In an increasingly competitive global market, sourcing reliable handheld air compressors can present significant challenges for B2B buyers, especially those operating across diverse regions such as Africa, South America, the Middle East, and Europe. Understanding the specific needs of your business—whether for automotive maintenance, construction, or recreational purposes—can be the difference between a successful procurement process and costly mistakes. This comprehensive guide on handheld air compressors not only elucidates the various types available, including electric and battery-powered models, but also explores their diverse applications, from tire inflation to powering pneumatic tools.

Moreover, it provides actionable insights on supplier vetting and cost considerations, empowering international buyers to make informed purchasing decisions. With a focus on quality, efficiency, and adaptability, this guide aims to equip businesses with the knowledge necessary to navigate the complexities of the air compressor market. By addressing key factors such as performance specifications, operational reliability, and long-term value, B2B buyers can confidently select products that meet their operational demands and enhance productivity. Dive into this essential resource to unlock the potential of handheld air compressors for your business needs.

| Nome del tipo | Caratteristiche distintive principali | Applicazioni primarie B2B | Brevi pro e contro per gli acquirenti |

|---|---|---|---|

| Corded Electric Compressors | Plugged into an AC outlet, high power output | Workshops, garages, manufacturing | Pro: High performance; Contro: Limited mobility |

| Battery-Powered Compressors | Rechargeable, portable, often compact | Fieldwork, emergency services, automotive | Pro: Convenient; Contro: Tempo di esecuzione limitato |

| Tire Inflators | Compact, designed primarily for tires | Automotive repair, roadside assistance | Pro: Fast inflation; Contro: Limited versatility |

| Dual-Power Compressors | Operates on both AC and DC power | Versatile applications, home use | Pro: Flexible power options; Contro: Heavier design |

| Mini Air Compressors | Ultra-compact, lightweight | Sports equipment, small inflatables | Pro: Highly portable; Contro: Lower power capacity |

Corded electric compressors are designed for high-demand applications, making them ideal for workshops and manufacturing environments. These compressors typically offer robust power outputs and can operate air tools continuously without interruption. B2B buyers should consider the required PSI and CFM ratings to ensure the compressor meets their specific operational needs. However, the limitation of mobility can be a drawback for businesses requiring frequent relocation of equipment.

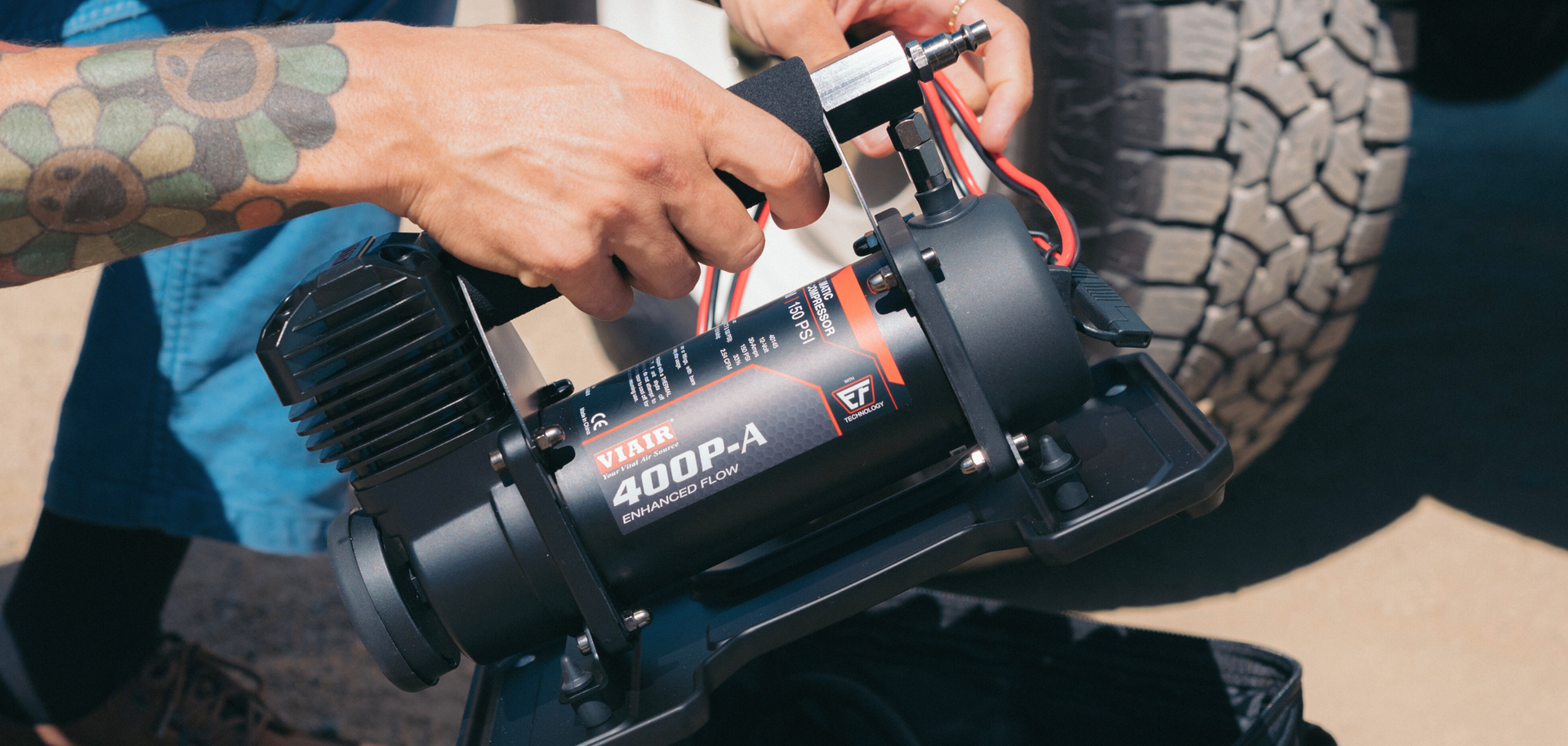

Battery-powered compressors are designed for enhanced portability, making them suitable for fieldwork and emergency applications. These compressors are usually compact and lightweight, allowing easy transport to remote job sites. When purchasing, businesses should evaluate battery life and charging time to ensure that the compressor can sustain operations throughout the workday. However, the limited run time may necessitate additional batteries for prolonged usage.

Tire inflators are specialized handheld air compressors tailored for quick and efficient tire inflation. They are compact and typically feature user-friendly interfaces, making them ideal for automotive repair shops and roadside assistance services. B2B buyers should look for models with automatic shut-off features to avoid over-inflation. While these devices excel at tire inflation, their limited versatility for other applications might be a consideration for businesses seeking multifunctional tools.

Dual-power compressors are versatile machines capable of operating on both AC and DC power sources. This flexibility makes them suitable for various applications, from home use to professional settings. B2B buyers should assess the specific power needs and portability requirements of their operations when considering these compressors. However, the added features and complexity may result in a heavier design, which could be a drawback for some users.

Mini air compressors are ultra-compact and lightweight, designed for specific applications such as inflating sports equipment and small inflatables. Their portability makes them an attractive option for small businesses or mobile service providers. When selecting a mini compressor, buyers should consider its power capacity and the range of compatible attachments. While these compressors are easy to transport, their lower power output may limit their use in more demanding applications.

| Industria/Settore | Specific Application of Handheld Air Compressors | Valore/Beneficio per l'azienda | Considerazioni chiave sull'approvvigionamento per questa applicazione |

|---|---|---|---|

| Riparazione di autoveicoli | Tire inflation and maintenance for vehicles | Reduces downtime for repairs and enhances service efficiency | Power source flexibility (12V, rechargeable), PSI capacity, portability |

| Costruzione | Operating pneumatic tools and inflating equipment | Increases productivity on-site and minimizes manual labor | Durability, weight, and ease of transport for job sites |

| Produzione | Cleaning machinery and components using compressed air | Improves equipment longevity and operational efficiency | Noise level, maintenance requirements, and compatibility with existing systems |

| Agricoltura | Inflating irrigation equipment and tools | Ensures efficient irrigation and reduces labor costs | Adaptability to different equipment and reliability under varied conditions |

| Ricreazione all'aperto | Inflating sports equipment and camping gear | Enhances customer experience and convenience for recreational activities | Size, weight, and multiple nozzle attachments for versatility |

In the automotive sector, handheld air compressors are essential for tire inflation and maintenance. They enable quick and efficient inflation, reducing vehicle downtime during repairs. Buyers from regions like Africa and South America should consider compressors with a robust PSI range to accommodate various vehicle types, including trucks and SUVs. Additionally, ease of transport and power source options, such as 12V car outlets, are crucial for mobile repair units.

In construction, handheld air compressors are used to operate pneumatic tools and inflate equipment like air mattresses and safety gear. This capability significantly boosts productivity on job sites by minimizing the need for manual labor. Buyers, especially in the Middle East where construction is booming, should prioritize durability and portability in their compressors to withstand harsh environments and rough handling.

Manufacturers leverage handheld air compressors for cleaning machinery and components, ensuring equipment longevity and operational efficiency. Compressed air is vital for removing debris and dust, which can hinder production. International buyers, particularly in Europe, should focus on noise levels and maintenance requirements to ensure compliance with local regulations while maintaining a productive workspace.

Illustrative image related to handheld air compressors

In agriculture, handheld air compressors are instrumental in inflating irrigation equipment and tools, facilitating efficient irrigation practices. This not only saves time but also reduces labor costs. Buyers from regions like Africa should look for compressors that can perform reliably under varying environmental conditions, ensuring consistent performance throughout the agricultural cycle.

For outdoor recreation, handheld air compressors are used to inflate sports equipment and camping gear, enhancing user convenience and experience. This application is particularly valuable for retailers and rental services in tourist-heavy regions. Key considerations for buyers include compact size, weight for easy transport, and the availability of multiple nozzle attachments to cater to various equipment types.

Il problema: B2B buyers in industries such as construction or automotive repair often face the challenge of inconsistent power supply when using handheld air compressors. This can lead to significant downtime, particularly in remote locations where access to electricity is limited. The frustration of being unable to inflate tires or power pneumatic tools can disrupt workflow and delay project timelines, resulting in lost productivity and increased costs.

La soluzione: To address this issue, buyers should consider sourcing handheld air compressors that offer multiple power options, including battery-operated models. When specifying products, look for compressors with high-capacity rechargeable batteries that can provide sufficient power for extended use without needing to be plugged in. Additionally, ensuring the compressor has a fast charging capability can minimize downtime between uses. For users working in diverse locations, incorporating a portable generator or solar-powered options as a backup can provide a reliable alternative power source, enabling uninterrupted operations even in remote settings.

Il problema: Many B2B buyers encounter difficulties when trying to achieve the correct PSI (pounds per square inch) levels for specific applications, such as inflating vehicle tires or operating air tools. This challenge is particularly relevant in sectors like logistics and transportation, where maintaining optimal tire pressure is crucial for safety and efficiency. Failing to achieve the desired PSI can lead to performance issues and increased wear on vehicles, posing a risk to operations.

Illustrative image related to handheld air compressors

La soluzione: Buyers should invest in handheld air compressors equipped with digital pressure gauges and automatic shut-off features. These functionalities allow users to set the desired pressure accurately, and the compressor will automatically stop inflating once that pressure is reached. This not only helps prevent over-inflation but also ensures that the correct pressure is maintained for different types of tires and applications. For those frequently working with various tire sizes, selecting models with adjustable PSI settings and multiple nozzle attachments can enhance versatility and efficiency in operations.

Il problema: Another common pain point for B2B buyers is the limited portability of handheld air compressors. In industries like landscaping or event management, where mobility is key, bulky compressors can be cumbersome to transport and store. Buyers may find themselves struggling to fit these devices into vehicles or storage spaces, leading to inefficiencies when moving between job sites.

La soluzione: To mitigate this issue, businesses should prioritize sourcing compact and lightweight handheld air compressors designed for easy transport. Models that feature ergonomic handles, built-in storage for cords and attachments, and lightweight materials can significantly enhance portability. When making purchasing decisions, consider evaluating the compressor’s dimensions and weight relative to the intended use case. Additionally, investing in wheeled versions or those that can be easily secured in a vehicle can streamline the logistics of moving equipment across different locations. Encouraging staff to adopt standardized storage solutions for tools and compressors can also help optimize space management and accessibility on job sites.

When selecting materials for handheld air compressors, B2B buyers must consider various factors that impact performance, durability, and cost. Here, we analyze four common materials used in the construction of handheld air compressors, focusing on their properties, advantages, disadvantages, and specific considerations for international markets.

Aluminum is a popular choice due to its lightweight nature and excellent corrosion resistance. It typically has a temperature rating of up to 150°C and can withstand pressures of around 150 PSI, making it suitable for various applications.

Pros and Cons: The primary advantage of aluminum is its low weight, which enhances portability. Additionally, it is resistant to rust, ensuring longevity in humid environments. However, aluminum can be more expensive than other materials and may require specialized manufacturing processes, increasing production complexity.

Impatto sull'applicazione: Aluminum’s compatibility with air and various gases makes it ideal for handheld air compressors. Its lightweight nature is particularly beneficial for users who need to transport the compressor frequently.

Considerazioni per gli acquirenti internazionali: Buyers from regions like Europe and the Middle East must ensure compliance with standards such as DIN and ASTM for aluminum components. In Africa and South America, where humidity can be high, the corrosion resistance of aluminum is a significant advantage.

Steel is another common material, known for its strength and durability. It typically has a pressure rating of up to 300 PSI and can handle high temperatures, making it suitable for heavy-duty applications.

Pros and Cons: Steel’s primary advantage is its robustness, which translates to a longer lifespan under strenuous conditions. However, it is heavier than aluminum, which may detract from portability. Additionally, steel is susceptible to rust if not properly treated, which can be a concern in humid climates.

Impatto sull'applicazione: Steel is ideal for compressors designed for industrial use or environments where durability is paramount. It can efficiently handle high-pressure applications, making it suitable for powering pneumatic tools.

Illustrative image related to handheld air compressors

Considerazioni per gli acquirenti internazionali: Buyers in regions like Germany may prioritize steel due to its strength and durability. However, they must consider the need for anti-corrosion coatings, especially in coastal areas or humid climates.

Plastic is increasingly used in handheld air compressors, particularly for housing and non-structural components. It offers a temperature rating of around 70°C and can handle pressures of up to 100 PSI.

Pros and Cons: The advantages of plastic include its lightweight nature and cost-effectiveness. It can be molded into complex shapes, allowing for innovative designs. However, plastic is less durable than metal options and may not withstand high temperatures or pressures.

Impatto sull'applicazione: Plastic components are often used in consumer-grade handheld air compressors, where weight and cost are critical factors. They are suitable for light-duty applications, such as inflating sports equipment or small tires.

Illustrative image related to handheld air compressors

Considerazioni per gli acquirenti internazionali: Buyers should ensure that the plastic used complies with safety standards in their region. In Europe, for example, compliance with REACH regulations is essential for any plastic components.

Rubber is primarily used for seals and hoses in handheld air compressors due to its flexibility and resistance to wear. It can typically handle temperatures up to 100°C and pressures of around 150 PSI.

Pros and Cons: Rubber’s flexibility allows for easy installation and a secure fit, preventing air leaks. However, it can degrade over time, especially when exposed to UV light or extreme temperatures, which may require more frequent replacements.

Impatto sull'applicazione: Rubber components are crucial for maintaining the efficiency of the compressor by ensuring airtight seals. They are essential in applications where mobility and quick setup are necessary.

Considerazioni per gli acquirenti internazionali: Buyers should check for compliance with international standards regarding rubber materials, particularly in regions with strict environmental regulations.

Illustrative image related to handheld air compressors

| Materiale | Typical Use Case for handheld air compressors | Vantaggio chiave | Svantaggi/limitazioni principali | Costo relativo (Basso/Medio/Alto) |

|---|---|---|---|---|

| Alluminio | Lightweight, portable compressors | Excellent corrosion resistance | Higher manufacturing costs | Medio |

| Acciaio | Heavy-duty industrial compressors | Exceptional strength and durability | Più pesante e soggetto a ruggine | Alto |

| Plastica | Consumer-grade compressors | Leggero e conveniente | Less durable under high pressure | Basso |

| Gomma | Seals and hoses in compressors | Flexibility and secure fit | Si degrada nel tempo con l'esposizione ai raggi UV | Medio |

This strategic material selection guide provides B2B buyers with essential insights into the materials used in handheld air compressors, enabling informed decisions that align with their operational needs and regional standards.

The manufacturing process of handheld air compressors involves several critical stages, each designed to ensure the final product meets industry standards for performance and reliability. The main stages include material preparation, forming, assembly, and finishing.

Material preparation is the foundation of the manufacturing process. High-quality materials, such as aluminum for lightweight components and steel for durability, are sourced. Suppliers should provide certifications verifying material quality, such as ASTM standards. Additionally, materials undergo chemical and physical testing to ensure they can withstand operational stresses and environmental factors.

The forming stage employs various techniques, including casting, machining, and stamping. For instance, the compressor housing may be cast from aluminum, while internal components like pistons and valves are often machined for precision. Advanced techniques such as CNC (Computer Numerical Control) machining ensure high accuracy, crucial for maintaining the compressor’s efficiency and longevity.

Illustrative image related to handheld air compressors

Once formed, components move to the assembly stage, where they are meticulously put together. This process can be manual or automated, depending on the production scale. Automated assembly lines enhance efficiency and consistency, while skilled workers perform quality checks at each step. Key focus areas during assembly include ensuring proper alignment of components and secure connections to prevent air leaks.

Finishing processes add the final touches to the product, including painting, coating, and surface treatment. These processes not only enhance aesthetics but also provide corrosion resistance, critical for outdoor use. Manufacturers often use powder coating, which is durable and environmentally friendly. Final quality checks are performed to ensure that the finish meets the specified requirements.

Quality assurance is paramount in the manufacturing of handheld air compressors, with several international standards guiding the process. ISO 9001 is the most recognized quality management standard, focusing on ensuring consistent quality in products and services. Compliance with ISO 9001 involves thorough documentation and regular audits to maintain quality control.

Illustrative image related to handheld air compressors

In addition to ISO standards, various industry-specific certifications can be critical for B2B buyers. The CE mark indicates compliance with European health, safety, and environmental protection standards, making it essential for suppliers targeting the European market. In regions like Africa and South America, certifications from local regulatory bodies can also be crucial. The API (American Petroleum Institute) certification, while specific to the oil and gas industry, can signal quality and reliability in compressors used in these sectors.

Quality control (QC) involves several checkpoints throughout the manufacturing process to ensure product integrity. These include:

Controllo qualità in entrata (CQI): This step assesses raw materials upon arrival. Materials are tested against specifications to prevent defects from entering the production line.

Controllo di qualità in corso d'opera (IPQC): Ongoing inspections during the manufacturing process help identify issues in real-time. This can include monitoring machine settings, conducting dimensional checks, and assessing assembly quality.

Controllo finale della qualità (CQC): Once assembly is complete, a comprehensive inspection is performed. This involves functional testing of the compressors, including pressure tests, noise level assessments, and performance evaluations to ensure they meet the required standards.

B2B buyers must take proactive steps to verify the quality control practices of their suppliers. Here are some effective strategies:

Audit dei fornitori: Conducting on-site audits allows buyers to assess the manufacturing environment, quality management systems, and adherence to international standards. This can be particularly important when sourcing from regions with varying compliance levels.

Richiesta di rapporti sulla qualità: Suppliers should provide detailed quality reports, including test results and compliance documentation. This transparency can foster trust and verify the supplier’s commitment to quality.

Ispezioni di terzi: Engaging third-party inspection services can provide an unbiased evaluation of the manufacturing process and product quality. These services can conduct inspections at various stages, from raw material sourcing to final assembly.

International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, must navigate unique challenges in quality control. Understanding local regulations and standards is crucial, as they can vary significantly across regions. For instance, compliance with CE standards is vital for European buyers, while buyers in Nigeria may need to consider the Standards Organization of Nigeria (SON) certifications.

Additionally, cultural differences can impact communication and expectations regarding quality. Establishing clear quality standards and maintaining open communication can help bridge these gaps and ensure a successful partnership.

The manufacturing processes and quality assurance practices for handheld air compressors are critical to ensuring product reliability and performance. By understanding the stages of manufacturing, international standards, and effective quality control measures, B2B buyers can make informed decisions when sourcing from global suppliers. Emphasizing quality at every stage of production not only enhances product performance but also builds trust and long-term relationships in the B2B marketplace.

Illustrative image related to handheld air compressors

In today’s competitive market, sourcing the right handheld air compressors can significantly impact operational efficiency and cost-effectiveness. This guide provides a structured approach to help B2B buyers navigate the procurement process, ensuring they select the best products for their needs.

Before beginning the sourcing process, clearly outline the technical requirements of the handheld air compressors you need. This includes specifications such as pressure ratings (PSI), power sources (12V, battery-operated, or AC), and intended applications (tire inflation, powering tools, etc.). Defining these specifications helps narrow down options and ensures that the compressors meet your operational demands.

Stay informed about the latest trends in handheld air compressors. Innovations such as faster inflation rates, compact designs, and energy-efficient models can enhance productivity. Understanding market trends helps you identify suppliers that offer cutting-edge technology, ensuring you make a competitive purchase.

Thoroughly vet potential suppliers before making commitments. Request detailed company profiles, including their manufacturing capabilities, certifications, and customer testimonials. Look for suppliers with experience in your industry or region, as they are more likely to understand your specific needs and challenges.

Before finalizing your order, request samples of the handheld air compressors you are considering. Testing samples allows you to evaluate performance, ease of use, and durability firsthand. Pay attention to features such as noise levels, weight, and portability, which are critical for operational efficiency.

Compare pricing across different suppliers, but don’t make decisions based solely on cost. Evaluate the total cost of ownership, including shipping, warranties, and after-sales support. Look for flexible payment terms that align with your budget and cash flow, as this can significantly affect your procurement strategy.

A robust warranty and after-sales support can save your business from unexpected costs in the future. Ensure that suppliers offer comprehensive warranty options and support services, including maintenance and repair. This is particularly important for equipment like air compressors, which may require ongoing servicing.

Once you have selected a supplier, ensure that all terms are clearly outlined in a formal purchase agreement. This should include delivery timelines, payment schedules, warranty details, and return policies. A well-drafted agreement protects your interests and establishes a clear understanding between both parties.

By following this checklist, B2B buyers can streamline the sourcing process for handheld air compressors, ensuring they select products that meet their operational requirements while fostering beneficial supplier relationships.

When sourcing handheld air compressors, understanding the cost structure is crucial for international B2B buyers. The primary cost components include:

I materiali: The quality of materials used, such as the motor, housing, and internal components, significantly impacts the price. Higher-grade metals and plastics will increase costs but can enhance durability and performance.

Lavoro: Labor costs vary by region and can be influenced by local wage rates, skill levels, and production methods. Countries with lower labor costs may offer competitive pricing, but this can sometimes come at the expense of quality.

Spese generali di produzione: This includes costs related to factory operations, such as utilities, equipment maintenance, and facility management. Efficient production processes can minimize these overheads, leading to more competitive pricing.

Utensili: Initial investments in tooling for specific designs or customizations can be significant. For unique or specialized products, these costs need to be factored into the overall pricing strategy.

Controllo qualità (CQ): Ensuring product reliability and safety through rigorous QC processes can add to costs but is essential for maintaining brand reputation and meeting regulatory standards, especially in markets like Europe and North America.

Logistica: Shipping, handling, and customs duties are crucial in determining the total cost, particularly for international buyers. Choosing the right Incoterms can help clarify responsibility for these costs.

Margine: Manufacturers and distributors typically add a margin to cover their risks and profit objectives. This can vary widely based on market conditions, competition, and perceived product value.

Several factors can influence pricing for handheld air compressors:

Volume e quantità minima d'ordine (MOQ): Bulk orders often lead to lower unit prices. Buyers should negotiate MOQs to achieve cost efficiencies.

Specifiche e personalizzazione: Custom features, such as higher PSI ratings or additional attachments, can increase costs. Buyers should balance the need for customization with budget constraints.

Qualità dei materiali e certificazioni: Products that meet international quality standards or have certifications (like ISO or CE) may come at a premium but often provide assurance of reliability and performance.

Fattori di fornitura: The reputation and reliability of suppliers can affect pricing. Established suppliers with a history of quality and service may command higher prices but can also reduce risk.

Incoterms: Understanding the implications of different shipping terms (e.g., FOB, CIF) is essential for managing logistics costs and responsibilities effectively.

Comprendere il costo totale di proprietà (TCO): Consider not just the initial purchase price but also long-term costs, such as maintenance, energy consumption, and potential downtime. This holistic view can aid in negotiations.

Leverage Market Research: Conduct thorough research on competitor pricing and market trends. This data can provide leverage during negotiations, allowing buyers to push for more favorable terms.

Build Long-term Relationships: Establishing ongoing relationships with suppliers can lead to better pricing and terms over time. Suppliers may offer discounts to repeat customers or for larger contracts.

Be Prepared to Walk Away: If negotiations stall, be ready to explore alternative suppliers. This can often prompt suppliers to provide better offers to retain business.

Consider Local Suppliers: For buyers in regions like Africa or South America, sourcing from local manufacturers may reduce shipping costs and lead times, offering a competitive edge in pricing.

International B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, must navigate complex pricing structures when sourcing handheld air compressors. Factors like local economic conditions, shipping logistics, and supplier reliability can significantly influence costs. Always seek to understand the total cost of ownership and leverage negotiation strategies to secure the best possible deal.

Dichiarazione di non responsabilità: Prices mentioned in this analysis are indicative and may vary based on market conditions, supplier negotiations, and regional factors. Always consult with suppliers for the most accurate and up-to-date pricing information.

In the industrial and automotive sectors, efficient inflation solutions are vital for maintaining operations and ensuring equipment readiness. Handheld air compressors are popular for their portability and ease of use, but they are not the only option available. This section explores viable alternatives, comparing their performance, cost, ease of implementation, maintenance, and best use cases, allowing B2B buyers to make informed decisions.

| Aspetto di confronto | Handheld Air Compressors | Tire Inflators | Manual Pumps |

|---|---|---|---|

| Prestazioni | Moderate PSI (up to 150) | Lower PSI (up to 130) | Very low PSI (variable) |

| Costo | $30 – $150 | $20 – $100 | $10 – $30 |

| Facilità di implementazione | Plug and play, compact | Simple, direct use | Requires manual effort |

| Manutenzione | Low, occasional cleaning | Minimal, battery checks | Low, manual checks |

| Il miglior caso d'uso | Vehicle and equipment inflation | Emergency roadside use | Sports equipment, small inflatables |

Tire inflators are compact devices designed primarily for inflating tires. They are often battery-operated or plug directly into a vehicle’s power outlet. While they typically have a lower PSI output compared to handheld air compressors, they excel in convenience, making them ideal for roadside emergencies. Their simplicity and ease of use are significant advantages; however, their limited versatility means they are not suitable for larger inflation tasks or air tools.

Manual pumps are the most basic inflation solution, relying on human effort to generate air pressure. They are cost-effective and require no power source, making them suitable for outdoor activities where electricity is unavailable. However, the performance is limited, with lower PSI capabilities and longer inflation times. Manual pumps are best for inflating sports balls or small inflatables but are impractical for frequent or large-scale tire inflation.

When selecting the right inflation solution, B2B buyers should consider the specific needs of their operations. Handheld air compressors are versatile and suitable for various applications, including automotive and industrial use. Tire inflators offer convenience and portability for emergency situations but may fall short in performance for larger tasks. Manual pumps, while the most economical option, are limited in functionality and best reserved for light-duty applications.

Illustrative image related to handheld air compressors

Ultimately, the choice depends on the operational requirements, budget constraints, and intended use. By carefully evaluating each option, businesses can ensure they invest in the most appropriate inflation solution to meet their needs effectively.

When selecting handheld air compressors for B2B applications, understanding their technical properties is crucial for making informed purchasing decisions. Here are some essential specifications that buyers should consider:

Pressione nominale (PSI)

The pressure rating, measured in pounds per square inch (PSI), indicates the maximum air pressure the compressor can generate. For handheld air compressors, a common range is between 70 and 150 PSI. This specification is vital because it determines the compressor’s ability to inflate various items effectively, from tires to sports equipment. A higher PSI allows for more versatile usage, making it suitable for a broader range of applications.

Air Flow Rate (CFM)

The air flow rate, measured in cubic feet per minute (CFM), indicates how much air the compressor can deliver at a specific pressure. For handheld models, a CFM rating of 1.0 to 3.0 is typical. This metric is important for B2B buyers as it affects the speed at which tasks can be completed. Higher CFM ratings mean faster inflation times, which can significantly enhance productivity, especially in commercial settings.

Fonte di alimentazione

Handheld air compressors can be powered by different sources, including electric (AC), battery-operated, or 12V car adapters. Understanding the power source is essential for buyers to ensure compatibility with their operational needs. For instance, battery-operated compressors provide greater portability, ideal for fieldwork, while electric models might be better suited for stationary tasks in workshops.

Capacità del serbatoio

The tank capacity, usually measured in gallons or liters, indicates the volume of air the compressor can store. Handheld models typically have smaller tanks ranging from 0.5 to 1.5 gallons. This property is significant because a larger tank allows for longer operation between refills, reducing downtime during tasks, which can be crucial in high-demand environments.

Weight and Portability

The weight of a handheld air compressor affects its portability. Typically, these compressors weigh between 5 to 15 pounds. For B2B buyers, especially those in industries requiring frequent transport, selecting a lightweight and compact model can streamline operations and reduce fatigue during use.

Durability and Material Grade

The material grade used in construction, such as high-grade plastic or metal, impacts the compressor’s durability and lifespan. A robust design is essential for industrial applications where equipment may be exposed to harsh environments. Investing in durable models can minimize maintenance costs and enhance the overall return on investment.

Familiarity with industry jargon is essential for B2B buyers to navigate procurement processes effectively. Here are some common terms related to handheld air compressors:

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of handheld air compressors, knowing the OEM can help buyers identify quality standards and compatibility with existing equipment.

MOQ (quantità minima d'ordine)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is crucial for businesses looking to manage inventory costs while ensuring they have enough units to meet demand.

RFQ (Richiesta di offerta)

An RFQ is a document that solicits price proposals from suppliers. B2B buyers often use RFQs to compare prices, terms, and conditions from different vendors, ensuring they receive the best value for their investments.

Incoterms (Termini commerciali internazionali)

These are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms helps buyers understand shipping responsibilities, risk, and costs associated with importing handheld air compressors.

Periodo di garanzia

This term defines the duration for which the manufacturer guarantees the product against defects. A robust warranty can indicate a manufacturer’s confidence in their product and provides buyers with assurance regarding the reliability of their investment.

Certification Standards

These refer to compliance with specific industry regulations or safety standards, such as ISO or CE certifications. Understanding these standards is important for buyers to ensure that the equipment meets safety, quality, and environmental regulations relevant to their operations.

By grasping these technical properties and trade terminologies, B2B buyers can make informed decisions that align with their operational needs and budget constraints, ultimately enhancing their purchasing strategy for handheld air compressors.

The handheld air compressor market is experiencing significant growth driven by increasing demand for portable, versatile, and efficient inflation solutions. As industries such as automotive, construction, and DIY projects flourish globally, particularly in regions like Africa, South America, the Middle East, and Europe, the need for reliable handheld air compressors is paramount. Key trends influencing this market include the rise of battery-powered and cordless models, which provide greater flexibility and convenience, appealing to both individual consumers and businesses. Additionally, advancements in technology are leading to features such as digital pressure gauges, automatic shut-off capabilities, and multi-functional use, allowing these compressors to cater to a wider array of applications—from inflating tires to powering pneumatic tools.

Illustrative image related to handheld air compressors

International B2B buyers are increasingly focused on sourcing products that emphasize efficiency and performance. As competition intensifies, suppliers are adopting innovative approaches to streamline production processes and reduce costs. For buyers in emerging markets, accessibility to reliable supply chains and robust after-sales support is crucial. Moreover, the demand for customized solutions tailored to specific industry needs is on the rise, prompting manufacturers to invest in product development and market research.

Sustainability and ethical sourcing are becoming increasingly important in the handheld air compressor sector, reflecting a global shift towards environmentally responsible practices. Buyers are now prioritizing products that minimize ecological impact, which includes using eco-friendly materials and manufacturing processes. This trend is particularly relevant for B2B buyers from regions with stringent environmental regulations, such as Europe.

The use of sustainable materials, such as recycled plastics and energy-efficient components, can significantly reduce the carbon footprint of handheld air compressors. Furthermore, obtaining ‘green’ certifications can enhance brand reputation and appeal to environmentally conscious consumers. Ethical sourcing practices, including fair labor standards and transparent supply chains, are also becoming critical for companies aiming to align with global sustainability goals. By prioritizing these values, B2B buyers can not only meet regulatory requirements but also foster long-term partnerships with suppliers committed to responsible practices.

The handheld air compressor has evolved significantly since its inception. Initially, air compressors were bulky, stationary machines primarily used in industrial settings. The demand for portable solutions grew in the late 20th century, driven by the rise of DIY culture and the automotive industry’s need for convenient tire inflation tools.

Advancements in technology, such as the development of lightweight materials and more efficient motors, paved the way for the modern handheld air compressor. The introduction of battery-powered models further revolutionized the market, allowing users to operate compressors without being tethered to a power source. This evolution has made handheld air compressors more accessible and practical for a diverse range of applications, from home use to professional settings, ultimately shaping the landscape of the current market.

How do I choose the right handheld air compressor for my business needs?

Selecting the right handheld air compressor involves evaluating several key factors. First, assess the compressor’s PSI (pounds per square inch) rating to ensure it meets the demands of your applications, whether for tire inflation or powering pneumatic tools. Consider the power source—battery-operated models offer portability, while plug-in options provide consistent power for prolonged use. Additionally, evaluate the weight and size for ease of transport and storage. Lastly, check for features like automatic shut-off and multiple nozzle attachments to enhance functionality and versatility.

What are the common applications for handheld air compressors in various industries?

Handheld air compressors are versatile tools used across multiple industries. In automotive, they are essential for tire inflation and minor repairs. In construction, they power nail guns and other pneumatic tools. They also find applications in agriculture for inflating equipment and cleaning tools. Furthermore, in the hospitality sector, they can be used to inflate air mattresses or pool toys. Understanding your industry-specific needs will help you select a model that can efficiently handle the required tasks.

What is the minimum order quantity (MOQ) for purchasing handheld air compressors?

The MOQ for handheld air compressors can vary significantly depending on the supplier and the model. Typically, established manufacturers may set an MOQ ranging from 50 to 100 units to ensure cost-effectiveness in production and shipping. However, some suppliers may offer flexible terms for smaller businesses or first-time buyers. It is crucial to communicate your requirements to potential suppliers to negotiate favorable terms that align with your purchasing strategy.

How can I verify the reliability of a supplier for handheld air compressors?

To ensure a supplier’s reliability, conduct thorough due diligence. Start by checking their business credentials, including registration and certifications relevant to manufacturing standards. Look for reviews or testimonials from previous clients, focusing on product quality and customer service. Request references and follow up with them to gauge their experiences. Additionally, consider visiting the supplier’s facility, if feasible, to assess their production processes and quality control measures firsthand.

What payment terms are typically offered by suppliers of handheld air compressors?

Payment terms can vary widely among suppliers, but common options include net 30, net 60, or even net 90 days, depending on your relationship with the supplier and order size. Some suppliers may require an upfront deposit, especially for larger orders, while others might offer credit terms after establishing a trustworthy relationship. It’s advisable to discuss payment options upfront to find a mutually beneficial arrangement that aligns with your cash flow needs.

What quality assurance processes should I expect from a reputable air compressor supplier?

Reputable suppliers should have comprehensive quality assurance processes in place. These may include rigorous testing of each unit for performance and safety standards, adherence to international certifications (like ISO), and thorough inspection during manufacturing. Request documentation of quality control measures, such as test results and compliance certifications. Additionally, inquire about their return policy and warranty offerings, which can serve as indicators of their commitment to product quality.

How can I ensure timely logistics and delivery for my air compressor orders?

To ensure timely logistics and delivery, first, clarify the expected lead times with your supplier. Discuss shipping methods and choose reliable carriers that have experience in international freight, especially to your region. Utilize tracking options to monitor your shipment in real-time. Additionally, consider local customs regulations and potential delays that may arise during importation. Building a strong relationship with your supplier can also enhance communication and expedite the logistics process.

Can handheld air compressors be customized for specific branding or features?

Many suppliers offer customization options for handheld air compressors, allowing you to add your branding or specific features. Customization may include color variations, logo placement, or tailored functionalities such as specialized nozzles. However, it’s essential to discuss these options early in the negotiation process, as they may affect the MOQ and lead time. Ensure that the supplier has experience in custom orders to achieve the desired quality and meet your branding requirements effectively.

Dominio: dewalt.com

Registrato: 1997 (28 anni)

Introduzione: DEWALT offers a range of air compressors including electric and gas models. Key products include:

1. DXCMS15016US – 1.6 Gal Quiet Roll Cage Oil Free Air Compressor

2. DXCMS13513US – 1.3 Gal XTREME Quiet Roll Cage Oil Free Air Compressor

3. DXCM20020US – 20 Gal XTREME Quiet 2 Stage Oil Free Air Compressor

4. DXCMS20045US – 4.5 Gal XTREME Quiet 2 Stage Oil Free Air Compressor

5. D55154 – 1.1 HP…

In summary, strategic sourcing of handheld air compressors is crucial for businesses aiming to enhance operational efficiency and meet diverse market demands. As these devices become integral in various sectors—ranging from automotive to construction—prioritizing quality, portability, and versatility will ensure that buyers can respond swiftly to customer needs. Features like automatic shut-off, digital pressure gauges, and multiple power options are not just conveniences; they are essential for maximizing productivity and minimizing downtime.

For international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, leveraging strategic sourcing can lead to significant cost savings and competitive advantages. Engaging with reputable suppliers who emphasize innovation and reliability will empower businesses to make informed purchasing decisions.

As you explore your options, consider how emerging trends, such as battery-powered models and multi-functional designs, can align with your long-term strategy. The future of handheld air compressors looks promising, and now is the time to invest wisely. Connect with trusted manufacturers and distributors to equip your operations for success in an evolving marketplace.

Le informazioni fornite in questa guida, compresi i contenuti relativi ai produttori, alle specifiche tecniche e all'analisi di mercato, hanno uno scopo puramente informativo ed educativo. Non costituiscono una consulenza professionale in materia di acquisti, né una consulenza finanziaria o legale.

Pur avendo compiuto ogni sforzo per garantire l'accuratezza e la tempestività delle informazioni, non siamo responsabili di eventuali errori, omissioni o informazioni non aggiornate. Le condizioni di mercato, i dettagli aziendali e gli standard tecnici sono soggetti a modifiche.

Gli acquirenti B2B devono condurre una due diligence indipendente e approfondita. prima di prendere qualsiasi decisione di acquisto. È necessario contattare direttamente i fornitori, verificare le certificazioni, richiedere campioni e chiedere una consulenza professionale. Il rischio di affidarsi alle informazioni contenute in questa guida è esclusivamente a carico del lettore.