflator is a prime example of how investing in the right equipment can yield long-term benefits, including reduced maintenance costs and increased productivity.

As you evaluate your options for tire inflators, consider the unique requirements of your market. Engage with local suppliers who understand regional challenges and can provide tailored solutions. The Ryobi tire inflator represents a promising investment, and now is the time to act. By prioritizing quality and strategic sourcing, you can position your business for success in an increasingly competitive landscape.

Le informazioni fornite in questa guida, compresi i contenuti relativi ai produttori, alle specifiche tecniche e all'analisi di mercato, hanno uno scopo puramente informativo ed educativo. Non costituiscono una consulenza professionale in materia di acquisti, né una consulenza finanziaria o legale.

Pur avendo compiuto ogni sforzo per garantire l'accuratezza e la tempestività delle informazioni, non siamo responsabili di eventuali errori, omissioni o informazioni non aggiornate. Le condizioni di mercato, i dettagli aziendali e gli standard tecnici sono soggetti a modifiche.

Gli acquirenti B2B devono condurre una due diligence indipendente e approfondita. prima di prendere qualsiasi decisione di acquisto. È necessario contattare direttamente i fornitori, verificare le certificazioni, richiedere campioni e chiedere una consulenza professionale. Il rischio di affidarsi alle informazioni contenute in questa guida è esclusivamente a carico del lettore.